Effect of Different Silane Coupling Agents on Properties of Waste Corrugated Paper Fiber/Polylactic Acid Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Instruments

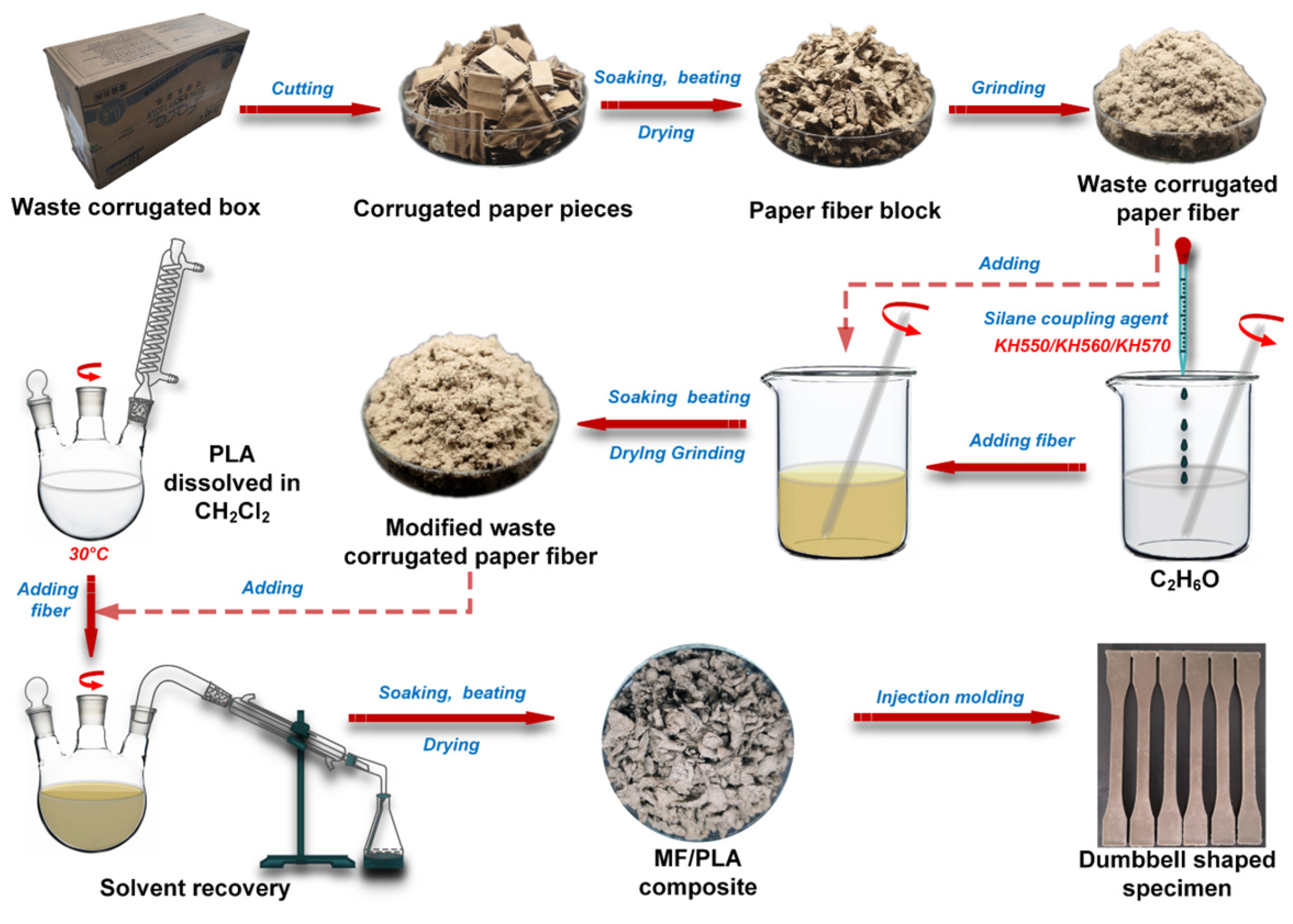

2.2. Extraction of Waste Corrugated Paper Fibers

2.3. Modification of WFs

2.4. The Preparation Process of MF/PLA Composites

2.5. Test and Characterization

3. Results and Discussion

3.1. Micromorphology of Modified Waste Corrugated Paper Fibers

3.2. Tensile Section Morphology of MF/PLA Composite

3.3. FT-IR Analysis of Modified Waste Corrugated Paper Fibers

3.4. Mechanical Properties of MF/PLA Composites

3.5. DSC Analysis of MF/PLA Composites

3.6. TG Analysis of MF/PLA Composites

3.7. XRD Analysis of MF/PLA Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.Y.; Mo, J.L.; Fu, Q.; Liu, Y.H.; Wang, S.F.; Nie, S.X. Wood-cellulose-fiber-based functional materials for triboelectric nanogenerators. Nano Energy 2021, 81, 105637. [Google Scholar] [CrossRef]

- Kenyó, C.; Renner, K.; Móczó, J.; Fekete, E.; Kröhnke, C.; Pukánszky, B. Effect of desiccant characteristics on the properties of PS/zeolite functional packaging materials. Polym. Compos. 2014, 35, 2112–2120. [Google Scholar] [CrossRef]

- Hortelano, C.; Ruiz-Bermejo, M.; de la Fuente, J.L. Solid-state polymerization of diaminomaleonitrile: Toward a new generation of conjugated functional materials. Polymer 2021, 223, 123696. [Google Scholar] [CrossRef]

- Shah, B.L.; Selke, S.E.; Walters, M.B.; Heiden, P.A. Effects of wood flour and chitosan on mechanical, chemical, and thermal properties of polylactide. Polym. Compos. 2008, 29, 655–663. [Google Scholar] [CrossRef]

