Review on Wood Deformation and Cracking during Moisture Loss

Abstract

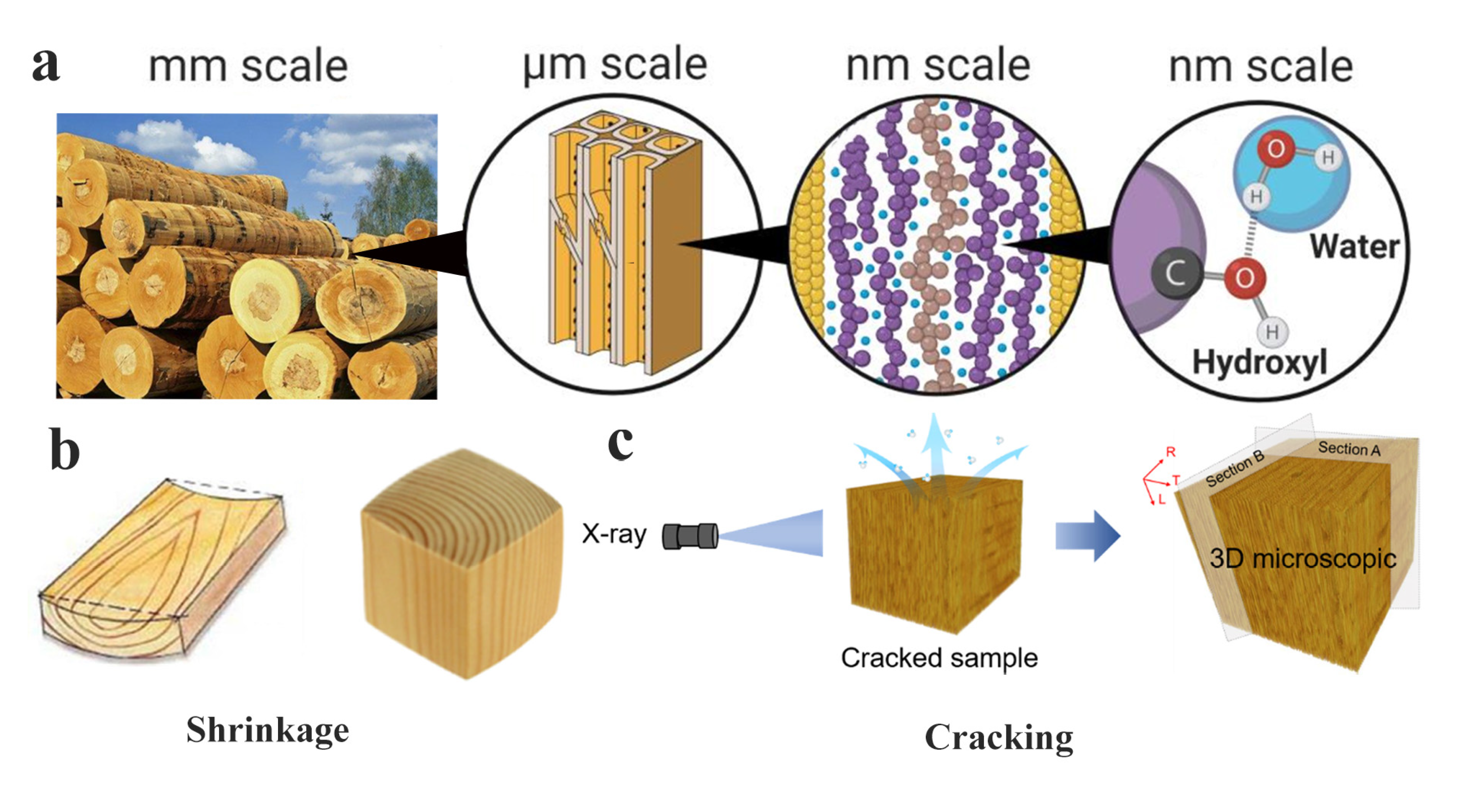

1. Introduction

2. Moisture in Wood

2.1. Existing State of Moisture in Wood

2.2. Interaction between Water Molecule and Wood Components

3. Causes of Wood Deformation and Cracking during Drying

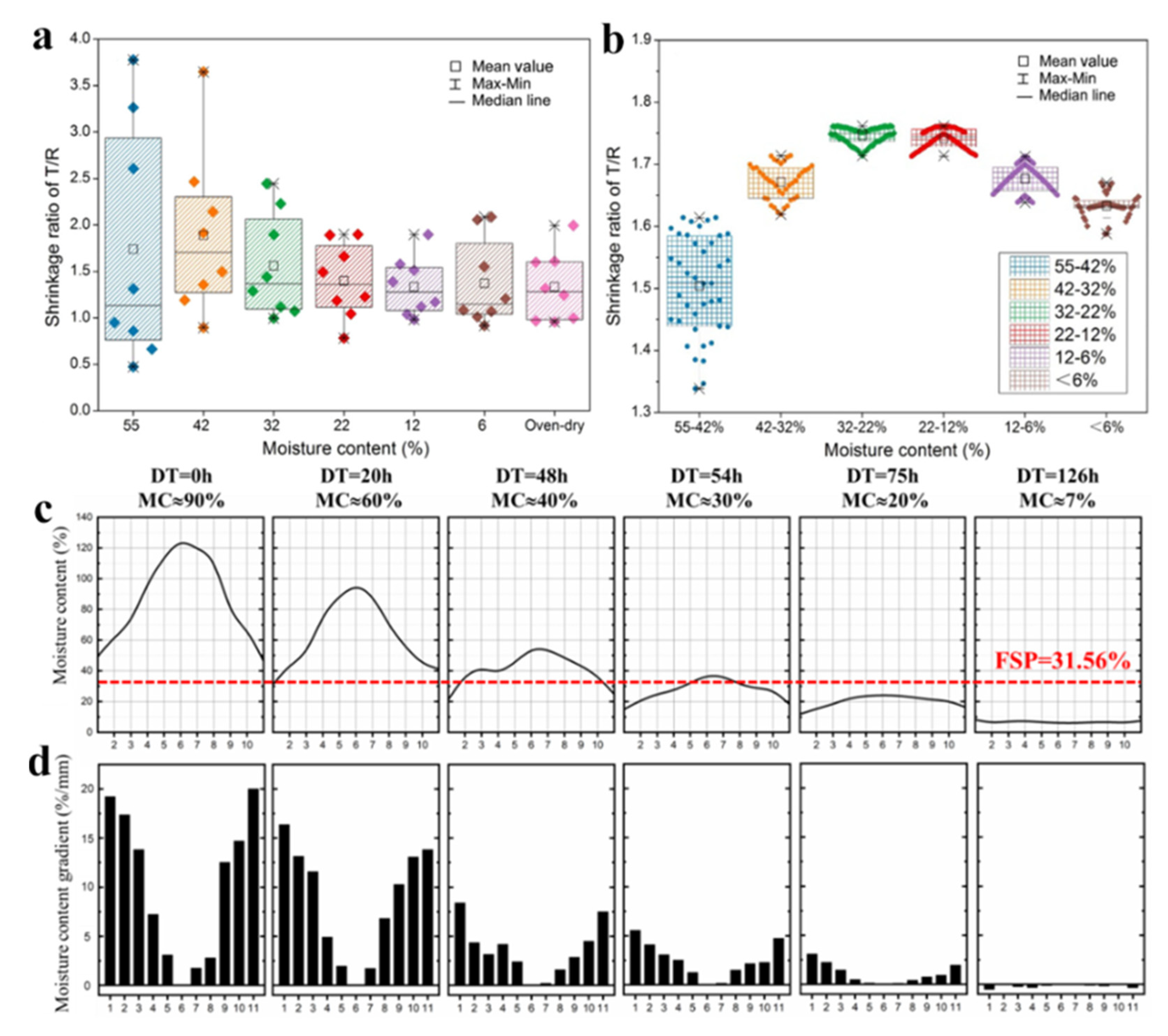

3.1. Shrinkage Anisotropy Stress

3.2. Moisture Content Gradient Stress

4. Relationship between Wood Mechanical Properties and Moisture Content

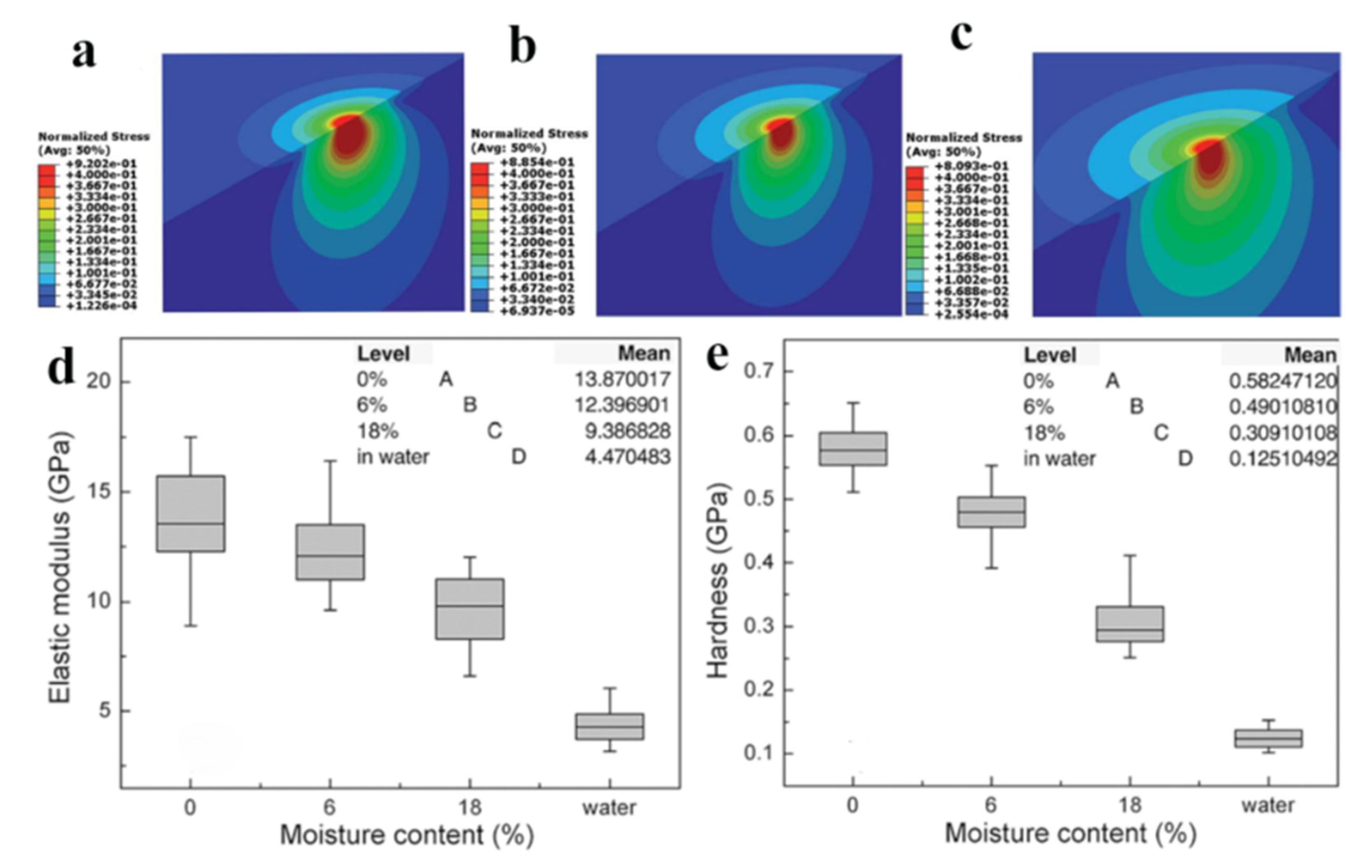

