Research Advances of Porous Polyimide—Based Composites with Low Dielectric Constant

Abstract

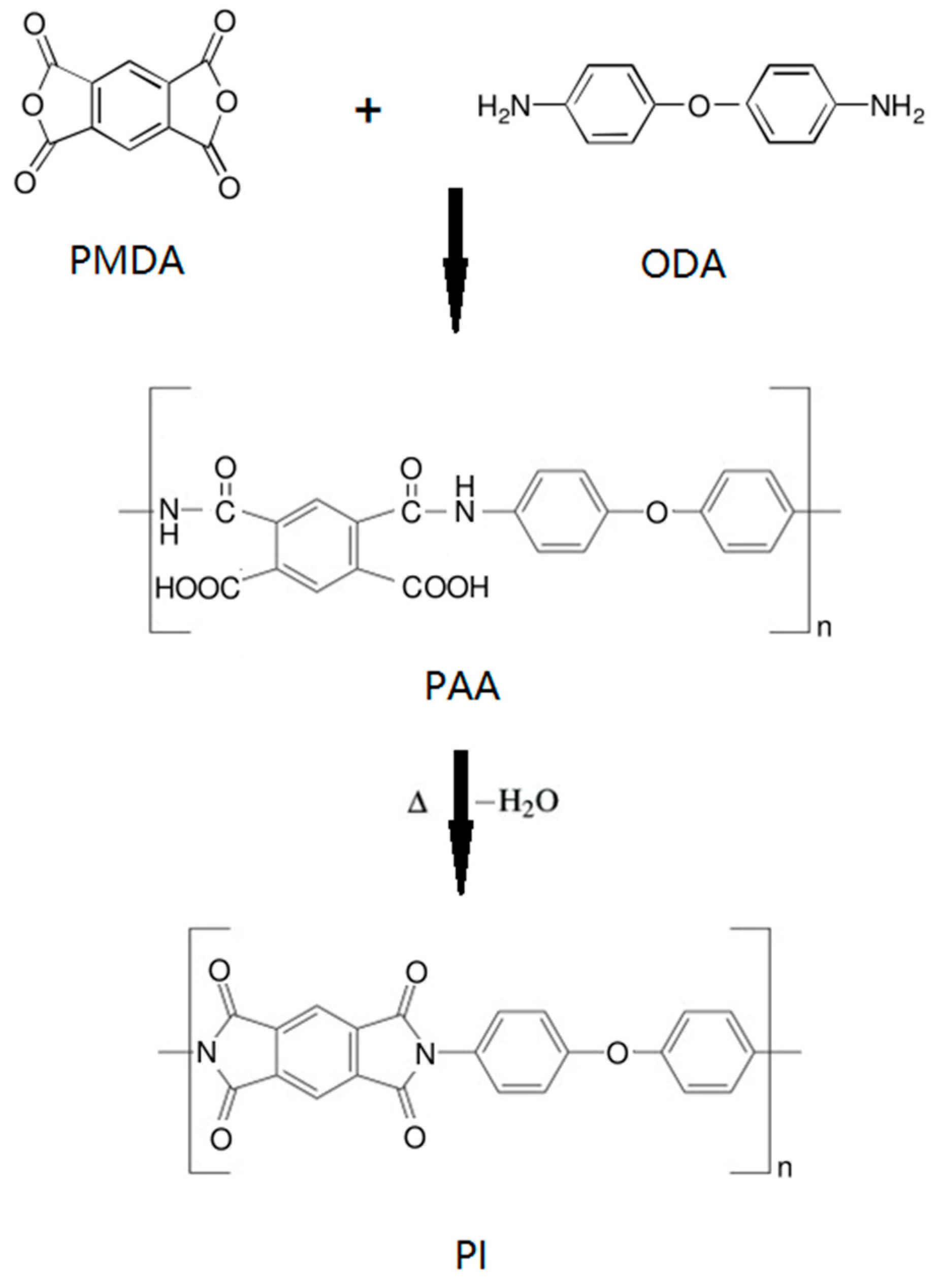

:1. Introduction

2. Methods for Reducing the Dielectric Constant of PI

3. Porous SiO2/PI Composite Material

3.1. Mesoporous SiO2/PI Composite Material

3.2. SiO2 Hollow Tube/PI Composite Material

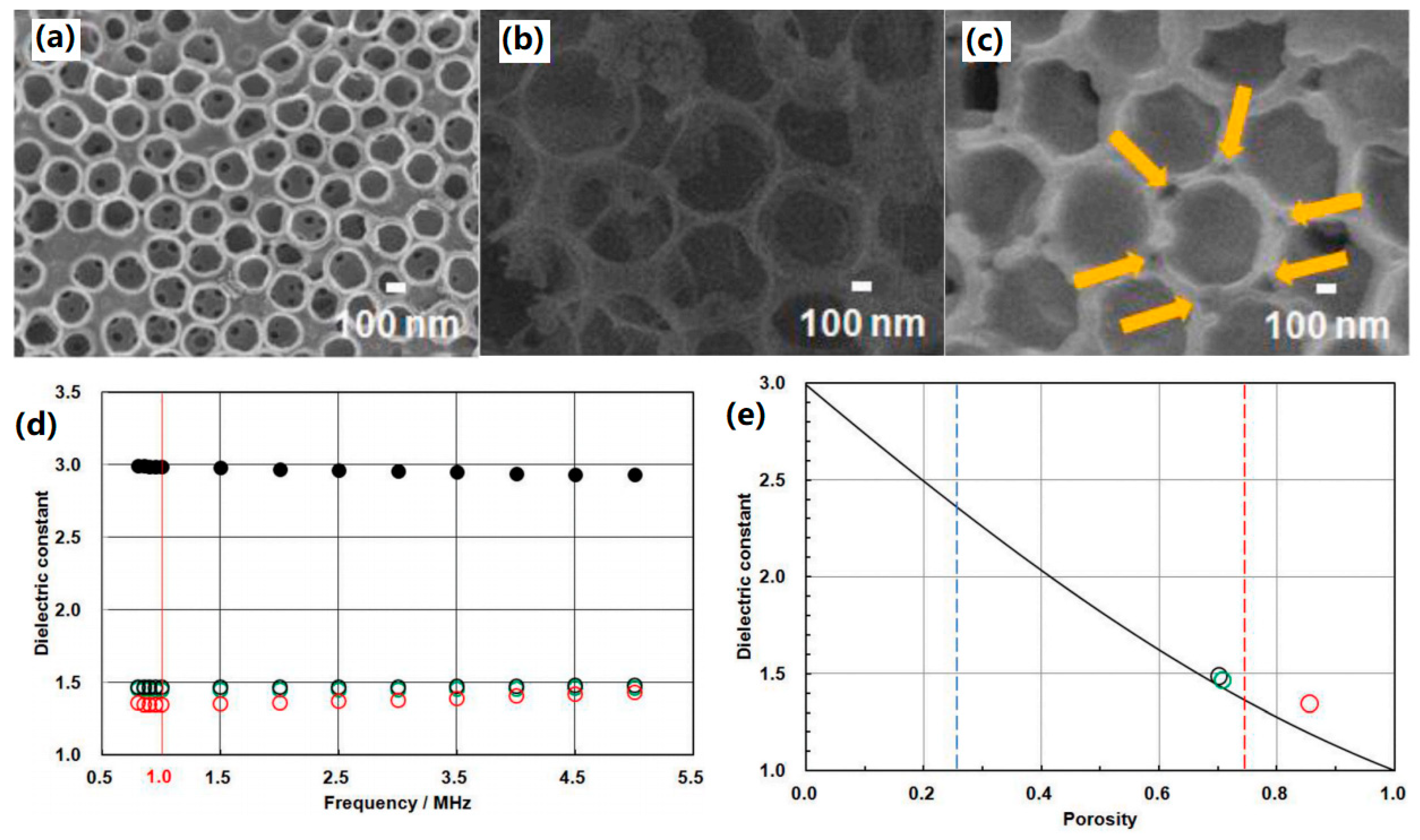

3.3. SiO2 Hollow Sphere/PI Composite Material

4. Graphene Derivative/PI Composite Materials

4.1. GO/PI Composite Materials

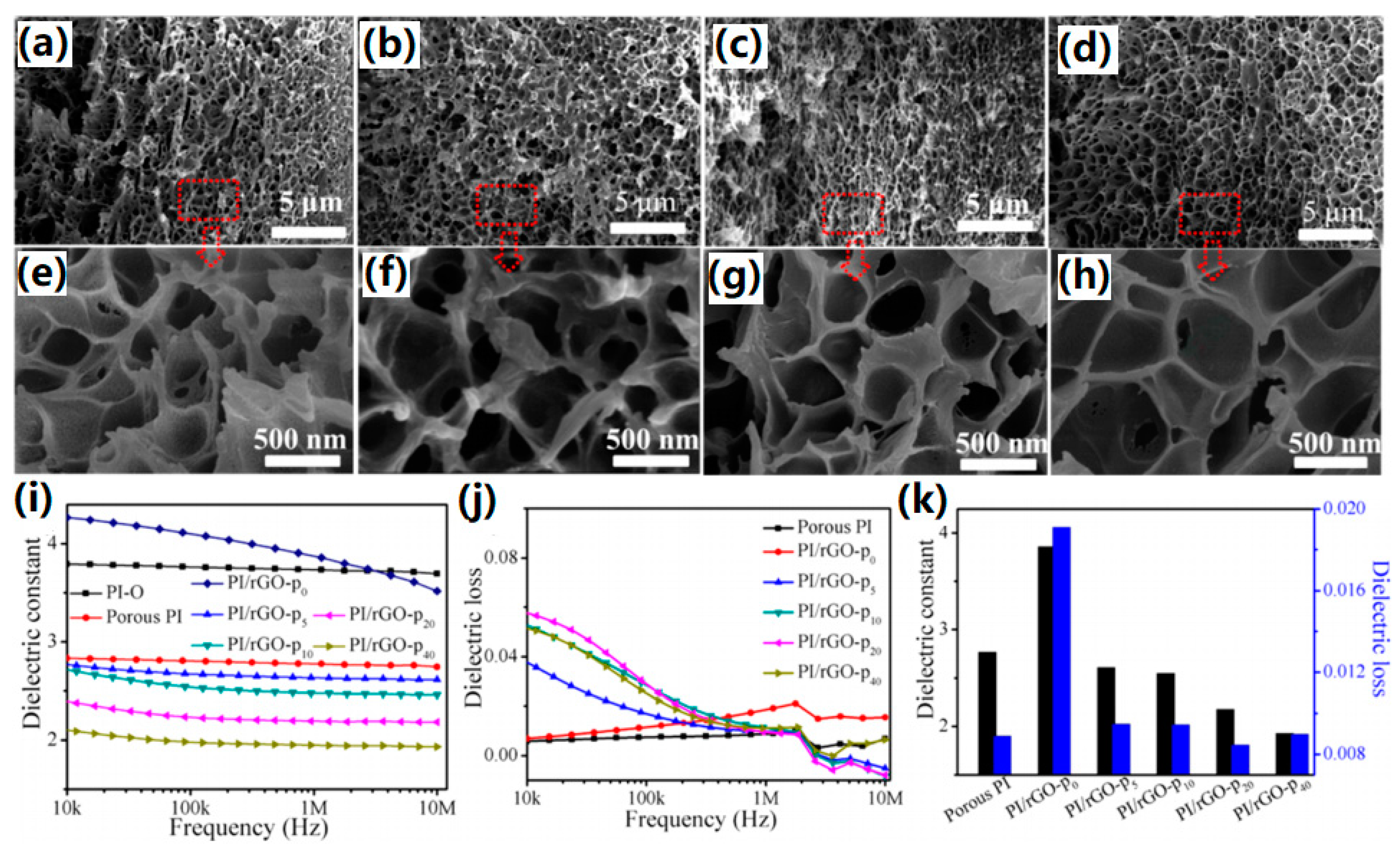

4.2. rGO/PI Composite Materials

4.3. FG/PI Composite Materials

5. Polyoxometalate/PI Composite Materials

6. Polyhedral Oligomeric Silsesquioxane/PI Composite Materials

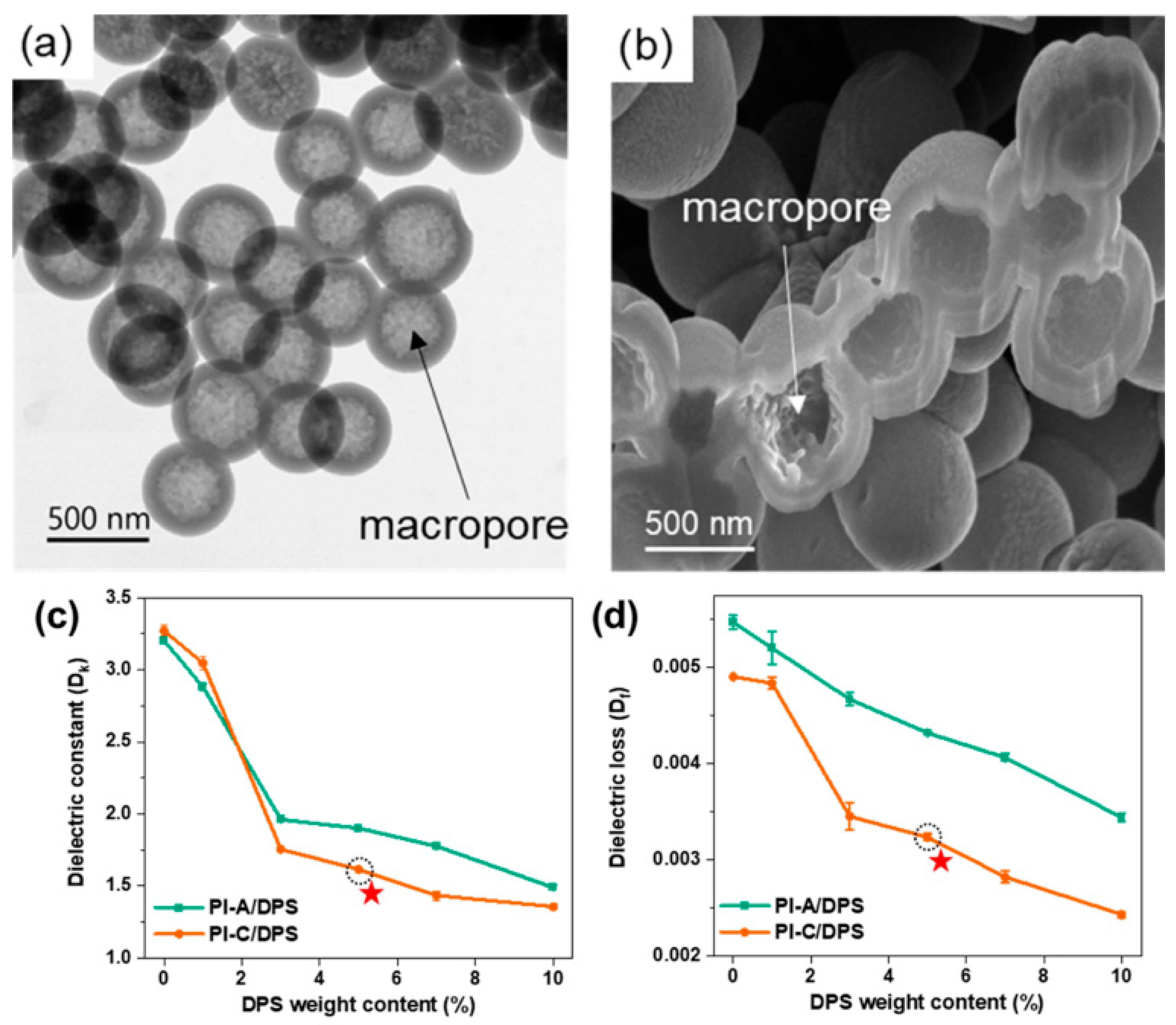

7. Hyperbranched Polysiloxane/PI Composite Materials

8. Other PI Composite Materials

9. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Maier, G. Low dielectric constant polymers for microelectronics. Prog. Polym. Sci. 2001, 26, 3–65. [Google Scholar] [CrossRef]

