The Study on the Morphology and Compression Properties of Microcellular TPU/Nanoclay Tissue Scaffolds for Potential Tissue Engineering Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

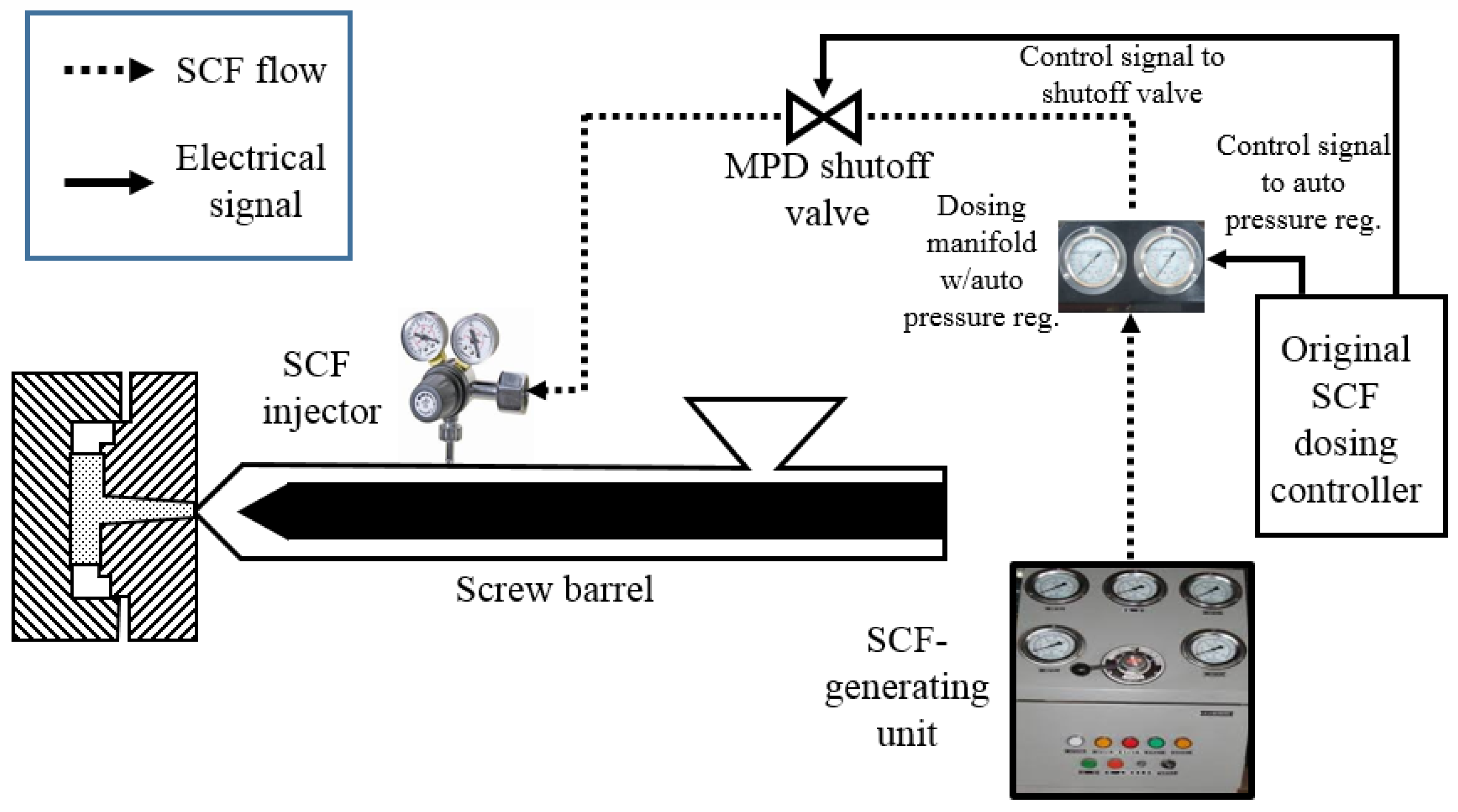

2.2. Preparation of the TPU Scaffolds

2.3. Characterization Methods

2.4. Experimental Procedures

3. Results

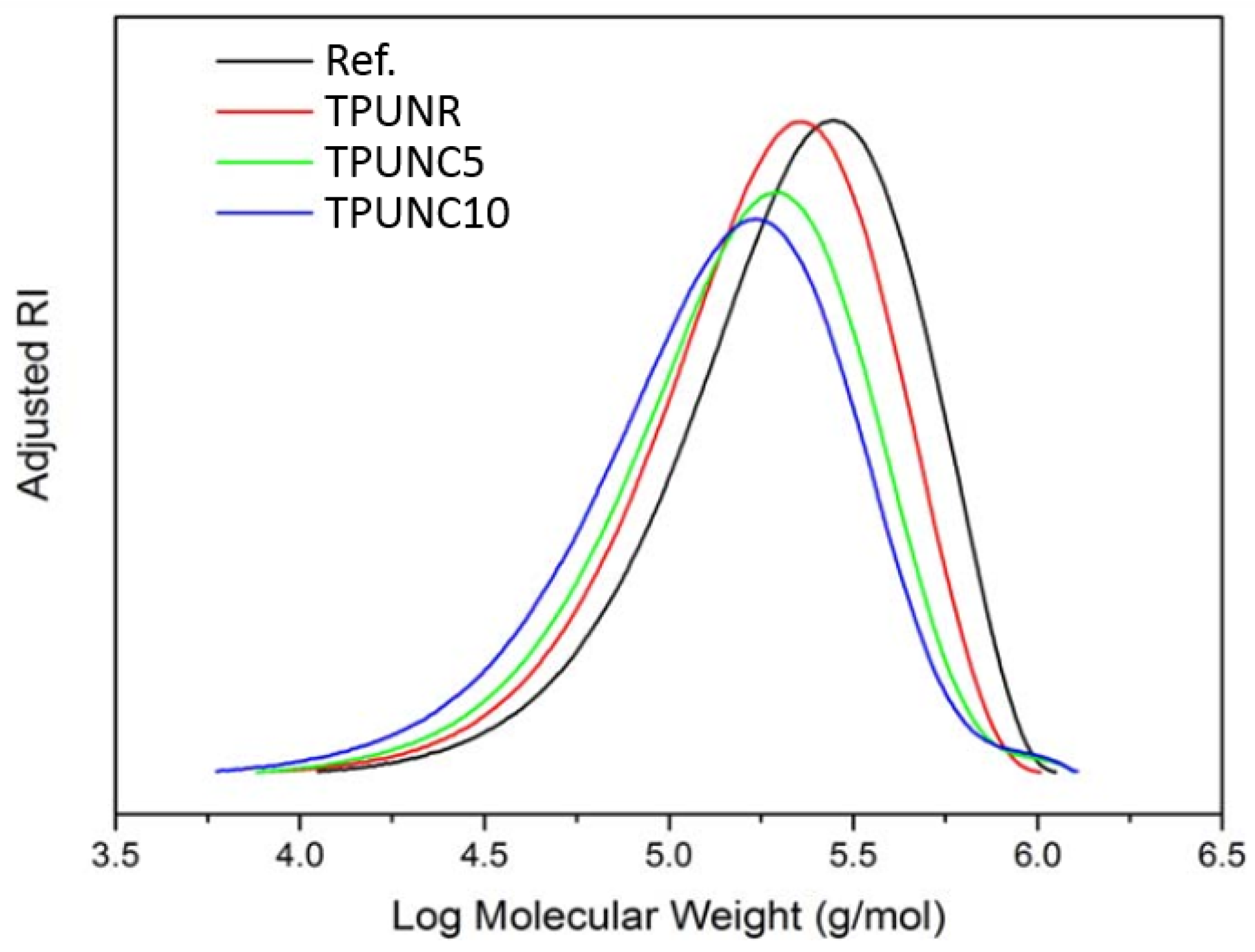

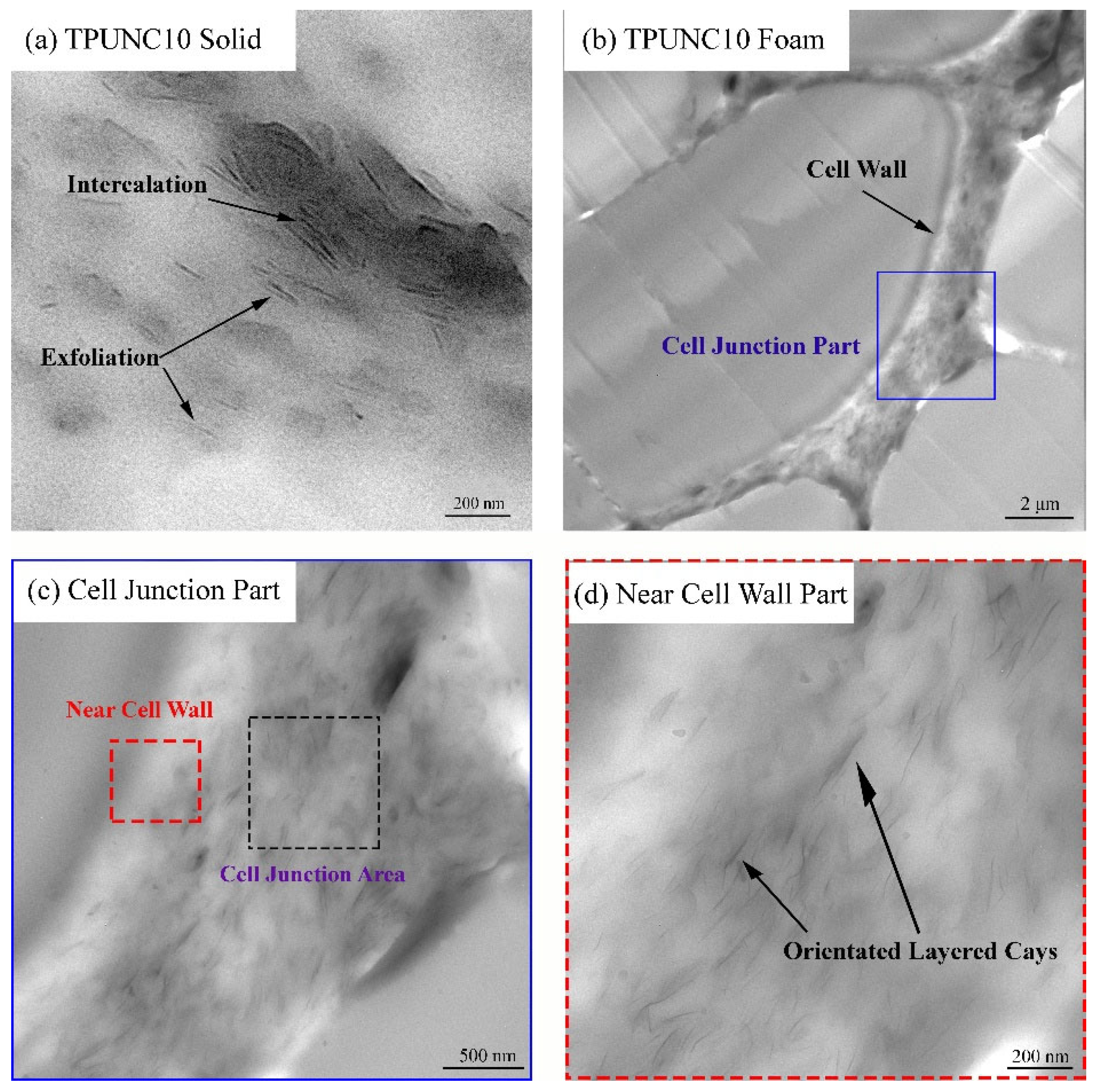

3.1. Structure of TPU Nano-Composites

3.2. Morphology of Microcellular TPU Nanocomposites

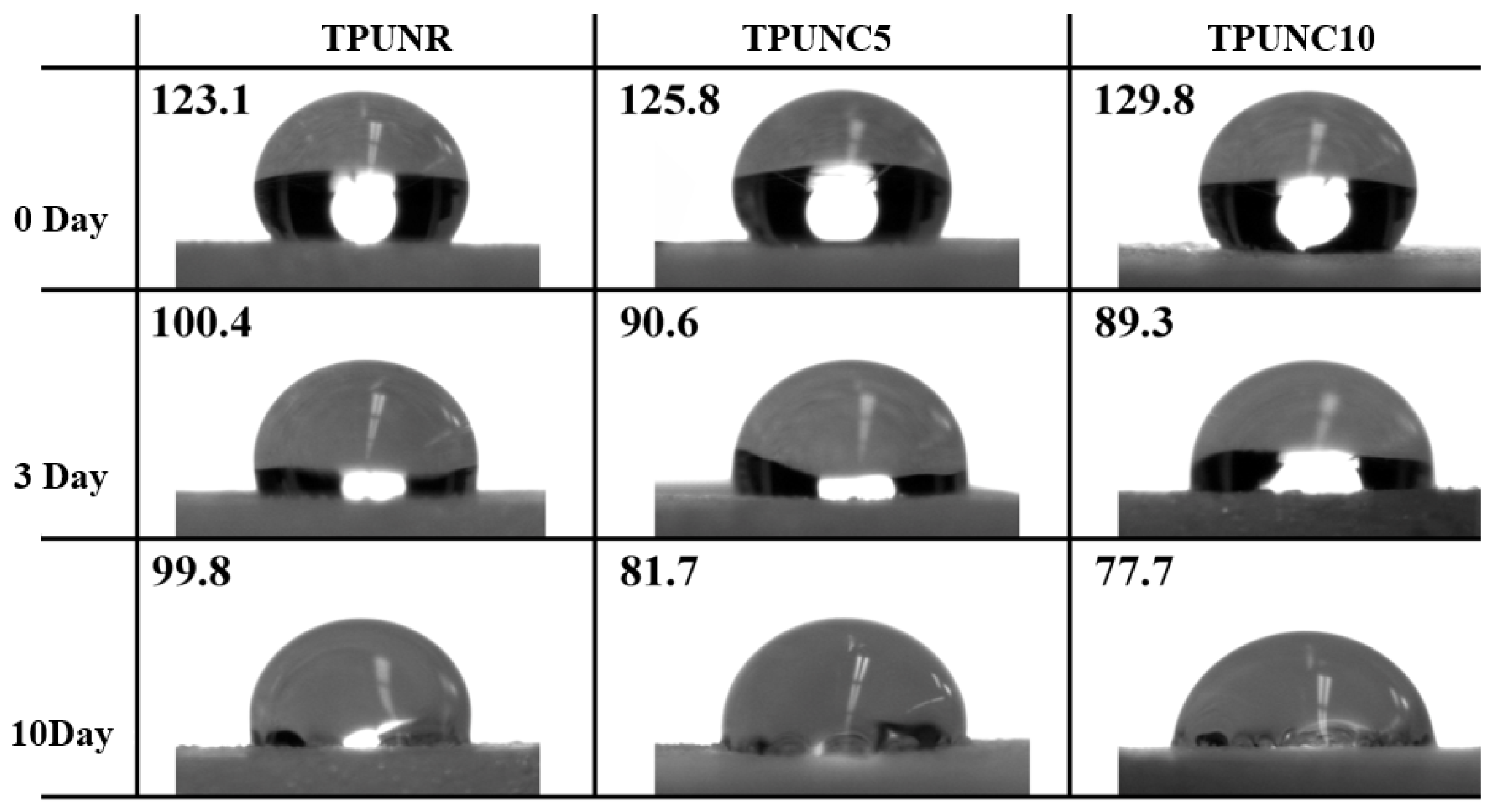

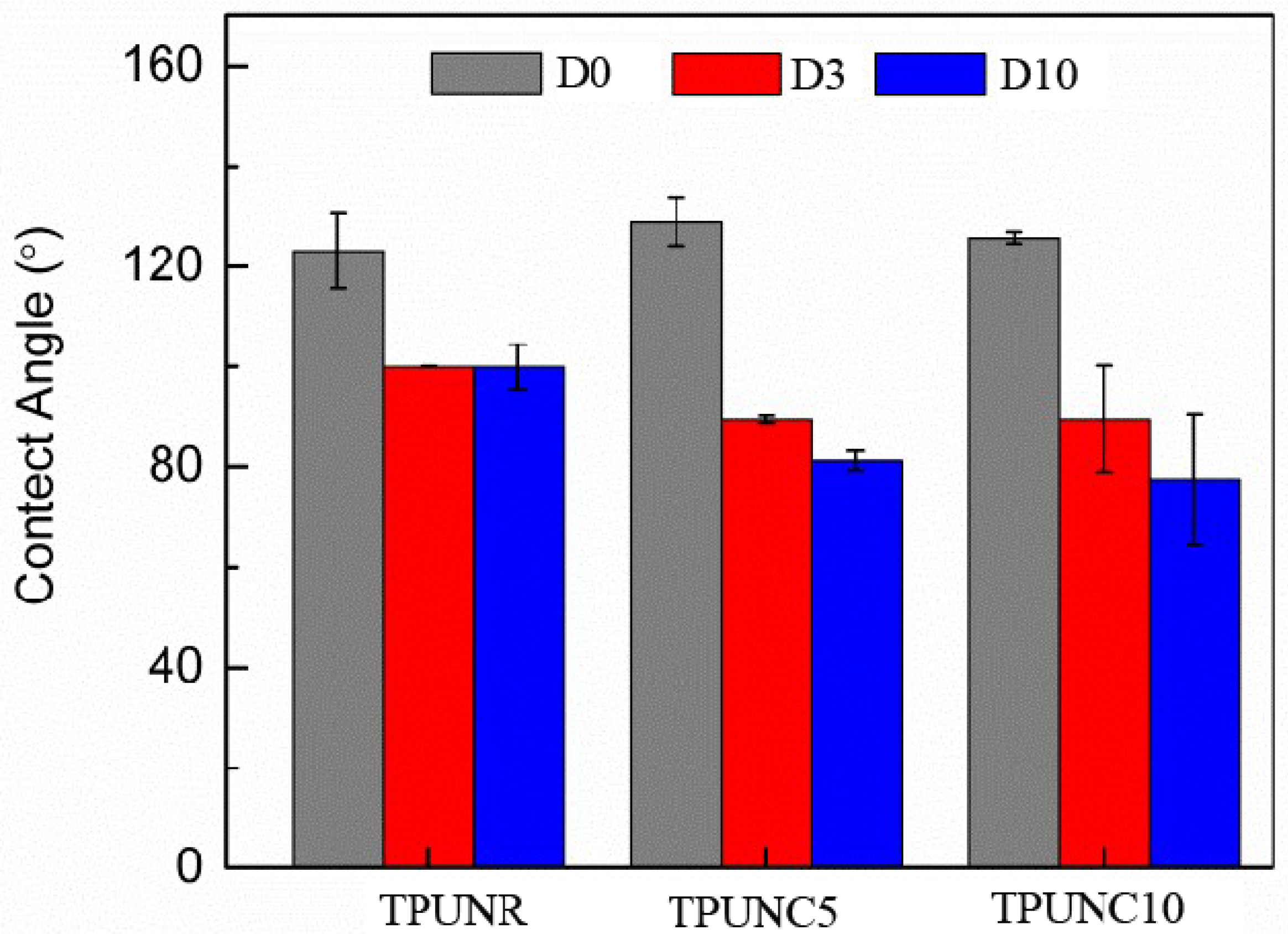

3.3. Wettability

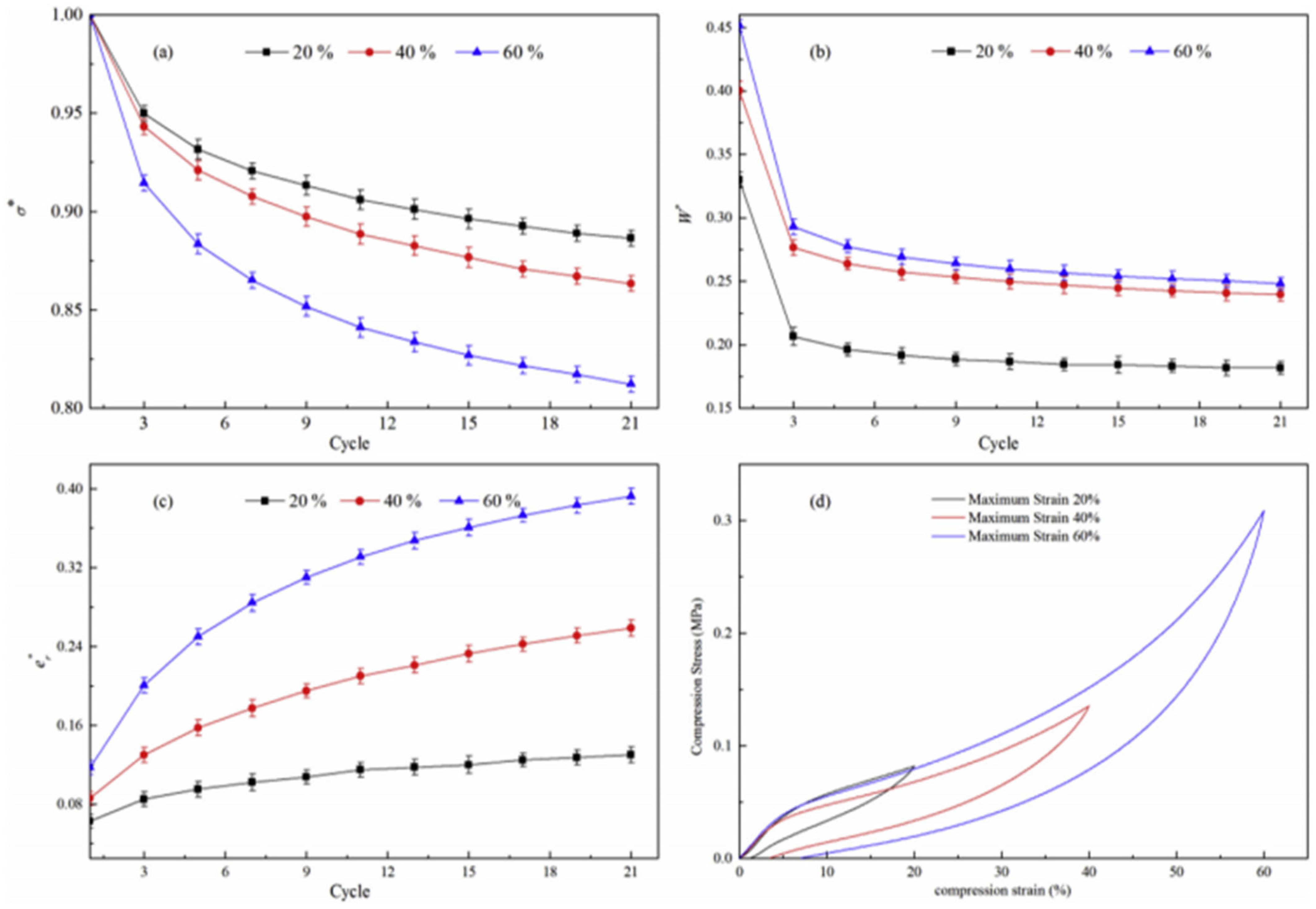

3.4. Mechanical Properties

