Comparison of Mechanical Properties of Ductile/Brittle Epoxy Resin BFRP-AL Joints under Different Immersion Solutions

Abstract

:1. Introduction

2. Experimental Process

2.1. Material Selection

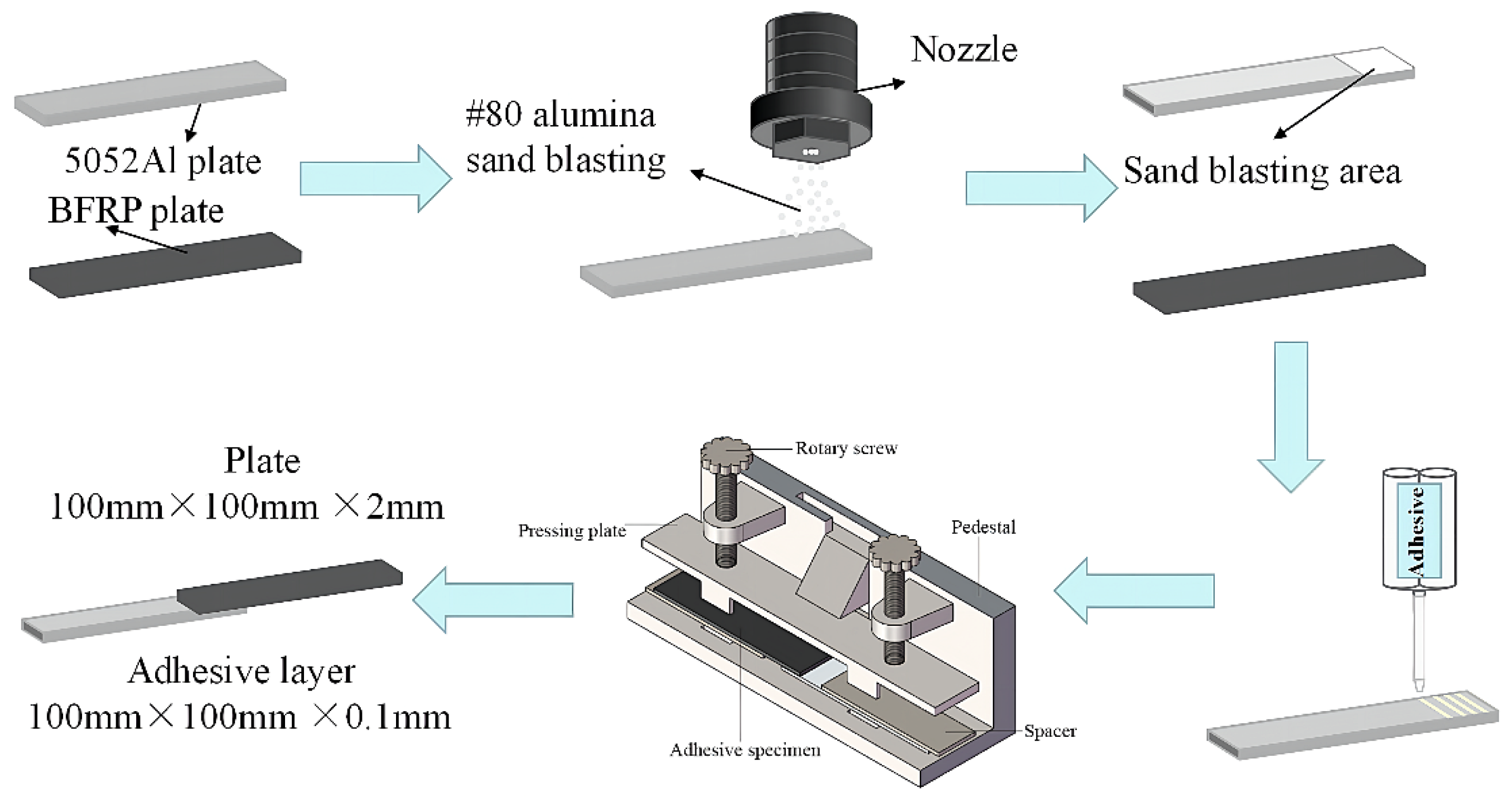

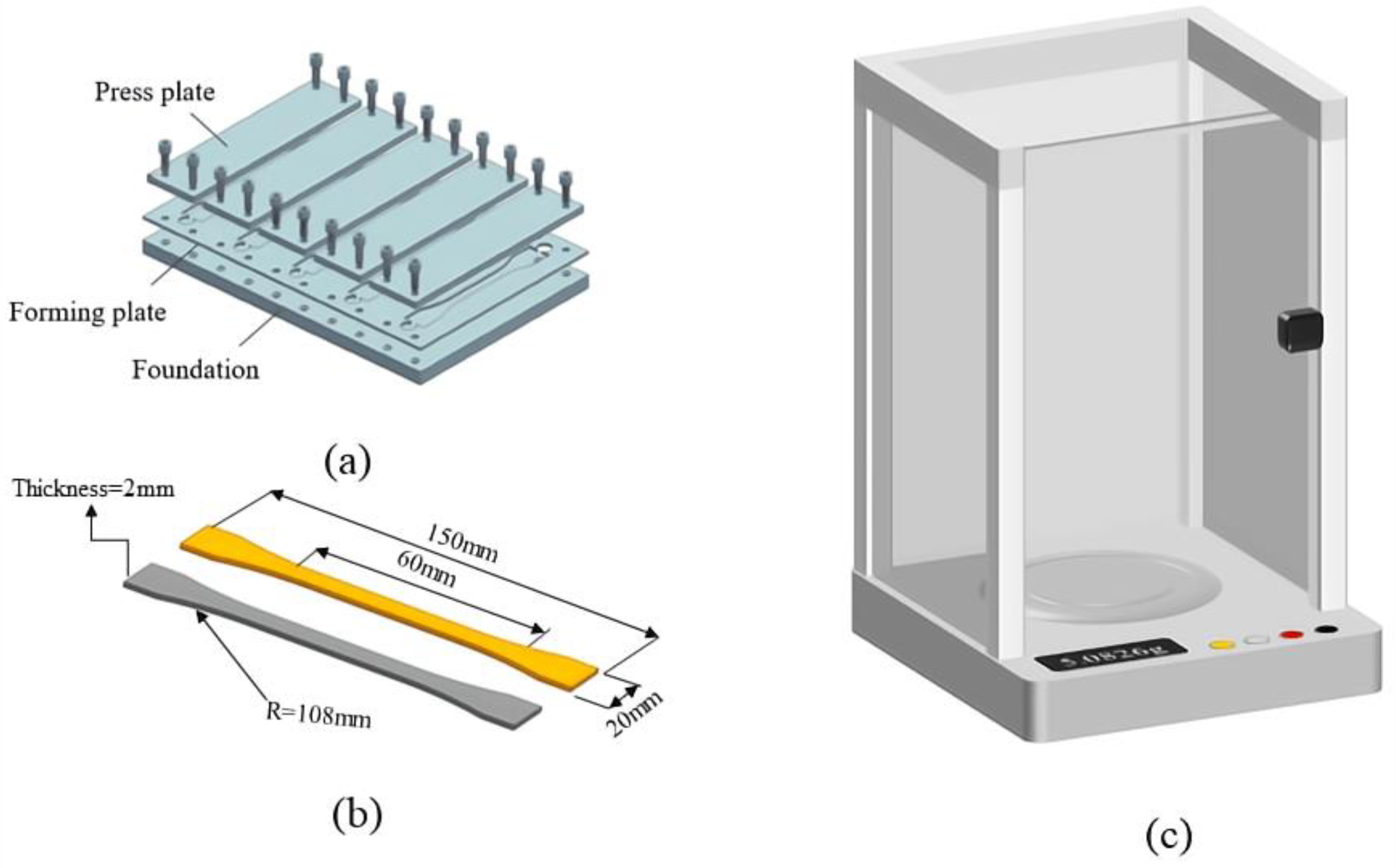

2.2. Preparation of Test Specimen

2.3. Experimental Scheme

2.3.1. Experimental Design

2.3.2. Quasi-Static Strength Test

2.3.3. Water Absorption Test

2.3.4. Glass Transition Temperature Test