- Porras, A.; Maranon, A. Development and characterization of a laminate composite material from polylactic acid (PLA) and woven bamboo fabric. Compos. Part B Eng. 2012, 43, 2782–2788. [Google Scholar] [CrossRef]

- Kanakannavar, S.; Pitchaimani, J. Fracture toughness of flax braided yarn woven PLA composites. Int. J. Polym. Anal. Charact. 2021, 26, 364–379. [Google Scholar] [CrossRef]

- Ou, Z.Q.; Zhou, Q.; Rao, X.; Yang, H.F.; Huo, C.Q.; Du, X.Y. Cellulose isolated from waste rubber wood and its application in PLA based composite films. Front. Bioeng. Biotechnol. 2021, 9, 666399. [Google Scholar] [CrossRef]

- Couture, A.; Lebrun, G.; Laperrière, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers. Compos. Struct. 2016, 154, 286–295. [Google Scholar] [CrossRef]

- Faludi, G.; Hári, J.; Renner, K.; Móczó, J.; Pukánszky, B. Fiber association and network formation in PLA/lignocellulosic fiber composites. Compos. Sci. Technol. 2013, 77, 67–73. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly(lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and pp composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Bartos, A.; Nagy, K.; Anggono, J.A.; Purwaningsih, H.; Móczó, J.; Pukánszky, B. Biobased PLA/sugarcane bagasse fiber composites: Effect of fiber characteristics and interfacial adhesion on properties. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106273. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S.; Boonmahitthisud, A. Study on structural and thermal properties of cellulose microfibers isolated from pineapple leaves using steam explosion. J. Environ. Chem. Eng. 2019, 7, 102836. [Google Scholar] [CrossRef]

- Langhorst, A.; Paxton, W.; Bollin, S.; Frantz, D.; Burkholder, J.; Kiziltas, A.; Mielewski, D. Heat-treated blue agave fiber composites. Compos. Part B Eng. 2019, 165, 712–724. [Google Scholar] [CrossRef]