- Bohr, M. Interconnect scaling—The real limiter to high performance ULSI. Solid State Technol. 1996, 9, 105. [Google Scholar]

- Li, Y.; Sun, G.; Zhou, Y.; Liu, G.; Wang, J.; Han, S. Progress in low dielectric polyimide film—A review. Prog. Org. Coat. 2022, 172, 107103. [Google Scholar] [CrossRef]

- Zheng, Y.; Yu, L.; Wang, Z.; Chen, X.; Li, J.; Zou, Y.; Li, D.; Li, L.; Hu, W. Functionalization of low-k polyimide gate dielectrics with self-assembly monolayer toward high-performance organic field-effect transistors and circuits. Adv. Mater. Interfaces 2021, 8, 2100217. [Google Scholar] [CrossRef]

- Hunt, H.; Lew, C.; Sun, M.; Yan, Y.; Davis, M. Pure-silica zeolite thin films by vapor phase transport of fluoride for low-k applications. Micropor. Mesopor. Mater. 2010, 128, 12–18. [Google Scholar] [CrossRef]

- Jousseaume, V.; Gourhant, O.; Gonon, P.; Zenasni, A.; Favennec, L. Dielectric constant of porous ultra low-k thin films. J. Electrochem Soc. 2012, 159, G49–G55. [Google Scholar] [CrossRef]

- Li, Y.; Ma, B.; Zhang, R.; Luo, X. Mechanically strong, thermal-insulated, and ultralow dielectric polyimide aerogels with adjustable crosslinking methods. Polymer 2022, 253, 125025. [Google Scholar] [CrossRef]

- Wan, B.; Dong, X.; Yang, X.; Wang, J.; Zheng, M.; Dang, Z.; Chen, G.; Zha, J. Rising of dynamic polyimide materials: A versatile dielectric for electrical and electronic applications. Adv. Mater. 2023, 2301185. [Google Scholar] [CrossRef]

- Wang, Z.; Fang, G.; He, J.; Yang, H.; Yang, S. Semi-aromatic thermosetting polyimide resins containing alicyclic units for achieving low melt viscosity and low dielectric constant. React. Funct. Polym. 2020, 146, 104411. [Google Scholar] [CrossRef]

- Lee, J.; Yan, Y.; Park, S.; Ahn, S.; Ha, C. A novel diamine containing ester and diphenylethane groups for colorless polyimide with a low dielectric constant and low water absorption. Polymers 2022, 14, 4504. [Google Scholar] [CrossRef]

- Li, X.; Lei, H.; Guo, J.; Wang, J.; Qi, S.; Tian, G.; Wu, D. Composition design and properties investigation of BPDA/PDA/TFDB co-polyimide films with low dielectric permittivity. J. Appl. Polym. Sci. 2019, 136, 47989. [Google Scholar] [CrossRef]

