A Highly Stretchable Force Sensitive and Temperature Sensitive Sensor Material with the Sandwich Structure of PDMS + PDMS/GaInSn + PDMS

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

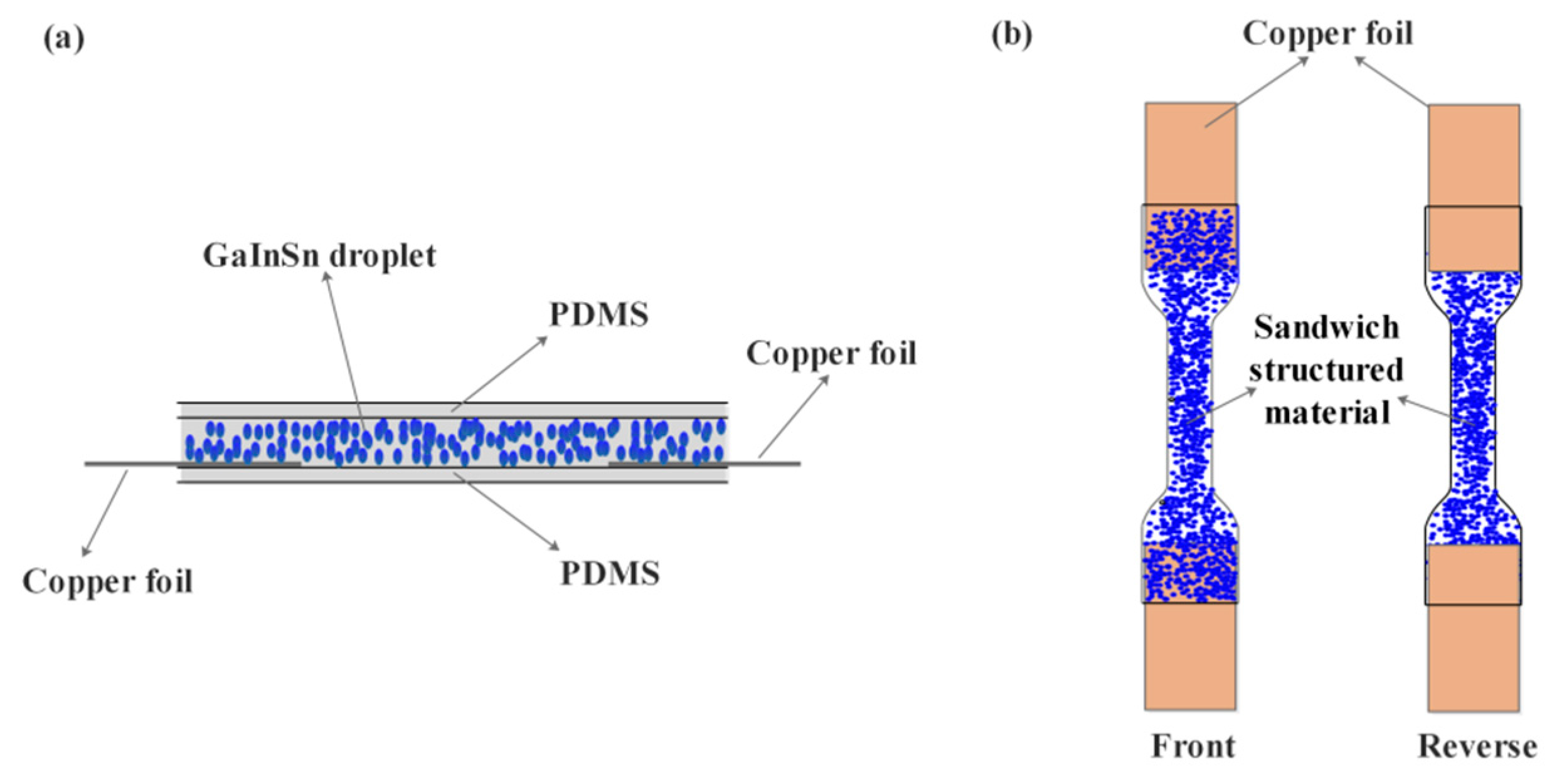

2.2. Preparation of the PDMS + PDMS/GaInSn + PDMS