Medical-Grade PLA Nanocomposites with Optimized Tungsten Carbide Nanofiller Content in MEX Additive Manufacturing: A Rheological, Morphological, and Thermomechanical Evaluation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Development of Nanocompounds

2.3. Three-Dimensionally Printed Samples’ Production Process

2.4. Analysis of Thermal Properties and Rheological Behavior

2.5. Analysis of Raman Spectroscopy

2.6. Evaluation of the Produced Filaments

2.7. Assessment of the Mechanical Properties

2.8. Examination of the Structure and Morphology of the 3D-Printed Specimens

3. Results

3.1. Estimation of Thermal Characteristics through Thermogravimetric Analysis and Differential Scanning Calorimetry

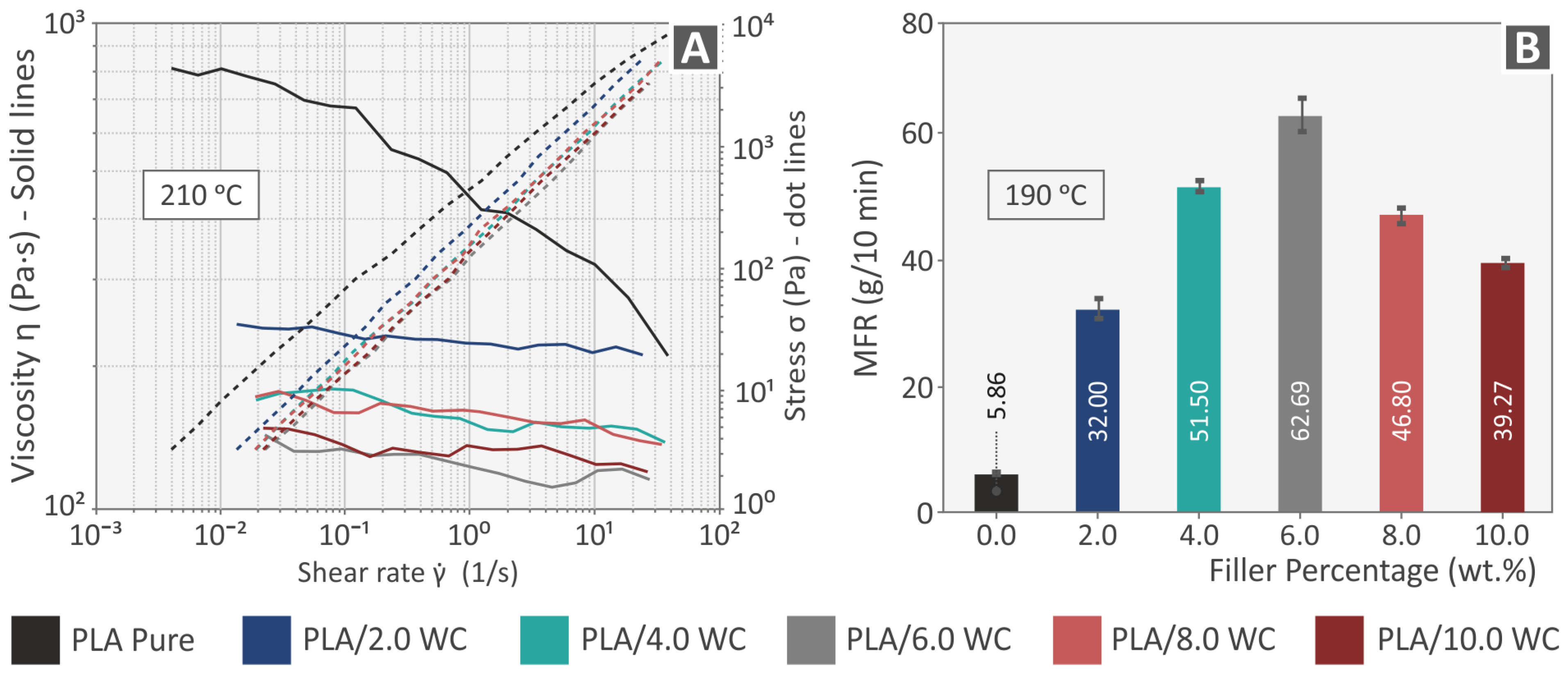

3.2. Examination of the Rheological Properties

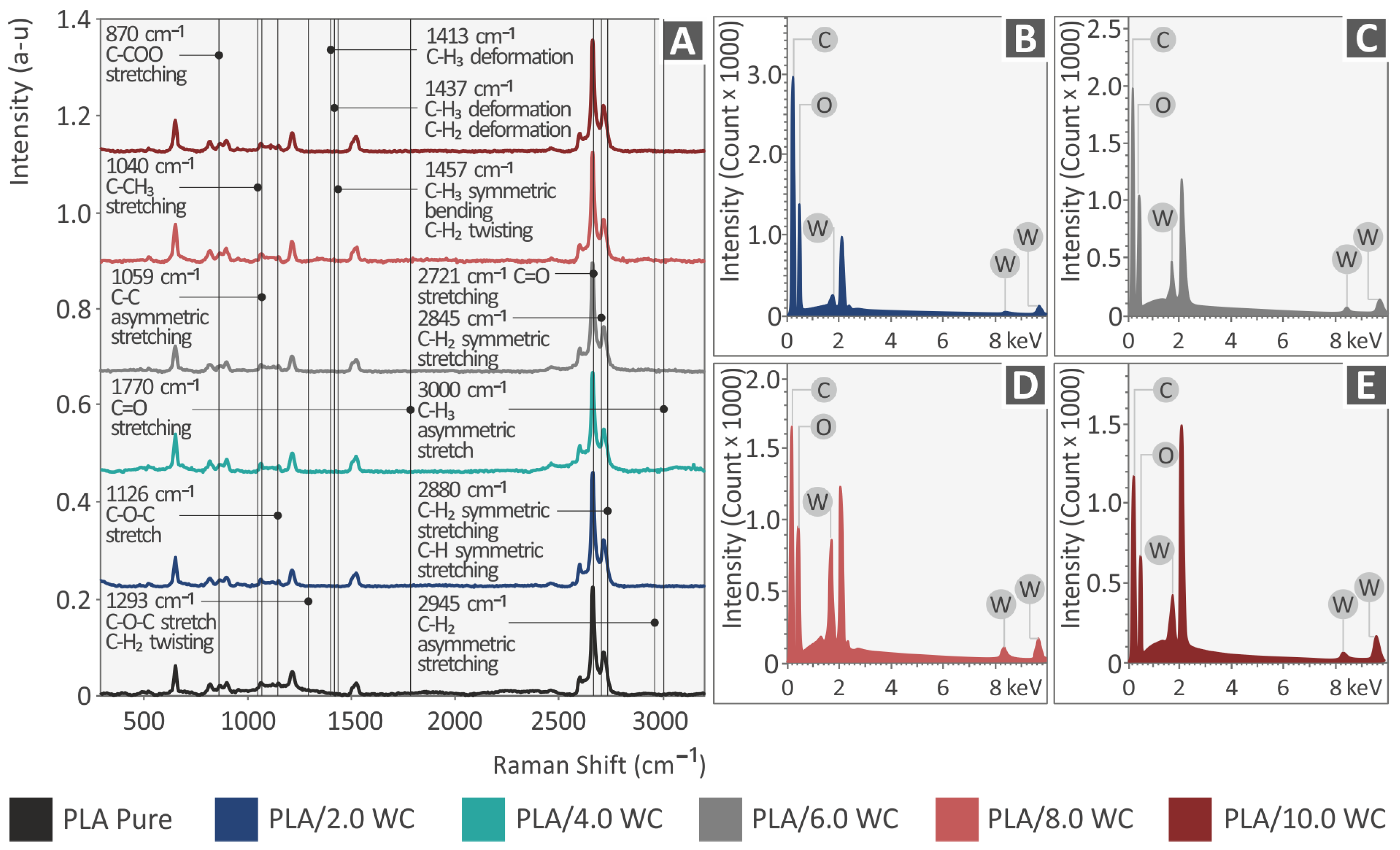

3.3. Raman Spectroscopy Examination

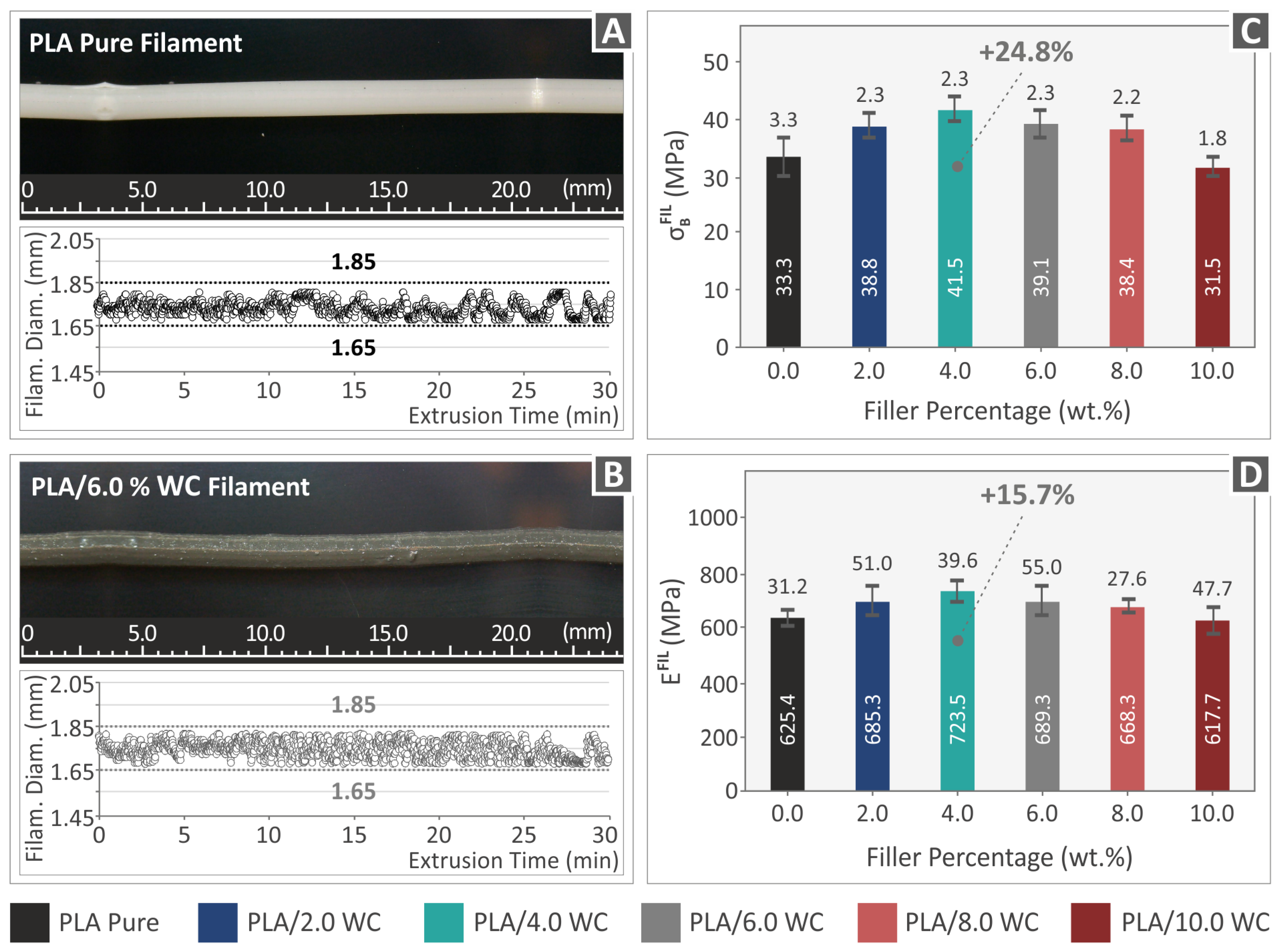

3.4. Evaluation of the Filament Performance