- Mehdipour-Ataei, S.; Saidi, S. Structure property relationships of low dielectric constant, nanoporous, thermally stable polyimides via grafting of poly (propylene glycol) oligomers. Polym. Adv. Technol. 2008, 19, 889–894. [Google Scholar] [CrossRef]

- Park, S.; Sohn, H.; Hong, S.; Shin, G. Influence of atmospheric fluorine plasma treatment on thermal and dielectric properties of polyimide film. J. Colloid Interf. Sci. 2009, 332, 246–250. [Google Scholar] [CrossRef]

- Zhao, G.; Ishizaka, T.; Kasai, H.; Hasegawa, M.; Furukawa, T.; Nakanishi, H.; Oikawa, H. Ultra-low-dielectric-constant films prepared from hollow polyimide nanoparticles possessing controllable core sizes. Chem. Mater. 2009, 21, 419–424. [Google Scholar] [CrossRef]

- Li, H.; Yang, J.; Dong, S.; Tian, F.; Li, X. Low dielectric constant polyimide obtained by four kinds of irradiation sources. Polymers 2020, 12, 879. [Google Scholar] [CrossRef] [Green Version]

- Alegaonkar, P.; Bhoraskar, V.; Balaya, P.; Goyal, P. Dielectric properties of 1 MeV electron-irradiated polyimide. Appl. Phys. Lett. 2002, 80, 640–642. [Google Scholar] [CrossRef]

- Krause, B.; Koops, G.H.; van der Vegt, N.; Wessling, M.; Wubbenhorst, M.; van Turnhout, J. Ultralow-k dielectrics made by supercritical foaming of thin polymer films. Adv. Mater. 2002, 14, 1041–1046. [Google Scholar] [CrossRef]

- Othman, M.; Ming, N.; Akil, H.; Ahmad, Z. Dependence of the dielectric constant on the fluorine content and porosity of polyimides. J. Appl. Polym. Sci. 2011, 121, 3192–3200. [Google Scholar] [CrossRef]

- Ju, J.; Wang, Q.; Wang, T.; Wang, C. Low dielectric, nanoporus fluorinated polyimide films prepared from PCL-PI-PCL triblock copolymer using retro-Diels-Alder reaction. J. Colloid Interf. Sci. 2013, 404, 36–41. [Google Scholar] [CrossRef] [Green Version]

- Simone, C.; Vaccaro, E.; Scola, D. The synthesis and characterization of highly fluorinated aromatic polyimides. J. Fluor. Chem. 2019, 224, 100–112. [Google Scholar] [CrossRef]

- Dong, W.; Guan, Y.; Shang, D. Novel soluble polyimides containing pyridine and fluorinated units: Preparation, characterization, and optical and electrical properties. RSC Adv. 2016, 6, 21662–21671. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, M.; Han, E.; Niu, H.; Wu, D. Structure-property relationship of low dielectric constant polyimide fibers containing fluorine groups. Polymer 2020, 206, 122884. [Google Scholar] [CrossRef]

- Li, H.; Kong, X.; Wang, S.; Gong, M.; Lin, X.; Zhang, L.; Wang, D. Sustainable dielectric films with ultralow permittivity form soluble fluorinated polyimide. Molecules 2023, 28, 3095. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Tang, J.; Hu, J.; Han, X.; Shang, Y.; Liu, H. One step fabrication of ultralow dielectric polyimide films consisting of size-controlled mesoporous nanoparticles. Colloid Surf. A 2011, 392, 178–186. [Google Scholar] [CrossRef]

- Kim, S.; Son, J.; Park, H.; Jeong, E.; Nam, K.; Bae, J. Polymer concentration and liquid-liquid demixing time correlation with porous structure of low dielectric polyimide in diffusion-driven phase separation. Polymers 2022, 14, 1425. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, P.; Dong, J.; Gan, F.; Zhao, X.; Zhang, Q. Preparation of low-k polyimide resin with outstanding stability of dielectric properties versus temperature by adding a reactive cardo-containing diluent. Compos. Part B-Eng. 2019, 177, 107401. [Google Scholar] [CrossRef]

- Li, J.; Zhang, G.; Zhu, Q.; Li, J.; Zhang, H.; Jing, Z. Synthesis and properties of ultralow dielectric constant porous polyimide films containing trifluoromethyl groups. J. Appl. Polym. Sci. 2017, 134, 44494. [Google Scholar] [CrossRef]

- Wang, W.; Vora, R.; Kang, E.; Neoh, K.; Ong, C.; Chen, L. Nanoporous ultralow-k films prepared from fluorinated polyimide with grafted poly(acrylic acid) side chains. Adv. Mater. 2004, 16, 54–57. [Google Scholar] [CrossRef]

- Lee, T.; Lim, J.; Chung, I.; Kim, I.; Ha, C. Preparation and characterization of polyimide/modified β–cyclodextrin nanocomposite films. Macromol. Res. 2010, 18, 120–128. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, J.; Wu, D.; Li, H.; Jin, R. A methodology for the preparation of nanoporous polyimide films with low dielectric constants. Thin. Solid Film. 2006, 510, 241–246. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, C.; Wang, T. Controllable low dielectric porous polyimide films templated by silica microspheres: Microstructure, formation mechanism, and properties. J. Colloid Interf. Sci. 2013, 389, 99–105. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, L.; Su, Q.; Zheng, H.; Huang, H.; Chan, H. Fluorinated polyimide-silica films with low permittivity and low dielectric loss. J. Mater. Sci. 2012, 47, 1958–1963. [Google Scholar] [CrossRef]

- Lv, P.; Dong, Z.; Dai, X.; Zhao, Y.; Qiu, X. Low-dielectric polyimide nanofoams derived from 4,4′–(hexafluoroisopropylidene) diphthalicanhydride and 2,2′–bis (trifluoromethyl)benzidine. RSC Adv. 2017, 8, 4848–4854. [Google Scholar] [CrossRef] [Green Version]

- Ding, C.; Li, R.; Yu, J.; Wang, X.; Huang, P. Synthesis of porous polyimide films with low dielectric constant and excellent mechanical properties by ambient pressure drying. J. Mater. Sci. 2022, 57, 9480–9492. [Google Scholar] [CrossRef]

- Lv, P.; Dong, Z.; Dai, X.; Qiu, X. Flexible polydimethylsiloxane-based porous polyimide films with an ultralow dielectric constant and remarkable water resistance. ACS Appl. Polym. Mater. 2019, 1, 2597–2605. [Google Scholar] [CrossRef]

