Monodisperse Fluorescent Polystyrene Microspheres for Staphylococcus aureus Aerosol Simulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Synthesis of Functional Submicron-Size Microspheres

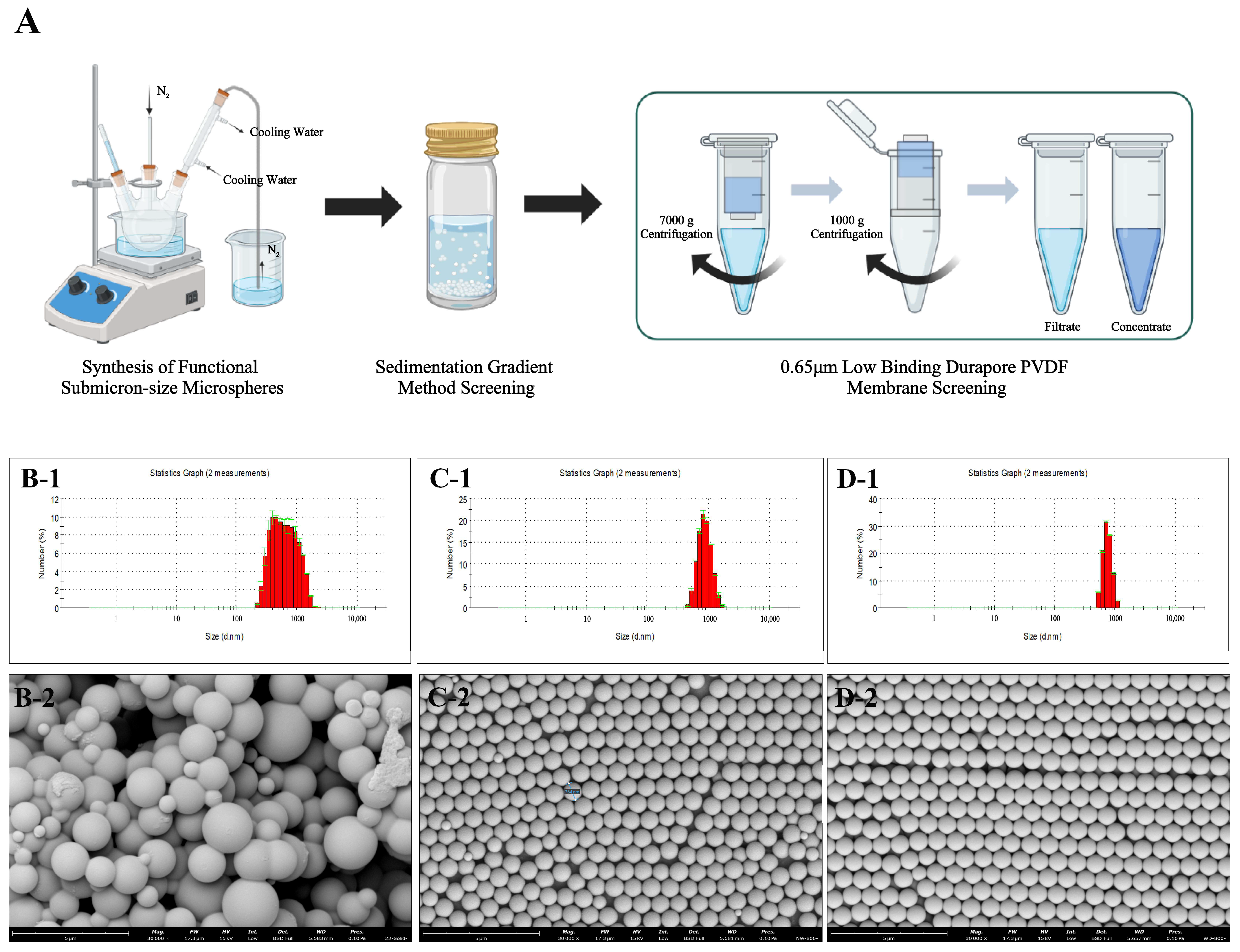

2.2.2. Screening of PS Microspheres

2.2.3. Characterization of Functional Submicron-Size Microspheres

2.2.4. Fluorescence Spectrum and Particle Size Distribution of SA