Sensor Material with the Sandwich Structure

2.3. Characteristic of the Sandwich-Structured PDMS + PDMS/GaInSn + PDMS Sensor Material

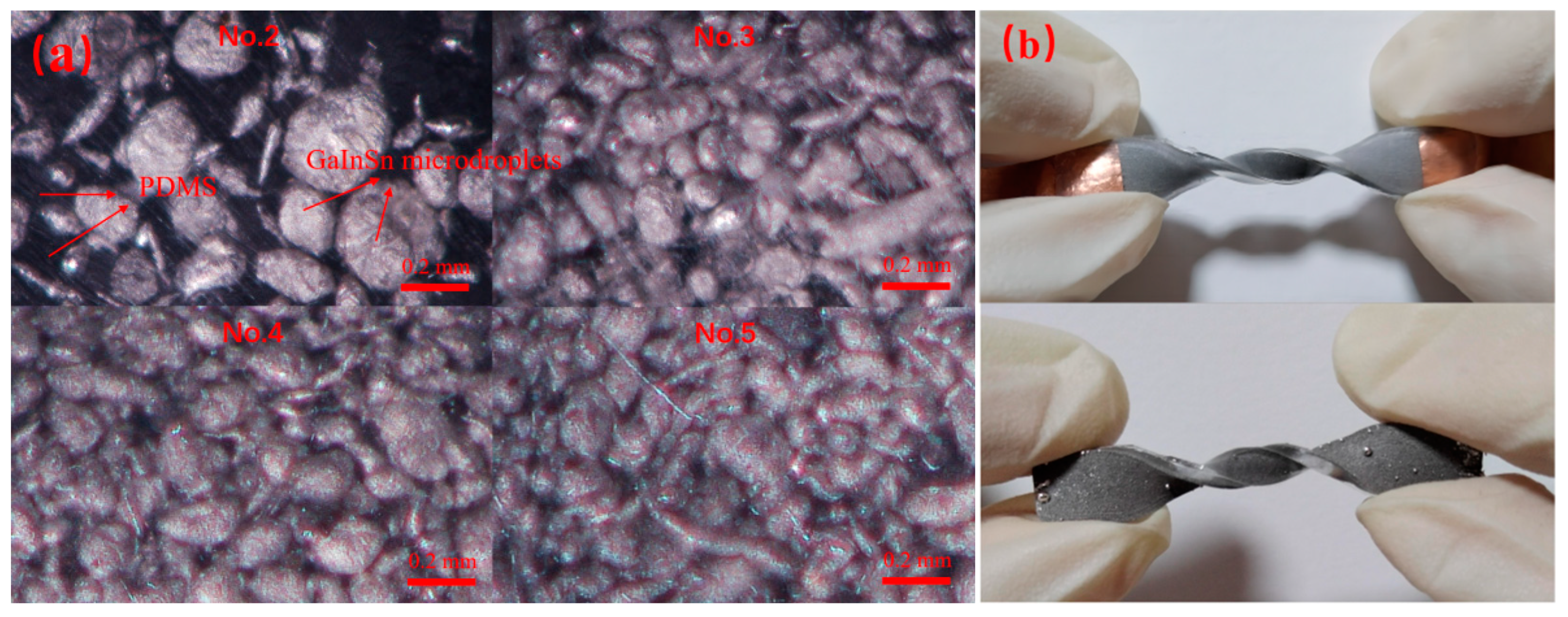

2.3.1. Morphology

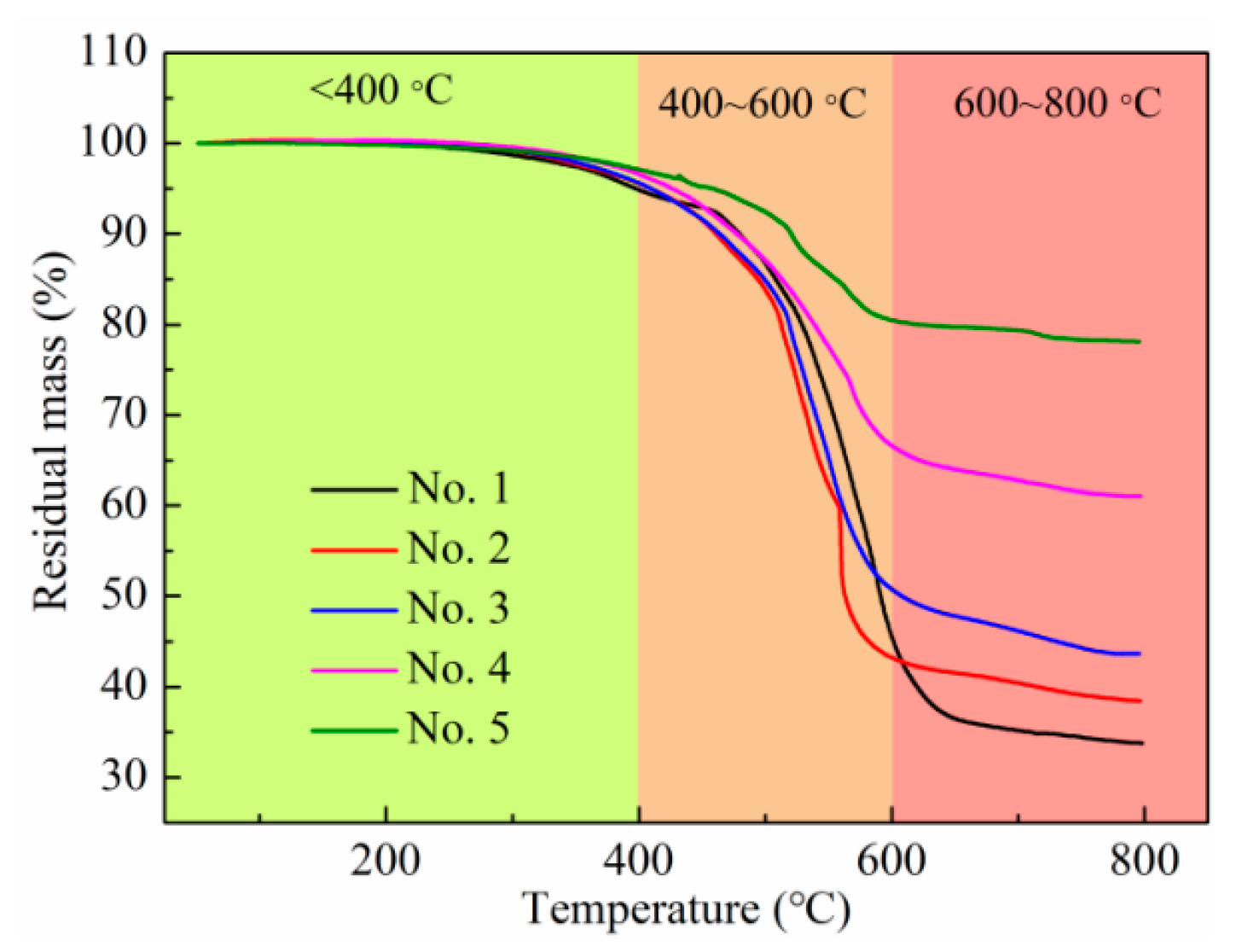

2.3.2. Thermal Performance

