Effect of Fabric Substrate and Introduction of Silk Fibroin on the Structural Color of Photonic Crystals

Abstract

:1. Introduction

2. Materials

3. Experiments

3.1. Synthesis of PS Microspheres

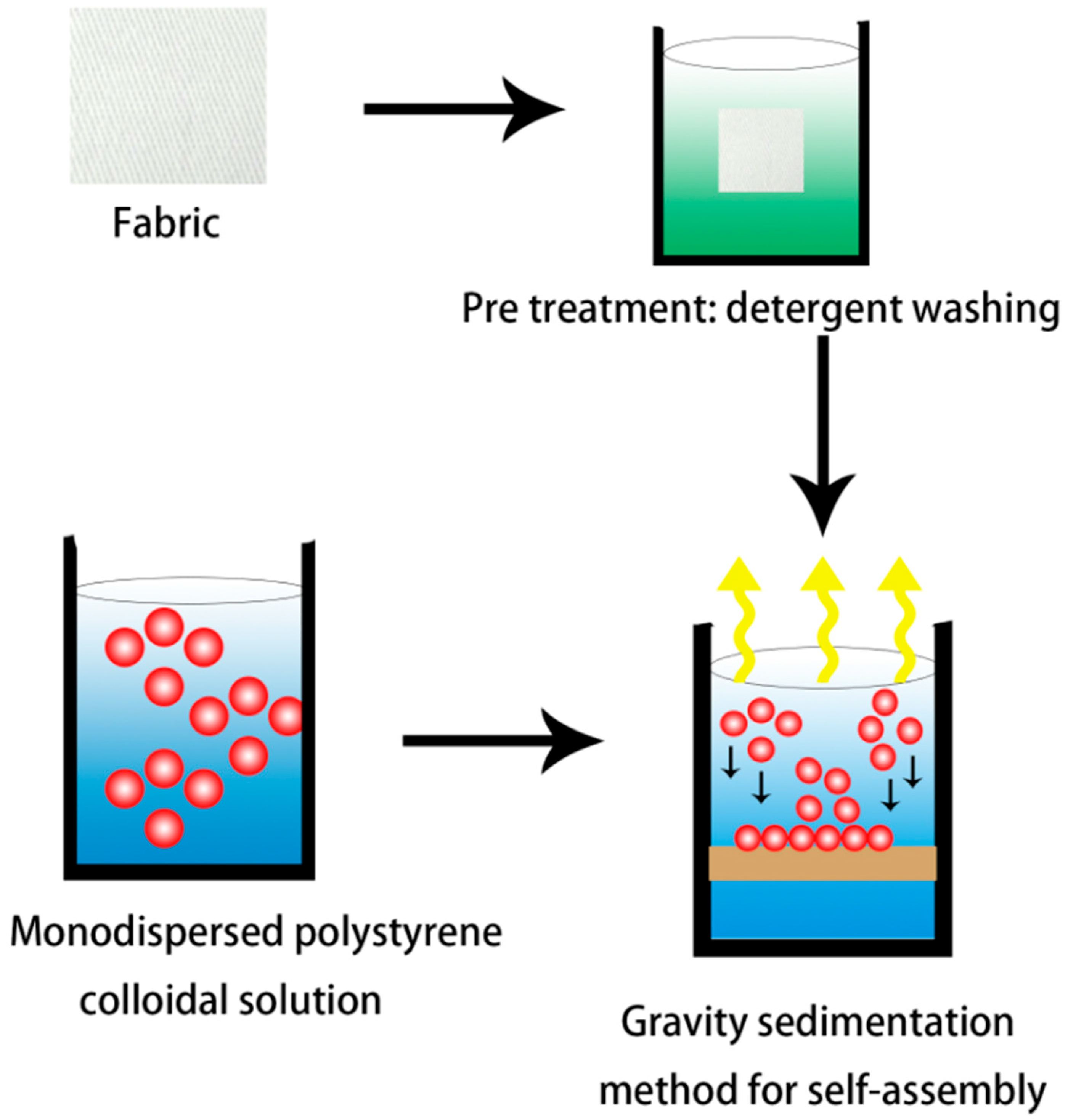

3.2. Self-Assembly of Photonic Crystals

3.3. Preparation of Silk Fibroin Solutions

3.4. Color Fastness Measurements

3.5. Characterization

4. Results and Discussions

