Evaluating a Novel Fly Ash Resin-Reinforced Cement’s Interactions under Acidic, Basic, High-Salinity, and High-Temperature Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

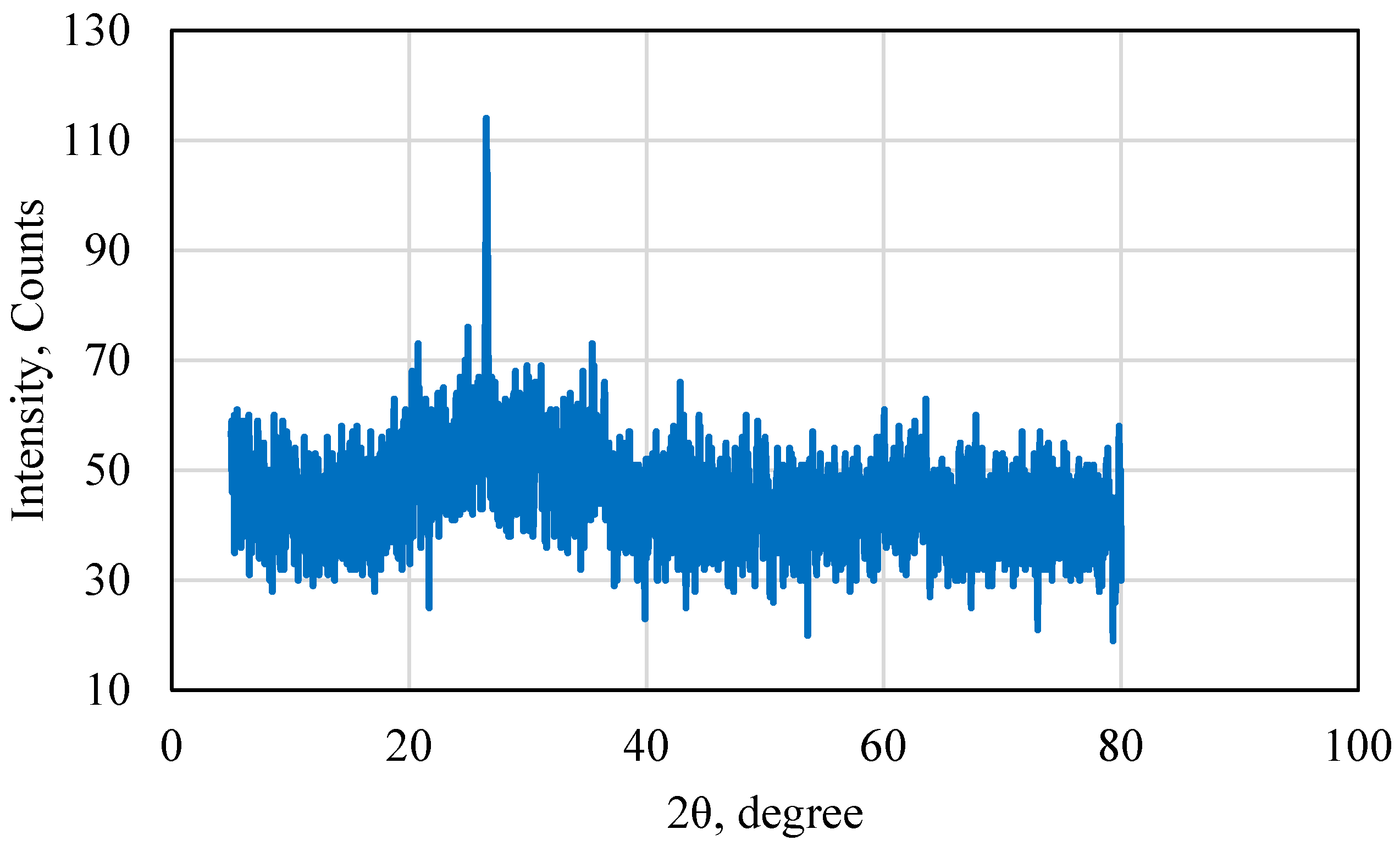

- Fly Ash: The fly ash used was provided by a chemical plant located in Southern Cairo, Egypt. It was provided as a fine powder with a light grey color due to the high aluminosilicate content and low iron oxide content. The fly ash was class F.

- Epoxy Resin: The epoxy resin was commercially available and was provided as a yellow, extremely viscous liquid. The yellow color was due to an added pigment to the resin. The resin had no bisphenol A concentration in it, which made it safe and easy to handle.

- Hardener: For every three parts of resin used, one part of hardener was added. The hardener was provided with the resin as a transparent slightly viscous fluid.

- Graduated Beakers: Beakers were used to weigh the different chemicals and determine their equivalent volumes before mixing. The beakers were made from borosilicate glass and could withstand temperatures up to 250 °C.

- High Accuracy Scale: The scale used had accuracy of four decimal places. This was necessary when weighing the hardener and the epoxy to ensure that the correct mixture was used in all samples.

- Silicon Molds: Spherical molds were used to mold perfect spheres of cement as samples for testing. Spheres were used instead of cubes to account for several experimental setups that could not accommodate a cube and required spherical samples.

2.2. Experimental Setup

2.3. Experimental Procedure

- Prepare the cement samples and leave them to cure overnight until fully set. Recover the samples and weigh them before running any experiment.

- Prepare the experimental solution in a transparent container and ensure that the volume of the solution prepared is sufficient to fully cover the cement sample. Place the cement sample in the container and begin the experiment.

- Leave the cement sample in the container for 7 consecutive days. Visually examine the sample every 6 h and weigh the sample every 24 h.

- Record the change in the weight of the sample every 24 h and plot the results after 7 days. Determine the weight increase or the weight decrease percentage with time to evaluate sample degradation.

2.4. Novel Cement Synthesis

- a.

- Weigh the pre-calculated mass of the chemicals, including the epoxy resin, the hardener, and the fly ash, and store each in a separate container.

- b.