4.1. Relationship between Wood Transverse Mechanical Properties and Moisture Content

4.2. Relationship between Mechanical Properties of Wood Cell Wall and Moisture Content

5. Study on the Law of Wood Deformation and Cracking

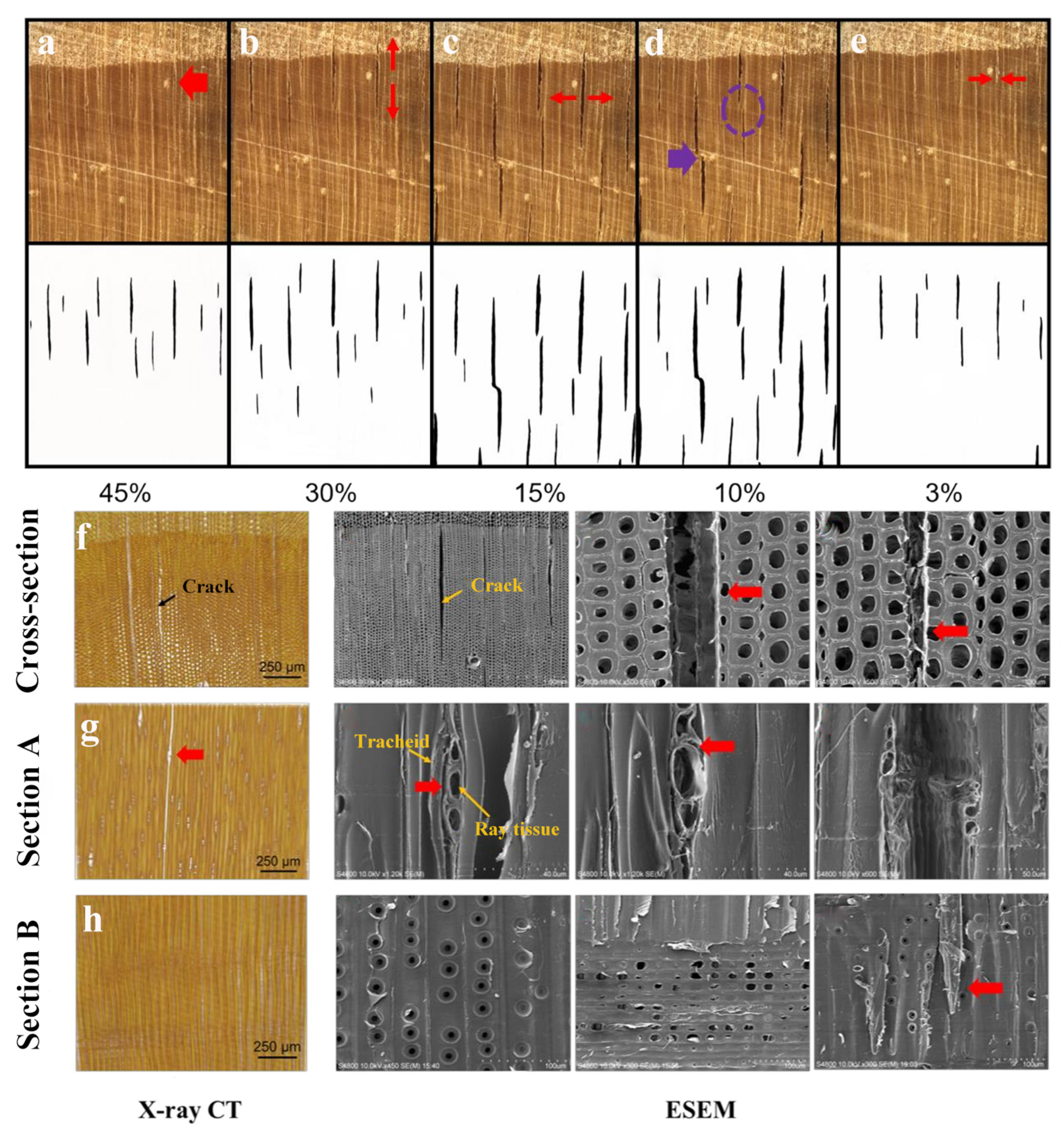

5.1. Study on Cracking in Macroscopic Scale

5.2. Study on Cracking in Cellular Scale

6. Summary and Prospect

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goldhahn, C.; Cabane, E.; Chanana, M. Sustainability in wood materials science: An opinion about current material development techniques