Mechanism of Accelerated Deterioration of High-Temperature Vulcanized Silicone Rubber under Multi-Factor Aging Tests Considering Temperature Cycling

Abstract

:1. Introduction

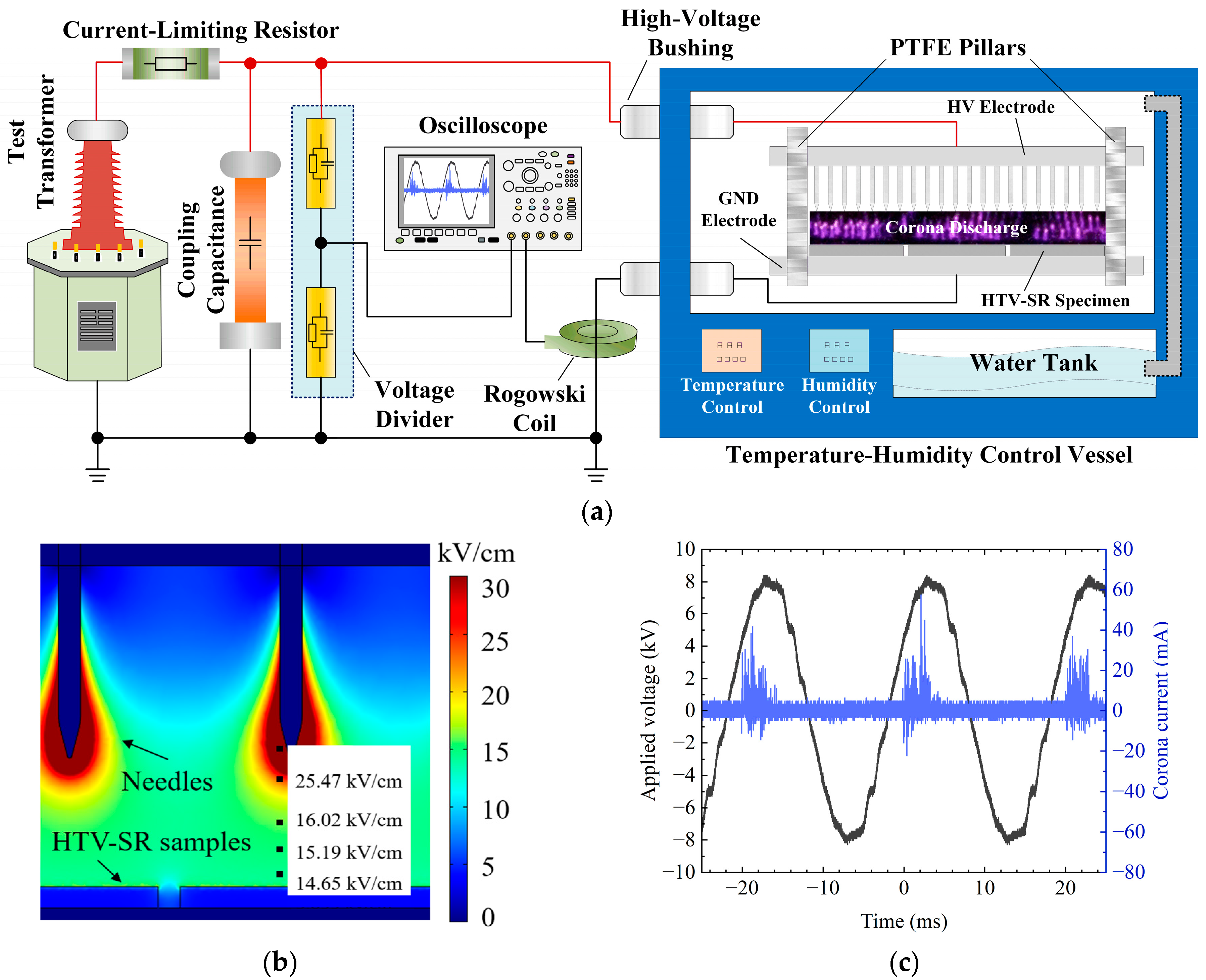

2. Experimental Details

2.1. Sample Preparation

2.2. Multi-Factor Aging of HTV-SR

