Application of Biological Glue–Clay Composite Substrate in Slope Ecological Restoration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Clay

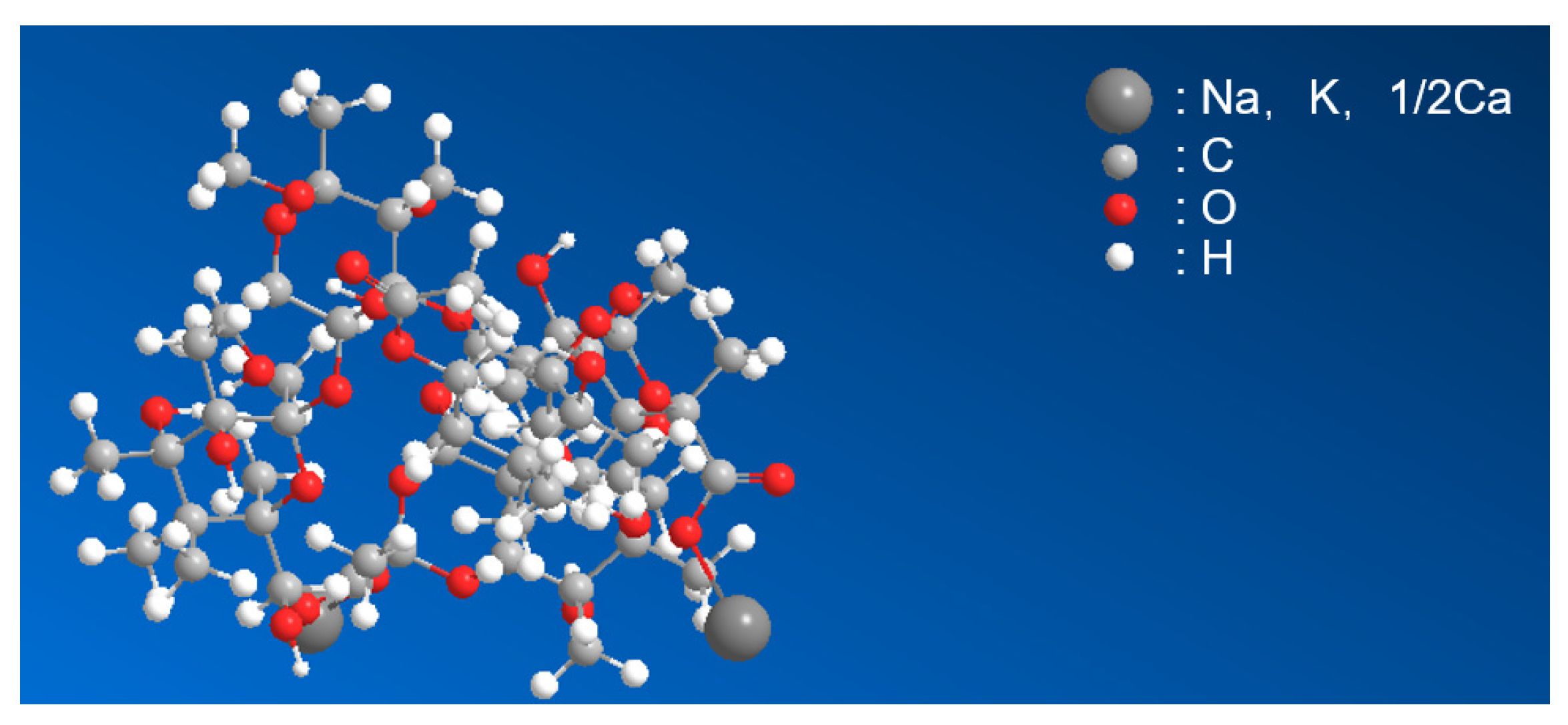

2.1.2. Xanthan Gum

2.1.3. Guar Gum

2.1.4. Composite Biogel

2.2. Methods

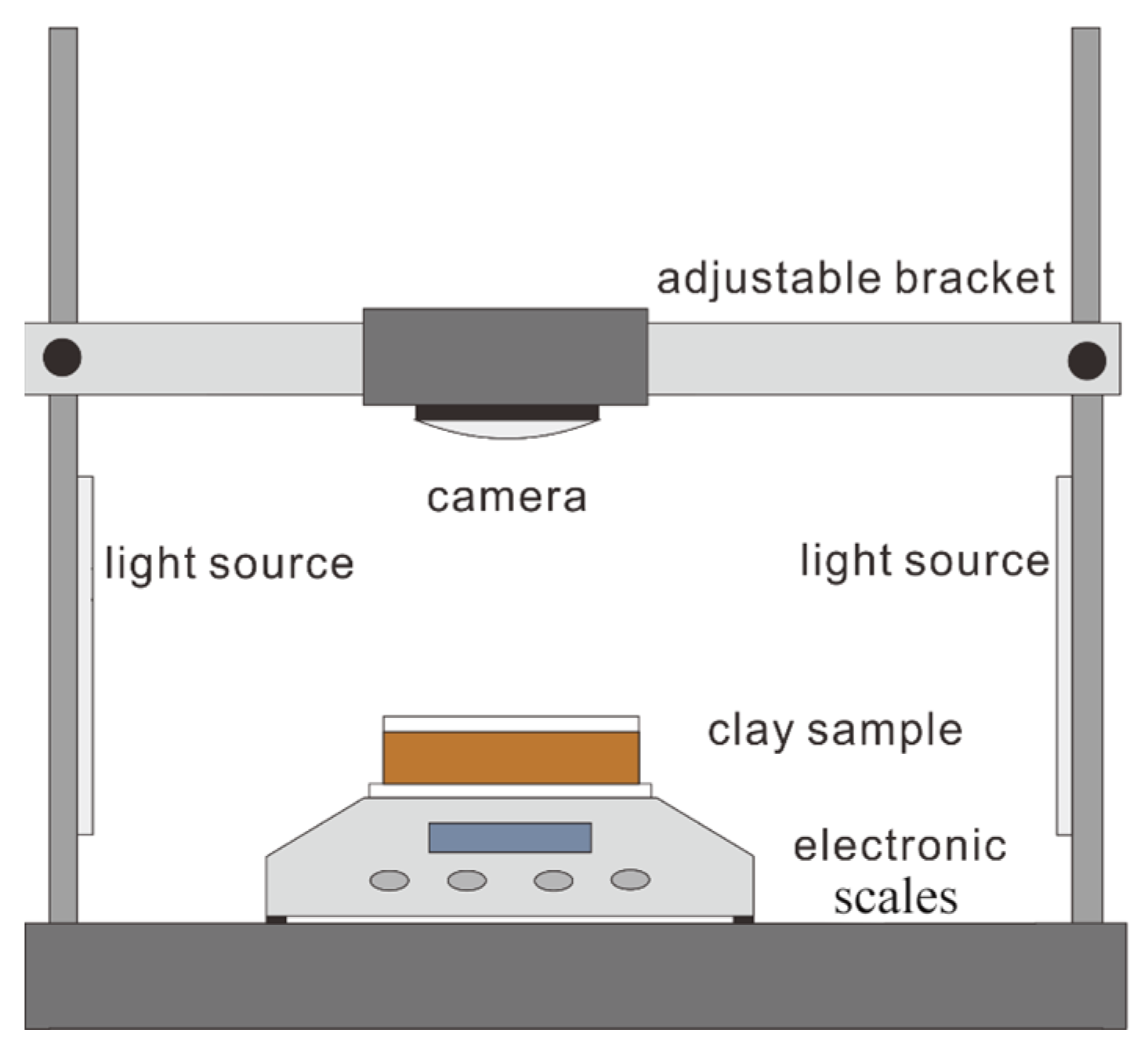

2.2.1. Testing of Evaporative Cracking Characterization of Modified Clays

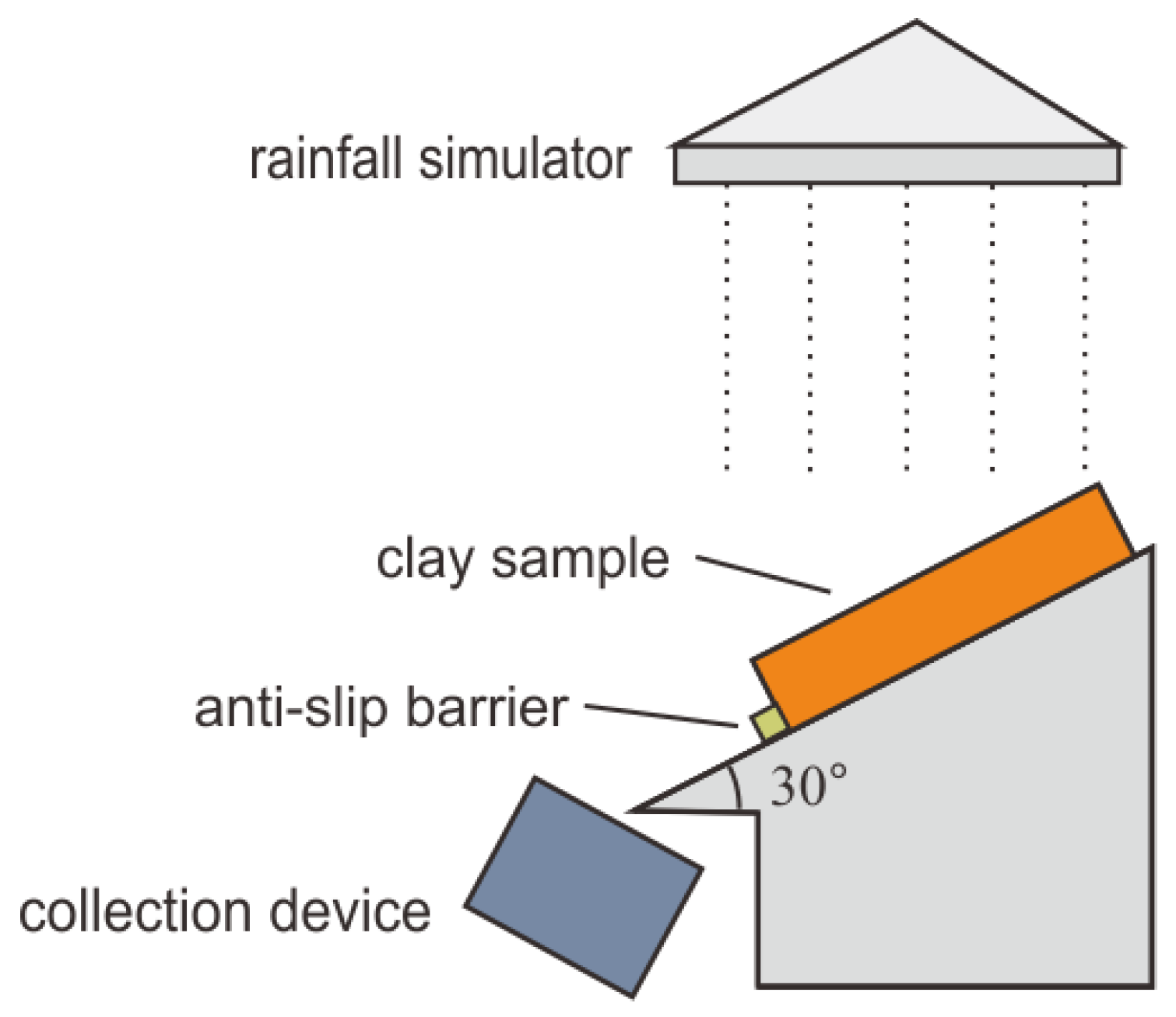

2.2.2. Testing of Improved Clay Scour Resistance Properties

