Study of a Conical Plasma Jet with a Cloth-Covered Nozzle for Polymer Treatment

Abstract

1. Introduction

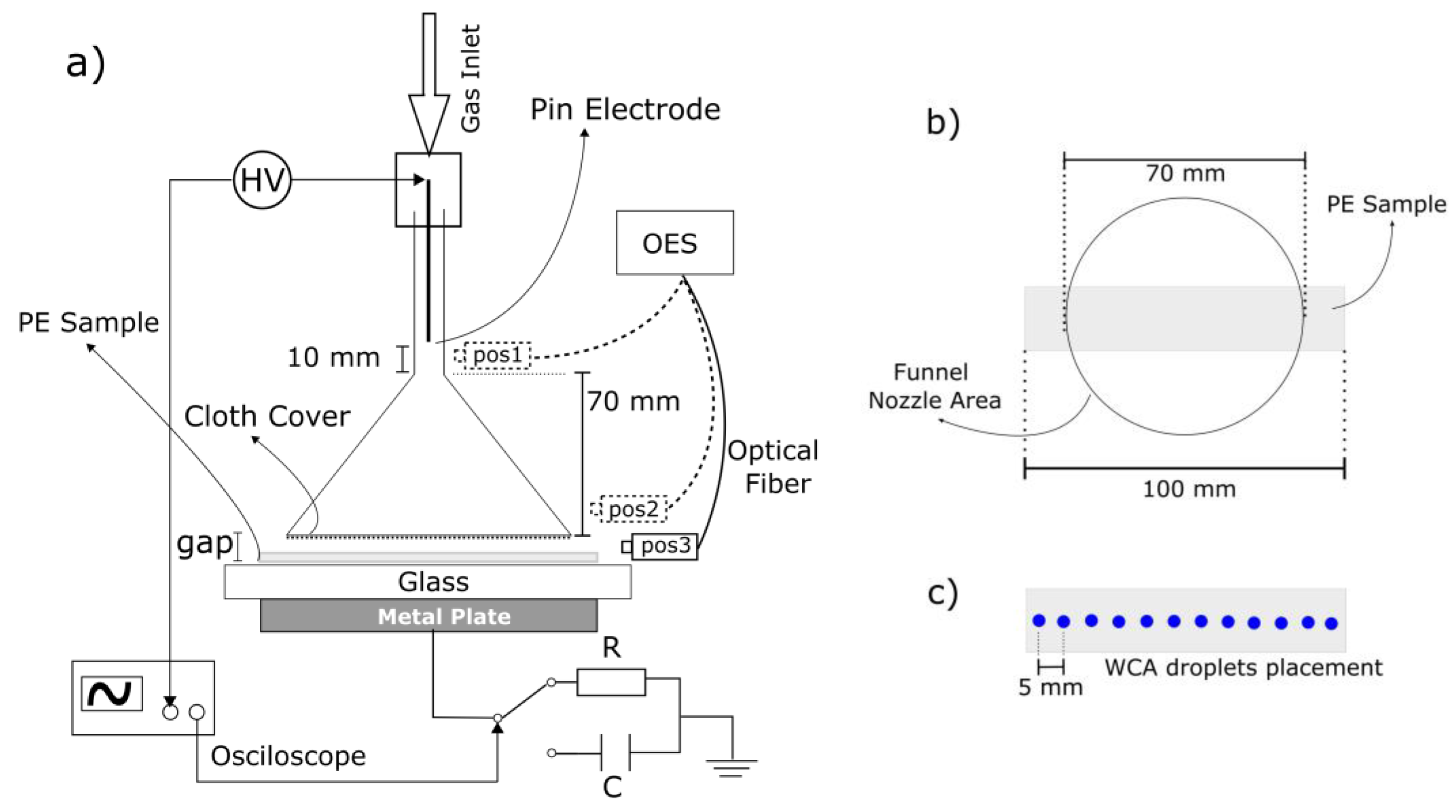

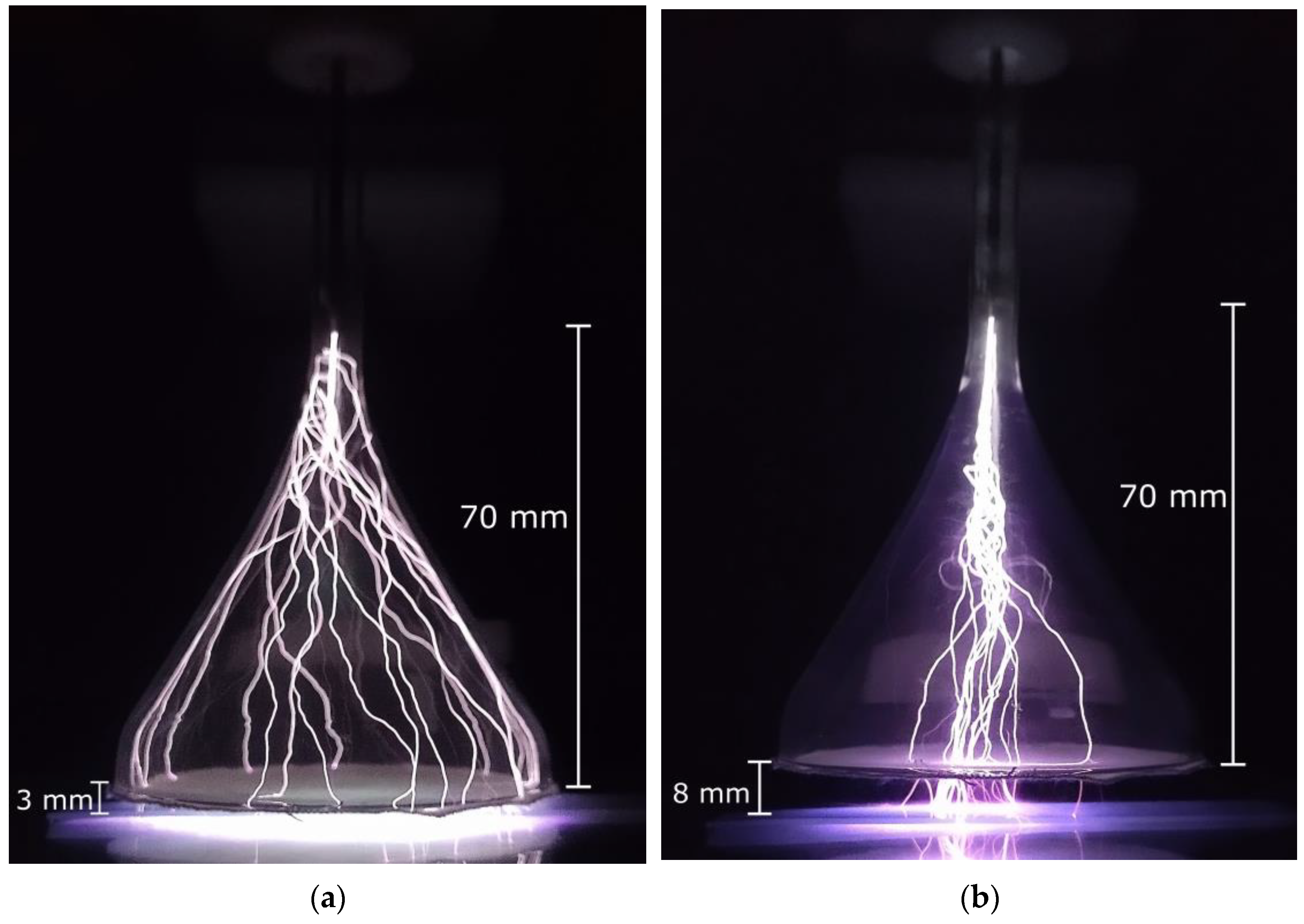

2. Materials and Methods

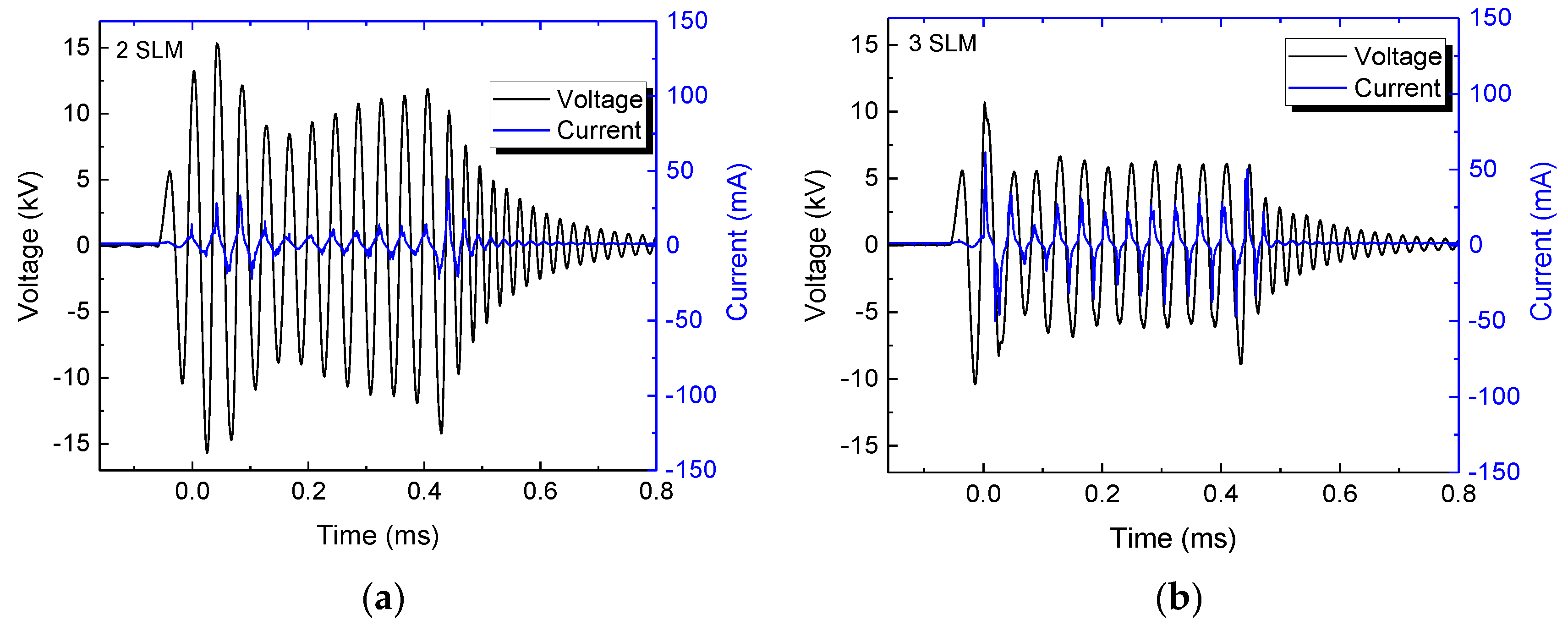