2.3. Characterization

2.3.1. Surface Morphology and Hydrophobicity

2.3.2. Chemical Properties

2.3.3. Mechanical Properties

2.3.4. Electrical Properties

3. Results

3.1. Surface Morphology and Hydrophobicity

3.1.1. Optical Micrograph

3.1.2. SEM Test

3.1.3. Hydrophobicity

3.2. Chemical and Mechanical Properties

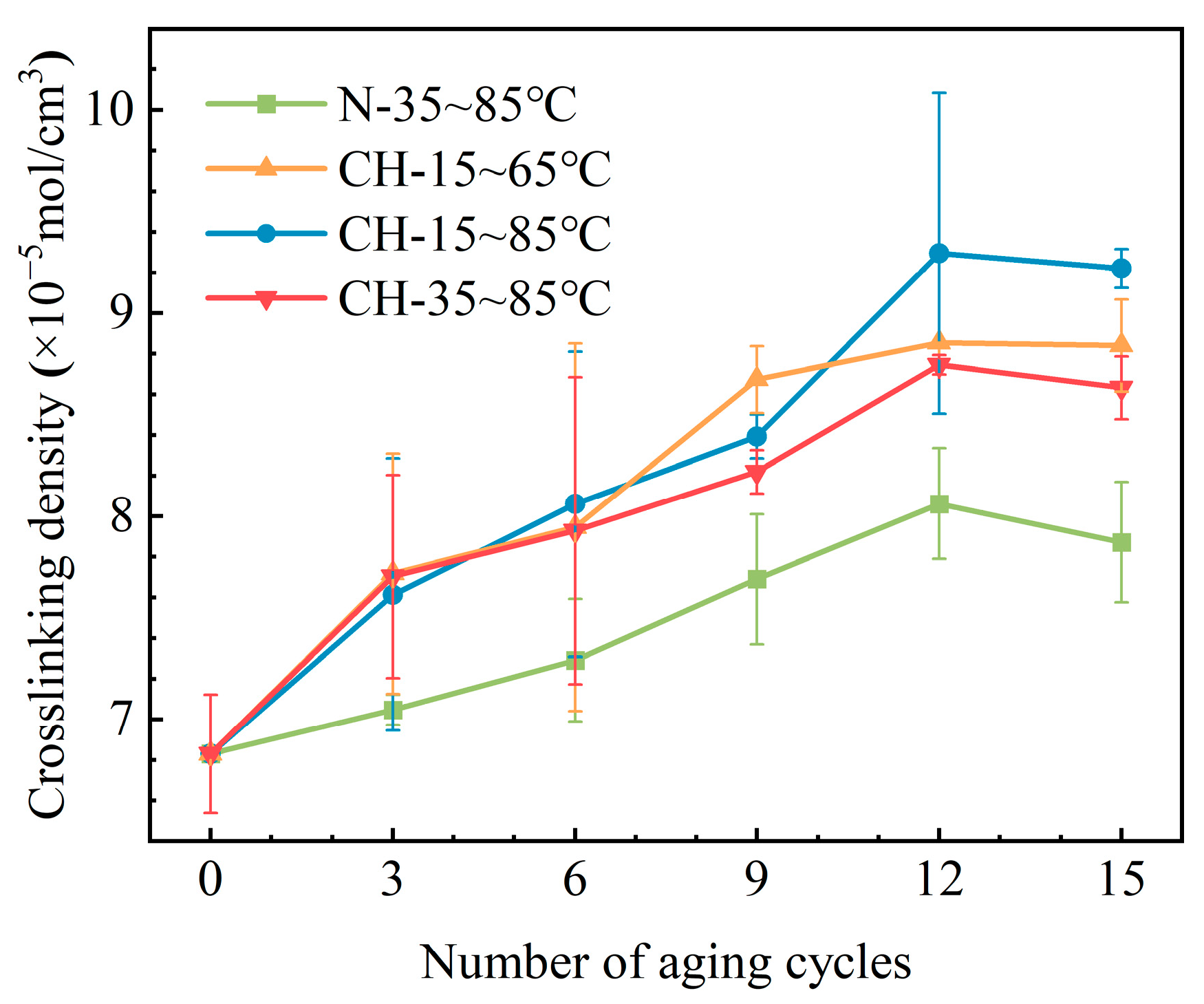

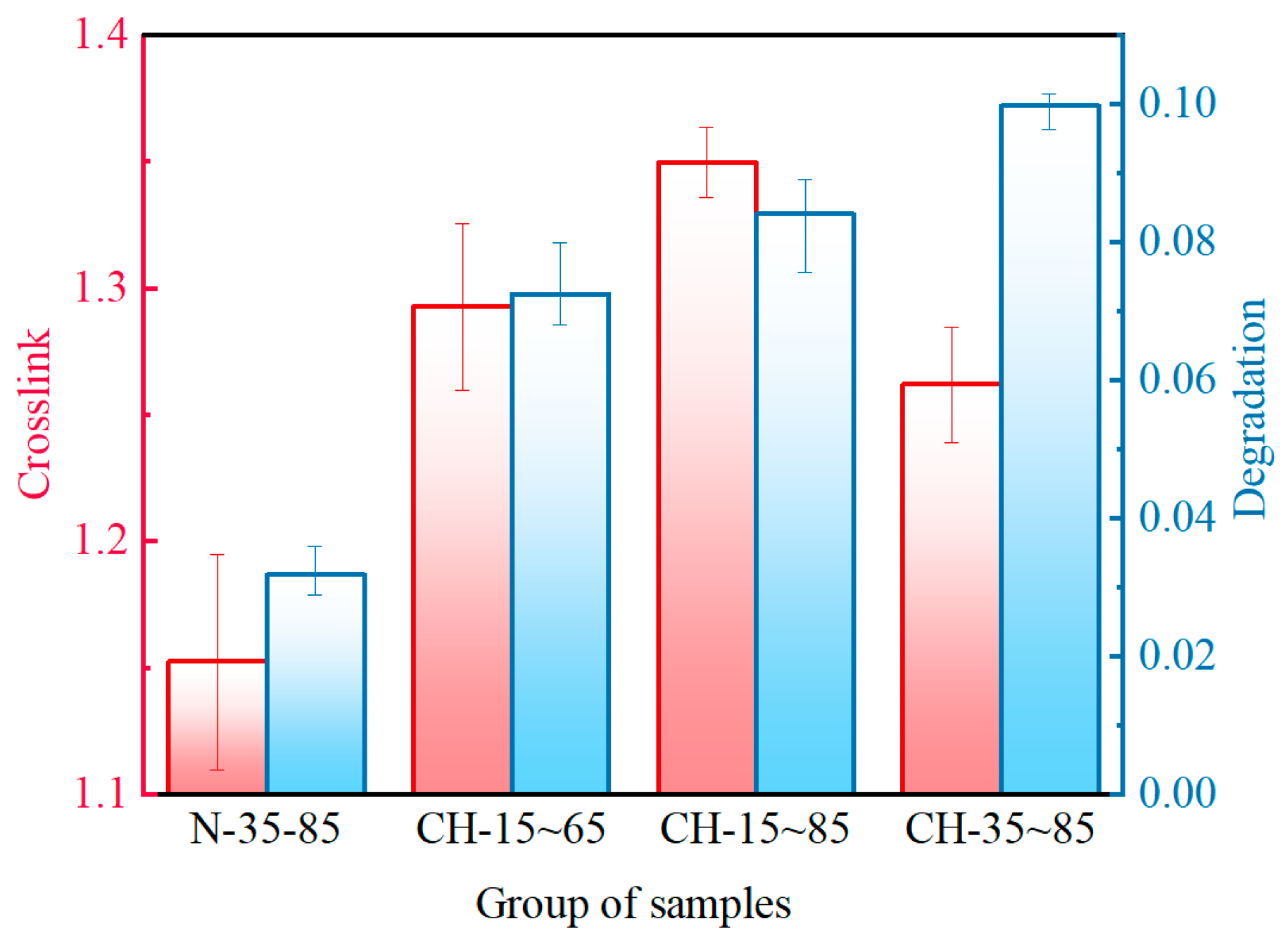

3.2.1. Crosslinking Density from Equilibrium Swelling Test

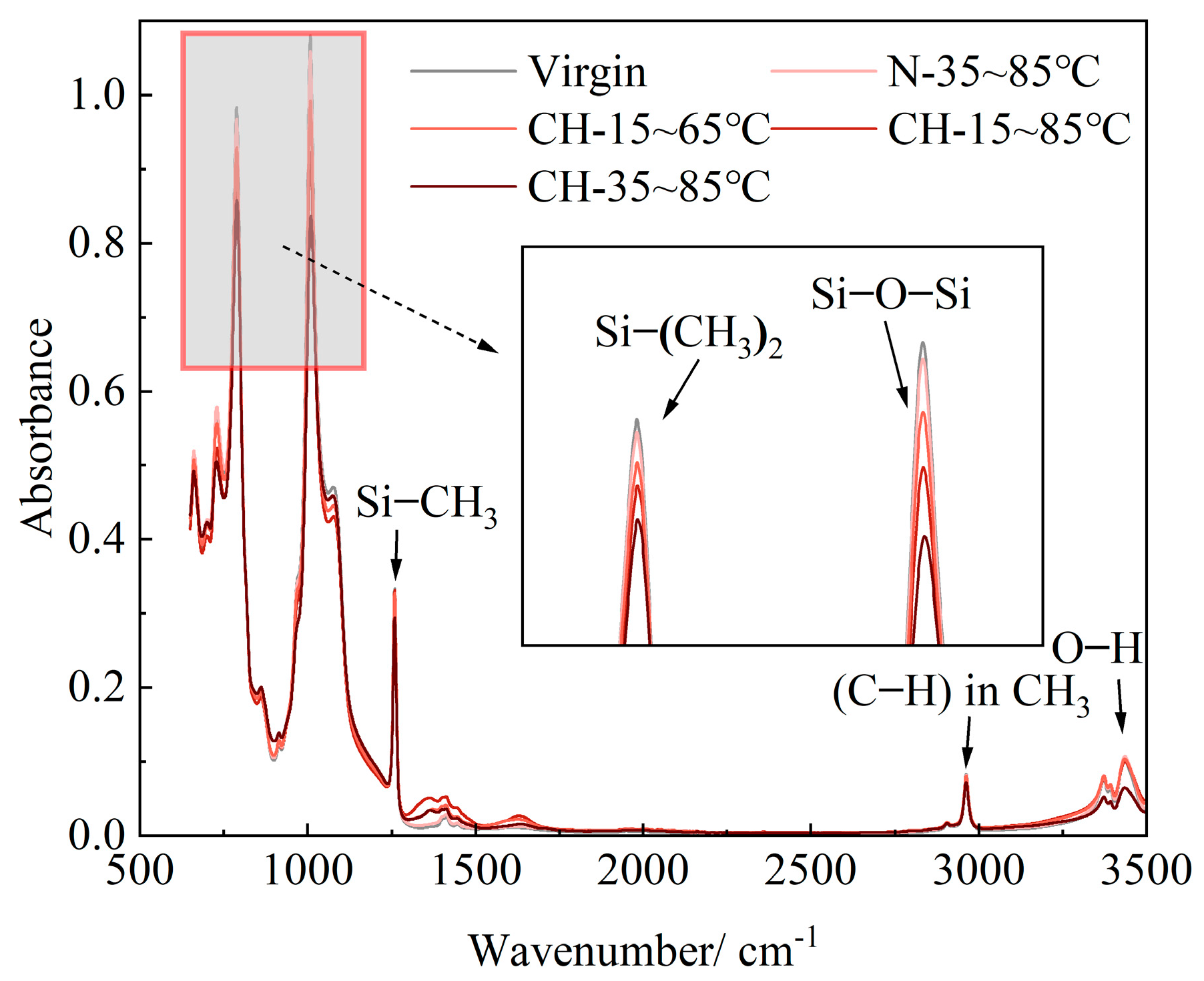

3.2.2. Degree of Degradation from FTIR Test

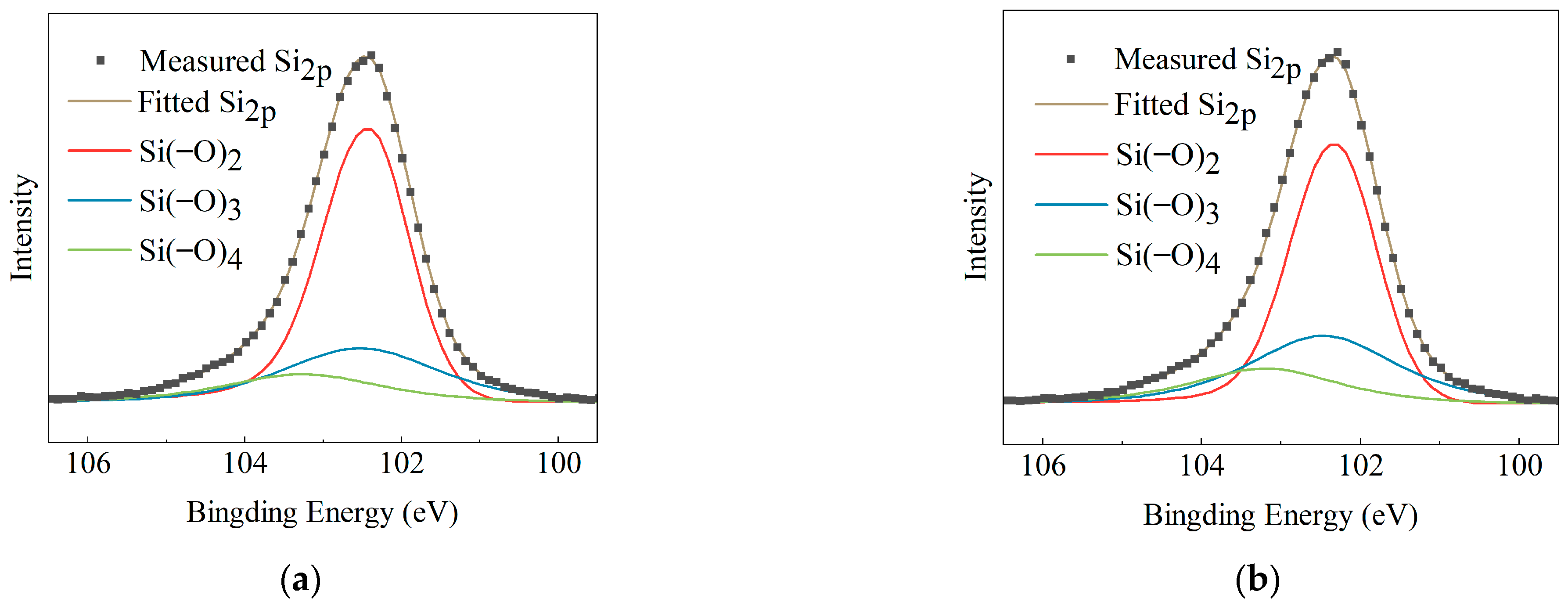