and the end of lifetime perspectives. Philos. Trans. R. Soc. A 2021, 379, 20200339. [Google Scholar] [CrossRef] [PubMed]

- Thybring, E.E.; Fredriksson, M. Wood modification as a tool to understand moisture in wood. Forests 2021, 12, 372. [Google Scholar] [CrossRef]

- Kojima, Y.; Yamamoto, H. Effect of moisture content on the longitudinal tensile creep behavior of wood. J. Wood Sci. 2005, 51, 462–467. [Google Scholar] [CrossRef]

- Mvondo, R.R.N.; Meukam, P.; Jeong, J.; Meneses, D.D.S.; Nkeng, E.G. Influence of water content on the mechanical and chemical properties of tropical wood species. Results Phys. 2017, 7, 2096–2103. [Google Scholar] [CrossRef]

- Startsev, O.V.; Makhonkov, A.; Erofeev, V.; Gudojnikov, S. Impact of moisture content on dynamic mechanical properties and transition temperatures of wood. Wood Mater. Sci. Eng. 2017, 12, 55–62. [Google Scholar] [CrossRef]

- Fu, W.L.; Guan, H.Y.; Kei, S. Effects of moisture content and grain direction on the elastic properties of beech wood based on experiment and finite element method. Forests 2021, 12, 610. [Google Scholar] [CrossRef]