- Pour the resin into a large plastic container. Ensure that all the resin has been displaced. This is done by leaving the resin to pour overnight while occasionally displacing it with a spatula.

- c.

- Place a small volume of fly ash in the resin and mix by hand. This is to avoid the formation of lumps in the slurry. The sample is constantly mixed until all fly ash is added. This takes two to six hours depending on the volume of fly ash. An electric blender is used initially to heat up the sample, which impacts the resin. Moreover, when a large mass of resin is added, the blender can no longer blend the resin–fly ash mixture efficiently.

- d.

- Once the resin–fly ash sample is well mixed and stable, the hardener is added while vigorously mixing all three components. It is important to note that once the hardener is added, the cement setting will begin. It is therefore important to quickly set the cement slurry in the mold before the slurry becomes too difficult to pour. This will usually happen 30 min to 1 h after the hardener is added, depending on the slurry formulation.

- e.

- Once the slurry is set in the mold, it is left to fully cure and set overnight for at least 12 h. The samples are then retrieved and visually inspected for air pockets or heterogeneities in the sample. If the sample has any heterogeneities or air pockets, it is discarded. The samples are then labeled and prepared for experimentation.

3. Results and Analysis

3.1. Base Experiment—Distilled Water

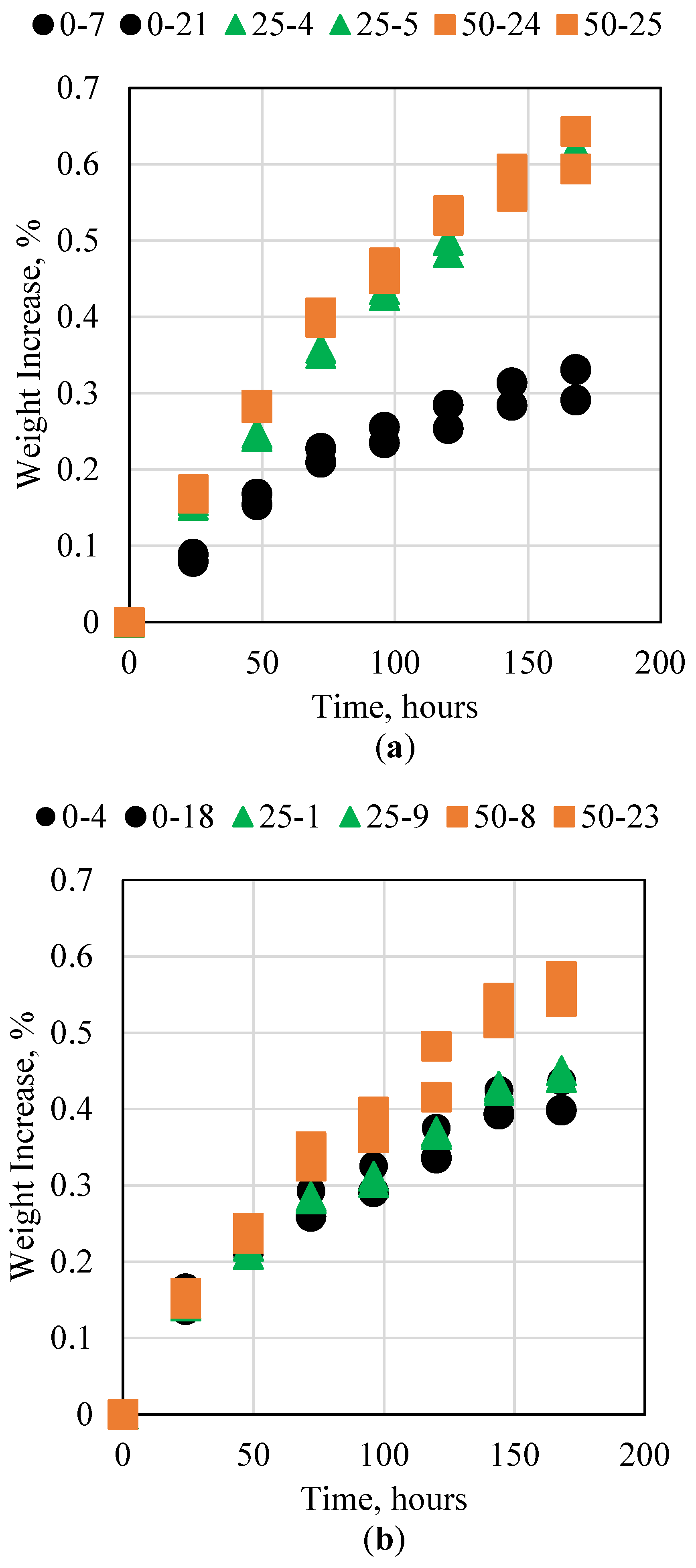

3.2. Cement Interaction with Acid

3.3. Cement Interaction with Base

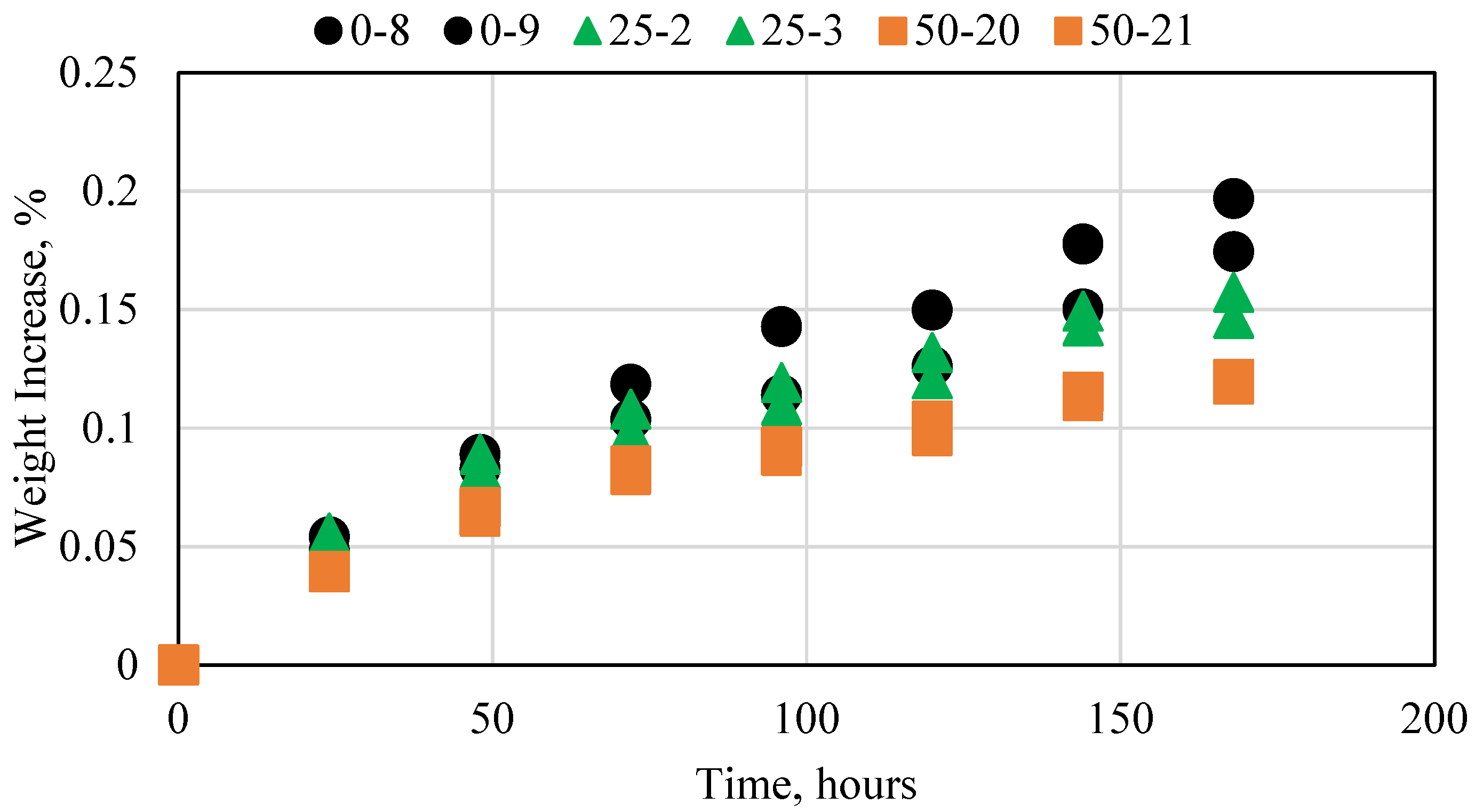

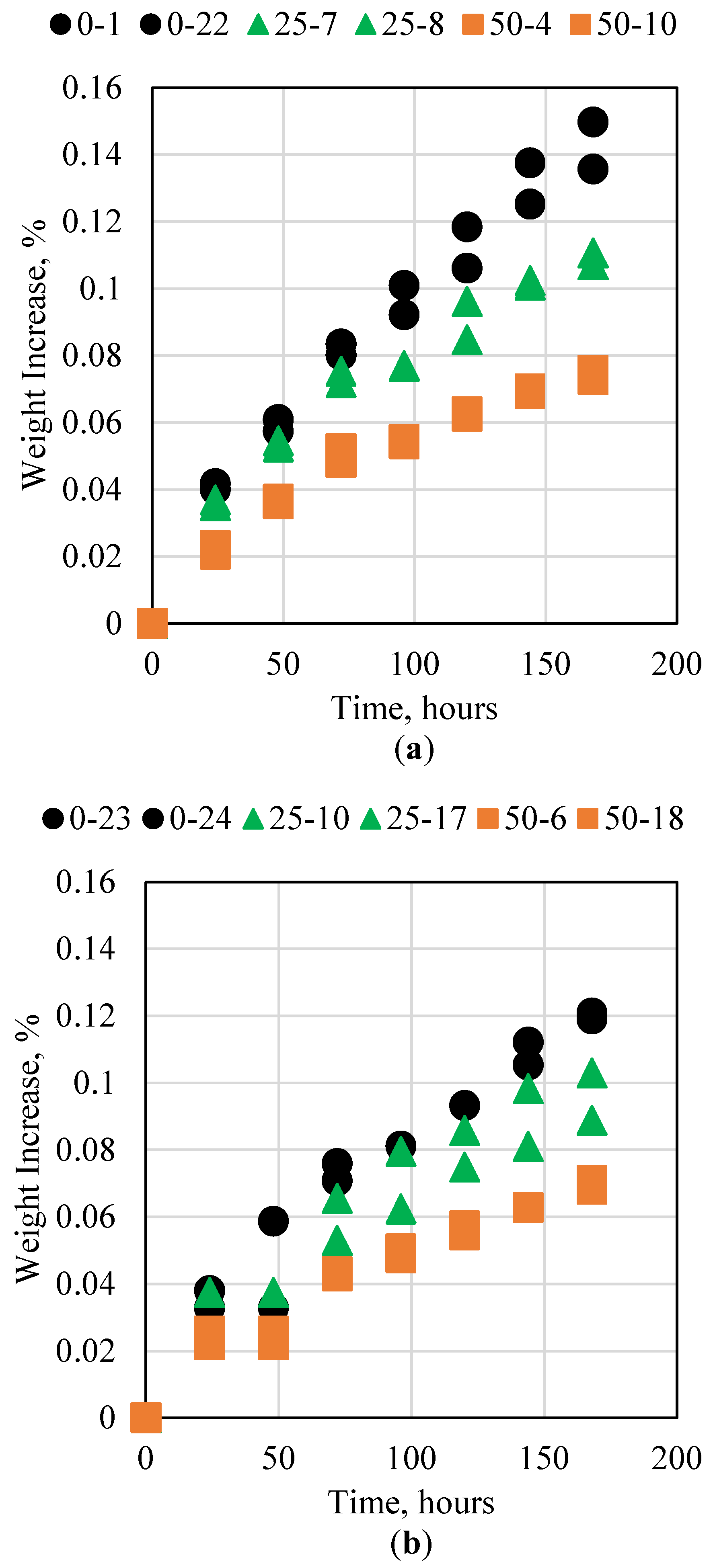

3.4. Cement Interaction with High Salinity

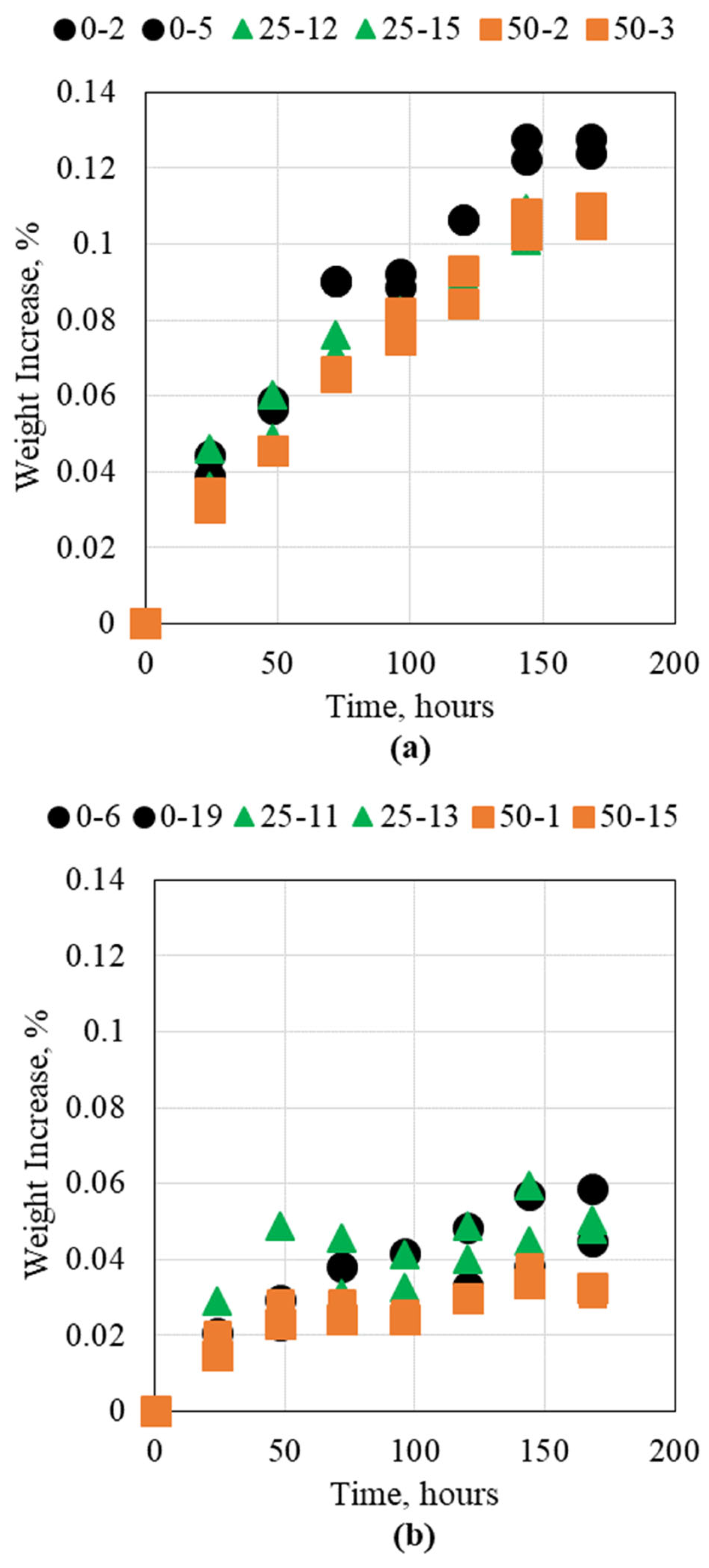

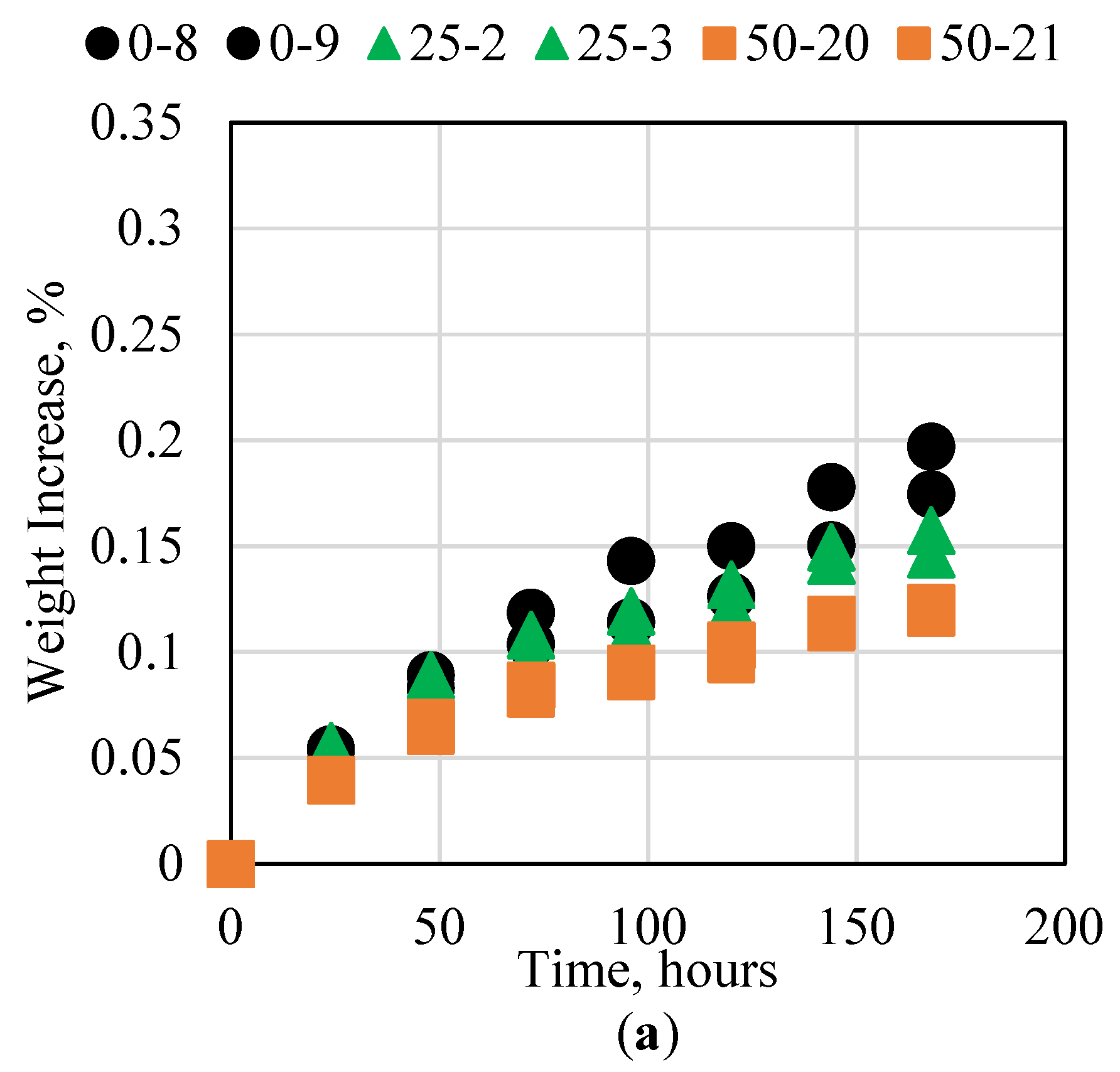