3.2.3. X-ray Photoelectron Spectra

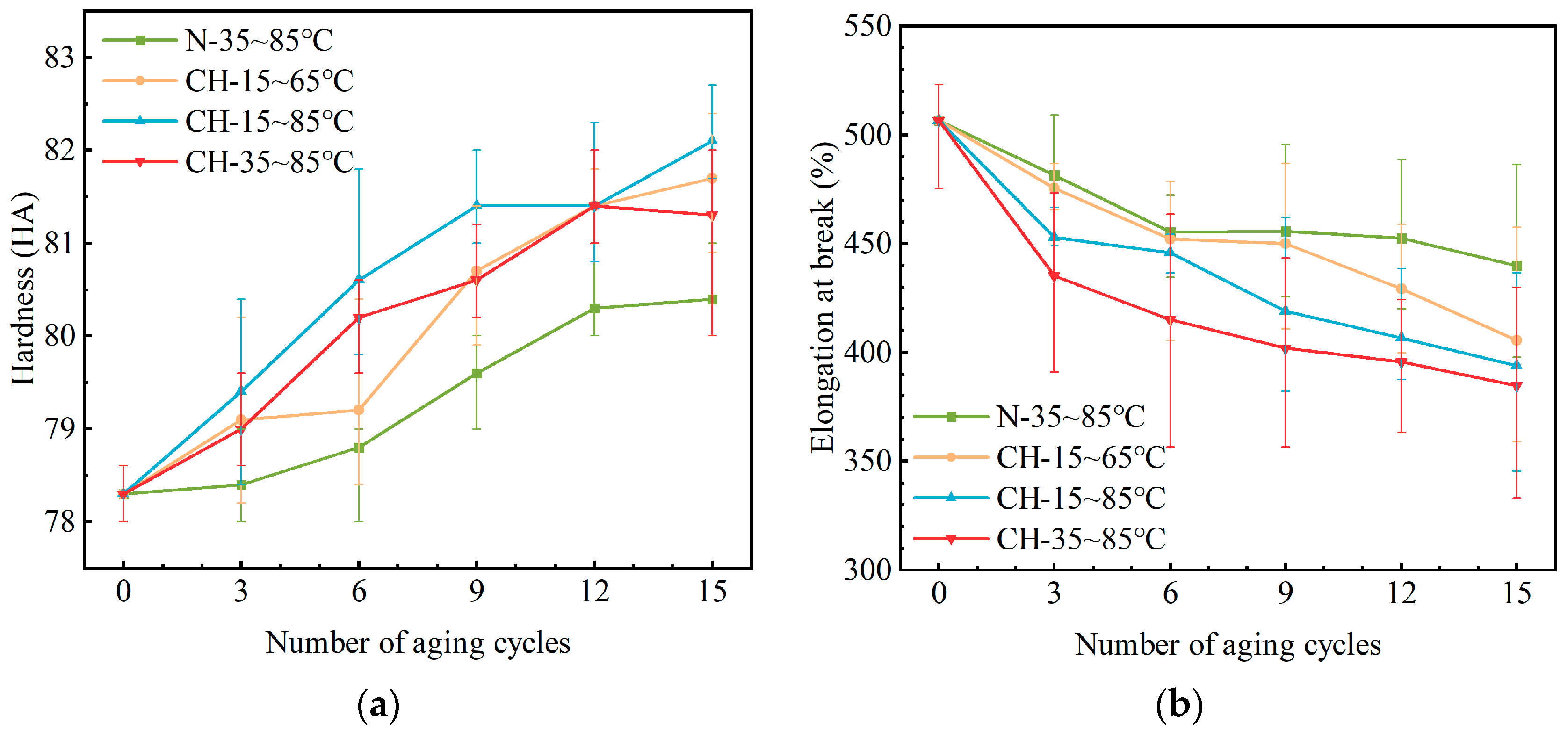

3.2.4. Hardness and Elongation at Break

3.3. Electrical Properties

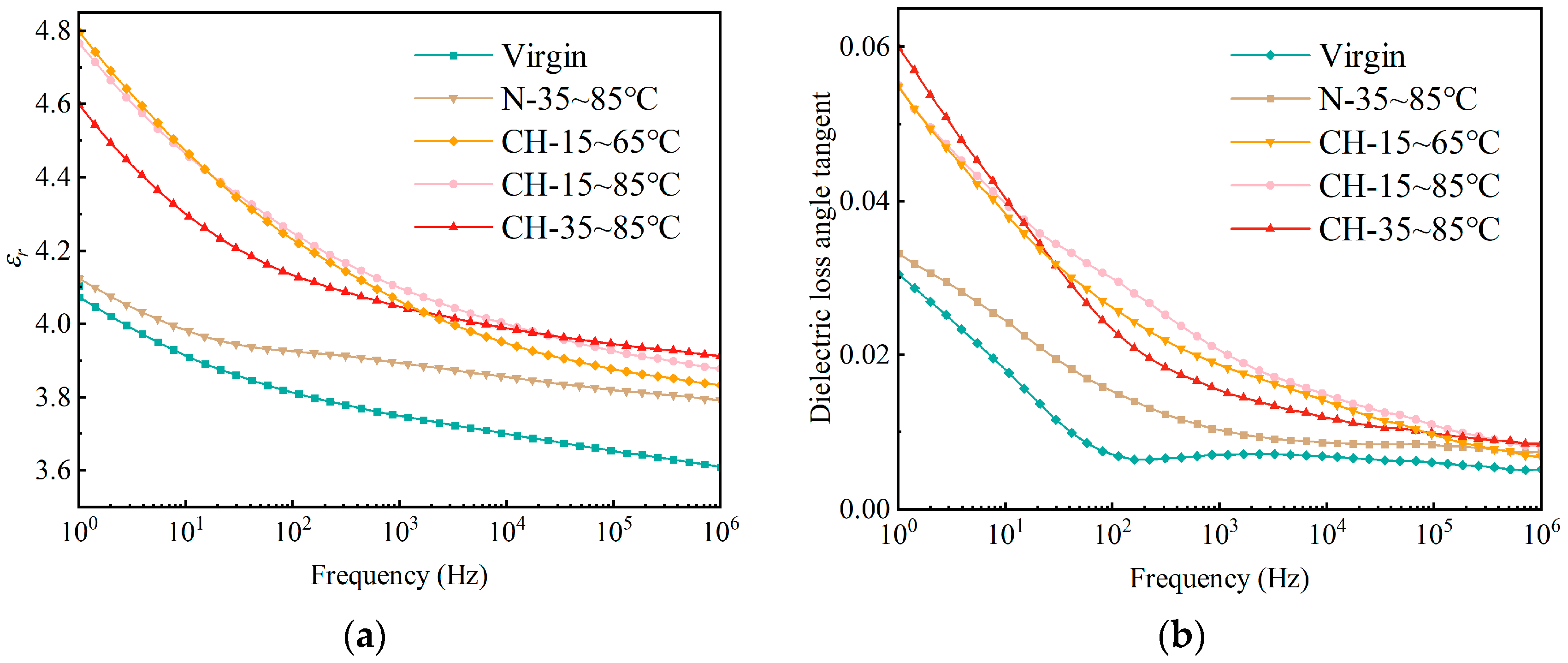

3.3.1. Dielectric Spectra

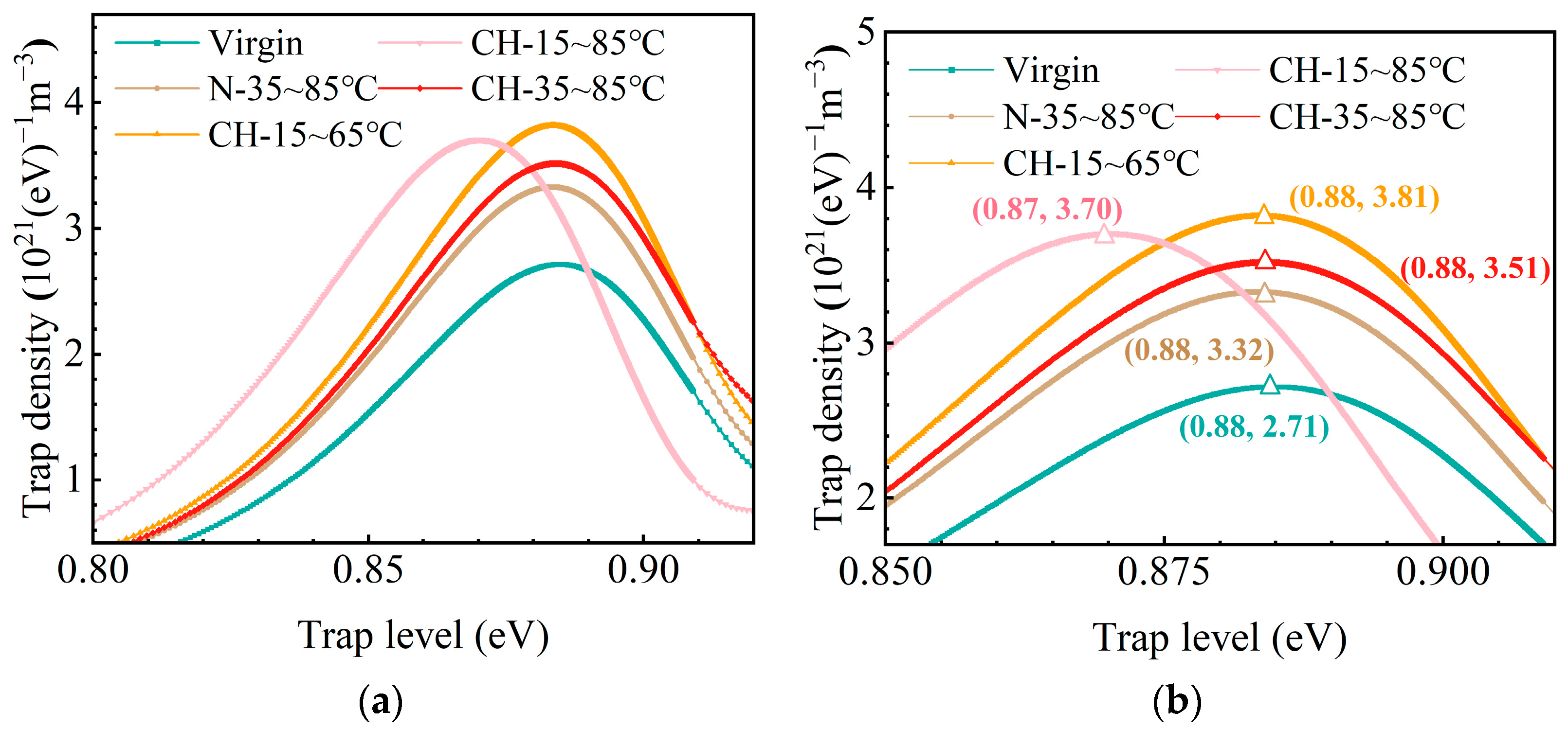

3.3.2. Trap Properties

4. Discussion