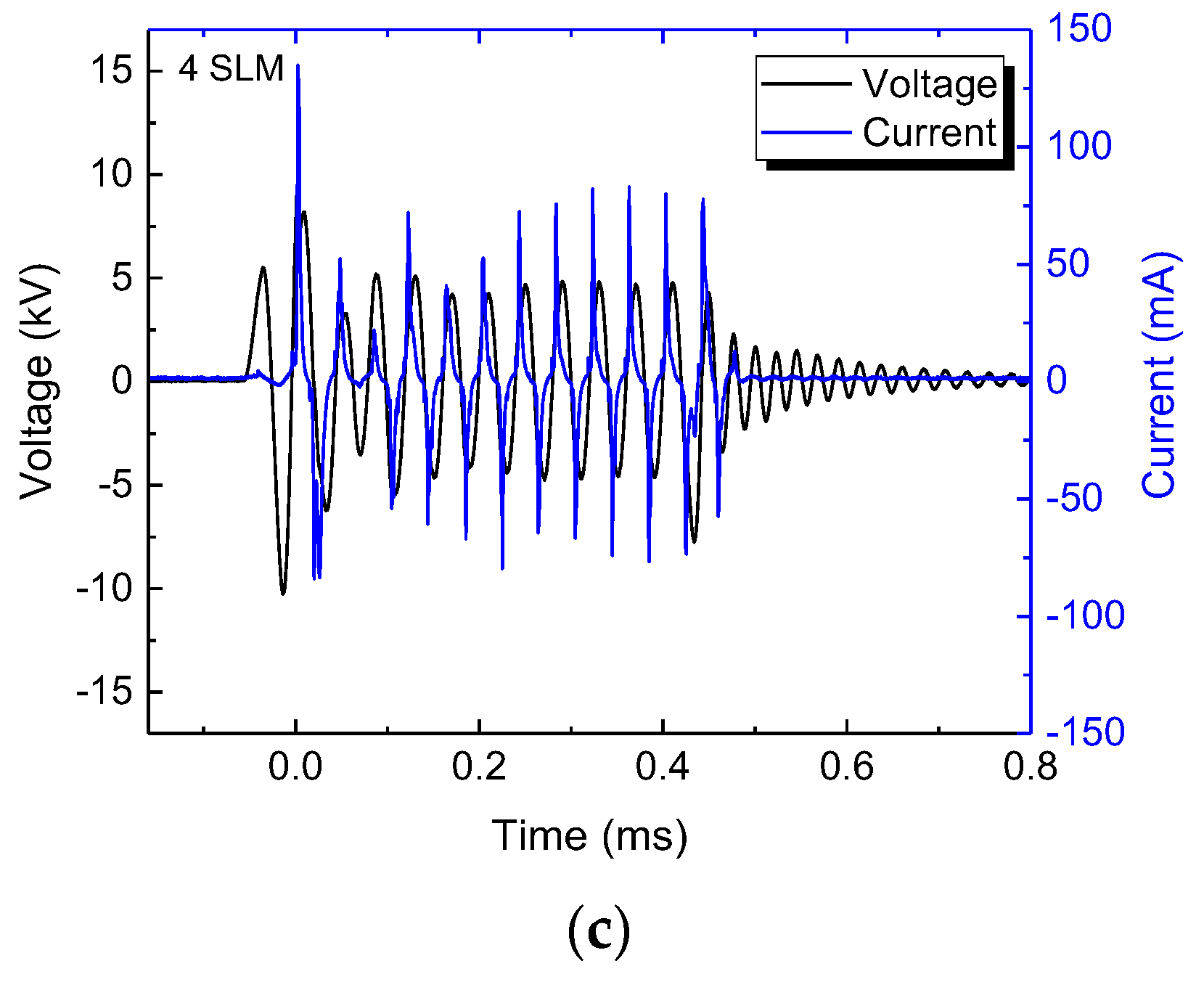

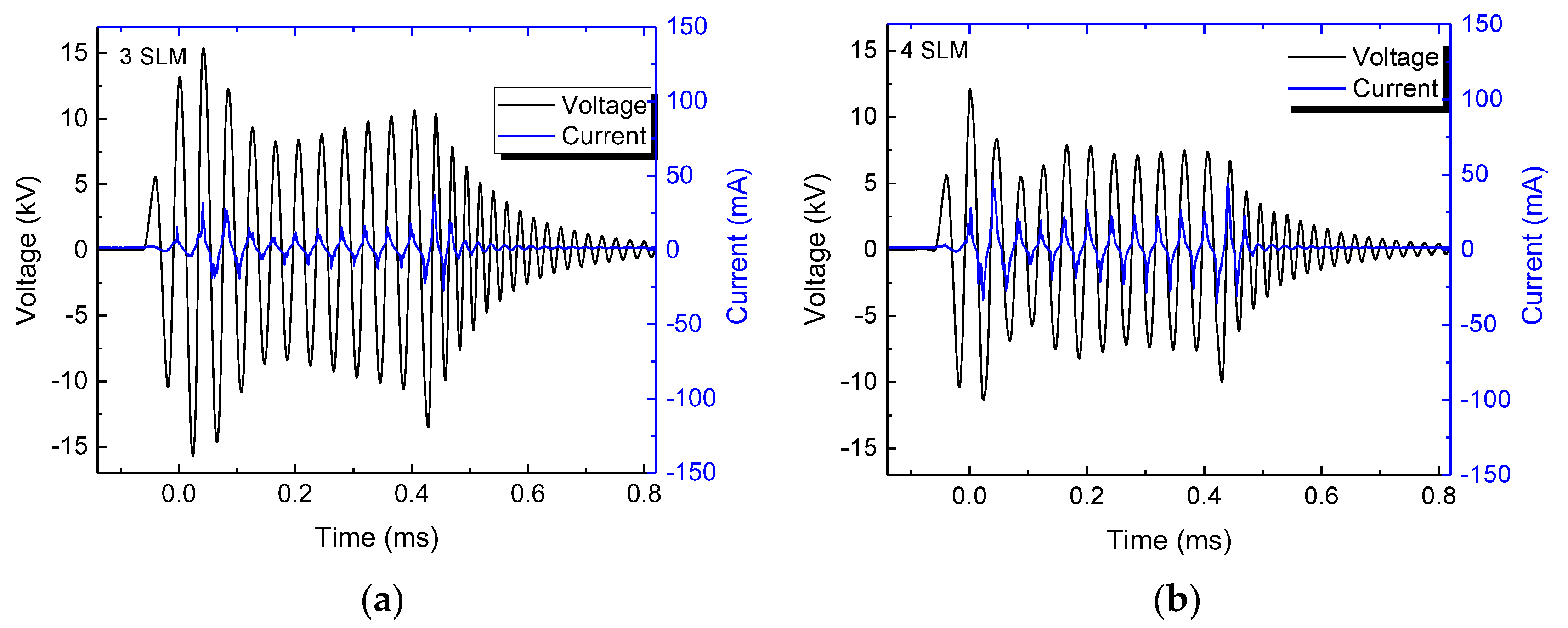

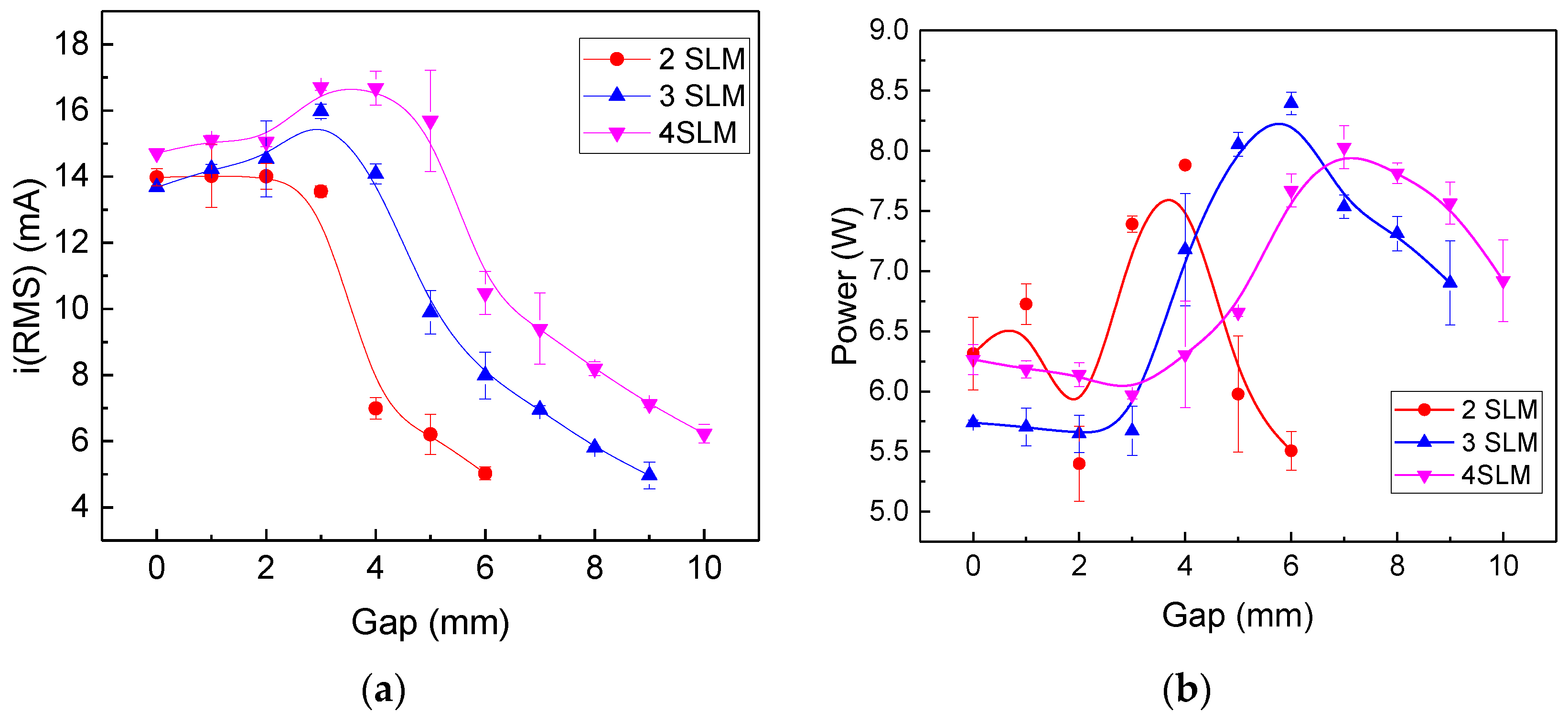

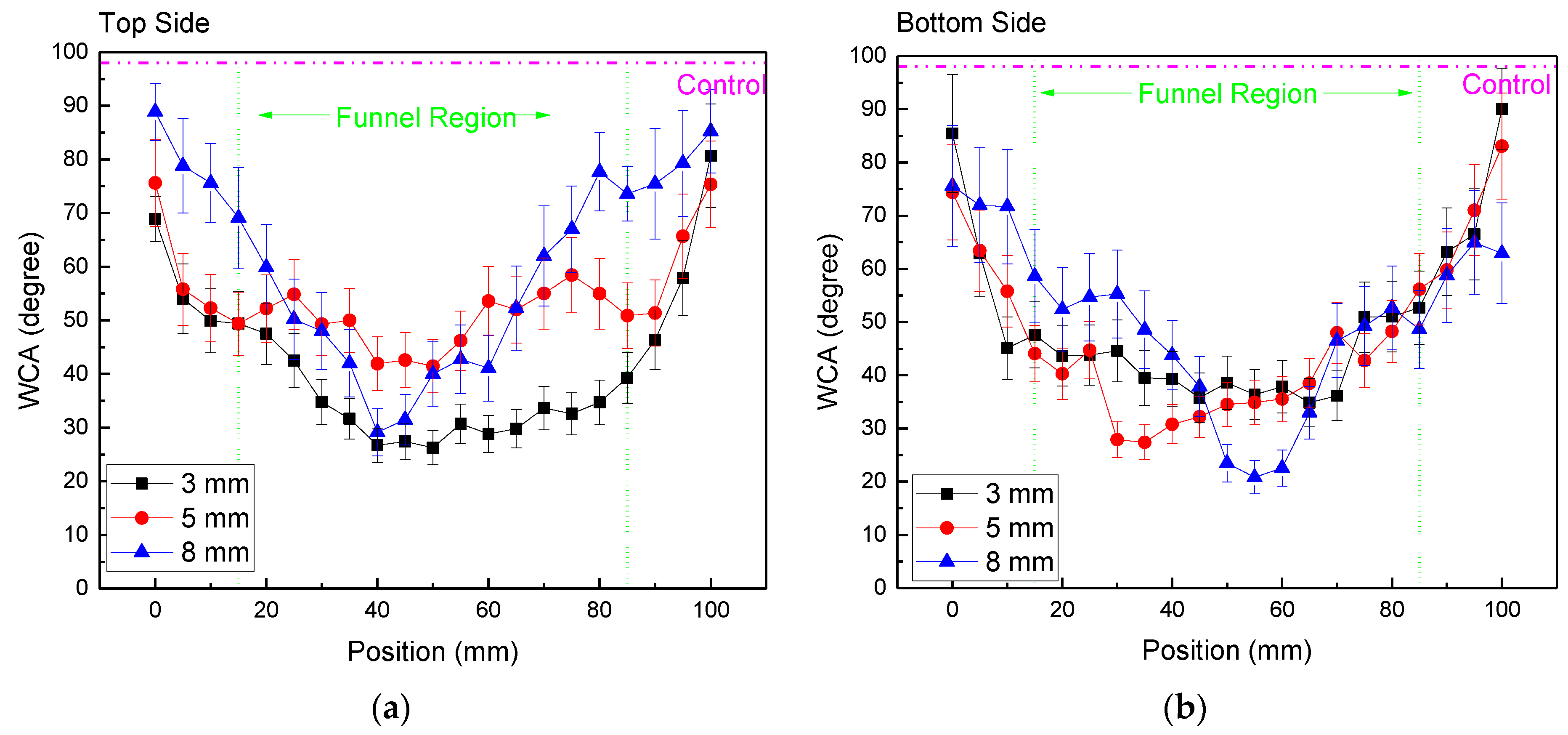

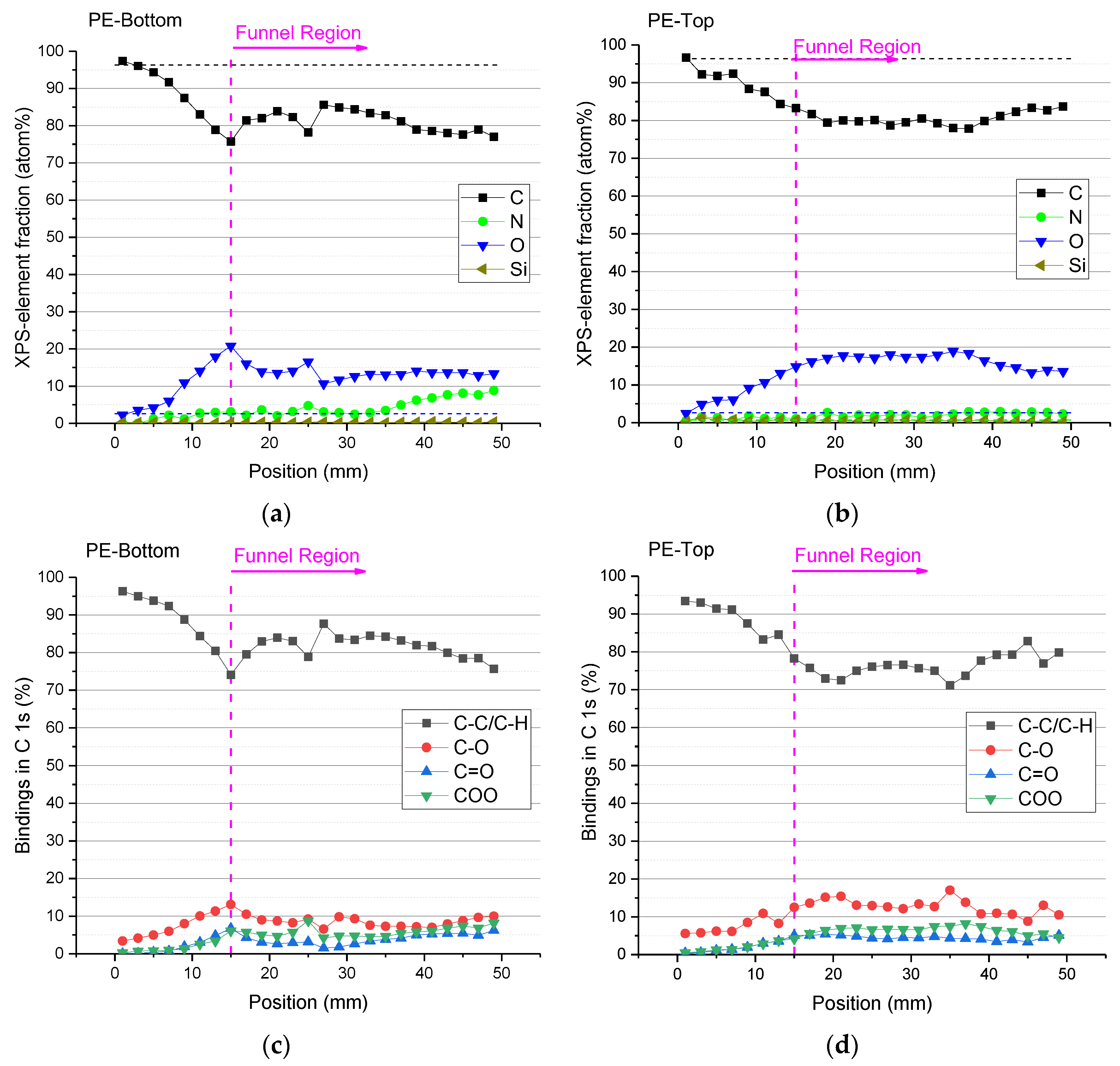