- Pejić, B.M.; Kramar, A.D.; Obradović, B.M.; Kuraica, M.M.; Žekić, A.A.; Kostić, M.M. Effect of plasma treatment on chemical composition, structure and sorption properties of lignocellulosic hemp fibers (Cannabis sativa L.). Carbohyd. Polym. 2020, 236, 116000. [Google Scholar] [CrossRef]

- Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M.R.; Siengchin, S.; Jawaid, M.; Anish, K.; Jyotishkumar, P. Characterization of raw and alkali treated new natural cellulosic fibers from tridax procumbens. Int. J. Biol. Macromol. 2019, 125, 99–108. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Kontou, E.; Georgousis, G. Effect of silane treatment loading on the flexural properties of PLA/flax unidirectional composites. Compos. Commun. 2018, 10, 6–10. [Google Scholar] [CrossRef]

- Li, W.H.; He, X.Y.; Zuo, Y.F.; Wang, S.; Wu, Y.Q. Study on the compatible interface of bamboo fiber/polylactic acid composites by in-situ solid phase grafting. Int. J. Biol. Macromol. 2019, 141, 325–332. [Google Scholar] [CrossRef]

- Joffre, T.; Segerholm, K.; Persson, C.; Bardage, S.L.; Luengo Hendriks, C.L.; Isaksson, P. Characterization of interfacial stress transfer ability in acetylation-treated wood fibre composites using X-ray microtomography. Ind. Crops Prod. 2017, 95, 43–49. [Google Scholar] [CrossRef]

- Avci, A.; Eker, A.; Bodur, M. Effect of coupling agent and alkali treatment on mechanical, thermal and morphological properties of flax-fiber-reinforced PLA composites. Green Mater. 2021, 9, 131–144. [Google Scholar] [CrossRef]

- Xie, Y.; Xiao, Z.; Militz, H.; Hao, X. Silane Coupling Agents Used in Natural Fiber/Plastic Composites. In Handbook of Composites from Renewable Materials, Functionalization; John Wiley & Sons: Hoboken, NJ, USA, 2017; Volume 4, pp. 1219–1228. [Google Scholar] [CrossRef]

- Mohd Ghazali, A.E.; Pickering, K.L. The effect of fibre surface treatment and coupling agents to improve the performance of natural fibres in PLA composites. J. Polym. Eng. 2021, 41, 842–853. [Google Scholar] [CrossRef]

- Chen, K.; Li, P.; Li, X.; Liao, C.; Zuo, Y. Effect of silane coupling agent on compatibility interface and properties of wheat straw/polylactic acid composites. Int. J. Biol. Macromol. 2021, 182, 2108–2116. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Niu, B.; Liu, R.; Chen, H.; Fang, X.; Wu, W.; Mu, H. Development of bio-based PLA/cellulose antibacterial packaging and its application for the storage of shiitake mushroom. Food Chem. 2023, 429, 136905. [Google Scholar] [CrossRef]

- Nandi, P.; Das, D. Mechanical, thermo-mechanical and biodegradation behaviour of surface-silanized nettle fabric-reinforced poly (lactic acid) composites. Mater. Chem. Phys. 2023, 297, 127381. [Google Scholar] [CrossRef]

- Zhang, C.L.; Yu, J.Y.; Feng, K.; Xue, L.H.; Xie, D. Synthesis and characterization of triethoxyvinylsilane surface modified layered double hydroxides and application in improving UV aging resistance of bitumen. Appl. Clay Sci. 2016, 120, 1–8. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Lu, T.J.; Liu, S.M.; Jiang, M.; Xu, X.L.; Wang, Y.; Wang, Z.Y.; Gou, J.; Hui, D.; Zhou, Z.W. Effects of modifications of bamboo cellulose fibers on the improved mechanical properties of cellulose reinforced poly (lactic acid) composites. Compos. Part B Eng. 2014, 62, 191–197. [Google Scholar] [CrossRef]