3. Results

3.1. Analysis of Evaporation–Cracking Tests

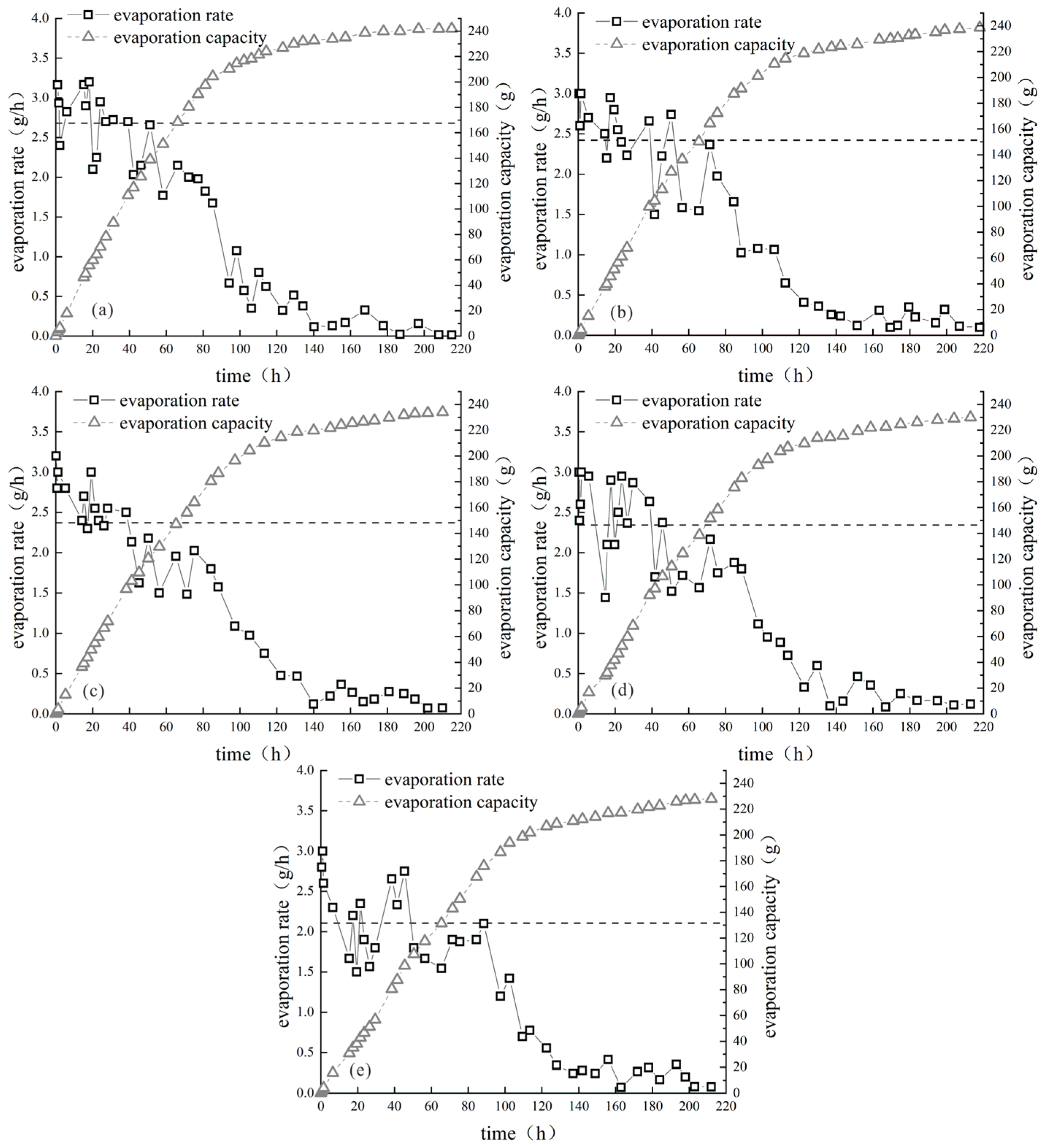

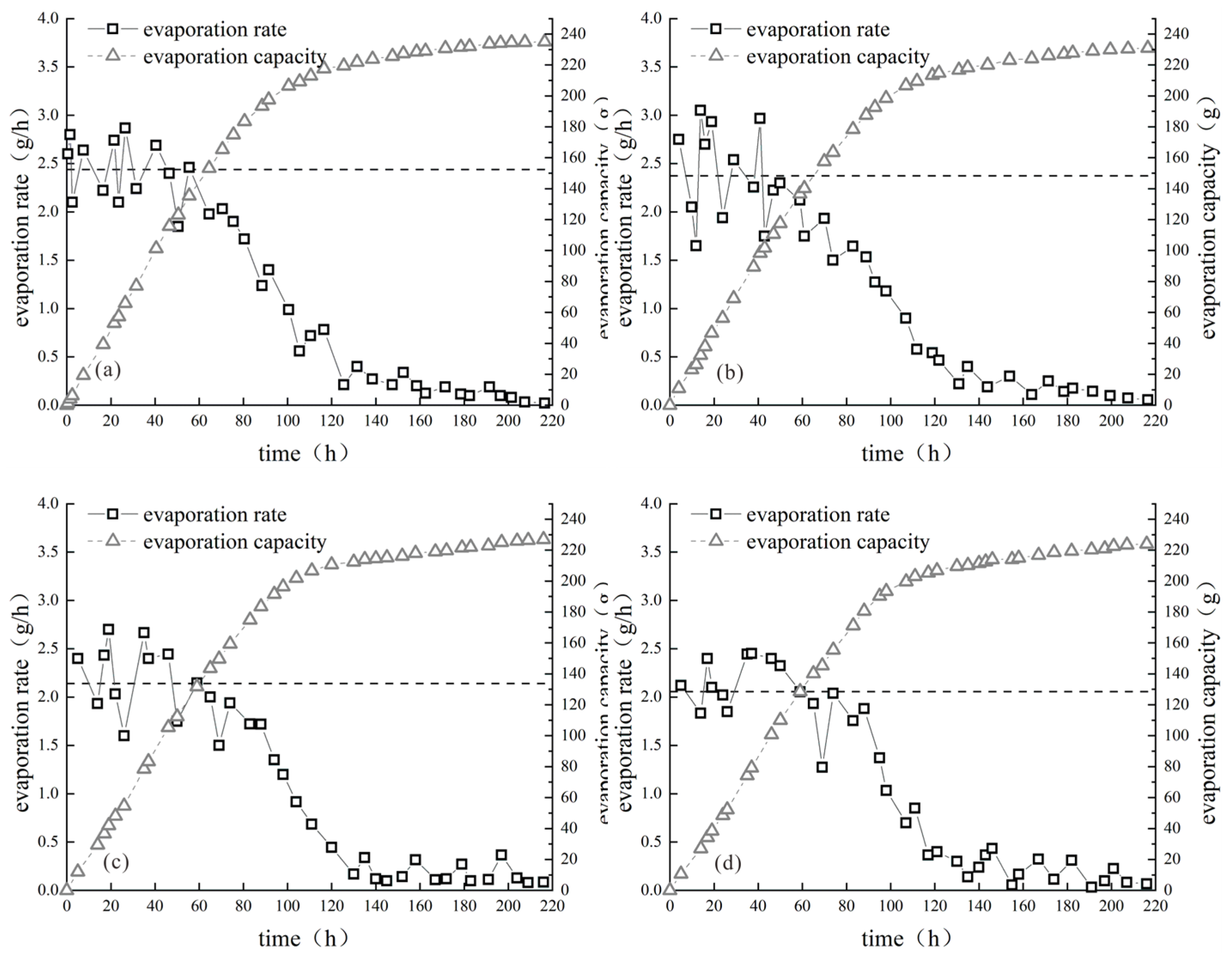

3.1.1. Analysis of Evaporation Characteristics

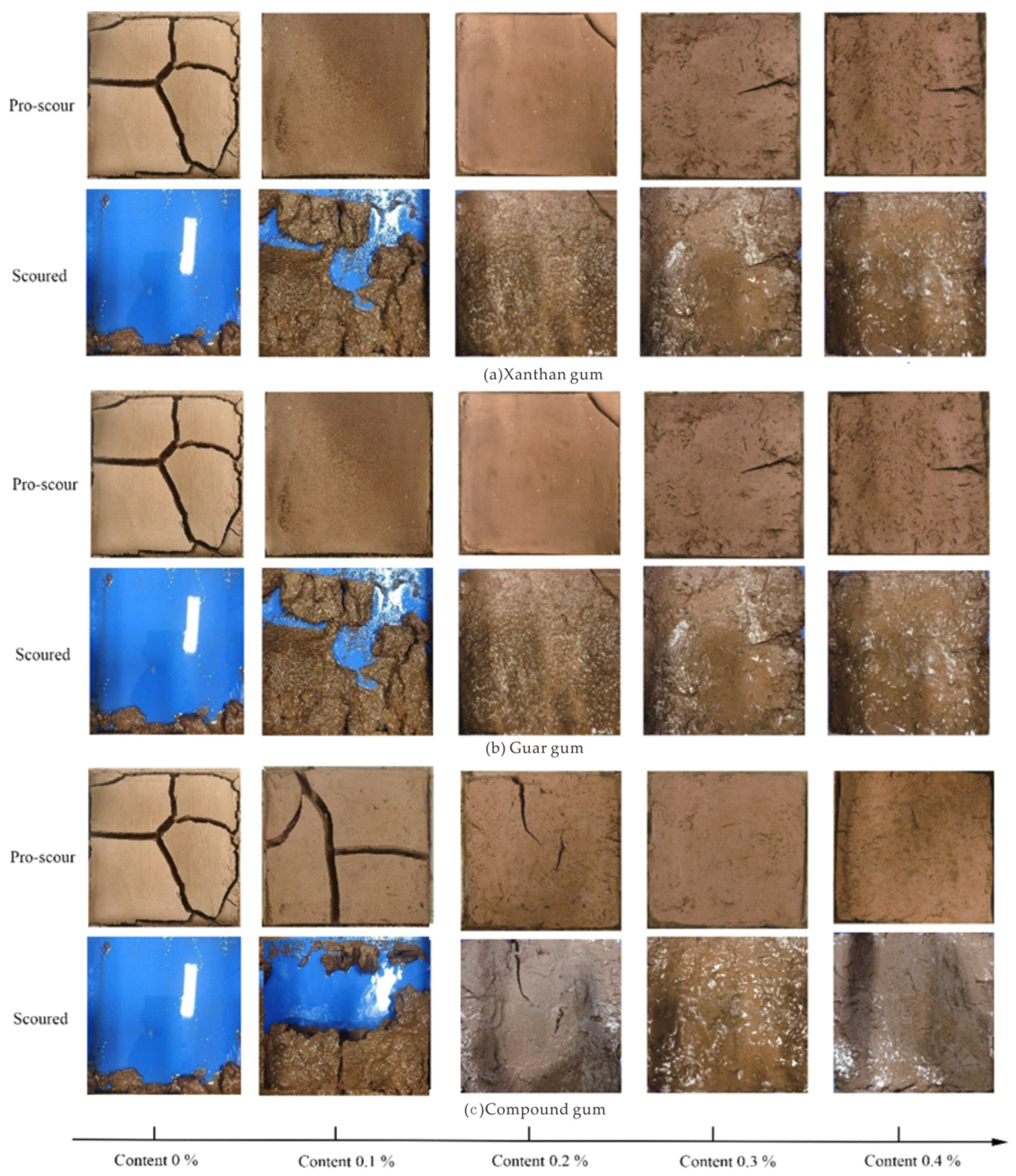

3.1.2. Analysis of Cracking Characteristics

3.2. Analysis of Scouring Resistance of Biogel-Improved Clays

3.2.1. Effect of Xanthan Gum Content on the Scouring Amount of Improved Clay

3.2.2. Effect of Biogel-Modified Clays on Scour Damage Patterns