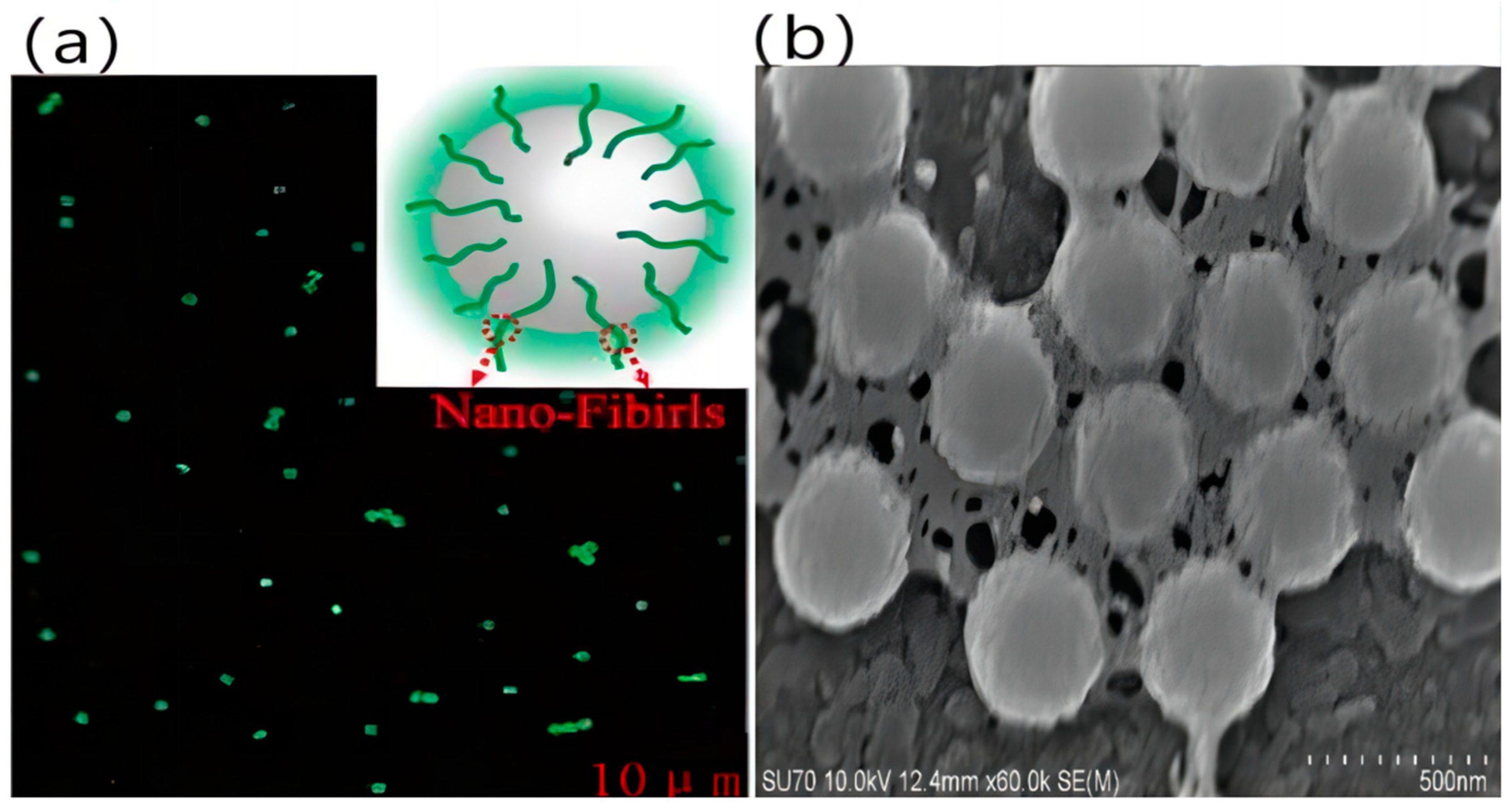

4.1. Dispersion of PS Microspheres

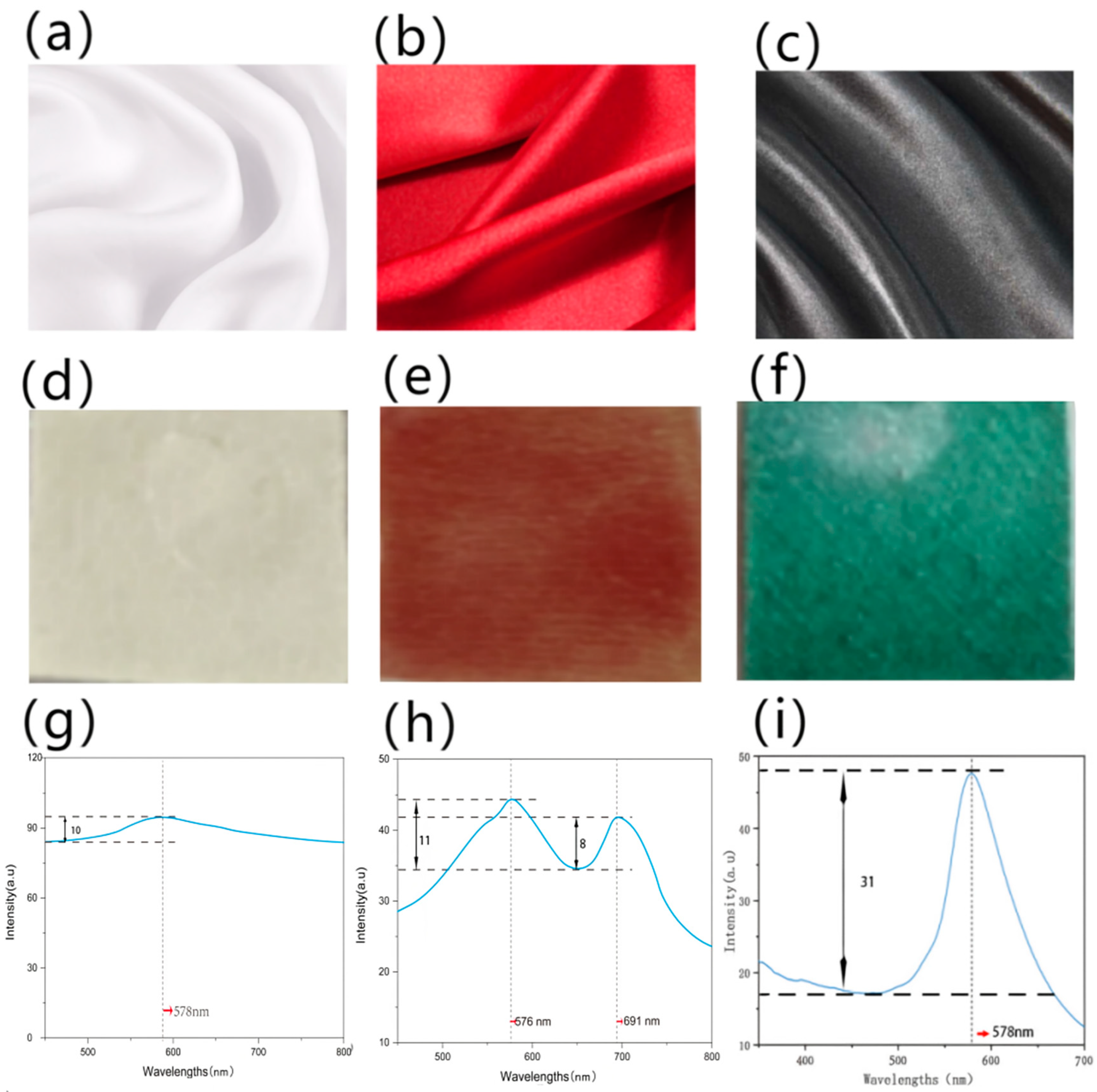

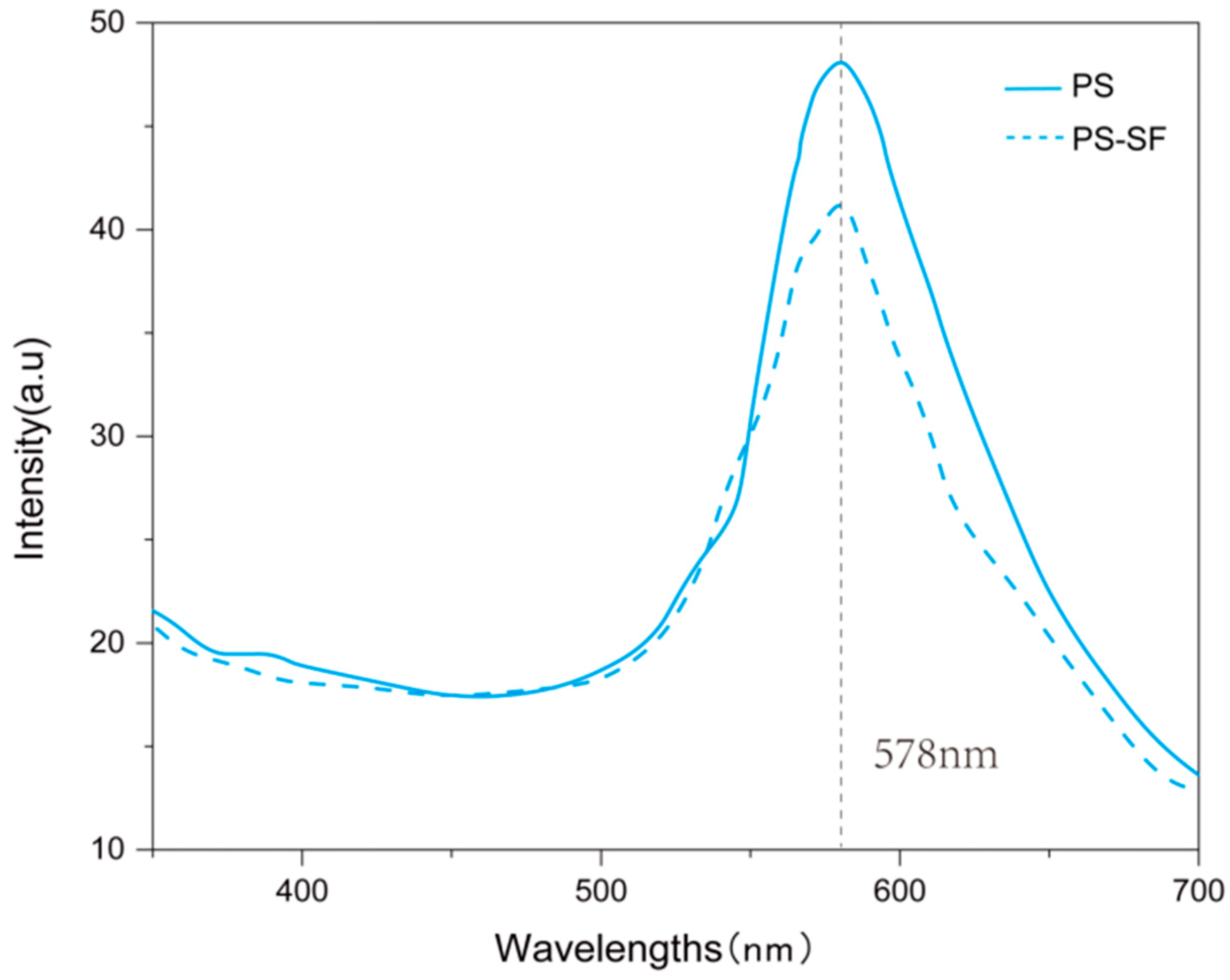

4.2. Effect of Raw Materials

4.3. Effect of Fabric Base Colors

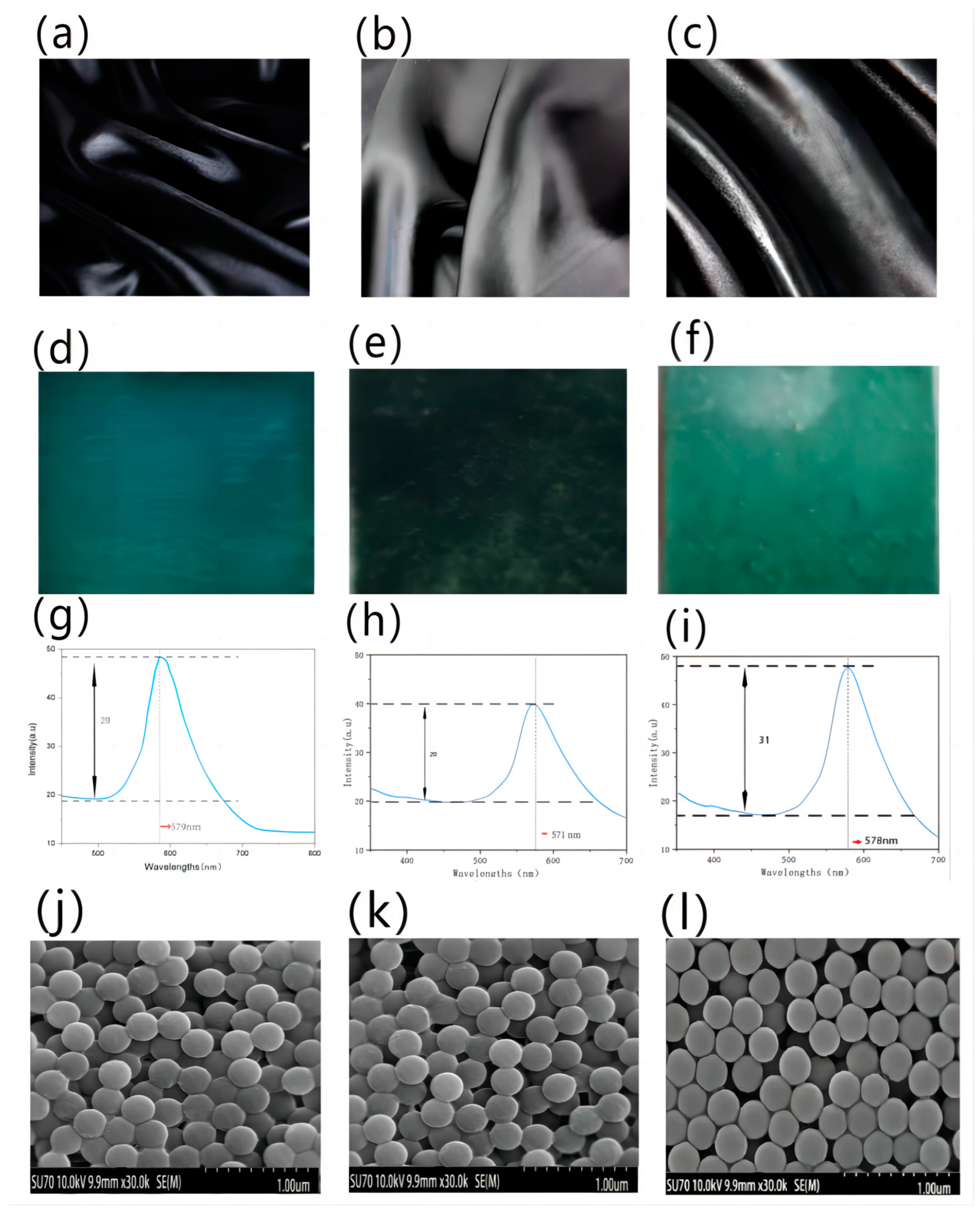

4.4. Effect of Fabric Weaves

4.5. Effect of Silk Fibroin on Color Fastness

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kinoshita, S.; Yoshioka, S. Structural