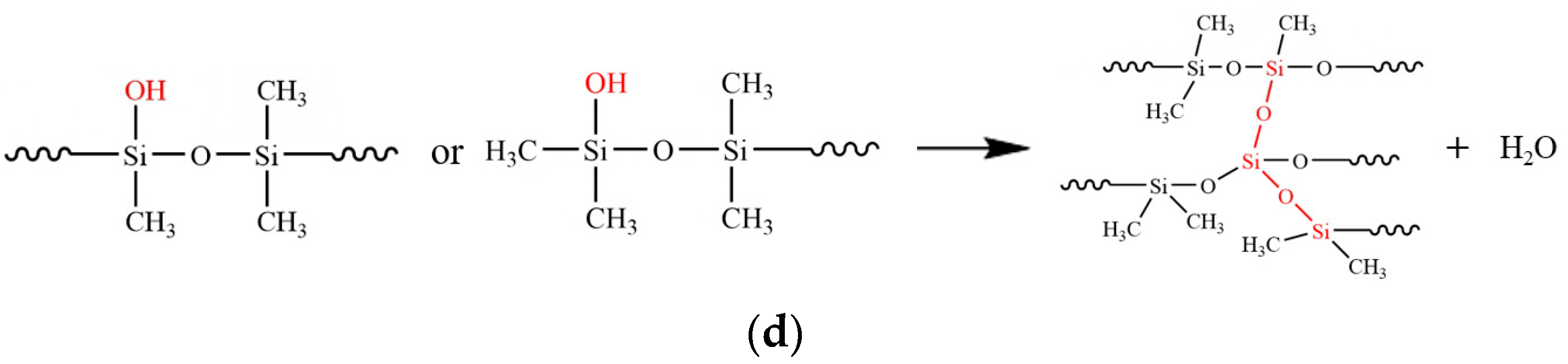

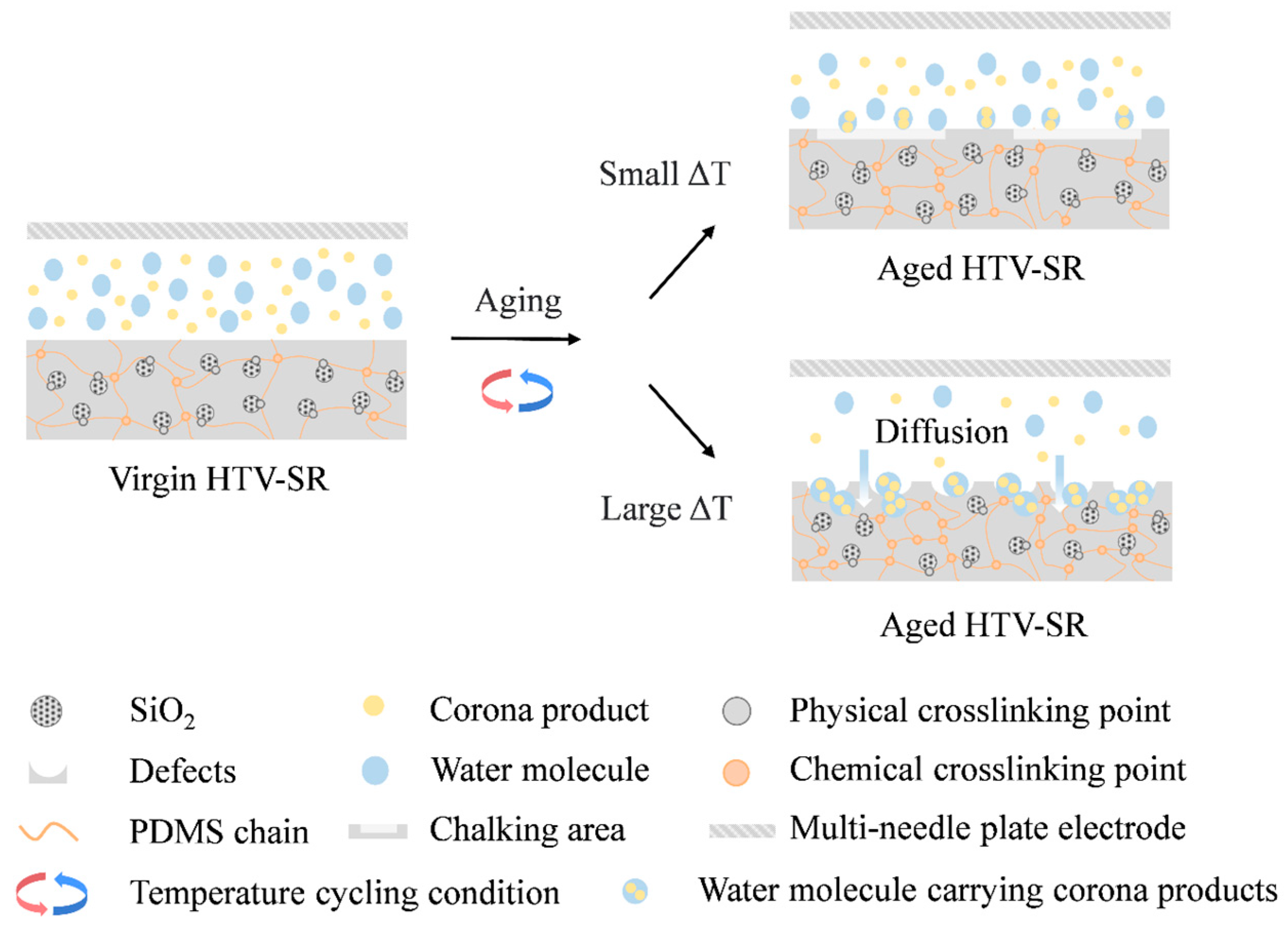

4.1. Multi-Factor Aging Mechanism of HTV-SR

4.2. Effects of Temperature Cycling on Aging Behaviors of HTV-SR

4.3. Comparison between Artificial Aging and Natural Aging

5. Conclusions

- (1)

- A multi-factor aging technique for insulator HTV-SR is proposed, which takes the alternating thermal stress into account and is more in line with the on-site aging process of HTV-SR. Compared to existing aging methods, the method in this paper investigates the influence of ΔT and the related water condensation phenomena.