2.2.5. Fluorescence Spectrum and Particle Size Distribution of f-PS Microspheres in Aerosols

3. Results

3.1. Analysis of PS Microsphere Preparation and Screening Process

3.1.1. Effect of Different St Concentrations on the Particle Size of Microspheres

3.1.2. Effect of Different Screening Methods on the Particle Size Distribution of Microspheres

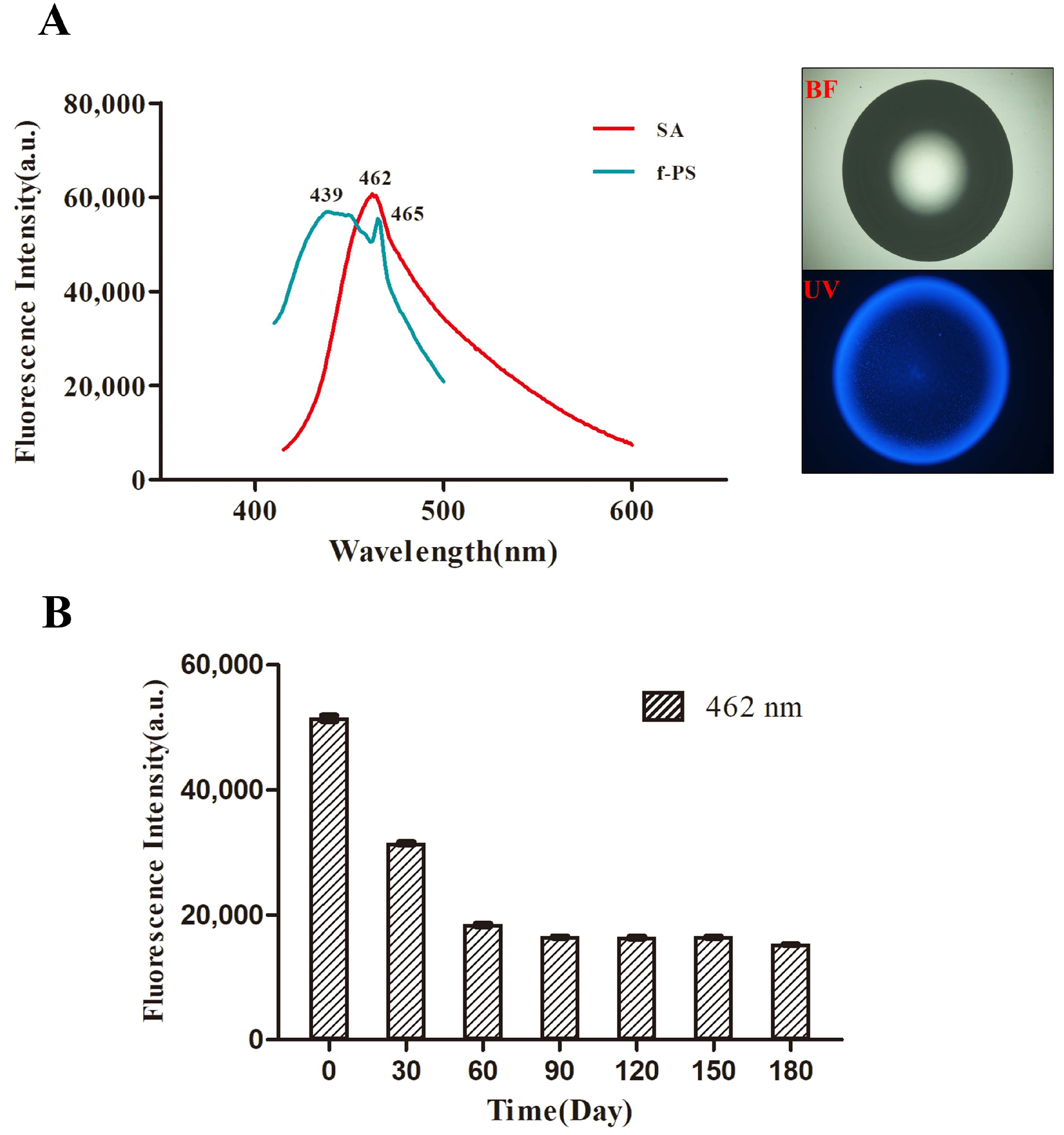

3.2. Fluorescence Spectra and Particle Size Distribution of f-PS Microspheres and SA