3.5. Cytocompatibility

4. Conclusions

- Scanning electron microscopy (SEM) analysis showed that the surface of the scaffolds exhibited uniform nanoclay dispersion, confirming the effective dispersion of nanoclay in the TPU matrix. In addition, optical microscopy observation showed that the scaffolds presented a delicate microcellular structure with regularly arranged pores, indicating effective foaming control during the preparation process;

- Compression test results showed that the microcellular TPU/nanoclay composite scaffolds exhibited excellent compression performance. During compression, the scaffolds exhibited linear stress-strain curves and maintained stable mechanical properties when a certain strain was reached. This indicates that the scaffold has a controllable deformation behavior when subjected to compressive loads and has a good energy absorption capacity;

- Nanoclay was successfully incorporated into TPU using electrostatic spinning with varying nanoclay contents (5 wt% and 10 wt%), resulting in TPUNC tissue scaffolds with excellent interfacial bonding between nanoclay and TPU;

- Water contact angle tests revealed that all three porous scaffolds initially exhibited hydrophobicity, but with increased time, the contact angle of the TPU porous scaffold gradually decreased as the nanoclay content increased, indicating improved wettability. Moreover, the porous TPUNC tissue scaffold demonstrated superior biocompatibility and biodegradability;

- Thermogravimetric analysis demonstrated enhanced thermal stability in the TPUNC composites. Tensile tests revealed that the inclusion of nanoclay led to increased tensile modulus and tensile strength in the TPUNC tissue scaffold, with the extent of improvement corresponding to the nanoclay content;

- Biocompatibility assessment using MG63 cells demonstrated that the TPUNC tissue scaffold exhibited varying effects on cell growth depending on the nanoclay content. Specifically, 5% nanoclay induced excessive oxidative stress in some cells, resulting in cell death. However, increasing the nanoclay content to 10% improved cell adhesion and proliferation on the tissue scaffold, making it a suitable addition for promoting cell growth;

- Taken together, the results clarify the relationship between the morphological characteristics and compressive properties of microcellular TPU/nanoclay composite scaffolds. Composite scaffolds are potentially valuable as support and cushioning materials in biomedical, engineering, and other applications and provide useful references for further research and applications in related fields.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Fakirov, S. Handbook of Condensation Thermoplastic Elastomers; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005. [Google Scholar]

