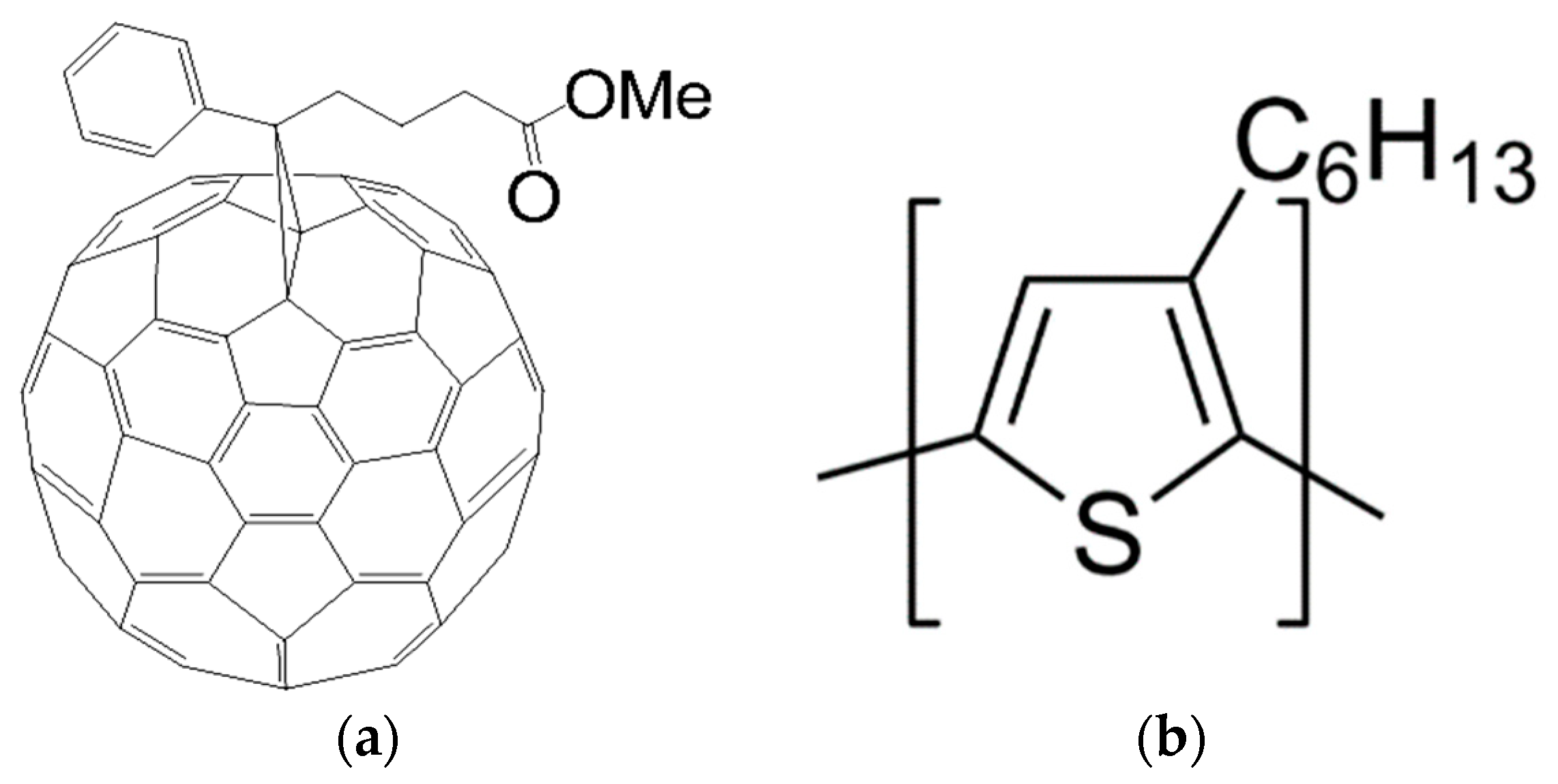

Variable Temperature Spectroscopic Ellipsometry as a Tool for Insight into the Optical Order in the P3HT:PC70BM and PC70BM Layers