- Li, Y.; Cao, Y.; Wu, S.; Ju, Y.; Zhang, X.; Lu, C.; Sun, W. Manipulative pore-formation of polyimide film for tuning the dielectric property via breath figure method. Polymer 2023, 269, 125731. [Google Scholar] [CrossRef]

- Kourakata, Y.; Onodera, T.; Kasai, H.; Jinnai, H.; Oikawa, H. Ultra-low dielectric properties of porous polyimide thin films fabricated by using the two kinds of templates with different sizes. Polymer 2021, 212, 123115. [Google Scholar] [CrossRef]

- Sun, W.; Yang, M.; Peng, K.; Fu, Y. All-organic hyper-crosslinked polymer/polyimide composite films with ultralow high-frequency dielectric constant. Macromol. Rapid Commun. 2023, 44, 2200956. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, L.; He, Z.; Xie, J.; Shi, L.; Zhang, M.; Zhang, W.; Cui, W. Tunable dielectric and other properties in high-performance sandwich-type polyimide films achieved by adjusting the porous structure. J. Mater. Chem. C 2019, 7, 7360–7370. [Google Scholar] [CrossRef]

- Qiu, G.; Ma, W.; Wu, L. Low dielectric constant polyimide mixtures fabricated by polyimide matrix and polyimide microsphere fillers. Polym. Int. 2020, 69, 485–491. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Feng, J. The development of low dielectric constant films. Prog. Chem. 2005, 17, 1001–1011. [Google Scholar]

- Yang, C.; Cho, A.; Pan, F.; Tsai, T.; Chao, K. Spin-on mesoporous silica films with ultralow dielectric constants, ordered pore structures, and hydrophobic surfaces. Adv. Mater. 2001, 13, 1099–1102. [Google Scholar] [CrossRef]

- Lin, J.; Wang, X. Novel low-k polyimide/mesoporous silica composite films: Preparation, microstructure and properties. Polymer 2007, 48, 318–329. [Google Scholar] [CrossRef]

- Lee, T.; Park, S.; Jung, Y.; Han, S.; Hanm, D.; Kim, I.; Ha, C. Preparation and characterization of polyimide/mesoporous silica hybrid nanocomposites based on water-soluble poly(amic acid) ammonium salt. Eur. Polym. J. 2009, 45, 19–29. [Google Scholar] [CrossRef]

- Huang, B.; Li, K.; Peng, M.; Cheng, J. Polyimide/fluorinated silica composite films with low dielectric constant and low water absorption. High Perform. Polym. 2022, 34, 434–443. [Google Scholar] [CrossRef]

- Min, C.; Wu, T.; Yang, W.; Chen, C. Functionalized mesoporous silica/polyimide nanocomposite thin films with improved mechanical properties and low dielectric constant. Compos. Sci. Technol. 2008, 68, 1570–1578. [Google Scholar] [CrossRef]

- Mathews, A.; Yuin, J.; Taesung, L.; Park, S.; Kim, I.; Ha, C. Microstructure and properties of fully aliphatic polyimide/mesoporous silica hybrid composites. Macromol. Res. 2009, 17, 638–645. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, S.; Li, Y.; Dang, Z.; Xin, J.; Fu, S.; Li, G.; Guo, R.; Li, L. Novel silica tube/polyimide composite films with variable low dielectric constant. Adv. Mater. 2005, 17, 1056–1059. [Google Scholar] [CrossRef]

- Zhang, Y.; Dang, Z.; Fu, S.; Xin, J.; Deng, J.; Wu, J.; Yang, S.; Li, L.; Yan, Q. Dielectric and dynamic mechanical properties of polylmide-clay nanocomposite films. Chem. Phys. Lett. 2005, 401, 553–557. [Google Scholar] [CrossRef]

- Yudin, V.; Otaigbe, J.; Gladchenko, S.; Olson, B.; Nazarenko, S.; Korytkov, E.; Gusarov, V. New polyimide nanocomposites based on silicate type nanotubes: Dispersion, processing and properties. Polymer 2007, 48, 1306–1315. [Google Scholar] [CrossRef]

- Chien, H.; Lin, S.; Chen, E.; Wu, T. Synthesis and dielectric properties of polyimide/hollow silica nanofiber composite. J. Mater. Sci.–Mater. El. 2023, 34, 64. [Google Scholar] [CrossRef]

- Zhou, H.; Wei, D.; Fan, Y.; Chen, H.; Yang, Y.; Yu, J.; Jin, L. Dielectric properties of polyimide/SiO2 hollow spheres composite films with ultralow dielectric constant. Mater. Sci. Eng. B 2016, 203, 13–18. [Google Scholar]

- Lee, S.; Choi, M.; Park, S.; Ha, C. Synthesis and characterization of hybrid films of polyimide and silica hollow spheres. Macromol. Res. 2011, 19, 599–607. [Google Scholar] [CrossRef]

- Kim, S.; Lee, Y.; Park, J.; So, Y.; Jung, H.T.; Ko, M.J.; Won, J.C.; Jeong, S.; Kim, Y. Green and facile synthesis of hybrid composites with ultralow dielectric properties from water-soluble polyimide and dual-porous silica nanoparticles. ACS Appl. Mater. Interfaces 2023, 15, 4408–4418. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Yin, C.; Zhao, X.; Li, Y.; Zhang, Q. High strength polyimide fibers with functionalized graphene. Polymer 2013, 54, 6415–6424. [Google Scholar] [CrossRef]

- Wang, J.; Yang, S.; Huang, Y.; Tien, H.; Chin, W.; Ma, C. Preparation and properties of graphene oxide/polyimide composite films with low dielectric constant and ultrahigh strength via in situ polymerization. J. Mater. Chem. 2011, 21, 13569–13575. [Google Scholar] [CrossRef]

- Liao, W.; Yang, S.; Hsiao, S.; Wang, Y.; Li, S.; Ma, C. Effect of octa(aminophenyl) polyhedral oligomeric silsesquioxane functionalized graphene oxide on the mechanical and dielectric properties of polyimide composites. ACS Appl. Mater. Interfaces 2014, 6, 15802–15812. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, J.; Yan, S.; Yuan, Y.; Liu, S. Dielectric properties of photocrosslinkable polyimide/functional graphene oxide composites. Mater. Lett. 2015, 157, 201–204. [Google Scholar] [CrossRef]