2.3.5. Fourier Transform Infrared Spectroscopy

3. Results and Discussion

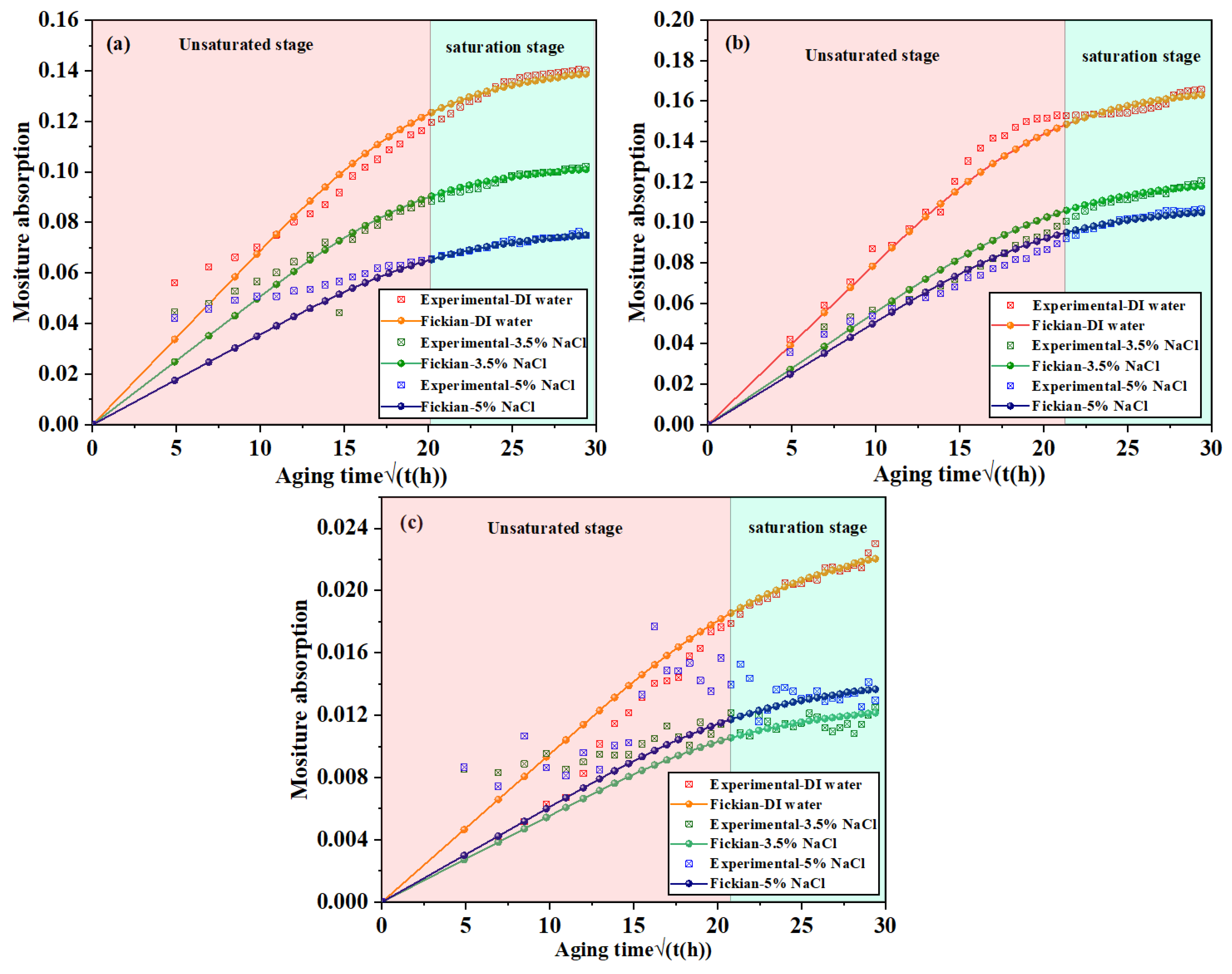

3.1. Moisture Absorption Analysis of Dog-Bone Tensile Sample

3.2. Differential Scanning Calorimetry Analysis

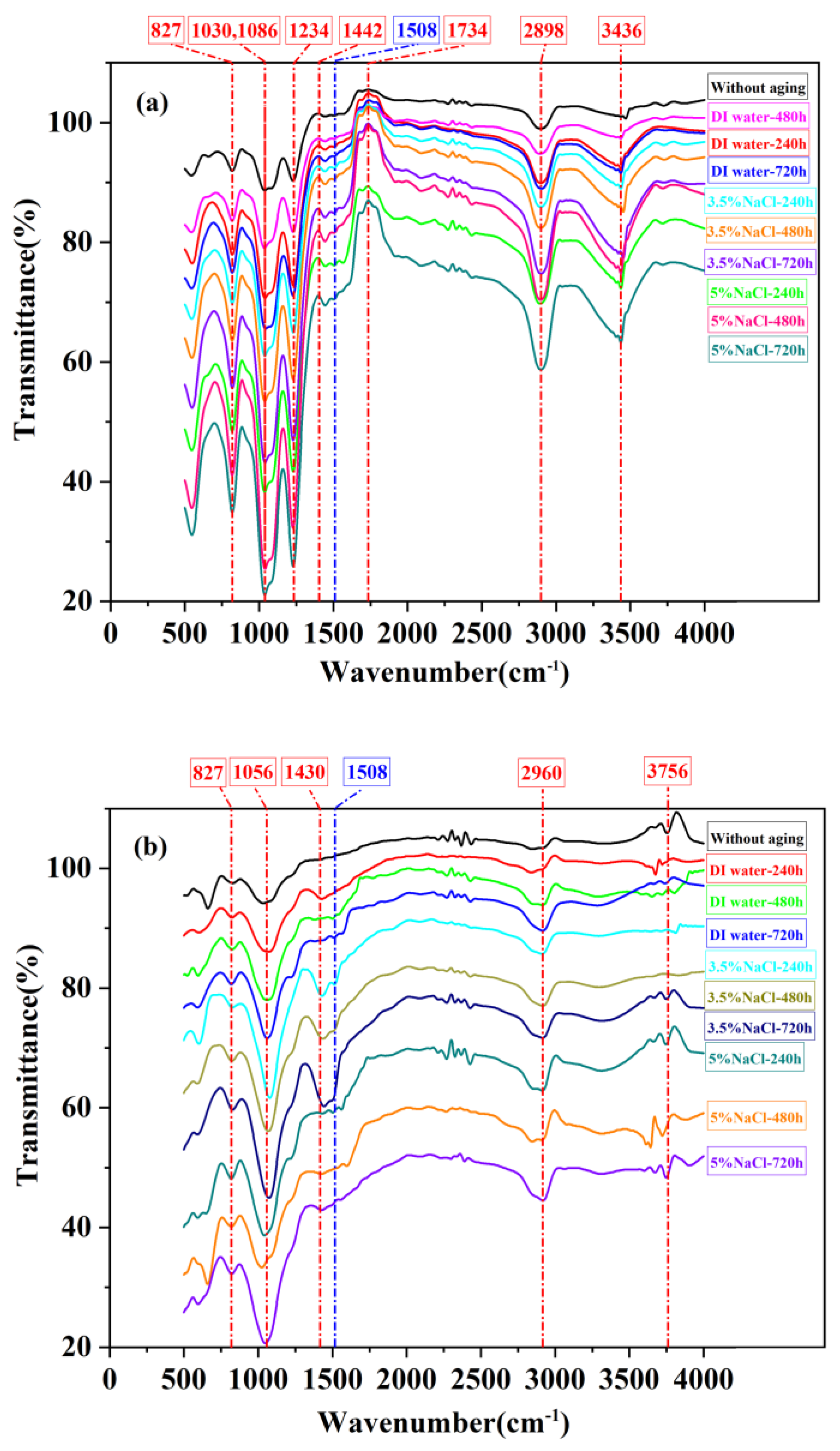

3.3. Fourier Infrared Spectrometer Analysis

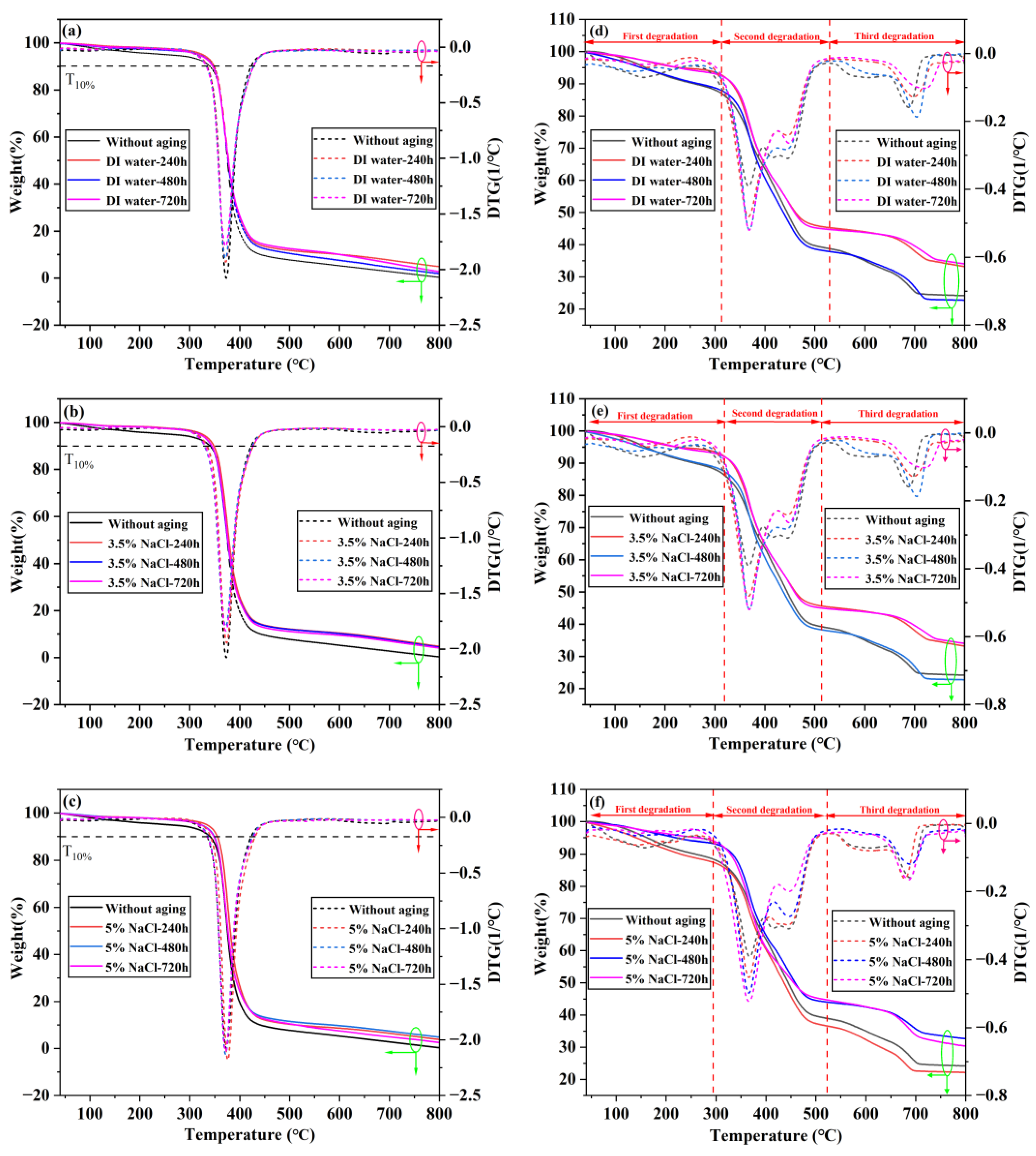

3.4. TGA-DTG Analysis

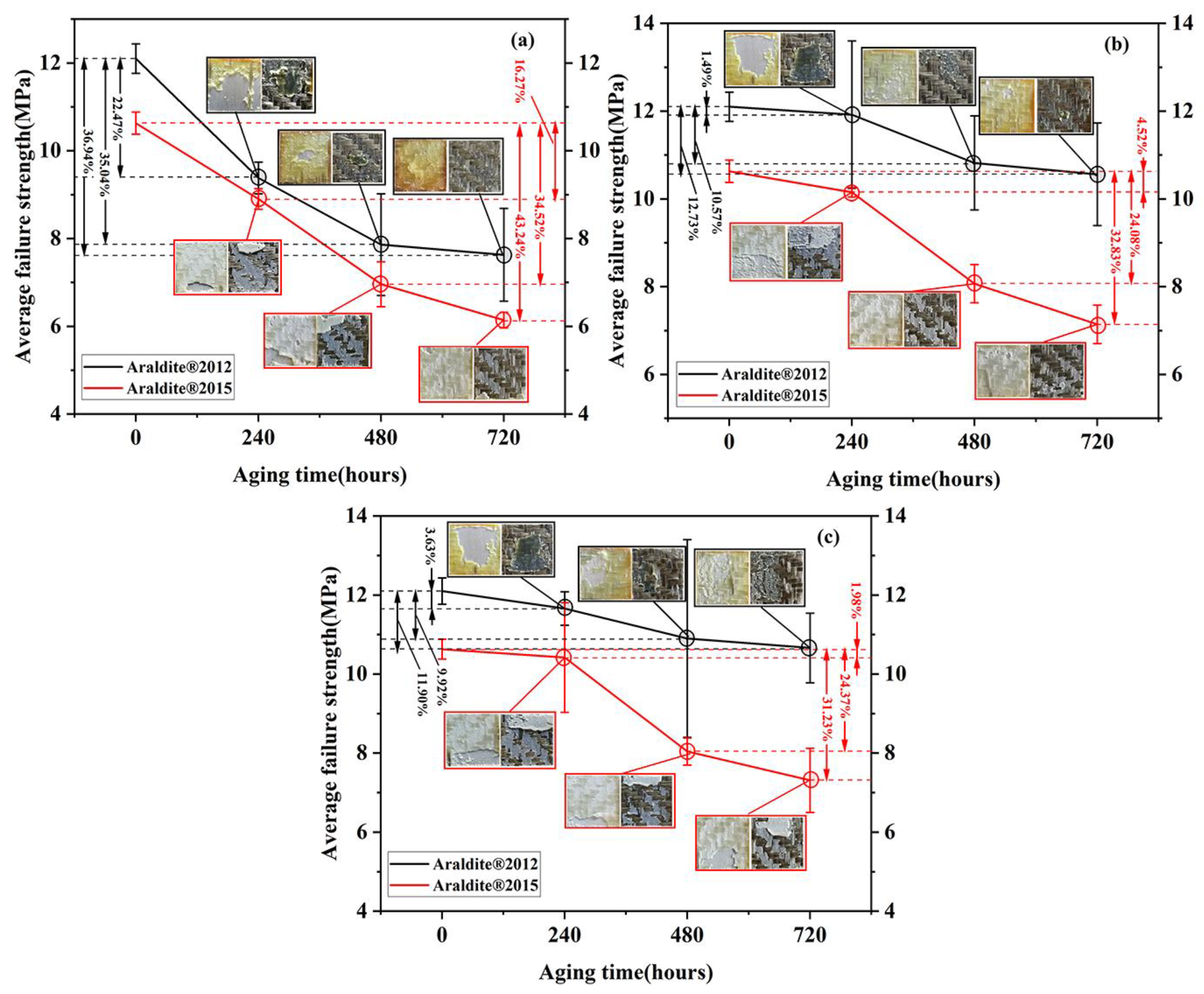

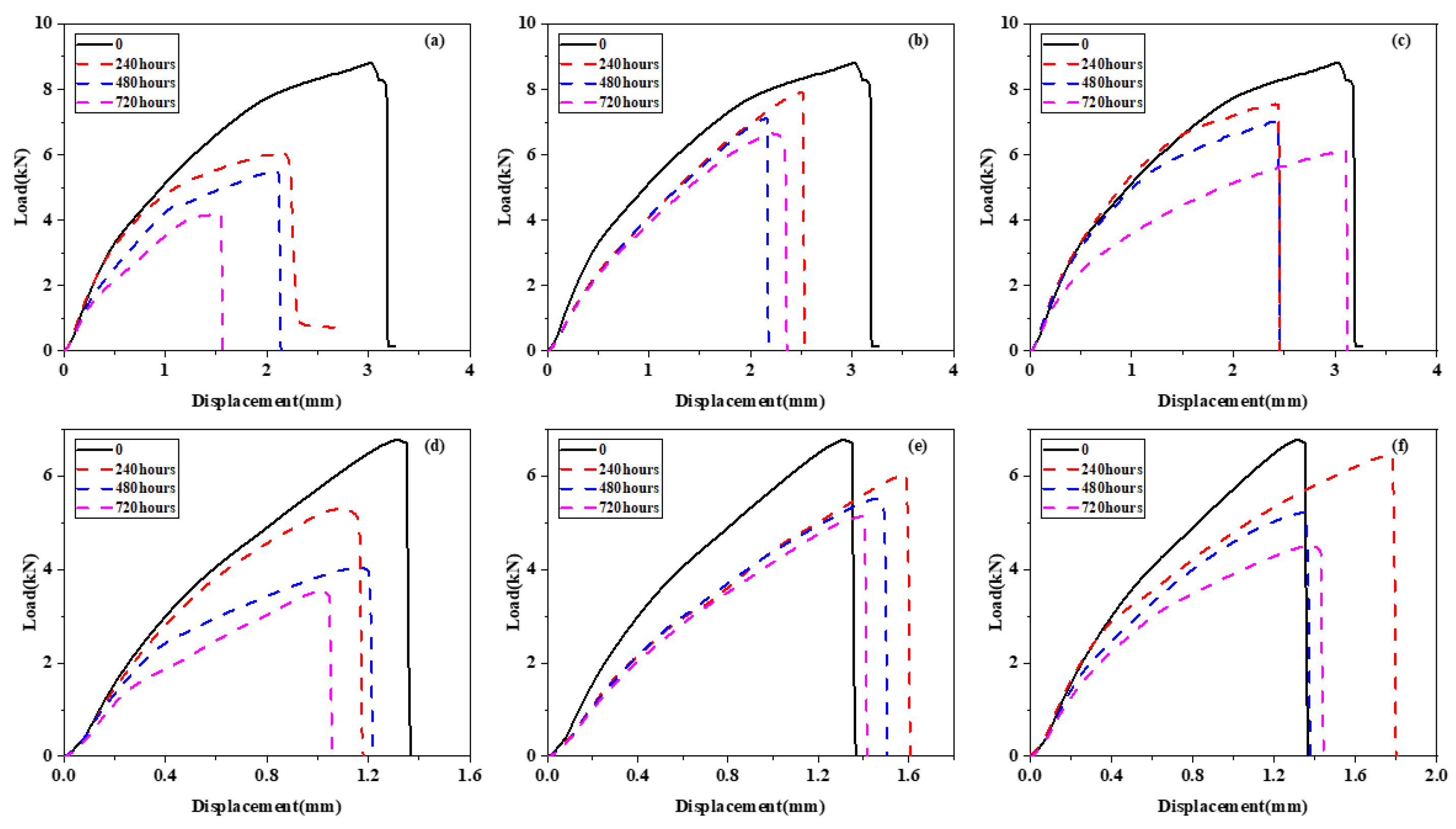