Abstract

:1. Introduction

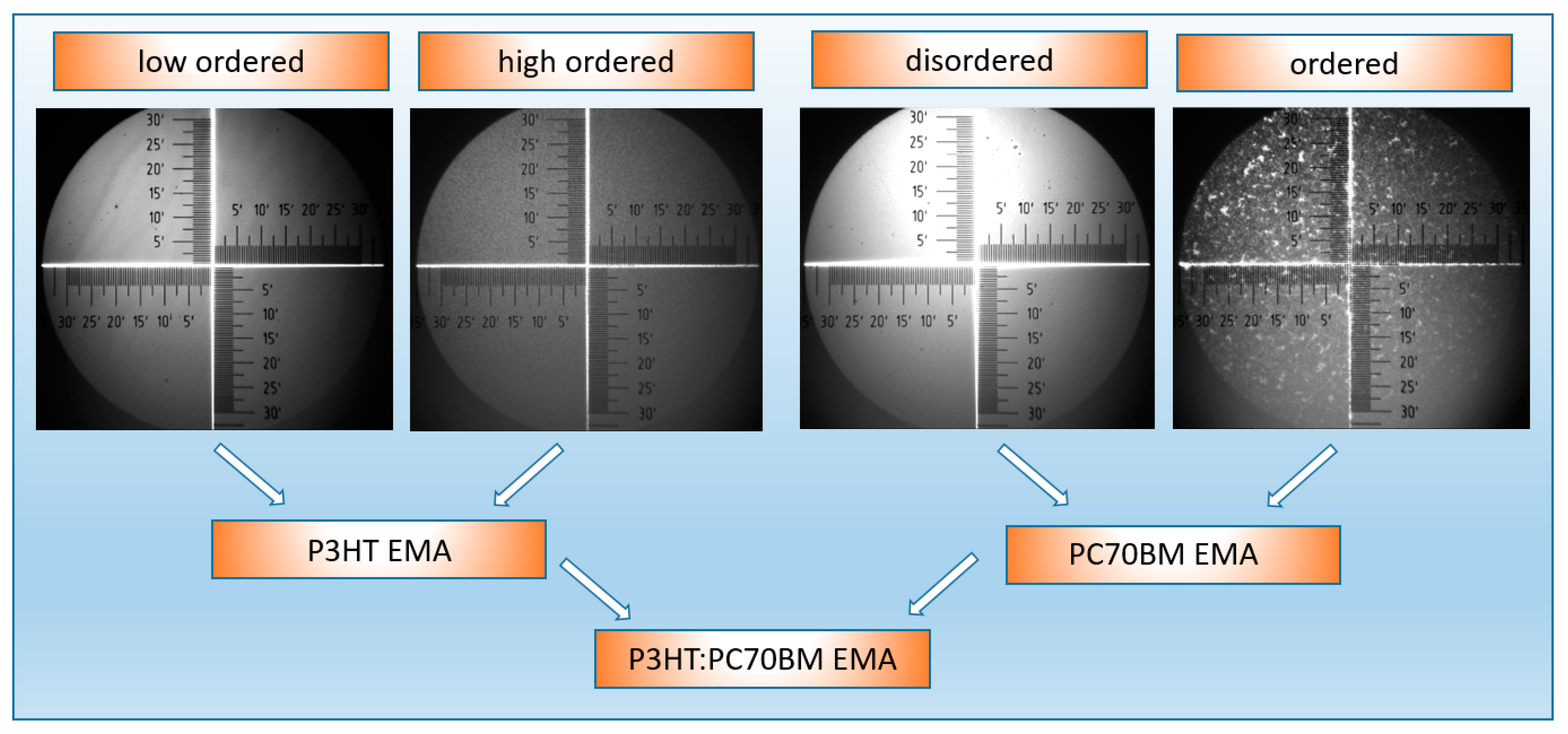

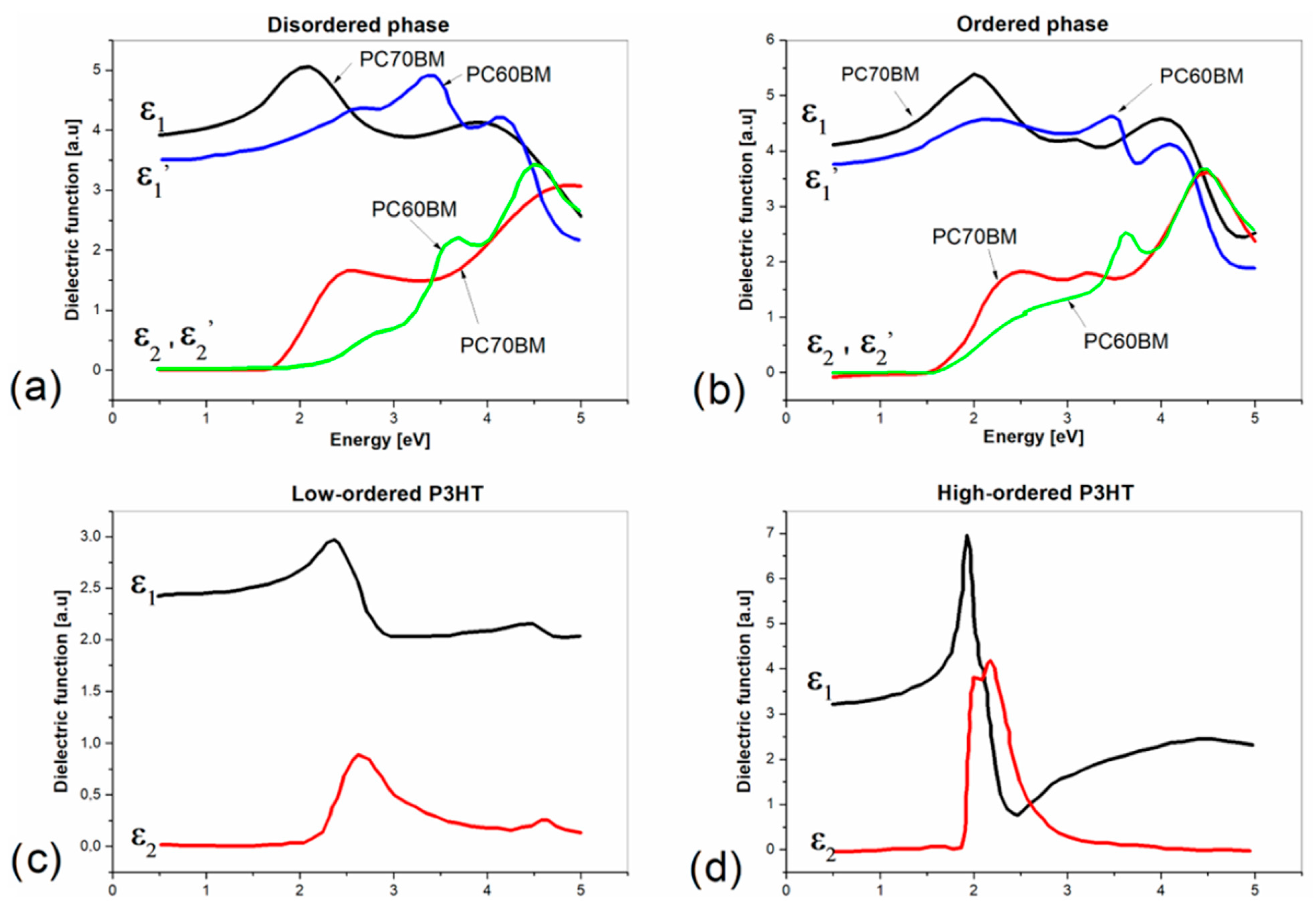

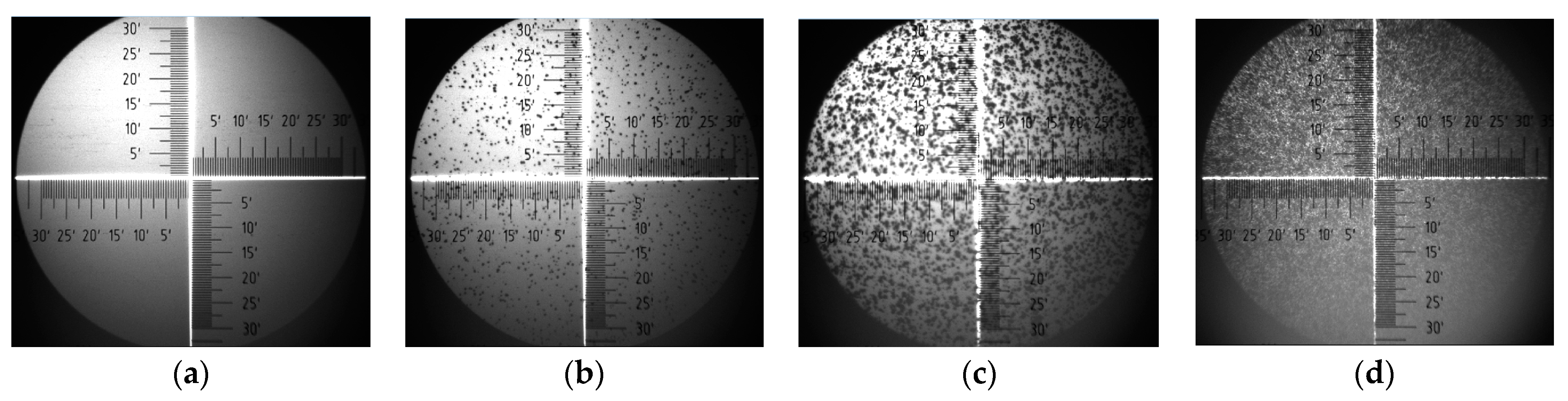

2. Experimental

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Takahashi, J.-I. Category theory and organic electronics. Phys. Open 2023, 15, 100148. [Google Scholar] [CrossRef]

- Baruah, R.K.; Yoo, H.; Lee, E.K. Interconnection Technologies for Flexible Electronics: Materials, Fabrications, and Applications. Micromachines 2023, 14, 1131. [Google Scholar] [CrossRef] [PubMed]

