Mechanically Tough and Highly Stretchable Hydrogels Based on Polyurethane for Sensitive Strain Sensor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MXene Nanosheet

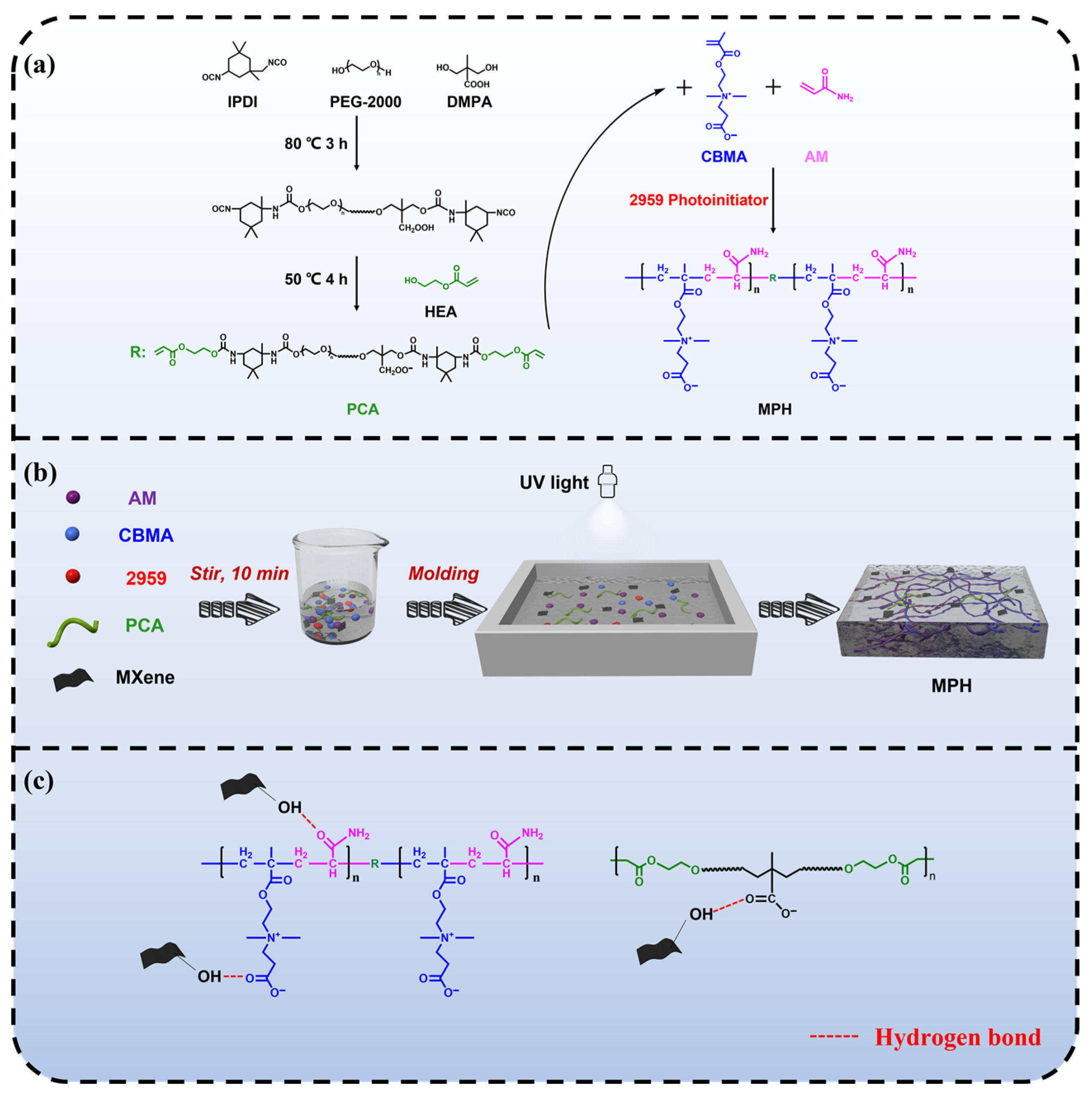

2.3. Synthesis of Macromolecular Polyurethane Crosslinking Agent (PCA)

2.4. Preparation of MXene-Poly(Urethane-Co-AM-Co-CBMA) Hydrogels (Labeled as MPH Nanocomposite Hydrogels)

2.5. Characterization

3. Results

3.1. Structural Characterization

3.2. Mechanical Properties

3.3. Electrical and Sensing Properties

3.4. Human Motion Monitoring Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Niu, H.; Li, H.; Gao, S.; Li, Y.; Wei, X.; Chen, Y.K.; Yue, W.J.; Zhou, W.J.; Shen, G.Z. Perception-to-Cognition Tactile Sensing Based on Artificial-Intelligence-Motivated Human Full-Skin Bionic Electronic Skin. Adv. Mater. 2022, 34, e2202622. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.; Park, S. Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics. Adv. Mater. 2019, 31, e1904765. [Google Scholar] [CrossRef] [PubMed]

- Ansari, A.A.; Malhotra, B.D. Current progress in organic–inorganic hetero-nano-interfaces based electrochemical biosensors for healthcare monitoring. Coord. Chem. Rev. 2022, 452, 214282. [Google Scholar] [CrossRef]

- Trung, T.Q.; Le, H.S.; Dang, T.M.L.; Ju, S.; Park, S.Y.; Lee, N.E. Freestanding, Fiber-Based, Wearable Temperature Sensor with Tunable Thermal Index for Healthcare Monitoring. Adv. Healthc. Mater. 2018, 7, e1800074. [Google Scholar] [CrossRef]

- Joo, D.H.; Kang, M.S.; Park, S.J.; Yu, S.A.; Park, W.T. Fabrication method of flexible strain sensors with CNTs and solvents. Sensor. Actuat. A-Phys. 2022, 345, 113775. [Google Scholar] [CrossRef]

- Singh, K.; Gupta, M.; Tripathi, C.C. Fabrication of flexible and sensitive laser-patterned serpentine-structured graphene–CNT paper for strain sensor applications. Appl. Phys. A-Mater. 2022, 128, 1131. [Google Scholar] [CrossRef]