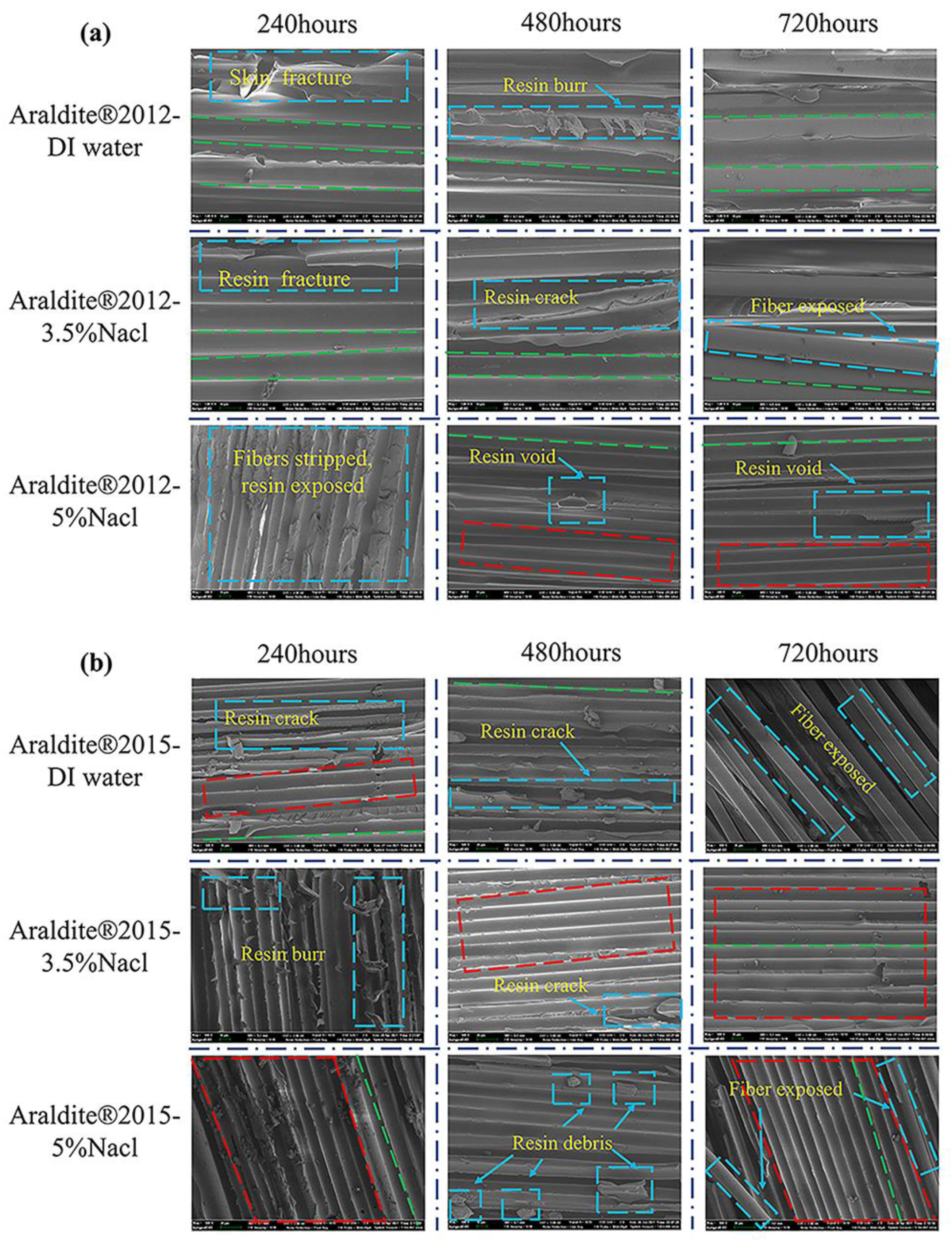

3.5. Failure Strength Analysis of Adhesive Joints

4. Conclusions

- In terms of average failure strength, the initial average failure strength of Araldite® 2012 adhesives is relatively higher than Araldite® 2015 adhesives. Within 0–480 h, the destruction strength of the two adhesives decreases significantly. In the salt solution environment, the average failure strength of the two adhesives increases, and the period of maximum decline in failure strength is delayed, from 0 to 480 h. As for stiffness, Araldite® 2012 can withstand larger loads and displacements than Araldite® 2015, and the stiffness attenuation of the two epoxy adhesives mainly occurs from 0–240 h. In terms of failure image, with the aging time prolongation, the Araldite® 2012 adhesive joint changes from interface failure to tear failure, while the Araldite® 2015 adhesive joint has both interface failure and tear failure during aging, and there is still a thin layer of adhesive on the part of the tear surface. Scanning electron microscopy (SEM) images of both Araldite® 2012 and Araldite® 2015 joints showed fiber withdrawal and resin damage due to tensile destruction.

- In the water absorption test, it can be seen that the moisture absorption of Araldite® 2015 bulk adhesive is higher than that of Araldite® 2012, and moisture absorption periods are also concentrated in 0–240 h.