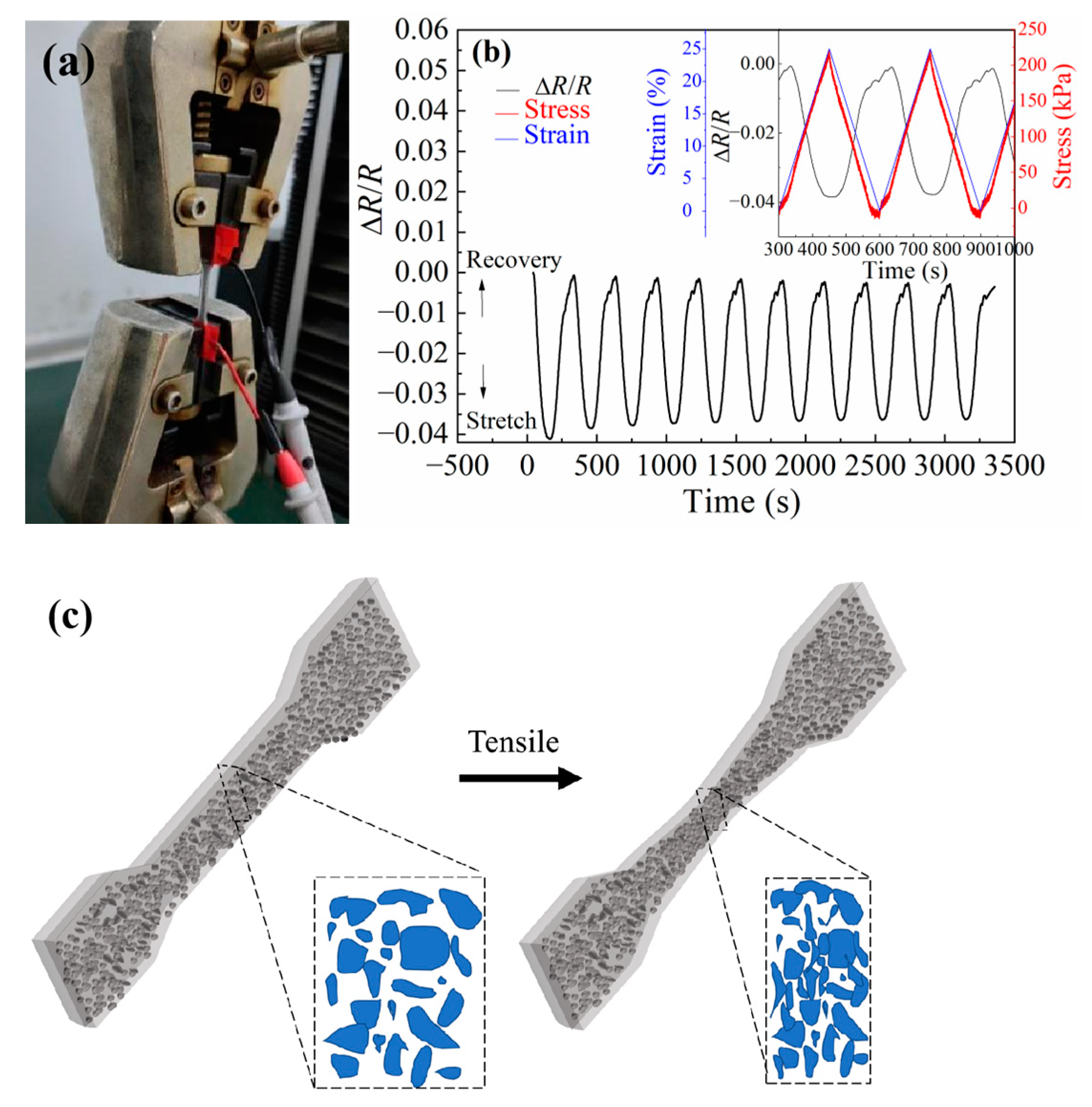

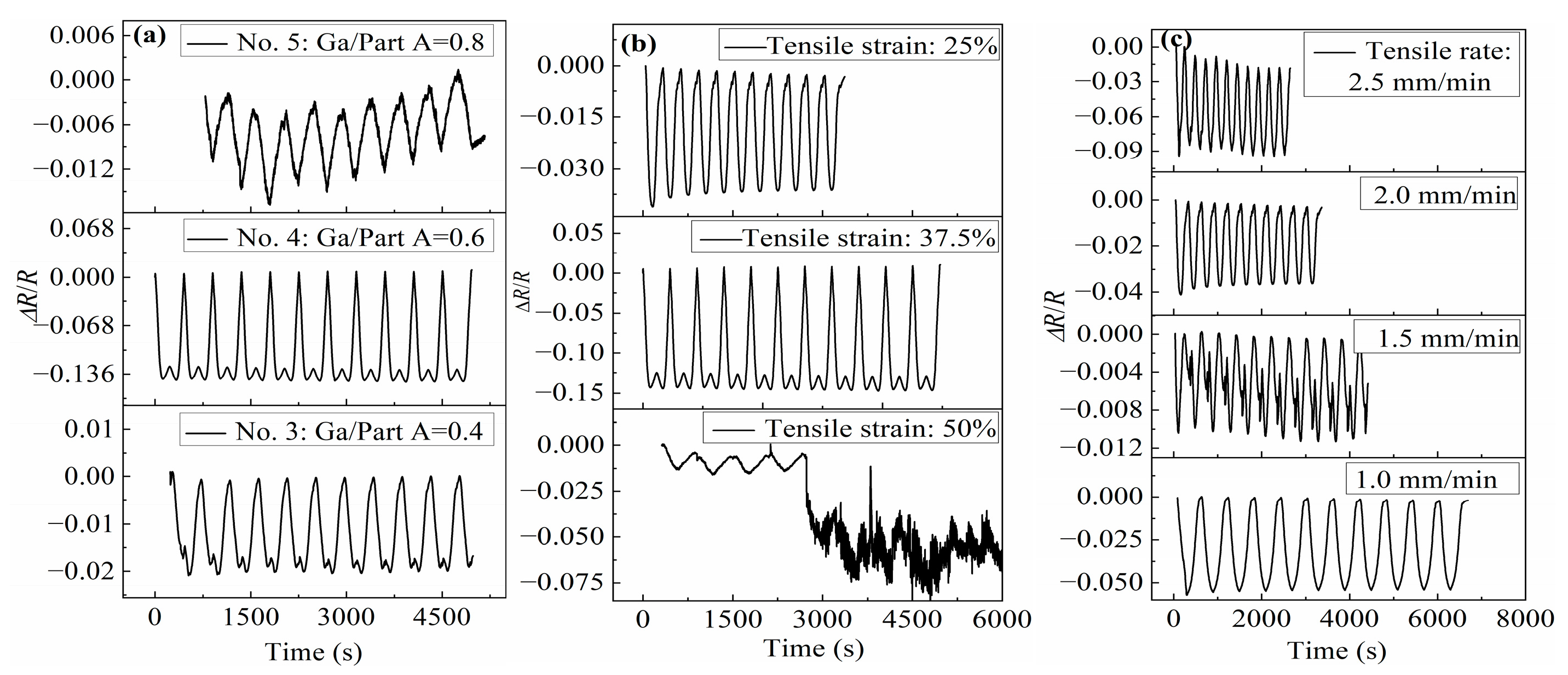

2.3.3. Deformation and Electrical Signal Measurement

2.3.4. Temperature Change and Electrical Signal Measurement

3. Results and Discussion

3.1. Morphology Analysis

3.2. Thermogravimetry Analysis