- Han, Y.; Ma, Y.; Zhang, J.; Yao, S.; Xu, K. Overall improvement in dielectric, water resistance and mechanical properties of polyimide film via synergy between GO and sandwich-type porous structure. Chem. Asian J. 2023, 18, e202201130. [Google Scholar] [CrossRef]

- Wang, T.; Li, J.; Niu, F.; Zhong, A.; Liu, J.; Liu, W.; Shan, L.; Zhang, G.; Sun, R.; Wong, C. Low-temperature curable and low-dielectric polyimide nanocomposites using aminoquinoline-functionalized graphene oxide nanosheets. Compos. Part B-Eng. 2022, 228, 109412. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, D.; Tong, F.; Lu, X.; Lu, Q. Low dielectric constant polyimide hybrid films prepared by in situ blow-balloon method. ACS Appl. Polym. Mater. 2019, 1, 2189–2196. [Google Scholar] [CrossRef]

- Wang, X.; Dai, Y.; Wang, W.; Ren, M.; Li, B.; Fan, G.; Liu, X. Fluorographene with high fluorine/carbon ratio: A nanofiller for preparing low-k polyimide hybrid films. ACS Appl. Mater. Interfaces 2014, 6, 16182–16188. [Google Scholar] [CrossRef] [PubMed]

- Pu, L.; Huang, X.; Wang, W.; Dai, Y.; Yang, J.; Zhang, H. Strategy to achieve ultralow dielectric constant for polyimide: Introduction of fluorinated blocks and fluorographene nanosheets by in situ polymerization. J. Mater. Sci.–Mater. El. 2019, 30, 14679–14686. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Zhang, K.; Zhao, J.; Li, Y. Preparation of polyimide films with ultra-low dielectric constant by phase inversion. Crystals 2021, 11, 1383. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, K.; Chen, X.; Dou, S.; Zhao, J.; Li, Y. Mechanical, dielectric and thermal properties of polyimide films with sandwich structure. Compos. Struct. 2021, 261, 113305. [Google Scholar] [CrossRef]

- Tan, L.; Liu, S.; Zeng, F.; Zhang, S.; Zhao, J.; Yu, Y. A low dielectric constant polyimide/polyoxometalate composite. Polym. Adv. Technol. 2011, 22, 209–214. [Google Scholar] [CrossRef]

- Chandramohan, A.; Nagendiran, S.; Alagar, M. Synthesis and Characterization of Polyhedral loligomeric sisquioxane-siloxane-modified polyimide hybrid nanocomposites. J. Compos. Mater. 2012, 46, 773–781. [Google Scholar] [CrossRef]

- Raftopoulos, K.; Pielichowski, K. Segmental dynamics in hybrid polymer/POSS nanomaterials. Prog. Polym. Sci. 2016, 52, 136–187. [Google Scholar] [CrossRef]

- Leu, C.; Chang, Y.; Wei, K. Polyimide-side-chain tethered polyhedral oligomeric silsesquioxane nanocomposites for low-dielectric film applications. Chem. Mater. 2003, 15, 3721–3727. [Google Scholar] [CrossRef]

- Wahab, M.; Mya, K.; He, C. Synthesis, morphology, and properties of hydroxyl terminated-POSS/polyimide low-k nanocomposite films. J. Polym. Sci. Pol. Chem. 2008, 46, 5887–5896. [Google Scholar] [CrossRef]

- Ye, Y.; Chen, W.; Wang, Y. Synthesis and properties of low-dielectric-constant polyimides with introduced reactive fluorine polyhedral oligomeric silsesquioxanes. J. Polym. Sci. Pol. Chem. 2006, 44, 5391–5402. [Google Scholar] [CrossRef]

- Ye, Y.; Ye, Y.; Chen, W.; Cheng, C.; Chang, F. A simple approach toward low-dielectric polyimide nanocomposites: Blending the polyimide precursor with a fluorinated polyhedral oligomeric silsesquioxane. J. Polym. Sci. Pol. Chem. 2008, 46, 6296–6304. [Google Scholar]

- Lee, Y.; Huang, J.; Kuo, S.; Chang, F. Low-dielectric, nanoporous polyimide films prepared from PEO-POSS nanoparticles. Polymer 2005, 46, 10056–10065. [Google Scholar] [CrossRef]

- Luo, K.; Song, G.; Wang, Y.; Yu, J.; Zhu, J.; Hu, Z. Low-k and recyclable high-performance POSS/polyimide composites based on Diels-Alder reaction. ACS Appl. Polym. Mater. 2019, 1, 944–952. [Google Scholar] [CrossRef]

- Revathi, R.; Hariharan, A.; Prabunathan, P.; Srinivasan, K. Multifunctional behavior of POSS-reinforced imidazole core polyimide nanocomposites. Polym. Bull. 2019, 76, 5059–5075. [Google Scholar]

- Chen, Z.; Zhou, Y.; Wu, Y.; Liu, S.; Huang, H.; Zhao, J. Fluorinated polyimide with polyhedral oligomeric silsesquioxane aggregates: Toward low dielectric constant and high toughness. Compos. Sci. Technol. 2019, 181, 107700. [Google Scholar]

- Zhang, Y.; Wu, B.; Wang, H.; Wu, H.; An, Y.; Zhi, X.; Liu, J. Nanocomposite films with potential applications as spacecraft antenna substrates with low dielectric features and good sustainability in atomic-oxygen environments. Nanomaterials 2021, 11, 1886. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhang, Y.; Zhao, J.; Mo, Y.; Liu, S. Imparting low dielectric constant and high toughness to polyimide via physical blending with trifluoropropyl polyhedral oligometric silsesquioxane. Polym. Eng. Sci. 2022, 62, 2809–2816. [Google Scholar] [CrossRef]

- He, Z.; Xie, J.; Liao, Z.; Ma, Y.; Zhang, M.; Zhang, W.; Yue, H.; Gao, X. Hierarchical porous structure contained composite polyimide film with enhanced dielectric and water resistance properties for dielectric material. Prog. Org. Coat. 2021, 151, 106030. [Google Scholar] [CrossRef]

- Ma, Y.; He, Z.; Liao, Z.; Xie, J.; Yue, H.; Gao, X. Facile strategy for low dielectric constant polyimide/silsesquioxane composite films: Structural design inspired from nature. J. Mater. Sci. 2021, 56, 7397–7408. [Google Scholar]