3.5. Cement Interaction with High-Temperature Water

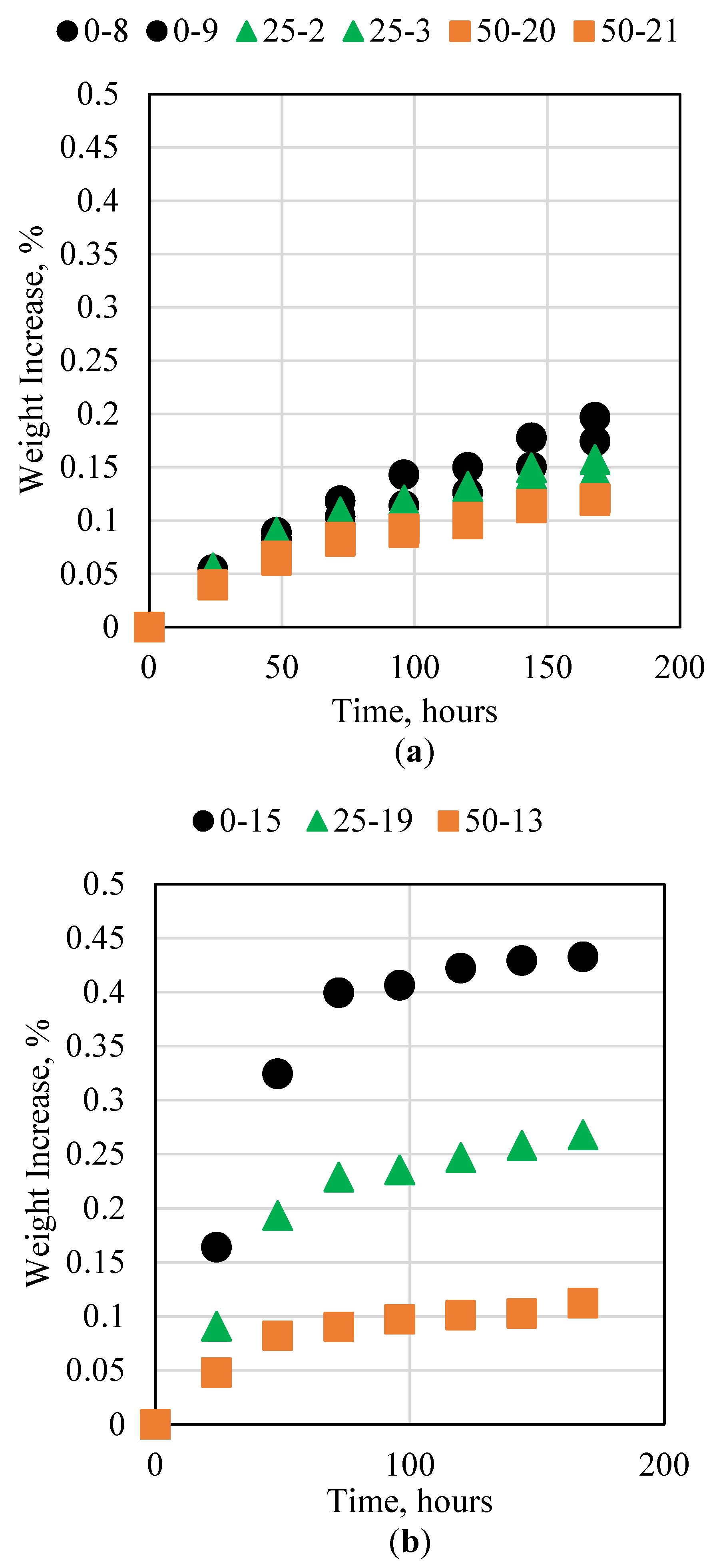

3.6. Cement Interaction with Carbon Dioxide

3.7. Cement Interaction with Crude Oil

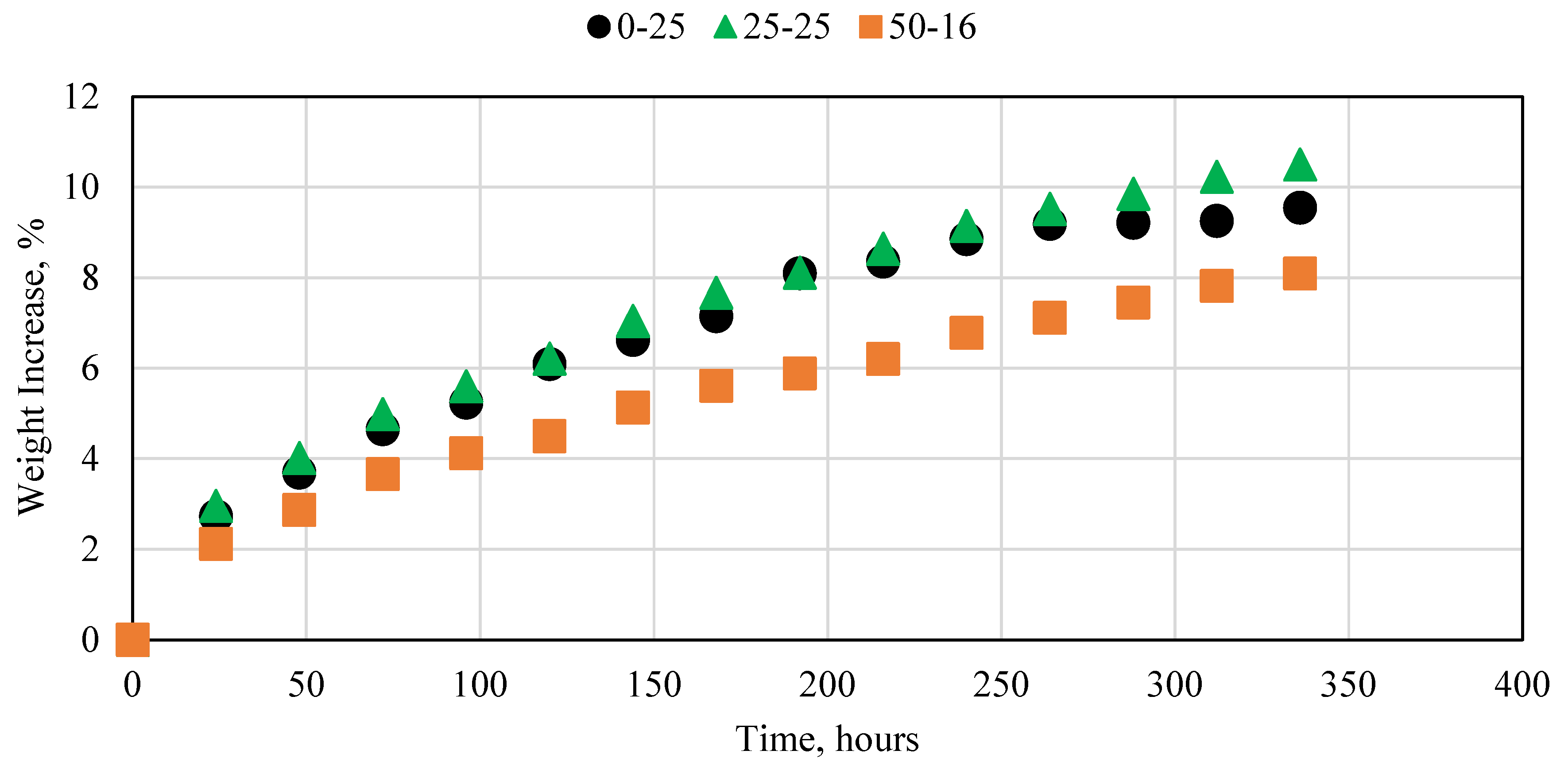

3.8. Cement Interaction with Acetone

4. Discussion

5. Conclusions

- The novel fly ash epoxy cement was found to have strong resistance to acidic and basic conditions. It also performed significantly well under high-salinity conditions and when subjected to high temperatures.

- At 100 °C, the novel fly ash epoxy cement lost weight, compared to all other experiments, where the samples gained weight. This was due to the resin melting, which resulted in the loss of small parts of the novel cement sample.

- The novel cement managed to withstand the high-pressure CO2 conditions with minimal degradation. This indicates the ability to use the cement for CO2 storage applications.