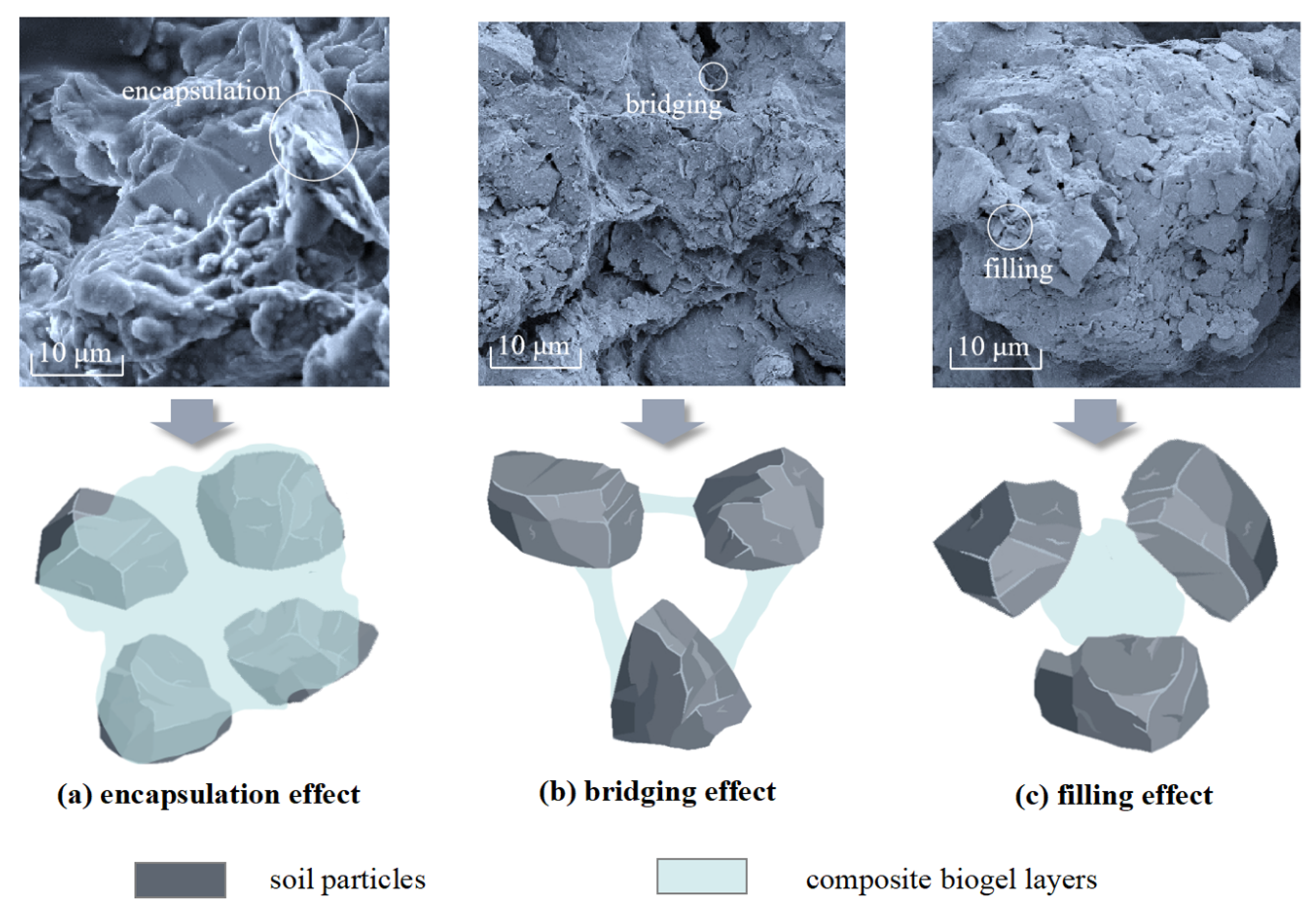

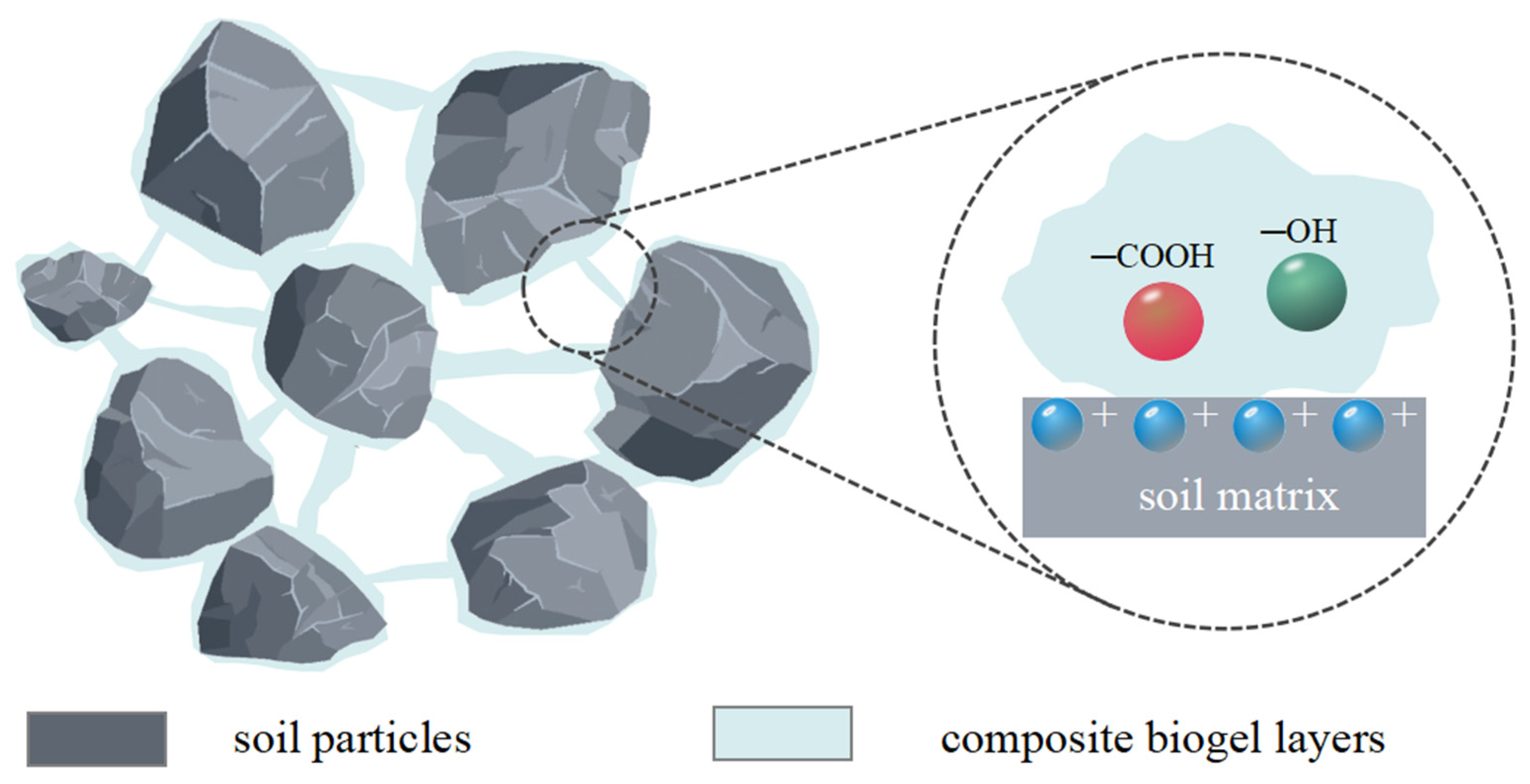

3.3. Analysis of the SEM Test Results

- (a)

- Encapsulation effect: The elastic film formed by the biopolymer in contact with water enveloped the soil particles, and the soil particles adhered to the elastic film and formed a relatively stable aggregate structure. This effectively maintained the state of the soil particles and resisted the forces exerted on them during cracking erosion.

- (b)

- Bridging effect: The elastic film produced by the biopolymer allowed noncontacting soil particles to be interconnected, forming a relatively stable unit within a certain range. This imparted stronger cohesion to the soil particles in the sample and resisted the displacement changes caused by external forces.

- (c)

- Pore filling: After adding the biopolymer to the soil, it formed a matrix with fine particles, reinforcing and filling the intergranular pores. This resulted in the formation of closed pores between some soil particles, preventing the ingress and egress of moisture and preventing the water content within the closed pores from evaporating. When subjected to erosive damage, external water did not penetrate and cause hydrolysis of soil particles.

4. Discussion

5. Conclusions

- The addition of biogel to clay improved the water retention properties of clay; clay with a lower biogel content had a lower average evaporation rate in the uniform evaporation stage, and the final evaporation of composite-biogel-modified clay was lower than that of single-biogel-modified clay. With an increase in biogel content, the average evaporation rate in the uniform evaporation stage decreased, and the onset of the deceleration and stabilization evaporation stages was delayed to some extent. This effect was most significant when the biogel content reached 0.4%.