- Zhang, R.; Ying, C.; Gao, H.; Liu, Q.; Fu, X.; Hu, S. Highly flexible strain sensors based on polydimethylsiloxane/carbon nanotubes (CNTs) prepared by a swelling/permeating method and enhanced sensitivity by CNTs surface modification. Compos. Sci. Technol. 2019, 171, 218–225. [Google Scholar] [CrossRef]

- Yu, Y.; Peng, S.; Blanloeuil, P.; Wu, S.; Wang, C.H. Wearable Temperature Sensors with Enhanced Sensitivity by Engineering Microcrack Morphology in PEDOT:PSS–PDMS Sensors. ACS Appl. Mater. Interfaces 2020, 12, 36578–36588. [Google Scholar] [CrossRef]

- Liu, D.; Zhou, H.; Zhao, Y.; Huyan, C.; Wang, Z.; Torun, H.; Guo, Z.; Dai, S.; Xu, B.B.; Chen, F. A Strand Entangled Supramolecular PANI/PAA Hydrogel Enabled Ultra-Stretchable Strain Sensor. Small 2022, 18, e2203258. [Google Scholar] [CrossRef]

- Li, G.; Li, C.; Li, G.; Yu, D.; Song, Z.; Wang, H.; Liu, X.; Liu, H.; Liu, W. Development of Conductive Hydrogels for Fabricating Flexible Strain Sensors. Small 2022, 18, e2101518. [Google Scholar] [CrossRef]

- Wang, H.; Li, X.; Ji, Y.; Xu, J.; Wang, S.; Du, X. Highly Transparent, Mechanical, and Self-Adhesive Zwitterionic Conductive Hydrogels with Polyurethane as Cross-Linker for Wireless Strain Sensors. J. Mater. Chem. B 2022, 10, 2933–2943. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Du, X.; Jiang, Y.; Xu, J.; Zhou, M.; Wang, H.; Cheng, X.; Du, Z. Synergetic enhancement of mechanical and fire-resistance performance of waterborne polyurethane by introducing two kinds of phosphorus–nitrogen flame retardant. J. Colloid Interf. Sci. 2019, 537, 197–205. [Google Scholar] [CrossRef] [PubMed]

- Lei, L.; Wang, H.; Jia, Q.; Tian, Y.; Wang, S. Highly stretchable, supersensitive, and self-adhesive ionohydrogels using waterborne polyurethane micelles as cross-linkers for wireless strain sensors. J. Mater. Chem. B 2023, 11, 7478–7489. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Kong, F.; Yang, J.; Xiong, X.; Gao, S.; Yuan, J.; Meng, S.; Chen, L. Flexible wearable sensor based on SF/EEP/GR/MXene nanocomposites. Appl. Phys. A-Mater. 2023, 129, 551. [Google Scholar] [CrossRef]