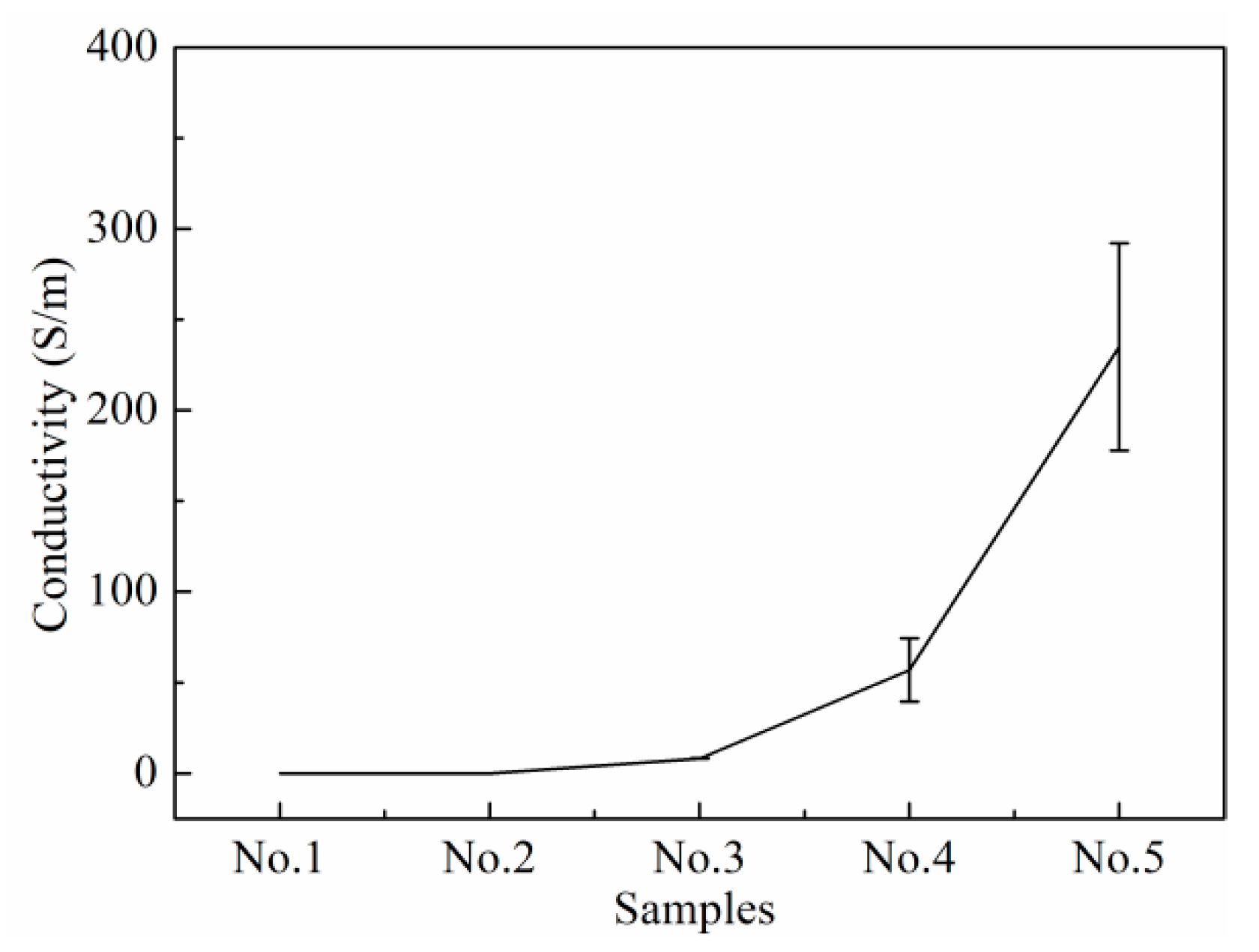

3.3. Deformation Generates Electrical Signal

3.4. Temperature Change Generates Electrical Signal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dickey, M.D. Stretchable and Soft Electronics using Liquid Metals. Adv. Mater. 2017, 29, 1606425. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, A.; Dejace, L.; Michaud, H.O.; Lacour, S.P. Harnessing the Rheological Properties of Liquid Metals To Shape Soft Electronic Conductors for Wearable Applications. Acc. Chem. Res. 2019, 52, 534–544. [Google Scholar] [CrossRef]