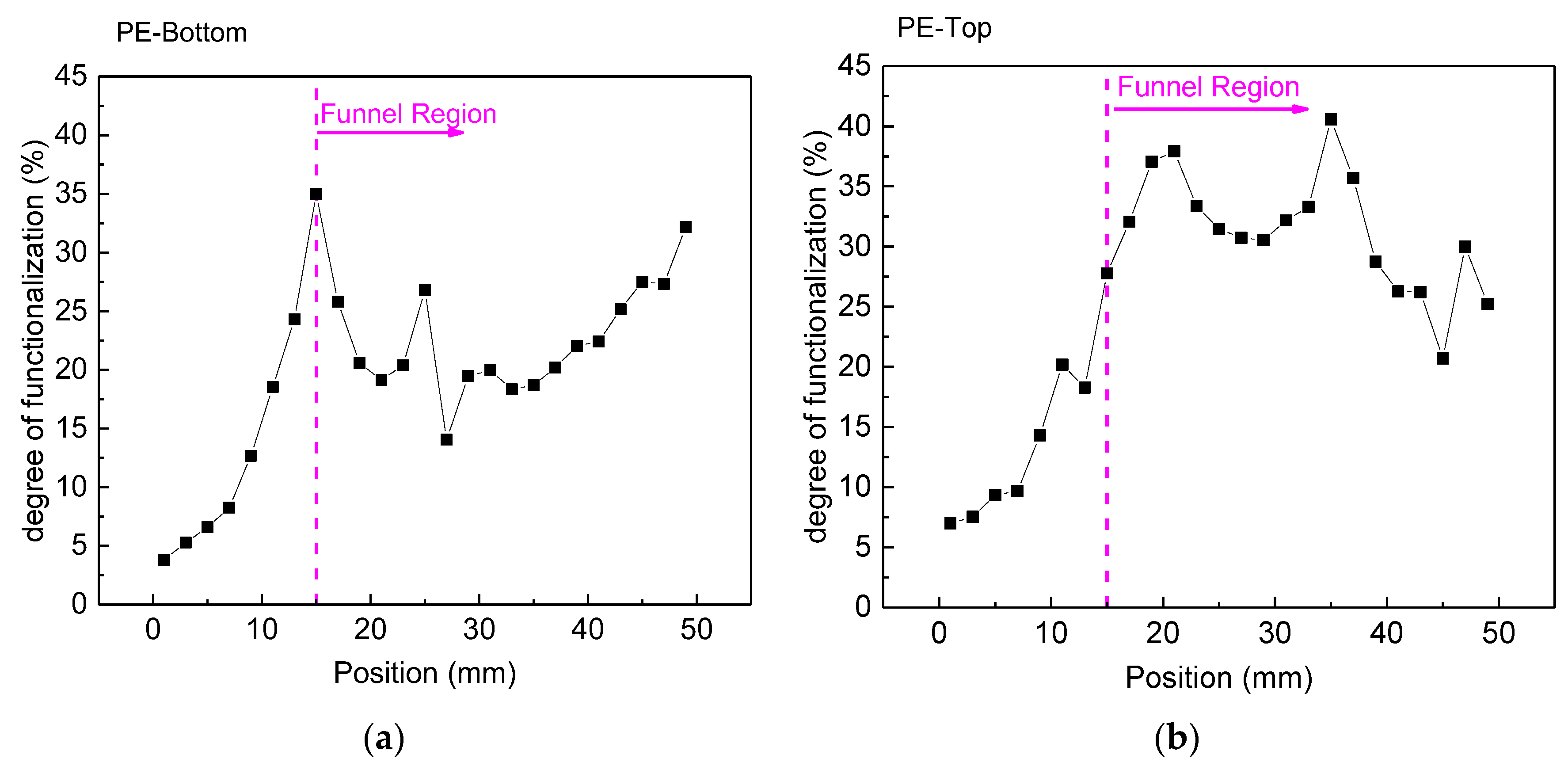

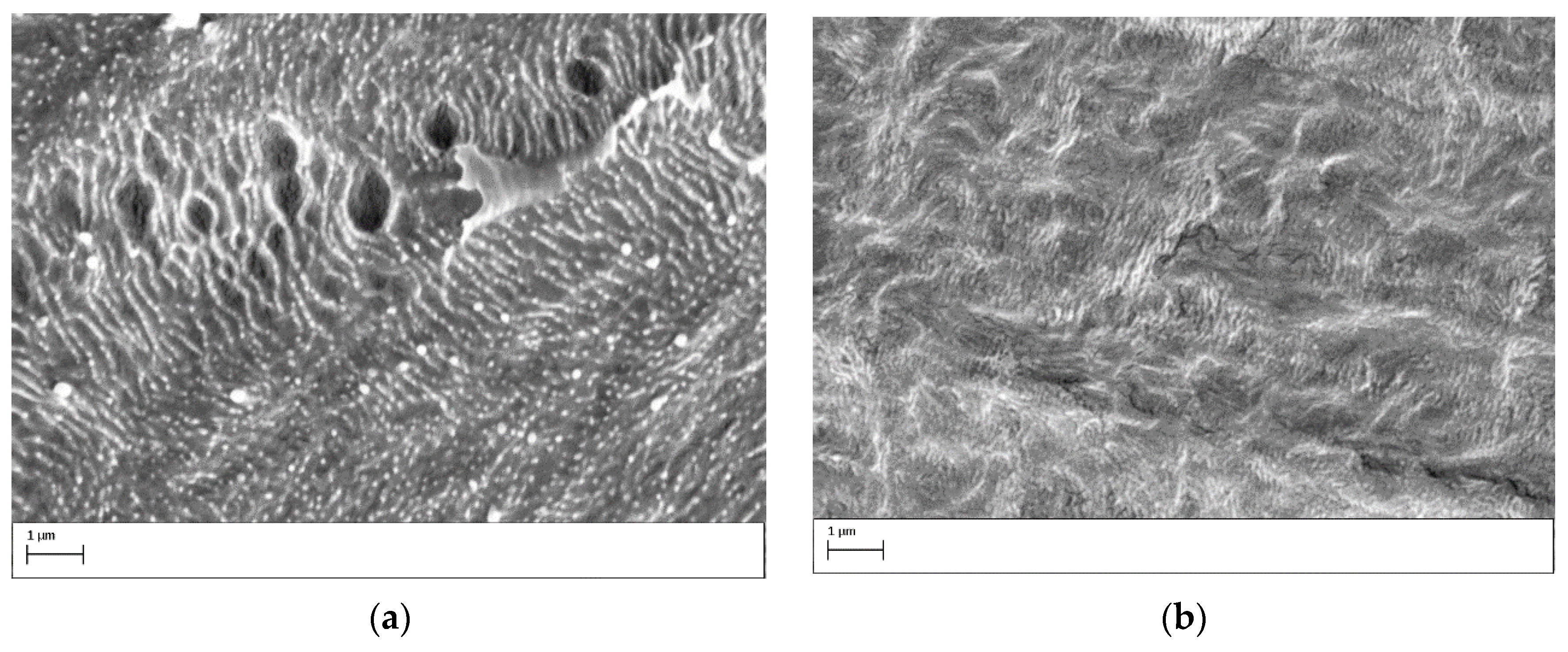

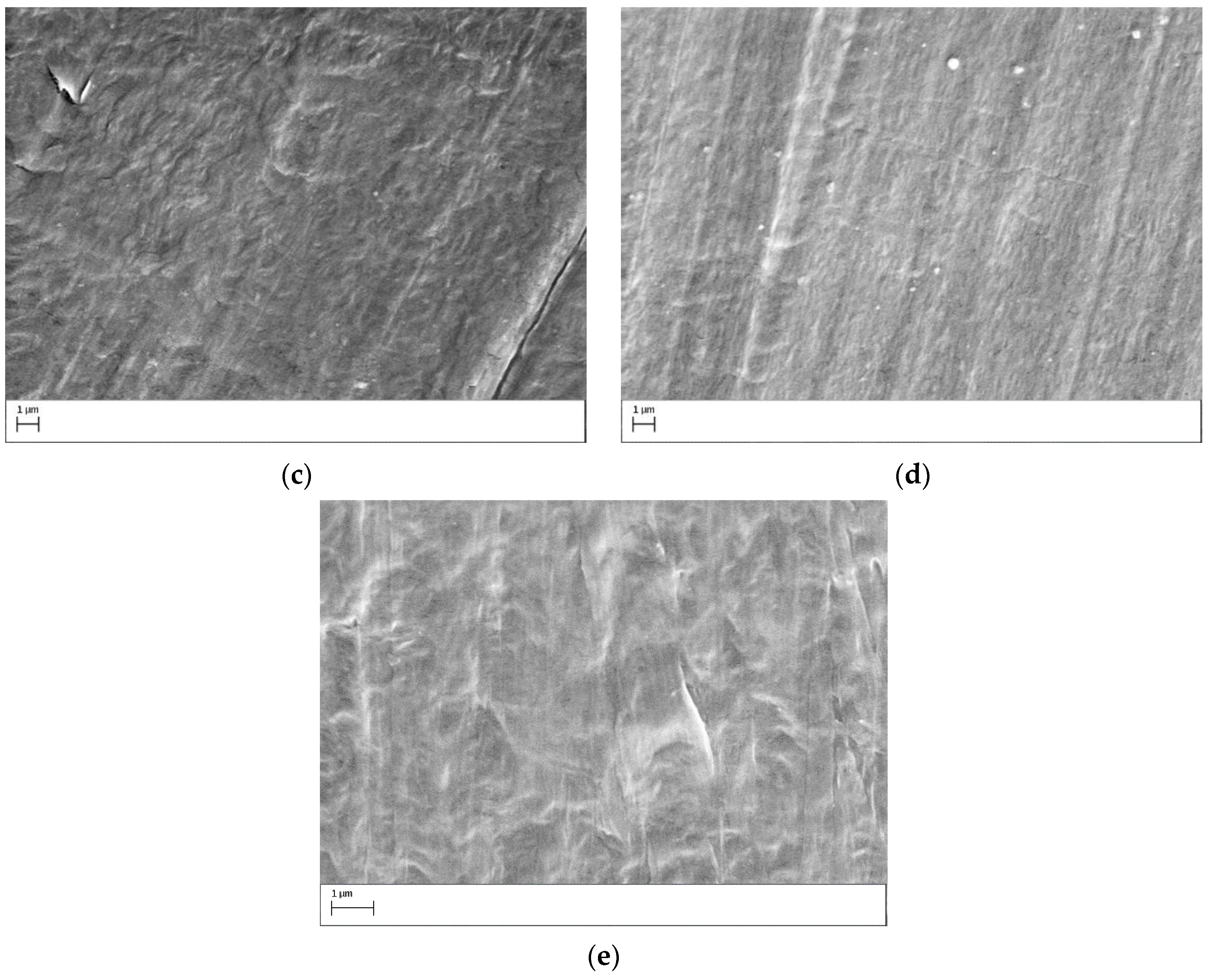

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Winter, J.; Brandenburg, R.; Weltmann, K.D. Atmospheric pressure plasma jets: An overview of devices and new directions. Plasma Sources Sci. Technol. 2015, 24, 064001. [Google Scholar] [CrossRef]

- Viegas, P.; Slikboer, E.; Bonaventura, Z.; Guaitella, O.; Sobota, A.; Bourdon, A. Physics of plasma jets and interaction with surfaces: Review on modelling and experiments. Plasma Sources Sci. Technol. 2022, 31, 053001. [Google Scholar] [CrossRef]

- Geng, J.; Yin, S.; Huang, S.; Tang, Q.; Luo, H.; Chen, F. Flexible cold plasma jet with controllable length and temperature for hydrophilic modification. Phys. Plasmas 2018, 25, 083508. [Google Scholar] [CrossRef]

- Corbella, C.; Portal, S.; Keidar, M. Flexible Cold Atmospheric Plasma Jet Sources. Plasma 2023, 6, 72–88. [Google Scholar] [CrossRef]