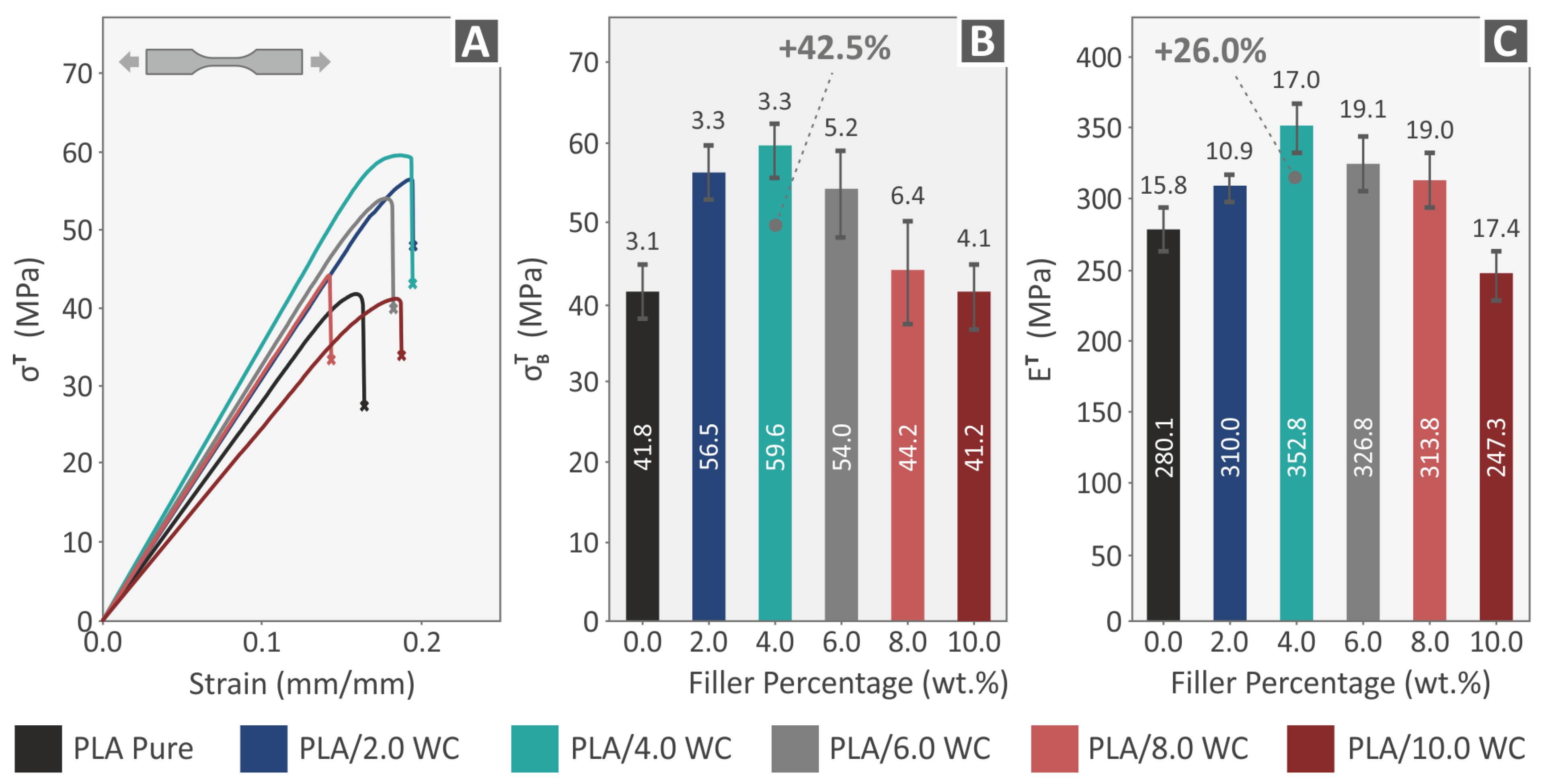

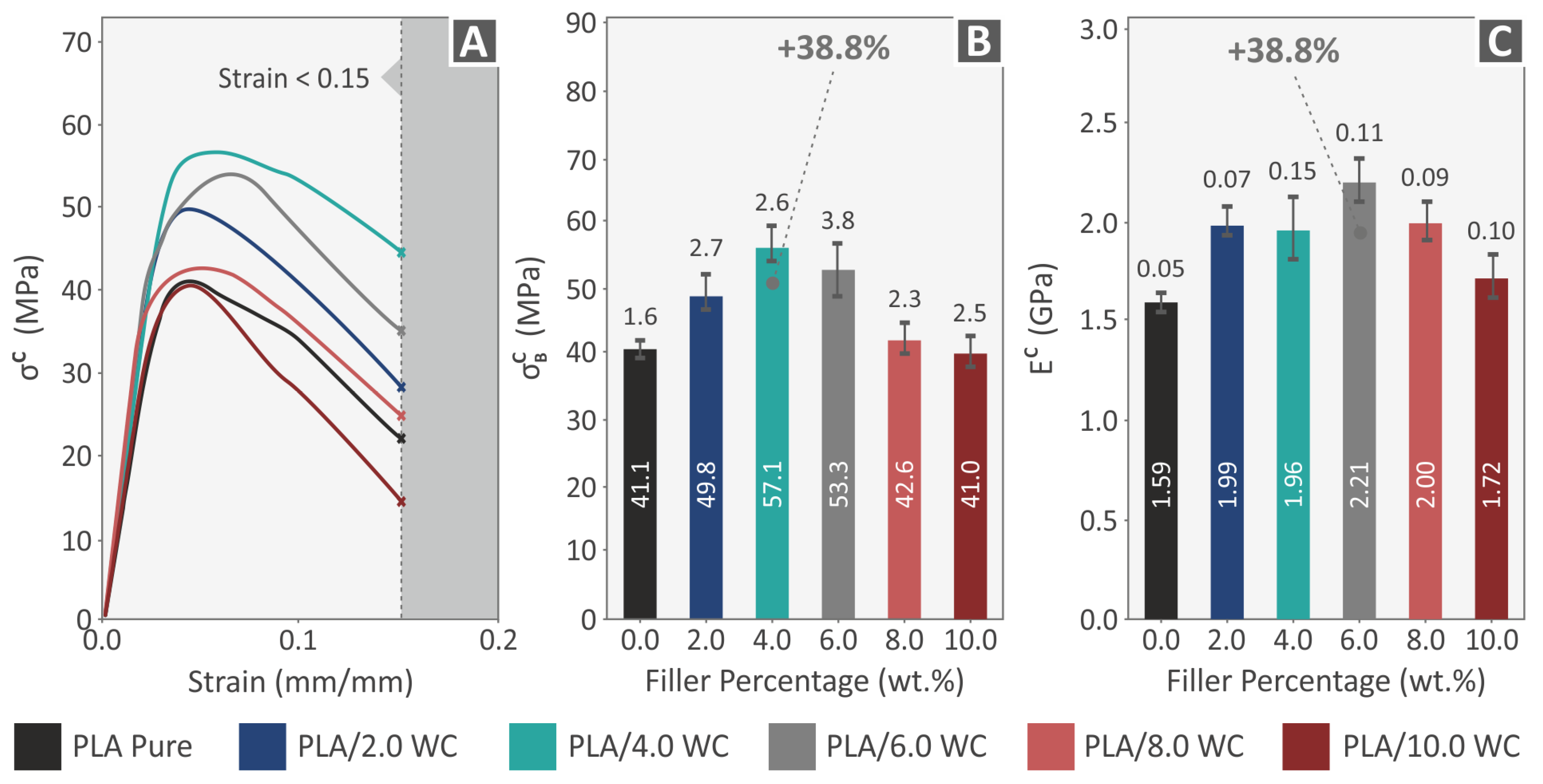

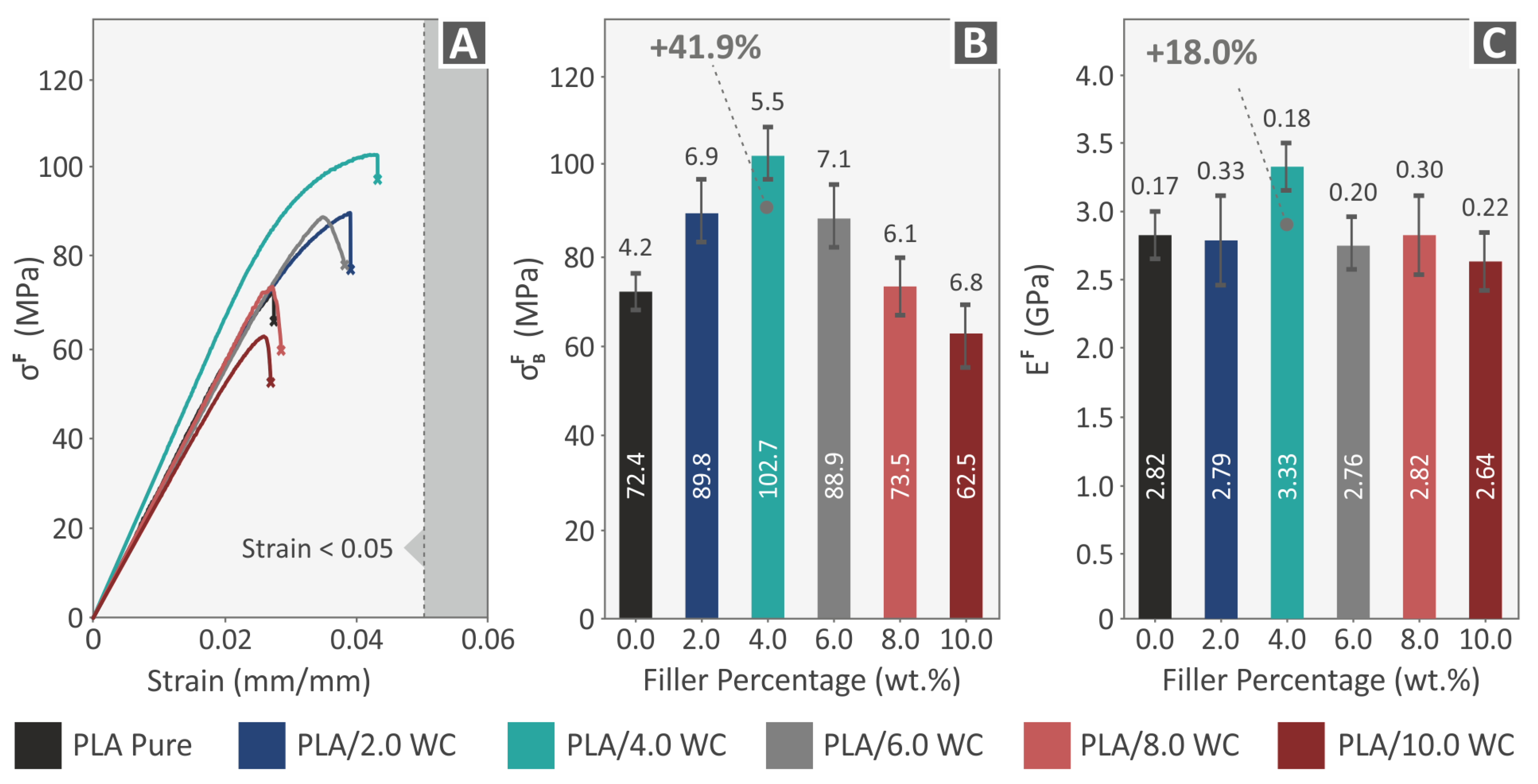

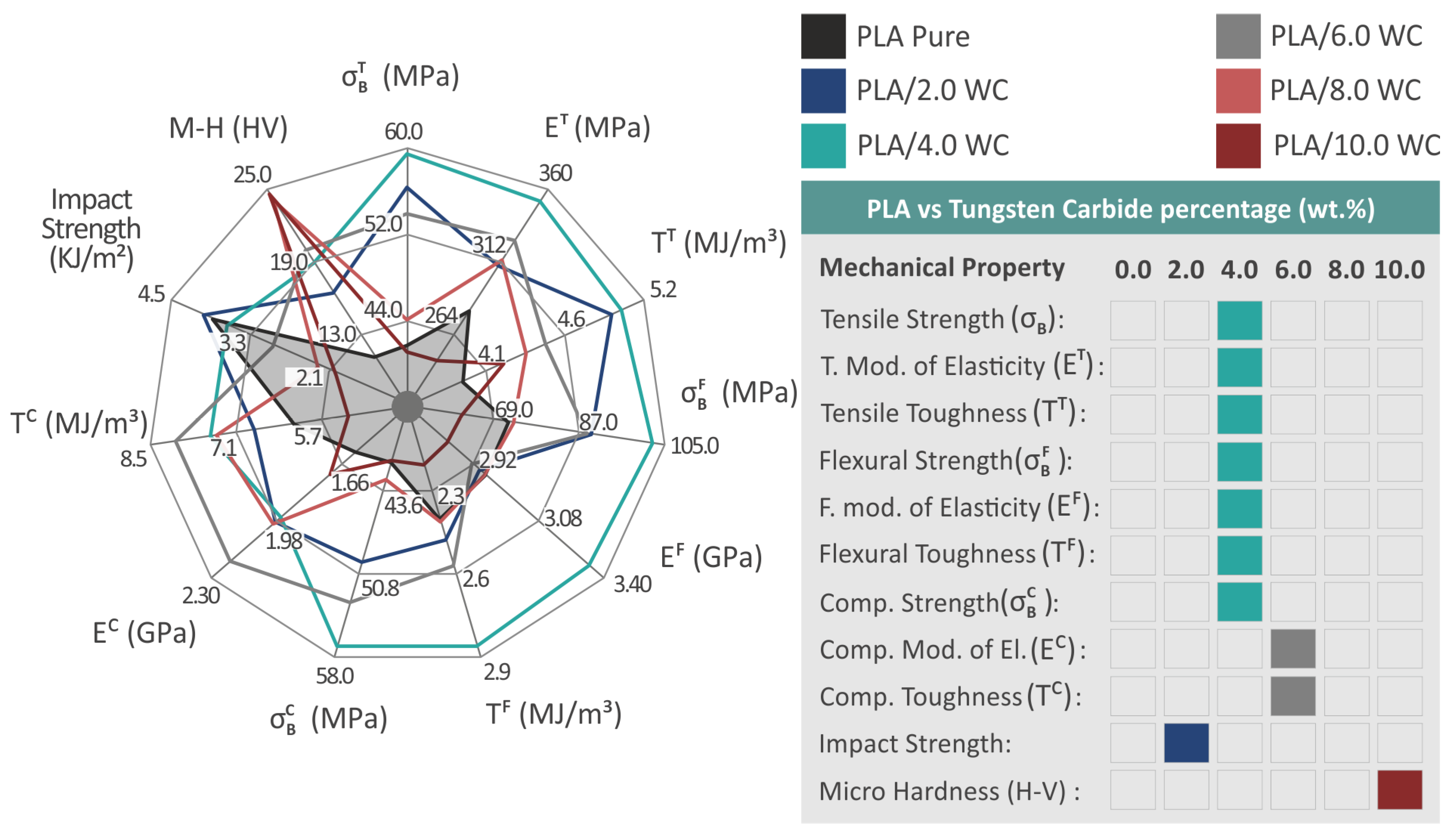

3.5. Evaluation of the 3D-Printed Specimens’ Mechanical Properties

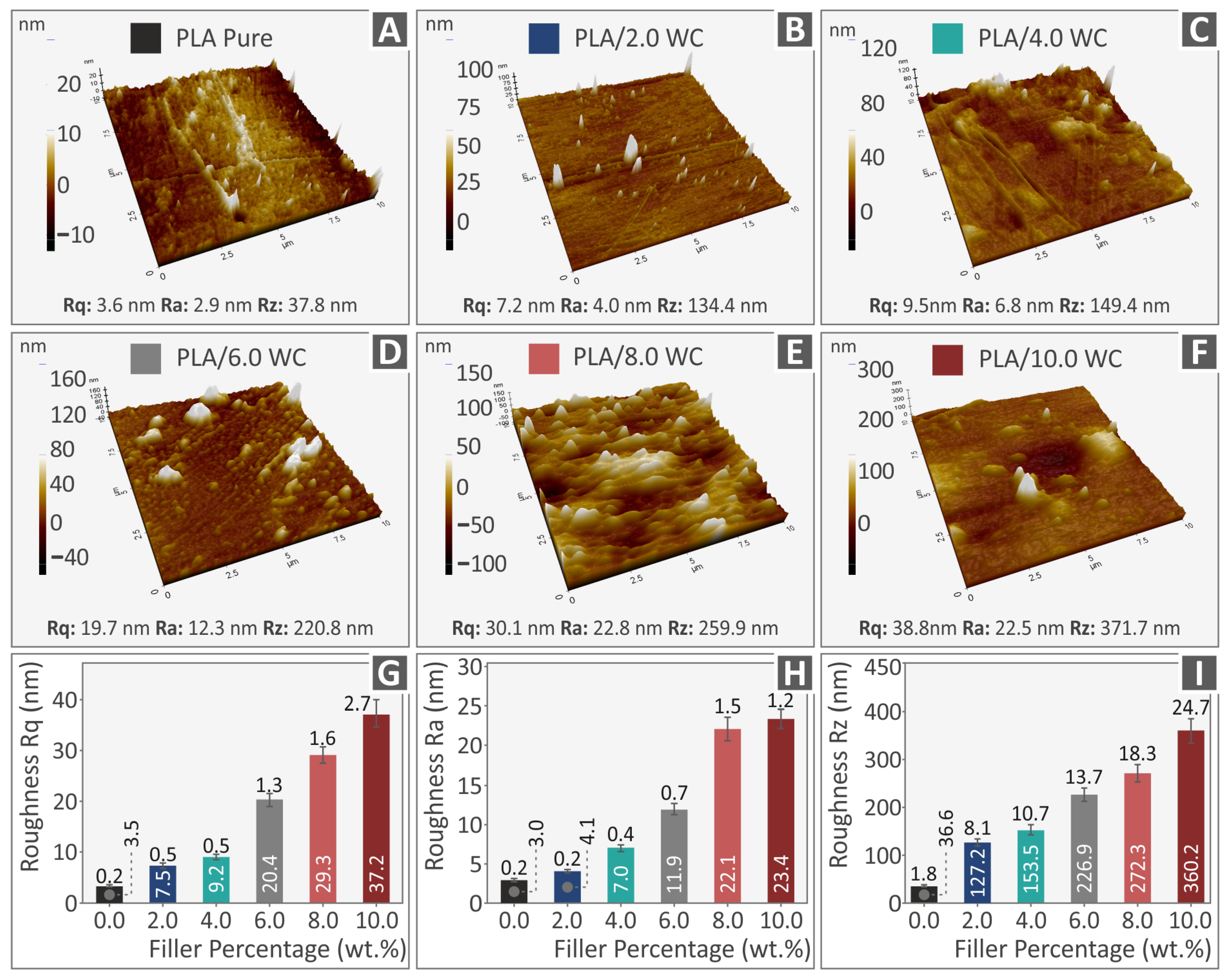

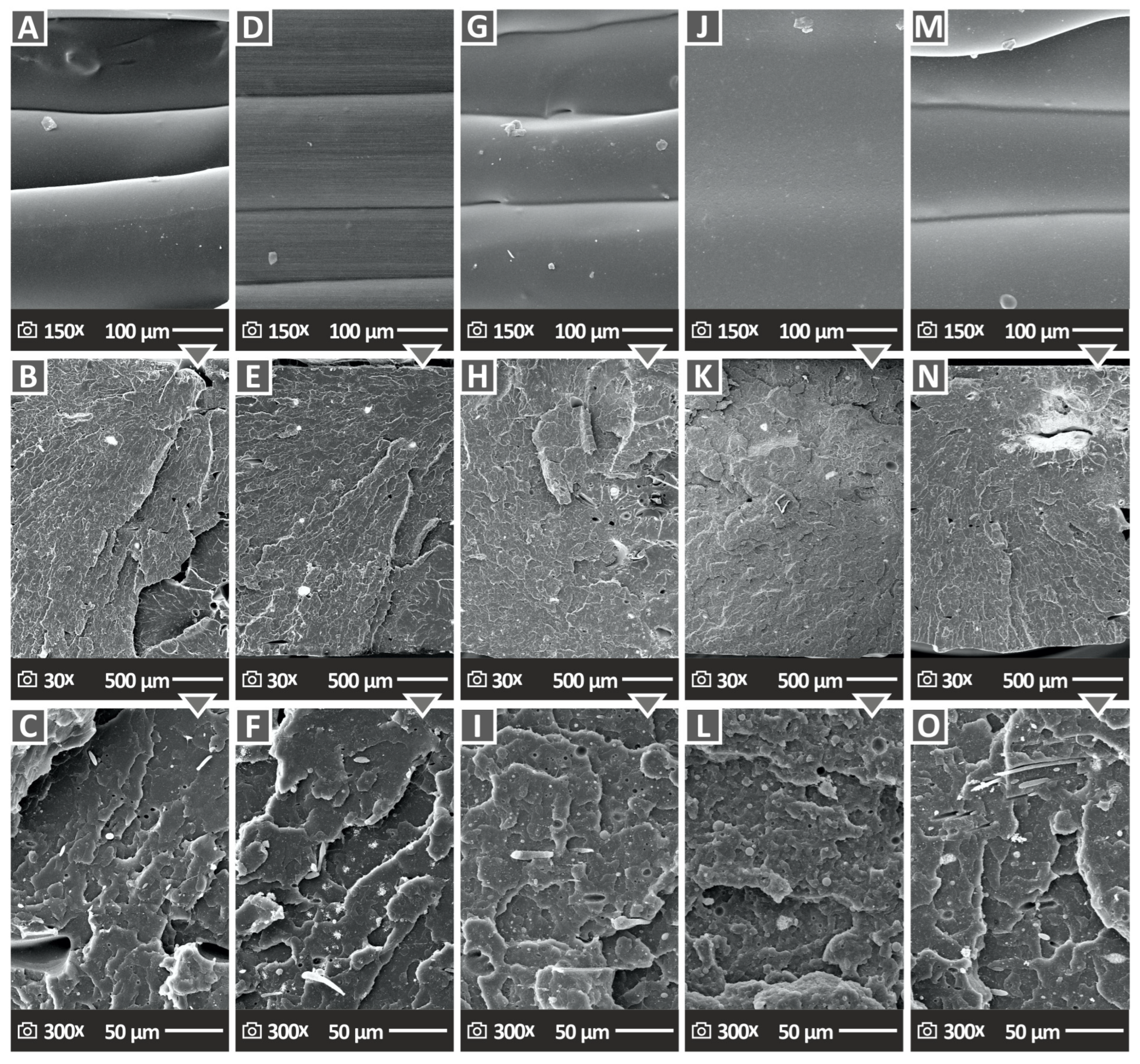

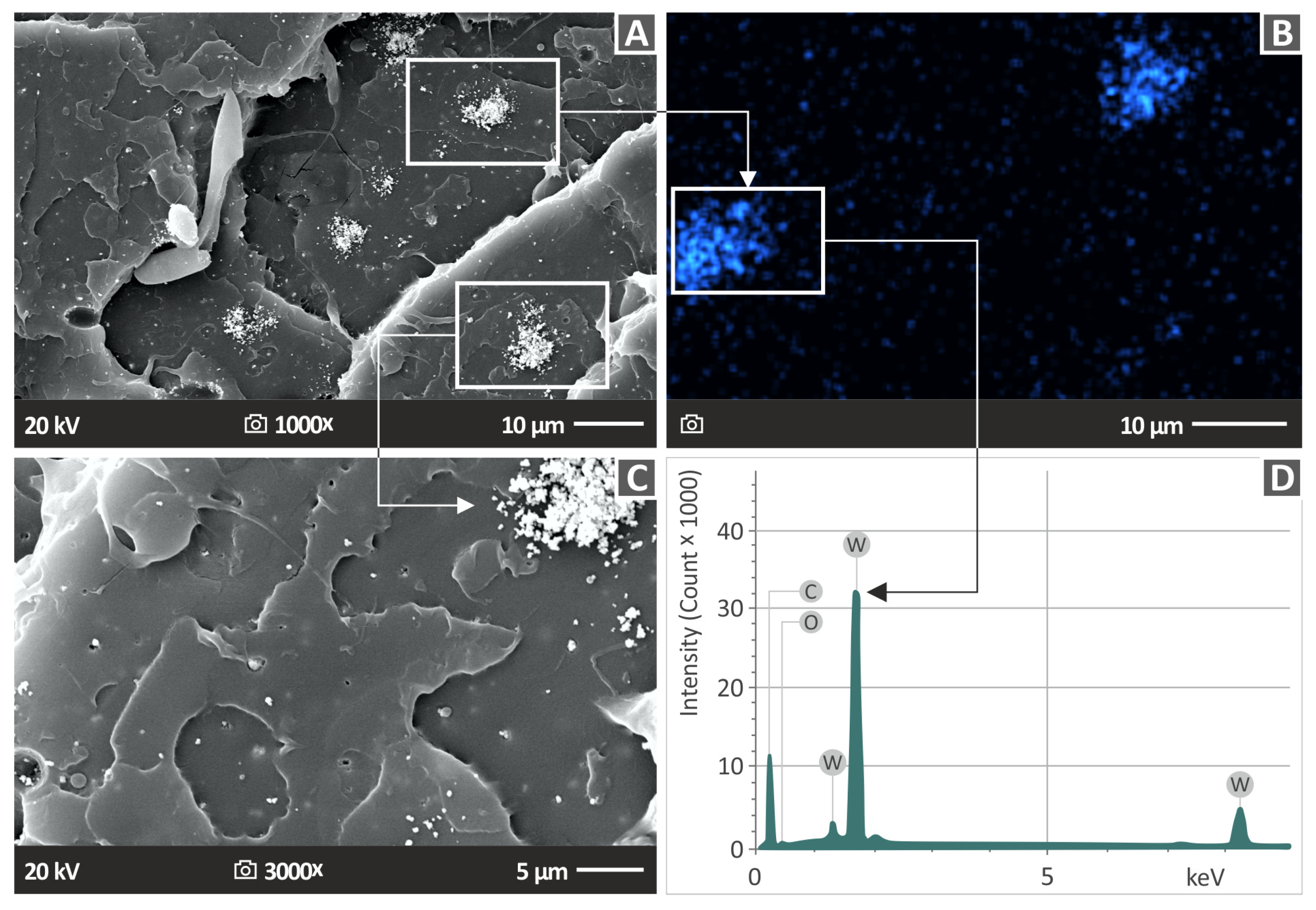

3.6. Three-Dimensionally Printed Specimens’ Morphological Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, N.; Leu, M.C. Additive Manufacturing: Technology, Applications and Research Needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Using Additive Manufacturing Applications for Design and Development of Food and Agricultural Equipments. Int. J. Mater. Prod. Technol. 2019, 58, 225–238. [Google Scholar] [CrossRef]

- Zgalat-Lozynskyy, O.B.; Matviichuk, O.O.; Tolochyn, O.I.; Ievdokymova, O.V.; Zgalat-Lozynska, N.O.; Zakiev, V.I. Polymer Materials Reinforced with Silicon Nitride Particles for 3D Printing. Powder Metall. Met. Ceram. 