- Nocetti, M.; Brunetti, M.; Bacher, M. Effect of moisture content on the flexural properties and dynamic modulus of elasticity of dimension chestnut timber. Eur. J. Wood Wood Prod. 2015, 73, 51–60. [Google Scholar] [CrossRef]

- Spear, M.; Walker, J.C.F. Dimensional instability in timber. In Primary Wood Processing; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar]

- Fu, Z.; Wang, H.; Li, J.; Lu, Y. Determination of Moisture Content and Shrinkage Strain during Wood Water Loss with Electrochemical Method. Polymers 2022, 14, 778. [Google Scholar] [CrossRef]

- Glass, S.; Zelinka, S. Moisture relations and physical properties of wood. In Chapter 4 in FPL-GTR-282; U.S. Department of Agriculture Forest Service: Washington, DC, USA, 2021. [Google Scholar]

- Fu, Z.; Zhao, J.; Huan, S.; Sun, X.; Cai, Y. The variation of tangential rheological properties caused by shrinkage anisotropy and moisture content gradient in white birch disks. Holzforschung 2015, 69, 573–579. [Google Scholar] [CrossRef]

- Kang, W.; Lee, N.H. Mathematical modeling to predict drying deformation and stress due to the differential shrinkage within a tree disk. Wood Sci. Technol. 2002, 36, 463–476. [Google Scholar] [CrossRef]

- Oltean, L.; Teischinger, A.; Hansmann, C. Influence of temperature on cracking and mechanical properties of wood during wood drying—A review. BioResources 2007, 2, 789–811. [Google Scholar] [CrossRef]

- Jankowsky, I.P.; Luiz, M.G. Review of wood drying research in Brazil: 1984–2004. Dry. Technol. 2006, 24, 447–455. [Google Scholar] [CrossRef]

- Ugolev, B.N.; Skuratov, N.V. Stress-strain state of wood at kiln drying. Wood Sci. Technol. 1992, 26, 209–217. [Google Scholar] [CrossRef]

- Fu, Z.; Zhao, J.; Lv, Y.; Huan, S.; Cai, Y. Stress characteristics and stress reversal mechanism of white birch (Betula platyphylla) disks under different drying conditions. Maderas Cienc. Tecnol. 2016, 18, 361–372. [Google Scholar]

- Zhao, Y. Studies on pre-treatment by compression for wood drying III: The reduction of moisture content, the recovery rate, and mechanical properties of wood compressed at different moisture content conditions. J. Wood Sci. 2017, 63, 209–215. [Google Scholar] [CrossRef]

- Gerhards, C.C. Effect of moisture content and temperature on the mechanical properties of wood: An analysis of immediate effects. Wood Fiber Sci. 1982, 14, 4–36. [Google Scholar] [CrossRef]

- Ishimaru, Y.; Oshima, K.; Iida, I. Changes in the mechanical properties of wood during a period of moisture conditioning. J. Wood Sci. 2001, 47, 254–261. [Google Scholar] [CrossRef]

- Soares, L.S.Z.R.; Fraga, I.; Paula, L.; Arroyo, F.; Ruthes, H.; Aquino, V.; Molina, J.C.; Panzera, T.H.; Branco, L.A.M.N.; Lahr, F.; et al. Influence of moisture content on physical and mechanical properties of Cedrelinga catenaeformis wood. BioResources 2021, 16, 6758. [Google Scholar] [CrossRef]

- Fredriksson, M.; Rüggeberg, M.; Nord-Larsen, T.; Beck, G.; Thybring, E.E. Water sorption in wood cell walls–data exploration of the influential physicochemical characteristics. Cellulose 2023, 30, 1857–1871. [Google Scholar] [CrossRef]

- Gao, Y.; Fu, Z.; Fu, F.; Zhou, Y.; Gao, X.; Zhou, F. The formation mechanism of microcracks and fracture morphology of wood during drying. Dry. Technol. 2022, 41, 1268–1277. [Google Scholar] [CrossRef]

- Li, J. Wood Science; Science Press: Beijing, China, 2014. [Google Scholar]

- Penvern, H.; Zhou, M.; Maillet, B.; Courtier-Murias, D.; Scheel, M.; Perrin, J.; Weitkamp, T.; Bardet, S.; Caré, S.; Coussot, P. How bound water regulates wood drying. Phys. Rev. Appl. 2020, 14, 054051. [Google Scholar] [CrossRef]