- Hoang, A.T.; Hu, L.; Katiyar, A.K.; Ahn, J.-H. Two-dimensional layered materials and heterostructures for flexible electronics. Matter 2022, 5, 4116–4132. [Google Scholar] [CrossRef]

- Obaid, S.N.; Chen, Z.; Lu, L. Advanced Electrical and Optical Microsystems for Biointerfacing. Adv. Intell. Syst. 2020, 2, 2000091. [Google Scholar] [CrossRef]

- Soldano, C. Engineering Dielectric Materials for High-Performance Organic Light Emitting Transistors (OLETs). Materials 2021, 14, 3756. [Google Scholar] [CrossRef]

- Swayamprabha, S.S.; Dubey, D.K.; Shahnawaz; Yadav, R.A.K.; Nagar, M.R.; Sharma, A.; Tung, F.-C.; Jou, J.-H. Approaches for Long Lifetime Organic Light Emitting Diodes. Adv. Sci. 2020, 8, 2002254. [Google Scholar] [CrossRef]

- Kim, K.; Yoo, H.; Lee, E.K. New Opportunities for Organic Semiconducting Polymers in Biomedical Applications. Polymers 2022, 14, 2960. [Google Scholar] [CrossRef]

- Liu, K.; Ouyang, B.; Guo, X.; Guo, Y.; Liu, Y. Advances in flexible organic field-effect transistors and their applications for flexible electronics. NPJ Flex. Electron. 2022, 6, 1. [Google Scholar] [CrossRef]

- Tang, C.W.; Vanslyke, S.A. Organic electroluminescent diodes. Appl. Phys. Lett. 1987, 51, 913–915. [Google Scholar] [CrossRef]