2021, 59, 515–527. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [PubMed]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical Parameters Influencing the Quality of Prototypes in Fused Deposition Modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Agarwala, M.K.; Jamalabad, V.R.; Langrana, N.A.; Safari, A.; Whalen, P.J.; Danforth, S.C. Structural Quality of Parts Processed by Fused Deposition. Rapid Prototyp. J. 1996, 2, 4–19. [Google Scholar] [CrossRef]

- Masood, S.H.; Song, W.Q. Development of New Metal/Polymer Materials for Rapid Tooling Using Fused Deposition Modelling. Mater. Des. 2004, 25, 587–594. [Google Scholar] [CrossRef]

- García Plaza, E.; Núñez López, P.J.; Caminero Torija, M.Á.; Chacón Muñoz, J.M. Analysis of PLA Geometric Properties Processed by FFF Additive Manufacturing: Effects of Process Parameters and Plate-Extruder Precision Motion. Polymers 2019, 11, 1581. [Google Scholar] [CrossRef]

- Pierre, J.; Iervolino, F.; Farahani, R.D.; Piccirelli, N.; Lévesque, M.; Therriault, D. Material Extrusion Additive Manufacturing of Multifunctional Sandwich Panels with Load-Bearing and Acoustic Capabilities for Aerospace Applications. Addit. Manuf. 2023, 61, 103344. [Google Scholar] [CrossRef]

- Pollard, D.; Ward, C.; Herrmann, G.; Etches, J. The Manufacture of Honeycomb Cores Using Fused Deposition Modeling. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 21–31. [Google Scholar] [CrossRef]

- Petousis, M.; Michailidis, N.; Papadakis, V.M.; Korlos, A.; Mountakis, N.; Argyros, A.; Dimitriou, E.; Charou, C.; Moutsopoulou, A.; Vidakis, N. Optimizing the Rheological and Thermomechanical Response of Acrylonitrile Butadiene Styrene/Silicon Nitride Nanocomposites in Material Extrusion Additive Manufacturing. Nanomaterials 2023, 13, 1588. [Google Scholar] [CrossRef] [PubMed]

- Fico, D.; Rizzo, D.; Casciaro, R.; Esposito Corcione, C. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Lubimyi, N.S.; Polshin, A.A.; Gerasimov, M.D.; Tikhonov, A.A.; Antsiferov, S.I.; Chetverikov, B.S.; Ryazantsev, V.G.; Brazhnik, J.; Ridvanov, İ. Justification of the Use of Composite Metal-Metal-Polymer Parts for Functional Structures. Polymers 2022, 14, 352. [Google Scholar] [CrossRef]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Moutsopoulou, A.; Papadakis, V.M.; Maravelakis, E. Emmanouel Maravelakis On the Substantial Mechanical Reinforcement of Polylactic Acid with Titanium Nitride Ceramic Nanofillers in Material Extrusion 3D Printing. Ceram. Int. 2023, 49, 16397–16411. [Google Scholar] [CrossRef]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Grammatikos, S.; Papadakis, V.; David, C.N.; Moutsopoulou, A.; Das, S.C. Silicon Carbide Nanoparticles as a Mechanical Boosting Agent in Material Extrusion 3D-Printed Polycarbonate. Polymers 2022, 14, 3492. [Google Scholar] [CrossRef] [PubMed]