- The novel cement can be easily removed or mitigated after placement and setting in oil and gas wells using acetone. This is a huge advantage over conventional cement.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Montes, P.; Bremner, T.W.; Kondratova, I. Eighteen-Year Performance of Epoxy-Coated Rebar in a Tunnel Structure Subjected to a Very Aggressive Chloride-Contaminated Environment. Corrosion 2004, 60, 974–981, NACE-04100974. [Google Scholar] [CrossRef]

- Fakher, S.; Khlaifat, A.L. Experimental Investigation of Polymer Injection in High Permeability Conduits for Material Sustainability and Behavior in Oil Reservoirs. Polymers 2023, 15, 2950. [Google Scholar] [CrossRef] [PubMed]

- Fakher, S.; Khlaifat, A.; Nameer, H. Improving electric submersible pumps efficiency and mean time between failure using permanent magnet motor. Upstream Oil Gas Technol. 2022, 9, 100074. [Google Scholar] [CrossRef]

- Fakher, S.; Al-Sakkaf, A.; Ali, M. Evaluating key parameters impacting asphaltene permeability reduction behavior in micro-pores during carbon dioxide injection. Fuel 2023, 339, 126933. [Google Scholar] [CrossRef]

- Fakher, S. Development of novel mathematical models for laboratory studies of hydrolyzed polyacrylamide polymer injectivity in high-permeability conduits. J. Pet. Explor. Prod. Technol. 2020, 10, 2035–2043. [Google Scholar] [CrossRef] [Green Version]

- Fakher, S.; Imqam, A. A simplified method for experimentally quantifying crude oil swelling during immiscible carbon dioxide injection. J. Pet. Explor. Prod. Technol. 2020, 10, 3031–3042. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Li, Y.; Lin, H.; Cao, C.-N. Electrochemical Impedance Spectroscopy Study on the Diffusion Behavior of Water through Epoxy Coatings. Corrosion 2003, 59, 817–820. [Google Scholar] [CrossRef]