Colors in Nature: The Role of Regularity and Irregularity in the Structure. ChemPhysChem 2010, 6, 1442–1459. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Li, Y.; Liu, G.; Fan, Q.; Shao, J. Study on the correlations between the structural colors of photonic crystals and the base colors of textile fabric substrates. Dye. Pigment. 2016, 133, 435–444. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, F.; Luo, H.; Zhu, J. Preparation of noniridescentstructurally colored PS@TiOand Air@C@Ti0, coreshellnanoparticles with enhanced color stability. ACS Appl. Mater. Interfaces 2019, 11, 34355–34363. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Ding, C.; Li, Q.; Yuan, W.; Peng, Y.; Hu, J.; Zhang, K.Q. Rapid fabrication of robust, washable.self-healing superhydrophobic fabrics with non-iridescent structuralcolor by facile spray coating. RSC Adv. 2017, 7, 8443–8452. [Google Scholar] [CrossRef]

- John, S. Strong localization of photons in certain disordered die lectric superlattices. Phys. Rev. Lett. 1987, 58, 2486–2489. [Google Scholar] [CrossRef]

- Yablonovitch, E. Inhibited spontaneous emission in solid state physics and electronics. Phys. Rev. Lett. 1987, 58, 2059–2062. [Google Scholar] [CrossRef]