- Yussuf, A.A.; Massoumi, I.; Hassan, A. Comparison of polylactic acid/kenaf and polylactic acid/rise husk composites: The influence of the natural fibers on the mechanical, thermal and biodegradability properties. J. Polym. Environ. 2010, 18, 422–429. [Google Scholar] [CrossRef]

- Way, C.; Dean, K.; Wu, D.; Palombo, E.A. Polylactic acid composites utilising sequential surface treatments of lignocellulose: Chemistry, morphology and properties. J. Polym. Environ. 2011, 19, 849–862. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Hemp fibre reinforced poly (lactic acid) composites. Adv. Mater. Res. 2007, 29, 337–340. [Google Scholar] [CrossRef]

- Cho, D.; Seo, J.M.; Lee, H.S.; Cho, C.W.; Park, W.H. Property improvement of natural fiber-reinforced green composites by water treatment. Adv. Compos. Mater. 2007, 16, 299–314. [Google Scholar] [CrossRef]

- Plackett, D. Maleated Polylactide as an Interfacial Compatibilizer in Biocomposites. J. Polym. Environ. 2004, 12, 131–138. [Google Scholar] [CrossRef]

- Su, J.; Jiang, Z.W.; Fang, C.Q.; Zheng, Y.M.; Yang, M.N.; Pei, L.; Huang, Z.G. The Reinforcing Effect of Waste Corrugated Paper Fiber on Polylactic Acid. Polymers 2022, 14, 3562. [Google Scholar] [CrossRef] [PubMed]

- Ren, G.Q.; Zhao, C.M. Research on the Pollution of Express Plastic Packaging Based on System Dynamics. E3S Web Conf. 2020, 165, 02011. [Google Scholar] [CrossRef]

- Wallis, C. Terrestrial fugitive plastic packaging-the blind spot in resolving plastic pollution. Green Mater. 2019, 8, 3–5. [Google Scholar] [CrossRef]

- Zambrano, F.; Marquez, R.; Jameel, H.; Venditti, R.; Gonzalez, R. Upcycling strategies for old corrugated containerboard to attain high-performance tissue paper: A viable answer to the packaging waste generation dilemma. Resour. Conserv. Recycl. 2021, 175, 105854. [Google Scholar] [CrossRef]

- Xue, H.; Deng, Y.; Zhou, Z.; Ren, L.; Meng, Q. Effect of two methods of van soest fibre detergent system on monosaccharide compositions of acid detergent residues. J. Anim. Feed Sci. 2007, 16, 500–505. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dickson, A.N.; Dowling, D.P. Evaluation of the mechanical performance of polymer parts fabricated using a production scale multi jet fusion printing process. Addit. Manuf. 2018, 22, 381–387. [Google Scholar] [CrossRef]

- Kurniawan, D.; Kim, B.S.; Lee, H.Y.; Lim, J.Y. Atmospheric pressure glow discharge plasma polymerization for surface treatment on sized basalt fiber/polylactic acid composites. Compos. Part B Eng. 2012, 43, 1010–1014. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Tarrés, Q.; Méndez, J.A.; Delgado-Aguilar, M.; Mutjé, P. Towards a good interphase between bleached kraft softwood fibers and poly (lactic) acid. Compos. Part B Eng. 2016, 99, 514–520. [Google Scholar] [CrossRef]

- Faludi, G.; Dora, G.; Renner, K.; Móczó, J.; Pukánszky, B. Biocomposite from polylactic acid and lignocellulosic fibers: Structure-property correlations. Carbohyd. Polym. 2013, 92, 1767–1775. [Google Scholar] [CrossRef] [PubMed]

