Washable and Flexible Screen-Printed Ag/AgCl Electrode on Textiles for ECG Monitoring

Abstract

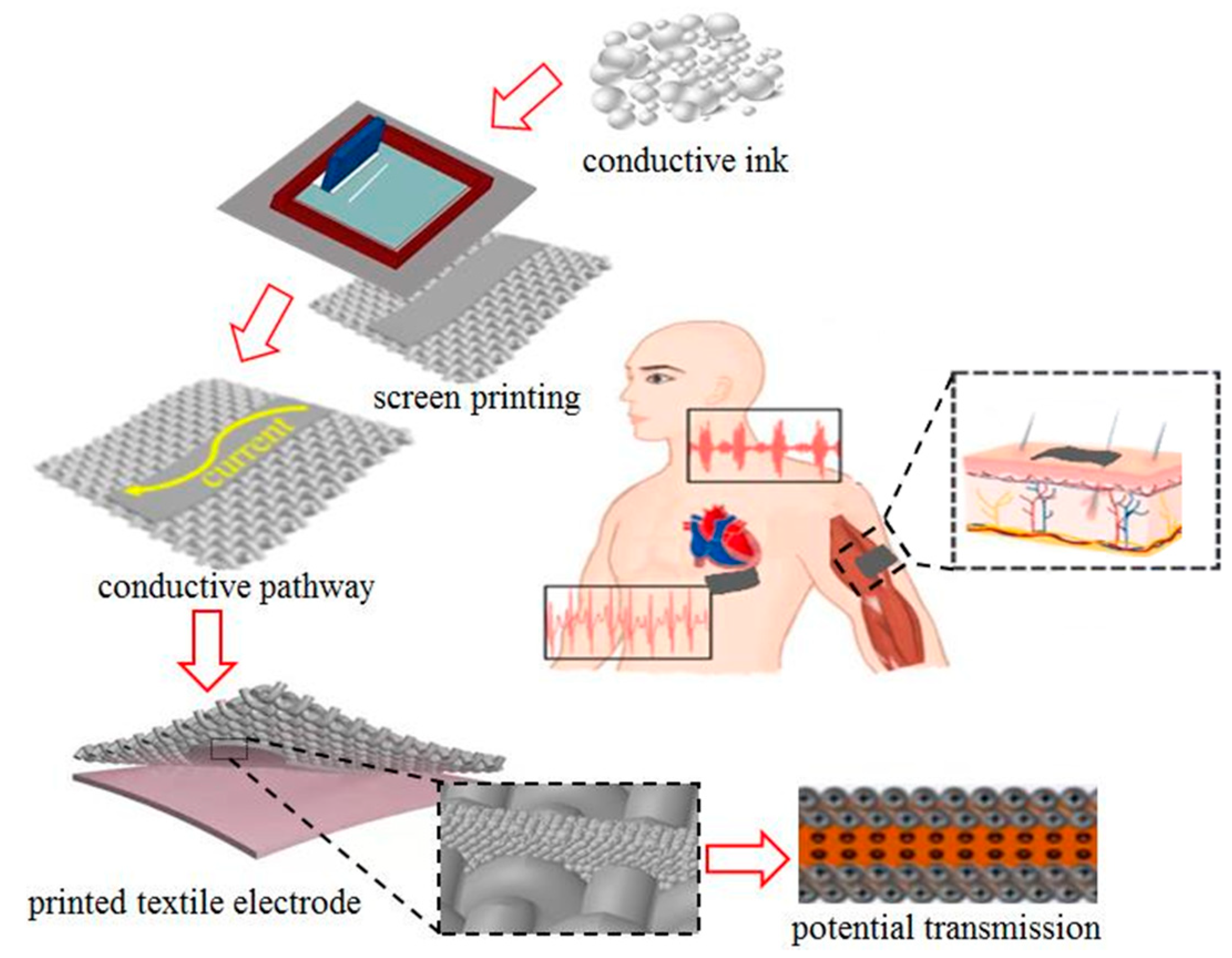

:1. Introduction

2. Materials and Methods

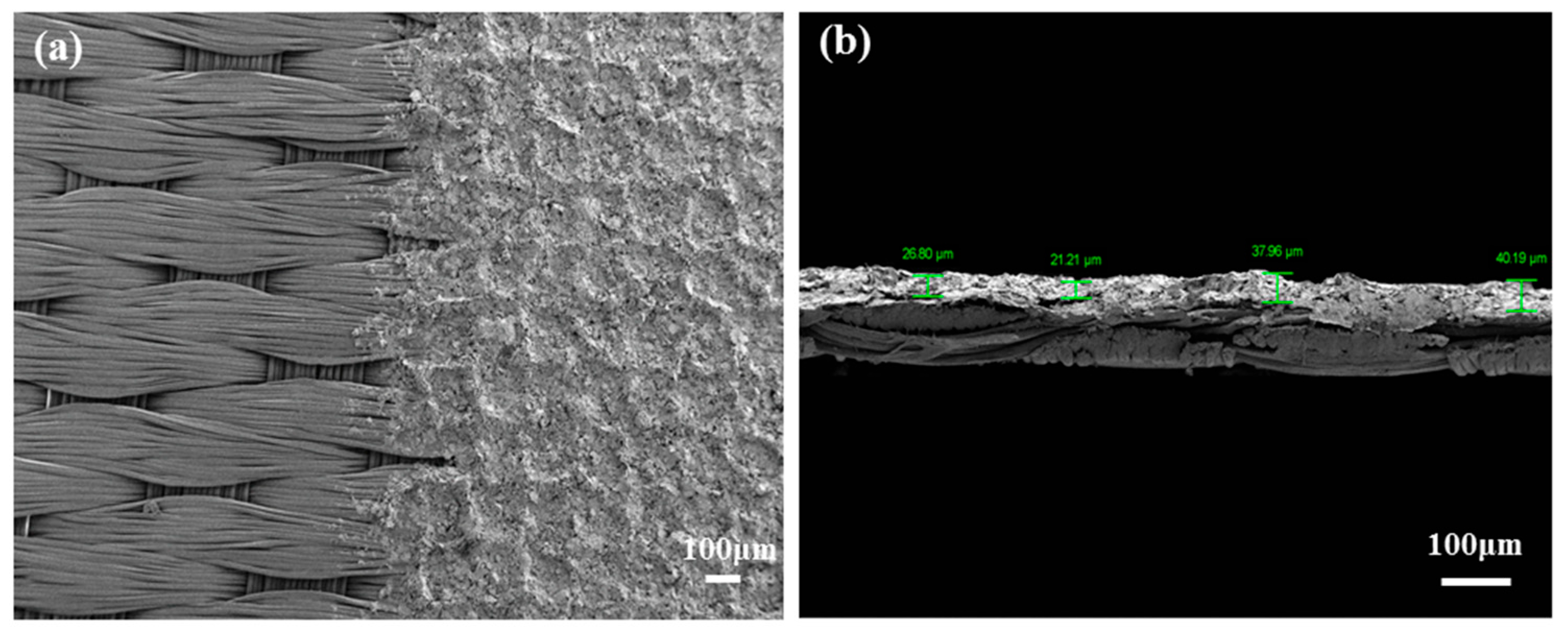

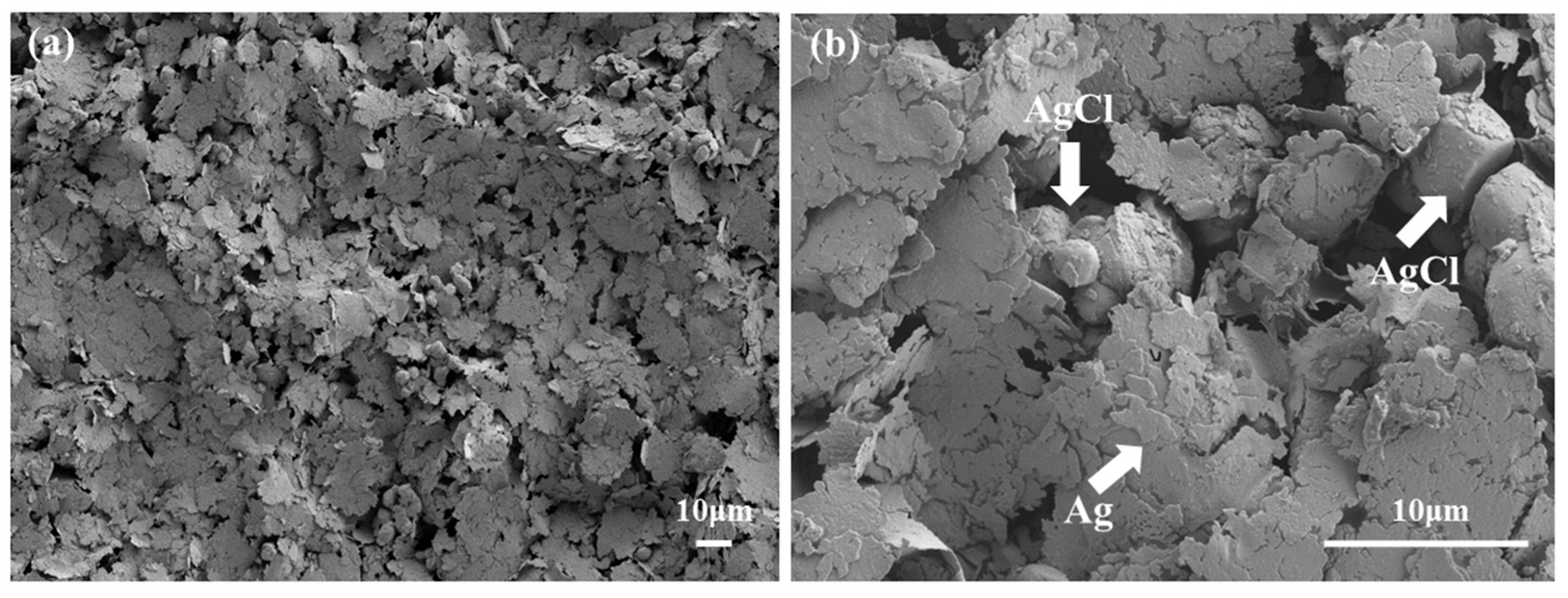

2.1. Materials and Fabrication

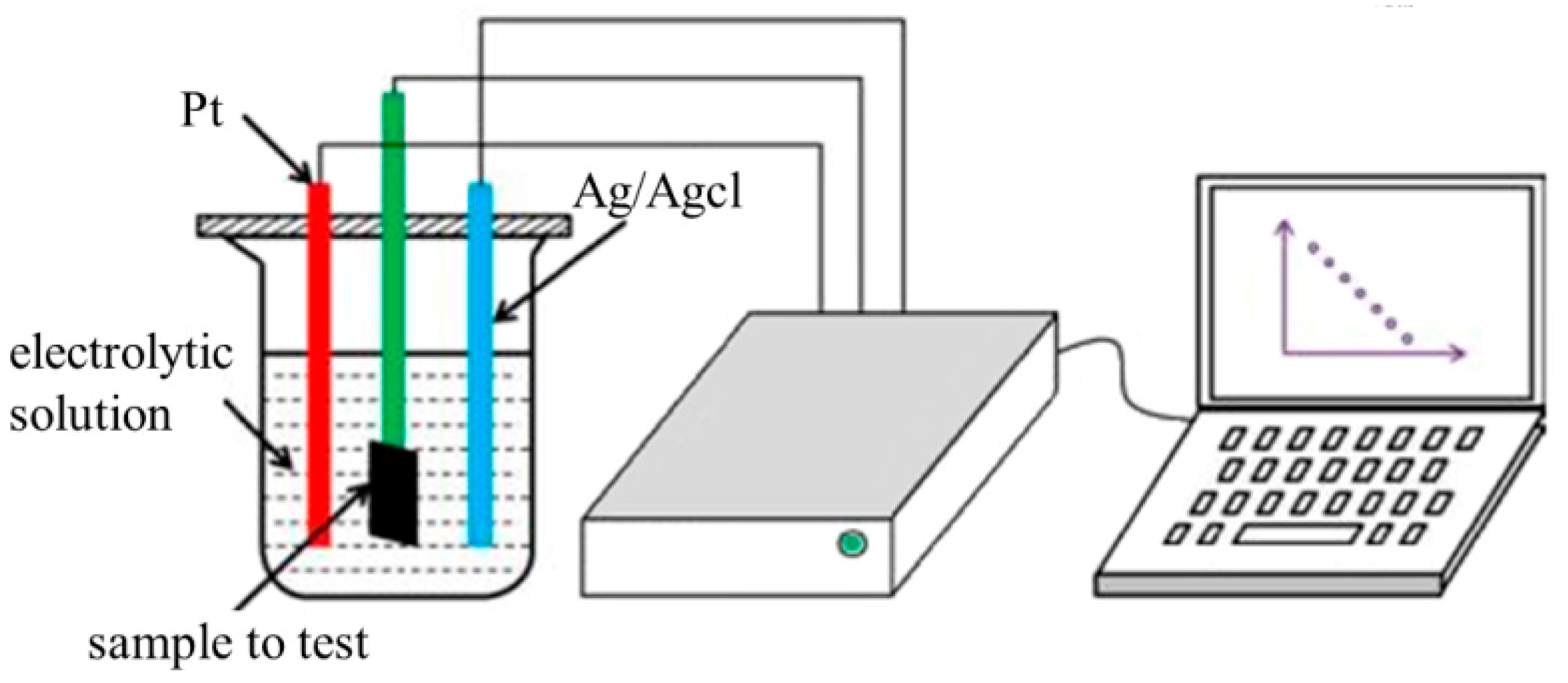

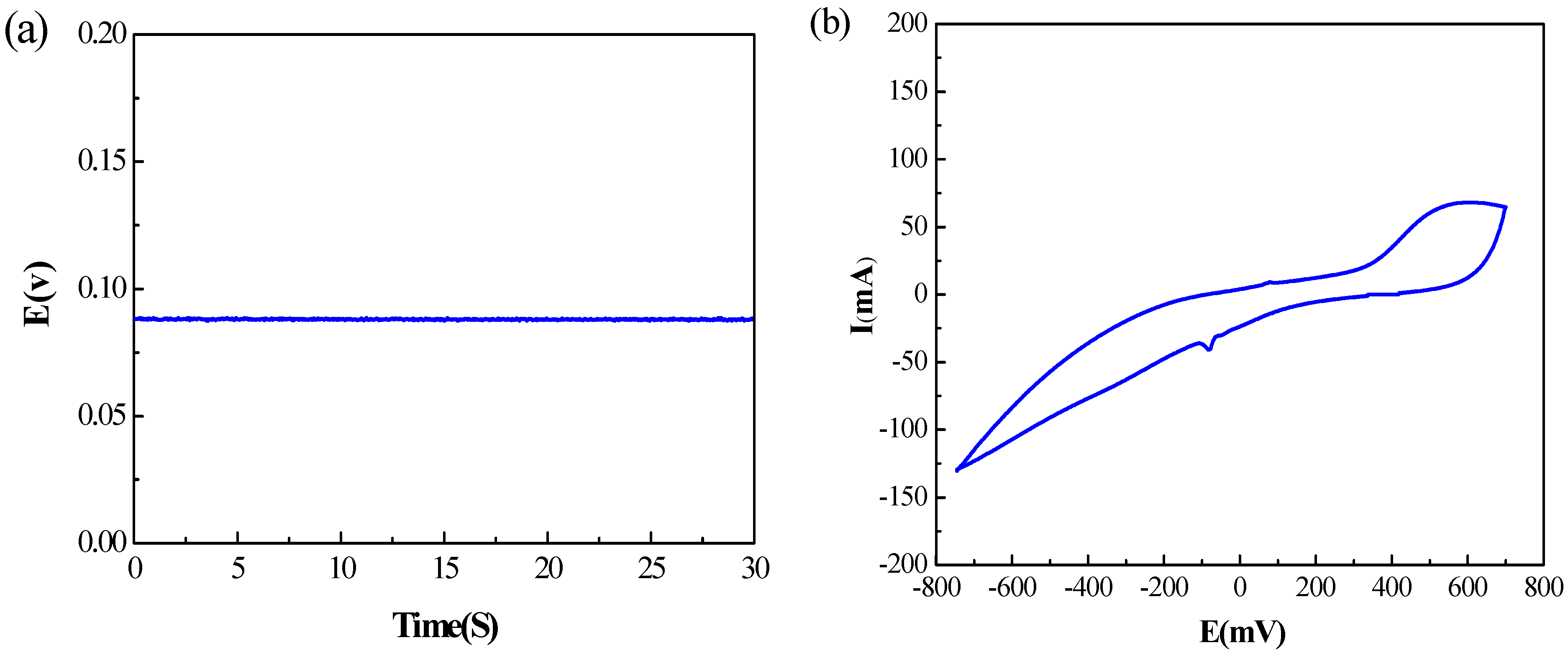

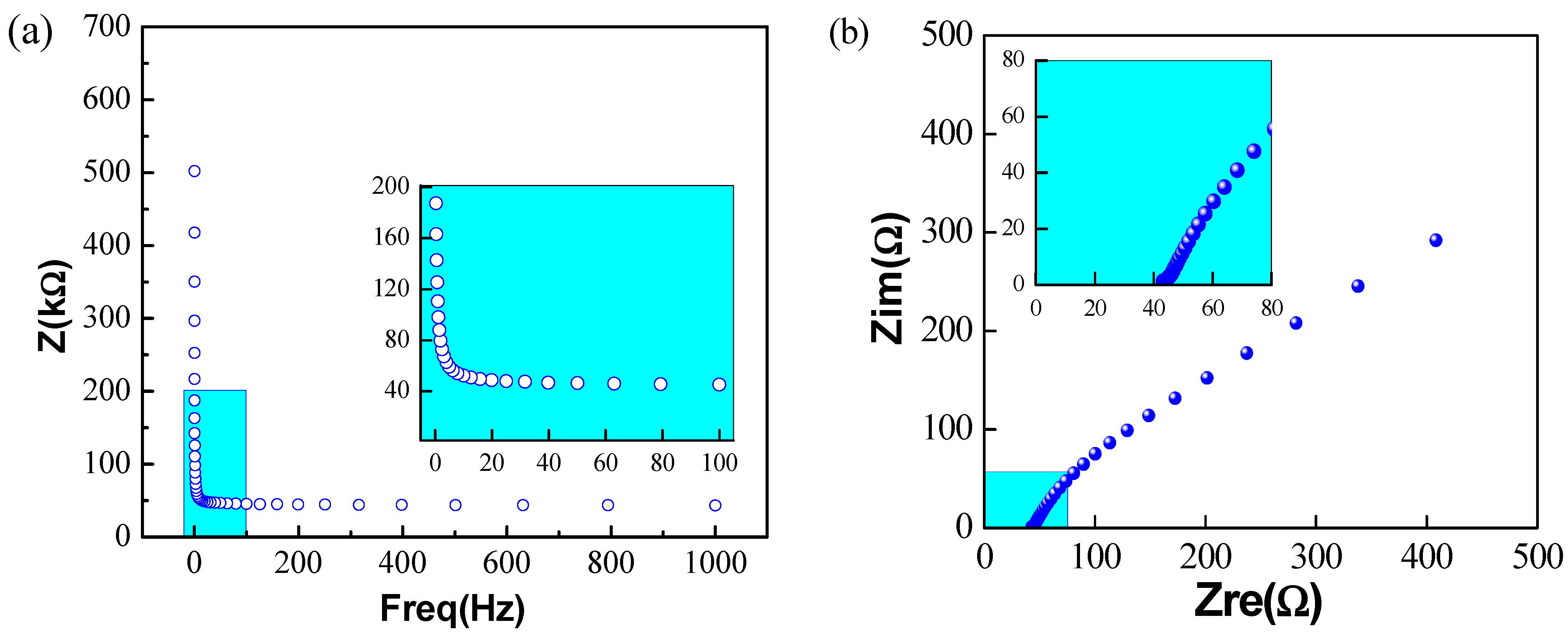

2.2. Electrical/Electrochemical Characterization

2.3. Durability Test

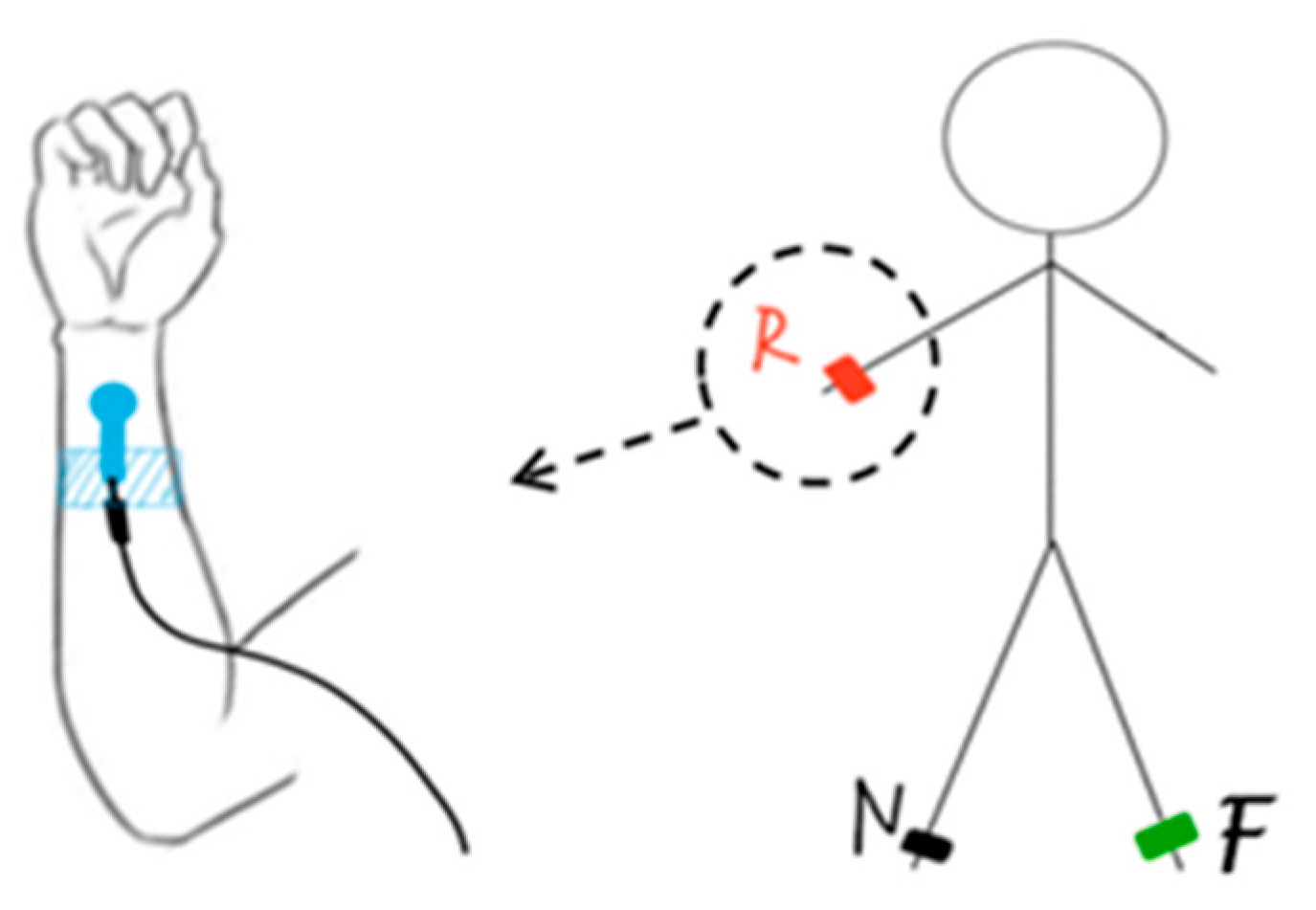

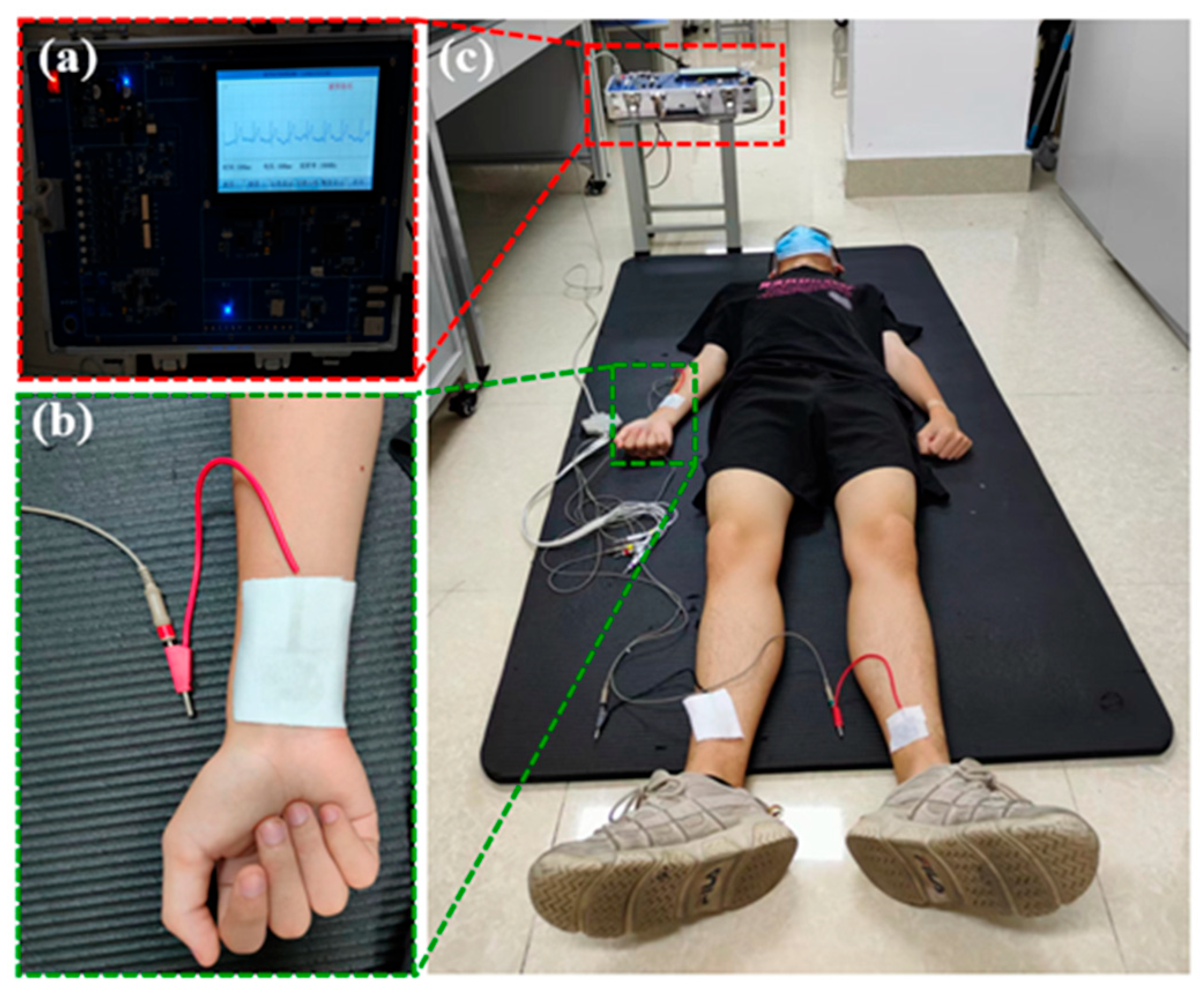

2.4. ECG Monitoring Acquisition

3. Results and Discussion

3.1. Electrical and Electrochemical Analysis

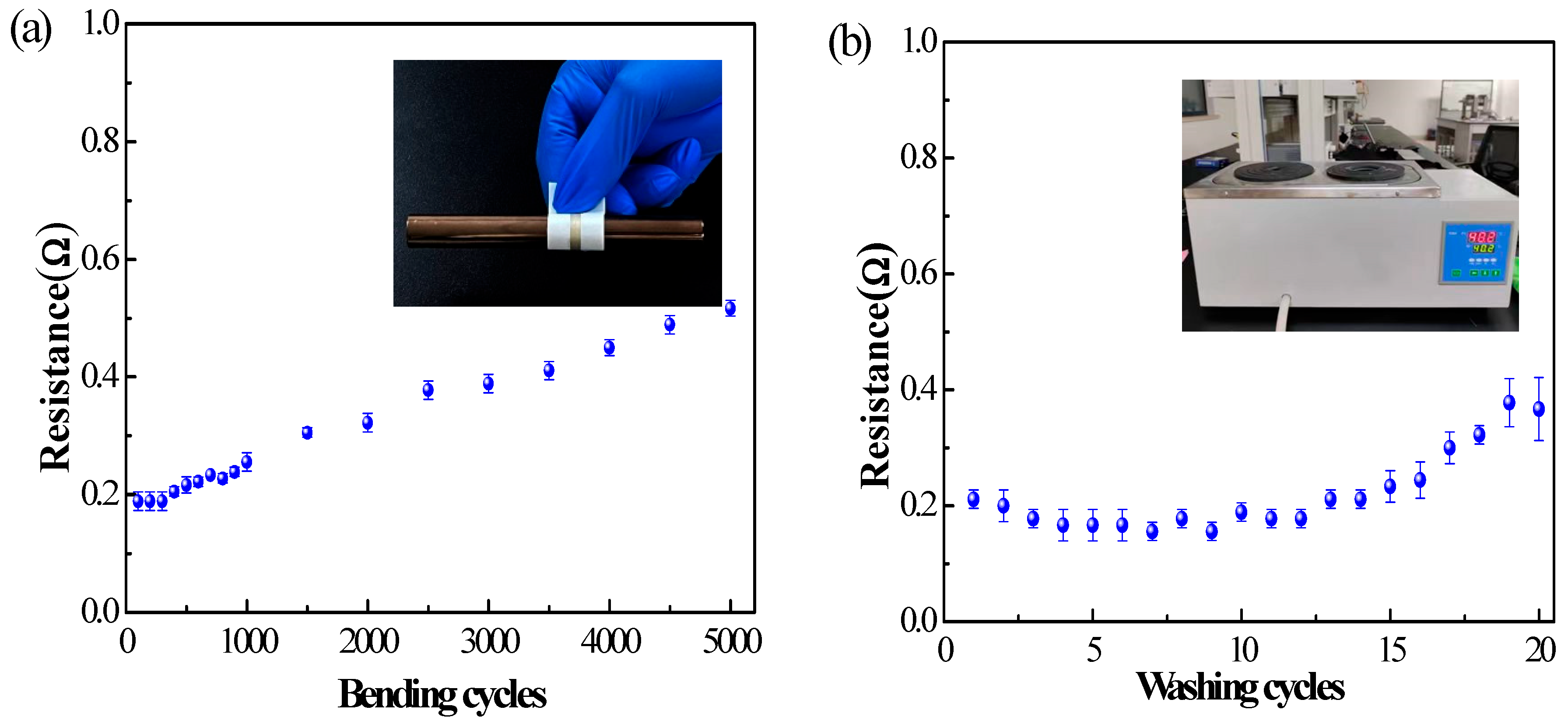

3.2. Durability Analysis

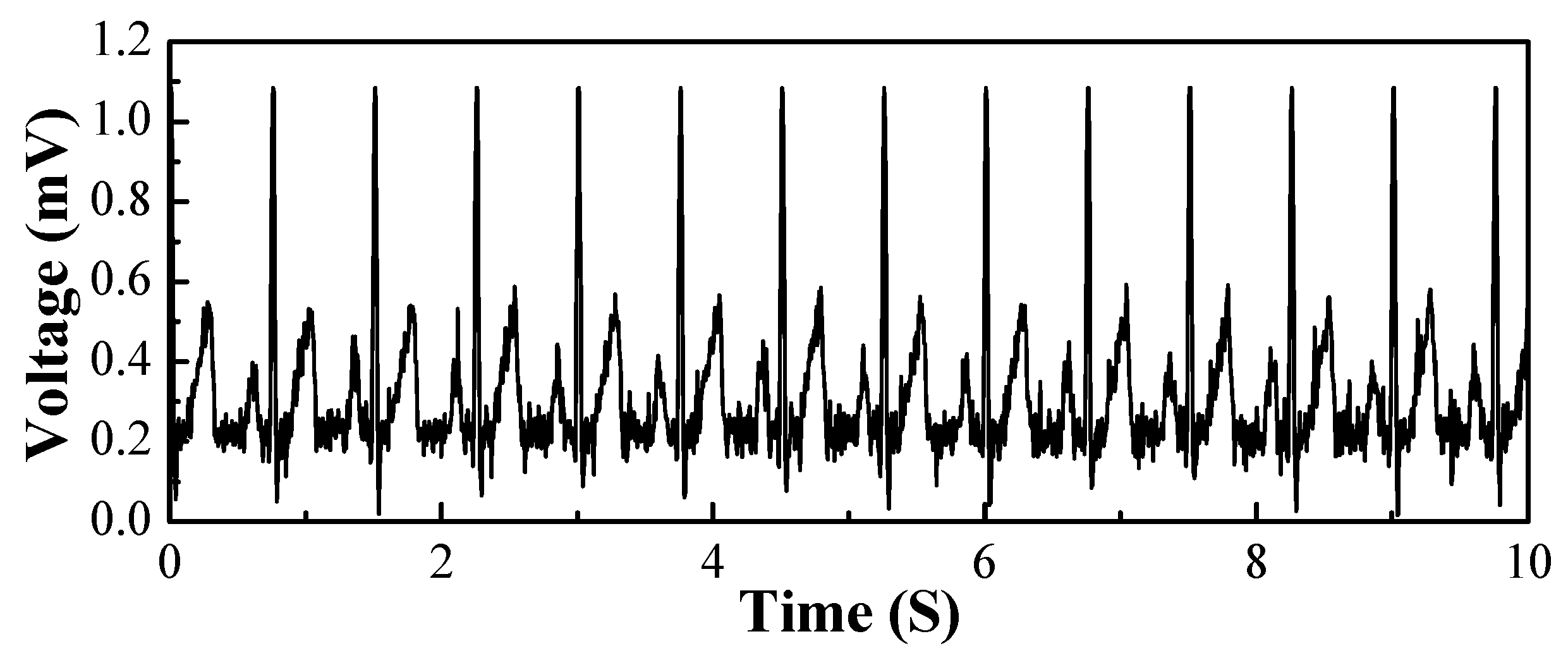