- Zhou, L.; Lei, J.; Wang, L.; Liu, Y.; Zhang, J. Highly efficient photo-Fenton degradation of methyl orange facilitated by slow light effect and hierarchical porous structure of Fe2O3-SiO2 photonic crystals. Appl. Catal. B Environ. 2018, 237, 1160–1167. [Google Scholar] [CrossRef]

- Yablonovitch, E. Photonic band gap structures. J. Opt. Soc. Am. B 1993, 10, 283–295. [Google Scholar] [CrossRef]

- Cheng, C.; Zhiqiang, D.; Haowen, C.; Yang, C.; Zhigang, Z.; Weiheng, S. Two dimensional photonic crystals. Prog. Chem. 2018, 30, 775–784. [Google Scholar]

- Gumus, M.; Giden, I.H.; Akcaalan, O.; Turduev, M.; Kurt, H. Enhanced superprism effect in symmetry reduced photonic crystals. Appl. Phys. Lett. 2018, 113, 131103. [Google Scholar] [CrossRef]

- Parimi, P.V.; Lu, W.T.; Vodo, P.; Sokoloff, J.; Derov, J.S.; Sridhar, S. Negative refraction and left-handed electromagnetism in microwave photonic crystals. Phys. Rev. Lett. 2004, 92, 127401. [Google Scholar] [CrossRef] [PubMed]

- Freymann, G.V.; Kitaev, V.; Lotsch, B.V.; Ozin, G.A. Bottom-up assembly of photonic crystals. Chem. Soc. Rev. 2013, 42, 2528–2554. [Google Scholar] [CrossRef]

- Meade, R.D.V.; Johnson, S.G.; Winn, J.N. Photonic Crystals: Molding the Flow of Light; Princeton University Press: Princeton, NJ, USA, 2011. [Google Scholar]

- Wang, W.; Gu, B.; Liang, L.; Hamilton, W. Fabrication of two-and three-dimemsional silica nanocolloidal particle arrays. J. Phys. Chem. B 2003, 107, 3400–3404. [Google Scholar] [CrossRef]

- Schroden, R.C.; Al-Daous, M.; Blanford, C.F.; Stein, A. optical properties of inverse opal photonic crystals. Chem. Manterials 2002, 14, 3305–3315. [Google Scholar] [CrossRef]

- Jia, G.; Zhenxiong, Z.; Ying, H.; Jianchen, H.; Keqin, Z. Research progress of chromogenic fibers based on photonic crystal structure. J. Text. Sci. 2023, 44, 212–221. [Google Scholar]

- Yong, G.; Lan, Z.; Jianzhong, S. Preparation of P (St HEA) photonic crystal structure chromogenic thin films on cotton fabrics. J. Zhejiang Univ. Technol. 2018, 39, 383–389. [Google Scholar]

- Jiao, D.; Liqin, C.; Guojin, L.; Jianzhong, S.; Lan, Z. Study on silica inverse opal photonic crystal on polyester fabric and its structure. J. Zhejiang Univ. Technol. 2018, 39, 1–6. [Google Scholar]

- Hao, L.; Wanbing, M.; Yiming, L.; Lan, Z.; Jianzhong, S.; Guojin, L. Preparation and Properties of Photonic Crystal Structure Colored Carbon Fiber/Polyester Blended Yarn. J. Text. Res. 2023, 44, 159–167. [Google Scholar]

- Shi, X.; He, J.; Xie, X.; Dou, R.; Lu, X. Photonic crystals with vivid structurecolor and robust mechanical strength. Dye. Pigment. 2019, 165, 137–143. [Google Scholar] [CrossRef]

- Liu, G.; Han, P.; Chai, L.; Li, Z.; Zhou, L. Fabrication of cotton fabrics withboth bright structural colors and strong hydrophobicity. Colloids Surf. A Physicochem. Eng. Asp. 2020, 600, 124991. [Google Scholar] [CrossRef]

- Yuan, X.; Xu, W.; Huang, F.; Wang, Q.; Wei, Q.; Chen, D. Structural colors of fabric from Ag/TiO2 composite films prepared by magnetron sputtering deposition. Int. J. Cloth. Sci. Technol. 2017, 29, 427–435. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, L.; Fan, Q.; Chai, L.; Shao, J. The vertical deposition selfassembly process and the formation mechanism of poly(styrene-comethacrylic acid) photonic crystals on polyester fabrics. J. Mater. Sci. 2016, 51, 2859–2868. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, L.; Wu, Y.; Wang, C.; Fan, Q.; Shao, J. The fabrication of full color P(StMAA) photonic crystal structure on polyester fabrics by vertical deposition self-assembly. J. Appl. Polym. Sci. 2015, 132, 41750–41759. [Google Scholar]