- Kyutoku, H.; Maeda, N.; Sakamoto, H.; Nishimura, H.; Yamada, K. Effect of surface treatment of cellulose fiber (CF) on durability of PLA/CF bio-composites. Carbohyd. Polym. 2019, 203, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Y.; Yao, X.D.; Sui, G.X.; Yin, L.M.; Wang, L.H. Properties of Xanthoceras sorbifolia Husk Fibers with Chemical Treatment for Applications in Polymer Composites. J. Mater. Sci. Technol. 2015, 31, 164–170. [Google Scholar] [CrossRef]

- Jamshidi, K.; Hyon, S.H.; Ikada, Y. Thermal characterization of polylactides. Polymer 1988, 29, 2229–2234. [Google Scholar] [CrossRef]

| Components | Lignin | Cellulose | Hemicellulose | Other |

|---|---|---|---|---|

| Content | 42.02 ± 0.09 | 13.23 ± 0.08 | 20.18 ± 0.02 | 25.06 ± 0.15 |

| Silane Coupling Agent | Sample | Coupling Agent (wt%) | WF (wt%) | PLA (wt%) |

|---|---|---|---|---|

| KH550 | MF/P5-2 | 2 | 25 | 75 |

| MF/P5-4 | 4 | 25 | 75 | |

| MF/P5-6 | 6 | 25 | 75 | |

| MF/P5-8 | 8 | 25 | 75 | |

| KH560 | MF/P6-2 | 2 | 25 | 75 |

| MF/P6-4 | 4 | 25 | 75 | |

| MF/P6-6 | 6 | 25 | 75 | |

| MF/P6-8 | 8 | 25 | 75 | |

| KH570 | MF/P7-2 | 2 | 25 | 75 |

| MF/P7-4 | 4 | 25 | 75 | |

| MF/P7-6 | 6 | 25 | 75 | |

| MF/P7-8 | 8 | 25 | 75 | |

| / | WF/P | / | 25 | 75 |

| Sample | ∆Hf/(J/g) | Xc/% |

|---|---|---|

| MF/P5-2 | 80.22 | 56.5 |

| MF/P5-4 | 88.33 | 62.21 |

| MF/P5-6 | 81.11 | 57.12 |

| MF/P5-8 | 72.56 | 51.1 |

| MF/P6-2 | 85.86 | 60.46 |

| MF/P6-4 | 93.12 | 65.58 |

| MF/P6-6 | 86.01 | 60.57 |

| MF/P6-8 | 86.06 | 60.61 |

| MF/P7-2 | 94.17 | 66.32 |

| MF/P7-4 | 87.14 | 61.36 |

| MF/P7-6 | 90.59 | 63.8 |

| MF/P7-8 | 84.11 | 59.23 |

| WF/P | 75.7 | 53.31 |

| PLA | 127.6 | 89.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Su, J.; Zheng, Y.; Fang, C.; Lei, W.; Li, L. Effect of Different Silane Coupling Agents on Properties of Waste Corrugated Paper Fiber/Polylactic Acid Composites. Polymers 2023, 15, 3525. https://doi.org/10.3390/polym15173525

Yang M, Su J, Zheng Y, Fang C, Lei W, Li L. Effect of Different Silane Coupling Agents on Properties of Waste Corrugated Paper Fiber/Polylactic Acid Composites. Polymers. 2023; 15(17):3525. https://doi.org/10.3390/polym15173525

Chicago/Turabian StyleYang, Mannan, Jian Su, Yamin Zheng, Changqing Fang, Wanqing Lei, and Lu Li. 2023. "Effect of Different Silane Coupling Agents on Properties of Waste Corrugated Paper Fiber/Polylactic Acid Composites" Polymers 15, no. 17: 3525. https://doi.org/10.3390/polym15173525

APA StyleYang, M., Su, J., Zheng, Y., Fang, C., Lei, W., & Li, L. (2023). Effect of Different Silane Coupling Agents on Properties of Waste Corrugated Paper Fiber/Polylactic Acid Composites. Polymers, 15(17), 3525. https://doi.org/10.3390/polym15173525