- Stagno, V.; Ricci, S.; Longo, S.; Verticchio, E.; Frasca, F.; Siani, A.M.; Capuani, S. Discrimination between softwood and hardwood based on hemicellulose content obtained with portable nuclear magnetic resonance. Cellulose 2022, 29, 7917–7934. [Google Scholar]

- Prawate, D.; Nirundorn, M.; Buhnnum, K. Evolution of internal stress during drying, cooling and conditioning of rubberwood lumber. Eur. J. Wood Wood Prod. 2010, 68, 1–12. [Google Scholar]

- Barber, N.F. A theoretical model of shrinking wood. Holzforschung 1968, 22, 97–103. [Google Scholar] [CrossRef]

- Cave, I.D. Theory of shrinkage of wood. Wood Sci. Technol. 1972, 6, 284–292. [Google Scholar] [CrossRef]

- Koponen, S.; Toratti, T.; Kanerva, P. Modelling longitudinal elastic and shrinkage properties of wood. Wood Sci. Technol. 1989, 23, 55–63. [Google Scholar] [CrossRef]

- Yamamoto, H. A model of the anisotropic swelling and shrinking process of wood. Part 1. Generalization of Barber’s wood fiber model. Wood Sci. Technol. 1999, 33, 311–325. [Google Scholar] [CrossRef]

- Yamamoto, H.; Sassus, F.; Ninomiya, M.; Gril, J. A model of anisotropic swelling and shrinking process of wood-Part 2. A simulation of shrinking wood. Wood Sci. Technol. 2001, 35, 167–181. [Google Scholar] [CrossRef]

- Yamashita, K.; Hirakawa, Y.; Nakatani, H.; Ikeda, M. Tangential and radial shrinkage variation within trees in sugi (Cryptomeria japonica) cultivars. J. Wood Sci. 2009, 55, 161–168. [Google Scholar] [CrossRef]

- Fu, Z.; Cai, Y.; Zhao, J.; Huan, S. The effect of shrinkage anisotropy on tangential rheological properties of Asian white birch disks. BioResources 2013, 8, 5235–5243. [Google Scholar] [CrossRef]

- Fu, Z.; Zhao, J.; Yang, Y.; Cai, Y. Variation of drying strains between tangential and radial directions in Asian White Birch. Forests 2016, 7, 59. [Google Scholar] [CrossRef]

- Gao, Y.; Fu, Z.; Zhou, Y.; Gao, X.; Zhou, F.; Cao, H. Moisture-Related Shrinkage Behavior of Wood at Macroscale and Cellular Level. Polymers 2022, 14, 5045. [Google Scholar]

- Glass, S.V.; Zelinka, S.L. Moisture Relations and Physical Properties of Wood, Wood Handbook: Wood as an Engineering Material; US Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Chapter 4. [Google Scholar]

- Larsen, F.; Ormarsson, S.; Olesen, J.F. Moisture-driven fracture in solid wood. Wood Mater. Sci. Eng. 2011, 6, 49–57. [Google Scholar] [CrossRef]

- Larsen, F.; Ormarsson, S. Numerical and experimental study of moisture-induced stress and strain field developments in timber logs. Wood Sci. Technol. 2013, 47, 837–852. [Google Scholar] [CrossRef]

- Pang, S. Modelling of stress development during drying and relief during steaming in Pinus radiata lumber. Dry. Technol. 2000, 18, 1677–1696. [Google Scholar] [CrossRef]

- Feng, Y.; Suchsland, O. Improved technique for measuring moisture content gradients in wood. For. Prod. J. 1993, 43, 56–58. [Google Scholar]

- Alkan, S.; Zhang, Y.; Lam, F. Moisture distribution changes and wetwood behavior in subalpine fir wood during drying using high X-ray energy industrial CT scanner. Dry. Technol. 2007, 25, 483–488. [Google Scholar] [CrossRef]

- Watanabe, K.; Saito, Y.; Avramidis, S.; Shida, S. Non-destructive measurement of moisture distribution in wood during drying using digital X-ray microscopy. Dry. Technol. 2008, 26, 590–595. [Google Scholar] [CrossRef]

- Cai, Z. A new method of determining moisture gradient in wood. For. Prod. J. 2008, 58, 41–45. [Google Scholar]

- Yu, L.; Hao, X.; Cai, L.; Shi, S.Q.; Jiang, J.; Lu, J. An investigation of moisture gradient in wood during drying using X-ray radiation and numeric methods. For. Prod. J. 2014, 64, 199–205. [Google Scholar] [CrossRef]