- Salauddin, M.; Rana, S.M.S.; Rahman, M.T.; Sharifuzzaman, M.; Maharjan, P.; Bhatta, T.; Cho, H.; Lee, S.H.; Park, C.; Shrestha, K.; et al. Fabric-Assisted MXene/Silicone Nanocomposite-Based Triboelectric Nanogenerators for Self-Powered Sensors and Wearable Electronics. Adv. Funct. Mater. 2022, 32, 2107143. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Sun, Y.; Wang, H.; Du, X.; Cheng, X.; Du, Z.; Wang, H. Skin-inspired nanofibrillated cellulose-reinforced hydrogels with high mechanical strength, long-term antibacterial, and self-recovery ability for wearable strain/pressure sensors. Carbohyd. Polym. 2021, 261, 117894. [Google Scholar] [CrossRef]

- Shen, X.; Zheng, Q.; Kim, J.K. Rational design of two-dimensional nanofillers for polymer nanocomposites toward multifunctional applications. Prog. Mater Sci. 2021, 115, 100708. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, S.; Liu, Z.; Lin, S.; Cheng, X.; Wang, H. Fabrication of organic/inorganic hybrid waterborne polyurethane coating based on CeNPs @mTi3C2Tx composites for anti-corrosion applications. Prog. Org. Coat. 2023, 182, 107668. [Google Scholar] [CrossRef]

- Wang, S.; Bi, S.; Zhang, L.; Liu, R.; Wang, H.; Gu, J. Skin-inspired antibacterial conductive hydrogels customized for wireless flexible sensor and collaborative wound healing. J. Mater. Chem. A 2023, 11, 14096–14107. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, S.; Chen, S.; Wei, Y.; Dong, X.; Liu, L. A highly stretchable and sensitive strain sensor based on graphene–elastomer composites with a novel double-interconnected network. J. Mater. Chem. C 2016, 4, 1024–1037. [Google Scholar] [CrossRef]

- Saeidi-Javash, M.; Du, Y.; Zeng, M.X.; Brian, C.W.; Zhang, Y. All-printed MXene-graphene nanosheet-based bimodal sensors for simultaneous strain and temperature sensing. ACS Appl. Electron. Mater. 2021, 3, 2341–2348. [Google Scholar] [CrossRef]

- Windisch, M.; Junghans, T. Hydrogel sensors for process monitoring. Adv. Sci. Technol.-Res. 2013, 77, 71–76. [Google Scholar]

- Liu, Z.; Zhang, T.; Yang, M.; Gao, W.; Zhang, J. Hydrogel pressure distribution sensors based on an imaging strategy and machine learning. ACS Appl. Electron. Mater. 2021, 67, 171–186. [Google Scholar] [CrossRef]

- Liu, Y.J.; Cao, W.T.; Ma, M.G.; Wan, P. Ultrasensitive wearable soft strain sensors of conductive, self-healing, and elastic hydrogels with synergistic “soft and hard” hybrid networks. ACS Appl. Mater. Interfaces 2017, 30, 25559–25570. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, X.; Lei, Z.; Wang, L.; Tian, M.; Zhu, S.; Xiao, H.; Tang, X.; Qu, L. Flexible MXene-decorated fabric with interwoven conductive networks for integrated joule heating, electromagnetic interference shielding, and strain sensing performances. ACS Appl. Mater. Interfaces 2020, 12, 14459–14467. [Google Scholar] [CrossRef]

- Xu, H.H.; Lv, Y.; Qiu, D.X.; Zhou, Y.J.; Zeng, H.X.; Chu, Y.C. An ultra-stretchable, highly sensitive and biocompatible capacitive strain sensor from an ionic nanocomposite for on-skin monitoring. Nanoscale 2019, 11, 1449–1457. [Google Scholar] [CrossRef]