- Colombo, P.; Bernardo, E.; Parcianello, G. Multifunctional Advanced Ceramics from Preceramic Polymers and Nano-Sized Active Fillers. J. Eur. Ceram. Soc. 2013, 33, 453–469. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic Material Properties of Fused Deposition Modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Rangarajan, S.; Qi, G.; Venkataraman, N.; Safari, A.; Danforth, S.C. Powder Processing, Rheology, and Mechanical Properties of Feedstock for Fused Deposition of Si3N4 Ceramics. J. Am. Ceram. Soc. 2000, 83, 1663–1669. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Tribological Behavior of Natural Fiber Reinforced PLA Composites. Wear 2013, 297, 829–840. [Google Scholar] [CrossRef]

- Nötzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef] [PubMed]

- Εkonomou, S.Ι.; Soe, S.; Stratakos, A.C. An Explorative Study on the Antimicrobial Effects and Mechanical Properties of 3D Printed PLA and TPU Surfaces Loaded with Ag and Cu against Nosocomial and Foodborne Pathogens. J. Mech. Behav. Biomed. Mater. 2023, 137, 105536. [Google Scholar] [CrossRef] [PubMed]

- Jašo, V.; Glenn, G.; Klamczynski, A.; Petrović, Z.S. Biodegradability Study of Polylactic Acid/ Thermoplastic Polyurethane Blends. Polym. Test. 2015, 47, 1–3. [Google Scholar] [CrossRef]

- Cao, Q.; Cai, Y.; Jing, B.; Liu, P. Structure and Mechanical Properties of Thermoplastic Polyurethane, Based on Hyperbranched Polyesters. J. Appl. Polym. Sci. 2006, 102, 5266–5273. [Google Scholar] [CrossRef]

- Choonara, Y.E.; du Toit, L.C.; Kumar, P.; Kondiah, P.P.D.; Pillay, V. 3D-Printing and the Effect on Medical Costs: A New Era? Expert. Rev. Pharmacoecon Outcomes Res. 2016, 16, 23–32. [Google Scholar] [CrossRef]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Karapidakis, E.; Moutsopoulou, A. Functionality Versus Sustainability for PLA in MEX 3D Printing: The Impact of Generic Process Control Factors on Flexural Response and Energy Efficiency. Polymers 2023, 15, 1232. [Google Scholar] [CrossRef]

- Doshi, M.; Mahale, A.; Kumar Singh, S.; Deshmukh, S. Printing Parameters and Materials Affecting Mechanical Properties of FDM-3D Printed Parts: Perspective and Prospects. Mater. Today Proc. 2022, 50, 2269–2275. [Google Scholar] [CrossRef]

- Vidakis, N.; David, C.; Petousis, M.; Sagris, D.; Mountakis, N.; Moutsopoulou, A. The Effect of Six Key Process Control Parameters on the Surface Roughness, Dimensional Accuracy, and Porosity in Material Extrusion 3D Printing of Polylactic Acid: Prediction Models and Optimization Supported by Robust Design Analysis. Adv. Ind. Manuf. Eng. 2022, 5, 100104. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Vidakis, N.; Petousis, M.; Mountakis, N. A Multi-Parametric Process Evaluation of the Mechanical Response of PLA in FFF 3D Printing. Mater. Manuf. Process. 2022, 38, 941–953. [Google Scholar] [CrossRef]

- Petousis, M.; Ninikas, K.; Vidakis, N.; Mountakis, N.; Kechagias, J.D. Multifunctional PLA/CNTs Nanocomposites Hybrid 3D Printing Integrating Material Extrusion and CO2 Laser Cutting. J. Manuf. Process. 2023, 86, 237–252. [Google Scholar] [CrossRef]

- De Bortoli, L.S.; de Farias, R.; Mezalira, D.Z.; Schabbach, L.M.; Fredel, M.C. Functionalized Carbon Nanotubes for 3D-Printed PLA-Nanocomposites: Effects on Thermal and Mechanical Properties. Mater. Today Commun. 2022, 31, 103402. [Google Scholar] [CrossRef]

- Chen, K.; Yu, L.; Cui, Y.; Jia, M.; Pan, K. Optimization of Printing Parameters of 3D-Printed Continuous Glass Fiber Reinforced Polylactic Acid Composites. Thin-Walled Struct. 2021, 164, 107717. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Vidakis, N.; Ninikas, K.; Petousis, M.; Vaxevanidis, N.M. Hybrid 3D Printing of Multifunctional Polylactic Acid/Carbon Black Nanocomposites Made with Material Extrusion and Post—Processed with CO2 Laser Cutting. Int. J. Adv. Manuf. Technol. 2022, 124, 1843–1861. [Google Scholar] [CrossRef]

- Tirado-Garcia, I.; Garcia-Gonzalez, D.; Garzon-Hernandez, S.; Rusinek, A.; Robles, G.; Martinez-Tarifa, J.M.; Arias, A. Conductive 3D Printed PLA Composites: On the Interplay of Mechanical, Electrical and Thermal Behaviours. Compos. Struct. 2021, 265, 113744. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kitek Kuzman, M. Effect of Printing Layer Thickness on Water Absorption and Mechanical Properties of 3D-Printed Wood/PLA Composite Materials. Int. J. Adv. Manuf. Technol. 2019, 102, 2195–2200. [Google Scholar] [CrossRef]

- Nonato, R.C.; Mei, L.H.I.; Bonse, B.C.; Leal, C.V.; Levy, C.E.; Oliveira, F.A.; Delarmelina, C.; Duarte, M.C.T.; Morales, A.R. Nanocomposites of PLA/ZnO Nanofibers for Medical Applications: Antimicrobial Effect, Thermal, and Mechanical Behavior under Cyclic Stress. Polym. Eng. Sci. 2022, 62, 1147–1155. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Ramezani Dana, H. Poly Lactic Acid (PLA) Polymers: From Properties to Biomedical Applications. Int. J. Polym. Mater. Polym. Biomater. 2022, 71, 1117–1130. [Google Scholar] [CrossRef]

- Vidakis, N.; Kalderis, D.; Petousis, M.; Maravelakis, E.; Mountakis, N.; Bolanakis, N.; Papadakis, V. Biochar Filler in MEX and VPP Additive Manufacturing: Characterization and Reinforcement Effects in Polylactic Acid and Standard Grade Resin Matrices. Biochar 2023, 5, 39. [Google Scholar] [CrossRef]

- Farias, N.C.; Major, I.; Devine, D.; Brennan Fournet, M.; Pezzoli, R.; Farshbaf Taghinezhad, S.; Hesabi, M. Multiple Recycling of a PLA/PHB Biopolymer Blend for Sustainable Packaging Applications: Rheology-Morphology, Thermal, and Mechanical Performance Analysis. Polym. Eng. Sci. 2022, 62, 1764–1774. [Google Scholar] [CrossRef]

- Yan, B.; Chen, K.; An, L. Enhanced Moderate Electric Field Dielectric Energy Storage Performance in (Bi0.5Na0.5)TiO3-Based Lead-Free Ceramics. Ceram. Int. 2022, 48, 37020–37026. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Vidakis, N.; Efstathiou, K.; Leyendecker, T.; Erkens, G.; Wenke, R.; Fuss, H.-G. Optimization of the Cutting Edge Radius of PVD Coated Inserts in Milling Considering Film Fatigue Failure Mechanisms. Surf. Coat. Technol. 2000, 133–134, 501–507. [Google Scholar] [CrossRef]

- Antoniadis, A.; Vidakis, N.; Bilalis, N. Fatigue Fracture Investigation of Cemented Carbide Tools in Gear Hobbing, Part 2: The Effect of Cutting Parameters on the Level of Tool Stresses—A Quantitative Parametric Analysis. J. Manuf. Sci. Eng. 2002, 124, 792–798. [Google Scholar] [CrossRef]