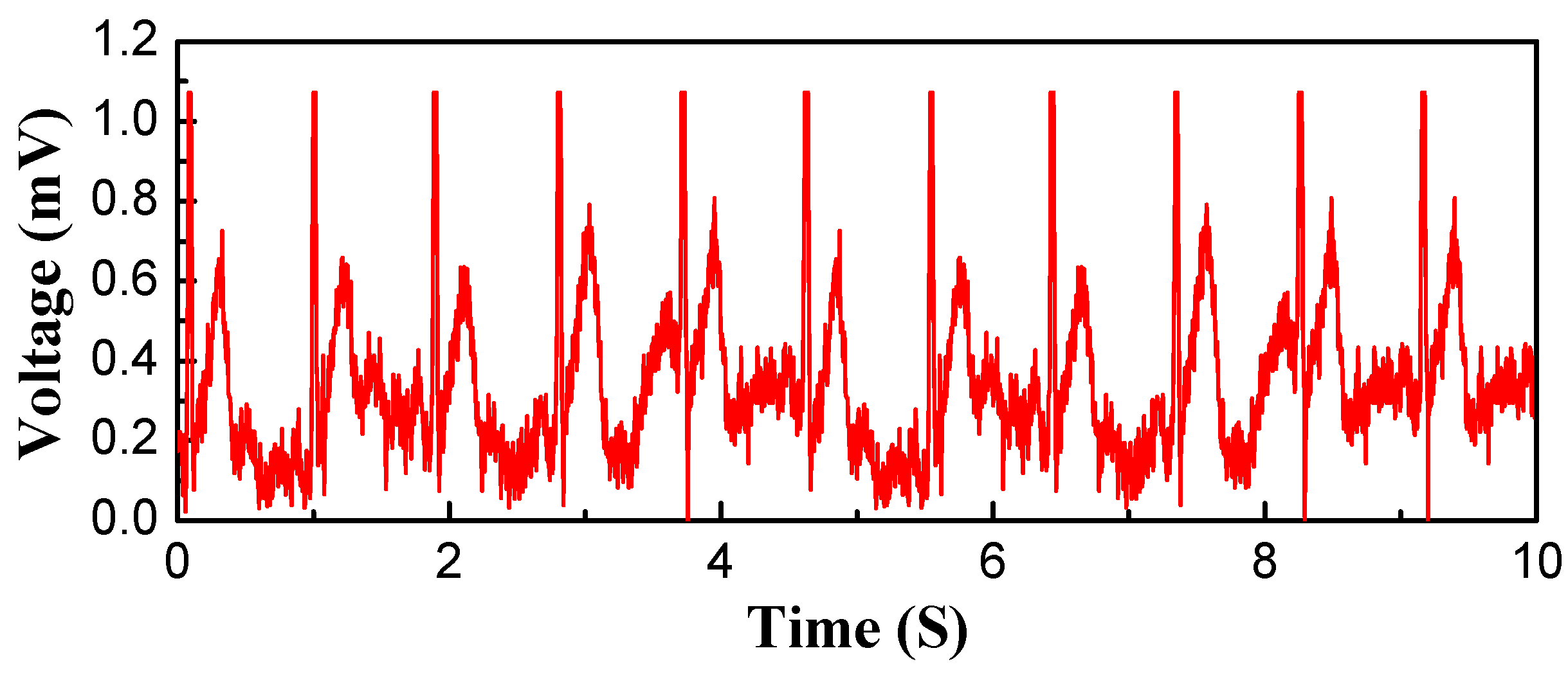

3.3. Signal Acquisition Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alvarez, P.; Sianis, A.; Brown, J.; Ali, A.; Briasoulis, A. Chronic disease management in heart failure: Focus on telemedicine and remote monitoring. Rev. Cardiovasc. Med. 2021, 22, 403–413. [Google Scholar] [CrossRef] [PubMed]

- Boettcher, S.W.; Oener, S.Z.; Lonergan, M.C.; Surendranath, Y.; Ardo, S.; Brozek, C.; Kempler, P.A. Potentially Confusing: Potentials in Electrochemistry. ACS Energy Lett. 2020, 6, 261–266. [Google Scholar] [CrossRef]

- Searle, A.; Kirkup, L. A direct comparison of wet, dry and insulating bioelectric recording. Physiol. Meas. 2000, 21, 271–283. [Google Scholar] [CrossRef] [PubMed]