- Xing, C.; Chen, S.; Xin, L.; Quan, L.; Qu, M.; Zou, Q.; Li, J.; Hui, T.; Liu, L.; Fan, D. Two-dimensional MXene (Ti3C2) integrated cellulose hydrogels: Toward smart three-dimensional network nanoplatforms exhibiting light-induced swelling and bimodal photothermal/chemotherapy anticancer activity. ACS Appl. Mater. Interfaces 2018, 27, 173–186. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, Y.L.; Wang, X.; Xing, L.; Ran, R. Stable, strain-sensitivity conductive hydrogel with anti-freezing capable, remoldability and reusability. ACS Appl. Mater. Interfaces 2018, 10, 113–123. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, J.; Zhang, X.; Tian, D.; Zhan, Z.; Lu, C. Ultrathin MXene/calcium alginate aerogel film for high-performance electromagnetic interference shielding. Adv. Mater. Interfaces 2019, 12, 1324–1341. [Google Scholar] [CrossRef]

- Larson, C.; Peele, B.; Li, S.; Robinson, S.; Totaro, M.; Beccai, L.; Mazzolai, B.; Shepherd, R. Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 2016, 351, 1071–1074. [Google Scholar] [CrossRef]

- Yang, B.; Yuan, W. Highly stretchable and transparent double-network hydrogel ionic conductors as flexible thermal-mechanical dual sensors and electroluminescent devices. ACS Appl. Mater. Interfaces 2019, 16, 1524–1540. [Google Scholar] [CrossRef] [PubMed]

- Ge, G.; Zhang, Y.; Shao, J.; Wang, W.; Si, W.; Huang, W.; Dong, X. Stretchable, transparent, and self-patterned hydrogel-based pressure sensor for human motions detection. Adv. Funct. Mater. 2018, 28, 1802571–1802576. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.Y.; Lin, Y.J.; Enriquez, E.; Peng, X.F.; Turng, L.S. Highly stretchable and biocompatible strain sensors based on mussel-inspired super-adhesive self-healing hydrogels for human motion monitoring. ACS Appl. Mater. Interfaces 2018, 28, 12581–12596. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Wang, M.; Wu, J. Stretchable, adhesive, self-healable, and conductive hydrogel-based deformable triboelectric nanogenerator for energy harvesting and human motion sensing. ACS Appl. Mater. Interfaces 2022, 14, 9126–9137. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Dong, Y.; Ma, S.; Ren, J.; Yang, X.; Wang, Y.; Lü, S. Superstretching MXene composite hydrogel as a bidirectional stress response thixotropic sensor. ACS Appl. Mater. Interfaces 2021, 13, 13629–13636. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wu, Z.; Wei, Y.; Ding, H.; Huang, W.; Gui, X.; Shi, W.; Shen, Y.; Tao, K.; Xie, X. Ultrasensitive and stretchable temperature sensors based on thermally stable and self-healing organohydrogels. ACS Appl. Mater. Interfaces 2020, 12, 19069–19079. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.H.; Zhang, Y.Z.; Kim, H.; Lei, Y.; Hong, S.; Wustoni, S.; Hama, A.; Inal, S.; Alshareef, H.N. Muscle fatigue sensor based on Ti3C2Tx MXene hydrogel. Small Methods 2021, 5, 2100819. [Google Scholar] [CrossRef]

- Tang, M.; Li, Z.; Wang, K.; Jiang, Y.; Tian, M.; Qin, Y.; Gong, Y.; Li, Z.; Wu, L. Ultrafast self-healing and self-adhesive polysiloxane towards reconfigurable on-skin electronics. J. Mater. Chem. A 2022, 10, 1750–1759. [Google Scholar] [CrossRef]

- Li, Q.; Chen, J.; Zhang, Y.; Chi, C.; Dong, G.; Lin, J.; Chen, Q. Superelastic, antifreezing, antidrying, and conductive organohydrogels for wearable strain sensors. ACS Appl. Mater. Interfaces 2021, 13, 51546–51555. [Google Scholar] [CrossRef]

- Wei, H.; Kong, D.; Li, T.; Xue, Q.; Wang, S.; Cui, D.; Huang, Y.; Wang, L.; Hu, S.; Wan, T. Solution-processable conductive composite hydrogels with multiple synergetic networks toward wearable pressure/strain sensors. ACS Sens. 2021, 6, 2938–2951. [Google Scholar] [CrossRef]