- Shin, W.S.; Hwang, Y.M.; So, W.-W.; Yoon, S.C.; Lee, C.J.; Moon, S.-J. Performance of P3HT/C70-PCBM Polymer Photovoltaic Devices According to Manufacturing Conditions. Mol. Cryst. Liq. Cryst. 2008, 491, 331–338. [Google Scholar] [CrossRef]

- Li, G.; Zhu, R.; Yang, Y. Polymer solar cells. Nat. Photonics 2012, 6, 153–161. [Google Scholar] [CrossRef]

- Kroon, R.; Lenes, M.; Hummelen, J.C.; Blom, P.W.M.; de Boer, B. Small Bandgap Polymers for Organic Solar Cells(Polymer Material Development in the Last 5 Years). Polym. Rev. 2008, 48, 531–582. [Google Scholar] [CrossRef]

- Grancharov, G.; Atanasova, M.-D.; Kalinova, R.; Gergova, R.; Popkirov, G.; Dikov, C.; Sendova-Vassileva, M. Flexible Polymer–Organic Solar Cells Based on P3HT:PCBM Bulk Heterojunction Active Layer Constructed under Environmental Conditions. Molecules 2021, 26, 6890. [Google Scholar] [CrossRef]

- Husen, M.J.; Aga, F.G.; Dibaba, S.T. Theoretical Performance Analysis of Inverted P3HT: PCBM Based Bulk Hetero-Junction Organic Solar Cells through Simulation. Adv. Mater. Sci. Eng. 2023, 2023, 4204298. [Google Scholar] [CrossRef]

- Xian, K.; Liu, Y.; Liu, J.; Yu, J.; Xing, Y.; Peng, Z.; Zhou, K.; Gao, M.; Zhao, W.; Lu, G.; et al. Delicate crystallinity control enables high-efficiency P3HT organic photovoltaic cells. J. Mater. Chem. A 2022, 10, 3418–3429. [Google Scholar] [CrossRef]

- Liang, Z.; He, J.; Zhao, B.; Gao, M.; Chen, Y.; Ye, L.; Li, M.; Geng, Y. 8.30% Efficiency P3HT-based all-polymer solar cells enabled by a miscible polymer acceptor with high energy levels and efficient electron transport. Sci. China Chem. 2023, 66, 216–227. [Google Scholar] [CrossRef]

- Su, Y.-W.; Lin, Y.-C.; Wei, K.-H. Evolving molecular architectures of donor–acceptor conjugated polymers for photovoltaic applications: From one-dimensional to branched to two-dimensional structures. J. Mater. Chem. A 2017, 5, 24051–24075. [Google Scholar] [CrossRef]

- Dridi, C.; Touafek, N.; Mahamdi, R. Inverted PTB7:PC70BM bulk heterojunction solar cell device simulations for various inorganic hole transport materials. Optik 2022, 252, 168447. [Google Scholar] [CrossRef]

- Moiz, S.A.; Alzahrani, M.S.; Alahmadi, A.N.M. Electron Transport Layer Optimization for Efficient PTB7:PC70BM Bulk-Het Erojunction Solar Cells. Polymers 2022, 14, 3610. [Google Scholar] [CrossRef]

- Kaewprajak, A.; Kumnorkaew, P.; Lohawet, K.; Duong, B.; Chonsut, T.; Kayunkid, N.; Saranrom, N.; Promarak, V. An unconventional blade coating for low-cost fabrication of PCDTBT: PC70BM polymer and CH3NH3PbIxCl3-x perovskite solar cells. Surf. Interfaces 2021, 23, 100969. [Google Scholar] [CrossRef]

- Alem, S.; Chu, T.-Y.; Tse, S.C.; Wakim, S.; Lu, J.; Movileanu, R.; Tao, Y.; Bélanger, F.; Désilets, D.; Beaupré, S.; et al. Effect of mixed solvents on PCDTBT:PC70BM based solar cells. Org. Electron. 2011, 12, 1788–1793. [Google Scholar] [CrossRef]