3.2.1. Comparison of Fluorescence Spectra of SA and f-PS Microspheres

3.2.2. Comparison of Particle Size Distribution of SA and f-PS Microspheres

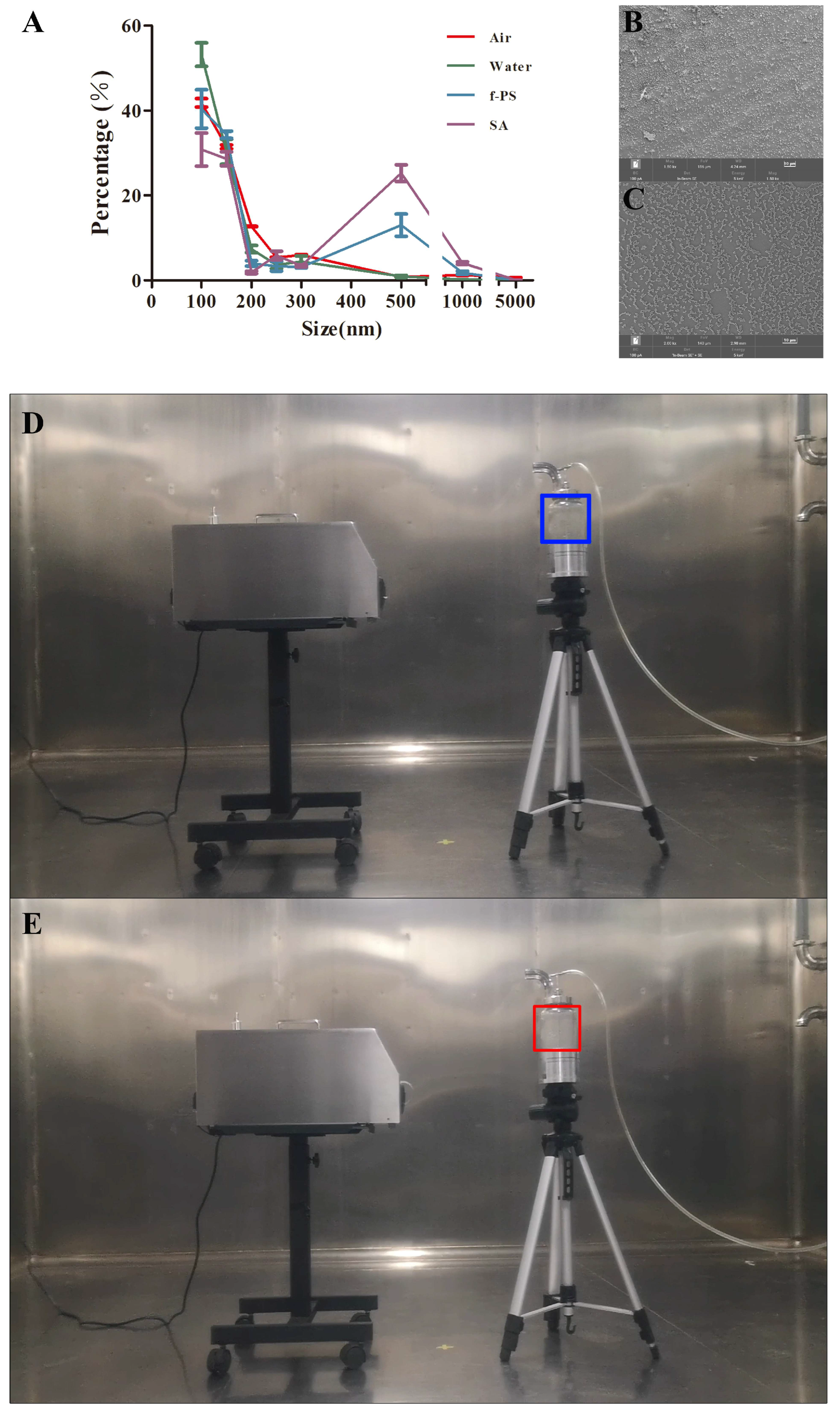

3.3. Comparison of Particle Size Distribution of SA and f-PS Microspheres in Aerosols

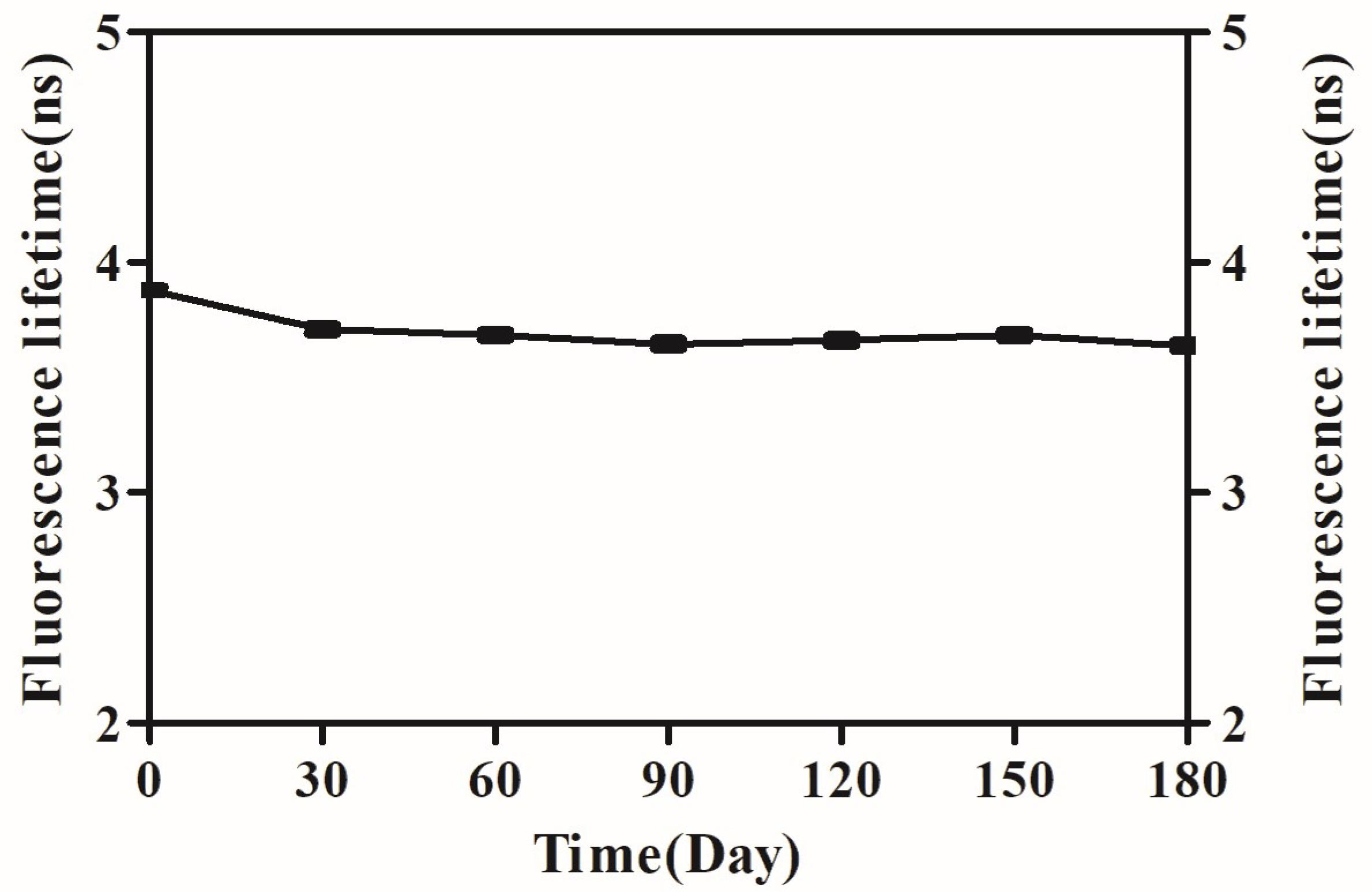

3.4. Fluorescence Lifetimes of f-PS Microspheres

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kwaśny, M.; Bombalska, A.; Kaliszewski, M.; Włodarski, M.; Kopczyński, K. Fluorescence Methods for the Detection of Bioaerosols in Their Civil and Military Applications. Sensors 2023, 23, 3339. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.; Yoo, K. A review of the emergence of antibiotic resistance in bioaerosols and its monitoring methods. Rev. Environ. Sci. Biotechnol. 2022, 21, 799–827. [Google Scholar] [CrossRef]