- Chaudhary, R.P.; Parameswaran, C.; Idrees, M.; Rasaki, A.S.; Liu, C.; Chen, Z.; Colombo, P. Additive Manufacturing of Polymer-Derived Ceramics: Materials, Technologies, Properties and Potential Applications. Prog. Mater. Sci. 2022, 128, 100969. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Sarraf, F.; Abbatinali, E.; Gorjan, L.; Sebastian, T.; Colombo, P.; Churakov, S.V.; Clemens, F. Effect of MgO Sintering Additive on Mullite Structures Manufactured by Fused Deposition Modeling (FDM) Technology. J. Eur. Ceram. Soc. 2021, 41, 6677–6686. [Google Scholar] [CrossRef]

- Ravikumar, K.; Kiran, K.; Sreebalaji, V.S. Characterization of Mechanical Properties of Aluminium/Tungsten Carbide Composites. Measurement 2017, 102, 142–149. [Google Scholar] [CrossRef]

- Visconti, I.C.; Langella, A.; Durante, M. The Wear Behaviour of Composite Materials with Epoxy Matrix Filled with Hard Powder. Appl. Compos. Mater. 2001, 8, 179–189. [Google Scholar] [CrossRef]

- Mohan, N.; Mahesha, C.R.; Rajaprakash, B.M. Erosive Wear Behaviour of WC Filled Glass Epoxy Composites. Procedia Eng. 2013, 68, 694–702. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Al-Ghamdi, H.; Almuqrin, A.H.; Yasmin, S.; Elsafi, M. A Study on the Gamma Radiation Protection Effectiveness of Nano/Micro-MgO-Reinforced Novel Silicon Rubber for Medical Applications. Polymers 2022, 14, 2867. [Google Scholar] [CrossRef]

- Azman, M.N.; Abualroos, N.J.; Yaacob, K.A.; Zainon, R. Feasibility of Nanomaterial Tungsten Carbide as Lead-Free Nanomaterial-Based Radiation Shielding. Radiat. Phys. Chem. 2023, 202, 110492. [Google Scholar] [CrossRef]

- Padmakumar, M. Additive Manufacturing of Tungsten Carbide Hardmetal Parts by Selective Laser Melting (SLM), Selective Laser Sintering (SLS) and Binder Jet 3D Printing (BJ3DP) Techniques. Lasers Manuf. Mater. Process. 2020, 7, 338–371. [Google Scholar] [CrossRef]

- Wolfe, T.; Shah, R.; Prough, K.; Trasorras, J.L. Coarse Cemented Carbide Produced via Binder Jetting 3D Printing. Int. J. Refract. Metals Hard Mater. 2023, 110, 106016. [Google Scholar] [CrossRef]

- Li, Y.; Chiovelli, S.; Remesat, D.; Rideout, B.; Ivey, M.; Serate, D.; Yuen, S.; Doucette, B.; Waldbillig, D. 3D Printing of Wear-Resistant Materials: A Review and Perspectives in Oil Sands Applications. In Proceedings of the AMPP Annual Conference + Expo, San Antonio, TX, USA, 6 March 2022. [Google Scholar]

- Wolfe, T.A.; Shah, R.M.; Prough, K.C.; Trasorras, J.L. Binder Jetting 3D Printed Cemented Carbide: Mechanical and Wear Properties of Medium and Coarse Grades. Int. J. Refract. Met. Hard Mater. 2023, 113, 106197. [Google Scholar] [CrossRef]

- Vidakis, N.; Moutsopoulou, A.; Petousis, M.; Michailidis, N.; Charou, C.; Papadakis, V.; Mountakis, N.; Dimitriou, E.; Argyros, A. Rheology and Thermomechanical Evaluation of Additively Manufactured Acrylonitrile Butadiene Styrene (ABS) with Optimized Tungsten Carbide (WC) Nano-Ceramic Content. Ceram. Int. 2023, in press. [CrossRef]

- ASTM D638-02a; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM D790-10; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D6110-02; Standard Test Methods for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM D695; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D1238-13; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM International: West Conshohocken, PA, USA, 2020.

- Gong, X.; Pan, L.; Tang, C.Y.; Chen, L.; Li, C.; Wu, C.; Law, W.-C.; Wang, X.; Tsui, C.P.; Xie, X. Investigating the Crystallization Behavior of Poly(Lactic Acid) Using CdSe/ZnS Quantum Dots as Heterogeneous Nucleating Agents. Compos. B Eng. 2016, 91, 103–110. [Google Scholar] [CrossRef]

- Huang, J.W.; Hung, Y.C.; Wen, Y.L.; Kang, C.C.; Yeh, M.Y. Polylactide/Nano-and Micro-Scale Silica Composite Films. II. Melting Behavior and Cold Crystallization. J. Appl. Polym. Sci. 2009, 112, 3149–3156. [Google Scholar] [CrossRef]

- Malinowski, R.; Janczak, K.; Rytlewski, P.; Raszkowska-Kaczor, A.; Moraczewski, K.; Żuk, T. Influence of Glass Microspheres on Selected Properties of Polylactide Composites. Compos. B Eng. 2015, 76, 13–19. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, G.; Wang, G. Investigation on the α/δ Crystal Transition of Poly(l-Lactic Acid) with Different Molecular Weights. Polymers 2021, 13, 3280. [Google Scholar] [CrossRef]

- Tee, Y.B.; Talib, R.A.; Abdan, K.; Chin, N.L.; Basha, R.K.; Yunos, K.F.M. Effect of Aminosilane Concentrations on the Properties of Poly(Lactic Acid)/Kenaf-Derived Cellulose Composites. Polym. Polym. Compos. 2017, 25, 63–76. [Google Scholar] [CrossRef]

- Pei, A.; Zhou, Q.; Berglund, L.A. Functionalized Cellulose Nanocrystals as Biobased Nucleation Agents in Poly(l-Lactide) (PLLA)—Crystallization and Mechanical Property Effects. Compos. Sci. Technol. 2010, 70, 815–821. [Google Scholar] [CrossRef]

- Farid, T.; Herrera, V.N.; Kristiina, O. Investigation of Crystalline Structure of Plasticized Poly (Lactic Acid)/Banana Nanofibers Composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 369, 12031. [Google Scholar] [CrossRef]

- Bassett, D.C.; Olley, R.H.; Al Raheil, I.A.M. On Crystallization Phenomena in PEEK. Polymer 1988, 29, 1745–1754. [Google Scholar] [CrossRef]

- Jonas, A.M.; Russell, T.P.; Yoon, D.Y. Synchrotron X-ray Scattering Studies of Crystallization of Poly(Ether-Ether-Ketone) from the Glass and Structural Changes during Subsequent Heating-Cooling Processes. Macromolecules 1995, 28, 8491–8503. [Google Scholar] [CrossRef]

- Gracia-Fernández, C.A.; Gómez-Barreiro, S.; López-Beceiro, J.; Naya, S.; Artiaga, R. New Approach to the Double Melting Peak of Poly(l-Lactic Acid) Observed by DSC. J. Mater. Res. 2012, 27, 1379–1382. [Google Scholar] [CrossRef]

- Arrigo, R.; Frache, A. FDM Printability of PLA Based-Materials: The Key Role of the Rheological Behavior. Polymers 2022, 14, 1754. [Google Scholar] [CrossRef]

- Yin, X.; Hong, L.; Liu, Z. A Study on the Fundamental Ceramic–Polymer Interactions in the High CeO2-Loading Polyethylene Glycol Blend. J. Eur. Ceram. Soc. 2005, 25, 3097–3107. [Google Scholar] [CrossRef]

- Xie, D.; Zhao, Y.; Li, Y.; LaChance, A.M.; Lai, J.; Sun, L.; Chen, J. Rheological, Thermal, and Degradation Properties of PLA/PPG Blends. Materials 2019, 12, 3519. [Google Scholar] [CrossRef]

- Cipriano, T.F.; Da Silva, A.L.N.; Da Fonseca Thomé Da Silva, A.H.M.; De Sousa, A.M.F.; Da Silva, G.M.; Rocha, M.G. Thermal, Rheological and Morphological Properties of Poly (Lactic Acid) (PLA) and Talc Composites. Polimeros 2014, 24, 276–282. [Google Scholar] [CrossRef]

- Lin, Z.; Guo, X.; He, Z.; Liang, X.; Wang, M.; Jin, G. Thermal Degradation Kinetics Study of Molten Polylactide Based on Raman Spectroscopy. Polym. Eng. Sci. 2021, 61, 201–210. [Google Scholar] [CrossRef]

- Resta, V.; Quarta, G.; Lomascolo, M.; Maruccio, L.; Calcagnile, L. Raman and Photoluminescence Spectroscopy of Polycarbonate Matrices Irradiated with Different Energy 28Si+ Ions. Vacuum 2015, 116, 82–89. [Google Scholar] [CrossRef]