- Alahmadi, A.N.M. Design of an Efficient PTB7:PC70BM-Based Polymer Solar Cell for 8% Efficiency. Polymers 2022, 14, 889. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Yang, J.; Wang, B.; Fu, X.; Zhou, C.; Zhou, H.; Xie, G.; Dong, K.; Jin, G. Performance Improvement of PCDTBT: PC70BM Polymer Solar Cells with 1,8-diiodooctane Solvent Additive. Preprints 2022, 2022050076. [Google Scholar] [CrossRef]

- Zhaozhao, B.; Ma, W. Calculating Structure-Performance Relationship in Organic Solar Cells. Matter 2020, 2, 14–16. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, C.; Zhan, X. Morphology Control in Organic Solar Cells. Adv. Energy Mater. 2018, 8, 1703147. [Google Scholar] [CrossRef]

- Biernat, M.; Dąbczyński, P.; Biernat, P.; Rysz, J. Phase Separation in PCDTBT:PCBM Blends: From Flory-Huggins Interaction P Parameters to Ternary Phase Diagrams. Chin. J. Polym. Sci. 2020, 38, 1025–1033. [Google Scholar] [CrossRef]

- Fanta, G.M.; Jarka, P.; Szeluga, U.; Tański, T.; Kim, J.Y. Phase behavior of amorphous/semicrystalline conjugated polymer blends. Polymers 2020, 12, 1726. [Google Scholar] [CrossRef]

- Gao, M.; Wang, W.; Hou, J.; Ye, L. Control of aggregated structure of photovoltaic polymers for high-efficiency solar cells. Aggregate 2021, 2, e46. [Google Scholar] [CrossRef]

- Bednarski, H.; Hajduk, B.; Domański, M.; Jarząbek, B.; Nitschke, P.; Łaba, K.; Wanic, A.; Łapkowski, M. Unveiling of polymer/fullerene blend films morphology by ellipsometrically determined optical order within polymer and fullerene phases. J. Polym. Sci. Pt. B Polym. Phys. 2018, 56, 1094–1100. [Google Scholar] [CrossRef]

- Hajduk, B.; Bednarski, H.; Trzebicka, B. Temperature-Dependent Spectroscopic Ellipsometry of Thin Polymer Films. J. Phys. Chem. B. 2020, 124, 3229–3251. [Google Scholar] [CrossRef]

- Jaglarz, J.; Małek, A.; Sanetra, J. Thermal Dependence of Optical Parameters of Thin Polythiophene Films Blended with PCBM. Polymers 2018, 10, 454. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Pearson, A.J.; Dunbar, A.D.F.; Staniec, P.A.; Watters, D.C.; Coles, D.; Yi, H.; Iraqi, A.; Lidzey, D.G.; Jones, R.A.L. Competition between substrate-mediated π-π stacking and surface-mediated Tg depression in ultrathin conjugated polymer films. Eur. Phys. J. E 2012, 35, 129. [Google Scholar] [CrossRef] [PubMed]

- El Ouakili, A.; Vignaud, G.; Balnois, E.; Bardeau, J.-F.; Grohens, Y. Glass transition temperatures of isotactic poly(methymeth acrylate) thin films and individual chains probed by multi wavelength ellipsometry. Eur. Phys. J. Appl. Phys. 2011, 56, 13703. [Google Scholar] [CrossRef]

- Xu, J.; Liu, Z.; Lan, Y.; Zuo, B.; Wang, X.; Yang, J.; Zhang, W.; Hu, W. Mobility Gradient of Poly(ethylene terephthalate) Chains near a Substrate Scaled by the Thickness of the Adsorbed Layer. Macromolecules 2017, 50, 6804–6812. [Google Scholar] [CrossRef]

- Hajduk, B.; Bednarski, H.; Jarka, P.; Janeczek, H.; Godzierz, M.; Tański, T. Thermal and optical properties of PMMA films reinforced with Nb2O5 nanoparticles. Sci. Rep. 2021, 11, 22531. [Google Scholar] [CrossRef]

- Hajduk, B.; Jarka, P.; Tański, T.; Bednarski, H.; Janeczek, H.; Gnida, P.; Fijalkowski, M. An Investigation of the Thermal Transitions and Physical Properties of Semiconducting PDPP4T:PDBPyBT Blend Films. Materials 2022, 15, 8392. [Google Scholar] [CrossRef] [PubMed]