- Shaw, D.; West, A.; Bredin, J.; Wagenaars, E. Mechanisms behind surface modification of polypropylene film using an atmospheric-pressure plasma jet. Plasma Sources Sci. Technol. 2016, 25, 065018. [Google Scholar] [CrossRef]

- Ma, C.; Nikiforov, A.; Hegemann, D.; De Geyter, N.; Morent, R.; Ostrikov, K. Plasma-controlled surface wettability: Recent advances and future applications. Int. Mater. Rev. 2023, 68, 82–119. [Google Scholar] [CrossRef]

- Birer, Ö. Reactivity zones around an atmospheric pressure plasma jet. Appl. Surf. Sci. 2015, 354, 420–428. [Google Scholar] [CrossRef]

- Cho, G.; Kim, Y.; Uhm, H.S. The jet-stream channels of gas and plasma in atmospheric-pressure plasma jets. J. Korean Phys. Soc. 2016, 69, 525–535. [Google Scholar] [CrossRef]

- Narimisa, M.; Onyshchenko, Y.; Morent, R.; De Geyter, N. Improvement of PET surface modification using an atmospheric pressure plasma jet with different shielding gases. Polymer 2021, 215, 123421. [Google Scholar] [CrossRef]

- Li, H.; Li, M.; Zhu, H.; Zhang, Y.; Du, X.; Chen, Z.; Xiao, W.; Liu, K. Realizing high efficiency and large-area sterilization by a rotating plasma jet device. Plasma Sci. Technol. 2022, 24, 045501. [Google Scholar] [CrossRef]

- Zhou, R.; Zhang, B.; Zhou, R.; Liu, F.; Fang, Z.; Ostrikov, K. Linear-field plasma jet arrays excited by high-voltage alternating current and nanosecond pulses. J. Appl. Phys. 2018, 124, 033301. [Google Scholar] [CrossRef]

- Wu, K.; Liu, J.; Wu, J.; Chen, M.; Ran, J.; Pang, X.; Jia, P.; Li, X.; Ren, C. A double-mode planar argon plume produced by varying the distance from an atmospheric pressure plasma jet. High Volt. 2023. [Google Scholar] [CrossRef]

- Joh, H.M.; Kang, H.R.; Chung, T.H.; Kim, S.J. Electrical and Optical Characterization of Atmospheric-Pressure Helium Plasma Jets Generated with a Pin Electrode: Effects of the Electrode Material, Ground Ring Electrode, and Nozzle Shape. IEEE Trans. Plasma Sci. 2014, 42, 3656–3667. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Li, G.; Wang, D. Cold large-diameter plasma jet near atmospheric pressure produced via a triple electrode configuration. Vacuum 2014, 101, 317–320. [Google Scholar] [CrossRef]

- Lv, X.; Ren, C.; Ma, T.; Feng, Y.; Wang, D. An Atmospheric Large-Scale Cold Plasma Jet. Plasma Sci. Technol. 2012, 14, 799–801. [Google Scholar] [CrossRef][Green Version]

- Polášková, K.; Nečas, D.; Dostál, L.; Klíma, M.; Fiala, P.; Zajíčková, L. Self-organization phenomena in cold atmospheric pressure plasma slit jet. Plasma Sources Sci. Technol. 2022, 31, 125014. [Google Scholar] [CrossRef]

- Omran, A.V.; Busco, G.; Ridou, L.; Dozias, S.; Grillon, C.; Pouvesle, J.-M.; Robert, E. Cold atmospheric single plasma jet for RONS delivery on large biological surfaces. Plasma Sources Sci. Technol. 2020, 29, 105002. [Google Scholar] [CrossRef]

- Johnson, M.J.; Boris, D.R.; Petrova, T.B.; Walton, S.G. Extending the volume of atmospheric pressure plasma jets through the use of additional helium gas streams. Plasma Sources Sci. Technol. 2020, 29, 015006. [Google Scholar] [CrossRef]

- Li, H.-P.; Nie, Q.-Y.; Yang, A.; Wang, Z.-B.; Bao, C.-Y. An Atmospheric Cold Plasma Jet with a Good Uniformity, Robust Stability, and High Intensity over a Large Area. IEEE Trans. Plasma Sci. 2014, 42, 2470–2471. [Google Scholar] [CrossRef]

- Nizard, H.; Gaudy, T.; Toutant, A.; Iacono, J.; Descamps, P.; Leempoel, P.; Massines, F. Influence of discharge and jet flow coupling on atmospheric pressure plasma homogeneity. J. Phys. D Appl. Phys. 2015, 48, 415204. [Google Scholar] [CrossRef]

- O’Connor, N.; Humphreys, H.; Daniels, S. Cooperative Merging of Atmospheric Pressure Plasma Jet Arrays. IEEE Trans. Plasma Sci. 2014, 42, 756–758. [Google Scholar] [CrossRef]

- O’Neill, F.T.; Twomey, B.; Law, V.J.; Milosavljevic, V.; Kong, M.G.; Anghel, S.D.; Dowling, D.P. Generation of Active Species in a Large Atmospheric-Pressure Plasma Jet. IEEE Trans. Plasma Sci. 2012, 40, 2994–3002. [Google Scholar] [CrossRef]

- Kang, H.R.; Chung, T.H.; Joh, H.M.; Kim, S.J. Effects of Dielectric Tube Shape and Pin-Electrode Diameter on the Plasma Plume in Atmospheric Pressure Helium Plasma Jets. IEEE Trans. Plasma Sci. 2017, 45, 691–697. [Google Scholar] [CrossRef]

- Yamamoto, A.; Kawano, Y.; Nakai, M.; Nakagawa, T.; Sakugawa, T.; Hosseini, H.; Akiyama, H. Investigation of gas flow dependence of plasma jet produced by pulsed power. IEEE Trans. Plasma Sci. 2015, 43, 3451–3455. [Google Scholar] [CrossRef]

- Ghasemi, M.; Olszewski, P.; Bradley, J.W.; Walsh, J.L. Interaction of multiple plasma plumes in an atmospheric pressure plasma jet array. J. Phys. D Appl. Phys. 2013, 46, 052001. [Google Scholar] [CrossRef]

- Mui, T.S.M.; Mota, R.P.; Quade, A.; Hein, L.R.d.O.; Kostov, K.G. Uniform surface modification of polyethylene terephthalate (PET) by atmospheric pressure plasma jet with a horn-like nozzle. Surf. Coat. Technol. 2018, 352, 338–347. [Google Scholar] [CrossRef]

- Kodaira, F.V.d.P.; Leal, B.H.S.; Tavares, T.F.; Quade, A.; Hein, L.R.d.O.; Chiappim, W.; Kostov, K.G. Simultaneous Treatment of Both Sides of the Polymer with a Conical-Shaped Atmospheric Pressure Plasma Jet. Polymers 2023, 15, 461. [Google Scholar] [CrossRef]