- Jia, M.; Wang, M.; Zhou, Y. A Flexible and Highly Sensitive Pressure Sense Electrode Based on Cotton Pulp for Wearable Electronics. Polymers 2023, 15, 2095. [Google Scholar] [CrossRef] [PubMed]

- Georgopoulou, A.; Srisawadi, S.; Wiroonpochit, P.; Clemens, F. Soft Wearable Piezoresistive Sensors Based on Natural Rubber Fabricated with a Customized Vat-Based Additive Manufacturing Process. Polymers 2023, 15, 2410. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Zuo, Y.; Wang, W. Multiscale Analysis of the Highly Stretchable Carbon-Based Polymer Strain Sensor. Polymers 2023, 15, 1780. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhu, Y. Highly Conductive and Stretchable Silver Nanowire Conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef]

- Ding, S.; Jiu, J.T.; Gao, Y.; Tian, Y.H.; Araki, T.; Sugahara, T.; Nagao, S.; Nogi, M.; Koga, H.; Suganuma, K.; et al. One-Step Fabrication of Stretchable Copper Nanowire Conductors by a Fast Photonic Sintering Technique and Its Application in Wearable Devices. ACS Appl. Mater. Interfaces 2016, 8, 6190–6199. [Google Scholar] [CrossRef]

- Chun, K.-Y.; Oh, Y.; Rho, J.; Ahn, J.-H.; Kim, Y.-J.; Choi, H.R.; Baik, S. Highly conductive, printable and stretchable composite films of carbon nanotubes and silver. Nat. Nanotechnol. 2010, 5, 853–857. [Google Scholar] [CrossRef]

- Shin, M.K.; Oh, J.; Lima, M.; Kozlov, M.E.; Kim, S.J.; Baughman, R.H. Elastomeric Conductive Composites Based on Carbon Nanotube Forests. Adv. Mater. 2010, 22, 2663–2667. [Google Scholar] [CrossRef]

- Yang, J.B.; Ding, M.Q.; Cai, W.R.; Xu, D.W.; Park, C.B. Lightweight and flexible sensors based on environmental-friendly poly(butylene adipate-co-terephthalate) composite foams with porous segregated conductive networks. J. Appl. Polym. Sci. 2023, 140, e53431. [Google Scholar] [CrossRef]

- Tao, Y.P.; Liu, Y.; Zhang, H.; Stevens, C.A.; Bilotti, E.; Peijs, T.; Busfield, J.J.C. Smart cord-rubber composites with integrated sensing capabilities by localised carbon nanotubes using a simple swelling and infusion method. Compos. Sci. Technol. 2018, 167, 24–31. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, S.Q.; Chen, S.; Wei, Y.; Dong, X.C.; Liu, L. Highly stretchable and sensitive strain sensor based on graphene-elastomer composites with a novel double-interconnected network. J. Mater. Chem. C 2016, 4, 6345–6352. [Google Scholar] [CrossRef]

- Zhang, X.J.; Sinha, T.K.; Kim, J.K.; Oh, J.S.; Lee, J. Fabrication of graphene reinforced silicone-based 3D printed tactile sensor: An approach towards an applicable piezo-sensor. J. Appl. Polym. Sci. 2022, 139, 52341. [Google Scholar] [CrossRef]

- Wang, T.T.; Wang, J.Q.; Li, Z.P.; Yue, M.Q.; Qing, X.L.; Zhang, P.X.; Liao, X.Z.; Fan, Z.J.; Yang, S.R. PVA/SA/MXene dual-network conductive hydrogel for wearable sensor to monitor human motions. J. Appl. Polym. Sci. 2022, 139, 51627. [Google Scholar] [CrossRef]

- Yu, Z.; Shang, J.; Niu, X.H.; Liu, Y.W.; Liu, G.; Dhanapal, P.; Zheng, Y.N.; Yang, H.L.; Wu, Y.Z.; Zhou, Y.L.; et al. A Composite Elastic Conductor with High Dynamic Stability Based on 3D-Calabash Bunch Conductive Network Structure for Wearable Devices. Adv. Electron. Mater. 2018, 4, 1800137. [Google Scholar] [CrossRef]

- Peng, H.; Xin, Y.M.; Xu, J.; Liu, H.Z.; Zhang, J.Y. Ultra-stretchable hydrogels with reactive liquid metals as asymmetric force-sensors. Mater. Horiz. 2019, 6, 618–625. [Google Scholar] [CrossRef]

- Zhang, Z.-P.; Xia, H. Nanoarchitectonics and Applications of Gallium-Based Liquid Metal Micro- and Nanoparticles. ChemNanoMat 2023, 9, e202300078. [Google Scholar] [CrossRef]