- (2)

- The aging degree of HTV-SR is largely affected by ΔT. Under small ΔT (50 °C), chalking corona rings emerge on the sample surface. Under large ΔT (70 °C), severe surface defects, poor hydrophobicity, high interfacial polarization, and shallow trap energy levels are obtained. It is due to the intrusion of water molecules and corona products into the inside of HTV-SR material, further accelerating the aging.

- (3)

- It is concluded that crosslinking and degradation chemical reactions are synergistic but vary with aging. When ΔT increases, the crosslinking degree rises while the degradation degree declines. The crosslink-degradation model with different occupancy ratios plays a decisive role in the aging behavior of HTV-SR.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, M.; Xue, J.; Wei, Y.; Li, G.; Zhang, G. Review of interface tailoring techniques and applications to improve insulation performance. High Volt. 2022, 7, 12–31. [Google Scholar] [CrossRef]

- Liang, X.; Gao, Y.; Wang, J.; Li, S. Rapid development of silicone rubber composite insulator in China. High Volt. Eng. 2016, 42, 2888–2896. (In Chinese) [Google Scholar]

- Shen, W.; Song, W.; Wang, G.; Niu, Y.; Wang, J.; Zhang, L.; Zhang, G. Influence of corona discharge on aging characteristics of HTV silicone rubber material. High Volt. Eng. 2013, 49, 1–7. (In Chinese) [Google Scholar]

- Zhang, G.; Zhao, L.; Zhou, R.; Shen, W.; Liang, X. Review on aging characterization and evaluation of silicon rubber composite insulator. High Volt. App. 2016, 52, 1–15. (In Chinese) [Google Scholar]

- Zhang, Z.; Zhang, Y.; Jiang, X.; Liang, T.; Hu, J. Study on aging characterization methods of composite insulators aging in natural environment for different years. Trans. China Electrotech. Soc. 2020, 35, 1368–1376. (In Chinese) [Google Scholar]

- Liang, X.; Zhang, Y.; Yin, Y.; Li, Z. 5000 h multi-stress test procedure for silicone rubber composite insulators and its applications in long-term performance evaluation. High Volt. Eng. 2012, 38, 2492–2498. (In Chinese) [Google Scholar]

- Yin, Y.; Liang, X.; Zhou, Y.; Cheng, Z.; Mao, S.; Li, X.; Dong, H. Tracking wheel test of composite insulators and comparison with inclined plane test. High Volt. Eng. 2005, 31, 6–8. (In Chinese) [Google Scholar]

- Wu, J.; Dong, J.; Wang, Y.; Gond, B. Thermal oxidation ageing effects on silicone rubber sealing performance. Polym. Degrad. Stabil. 2017, 135, 43–53. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Zhang, L.; Guo, D.; Zhang, X.; Wang, M. Electrical tree initiation of silicone rubber after thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 748–756. [Google Scholar] [CrossRef]

- Nazir, M.; Phung, B. Accelerated ultraviolet weathering investigation on micro-/nano-SiO2 filled silicone rubber composites. High Volt. 2018, 3, 295–302. [Google Scholar] [CrossRef]

- Jin, F.; Zhou, Y.; Liang, B.; Liang, X.; Liu, Z.; Zhang, L. Effect of UV radiation aging on creepage discharge characteristics of high temperature vulcanized silicon rubber at high altitude. Plasma Sci. Technol. 2019, 21, 054003. [Google Scholar] [CrossRef]

- Song, W.; Shen, W.; Wang, G.; Wang, Y.; Zhang, G. Influence of corona discharge aging on trap characteristics of high temperature vulcanized silicon rubber material. High Volt. Eng. 2013, 39, 979–986. (In Chinese) [Google Scholar]

- Nazir, M.; Phung, B.; Hoffman, M. Performance of silicone rubber composites with SiO2 micro/nano-filler under AC corona discharge. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2804–2815. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X. Research on property variation of silicone rubber and EPDM rubber under interfacial multi-stresses. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 2027–2035. [Google Scholar] [CrossRef]

- Bi, M.; Deng, R.; Jiang, T.; Chen, X.; Pan, A.; Zhu, L. Study on corona aging characteristics of silicone rubber material under different environmental conditions. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 534–542. [Google Scholar] [CrossRef]

- Hu, H.; Jia, Z.; Wang, X. Aging mechanism of silicone rubber under thermal-tensile coupling effect. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 185–192. [Google Scholar] [CrossRef]

- Hu, H.; Xie, C.; Wang, R.; Gou, B.; Luo, S.; Zhou, J. Effects of electrical-hydrothermal aging degradation on dielectric and trap properties of high temperature vulcanized silicone rubber materials. RSC Adv. 2020, 10, 3805–3816. [Google Scholar]

- Liang, Y.; Gao, T.; Wang, X.; Sun, M. Microstructure evolution of silicone rubber used for composite insulators under the effects of electric field and temperature. Trans. China Electrotech. Soc. 2020, 35, 1575–1583. (In Chinese) [Google Scholar]

- Wang, X.; Wang, H.; Chen, F.; Wu, K.; Cui, J. Insulation swelling mechanism and influencing factors of silicone grease coated in cable accessories. High Volt. Eng. 2020, 46, 3177–3186. (In Chinese) [Google Scholar]

- Cui, T.; Chao, Y.; Van, Z. Thermal stress development of liquid silicone rubber seal under temperature cycling. Polym. Test. 2013, 32, 1202–1208. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, L.; Guan, Z.; Zhang, F. Research on aged interfaces of composite insulators after extended water diffusion tests. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3676–3682. [Google Scholar] [CrossRef]

- Nakamura, K.; Hatori, K.; Iura, S.; Kusakabe, Y.; Thal, E.; Wiesner, E. The test method to confirm robustness against condensation. In Proceedings of the 21st European Conference on Power Electronics and Applications, Genova, Italy, 2–5 September 2019. [Google Scholar]

- Niu, L.; Fang, J.; Li, Y.; Lun, Y.; Pan, S.; Zhao, Y.; Wei, C.; Fang, P. Effect of surface structure of silicone-SiO2 composite coatings on its condensation and flashover characteristics. J. Wuhan. Univ. (Nat. Sci. Ed.) 2022, 1–9. (In Chinese) [Google Scholar]