- Zhou, L.; Wu, Y.; Liu, G.; Li, Y.; Fan, Q.; Shao, J. Fabrication of high-quality silica photonic crystals on polyester fabrics by gravitational sedimentation self-assembly. Color. Technol. 2015, 131, 413–423. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, L.; Zhang, G.; Li, Y.; Chai, L.; Fan, Q.; Shao, J. Fabrication of patterned photonic crystals with brilliant structural colors on fabric substrates using ink-jet printing technology. Mater. Des. 2017, 114, 10–17. [Google Scholar] [CrossRef]

- Li, Y.; Chai, L.; Wang, X.; Zhou, L.; Fan, Q.; Shao, J. Facile fabrication of amorphous photonic structures with non-iridescent and highly-stable structural color on textile substrates. Materials 2018, 11, 2500. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Hu, M.; Zhou, L.; Chai, L.; Fan, Q.; Shao, J. Patterned SiO2 /PUA inverse opal photonic crystals with high color saturation and tough mechanical strength. Langmuir ACS J. Surf. Colloids 2019, 35, 14282–14290. [Google Scholar] [CrossRef]

- Johnson, N.P.; McComb, D.W.; Richel, A.; Treble, B.M.; De La Rue, R.M. Synthesis and optical properties of opal and inverse opal photonic crystals. Synth. Met. 2001, 116, 469–473. [Google Scholar] [CrossRef]

- Wijnhoven, J.E.; Vos, W.L. Preparation of photonic crystals made of air spheres in titania. Science 1998, 281, 802–804. [Google Scholar] [CrossRef]

- Edrington, A.C.; Urbas, A.M.; DeRege, P.; Chen, C.X.; Swager, T.M.; Hadjichristidis, N.; Xenidou, M.; Fetters, L.J.; Joannopoulos, J.D.; Fink, Y.; et al. Polymer-based photonic crystals. Adv. Mater. 2001, 13, 421–425. [Google Scholar] [CrossRef]

- Baba, T. Slow light in photonic crystals. Nat. Photonics 2008, 2, 465–473. [Google Scholar] [CrossRef]

- Kivshar, Y.S.; Agrawal, G.P. Optical Solitons: From Fibers to Photonic Crystals; Academic Press: San Diego, CA, USA, 2003. [Google Scholar]

- Park, J.H.; Kim, M.H.; Jeong, L.; Cho, D.; Kwon, O.H.; Park, W.H. Effect of surfactants on sol–gel transition of silk fibroin. J. Sol Gel Sci. Technol. 2014, 71, 364–371. [Google Scholar] [CrossRef]

- Yang, S.; Chen, Z.; Liu, X. Prediction of crystallization of a colloid-protein complex by controlled complex selfassembly at the solution surface. Arab. J. Chem. 2021, 14, 103387. [Google Scholar]

- GB/T 3920—2008; Textiles—Tests for Colour Fastness—Colour Fastness to Rubbing. National Standard of the People’s Republic of China: Beijing, China, 2008.

- GB/T 3921—2008; Textiles—Tests for Colour Fastness—Colour Fastness to Washing with Soap or Soap and Soda. National Standard of the People’s Republic of China: Beijing, China, 2008.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Xiang, H.; Wang, Y.; Chen, K.; Gao, W. Effect of Fabric Substrate and Introduction of Silk Fibroin on the Structural Color of Photonic Crystals. Polymers 2023, 15, 3551. https://doi.org/10.3390/polym15173551

Yang S, Xiang H, Wang Y, Chen K, Gao W. Effect of Fabric Substrate and Introduction of Silk Fibroin on the Structural Color of Photonic Crystals. Polymers. 2023; 15(17):3551. https://doi.org/10.3390/polym15173551

Chicago/Turabian StyleYang, Shu, Hongming Xiang, Yingwen Wang, Kaikai Chen, and Weihong Gao. 2023. "Effect of Fabric Substrate and Introduction of Silk Fibroin on the Structural Color of Photonic Crystals" Polymers 15, no. 17: 3551. https://doi.org/10.3390/polym15173551