- Cooper, S.L.; Tobolsky, A.V. Properties of linear elastomeric polyurethanes. J. Appl. Polym. Sci. 1966, 10, 1837. [Google Scholar] [CrossRef]

- Bartolome, L.; Aurrekoetxea, J.; Urchegui, M.A.; Tato, W. The influences of deformation state and experimental conditions on inelastic behaviour of an extruded thermoplastic polyurethane elastomer. Mater. Des. 2013, 49, 974–980. [Google Scholar] [CrossRef]

- Muschalek, R.; Nash, L.; Jones, R.; Hasan, S.M.; Keller, B.K.; Monroe, M.B.B.; Maitland, D.J. Effects of sterilization on shape memory polyurethane embolic foam devices. J. Med. Devices 2017, 11, 0310111–310119. [Google Scholar] [CrossRef]

- Tobushi, H.; Hayashi, S.; Hoshio, K.; Ejiri, Y. Shape recovery and irrecoverable strain control in polyurethane shape-memory polymer. Sci. Technol. Adv. Mater. 2008, 9, 015009. [Google Scholar] [CrossRef]

- Safranski, D.L.; Boothby, J.M.; Kelly, C.N.; Beatty, K.; Lakhera, N.; Frick, C.P.; Lin, A.; Guldberg, R.E.; Griffis, J.C. Ther-mo-mechanical behavior and structure of melt blown shape-memory polyurethane nonwovens. J. Mech. Behav. Biomed. Mater 2016, 62, 545–555. [Google Scholar] [CrossRef]

- Ping, P.; Wang, W.; Chen, X.; Jing, X. Poly (epsilon-caprolactone) polyurethane and its shape-memory property. Biomacromolecules 2005, 6, 587–592. [Google Scholar] [CrossRef]

- Barroqueiro, B.; Andrade-Campos, A.; Valente, R.A.F.; Neto, V. Metal Additive Manufacturing Cycle in Aerospace Industry: A Comprehensive Review. J. Manuf. Mater. Process. 2019, 3, 52. [Google Scholar] [CrossRef]

- Mărieş, G.R.E.; Bandur, G.; Rusu, G. Influence of processing temperature on some mechanical-physical properties of thermo-plastic polyurethane desmopan KA 8377 used for injection moulding of performance sport products. Chem. Bull. Politeh. Univ. 2008, 53, 131–134. [Google Scholar]

- Lin, J.-H.; Chuang, Y.-C.; Li, T.-T.; Huang, C.-H.; Huang, C.-L.; Chen, Y.-S.; Lou, C.-W. Effects of perforation on rigid PU foam plates: Acoustic and mechanical properties. Materials 2016, 9, 1000. [Google Scholar] [CrossRef]

- Zhang, D.; Petersen, K.M.; Grunlan, M.A. Inorganic-organic shape memory polymer (SMP) foams with highly tunable proper-ties. ACS Appl. Mater. Interfaces 2013, 5, 186–191. [Google Scholar] [CrossRef]

- Nash, L.D.; Docherty, N.C.; Monroe, M.B.B.; Ezell, K.P.; Carrow, J.K.; Hasan, S.M.; Gaharwar, A.K.; Maitland, D.J. Cold plasma reticulation of shape memory embolic tissue scaffolds. Macromol. Rapid Commun. 2016, 37, 1945–1951. [Google Scholar] [CrossRef] [PubMed]

- Metcalfe, A.; Desfaits, A.-C.; Salazkin, I.; Yahia, L.; Sokolowski, W.M.; Raymond, J. Cold hibernated elastic memory foams for endovascular interventions. Biomaterials 2003, 24, 491–497. [Google Scholar] [CrossRef] [PubMed]

- Augustine, R.; Kalarikkal, N.; Thomas, S. A facile and rapid method for the black pepper leaf mediated green synthesis of silver nanoparticles and the antimicrobial study. Appl. Nanosci. 2014, 4, 809–818. [Google Scholar] [CrossRef][Green Version]

- Augustine, R.; Kalarikkal, N.; Thomas, S. Electrospun PCL membranes incorporated with biosynthesized silver nanoparticles as antibacterial wound dressings. Appl. Nanosci. 2016, 6, 337–344. [Google Scholar] [CrossRef]

- Mohan, S.; Oluwafemi, O.S.; George, S.C.; Jayachandran, V.; Lewu, F.B.; Songca, S.P.; Kalarikkal, N.; Thomas, S. Completely green synthesis of dextrose reduced silver nanoparticles, its antimicrobial and sensing properties. Carbohydr. Polym. 2014, 106, 469–474. [Google Scholar] [CrossRef] [PubMed]

- Mohan, S.; Oluwafemi, O.S.; Songca, S.P.; Jayachandran, V.; Rouxel, D.; Joubert, O.; Kalarikkal, N.; Thomas, S. Synthesis, antibacterial, cytotoxicity and sensing properties of starch-capped silver nanoparticles. J. Mol. Liq. 2016, 213, 75–81. [Google Scholar] [CrossRef]