- The incorporation of biogels improved the anticracking performance of the samples. With an increase in the biogel content, the number of cracks and degree of crack development in the specimen were significantly reduced. With the evaporation of water from the specimen, the specimen contracted significantly. Different content of xanthan gum improved clay sample cracking to a different degree; guar gum improved clay sample anticracking properties more than xanthan gum, and at higher gum content, larger cracks did not occur; composite-gum-improved clay samples with a content of more than 0.2% did not produce clear cracks.

- The addition of biogum significantly improved the scour resistance of the clay specimens. The abrasion resistance of the clay specimens modified with xanthan gum was better than that of the clay specimens modified with guar gum. The abrasion resistance of the composite-gum-amended clay specimens was significantly higher than that of a single biogum. With the incorporation of biogum, the degree of abrasion damage of the samples was reduced. When the biogum content reached 0.2%, the specimens did not show any clear abrasion damage, demonstrating the beneficial effects of incorporating biogel into clay, particularly in terms of water retention, crack resistance, and scour resistance. This study highlights the potential applications of improved biogel clays in various fields.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, C.; Hu, G.; Mei, H.; Zhu, X.; Xue, J.; Liu, J.; Zhang, F.; Che, W.; Chen, Z.; Song, Z. Using PVA and Attapulgite for the Stabilization of Clayey Soil. Polymers 2022, 14, 4752. [Google Scholar] [CrossRef] [PubMed]

- Chaiyaput, S.; Ayawanna, J.; Jongpradist, P.; Hatairat, P.; Sukkarak, R.; Jamsawang, P. Application of a cement-clay-air foam mixture as a lightweight embankment material for construction on soft clay. Case Stud. Constr. Mater. 2023, 18, e02188. [Google Scholar] [CrossRef]

- Yi, Y.; Gu, L.; Liu, S. Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl. Clay Sci. 2014, 103, 71–76. [Google Scholar] [CrossRef]

- Patil, U.; Shelton, A.; Aquino, E. Bioengineering Solution to Prevent Rainfall-Induced Slope Failures in Tropical Soil. Land 2021, 10, 299. [Google Scholar] [CrossRef]

- Jia, G.; Zhan, T.; Chen, Y.; Fredlund, D. Performance of a large-scale slope model subjected to rising and lowering water levels. Eng. Geol. 2009, 106, 92–103. [Google Scholar] [CrossRef]

- Fatehi, H.; Abtahi, S.M.; Hashemolhosseini, H.; Hejazi, S.M. A novel study on using protein based biopolymers in soil strengthening. Constr. Build. Mater. 2018, 167, 813–821. [Google Scholar] [CrossRef]

- Mosallanejad, A.; Taghvaei, H.; Mirsoleimani-azizi, S.M.; Mohammadi, A.; Rahimpour, M.R. Plasma upgrading of 4methylanisole: A novel approach for hydrodeoxygenation of bio oil without using a hydrogen source. Chem. Eng. Res. Des. 2017, 121, 113–124. [Google Scholar] [CrossRef]

- Bosoaga, A.; Masek, O.; Oakey, J.E. CO2 Capture Technologies for Cement Industry. Energy Procedia 2009, 1, 133–140. [Google Scholar] [CrossRef]

- Naeini, S.A.; Naderinia, B.; Izadi, E. Unconfined compressive strength of clayey soils stabilized with waterborne polymer. KSCE J. Civ. Eng. 2012, 16, 943–949. [Google Scholar] [CrossRef]

- Mousavi, F.; Abdi, E.; Rahimi, H. Effect of polymer stabilizer on swelling potential and CBR of forest road material. KSCE J. Civ. Eng. 2014, 18, 2064–2071. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Jiang, H.; Huang, H.; Wang, G.; Kamai, T. Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer. Eng. Geol. 2011, 117, 114–120. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Kanungo, D.P.; Song, Z.; Bai, Y.; Wang, Y.; Li, D.; Qian, W. Topsoil reinforcement of sandy slope for preventing erosion using water-based polyurethane soil stabilizer. Eng. Geol. 2019, 252, 125–135. [Google Scholar] [CrossRef]

- Onyejekwe, S.; Ghataora, G.S. Soil stabilization using proprietary liquid chemical stabilizers: Sulphonated oil and a polymer. Bull. Eng. Geol. Environ. 2015, 74, 651–665. [Google Scholar] [CrossRef]

- Zezin, A.B.; Mikheikin, S.V.; Rogacheva, V.B.; Zansokhova, M.F.; Sybachin, A.V.; Yaroslavov, A.A. Polymeric stabilizers for protection of soil and ground against wind and water erosion. Adv. Colloid. Interface Sci. 2015, 226 Pt A, 17–23. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Lu, Y.; Feng, Q.; Zhang, F.; Qi, C.; Wei, J.; Kanungo, D.P.; Maschke, U. Effect of Polyvinyl Acetate Stabilization on the Swelling-Shrinkage Properties of Expansive Soil. Int. J. Polym. Sci. 2017, 2017, 8128020. [Google Scholar] [CrossRef]

- Mapossa, A.B.; da Silva Júnior, A.H.; de Oliveira, C.R.S.; Mhike, W. Thermal, Morphological and Mechanical Properties of Multifunctional Composites Based on Biodegradable Polymers/Bentonite Clay: A Review. Polymers 2023, 15, 3443. [Google Scholar] [CrossRef]