- Xu, Z.Q.; Wu, Y.; Shen, F.X.; Chen, Q.; Tan, M.M.; Yao, M.S. Bioaerosol science, technology and engineering: Past, present, and future. Aerosol. Sci. Technol. 2011, 45, 1337–1349. [Google Scholar] [CrossRef]

- Després, V.R.; Huffman, J.A.; Burrows, S.M.; Hoose, C.; Safatov, A.S.; Buryak, G.; Fröhlich-Nowoisky, J.; Elbert, W.; Andreae, M.O.; Pöschl, U.; et al. Primary biological aerosol particles in the atmosphere: A review. Tellus. B Chem. Phys. Meteorol. 2012, 64, 15598. [Google Scholar] [CrossRef]

- Fröhlich-Nowoisky, J.; Kampf, C.J.; Weber, B.; Huffman, J.A.; Pöhlker, C.; Andreae, M.O.; Lang-Yona, N.; Burrows, S.M.; Gunthe, S.S.; Elbert, W.; et al. Bioaerosols in the Earth system: Climate, health, and ecosystem interactions. Atmos. Res. 2016, 182, 346–376. [Google Scholar] [CrossRef]

- Yue, S.; Ren, H.; Fan, S.; Wei, L.; Zhao, J.; Bao, M.; Hou, S.; Zhan, J.; Zhao, W.; Ren, L.; et al. High abundance of fluorescent biological aerosol particles in winter in Beijing, China. ACS Earth Space Chem. 2017, 1, 493–502. [Google Scholar] [CrossRef]

- Kim, K.H.; Kabir, E.; Jahan, S.A. Airborne bioaerosols and their impact on human health. J. Environ. Sci. 2018, 67, 23–35. [Google Scholar] [CrossRef]

- Mentese, S.; Arisoy, M.; Rad, A.Y.; Güllü, G. Bacteria and fungi levels in various indoor and outdoor environments in Ankara. Turk. Clean 2009, 37, 487–493. [Google Scholar] [CrossRef]

- Du, P.; Du, R.; Ren, W.; Lu, Z.; Fu, P. Seasonal variation characteristic of inhalable microbial communities in PM2.5 in Beijing city. China Sci. Total Environ. 2018, 610–611, 308–315. [Google Scholar] [CrossRef]

- Gao, X.-L.; Shao, M.-F.; Wang, Q.; Wang, L.-T.; Fang, W.-Y.; Ouyang, F.; Li, J. Airborne microbial communities in the atmospheric environment of urban hospitals in China. J. Hazard Mater. 2018, 349, 10–17. [Google Scholar] [CrossRef]

- Yu, Y.; Liang, Z.; Liao, W.; Ye, Z.; Li, G.; An, T. Contributions of meat waste decomposition to the abundance and diversity of pathogens and antibiotic-resistance genes in the atmosphere. Sci. Total Environ. 2021, 784, 147128. [Google Scholar] [CrossRef]

- Kumari, P.; Woo, C.; Yamamoto, N.; Choi, H. Variations in abundance, diversity and community composition of airborne fungi in swine houses across seasons. Sci. Rep. 2016, 6, 37929. [Google Scholar] [CrossRef]

- Frączek, K.; Kozdrój, J.; Górny, R.L.; Cyprowski, M.; Gołofit-Szymczak, M. Fungal air contamination in distinct sites within a municipal landfill area. Int. J. Environ. Sci. Technol. 2017, 14, 2637–2648. [Google Scholar] [CrossRef]

- Dai, P.; Shen, D.; Tang, Q.; Huang, K.; Li, C. PM2. 5 from a broiler breeding production system: The characteristics and microbial community analysis. Environ. Pollut. 2020, 256, 113368. [Google Scholar] [CrossRef] [PubMed]

- Xie, W.; Li, Y.; Bai, W.; Hou, J.; Ma, T.; Zeng, X.; Zhang, L.; An, T. The source and transport of bioaerosols in the air: A review. Front. Environ. Sci. Eng. 2021, 15, 44. [Google Scholar] [CrossRef]

- Teng, X.; Ding, X.; She, Z.; Li, Y.; Xiong, X. Preparation of Functionalized Magnetic Polystyrene Microspheres and Their Application in Food Safety Detection. Polymers 2022, 15, 77. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.; Huang, W.; Guo, B.; Sun, Y.; Shen, H. Preparation and Lubricating Properties of Polystyrene Composite Microspheres. Materials 2023, 16, 3071. [Google Scholar] [CrossRef]