- Mai, T.T.; Morishita, Y.; Urayama, K. Novel features of the mullins effect in filled elastomers revealed by stretching measurements in various geometries. Soft Matter 2017, 13, 1966–1977. [Google Scholar] [CrossRef]

- Duling, R.R.; Dupaix, R.B.; Katsube, N.; Lannutti, J. Mechanical characterization of electrospun polycaprolactone (PCL): A po-tential scaffold for tissue engineering. J. Biomech. Eng. 2008, 130, 52–56. [Google Scholar] [CrossRef]

- Goudarzi, M.; Ghanbari, D.; Salavati-Niasari, M.; Ahmadi, A. Synthesis and characterization of Al(OH)3, Al2O3 nanoparticles and polymeric nanocomposites. J. Clust. Sci. 2016, 27, 25–38. [Google Scholar] [CrossRef]

- Rath, S.K.; Sudarshan, K.; Bhavsar, R.S.; Kharul, U.K.; Pujari, P.K.; Patri, M.; Khakhar, D.V. Characterizing the nanoclay induced constrained amorphous region in model segmented polyurethane–urea/clay nanocomposites and its implications on gas barrier properties. Phys. Chem. Chem. Phys. 2016, 18, 1487–1499. [Google Scholar] [CrossRef]

- Shekarabi, A.S.; Oromiehie, A.R.; Vaziri, A.; Ardjmand, M.; Safekordi, A.A. Investigation of the effect of nanoclay on the prop-erties of quince seed mucilage edible films. Food Sci. Nutr. 2014, 2, 821–827. [Google Scholar] [CrossRef] [PubMed]

- Osman, A.F.; Fitri, T.F.M.; Rakibuddin, M.; Hashim, F.; Johari, S.A.T.T.; Ananthakrishnan, R.; Ramli, R. Pre-dispersed organo-montmorillonite (organo-MMT) nanofiller: Morphology, cytocompatibility and impact on flexibility, toughness and biostability of biomedical ethyl vinyl acetate (EVA) copolymer. Mater. Sci. Eng. C Mater. Blol. Appi. 2017, 74, 194–206. [Google Scholar] [CrossRef] [PubMed]

- Kaynak, C.; Gunduz, H.O.; Isitman, N.A. Use of nanoclay as an environmentally friendly flame retardant synergist in poly-amide-6. J. Nanosci. Nanotechnol. 2010, 10, 7374–7381. [Google Scholar] [CrossRef] [PubMed]

- Ghanbari, D.; Salavati-Niasari, M. Synthesis of urchin-like CdS-Fe3O4 nanocomposite and its application in flame retardancy of magnetic cellulose acetate. J. Ind. Eng. Chem. 2015, 24, 284–292. [Google Scholar] [CrossRef]

- Jamshidi, P.; Ghanbari, D.; Salavati-Niasari, M. Sonochemical synthesis of La(OH)3 nanoparticle and its influence on the flame retardancy of cellulose acetate nanocomposite. J. Ind. Eng. Chem. 2014, 20, 3507–3512. [Google Scholar] [CrossRef]

- Yousefi, M.; Noori, E.; Ghanbari, D.; Salavati-Niasari, M.; Gholami, T. A facile room temperature synthesis of zinc oxide nanostructure and its influence on the flame retardancy of poly vinyl alcohol. J. Clust. Sci. 2013, 25, 397–408. [Google Scholar] [CrossRef]

- Shayan, M.; Azizi, H.; Ghasemi, I.; Karrabi, M. Effect of modified starch and nanoclay particles on biodegradability and me-chanical properties of cross linked poly lactic acid. Carbohydr. Polym. 2015, 124, 237–244. [Google Scholar] [CrossRef]

- Ahmadian-Fard-Fini, S.; Ghanbari, D.; Salavati-Niasari, M. Photoluminescence carbon dot as a sensor for detecting of Pseu-domonas aeruginosa bacteria: Hydrothermal synthesis of magnetic hollow NiFe2O4-carbon dots nanocomposite material. Compos. B Eng. 2019, 161, 564–577. [Google Scholar] [CrossRef]

- Ahmadian-Fard-Fini, S.; Salavati-Niasari, M.; Ghanbari, D. Hydrothermal green synthesis of magnetic Fe3O4-carbon dots by lemon and grape fruit extracts and as a photoluminescence sensor for detecting of E. coli bacteria. Spectrochim. Acta 2018, 203, 481–493. [Google Scholar] [CrossRef]

- Ghanbari, D.; Salavati-Niasari, M.; Esmaeili-Zare, M.; Jamshidi, P.; Akhtarianfar, F. Hdrothermal synthesis of CuS nanostructures and their application on preparation of ABS-based nanocomposite. J. Ind. Eng. Chem. 2014, 20, 3709–3713. [Google Scholar] [CrossRef]

- Das, P.; Malho, J.-M.; Rahimi, K.; Schacher, F.H.; Wang, B.; Demco, D.E.; Walther, A. Nacre-mimetics with synthetic nanoclays up to ultrahigh aspect ratios. Nat. Commun. 2015, 6, 5967. [Google Scholar] [CrossRef] [PubMed]