- Hajduk, B.; Bednarski, H.; Jarząbek, B.; Janeczek, H.; Nitschke, P. P3HT:PCBM blend films phase diagram on the base of variable-temperature spectroscopic ellipsometry. Beilst. J. Nanot. 2018, 9, 1108–1115. [Google Scholar] [CrossRef]

- Hajduk, B.; Bednarski, H.; Domański, M.; Jarząbek, B.; Trzebicka, B. Thermal Transitions in P3HT:PC60BM Films Based on Electrical Resistance Measurements. Polymers 2020, 12, 1458. [Google Scholar] [CrossRef]

- Mei, Z.; Chung, D.D.L. Glass transition and melting behavior of carbon fiber reinforced thermoplastic composite, studied by electrical resistance measurement. Polym. Compos. 2000, 21, 711–715. [Google Scholar] [CrossRef]

- Richter, U. SpectraRay/3 Software Manual; Sentech Instruments GmbH: Berlin, Germany, 2011. [Google Scholar]

- Abu-Zahra, N.; Algazzar, M. Effect of Crystallinity on the Performance of P3HT/PC70BM/n-Dodecylthiol Polymer Solar Cells. J. Sol. Energy Eng. 2014, 136, 021023. [Google Scholar] [CrossRef]

- Engmann, S.; Turkovic, V.; Denner, P.; Hoppe, H.; Gobsch, G. Improvement of photovoltaic performance by ternary blending of amorphous and semi-crystalline polymer analogues with PCBM. J. Polym. Sci. Pt. B Polym. Phys. 2012, 50, 1363. [Google Scholar] [CrossRef]

- Kostruba, A.; Stetsyshyn, Y.; Mayevska, S.; Yakovlev, M.; Vankevych, P.; Nastishin, Y.; Kravets, V. Composition, Thickness and Properties of Grafted Copolymer Brush Coatings Determined by Ellipsometry: Calculation and Prediction. Soft. Matt. 2018, 14, 1016–1025. [Google Scholar] [CrossRef] [PubMed]

- Ng, A.; Li, C.H.; Fung, M.K.; Djurišić, A.B.; Zapien, J.A.; Chan, W.K.; Cheung, K.Y.; Wong, W.-Y. Accurate Determination of the Index of Refraction of Polymer Blend Films by Spectroscopic Ellipsometry. J. Phys. Chem. C 2010, 114, 15094–15101. [Google Scholar] [CrossRef]

- Kostruba, A.M. Influence of the graphene substrate on morphology of the gold thin film. Spectroscopic ellipsometry study. Appl. Surf. Sci. 2013, 283, 603–611. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajduk, B.; Jarka, P.; Bednarski, H.; Tański, T. Variable Temperature Spectroscopic Ellipsometry as a Tool for Insight into the Optical Order in the P3HT:PC70BM and PC70BM Layers. Polymers 2023, 15, 3752. https://doi.org/10.3390/polym15183752

Hajduk B, Jarka P, Bednarski H, Tański T. Variable Temperature Spectroscopic Ellipsometry as a Tool for Insight into the Optical Order in the P3HT:PC70BM and PC70BM Layers. Polymers. 2023; 15(18):3752. https://doi.org/10.3390/polym15183752

Chicago/Turabian StyleHajduk, Barbara, Paweł Jarka, Henryk Bednarski, and Tomasz Tański. 2023. "Variable Temperature Spectroscopic Ellipsometry as a Tool for Insight into the Optical Order in the P3HT:PC70BM and PC70BM Layers" Polymers 15, no. 18: 3752. https://doi.org/10.3390/polym15183752

APA StyleHajduk, B., Jarka, P., Bednarski, H., & Tański, T. (2023). Variable Temperature Spectroscopic Ellipsometry as a Tool for Insight into the Optical Order in the P3HT:PC70BM and PC70BM Layers. Polymers, 15(18), 3752. https://doi.org/10.3390/polym15183752