- Al-Yami, A. An Overview of Different Chemicals Used in Designing Cement Slurries for Oil and Gas Wells. In Proceedings of the 2015 Kuwait Oil & Gas Show Conference, Mishref, Kuwait, 11–14 October 2015. SPE 175259. [Google Scholar]

- Bensted, J. Retardation of Cement Slurries to 250ºF. In Proceedings of the 1991 SPE Offshore Europe, Aberdeen, UK, 3–6 September 1991. SPE 23073. [Google Scholar]

- Brothers, L.E.; Chatterji, J.; Childs, J.D.; Vinson, E.F. Synthetic Retarder for High-Strength Cements. In Proceedings of the 1991 SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 11–14 March 1991. SPE 21976. [Google Scholar]

- Iremonger, S.; Cheung, B.; Carey, J. Direct Strain Mapping of a Cement Sheath; A New Tool for Understanding and Preventing Cement Failure in Thermal Wells. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 28–30 November 2017. [Google Scholar] [CrossRef] [Green Version]

- Metwally, M. Effect of Gaseous Additives On Steam Processes For Lindbergh Field, Alberta. J. Can. Pet. Technol. 1990, 29, 26–30. [Google Scholar] [CrossRef]

- Shadravan, A.; Schubert, J.; Amani, M.; Teodoriu, C. Using Fatigue-Failure Envelope for Cement-Sheath-Integrity Evaluation. SPE Drill. Complet. 2015, 30, 68–75. [Google Scholar] [CrossRef]

- Goodwin, K.J.; Crook, R.J. Cement Sheath Stress Failure. SPE Drill. Eng. 1992, 7, 291–296. [Google Scholar] [CrossRef]

- Ding, L.; Chen, W.; Han, C.; Geng, H.; Zhang, Q. Research on a Typical Casing Failure during Drilling of Cement Plugs in Ultradeep Wells. SPE J. 2023, 1–14. [Google Scholar] [CrossRef]

- Meng, M.; Frash, L.; Carey, J.W.; Niu, Z.; Zhang, W.; Guy, N.; Lei, Z.; Li, W.; Welch, N. Predicting Cement-Sheath Integrity with Consideration of Initial State of Stress and Thermoporoelastic Effects. SPE J. 2021, 26, 3505–3528. [Google Scholar] [CrossRef]

- Pollock, R.; Beecroft, W.; Carter, L. Cementing Practices for Thermal Wells. J. Can. Pet. Technol. 1966, 5, 130–134. [Google Scholar] [CrossRef]

- Kalil, I.A.; McSpadden, A.R. Casing Burst Stresses in Particulate-Filled Annuli: Where Is the Cement? SPE Drill. Complet. 2012, 27, 473–485. [Google Scholar] [CrossRef]

- Thiercelin, M.J.; Dargaud, B.; Baret, J.F.; Rodriquez, W.J. Cement Design Based on Cement Mechanical Response. SPE Drill. Complet. 1998, 13, 266–273. [Google Scholar] [CrossRef]

- Forbes, D.; Uswak, G. Detection of Gas Migration Behind Casing Using Ultrasonic Imaging Methods. J. Can. Pet. Technol. 1992, 31, 18–25. [Google Scholar] [CrossRef]

- Hassan, A.; Chandra, V.; Yutkin, M.P.; Patzek, T.W.; Espinoza, D.N. Imaging and Characterization of Microporous Carbonates Using Confocal and Electron Microscopy of Epoxy Pore Casts. SPE J. 2019, 24, 1220–1233. [Google Scholar] [CrossRef]

- Shao, Y.; Li, Y.; Du, Y.; Wang, F. Enhancement of the Protectiveness of Epoxy Coatings with Surface-Modified Nano-Titanium Particles. Corrosion 2006, 62, 483–490, NACE-06060483. [Google Scholar] [CrossRef]

- Singh, D.; Ghosh, R. Unexpected Deterioration of Fusion-Bonded Epoxy-Coated Rebars Embedded in Chloride-Contaminated Concrete Environments. Corrosion 2005, 61, 815–829, NACE-05080815. [Google Scholar] [CrossRef]

- Spinks, G.M.; Dominis, A.J.; Wallace, G.G. Comparison of Emeraldine Salt, Emeraldine Base, and Epoxy Coatings for Corrosion Protection of Steel During Immersion in a Saline Solution. Corrosion 2003, 59, 22–31, NACE-03010022. [Google Scholar] [CrossRef]

- Kosek, J.R.; DuPont, J.N.; Marder, A.R. Effect of Porosity on Resistance of Epoxy Coatings to Cold-Wall Blistering. Corrosion 1995, 51, 861–871, NACE-95110861. [Google Scholar] [CrossRef]

- Mansfeld, F. Discussion: Effectiveness of Ion Vapor-Deposited Aluminum as a Primer for Epoxy and Urethane Topcoats. Corrosion 1994, 50, 609–612, NACE-94080609. [Google Scholar] [CrossRef]

- Shaughnessy, C.; Salathiel, W.; Penberthy, W.J. A New, Low-Viscosity, Epoxy Sand-Consolidation Process. J. Pet. Technol. 1978, 30, 1805–1812. [Google Scholar] [CrossRef]

- Copeland, C.; McAuley, J. Controlling Sand With an Epoxy-Coated, High-Solids-Content Gravel Slurry. J. Pet. Technol. 1974, 26, 1215–1220. [Google Scholar] [CrossRef]

- Carpenter, C. Microchannel Remediation of a Cement Packer Unlocks Mature-Field Potential. J. Pet. Technol. 2019, 71, 56–57. [Google Scholar] [CrossRef]

- Leggat, R.B.; Zhang, W.; Buchheit, R.G.; Taylor, S.R. Performance of Hydrotalcite Conversion Treatments on AA2024-T3 When Used in a Coating System. Corrosion 2002, 58, 322–328, NACE-02040322. [Google Scholar] [CrossRef]