- Dempsey, D.K.; Robinson, J.L.; Iyer, A.V.; Parakka, J.P.; Bezwada, R.S.; Cosgriff-Hernandez, E.M. Characterization of a resorbable poly(ester urethane) with biodegradable hard segments. J. Biomater. Sci. Polym. Ed. 2014, 25, 535–554. [Google Scholar] [CrossRef] [PubMed]

- Kanyanta, V.; Ivankovic, A. Mechanical characterisation of polyurethane elastomer for biomedical applications. J. Mech. Behav. Biomed. Mater. 2010, 3, 51–62. [Google Scholar] [CrossRef] [PubMed]

- Su, P.; Yang, Y.; Xiao, J.; Song, Y. Corneal hyper-viscoelastic model: Derivations, experiments, and simulations. Acta Bioeng. Biomech. 2015, 17, 73–84. [Google Scholar] [CrossRef]

- Veljković, D.; Ranković, V.J.; Pantovic, S.; Rosić, M.A.; Kojić, M.R. Hyperelastic behavior of porcine aorta segment under extension-inflation tests fitted with various phenomenological models. Acta Bioeng. Biomech. 2014, 16, 37–45. [Google Scholar]

- Dargazany, R.; Itskov, M. Constitutive modeling of the Mullins effect and cyclic stress softening in filled elastomers. Phys. Rev. E-Stat. Nonlinear Soft Matter Phys. 2013, 88, 012602. [Google Scholar] [CrossRef]

- Maiti, A.; Small, W.; Gee, R.H.; Weisgraber, T.H.; Chinn, S.C.; Wilson, T.S.; Maxwell, R.S. Mullins effect in a filled elastomer under uniaxial tension. Phys. Rev. E-Stat. Nonlinear Soft Matter Phys. 2014, 89, 012602. [Google Scholar] [CrossRef]

- Makki, M.; Ayoub, G.; Abdul-Hameed, H.; Zaïri, F.; Mansoor, B.; Naït-Abdelaziz, M.; Ouederni, M. Mullins effect in polyethylene and its dependency on crystal content: A network alteration model. J. Mech. Behav. Biomed. Mater. 2017, 75, 442–454. [Google Scholar] [CrossRef]

- EzEldeen, M.; Loos, J.; Nejad, Z.M.; Cristaldi, M.; Murgia, D.; Braem, A.; Jacobs, R. 3D-printing-assisted fabrication of chitosan scaffolds from different sources and cross-linkers for dental tissue engineering. Eur. Cell Mater. 2021, 41, 485–501. [Google Scholar] [CrossRef]

- Ray, S.S.; Okamoto, M. Polymer/Layered Silicate Nanocomposites: A Review from Preparation to Processing. Prog. Polym. Sci. 2003, 28, 1539. [Google Scholar]

- Thomas Ellingham, L.D.; Turng, L.-S. Sub-critical gas-assisted processing using CO2 foaming to enhance the exfoliation of graphene in polypropylene graphene nanocomposites. Polymer 2017, 117, 132–139. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, F.; Niu, J.; Wang, Z. Superhydrophobic surfaces: From structural control to functional application. J. Mater. Chem. 2008, 18, 621–633. [Google Scholar] [CrossRef]

- Buckley, C.P.; Wu, J.; Haughie, D.W. The integrity of welded interfaces in ultra high molecular weight polyethylene: Part 1—Model. Biomaterials 2006, 27, 3178–3186. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value |

|---|---|

| Injection speed (cm3/s) | 50 |

| Mold temperature (°C) | 45 |

| Cooling time (s) | 13 |

| SCF flow rate (kg/h) | 0.8 |

| SCF injection pressure (MPa) | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, T.; Xiao, H.-C.; Wang, X.-C.; Liu, C.-T.; Wu, L.; Guo, Y.-G.; Dong, B.-B.; Turng, L.-S. The Study on the Morphology and Compression Properties of Microcellular TPU/Nanoclay Tissue Scaffolds for Potential Tissue Engineering Applications. Polymers 2023, 15, 3647. https://doi.org/10.3390/polym15173647

Geng T, Xiao H-C, Wang X-C, Liu C-T, Wu L, Guo Y-G, Dong B-B, Turng L-S. The Study on the Morphology and Compression Properties of Microcellular TPU/Nanoclay Tissue Scaffolds for Potential Tissue Engineering Applications. Polymers. 2023; 15(17):3647. https://doi.org/10.3390/polym15173647

Chicago/Turabian StyleGeng, Tie, Han-Chi Xiao, Xin-Chao Wang, Chun-Tai Liu, Lan Wu, Yong-Gang Guo, Bin-Bin Dong, and Lih-Sheng Turng. 2023. "The Study on the Morphology and Compression Properties of Microcellular TPU/Nanoclay Tissue Scaffolds for Potential Tissue Engineering Applications" Polymers 15, no. 17: 3647. https://doi.org/10.3390/polym15173647

APA StyleGeng, T., Xiao, H.-C., Wang, X.-C., Liu, C.-T., Wu, L., Guo, Y.-G., Dong, B.-B., & Turng, L.-S. (2023). The Study on the Morphology and Compression Properties of Microcellular TPU/Nanoclay Tissue Scaffolds for Potential Tissue Engineering Applications. Polymers, 15(17), 3647. https://doi.org/10.3390/polym15173647