- Cristy, A. Chapter 3 Theory of infrared spectroscopy. Compr. Anal. Chem. 2001, 35, 19–40. [Google Scholar]

- Gehrke, S. Synthesis, equilibrium swelling, kinetics, permeability and applications of environmentally responsive gels. In Responsive Gels: Volume Transitions II; Springer: Berlin/Heidelberg, Germany, 2005; Volume 1, pp. 81–144. [Google Scholar]

- Shen, W.; Mu, H.; Zhang, G.; Deng, J.; Tu, D. Identification of electron and hole trap based on isothermal surface potential decay model. J. Appl. Phys. 2013, 113, 083706. [Google Scholar] [CrossRef]

- Chen, C.; Jia, Z.; Ye, W.; Guan, Z.; Li, Y. Thermo-oxidative aging analysis of HTV silicone rubber used for outdoor insulation. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1761–1772. [Google Scholar] [CrossRef]

- Ning, K.; Tang, Z.; Xie, P.; Hu, J.; Fu, Z. Study on silicone rubber composite insulator modified by high-energy electron beam irradiation. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 31–40. [Google Scholar] [CrossRef]

- Bao, W.; Liang, X.; Liu, Y.; Gao, Y.; Wang, J. Effects of AC and DC corona on the surface properties of silicone rubber: Characterization by contact angle measurements and XPS high resolution scan. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2911–2919. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, K.; Zhu, G.; Liang, Z.; Fu, Y. Effect of thermal cycling on the interface pressure of cable accessories and their strips material properties. High Volt. Eng. 2022, 48, 2198–2207. (In Chinese) [Google Scholar]

- Grosse, C. A program for the fitting of up to three Havriliak-Negami dispersions to dielectric data. J. Colloid. Interface Sci. 2021, 600, 318–323. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, W.; Wang, C.; Li, J.; Sun, P.; Deng, J.; Zhang, G. Eco-friendly thermoplastic alternatives to epoxy resin for support insulators. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 518–527. [Google Scholar] [CrossRef]

- Chao, Y.; Xie, C.; Li, L.; Xu, X.; Gubanski, S.; He, Z. Dielectric response characterization of in-service aged sheds of (U) HVDC silicone rubber composite insulators. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1418–1426. [Google Scholar]

- Chao, W.; Gao, Y.; Liang, X.; Gubanski, S.; Wang, Q.; Bao, W.; Li, S. Manifestation of interactions of nano-silica in silicone rubber investigated by low-frequency dielectric spectroscopy and mechanical tests. Polymers 2019, 11, 717. [Google Scholar]

- Kang, W.; Meng, S.; Li, S.; Min, D.; Li, Z.; Li, S. Molecular chain motion and electrode polarization properties of silicone rubber. High Volt. Eng. 2018, 44, 3798–3807. (In Chinese) [Google Scholar]

- Wang, T.; Li, X.; Zhang, B.; Li, D.; Liu, J.; Zhang, G. Basic reason for the accumulation of charge on the surface of polymer dielectrics. Sci. China Mater. 2022, 65, 2884–2888. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, J.; Wan, X.; Jiang, X.; Hu, J. Mechanical properties of high temperature vulcanized silicone rubber aged in the natural environment. Polymers 2022, 14, 4439. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Wang, L.; Guan, Z.; Zhang, F. Aging characterization and lifespan prediction of silicone rubber material utilized for composite insulators in areas of atypical warmth and humidity. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3547–3555. [Google Scholar] [CrossRef]

| Group | Trange (°C) | Tmean (°C) | ΔT (°C) | Corona (C) |

|---|---|---|---|---|

| Humidity (H) | ||||

| N-35~85 °C | 35–85 | 60 | 50 | × |

| CH-15~65 °C | 15–65 | 40 | 50 | √ |

| CH-15~85 °C | 15–85 | 50 | 70 | √ |

| CH-35~85 °C | 35–85 | 60 | 50 | √ |

| Sample | Si(−O)2 | Si(−O)3 | Si(−O)4 | Highly Oxidized Si (Si(−O)3 + Si(−O)4) |

|---|---|---|---|---|

| Virgin | 80.00% | 13.60% | 6.40% | 20.00% |

| N-35~85 °C | 76.93% | 15.38% | 7.69% | 23.07% |

| CH-15~65 °C | 39.91% | 44.84% | 13.45% | 58.29% |

| CH-15~85 °C | 39.60% | 20.40% | 40.00% | 60.40% |

| CH-35~85 °C | 50.00% | 33.00% | 17.00% | 50.00% |

| Group | MWS Relaxation | β-Relaxation | ||

|---|---|---|---|---|

| fp (Hz) | Δε | fp (Hz) | Δε | |

| Virgin | 0.131 | 0.819 | 6724 | 0.021 |

| N-35~85 °C | 0.519 | 0.960 | 43,262 | 0.022 |

| CH-15~65 °C | 0.218 | 1.735 | 34,572 | 0.022 |

| CH-15~85 °C | 0.255 | 1.825 | 16,939 | 0.027 |

| CH-35~85 °C | 0.562 | 1.687 | 58,715 | 0.031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, S.; Li, W.; Peng, Y.; Zhang, Y.; Zhang, G. Mechanism of Accelerated Deterioration of High-Temperature Vulcanized Silicone Rubber under Multi-Factor Aging Tests Considering Temperature Cycling. Polymers 2023, 15, 3210. https://doi.org/10.3390/polym15153210

Zeng S, Li W, Peng Y, Zhang Y, Zhang G. Mechanism of Accelerated Deterioration of High-Temperature Vulcanized Silicone Rubber under Multi-Factor Aging Tests Considering Temperature Cycling. Polymers. 2023; 15(15):3210. https://doi.org/10.3390/polym15153210

Chicago/Turabian StyleZeng, Shiyin, Wendong Li, Yanan Peng, Yucheng Zhang, and Guanjun Zhang. 2023. "Mechanism of Accelerated Deterioration of High-Temperature Vulcanized Silicone Rubber under Multi-Factor Aging Tests Considering Temperature Cycling" Polymers 15, no. 15: 3210. https://doi.org/10.3390/polym15153210