- From the test characterization, FTIR images show that the two adhesives belong to epoxy adhesives, so the group absorption peaks are similar, and both have hydrolysis of ester groups. However, due to the differences in composition, absorption peaks are still different. The absorption peaks of the two adhesives decrease with the aging time. As can be seen from TGA-DTG images, both Araldite® 2012 and Araldite® 2015 have a large degree of thermogravimetric loss near 360 °C, but Araldite® 2012 has only one degradation stage, while Araldite® 2015 has three, which also indicates the difference in composition.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Elmarakbi, A. Advanced Composite Materials for Automotive Applications: Structural Integrity and Crashworthiness; John Wiley & Sons Ltd.: West Sussex, UK, 2013. [Google Scholar]

- Zhao, T.; Li, Y.; Zhang, C.; Yao, L.; Huang, Y.; Huang, Z.; Chen, C.; Wang, W.; Zu, L.; Zhou, H.; et al. Fundamental mechanical problems in high-performance aerospace composite structures: State-of-art review. Acta. Aeronaut. Astronaut. Sin. 2022, 43, 526851. [Google Scholar] [CrossRef]

- Toozandehjani, M.; Kamarudin, N.; Dashtizadeh, Z.; Lim, E.Y.; Gomes, A.; Gomes, C. Conventional and Advanced Composites in Aerospace Industry: Technologies Revisited. Am. J. Aerosp. Eng. 2018, 5. [Google Scholar] [CrossRef]

- Subagia, I.D.G.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Dehkordi, M.T.; Nosraty, H.; Shokrieh, M.M.; Minak, G.; Ghelli, D. Low velocity impact properties of intra-ply hybrid composites based on basalt and nylon woven fabrics. Mater. Des. 2010, 31, 3835–3844. [Google Scholar] [CrossRef]

- Han, S.H.; Oh, H.J.; Lee, H.C.; Kim, S.S. The effect of post-processing of carbon fibers on the mechanical properties of epoxy-based composites. Compos. Part B Eng. 2013, 45, 172–177. [Google Scholar] [CrossRef]

- Das, M.; Sahu, S.; Parhi, D. Composite materials and their damage detection using AI techniques for aerospace application: A brief review. Mater. Today Proc. 2020, 44, 955–960. [Google Scholar] [CrossRef]

- Reddy, S.S.P.; Suresh, R.; Hanamantraygouda, M.B.; Shivakumar, B. Use of composite materials and hybrid composites in wind turbine blades. Mater. Today Proc. 2021, 46, 2827–2830. [Google Scholar] [CrossRef]

- Cakir, F. Evaluation of mechanical properties of chopped glass/basalt fibers reinforced polymer mortars. Case Stud. Constr. Mater. 2021, 15, e00612. [Google Scholar] [CrossRef]

- Liu, S.; Wang, X.; Rawat, P.; Chen, Z.; Shi, C.; Zhu, D. Experimental study and analytical modeling on tensile performance of basalt textile reinforced concrete. Constr. Build. Mater. 2020, 267, 120972. [Google Scholar] [CrossRef]

- Wang, S.; Yao, Y.; Tang, C.; Li, G.; Cui, J. Mechanical characteristics, constitutive models and fracture behaviors of short basalt fiber reinforced thermoplastic composites under varying strain rates. Compos. Part B Eng. 2021, 218, 108933. [Google Scholar] [CrossRef]

- Liu, F.; Deng, C.; He, X. Fatigue reliability analysis of 5052 aluminium alloy self-piercing riveted joints with given confidence. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 475. [Google Scholar] [CrossRef]

- Mehboob, A.; Chang, S.-H. Effect of composite bone plates on callus generation and healing of fractured tibia with different screw configurations. Compos. Sci. Technol. 2018, 167, 96–105. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Z.; Pan, S.; Tan, Z. Comparison on failure behavior of three-dimensional woven carbon/carbon composites joints subjected to out-of-plane loading at room and high temperature. Compos. Commun. 2020, 23, 100567. [Google Scholar] [CrossRef]

- Zhang, T.; Meng, J.; Pan, Q.; Sun, B. The influence of adhesive porosity on composite joints. Compos. Commun. 2019, 15, 87–91. [Google Scholar] [CrossRef]

- Dhilipkumar, T.; Rajesh, M. Enhancing strength and stiffness of composite joint through co-cure technique. Compos. Commun. 2021, 27, 100878. [Google Scholar] [CrossRef]

- Da Silva, L.F.M.; Öchsner, A.; Adams, R.D. (Eds.) Handbook of Adhesion Technology, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Kahraman, R.; Sunar, M.; Yilbas, B. Influence of adhesive thickness and filler content on the mechanical performance of aluminum single-lap joints bonded with aluminum powder filled epoxy adhesive. J. Am. Acad. Dermatol. 2008, 205, 183–189. [Google Scholar] [CrossRef]

- Shin, M.J.; Shin, Y.J.; Hwang, S.W.; Shin, J.S. Microencapsulation of imidazole curing agent by solvent evaporation method using W/O/W emulsion. J. Appl. Polym. Sci. 2012, 129, 1036–1044. [Google Scholar] [CrossRef]

- Qin, G.; Na, J.; Mu, W.; Tan, W.; Yang, J.; Ren, J. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive, CFRP and adhesively bonded CFRP-aluminum alloy joints. Compos. Part B Eng. 2018, 154, 43–55. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Environmental durability of adhesively bonded FRP/steel joints in civil engineering applications: State of the art. Compos. Part B Eng. 2015, 81, 259–275. [Google Scholar] [CrossRef]

- Bond, D.A.; Smith, P.A. Modeling the Transport of Low-Molecular-Weight Penetrants Within Polymer Matrix Composites. Appl. Mech. Rev. 2006, 59, 249–268. [Google Scholar] [CrossRef]

- Yang, P.; Chen, C.; Wang, D.; Ma, H.; Du, Y.; Cai, D.; Zhang, X.; Wu, Z. Kinetics, reaction pathways, and mechanism investigation for improved environmental remediation by 0D/3D CdTe/Bi2WO6 Z-scheme catalyst. Appl. Catal. B Environ. 2021, 285, 119877. [Google Scholar] [CrossRef]

- Li, S.; Guo, S.; Yao, Y.; Jin, Z.; Shi, C.; Zhu, D. The effects of aging in seawater and SWSSC and strain rate on the tensile performance of GFRP/BFRP composites: A critical review. Constr. Build. Mater. 2021, 282, 122534. [Google Scholar] [CrossRef]

- Niu, R.; Yang, Y.; Liu, Z.; Ding, Z.; Peng, H.; Fan, Y. Durability of Two Epoxy Adhesive BFRP Joints Dipped in Seawater under High Temperature Environment. Polymers 2023, 15, 3232. [Google Scholar] [CrossRef] [PubMed]

- ISO 4587:2003; Adhesives-Determination of Tensile Lap-Shear Strength of Rigid-To-Rigid Bonded Assemblies. ISO: Geneva, Switzerland, 2003.

- ASTM D5868-01(2014); Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM International: West Conshohocken, PA, USA, 2014.