- Xin, Y.M.; Peng, H.; Xu, J.; Zhang, J.Y. Ultrauniform Embedded Liquid Metal in Sulfur Polymers for Recyclable, Conductive, and Self-Healable Materials. Adv. Funct. Mater. 2019, 29, 1808989. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, H.Z.; Li, T.Q.; Zhang, J.Y. Hybrid Metallic Foam with Superior Elasticity, High Electrical Conductivity, and Pressure Sensitivity. ACS Appl. Mater. Interfaces 2020, 12, 6489–6495. [Google Scholar] [CrossRef]

- Xin, Y.M.; Zhang, S.L.; Lou, Y.; Xu, J.; Zhang, J.Y. Determinative Energy Dissipation in Liquid Metal Polymer Composites for Advanced Electronic Applications. Adv. Mater. Technol. 2020, 5, 2000018. [Google Scholar] [CrossRef]

- Lou, Y.; Liu, H.Z.; Zhang, J.Y. Liquid metals in plastics for super-toughness and high-performance force sensors. Chem. Eng. J. 2020, 399, 125732. [Google Scholar] [CrossRef]

- Kazem, N.; Hellebrekers, T.; Majidi, C. Soft Multifunctional Composites and Emulsions with Liquid Metals. Adv. Mater. 2017, 29, 1605985. [Google Scholar] [CrossRef]

- Wang, Y.L.; Qin, W.J.; Yang, M.; Tian, Z.H.; Guo, W.J.; Sun, J.K.; Zhou, X.; Fei, B.; An, B.G.; Sun, R.M.; et al. High Linearity, Low Hysteresis Ti3C2Tx MXene/AgNW/Liquid Metal Self-Healing Strain Sensor Modulated by Dynamic Disulfide and Hydrogen Bonds. Adv. Funct. Mater. 2023, 2301587. [Google Scholar] [CrossRef]

- Wang, H.Z.; Yao, Y.Y.; He, Z.Z.; Rao, W.; Hu, L.; Chen, S.; Lin, J.; Gao, J.Y.; Zhang, P.J.; Sun, X.Y.; et al. A Highly Stretchable Liquid Metal Polymer as Reversible Transitional Insulator and Conductor. Adv. Mater. 2019, 31, 1901337. [Google Scholar] [CrossRef] [PubMed]

- Krisnadi, F.; Nguyen, L.L.; Ma, J.A.; Kulkarni, M.R.; Mathews, N.; Dickey, M.D. Directed Assembly of Liquid Metal-Elastomer Conductors for Stretchable and Self-Healing Electronics. Adv. Mater. 2020, 32, 2001642. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, M.; Pearce, G.; Yu, Y.Y.; Sha, Z.; Zhou, Y.; Yuen, A.C.Y.; Tao, C.Y.; Boyer, C.; Huang, F.; et al. Strain stiffening and positive piezoconductive effect of liquid metal/elastomer soft composites. Compos. Sci. Technol. 2021, 201, 108497. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Liu, S.; Kim, S.Y.; Henry, K.E.; Shah, D.S.; Kramer-Bottiglio, R. Printed and Laser-Activated Liquid Metal-Elastomer Conductors Enabled by Ethanol/PDMS/Liquid Metal Double Emulsions. ACS Appl. Mater. Interfaces 2021, 13, 28729–28736. [Google Scholar] [CrossRef]

- Johnston, L.; Yang, J.; Han, J.L.; Kalantar-Zadeh, K.; Tang, J.B. Intermetallic wetting enabled high resolution liquid metal patterning for 3D and flexible electronics. J. Mater. Chem. C 2022, 10, 921–931. [Google Scholar] [CrossRef]

- Pasha, A.; Khasim, S.; Darwish, A.A.A.; Hamdalla, T.A.; Al-Ghamdi, S.A.; Alfadhli, S. Flexible, stretchable and electrically conductive PDMS decorated with polypyrrole/manganese-iron oxide nanocomposite as a multifunctional material for high performance EMI shielding applications. Synth. Met. 2022, 283, 116984. [Google Scholar] [CrossRef]

- Mitra, A.; Xu, K.; Babu, S.; Choi, J.H.; Lee, J.-B. Liquid-Metal-Enabled Flexible Metasurface with Self-Healing Characteristics. Adv. Mater. Interfaces 2022, 9, 2102141. [Google Scholar] [CrossRef]

- Markvicka, E.J.; Bartlett, M.D.; Huang, X.N.; Majidi, C. An autonomously electrically self-healing liquid metal-elastomer composite for robust soft-matter robotics and electronics. Nat. Mater. 2018, 17, 618–624. [Google Scholar] [CrossRef] [PubMed]