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive Characterization of the Polycarbonate—Octadecylamine Interface by Surface Enhanced Raman Spectroscopy. Polym. Test. 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Stuart, B.H. Temperature Studies of Polycarbonate Using Fourier Transform Raman Spectroscopy. Polym. Bull. 1996, 36, 341–346. [Google Scholar] [CrossRef]

- Zou, H.; Yi, C.; Wang, L.; Liu, H.; Xu, W. Thermal Degradation of Poly(Lactic Acid) Measured by Thermogravimetry Coupled to Fourier Transform Infrared Spectroscopy. J. Therm. Anal. Calorim. 2009, 97, 929–935. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing Cellulose Structures with Vibrational Spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Liu, X.; Zou, Y.; Li, W.; Cao, G.; Chen, W. Kinetics of Thermo-Oxidative and Thermal Degradation of Poly(d,l-Lactide) (PDLLA) at Processing Temperature. Polym. Degrad. Stab. 2006, 91, 3259–3265. [Google Scholar] [CrossRef]

- Yasa, E.; Ersoy, K. Dimensional Accuracy and Mechanical Properties of Chopped Carbon Reinforced Polymers Produced by Material Extrusion Additive Manufacturing. Materials 2019, 12, 3885. [Google Scholar] [CrossRef]

- Vidakis, N.; Mangelis, P.; Petousis, M.; Mountakis, N.; Papadakis, V.; Moutsopoulou, A.; Tsikritzis, D. Mechanical Reinforcement of ABS with Optimized Nano Titanium Nitride Content for Material Extrusion 3D Printing. Nanomaterials 2023, 13, 669. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Fracture Behavior of 3D Printed Carbon Fiber-Reinforced Polymer Composites. Compos. Sci. Technol. 2021, 208, 108741. [Google Scholar] [CrossRef]

- Mostafa, S.A.; Faried, A.S.; Farghali, A.A.; EL-Deeb, M.M.; Tawfik, T.A.; Majer, S.; Abd Elrahman, M. Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC. Materials 2020, 13, 4530. [Google Scholar] [CrossRef]

- Tamayo-Vegas, S.; Muhsan, A.; Liu, C.; Tarfaoui, M.; Lafdi, K. The Effect of Agglomeration on the Electrical and Mechanical Properties of Polymer Matrix Nanocomposites Reinforced with Carbon Nanotubes. Polymers 2022, 14, 1842. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Wu, Y.; Li, J.; Peng, X.; Yin, D.; Wang, J.; Wang, X.; Jin, M.; Yao, Z.; Shen, X.; et al. Toughening and Heat-Resistant Modification of Degradable PLA/PBS-Based Composites by Using Glass Fiber/Silicon Dioxide Hybrid Fillers. Polymers 2022, 14, 3237. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.P.; Zhang, M.; Chan, D. Toughening of a Brittle Thermosetting Polymer: Effects of Reinforcement Particle Size and Volume Fraction. J. Mater. Sci. 2002, 37, 781–788. [Google Scholar] [CrossRef]

- Mittal, G.; Rhee, K.Y.; Mišković-Stanković, V.; Hui, D. Reinforcements in Multi-Scale Polymer Composites: Processing, Properties, and Applications. Compos. B Eng. 2018, 138, 122–139. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef]

- Liu, H.; Brinson, L.C. Reinforcing Efficiency of Nanoparticles: A Simple Comparison for Polymer Nanocomposites. Compos. Sci. Technol. 2008, 68, 1502–1512. [Google Scholar] [CrossRef]

- George, S.; Joseph, R.; Thomas, S.; Varughese, K.T. Blends of Isotactic Polypropylene and Nitrile Rubber: Morphology, Mechanical Properties and Compatibilization. Polymer 1995, 36, 4405–4416. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. A Simulation Work for the Influences of Aggregation/Agglomeration of Clay Layers on the Tensile Properties of Nanocomposites. JOM 2019, 71, 3989–3995. [Google Scholar] [CrossRef]

- Shahramforouz, F.; Hejazi, S.M.; Taherizadeh, A. Evaluating the Tribological and Mechanical Properties of Filament Wound Composite Incorporated with PTFE Fibers and Tungsten Carbide Filler Applicable for Self-Lubricating Bearings. Surf. Topogr. 2021, 9, 35039. [Google Scholar] [CrossRef]

- Ullegaddi, K.; Shivarudraiah, R.M.C. Significance of Tungsten Carbide Filler Reinforcement on Ultimate Tensile Strength of Basalt Fiber Epoxy Composites. Int. J. Recent Technol. Eng. 2020, 8, 7913–7916. [Google Scholar] [CrossRef]

| Tg (°C) | Tc (°C) | Tm (°C) | ΔHc (J/g) | ΔHm (J/g) | Xc (%) | |

|---|---|---|---|---|---|---|

| PLA Pure | 59.47 | 89.37 | 150.68 | −11.117 | 30.473 | 20.81 |

| PLA/2.0 WC | 59.57 | 120.47 | 151.82 | −6.9015 | 24.608 | 21.24 |

| PLA/4.0 WC | 58.89 | 121.91 | 151.92 | −5.8795 | 21.054 | 21.68 |

| PLA/6.0 WC | 60.15 | 123.55 | 152.41 | −3.5875 | 15.599 | 22.14 |

| PLA/8.0 WC | 59.91 | 122.39 | 152.06 | −5.0402 | 21.534 | 22.62 |

| PLA/10.0 WC | 59.83 | 123.21 | 151.83 | −7.4067 | 19.716 | 23.13 |

| Wave Number (cm−1) | Intensity | Raman Peak Assignment |

|---|---|---|

| 870 | Medium | C-COO stretching [75] |

| 1040 | Small | C-CH3 stretching [75] |

| 1059 | Small | C−C asymmetric stretching |

| 1126 | Medium | C-O-C stretching [76] |

| 1293 | Medium | C-O-C stretching [76]; C-H2 twisting [77] |

| 1413 | Small | C-H3 deformation [78] |

| 1437 | Medium | C-H3 deformation [78] C-H2 deformation [77] |

| 1457 | Medium | C-H3 symmetric bending [75,76]; C-H2 twisting [77] |

| 1770 | Medium | C=O stretching [75,76] |

| 2721 | Small | C=O stretching [79] |

| 2845 | Major | C-H2 symmetric stretching [80] |

| 2880 | Major | C-H2 symmetric stretching [80]; C-H symmetric stretching [81] |

| 2945 | Major | C-H2 asymmetric stretching [80] |

| 3000 | Medium | C-H3 asymmetric stretch [81] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Moutsopoulou, A.; Petousis, M.; Michailidis, N.; Charou, C.; Mountakis, N.; Argyros, A.; Papadakis, V.; Dimitriou, E. Medical-Grade PLA Nanocomposites with Optimized Tungsten Carbide Nanofiller Content in MEX Additive Manufacturing: A Rheological, Morphological, and Thermomechanical Evaluation. Polymers 2023, 15, 3883. https://doi.org/10.3390/polym15193883

Vidakis N, Moutsopoulou A, Petousis M, Michailidis N, Charou C, Mountakis N, Argyros A, Papadakis V, Dimitriou E. Medical-Grade PLA Nanocomposites with Optimized Tungsten Carbide Nanofiller Content in MEX Additive Manufacturing: A Rheological, Morphological, and Thermomechanical Evaluation. Polymers. 2023; 15(19):3883. https://doi.org/10.3390/polym15193883

Chicago/Turabian StyleVidakis, Nectarios, Amalia Moutsopoulou, Markos Petousis, Nikolaos Michailidis, Chrysa Charou, Nikolaos Mountakis, Apostolos Argyros, Vassilis Papadakis, and Evgenia Dimitriou. 2023. "Medical-Grade PLA Nanocomposites with Optimized Tungsten Carbide Nanofiller Content in MEX Additive Manufacturing: A Rheological, Morphological, and Thermomechanical Evaluation" Polymers 15, no. 19: 3883. https://doi.org/10.3390/polym15193883

APA StyleVidakis, N., Moutsopoulou, A., Petousis, M., Michailidis, N., Charou, C., Mountakis, N., Argyros, A., Papadakis, V., & Dimitriou, E. (2023). Medical-Grade PLA Nanocomposites with Optimized Tungsten Carbide Nanofiller Content in MEX Additive Manufacturing: A Rheological, Morphological, and Thermomechanical Evaluation. Polymers, 15(19), 3883. https://doi.org/10.3390/polym15193883