- ISO 527-2:2012; Plastics-Determination of Tensile Properties-Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- GB/T 19466.1-2004; Standardization Administration of the People’s Republic of China. Plastics-Differential Scanning Calorimetry DSC-Part I: General Principles. Chinese Standard Press: Beijing, China, 2004. (In Chinese)

- Leisen, J.; Hojjatie, B.; Coffin, D.W.; Beckham, H.W. In-plane moisture transport in paper detected by magnetic resonance imaging. Dry. Technol. 2001, 19, 199–206. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Effect of water, seawater and alkaline solution ageing on mechanical properties of flax fabric/epoxy composites used for civil engineering applications. Constr. Build. Mater. 2015, 99, 118–127. [Google Scholar] [CrossRef]

- Böer, P.; Holliday, L.; Kang, T.H.-K. Independent environmental effects on durability of fiber-reinforced polymer wraps in civil applications: A review. Constr. Build. Mater. 2013, 48, 360–370. [Google Scholar] [CrossRef]

- Karbhari, V.M. Woodhead Publishing Series in Civil and Structural Engineering, 1st ed.; Woodhead Publishing: Canbridge, UK, 2007; ISBN 978-1-84569-035-9. [Google Scholar]

- Zanni-Deffarges, M.; Shanahan, M. Diffusion of water into an epoxy adhesive: Comparison between bulk behaviour and adhesive joints. Int. J. Adhes. Adhes. 1995, 15, 137–142. [Google Scholar] [CrossRef]

- Stazi, F.; Giampaoli, M.; Rossi, M.; Munafò, P. Environmental ageing on GFRP pultruded joints: Comparison between different adhesives. Compos. Struct. 2015, 133, 404–414. [Google Scholar] [CrossRef]

- Bhagavathi, L.R.; Deshpande, A.P.; Ram, G.J.; Panigrahi, S. Effect of cellulosic fillers addition on curing and adhesion strength of moisture-curing one-component polyurethane adhesives. Int. J. Adhes. Adhes. 2021, 108, 102871. [Google Scholar] [CrossRef]

- Ulus, H.; Kaybal, H.B.; Cacık, F.; Eskizeybek, V.; Avcı, A. Fracture and dynamic mechanical analysis of seawater aged aluminum-BFRP hybrid adhesive joints. Eng. Fract. Mech. 2022, 268. [Google Scholar] [CrossRef]

- Almutairi, B.; Binhasan, M.; Shabib, S.; Al-Qahtani, A.S.; Tulbah, H.I.; Al-Aali, K.A.; Vohra, F.; Abduljabbar, T. Adhesive bond integrity of silanized zirconia nanoparticles in polymeric resin dentin bonding agent. An FTIR, SEM, and micro-tensile experiment. Int. J. Adhes. Adhes. 2022, 114. [Google Scholar] [CrossRef]

- Ogasawara, T.; Hirano, Y.; Yoshimura, A. Coupled thermal–electrical analysis for carbon fiber/epoxy composites exposed to simulated lightning current. Compos. Part A Appl. Sci. Manuf. 2010, 41, 973–981. [Google Scholar] [CrossRef]

- Pei, Y.-M.; Wang, K.; Zhan, M.-S.; Xu, W.; Ding, X.-J. Thermal-oxidative aging of DGEBA/EPN/LMPA epoxy system: Chemical structure and thermal–mechanical properties. Polym. Degrad. Stab. 2011, 96, 1179–1186. [Google Scholar] [CrossRef]

- Sciolti, M.S.; Frigione, M.; Aiello, M.A. Wet Lay-Up Manufactured FRPs for Concrete and Masonry Repair: Influence of Water on the Properties of Composites and on Their Epoxy Components. J. Compos. Constr. 2010, 14, 823–833. [Google Scholar] [CrossRef]

- Zhang, Y.; Adams, R.; da Silva, L.F. Absorption and glass transition temperature of adhesives exposed to water and toluene. Int. J. Adhes. Adhes. 2014, 50, 85–92. [Google Scholar] [CrossRef]

- Petrie, E.M. How Moisture Affects Adhesives, Sealants, and Coatings. Met. Finish. 2011, 109, 36–48. [Google Scholar] [CrossRef]

- Hosur, M.V.; Islam, S.M.W.; Vaidya, U.K.; Dutta, P.K.; Jeelani, S. Effects of Temperature and Moisture on the High Strain Rate Compression Response of Graphite/Epoxy Composites. J. Eng. Mater. Technol. 2003, 125, 394–401. [Google Scholar] [CrossRef]

- Liu, S.; Cheng, X.; Zhang, Q.; Zhang, J.; Bao, J.; Guo, X. An investigation of hygrothermal effects on adhesive materials and double lap shear joints of CFRP composite laminates. Compos. Part B Eng. 2016, 91, 431–440. [Google Scholar] [CrossRef]

- Loh, W.K.; Crocombe, A.D.; Wahab, M.M.A.; Watts, J.F.; Ashcroft, I.A. The effect of moisture on the failure locus and fracture energy of an epoxy–steel interface. J. Adhes. Sci. Technol. 2002, 16, 1407–1429. [Google Scholar] [CrossRef]

- Lunder, O.; Simensen, C.; Yu, Y.; Nisancioglu, K. Formation and characterisation of Ti–Zr based conversion layers on AA6060 aluminium. Surf. Coatings Technol. 2004, 184, 278–290. [Google Scholar] [CrossRef]

- Deb, A.; Malvade, I.; Biswas, P.; Schroeder, J. An experimental and analytical study of the mechanical behaviour of adhesively bonded joints for variable extension rates and temperatures. Int. J. Adhes. Adhes. 2008, 28, 1–15. [Google Scholar] [CrossRef]

- Galvez, P.; de Armentia, S.L.; Abenojar, J.; Martinez, M.A. Effect of moisture and temperature on thermal and mechanical properties of structural polyurethane adhesive joints. Compos. Struct. 2020, 247, 112443. [Google Scholar] [CrossRef]

| GT-807A/GT807B Epoxy Resin | Basalt Fiber Unidirectional Fabric | ||

|---|---|---|---|

| Cure condition | 25 °C × 24 h + 90 °C × 3 h | Density/(g/cm2) | 0.00265 |

| Density/(kg/m3) | 0.0015 | Tensile strength/(MPa) | 2100 |

| Tensile strength/(MPa) | 75.5 | Young’s modulus/(GPa) | 105 |

| Tensile modulus/(MPa) | 3282.5 | Nominal thickness/(mm) | 0.115 |

| Tg/(°C) | ≥80 | Single fiber size/(μm) | 13 |

| Mechanical Properties | Numerical Value |

|---|---|

| Density/(kg/m3) | 2730 |

| Young’s modulus/(GPa) | 70 |

| Poisson’s radio | 0.33 |

| Yield strength/MPa | 227 |

| Tensile strength/MPa | 378 |

| Araldite® 2012 | Araldite® 2015 | |

|---|---|---|

| Young’s modulus/E(GPa) | 1.65 | 1.85 |

| Shear modulus/G(GPa) | 0.25 | 0.56 |

| Density/(kg/m3) | 1.18 | 1.60 |

| Poisson’s radio | 0.43 | 0.33 |

| Araldite® 2012 | Araldite® 2015 | Thickness (T = 2 h, mm) | |||

|---|---|---|---|---|---|

| Saturation Moisture Uptake M∞ (%) | Diffusion Coefficient D × 10−3 (mm2/s) | Saturation Moisture Uptake M∞ (%) | Diffusion Coefficient D × 10−3 (mm2/s) | ||