- Zhai, W.; Zhu, J.; Wang, Z.; Zhao, Y.; Zhan, P.; Wang, S.; Zheng, G.; Shao, C.; Dai, K.; Liu, C.; et al. Stretchable, sensitive strain sensors with a wide workable range and low detection limit for wearable electronic skins. ACS Appl. Mater. Interfaces 2022, 14, 4562–4570. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J. Lightweight, robust, conductive composite fibers based on MXene@aramid nanofibers as sensors for smart fabrics. ACS Appl. Mater. Interfaces 2021, 13, 41933–41945. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Xiao, X.; Li, Z.; Li, K.; Cheng, N.; Li, S.; Low, J.H.; Jing, L.; Fu, X.; Achavananthadith, S.; et al. Wireless Ti3C2Tx MXene strain sensor with ultrahigh sensitivity and designated working windows for soft exoskeletons. ACS Nano 2020, 14, 11860–11875. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Li, Z.; Xiong, Z.; Wang, Y.; Yang, H.; Xu, W.; Jing, L.; Ding, M.; Zhu, J.; Ho, J.S.; et al. Thermal camouflaging MXene robotic skin with bio-inspired stimulus sensation and wireless communication. Adv. Funct. Mater. 2022, 34, 462–470. [Google Scholar] [CrossRef]

- Qin, R.; Shan, G.; Hu, M.; Huang, W. Two-dimensional transition metal carbides and/or nitrides (MXenes) and their applications in sensors. Mat. Today Phys. 2021, 3, 42–49. [Google Scholar] [CrossRef]

- Liu, H.; Wang, W.; Xiang, H.; Wu, H.; Li, Z.; Zhou, H.; Huang, W. Paper-based flexible strain and pressure sensor with enhanced mechanical strength and super-hydrophobicity that can work under water. J. Mater. Chem. C 2022, 10, 3908–3918. [Google Scholar] [CrossRef]

- Xue, P.; Chen, C.; Diao, D. Ultra-sensitive flexible strain sensor based on graphene nanocrystallite carbon film with wrinkle structure. Carbon 2019, 147, 1864–1875. [Google Scholar] [CrossRef]

- Yao, H.B.; Ge, J.; Wang, C.F.; Wang, X.; Hu, W.; Zheng, Z.J.; Ni, Y.; Yu, S.H. Pressure sensors: A flexible and highly pressure-sensitive graphene–polyurethane sponge based on fractured microstructure design. Adv. Mater. 2013, 10, 338–348. [Google Scholar]

- Yuan, W.; Qu, X.; Lu, Y.; Zhao, W.; Ren, Y.; Wang, Q.; Wang, W.; Dong, X. MXene-composited highly stretchable, sensitive and durable hydrogel for flexible strain sensors. Chin. Chem. Lett. 2020, 232, 908–923. [Google Scholar] [CrossRef]

- Wang, L.; Tian, M.; Zhang, Y.; Sun, F.; Qi, X.; Liu, Y.; Qu, L. Helical core-sheath elastic yarn-based dual strain/humidity sensors with MXene sensing layer. J. Mater. Sci. 2020, 55, 184–196. [Google Scholar] [CrossRef]

| Sample | PCA (wt%) | AM (g) | CBMA (mg) | 2959 (mg) | MXene (g) |

|---|---|---|---|---|---|

| M0.2P0H | 0 | 2.0 | 64 | 63 | 0.20 |

| M0.2P0.5H | 0.5 | 2.0 | 64 | 63 | 0.20 |

| M0.2P1H | 1.0 | 2.0 | 64 | 63 | 0.20 |

| M0.2P2H | 2.0 | 2.0 | 64 | 63 | 0.20 |

| M0.2P4H | 4.0 | 2.0 | 64 | 63 | 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Wang, S.; Wang, H.; Gu, J. Mechanically Tough and Highly Stretchable Hydrogels Based on Polyurethane for Sensitive Strain Sensor. Polymers 2023, 15, 3902. https://doi.org/10.3390/polym15193902

Shi J, Wang S, Wang H, Gu J. Mechanically Tough and Highly Stretchable Hydrogels Based on Polyurethane for Sensitive Strain Sensor. Polymers. 2023; 15(19):3902. https://doi.org/10.3390/polym15193902

Chicago/Turabian StyleShi, Jianyang, Shuang Wang, Haibo Wang, and Jun Gu. 2023. "Mechanically Tough and Highly Stretchable Hydrogels Based on Polyurethane for Sensitive Strain Sensor" Polymers 15, no. 19: 3902. https://doi.org/10.3390/polym15193902