- Cooper, C.B.; Arutselvan, K.; Liu, Y.; Armstrong, D.; Lin, Y.L.; Khan, M.R.; Genzer, J.; Dickey, M.D. Stretchable Capacitive Sensors of Torsion, Strain, and Touch Using Double Helix Liquid Metal Fibers. Adv. Funct. Mater. 2017, 27, 1605630. [Google Scholar] [CrossRef]

- Tavakoli, M.; Malakooti, M.H.; Paisana, H.; Ohm, Y.; Green Marques, D.; Alhais Lopes, P.; Piedade, A.P.; de Almeida, A.T.; Majidi, C. EGaIn-Assisted Room-Temperature Sintering of Silver Nanoparticles for Stretchable, Inkjet-Printed, Thin-Film Electronics. Adv. Mater. 2018, 30, 1801852. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Li, M.X.; Ouyang, C.; Lu, T.J.; Li, F.; Xu, F. Biofriendly, Stretchable, and Reusable Hydrogel Electronics as Wearable Force Sensors. Small 2018, 14, 1801711. [Google Scholar] [CrossRef] [PubMed]

- Michaud, H.O.; Lacour, S.P. Liquid electromigration in gallium-based biphasic thin films. APL Mater. 2019, 7, 031504. [Google Scholar] [CrossRef]

- Zavickis, J.; Knite, M.; Podins, G.; Linarts, A.; Orlovs, R. Polyisoprene-nanostructured carbon composite-A soft alternative for pressure sensor application. Sens. Actuators A Phys. 2011, 171, 38–42. [Google Scholar] [CrossRef]

- Rashid, I.A.; Irfan, M.S.; Gill, Y.Q.; Nazar, R.; Saeed, F.; Afzal, A.; Ehsan, H.; Qaiser, A.A.; Shakoor, A. Stretchable strain sensors based on polyaniline/thermoplastic polyurethane blends. Polym. Bull. 2020, 77, 1081–1093. [Google Scholar] [CrossRef]

- Boland, C.S.; Khan, U.; Backes, C.; O’Neill, A.; McCauley, J.; Duane, S.; Shanker, R.; Liu, Y.; Jurewicz, I.; Dalton, A.B.; et al. Sensitive, High-Strain, High-Rate Bodily Motion Sensors Based on Graphene-Rubber Composites. ACS Nano 2014, 8, 8819–8830. [Google Scholar] [CrossRef]

- Lu, S.W.; Zhao, C.X.; Zhang, L.; Chen, D.; Chen, D.D.; Wang, X.Q.; Ma, K.M. Real time monitoring of the curing degree and the manufacturing process of fiber reinforced composites with a carbon nanotube buckypaper sensor. RSC Adv. 2018, 8, 22078–22085. [Google Scholar] [CrossRef]

- Zhang, R.; Baxendale, M.; Peijs, T. Universal resistivity-strain dependence of carbon nanotube/polymer composites. Phys. Rev. B 2007, 76, 195433. [Google Scholar] [CrossRef]

| Samples | GaInSn/Part A | Part A (g) | Part B (g) | GaInSn (g) |

|---|---|---|---|---|

| No. 1 | 0 | 2.0 | 0.2 | 0 |

| No. 2 | 0.2 | 2.0 | 0.2 | 0.4 |

| No. 3 | 0.4 | 2.0 | 0.2 | 0.8 |

| No. 4 | 0.6 | 2.0 | 0.2 | 1.2 |

| No. 5 | 0.8 | 2.0 | 0.2 | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Zhai, Q.; Bao, F.; Zhao, D.; Lu, Z.; Wang, J.; Wang, W. A Highly Stretchable Force Sensitive and Temperature Sensitive Sensor Material with the Sandwich Structure of PDMS + PDMS/GaInSn + PDMS. Polymers 2023, 15, 3776. https://doi.org/10.3390/polym15183776

Zhang R, Zhai Q, Bao F, Zhao D, Lu Z, Wang J, Wang W. A Highly Stretchable Force Sensitive and Temperature Sensitive Sensor Material with the Sandwich Structure of PDMS + PDMS/GaInSn + PDMS. Polymers. 2023; 15(18):3776. https://doi.org/10.3390/polym15183776

Chicago/Turabian StyleZhang, Rongmin, Qianqian Zhai, Fandou Bao, Di Zhao, Zhihua Lu, Jing Wang, and Weina Wang. 2023. "A Highly Stretchable Force Sensitive and Temperature Sensitive Sensor Material with the Sandwich Structure of PDMS + PDMS/GaInSn + PDMS" Polymers 15, no. 18: 3776. https://doi.org/10.3390/polym15183776