- Zhao, Z.; Sun, J.; Liu, F.; Bai, Y.; Wang, R.; Geng, Y.; Li, Y.; Liu, C. High-Temperature-Resistant Thermal Shape Memory Polymers as Lost Circulation Materials for Fracture Formations. SPE J. 2023, 1–13. [Google Scholar] [CrossRef]

- Fakher, S.; Yousef, A.; Al-Sakkaf, A.; Eldakar, S. Asphaltene onset pressure measurement and calculation techniques: A review. Petroleum, 2023; in press. [Google Scholar] [CrossRef]

- Fakher, S.; Fakher, A. Investigating the Use of CO2 as a Hydraulic Fracturing Fluid for Water Sustainability and Environmental Friendliness. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Virtual, 12–14 October 2021. [Google Scholar] [CrossRef]

- Fakher, S.; Elgahawy, Y.; Abdelaal, H.; Imqam, A. Will Carbon Dioxide Injection in Shale Reservoirs Produce from the Shale Matrix, Natural Fractures, or Hydraulic Fractures? In Proceedings of the SPE Western Regional Meeting, Virtual, 20–22 April 2021. [Google Scholar] [CrossRef]

- Fakher, S.; Elgahawy, Y.; Abdelaal, H.; Imqam, A. What are the Dominant Flow Regimes During Carbon Dioxide Propagation in Shale Reservoirs’ Matrix, Natural Fractures and Hydraulic Fractures? In Proceedings of the SPE Western Regional Meeting, Virtual, 20–22 April 2021. [Google Scholar] [CrossRef]

- Fakher, S.; El-Tonbary, A.; Abdelaal, H.; Elgahawy, Y.; Imqam, A. Carbon Dioxide Sequestration in Unconventional Shale Reservoirs Via Physical Adsorption: An Experimental Investigation. In Proceedings of the SPE Europec, Virtual, 1–3 December 2020. [Google Scholar] [CrossRef]

- Fakher, S.; Imqam, A. Flow of carbon dioxide in micro and nano pores and its interaction with crude oil to induce asphaltene instability. SN Appl. Sci. 2020, 2, 1039. [Google Scholar] [CrossRef]

| Fly Ash Concentration, wt% | Density, kg/m3 |

|---|---|

| 0 | 1330 |

| 25 | 1450 |

| 50 | 1700 |

| 70 | 1980 |

| Parameter | Sample | Temperature, °C | Pressure, psi | Sample Change | Impact |

|---|---|---|---|---|---|

| DI Water | 0% FA | 25 | 14.7 | Increase | 0.184 |

| 25% FA | 0.146 | ||||

| 50% FA | 0.118 | ||||

| 15% HCl | 0% FA | 25 | 14.7 | Increase | 0.31 |

| 25% FA | 0.6 | ||||

| 50% FA | 0.62 | ||||

| 28% HCl | 0% FA | 25 | 14.7 | Increase | 0.42 |

| 25% FA | 0.45 | ||||

| 50% FA | 0.55 | ||||

| 15% NaOH | 0% FA | 25 | 14.7 | Increase | 0.126 |

| 25% FA | 0.105 | ||||

| 50% FA | 0.105 | ||||

| 28% NaOH | 0% FA | 25 | 14.7 | Increase | 0.06 |

| 25% FA | 0.05 | ||||

| 50% FA | 0.03 | ||||

| 15% NaCl | 0% FA | 25 | 14.7 | Increase | 0.14 |

| 25% FA | 0.11 | ||||

| 50% FA | 0.08 | ||||

| 20% NaCl | 0% FA | 25 | 14.7 | Increase | 0.12 |

| 25% FA | 0.08 | ||||

| 50% FA | 0.07 | ||||

| DI Water 40 °C | 0% FA | 40 | 14.7 | Increase | 0.33 |

| 25% FA | 0.27 | ||||

| 50% FA | 0.20 | ||||

| DI Water 60 °C | 0% FA | 60 | 14.7 | Increase | 0.33 |

| 25% FA | 0.25 | ||||

| 50% FA | 0.24 | ||||

| DI Water 100 °C | 0% FA | 100 | 14.7 | Decrease | 3 |

| 25% FA | 0.73 | ||||

| 50% FA | 0.04 | ||||

| CO2 500 psi | 0% FA | 60 | 500 | Increase | 0.35 |

| 25% FA | 0.26 | ||||

| 50% FA | 0.32 | ||||

| CO2 1000 psi | 0% FA | 60 | 1000 | Increase | 0.47 |

| 25% FA | 0.38 | ||||

| 50% FA | 0.45 | ||||

| Crude Oil | 0% FA | 25 | 14.7 | Increase | 0.43 |

| 25% FA | 0.27 | ||||

| 50% FA | 0.112 | ||||

| Acetone | 0% FA | 25 | 14.7 | Increase | 9.5 |

| 25% FA | 10.5 | ||||

| 50% FA | 8.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fakher, S.; El-Sayed, A.; Sameh, L.; Abdeltawab, B. Evaluating a Novel Fly Ash Resin-Reinforced Cement’s Interactions under Acidic, Basic, High-Salinity, and High-Temperature Conditions. Polymers 2023, 15, 3404. https://doi.org/10.3390/polym15163404

Fakher S, El-Sayed A, Sameh L, Abdeltawab B. Evaluating a Novel Fly Ash Resin-Reinforced Cement’s Interactions under Acidic, Basic, High-Salinity, and High-Temperature Conditions. Polymers. 2023; 15(16):3404. https://doi.org/10.3390/polym15163404

Chicago/Turabian StyleFakher, Sherif, Ali El-Sayed, Layla Sameh, and Bassel Abdeltawab. 2023. "Evaluating a Novel Fly Ash Resin-Reinforced Cement’s Interactions under Acidic, Basic, High-Salinity, and High-Temperature Conditions" Polymers 15, no. 16: 3404. https://doi.org/10.3390/polym15163404