| DI Water | 14.05 | 1.89 | 16.57 | 1.83 | 2 |

| 3.5% NaCl | 10.22 | 1.94 | 12.07 | 1.68 | 2 |

| 5% NaCl | 7.49 | 1.79 | 10.66 | 1.79 | 2 |

| Sample (BFRP) | Saturation Moisture Uptake M∞(%) | Diffusion Coefficient D × 10−3 (mm2/s) | Thickness (T = 2 h, mm) |

|---|---|---|---|

| DI Water | 2.30 | 1.34 | 2 |

| 3.5% NaCl | 1.25 | 1.55 | 2 |

| 5% NaCl | 1.41 | 1.48 | 2 |

| Glass Transition Temperature(Tg/°C) | ||||||

|---|---|---|---|---|---|---|

| Araldite® 2012 | Araldite® 2015 | |||||

| Time (h) | DI Water | 3.5% NaCl | 5% NaCl | DI Water | 3.5% NaCl | 5% NaCl |

| 0 | 43.78 | 61.75 | ||||

| 240 | 29.47 | 30.49 | 31.81 | 34.58 | 42.53 | 46.25 |

| 480 | 23.98 | 27.97 | 28.11 | 30.64 | 40.38 | 42.48 |

| 720 | 23.02 | 25.74 | 27.96 | 27.12 | 36.64 | 39.30 |

| Araldite® 2012 | Araldite® 2015 | ||

|---|---|---|---|

| Wavenumber/cm−1 | Functional Group | Wavenumber/cm−1 | Functional Group |

| 827 | p-phenylene groups | 827 | p-phenylene groups |

| 1030, 1086 | Stretching of the trans forms of the ether linkage | 1056 | Stretching of the trans forms of the ether linkage |

| 1234 | Stretching mode for aromatic ether | 1430 | C-H bending vibration of the ester group |

| 1442 | C-H bending vibration of the ester group | 2960 | -CH3 sway deformation vibration vibration |

| 1726 | ester group-(C=O)-O | 3756 | -OH asymmetrical stretching |

| 2898 | -CH3 symmetric stretching | ||

| 3436 | -OH symmetric stretching | ||

| Environment | Aging Time (h) | Initial Pyrolysis Temperature (°C) | Maximum Weight Loss Rate Temperature (°C) | Residue Rate (%) |

|---|---|---|---|---|

| Without aging | 0 | 340.0 | 373.3 | 0 |

| DI water | 240 | 348.7 | 372.5 | 4.89% |

| 480 | 346.2 | 371.7 | 1.88% | |

| 720 | 345.7 | 371.7 | 2.68% | |

| 3.5% NaCl | 240 | 347.5 | 374.2 | 4.82% |

| 480 | 343.3 | 371.2 | 4.43% | |

| 720 | 344.2 | 372.5 | 4.15% | |

| 5% NaCl | 240 | 355.3 | 375.8 | 3.79% |

| 480 | 348.8 | 371.7 | 4.82% | |

| 720 | 347.9 | 371.7 | 2.56% |

| Environment | Aging Time (h) | First Degration’s Temperature (°C) | Second Degration’s Temperature (°C) | Third Degration’s Temperature (°C) |

|---|---|---|---|---|

| Without aging | 0 | 157.5 | 367.5 | 688.3 |

| DI water | 240 | 165.0 | 366.7 | 697.5 |

| 480 | 135.4 | 369.2 | 704.2 | |

| 720 | 150.0 | 368.3 | 718.8 | |

| 3.5% NaCl | 240 | 165.0 | 366.7 | 679.5 |

| 480 | 134.5 | 368.3 | 704.2 | |

| 720 | 150.0 | 368.3 | 718.7 | |

| 5% NaCl | 240 | 136.7 | 365.8 | 678.3 |

| 480 | 142.8 | 365.0 | 689.2 | |

| 720 | 146.7 | 365.8 | 685.8 |

| Average Failure Strength (MPa) | ||||||

|---|---|---|---|---|---|---|

| Araldite® 2012 | Araldite® 2015 | |||||

| Time (h) | DI Water | 3.5% NaCl | 5% NaCl | DI Water | 3.5% NaCl | 5% NaCl |

| 0 | 12.10 | 12.10 | 12.10 | 10.63 | 10.63 | 10.63 |

| 240 | 9.38 | 11.92 | 11.66 | 8.90 | 10.15 | 10.42 |

| 480 | 7.86 | 10.82 | 10.90 | 6.96 | 8.07 | 8.04 |

| 720 | 7.63 | 10.56 | 10.66 | 6.14 | 7.14 | 7.31 |

| Failure Load (kN) | ||||||

|---|---|---|---|---|---|---|

| Araldite® 2012 | Araldite® 2015 | |||||

| Time (h) | DI Water | 3.5% NaCl | 5% NaCl | DI Water | 3.5% NaCl | 5% NaCl |

| 0 | 8.814 | 8.814 | 8.814 | 6.775 | 6.775 | 6.775 |

| 240 | 6.053 | 7.894 | 7.550 | 5.293 | 6.040 | 6.450 |

| 480 | 5.484 | 7.104 | 7.016 | 4.026 | 5.513 | 5.221 |

| 720 | 4.186 | 6.648 | 6.106 | 3.532 | 5.137 | 4.506 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Ding, Z.; Fan, Y.; Luo, Y.; Yang, Y. Comparison of Mechanical Properties of Ductile/Brittle Epoxy Resin BFRP-AL Joints under Different Immersion Solutions. Polymers 2023, 15, 3892. https://doi.org/10.3390/polym15193892

Liu H, Ding Z, Fan Y, Luo Y, Yang Y. Comparison of Mechanical Properties of Ductile/Brittle Epoxy Resin BFRP-AL Joints under Different Immersion Solutions. Polymers. 2023; 15(19):3892. https://doi.org/10.3390/polym15193892

Chicago/Turabian StyleLiu, Haichao, Ziyang Ding, Yisa Fan, Yang Luo, and Yang Yang. 2023. "Comparison of Mechanical Properties of Ductile/Brittle Epoxy Resin BFRP-AL Joints under Different Immersion Solutions" Polymers 15, no. 19: 3892. https://doi.org/10.3390/polym15193892

APA StyleLiu, H., Ding, Z., Fan, Y., Luo, Y., & Yang, Y. (2023). Comparison of Mechanical Properties of Ductile/Brittle Epoxy Resin BFRP-AL Joints under Different Immersion Solutions. Polymers, 15(19), 3892. https://doi.org/10.3390/polym15193892