- Zhao, W.; Lu, C.; Zhao, H.; Huang, J.; Zhan, J.; Cao, X.; Li, R.; Wu, W. Achieving hydrophobic ultralow dielectric constant polyimide composites: Combined efforts of fluorination and porous fillers. Macromol. Mater. Eng. 2022, 307, 2200291. [Google Scholar] [CrossRef]

- Dong, J.; Yang, C.; Cheng, Y.; Wu, T.; Zhao, X.; Zhang, Q. Facile method for fabricating low dielectric constant polyimide fibers with hyperbranched polysiloxane. J. Mater. Chem. C 2017, 5, 2818–2825. [Google Scholar] [CrossRef]

- Krauter, G.; Schumacher, A.; Gosele, U. Low temperature silicon direct bonding for application in micromechanics: Bonding energies for different combinations of oxides. Sens. Actuat. A Phys. 1998, 70, 271–275. [Google Scholar] [CrossRef]

- Li, X.; Zhu, X.; Dong, J.; Zhao, X.; Zhang, Q. Preparation of low-dielectric permittivity polyimide resins with high surface activity from chemically bonded hyperbranched polysiloxane. Chin. J. Polym. Sci. 2021, 39, 1200–1210. [Google Scholar] [CrossRef]

- Lian, R.; Lei, X.; Chen, Y.; Zhang, Q. Hyperbranched-polysiloxane-based hyperbranched polyimide films with low dielectric permittivity and high mechanical and thermal properties. J. Appl. Polym. Sci. 2019, 136, 47771. [Google Scholar] [CrossRef]

- Wang, H.; Dong, R.; Chu, H.; Chang, K.; Lee, W. Improvements on the synthesis and properties of fluorinated polyimide-clay nanocomposites by using double-swelling agents. Mater. Chem. Phys. 2005, 94, 42–51. [Google Scholar] [CrossRef]

- Dong, X.; Wan, B.; Feng, Y.; Min, D.; Zheng, M.; Xu, H.; Dang, Z.; Chen, G.; Zha, J. Ultra-low-permittivity, high hydrophobic and excellent thermally stable fluoroelastomer/polyimide composite films employing dielectric reduction. Eur. Polym. J. 2022, 181, 111667. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, H.; Nie, Y.; Fang, X.; Chen, G. Composite films with low dielectric constant and dielectric loss factor at high frequency prepared from polyimide and polytetrafluoroethylene. Polym. Eng. Sci. 2022, 62, 4226–4234. [Google Scholar] [CrossRef]

- Cheng, T.; Lv, G.; Li, Y.; Yun, H.; Zang, L.; Deng, Y.; Lin, L.; Luo, X.; Nan, J. Low dielectric polyimide/fluorinated ethylene propylene (PI/FEP) nanocomposite film for high-frequency flexible circuit board application. Macromol. Mater. Eng. 2021, 306, 2100086. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Gong, Y.; Zhao, H.; Liu, Z.; Tao, L.; Peng, Y.; Ma, K.; Hu, Z.; Dastan, D. Polyimide/crown ether composite with low dielectric constant and low dielectric loss for high signal transmission. RSC Adv. 2023, 13, 7585–7596. [Google Scholar] [CrossRef]

- Zhang, Y.; He, J.; Yang, R. Ultra-low dielectric constant and high thermal stability of low-crosslinked polyimide with zinc tetraamino phthalocyanine. J. Mater. Sci. 2022, 57, 16064–16079. [Google Scholar] [CrossRef]

- Wang, L.; Gong, G.; Shen, J.; Leng, J. Fabrication of low dielectric constant polyimide/TiO2 nanofibers with enhanced UV-light shielding properties. High Perform. Polym. 2019, 31, 986–995. [Google Scholar]

- Huang, Z.; Zhao, J. Low-k and superior comprehensive property hybrid materials of a fluorinated polyimide and pure silica zeolite. RSC Adv. 2016, 6, 34825–34832. [Google Scholar] [CrossRef]

- Xu, C.; Wang, X.; Yu, Z.; Gu, J.; Feng, X.; Zhang, S. A superhydrophobic fluorinated-silica/polyimide nanofiber membrane with ultra-low dielectric constant. J. Mater. Sci. 2023, 58, 5599–5609. [Google Scholar] [CrossRef]

- Cao, X.; Wen, J.; Song, L.; Liu, X.; He, G. Polyimide hollow glass microspheres composite films with low dielectric constant and excellent thermal performance. J. Appl. Polym. Sci. 2021, 138, e50600. [Google Scholar] [CrossRef]

- Kurinchyselvan, S.; Hariharan, A.; Prabunathan, P.; Gomathipriya, P.; Alagar, M. Fluorinated polyimide nanocomposites for low k dielectric applications. J. Polym. Res. 2019, 26, 207. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, J.; Li, J.; Lv, X.; Shan, L.; Zhang, G.; Sun, R.; Wong, C. Aminoquinoline-functionalized fluorographene quantum dots for low-temperature curable and low-dielectric photosensitive polyimide nanocomposites. Compos. Commun. 2023, 38, 101469. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Nie, H.; Kang, E. Low-k nanocomposite films based on polyimides with grafted polyhedral oligomeric silsesquioxane. J. Appl. Polym. Sci. 2006, 99, 2226–2232. [Google Scholar]

- Huang, C.; Li, J.; Xie, G.; Han, F.; Huang, D.; Zhang, F.; Zhang, B.; Zhang, G.; Sun, R.; Wong, C. Low-dielectric constant and low temperature curable polyimide/POSS nanocomposites. Macromol. Mater. Eng. 2019, 304, 1900505. [Google Scholar] [CrossRef]

- Devaraju, S.; Vengatesan, M.; Selvi, M.; Kumar, A.; Alagar, M. Synthesis and characterization of bisphenol—A ether diamine-based polyimide POSS nanocomposites for low k dielectric and flame-retardant applications. High Perform. Polym. 2021, 24, 85–96. [Google Scholar] [CrossRef]

- Devaraju, S.; Vengatesan, M.; Alagar, M. Studies on thermal and dielectric properties of ether linked cyclohexyl diamine (ELCD)–based polyimide POSS nanocomposites (POSS-PI). High Perform. Polym. 2011, 23, 99–111. [Google Scholar]