- Punith, N.; Singh, A.K.; Ananthanarasimhan, J.; Boopathy, B.; Chatterjee, R.; Hemanth, M.; Chakravortty, D.; Rao, L. Generation of neutral pH high-strength plasma-activated water from a pin to water discharge and its bactericidal activity on multidrug-resistant pathogens. Plasma Process. Polym. 2023, 20, 2200133. [Google Scholar] [CrossRef]

- Knuuttila, H.; Lehtinen, A.; Nummila-Pakarinen, A. Advanced Polyethylene Technologies—Controlled Material Properties. In Long Term Properties of Polyolefins; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2004; pp. 13–28. [Google Scholar] [CrossRef]

- Van Deynse, A.; Cools, P.; Leys, C.; Morent, R.; De Geyter, N. Surface modification of polyethylene in an argon atmospheric pressure plasma jet. Surf. Coat. Technol. 2015, 276, 384–390. [Google Scholar] [CrossRef]

- Organski, L.; Wang, X.; Myers, A.; Chen, Y.-C.; Park, K.; Horava, S.D.; Richard, C.A.; Yeo, Y.; Shashurin, A. Inner surface modification of polyethylene tubing induced by dielectric barrier discharge plasma. J. Vac. Sci. Technol. A 2022, 40, 063005. [Google Scholar] [CrossRef]

- Neto, J.F.d.M.; de Souza, I.A.; Feitor, M.C.; Targino, T.G.; Diniz, G.F.; Libório, M.S.; Sousa, R.R.M.; Costa, T.H.d.C. Study of High-Density Polyethylene (HDPE) Kinetics Modification Treated by Dielectric Barrier Discharge (DBD) Plasma. Polymers 2020, 12, 2422. [Google Scholar] [CrossRef]

- Šourková, H.J.; Weberová, Z.; Antoň, J.; Špatenka, P. Wettability and Adhesion of Polyethylene Powder Treated with Non-Equilibrium Various Gaseous Plasma in Semi-Industrial Equipment. Materials 2022, 15, 686. [Google Scholar] [CrossRef]

- Murthy, V.S.M.D.; Vaidya, U. Improving the adhesion of glass/polypropylene (glass-PP) and high-density polyethylene (HDPE) surfaces by open air plasma treatment. Int. J. Adhes. Adhes. 2019, 95, 102435. [Google Scholar] [CrossRef]

- Penkov, O.V.; Khadem, M.; Lim, W.-S.; Kim, D.-E. A review of recent applications of atmospheric pressure plasma jets for materials processing. J. Coat. Technol. Res. 2015, 12, 225–235. [Google Scholar] [CrossRef]

- Cvelbar, U.; Walsh, J.L.; Černák, M.; de Vries, H.W.; Reuter, S.; Belmonte, T.; Corbella, C.; Miron, C.; Hojnik, N.; Jurov, A.; et al. White paper on the future of plasma science and technology in plastics and textiles. Plasma Process. Polym. 2019, 16, 1700228. [Google Scholar] [CrossRef]

- Luan, P.; Kondeti, V.S.S.K.; Knoll, A.J.; Bruggeman, P.J.; Oehrlein, G.S. Effect of water vapor on plasma processing at atmospheric pressure: Polymer etching and surface modification by an Ar/H2O plasma jet. J. Vac. Sci. Technol. A 2019, 37, 031305. [Google Scholar] [CrossRef]

- Chemello, G.; Knigge, X.; Ciornii, D.; Reed, B.P.; Pollard, A.J.; Clifford, C.A.; Howe, T.; Vyas, N.; Hodoroaba, V.; Radnik, J. Influence of the Morphology on the Functionalization of Graphene Nanoplatelets Analyzed by Comparative Photoelectron Spectroscopy with Soft and Hard X-rays. Adv. Mater. Interfaces 2023, 10, 2300116. [Google Scholar] [CrossRef]

- Thiha, A.; Ibrahim, F.; Muniandy, S.; Madou, M.J. Microplasma direct writing for site-selective surface functionalization of carbon microelectrodes. Microsyst. Nanoeng. 2019, 5, 62. [Google Scholar] [CrossRef]

- Merenda, A.; Ligneris, E.D.; Sears, K.; Chaffraix, T.; Magniez, K.; Cornu, D.; Schütz, J.A.; Dumée, L.F. Assessing the temporal stability of surface functional groups introduced by plasma treatments on the outer shells of carbon nanotubes. Sci. Rep. 2016, 6, 31565. [Google Scholar] [CrossRef]

- Booth, J.-P.; Mozetic, M.; Nikiforov, A.Y.; Oehr, C. Foundations of plasma surface functionalisation of polymers for industrial and biological applications. Plasma Sources Sci. Technol. 2022, 31, 103001. [Google Scholar] [CrossRef]

- Williamson, J.B.; Lewis, S.E.; Johnson, R.R.; Manning, I.M.; Leibfarth, F.A. C−H Functionalization of Commodity Polymers. Angew. Chem. Int. Ed. 2019, 58, 8654–8668. [Google Scholar] [CrossRef] [PubMed]

- Dell’Orto, E.C.; Vaccaro, A.; Riccardi, C. Morphological and chemical analysis of PP film treated by Dielectric Barrier Discharge. J. Phys. Conf. Ser. 2014, 550, 012032. [Google Scholar] [CrossRef]

- Kehrer, M.; Rottensteiner, A.; Hartl, W.; Duchoslav, J.; Thomas, S.; Stifter, D. Cold atmospheric pressure plasma treatment for adhesion improvement on polypropylene surfaces. Surf. Coat. Technol. 2020, 403, 126389. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kodaira, F.V.d.P.; Almeida, A.C.d.P.L.; Tavares, T.F.; Quade, A.; Hein, L.R.d.O.; Kostov, K.G. Study of a Conical Plasma Jet with a Cloth-Covered Nozzle for Polymer Treatment. Polymers 2023, 15, 3344. https://doi.org/10.3390/polym15163344

Kodaira FVdP, Almeida ACdPL, Tavares TF, Quade A, Hein LRdO, Kostov KG. Study of a Conical Plasma Jet with a Cloth-Covered Nozzle for Polymer Treatment. Polymers. 2023; 15(16):3344. https://doi.org/10.3390/polym15163344

Chicago/Turabian StyleKodaira, Felipe Vicente de Paula, Ana Carla de Paula Leite Almeida, Thayna Fernandes Tavares, Antje Quade, Luis Rogério de Oliveira Hein, and Konstantin Georgiev Kostov. 2023. "Study of a Conical Plasma Jet with a Cloth-Covered Nozzle for Polymer Treatment" Polymers 15, no. 16: 3344. https://doi.org/10.3390/polym15163344

APA StyleKodaira, F. V. d. P., Almeida, A. C. d. P. L., Tavares, T. F., Quade, A., Hein, L. R. d. O., & Kostov, K. G. (2023). Study of a Conical Plasma Jet with a Cloth-Covered Nozzle for Polymer Treatment. Polymers, 15(16), 3344. https://doi.org/10.3390/polym15163344