- Gruetzmann, A.; Hansen, S.; Müller, J. Novel dry electrodes for ECG monitoring. Physiol. Meas. 2007, 28, 1375–1390. [Google Scholar] [CrossRef] [PubMed]

- Nunes, T.; da Silva, H.P. Characterization and validation of flexible dry electrodes for wearable integration. Sensors 2023, 23, 1468. [Google Scholar] [CrossRef] [PubMed]

- Nigusse, A.B.; Mengistie, D.A.; Malengier, B.; Tseghai, G.B.; Van Langenhove, L. Wearable smart textiles for long-term electrocardiography monitoring-A review. Sensors 2021, 21, 4174. [Google Scholar] [CrossRef]

- Wang, W.; Li, T.; Liu, K.; Wang, S.; Peng, H. Effects of three fabric weave textures on the electrochemical and electrical properties of reduced graphene/textile flexible electrodes. RSC Adv. 2020, 10, 6249–6258. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, N.; Gao, Q.; Li, H.; Wang, Z. Design, characterization, and performance of woven fabric electrodes for electrocardiogram signal monitoring. Sensors 2022, 22, 5472. [Google Scholar] [CrossRef]

- Euler, L.; Guo, L.; Persson, N.-K. Textile electrodes: Influence of knitting construction and pressure on the contact impedance. Sensors 2021, 21, 1578. [Google Scholar] [CrossRef]

- Kim, H.; Kim, S.; Lim, D.; Jeong, W. Development and characterization of embroidery-based textile electrodes for surface EMG detection. Sensors 2022, 22, 4746. [Google Scholar] [CrossRef]

- Bayrau, N.A.; Malengier, B.; Alemu, M.D.; Lieva, V.L. A washable silver-printed textile electrode for ECG monitoring. Eng. Proc. 2021, 6, 63. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, Y.; Yang, H.; Liu, Q.; Wang, M.; Xiong, F.; Chen, D.; Du, L. Fabric electrode monitoring of dynamic and static ECG signal and comfort performance. Coatings 2023, 13, 289. [Google Scholar] [CrossRef]

- Yokus, M.A.; Jur, J.S. Fabric-based wearable dry electrodes for body surface biopotential recording. IEEE Trans. Biomed. Eng. 2016, 63, 423–430. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Luo, M.; He, P.; Guo, X.; Yang, J. Screen printed graphene electrodes on textile for wearable electrocardiogram monitoring. Appl. Phys. A 2019, 125, 714. [Google Scholar] [CrossRef]

- Yapici, M.K.; Alkhidir, T.; Samad, Y.A.; Liao, K. Graphene-clad textile electrodes for electrocardiogram monitoring. Sens. Actuators B Chem. 2015, 221, 1469–1474. [Google Scholar] [CrossRef]

- Zhou, Y.; Ding, X.; Hu, J.Y.; Duan, Y.R. PPy/cotton fabric composite electrode for electrocardiogram monitoring. In Proceedings of the 3rd International Conference on Chemical, Metallurgical Engineering (ICCMME 2013), Zhuhai, China, 10–11 December 2013; pp. 1122–1125. [Google Scholar]

- Sinha, S.K.; Noh, Y.; Reljin, N.; Treich, G.M.; Hajeb-Mohammadalipour, S.; Guo, Y.; Chon, K.H.; Sotzing, G.A. Screen-printed PEDOT:PSS electrodes on commercial finished textiles for electrocardiography. ACS Appl. Mater. Interfaces 2017, 9, 37528. [Google Scholar] [CrossRef]

- Achilli, A.; Bonfiglio, A.; Pani, D. Design and characterization of screen-printed textile electrodes for ECG monitoring. IEEE Sens. J. 2019, 18, 4097–4107. [Google Scholar] [CrossRef]

- Kurniawan, J.F.; Allegra, A.B.; Pham, T.; Nguyen, A.K.L.; Sit, N.L.J.; Tjhia, B.; Shin, A.J.; Coleman, T.P. Electrochemical performance study of Ag/AgCl and Au flexible electrodes for unobtrusive monitoring of human biopotentials. Nano Sel. 2022, 3, 1277–1287. [Google Scholar] [CrossRef]

- Moya, A.; Pol, R.; Martinez-Cuadrado, A.; Villa, R.; Gabriel, G.; Baeza, M. Stable full-inkjet-printed solid-state Ag/AgCl reference electrode. Anal. Chem. 2019, 91, 15539–15546. [Google Scholar] [CrossRef]

- Kurniawan, J.F.; Tjhia, B.; Wu, V.M.; Shin, A.; Sit, N.L.J.; Pham, T.; Nguyen, A.; Li, C.; Kumar, R.; Aguilar-Rivera, M.; et al. An adhesive-integrated stretchable silver-silver chloride electrode array for unobtrusive monitoring of gastric neuromuscular activity. Adv. Mater. Technol. 2021, 6, 2001229. [Google Scholar] [CrossRef]