- Liu, S.; Feng, Q.; Li, Y.; Chen, Z.; Zhao, J. Simultaneously improving dielectric and mechanical properties of crown ether/fluorinated polyimide films with necklace-like supramolecular structure. Macromol. Chem. Phys. 2020, 221, 2000256. [Google Scholar] [CrossRef]

- Shi, C.; Liu, S.; Wu, Y.; Cheng, K.; Zhao, J.; Fu, Y. Dielectric constant, thermal and mechanical properties of ladder-like polypropylsilsesquioxane/crown ether-polyimide nanocomposites. Macromol. Chem. Phys. 2019, 220, 1900017. [Google Scholar] [CrossRef]

- Zhang, J.; Sui, Y.; Li, J.; Shan, L.; Niu, F.; Zhang, G.; Sun, R. Low-dielectric and low-temperature curable fluorinated nano carbon/polyimide composites with 6–aminoquinoline for end capping. Polym. Compos. 2023, 44, 886–896. [Google Scholar] [CrossRef]

- Wang, L.; Tomura, S.; Ohashi, F.; Maeda, M.; Suzuki, M.; Inukai, K. Synthesis of single silica nanotubes in the presence of citric acid. J. Mater. Chem. 2001, 11, 1465–1468. [Google Scholar] [CrossRef]

- Song, N.; Yao, H.; Ma, T.; Wang, T.; Shi, K.; Tian, Y.; Zhang, B.; Zhu, S.; Zhang, Y.; Guan, S. Decreasing the dielectric constant and water uptake by introducing hydrophobic cross-linked networks into co-polyimide films. Appl. Surf. Sci. 2019, 480, 990–997. [Google Scholar] [CrossRef]

- Yang, K.; Kang, Y.; Ahn, H.; Kim, D.; Park, N.; Choi, S.; Won, J.; Kim, Y. Porous boron nitride/polyimide composite films with high thermal diffusivity and low dielectric properties via high internal phase Pickering emulsion method. J. Ind. Eng. Chem. 2020, 82, 173–179. [Google Scholar] [CrossRef]

| Additive | Dielectric Constant | Frequency | Ref. |

|---|---|---|---|

| SiO2 | 2.61 | 1 MHz | [43] |

| 2.45 | 1 kHz | [44] | |

| 2.61 | 10 MHz | [45] | |

| 2.6 | 1 MHz | [46] | |

| 2.5 | 1 MHz | [47] | |

| 2.9 | 1 MHz | [48] | |

| 2.2 | 1 kHz | [50] | |

| 2.58 | 28 GHz | [51] | |

| 2.09 | 1 kHz | [52] | |

| 2.24 | 1 kHz | [53] | |

| 1.62 | 28 GHz | [54] | |

| 2.65 | 1 MHz | [93] | |

| 1.81 | 1 MHz | [94] | |

| Glass | 2.21 | 1 MHz | [95] |

| GO | 2.58 | 10 MHz | [58] |

| 2.21 | 10 MHz | [59] | |

| 2.0 | 1 GHz | [56] | |

| 1.9 | 1 GHz | [57] | |

| 2.58 | 10 MHz | [58] | |

| 2.21 | 10 MHz | [59] | |

| 2.96 | 1 MHz | [60] | |

| 2.1 | 1 MHz | [96] | |

| rGO | 1.93 | 1 MHz | [61] |

| FG | 2.1 | 1 MHz | [62] |

| 1.77 | 1 kHz | [63] | |

| 1.56 | 10 kHz | [64] | |

| 1.92 | 10 kHz | [65] | |

| 2.65 | 1 MHz | [97] | |

| POM | 2.05 | 1 MHz | [66] |

| POSS | 2.4 | 1 MHz | [69] |

| 2.53 | - | [70] | |

| 2.30 | 100 kHz | [71] | |

| 2.12 | 100 kHz | [72] | |

| 2.25 | 1 MHz | [73] | |

| 2.25 | 1 MHz | [74] | |

| 2.1 | 1 MHz | [75] | |

| 2.09 | 10 MHz | [76] | |

| 2.52 | 1 MHz | [77] | |

| 2.47 | 10 MHz | [78] | |

| 2.42 | 1 MHz | [79] | |

| 2.28 | 1 MHz | [80] | |

| 2.21 | 1 MHz | [98] | |

| 2.6 | 1 MHz | [99] | |

| 2.68 | 1 MHz | [100] | |

| 2.6 | 1 MHz | [101] | |

| HBPSi | 2.19 | 10 MHz | [83] |

| 2.8 | 1 MHz | [84] | |

| SiO2/POSS/PI | 1.88 | 1 MHz | [85] |

| Montmorillonite | 2.6 | 1 MHz | [86] |

| FEM | 1.21 | 1 MHz | [87] |

| PTFE | 2.42 | 10 GHz | [88] |

| FEP | 2.69 | 10 GHz | [89] |

| CE | 2.33 | 10 GHz | [90] |

| 2.74 | 1 MHz | [102] | |

| Polypropylsilsesquioxane/CE | 2.71 | 1 MHz | [103] |

| TAPcZn | 2.33 | 1 MHz | [91] |

| Fluorinated nanocarbon | 2.75 | 1 MHz | [104] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, Z.; Sun, H.; Guo, Y.; Du, J.; Li, L.; Li, Q.; Yang, J.; Zhang, J.; Wu, W.; Yang, S. Research Advances of Porous Polyimide—Based Composites with Low Dielectric Constant. Polymers 2023, 15, 3341. https://doi.org/10.3390/polym15163341

Pang Z, Sun H, Guo Y, Du J, Li L, Li Q, Yang J, Zhang J, Wu W, Yang S. Research Advances of Porous Polyimide—Based Composites with Low Dielectric Constant. Polymers. 2023; 15(16):3341. https://doi.org/10.3390/polym15163341

Chicago/Turabian StylePang, Zhenjiang, Hengchao Sun, Yan Guo, Jun Du, Liang Li, Qiuyang Li, Junzhong Yang, Jijun Zhang, Weiguo Wu, and Sen Yang. 2023. "Research Advances of Porous Polyimide—Based Composites with Low Dielectric Constant" Polymers 15, no. 16: 3341. https://doi.org/10.3390/polym15163341

APA StylePang, Z., Sun, H., Guo, Y., Du, J., Li, L., Li, Q., Yang, J., Zhang, J., Wu, W., & Yang, S. (2023). Research Advances of Porous Polyimide—Based Composites with Low Dielectric Constant. Polymers, 15(16), 3341. https://doi.org/10.3390/polym15163341