- Caruso, M.R.; D’Agostino, G.; Milioto, S.; Cavallaro, G.; Lazzara, G. A review on biopolymer-based treatments for consolidation and surface protection of cultural heritage materials. J. Mater. Sci. 2023, 58, 12954–12975. [Google Scholar]

- Hossein, S.; Mohammad, B.; Ali, R. Use of hydrophilic polymeric stabilizer to improve strength and durability of fine-grained soils. Cold Reg. Sci. Technol. 2019, 157, 187–195. [Google Scholar] [CrossRef]

- Kalra, N.; Jain, M.; Joshi, H.; Choudhary, R.; Harit, R.; Vatsa, B.; Sharma, S.; Kumar, V. Flyash as a soil conditioner and fertilizer. Bioresour. Technol. 1998, 64, 163–167. [Google Scholar] [CrossRef]

- Chang, L.; Cho, G. Strengthening of korean residual soil with β-1,3/1,6-glucan biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Cabalar, A.; Canakci, H. Direct Shear tests on sand treated with xanthan gum. Proc. Inst. Civ. Eng. Ground Improv. 2011, 164, 57–64. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Christopher, L. Xanthan gum biopolymer: An eco-friendly additive for stabilization of tropicalorganic peat. Environ. Earth Sci. 2016, 75, 825. [Google Scholar] [CrossRef]

- Morris, E.R.; Rees, D.A.; Young, G.; Walkinshaw, M.D.; Darke, A. Order-Disorder Transition for a Bacterial Polysaccharide in Solution—Role for Polysaccharide Conformation in Recognition between Xanthomonas Pathogen and Its Plant Host. J. Mol. Biol. 1977, 110, 1–16. [Google Scholar] [CrossRef] [PubMed]

- ASTM Standard D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- Casas, J.; Mohedano, A.; Ochoa, F. Viscosity of guar gum and xanthan/guar gum mixture solutions. J. Sci. Food Agr. 2000, 80, 1722–1727. [Google Scholar] [CrossRef]

- Gidley, M.J.; Eggleston, G.; Morris, E.R. Selective Removal of Alpha-D-Galactose Side-Chains from Rhizobium Capsular Polysaccharide by Guar Alpha-D-Galactosidase—Effect on Conformational Stability and Gelation. Carbohydr. Res. 1992, 231, 185–196. [Google Scholar] [CrossRef]

- Tako, M.; Asato, A.; Nakamura, S. Rheological Aspects of the Intermolecular Interaction between Xanthan and Locust Bean Gum in Aqueous Media. Agric. Biol. Chem. 2014, 48, 2995–3000. [Google Scholar] [CrossRef]

- Tako, M. Synergistic Interaction between Deacylated Xanthan and Galactomannan. J. Carbohydr. Chem. 1991, 10, 619–633. [Google Scholar] [CrossRef]

- Chang, I.; Jeon, M.K.; Cho, G.C. Application of microbial biopolymers as an alternative construction binder for earth buildings in underdeveloped Countries. Int. Polym. Sci. 2015, 2015, 326745. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Zhang, J.; Jiang, T.; Wang, S.; Zhao, J.; Meng, Z. Water retention characteristics and vegetation growth of biopolymer-treated silt soils. Soil. Tillage Res. 2023, 225, 105544. [Google Scholar] [CrossRef]

| Compound Name | SiO2 | Al2O3 | CaO | Fe2O3 | MnO | MgO | Na2O | K2O | Other |

|---|---|---|---|---|---|---|---|---|---|

| Mass percentage (%) | 61.12 | 14.60 | 10.74 | 2.15 | 2.01 | 1.96 | 1.74 | 1.64 | 4.04 |

| Item | CAS No. | Melting Point (°C) | Boiling Point (°C) | Granularity mm | pH | Ash Content (%) | Drying Loss (%) | Viscosity (MPa·s) |

|---|---|---|---|---|---|---|---|---|

| Information | 11138-66-2 | 64.4 | 180.0 | <0.18 | 7.0 | ≤13.0 | ≤15.0 | >600 |

| Item | CAS No. | Odor | Stability | Melting Point (°C) | Specific Spin | Ash Content (%) | Drying Loss (%) | Viscosity (MPa·s) |

|---|---|---|---|---|---|---|---|---|

| Information | 9000-30-0 | Slightly odorous | Stable | >220 | D25 + 53° | ≤1.5 | ≤12.0 | >300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Zheng, J.; Gao, Y.; Xue, J.; Hu, G.; Che, W.; Song, Z.; Liu, J.; Huang, T.; Wu, P. Application of Biological Glue–Clay Composite Substrate in Slope Ecological Restoration. Polymers 2023, 15, 3763. https://doi.org/10.3390/polym15183763

Zhu X, Zheng J, Gao Y, Xue J, Hu G, Che W, Song Z, Liu J, Huang T, Wu P. Application of Biological Glue–Clay Composite Substrate in Slope Ecological Restoration. Polymers. 2023; 15(18):3763. https://doi.org/10.3390/polym15183763

Chicago/Turabian StyleZhu, Xufen, Jiaqiang Zheng, Yuliang Gao, Jian Xue, Guochang Hu, Wenyue Che, Zezhuo Song, Jin Liu, Tingwei Huang, and Peng Wu. 2023. "Application of Biological Glue–Clay Composite Substrate in Slope Ecological Restoration" Polymers 15, no. 18: 3763. https://doi.org/10.3390/polym15183763