- Ma, H.; Li, J.; Zhou, J.; Luo, Q.; Wu, W.; Mao, Z.; Ma, W. Screen-printed carbon black/recycled sericin@fabrics for wearable sensors to monitor sweat loss. ACS Appl. Mater. Interfaces 2022, 14, 11813–11819. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, Q.; Tao, X. Sensing Mechanism of a Carbon Nanocomposite-printed Fabric as a Strain Sensor. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106350. [Google Scholar] [CrossRef]

- Gong, X.; Huang, K.; Wu, Y.-H.; Zhang, X.-S. Recent progress on screen-printed flexible sensors for human health monitoring. Sens. Actuators A-Phys. 2022, 345, 113821. [Google Scholar] [CrossRef]

- Hasni, U.; Piper, M.E.; Lundquist, J.; Topsakal, E. Screen-printed fabric antennas for wearable applications. IEEE Open J. Antennas Propag. 2021, 2, 591–598. [Google Scholar] [CrossRef]

- Tu, H.; Hu, J.; Bai, H.; Jiang, H.; Hong, H.; Ding, X.; Yang, X.; Yan, X. Effect of curing conditions on electrical properties of screen-printed fabric antenna for UHF RFID tags. AATCC J. Res. 2022, 6, 24–27. [Google Scholar] [CrossRef]

- Zheng, C.; Hu, J.; Jiang, J. Substrate effect and structure optimization of fabric-based circularly polarized dipole antenna for radio frequency energy harvesting. Text. Res. J. 2023, 17–18, 3956–3968. [Google Scholar] [CrossRef]

- Uz Zaman, S.; Tao, X.; Cochrane, C.; Koncar, V. Understanding the washing damage to textile ECG dry skin electrodes, embroidered and fabric-based; set up of equivalent laboratory tests. Sensors 2020, 20, 1272. [Google Scholar] [CrossRef]

- Krasteva, V.T.; Papazov, S.P. Estimation of current density distribution under electrodes for external defibrillation. Biomed. Eng. Online 2002, 1, 7. [Google Scholar] [CrossRef]

- Marozas, V.; Petrenas, A.; Daukantas, S.; Lukosevicius, A. A comparison of conductive textile-based and silver/silver chloride gel electrodes in exercise electrocardiogram recordings. J. Electrocardiol. 2011, 44, 189–194. [Google Scholar] [CrossRef]

- Kazani, I.; Hertleer, C.; Mey, G.D.; Guxho, G.; Langenhove, L.V. Electrochemical impedance spectroscopy and the sweat/textile electrode interface. J. Nat. Tech. Sci. 2016, XXI. [Google Scholar]

- ISO 3160-2; Watch-Cases and Accessories—Gold Alloy Coverings—Part 2: Determination of Fineness, Thickness, Corrosion Resistance and Adhesion. ISO: Geneva, Switzerland, 2015.

- ISO 6300; Textiles—Domestic Washing and Drying Procedures for Textile Testing. ISO: Geneva, Switzerland, 2021.

- Yue, B.; Wang, C.; Ding, X.; Wallace, G.G. Electrochemically synthesized stretchable polypyrrole/fabric electrodes for supercapacitor. Electrochim. Acta 2013, 113, 17–22. [Google Scholar] [CrossRef]

- DiSpirito, H.J.; Mitchell, J.T.; Vardakas, P.M.; Amir, S.A.B. Optimizing Novel ECG Electrodes. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2013. [Google Scholar]

- Zhou, Y.; Ding, X.; Zhang, J.; Duan, Y.; Hu, J.; Yang, X. Fabrication of conductive fabric as textile electrode for ECG monitoring. Fibers Polym. 2014, 15, 2260–2264. [Google Scholar] [CrossRef]

- Hong, H.; Hu, J.; Yan, X. Effect of the basic surface properties of woven lining fabric on printing precision and electrical performance of screen-printed conductive lines. Text. Res. J. 2019, 90, 1212–1223. [Google Scholar] [CrossRef]

- Ankhili, A.; Tao, X.; Cochrane, C.; Coulon, D.; Koncar, V. Study on the measurement method of skin textile electrodes contact impedance. J. Fash. Technol. Text. Eng. 2018. [Google Scholar] [CrossRef]

- Geddes, L.A. Historical evolution of circuit models for the electrode-electrolyte interface. Ann. Biomed. Eng. 1997, 25, 1–14. [Google Scholar] [CrossRef]

- Cömert, A.; Honkala, M.; Hyttinen, J. Effect of pressure and padding on motion artifact of textile electrodes. Biomed. Eng. Online 2013, 12, 26. [Google Scholar] [CrossRef]

- Puurtinen, M.M.; Komulainen, S.M.; Kauppinen, P.K.; Malmivuo, J.A.V.; Hyttinen, J.A.K. Measurement of noise and impedance of dry and wet textile electrodes, and textile elec-trodes with hydrogel. In Proceedings of the 28th IEEE EMBS Annual International Conference, New York City, NY, USA, 30 August–3 September 2006; pp. 6012–6015. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, H.; Li, X.; Lin, X.; Lang, C.; Gao, Y. Washable and Flexible Screen-Printed Ag/AgCl Electrode on Textiles for ECG Monitoring. Polymers 2023, 15, 3665. https://doi.org/10.3390/polym15183665

Tu H, Li X, Lin X, Lang C, Gao Y. Washable and Flexible Screen-Printed Ag/AgCl Electrode on Textiles for ECG Monitoring. Polymers. 2023; 15(18):3665. https://doi.org/10.3390/polym15183665

Chicago/Turabian StyleTu, Huating, Xiaoou Li, Xiangde Lin, Chenhong Lang, and Yang Gao. 2023. "Washable and Flexible Screen-Printed Ag/AgCl Electrode on Textiles for ECG Monitoring" Polymers 15, no. 18: 3665. https://doi.org/10.3390/polym15183665

APA StyleTu, H., Li, X., Lin, X., Lang, C., & Gao, Y. (2023). Washable and Flexible Screen-Printed Ag/AgCl Electrode on Textiles for ECG Monitoring. Polymers, 15(18), 3665. https://doi.org/10.3390/polym15183665