- Xu, K.; Lu, J.; Gao, Y.; Wu, Y.; Li, X. Determination of moisture content and moisture content profiles in wood during drying by low-field nuclear magnetic resonance. Dry. Technol. 2017, 35, 1909–1918. [Google Scholar] [CrossRef]

- Fredriksson, M.; Thygesen, L.G. The states of water in Norway spruce (Picea abies (L.) Karst.) studied by low-field nuclear magnetic resonance (LFNMR) relaxometry: Assignment of free-water populations based on quantitative wood anatomy. Holzforschung 2017, 71, 77–90. [Google Scholar] [CrossRef]

- Li, J.; Ma, E. Characterization of water in wood by time-domain nuclear magnetic resonance spectroscopy (TD-NMR): A review. Forests 2021, 12, 886. [Google Scholar] [CrossRef]

- Pang, S. Moisture content gradient in a softwood board during drying: Simulation from a 2-D model and measurement. Wood Sci. Technol. 1996, 30, 165–178. [Google Scholar] [CrossRef]

- Pang, S.; Wiberg, P. Model predicted and CT scanned moisture distribution in a Pinus radiata board during drying. Eur. J. Wood Wood Prod. 1998, 56, 9–14. [Google Scholar] [CrossRef]

- Haquea, N. Simulation of temperature and moisture content profiles in a Pinus radiata board during high-temperature drying. Dry. Technol. 2007, 25, 547–555. [Google Scholar] [CrossRef]

- Yamashita, K.; Hirakawa, Y.; Saito, S.; Nakatani, H.; Ikeda, M.; Ohta, M. Effect of cross-sectional dimensions on bow and surface checking of sugi (Cryptomeria japonica) boxed-heart square timber dried by conventional kiln drying. J. Wood Sci. 2014, 60, 1–11. [Google Scholar] [CrossRef]

- Gao, Y.; Zhou, Y.; Fu, Z. Interdependence of shrinkage behavior between wood macroscopic and cellular level during moisture content loss. Dry Technol. 2022, 40, 3241–3248. [Google Scholar] [CrossRef]

- Ozyhar, T.; Hering, S.; Niemz, P. Moisture-dependent elastic and strength anisotropy of European beech wood in tension. J. Mater. Sci. 2012, 47, 6141–6150. [Google Scholar] [CrossRef]

- Jiang, J.; Bachtiar, E.V.; Lu, J.; Niemz, P. Moisture-dependent orthotropic elasticity and strength properties of Chinese fir wood. Eur. J. Wood Wood Prod. 2017, 75, 927–938. [Google Scholar]

- Miyoshi, Y.; Kojiro, K.; Furuta, Y. Effects of density and anatomical feature on mechanical properties of various wood species in lateral tension. J. Wood Sci. 2018, 64, 509–514. [Google Scholar] [CrossRef]

- Zhan, T.; Kuai, B.; Lyu, C.; Wang, X.; Xu, K.; Zhang, Y. Moisture dependence of the tensile strength perpendicular to grain of poplar and Chinese fir. J. For. Eng. 2019, 4, 34–39. [Google Scholar]

- Yue, K.; Song, X.; Cheng, X.; Lai, Y.; Jia, C.; Lu, W.; Liu, W. Study on moisture stresses in Chinese fir glued laminated timber. J. For. Eng. 2019, 4, 35–40. [Google Scholar]

- Yamamoto, H.; Kojima, Y. Properties of the cell wall constituents in relation to the longitudinal elasticity of wood, Part 1: Formulation of the longitudinal elasticity of an isolated wood fiber. Wood Sci. Technol. 2002, 36, 55–74. [Google Scholar]

- Kojima, Y.; Yamamoto, H. Properties of the cell wall constituents in relation to the longitudinal elasticity of wood part 2: Origin of the moisture dependency of the longitudinal elasticity of wood. Wood Sci. Technol. 2004, 37, 427–434. [Google Scholar]

- Yu, Y.; Fei, B.; Wang, H.; Tian, G. Longitudinal mechanical properties of cell wall of masson pine (Pinus massoniana lamb) as related to moisture content: A nanoindentation study. Holzforschung 2011, 65, 121–126. [Google Scholar]

- Meng, Y.; Xia, Y.; Young, T.M.; Cai, Z.; Wang, S. Viscoelasticity of wood cell walls with different moisture content as measured by nanoindentation. Rsc Adv. 2015, 5, 47538–47547. [Google Scholar]