- Hao, Y.; Xu, H.; Li, X.; Wei, Z.; Zhang, Y. Mesoporous polystyrene-based microspheres with polar functional surface groups synthesized from double emulsion for selective isolation of acetoside. J. Chromatogr. A 2022, 1662, 462720. [Google Scholar] [CrossRef]

- El Hayek, E.; Castillo, E.; In, J.G.; Garcia, M.; Cerrato, J.; Brearley, A.; Gonzalez-Estrella, J.; Herbert, G.; Bleske, B.; Benavidez, A.; et al. Photoaging of polystyrene microspheres causes oxidative alterations to surface physicochemistry and enhances airway epithelial toxicity. Toxicol. Sci. 2023, 193, 90–102. [Google Scholar] [CrossRef]

- Guo, J.; Wu, Y.; Gong, Z.; Chen, X.; Cao, F.; Kala, S.; Qiu, Z.; Zhao, X.; Chen, J.; He, D.; et al. Photonic Nanojet-Mediated Optogenetics. Adv. Sci. 2022, 9, e2104140. [Google Scholar] [CrossRef]

- Nikam, S.B.; Asha, S.K. Enantioselective Separation of Amino Acids Using Chiral Polystyrene Microspheres Synthesized by a Post-Polymer Modification Approach. ACS Polym. Au 2022, 2, 257–265. [Google Scholar] [CrossRef]

- Ghaffar, I.; Javid, A.; Mehmood, S.; Hussain, A. Uptake of Cu2+ by unicellular microalga Chlorella vulgaris from synthetic wastewaters is attenuated by polystyrene microspheres. Chemosphere 2022, 290, 133333. [Google Scholar] [CrossRef] [PubMed]

- Gandolfi, I.; Bertolini, V.; Bestetti, G.; Ambrosini, R.; Innocente, E.; Rampazzo, G.; Papacchini, M.; Franzetti, A. Spatio-temporal variability of airborne bacterial communities and their correlation with particulate matter chemical composition across two urban areas. Appl. Microbiol. Biotechnol. 2015, 99, 4867–4877. [Google Scholar] [CrossRef]

- Wu, B.; Duan, H.Y.; Qi, Q.; Cai, Y.M.; Zhong, Z.B.; Chai, T.J. Identifying virulence factor genes in E. coli in animal houses and their transmission to outside environments. J. Aerosol. Sci. 2018, 117, 189–199. [Google Scholar] [CrossRef]

- Thorsen, T.; Roberts, R.W.; Arnold, F.H.; Quake, S.R. Dynamic pattern formation in a vesicle-generating microfluidic device. Phys. Rev. Lett. 2001, 86, 4163–4166. [Google Scholar] [CrossRef]

- Nisisako, T.; Torii, T.; Higuchi, T. Droplet formation in a microchannel network. Lab Chip. 2002, 2, 24–26. [Google Scholar] [CrossRef] [PubMed]

- Garstecki, P.; Fuerstman, M.J.; Stone, H.A.; Whitesides, G.M. Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up. Lab Chip. 2006, 6, 437–446. [Google Scholar] [CrossRef] [PubMed]

- Gañán-Calvo, A.M.; Gordillo, J.M. Perfectly monodisperse microbubbling by capillary flow focusing. Phys. Rev. Lett. 2001, 87 Pt 1, 274501. [Google Scholar] [CrossRef]

- Alemrayat, B.; Elrayess, M.A.; Alany, R.G.; Elhissi, A.; Younes, H.M. Preparation and optimization of monodisperse polymeric microparticles using modified vibrating orifice aerosol generator for controlled delivery of letrozole in breast cancer therapy. Drug Dev. Ind. Pharm. 2018, 44, 1953–1965. [Google Scholar] [CrossRef]

- Morais, A.Í.S.; Vieira, E.G.; Afewerki, S.; Sousa, R.B.; Honorio, L.M.C.; Cambrussi, A.N.C.O.; Santos, J.A.; Bezerra, R.D.S.; Furtini, J.A.O.; Silva-Filho, E.C.; et al. Fabrication of Polymeric Microparticles by Electrospray: The Impact of Experimental Parameters. J. Funct. Biomater. 2020, 11, 4. [Google Scholar] [CrossRef]