- Wahl, P.; Hanhijärvi, A.; Silvennoinen, R. Investigation of microcracks in wood with laser speckle intensity. Opt. Eng. 2001, 40, 788–792. [Google Scholar]

- Hanhijärvi, A.; Wahl, P.; Räsänen, J.; Silvennoinen, R. Observation of development of microcracks on wood surface caused by drying stresses. Holzforschung 2003, 57, 561–565. [Google Scholar] [CrossRef]

- Yamashita, K.; Hirakawa, Y.; Saito, S.; Nakatani, H.; Ikeda, M.; Ohta, M. Surface-check variation in boxed-heart square timber of sugi (Cryptomeria japonica) cultivars dried by the conventional kiln drying. J. Wood Sci. 2012, 58, 259–266. [Google Scholar]

- Yamashita, K.; Hirakawa, Y.; Saito, S.; Ikeda, M.; Ohta, M. Internal-check variation in boxed-heart square timber of sugi (Cryptomeria japonica) cultivars dried by high-temperature kiln drying. J. Wood Sci. 2012, 58, 375–382. [Google Scholar]

- Phonetip, K.; Ozarska, B.; Brodie, G.I. Comparing two internal check measurement methods for wood drying quality assessment. Eur. J. Wood Wood Prod. 2017, 75, 139–142. [Google Scholar]

- Larsen, F.; Ormarsson, S. Experimental and finite element study of the effect of temperature and moisture on the tangential tensile strength and fracture behavior in timber logs. Holzforschung 2014, 68, 133–140. [Google Scholar]

- Fan, X. Study on the Detection Method of Micro Crack Growth in Larch Drying Process. Master’s Thesis, Northeast Forestry University, Harbin, China, 2019; pp. 25–31. [Google Scholar]

- Sakagami, H. Microcrack propagation in transverse surface from heartwood to sapwood during drying. J. Wood Sci. 2019, 65, 33. [Google Scholar]

- Botter-Kuisch, H.P.; Bulcke, J.V.D.; Baetens, J.M.; Van Acker, J. Cracking the code: Real-time monitoring of wood drying and the occurrence of cracks. Wood Sci. Technol. 2020, 54, 1029–1049. [Google Scholar]

- Wang, H.H.; Youngs, R.L. Drying stress and check development in the wood of two oaks. IAWA J. 1996, 17, 15–30. [Google Scholar]

- Saka, S.; Goring, D.A.I. Localization of Lignins in Wood Cell Walls, Biosynthesis and Biodegradation of Wood Components; Academic Press: Orlando, FL, USA, 1985. [Google Scholar]

- Sakagami, H.; Tsuda, K.; Matsumura, J.; Oda, K. Microcracks occurring during drying visualized by confocal laser scanning microscopy. IAWA J. 2009, 30, 179–187. [Google Scholar]

- Yamamoto, H.; Sakagami, H.; Kijidani, Y.; Matsumura, J. Dependence of microcrack behavior in wood on moisture content during drying. Adv. Mater. Sci. Eng. 2013, 2013, 802639. [Google Scholar]

- Torgovnikov, G.; Vinden, P. High-intensity microwave wood modification for increasing permeability. For. Prod. J. 2009, 59, 84. [Google Scholar]

- Torgovnikov, G.; Vinden, P. Microwave wood modification technology and its applications. For. Prod. J. 2010, 60, 173–182. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Z.; Chen, J.; Zhang, Y.; Xie, F.; Lu, Y. Review on Wood Deformation and Cracking during Moisture Loss. Polymers 2023, 15, 3295. https://doi.org/10.3390/polym15153295

Fu Z, Chen J, Zhang Y, Xie F, Lu Y. Review on Wood Deformation and Cracking during Moisture Loss. Polymers. 2023; 15(15):3295. https://doi.org/10.3390/polym15153295

Chicago/Turabian StyleFu, Zongying, Jiaxing Chen, Yongyue Zhang, Feifan Xie, and Yun Lu. 2023. "Review on Wood Deformation and Cracking during Moisture Loss" Polymers 15, no. 15: 3295. https://doi.org/10.3390/polym15153295

APA StyleFu, Z., Chen, J., Zhang, Y., Xie, F., & Lu, Y. (2023). Review on Wood Deformation and Cracking during Moisture Loss. Polymers, 15(15), 3295. https://doi.org/10.3390/polym15153295