- Agranovski, I.E.; Usachev, E.V.; Agranovski, E.; Usacheva, O.V. Miniature PCR based portable bioaerosol monitor development. J. Appl. Microbiol. 2017, 122, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Patterson, B.; Dinkele, R.; Gessner, S.; Morrow, C.; Kamariza, M.; Bertozzi, C.R.; Kamholz, A.; Bryden, W.; Call, C.; Warner, D.F.; et al. Sensitivity optimisation of tuberculosis bioaerosol sampling. PLoS ONE 2020, 15, e0238193. [Google Scholar] [CrossRef]

- Zajmi, A.; Hashim, N.M.; Noordin, M.I.; Khalifa, S.A.M.; Ramli, F.; Ali, H.M.; El-Seedi, H.R. Ultrastructural Study on the Antibacterial Activity of Artonin E versus Streptomycin against Staphylococcus aureus Strains. PLoS ONE 2015, 10, e0128157. [Google Scholar] [CrossRef] [PubMed]

- de Mesy Bentley, K.L.; Trombetta, R.; Nishitani, K.; Bello-Irizarry, S.N.; Ninomiya, M.; Zhang, L.; Chung, H.L.; McGrath, J.L.; Daiss, J.L.; Awad, H.A.; et al. Evidence of Staphylococcus Aureus Deformation, Proliferation, and Migration in Canaliculi of Live Cortical Bone in Murine Models of Osteomyelitis. J. Bone Miner Res. 2017, 32, 985–990. [Google Scholar] [CrossRef]

- Qu, J.-B.; Xu, Y.-L.; Liu, Y.; Wang, Y.; Sui, Y.; Liu, J.-G.; Wang, X. Inherently fluorescent polystyrene microspheres for coating, sensing and cellular imaging. Colloids Surf. B Biointerfaces 2017, 152, 475–481. [Google Scholar] [CrossRef]

- Tong, S.Y.; Davis, J.S.; Eichenberger, E.; Holland, T.L.; Fowler, V.G., Jr. Staphylococcus aureus infections: Epidemiology, pathophysiology, clinical manifestations, and management. Clin. Microbiol. Rev. 2015, 28, 603–661. [Google Scholar] [CrossRef]

- McCaig, L.F.; McDonald, L.C.; Mandal, S.; Jernigan, D.B. Staphylococcus aureus-associated skin and soft tissue infections in ambulatory care. Emerg. Infect. Dis. 2006, 12, 1715–1723. [Google Scholar] [CrossRef]

| St | PVP | AIBN | H2O | Temperature | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6% | 10% | 14% | 1% | 3% | 5% | 0.6% | 1% | 1.4% | 0 | 10% | 20% | 60 °C | 70 °C | 80 °C | |

| Size (nm) | 560 | 722 | 779 | 1015 | 722 | 659 | 516 | 722 | 964 | 329 | 722 | 821 | 904 | 722 | 887 |

| CV (%) | 13.6 | 15.8 | 18.7 | 19.8 | 15.8 | 12.9 | 18.7 | 15.8 | 14.9 | 18.5 | 15.8 | 16.8 | 18.9 | 15.8 | 17.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Li, F.; Liu, B.; Yang, K.; Tian, F.; Cheng, Z.; Ding, S.; Hou, K. Monodisperse Fluorescent Polystyrene Microspheres for Staphylococcus aureus Aerosol Simulation. Polymers 2023, 15, 3614. https://doi.org/10.3390/polym15173614

Lu S, Li F, Liu B, Yang K, Tian F, Cheng Z, Ding S, Hou K. Monodisperse Fluorescent Polystyrene Microspheres for Staphylococcus aureus Aerosol Simulation. Polymers. 2023; 15(17):3614. https://doi.org/10.3390/polym15173614

Chicago/Turabian StyleLu, Siyu, Fan Li, Bo Liu, Kun Yang, Feng Tian, Zhi Cheng, Sheng Ding, and Kexin Hou. 2023. "Monodisperse Fluorescent Polystyrene Microspheres for Staphylococcus aureus Aerosol Simulation" Polymers 15, no. 17: 3614. https://doi.org/10.3390/polym15173614