Influence of Particle Size on the Mechanical Performance and Sintering Quality of Peanut Husk Powder/PES Composites Fabricated through Selective Laser Sintering

Abstract

1. Introduction

2. Materials and Methods

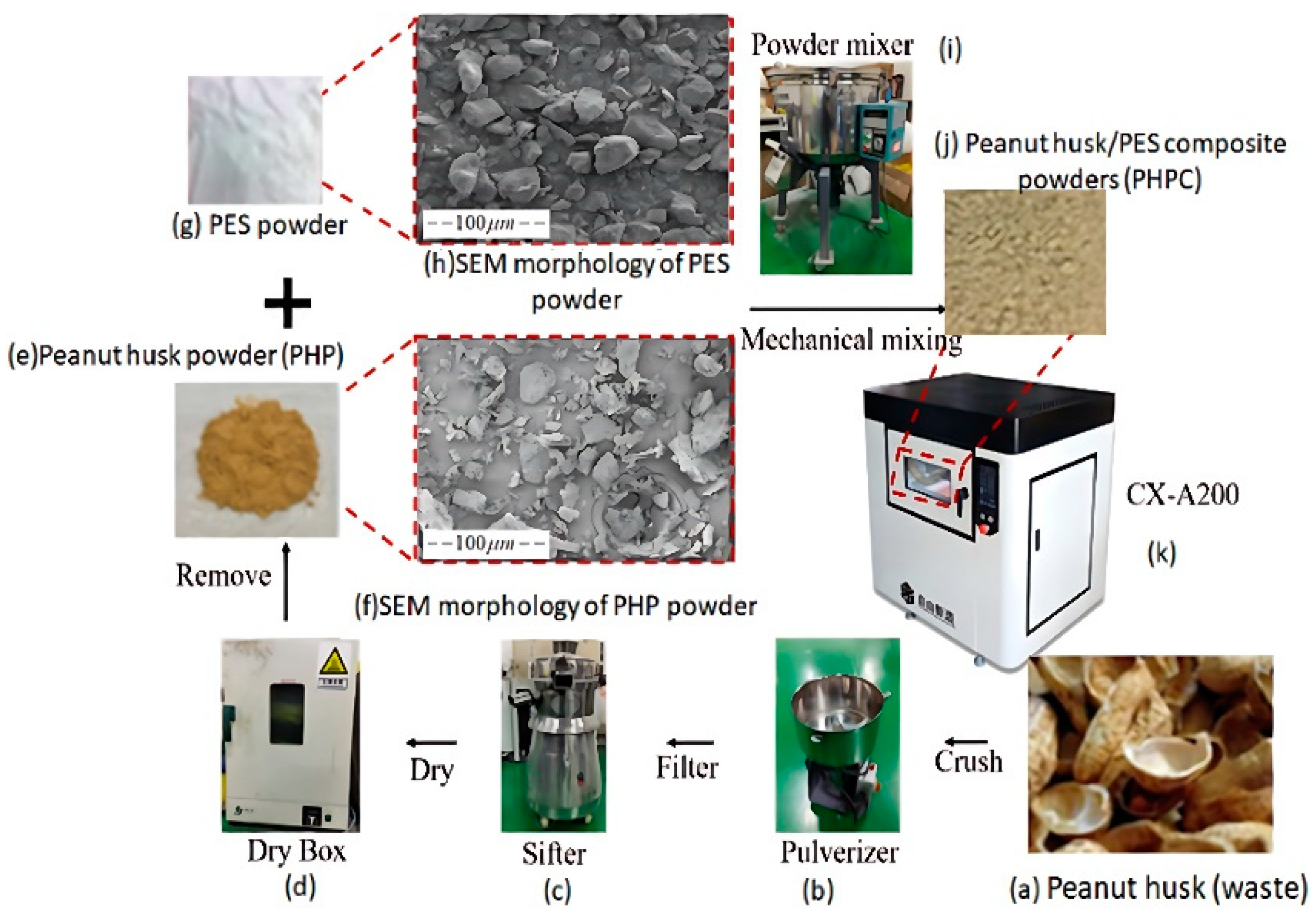

2.1. Raw Materials

2.2. Preparation of PHPC

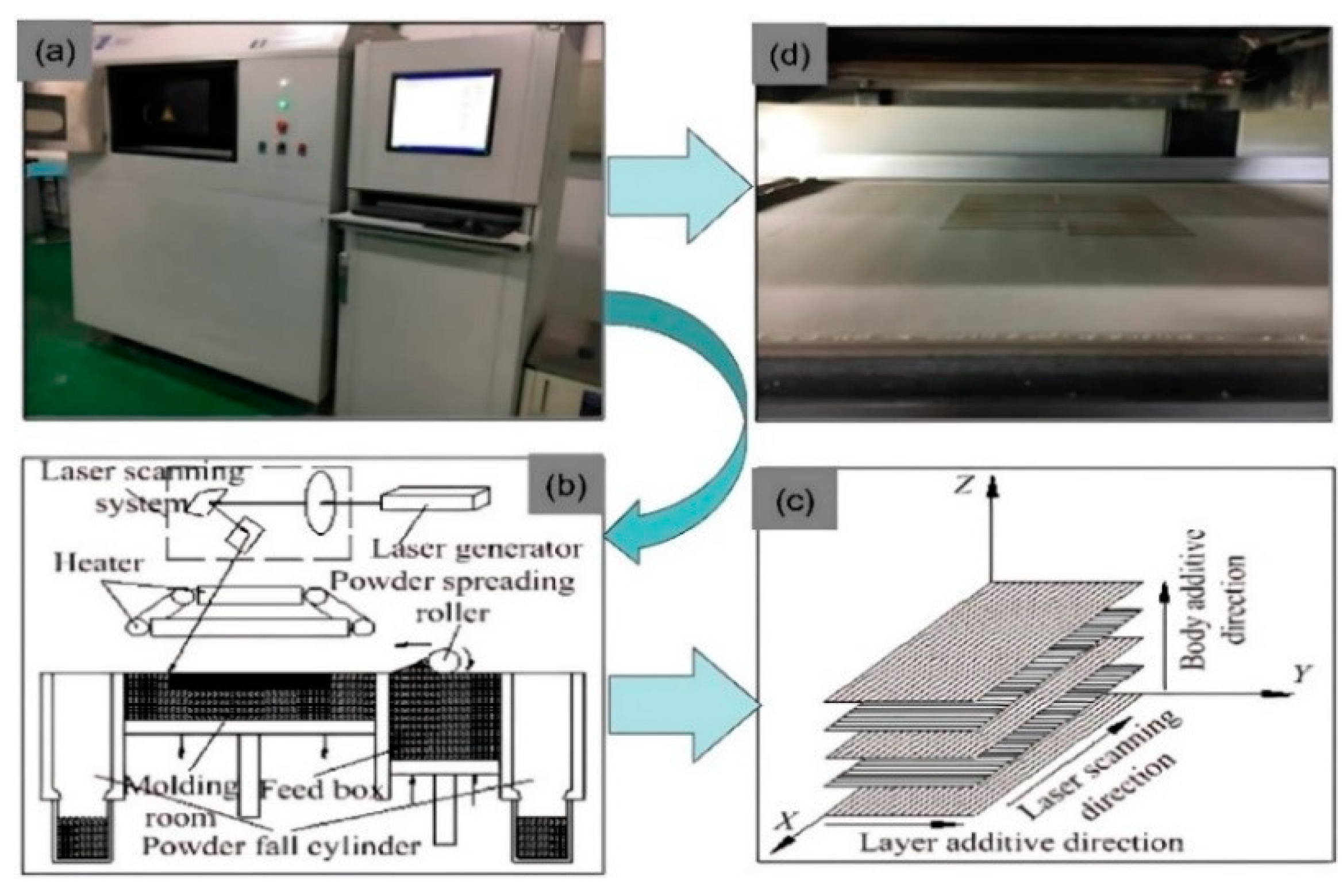

2.3. SLS Experiment

2.4. The Fabrication of the PHPC SLS Specimens

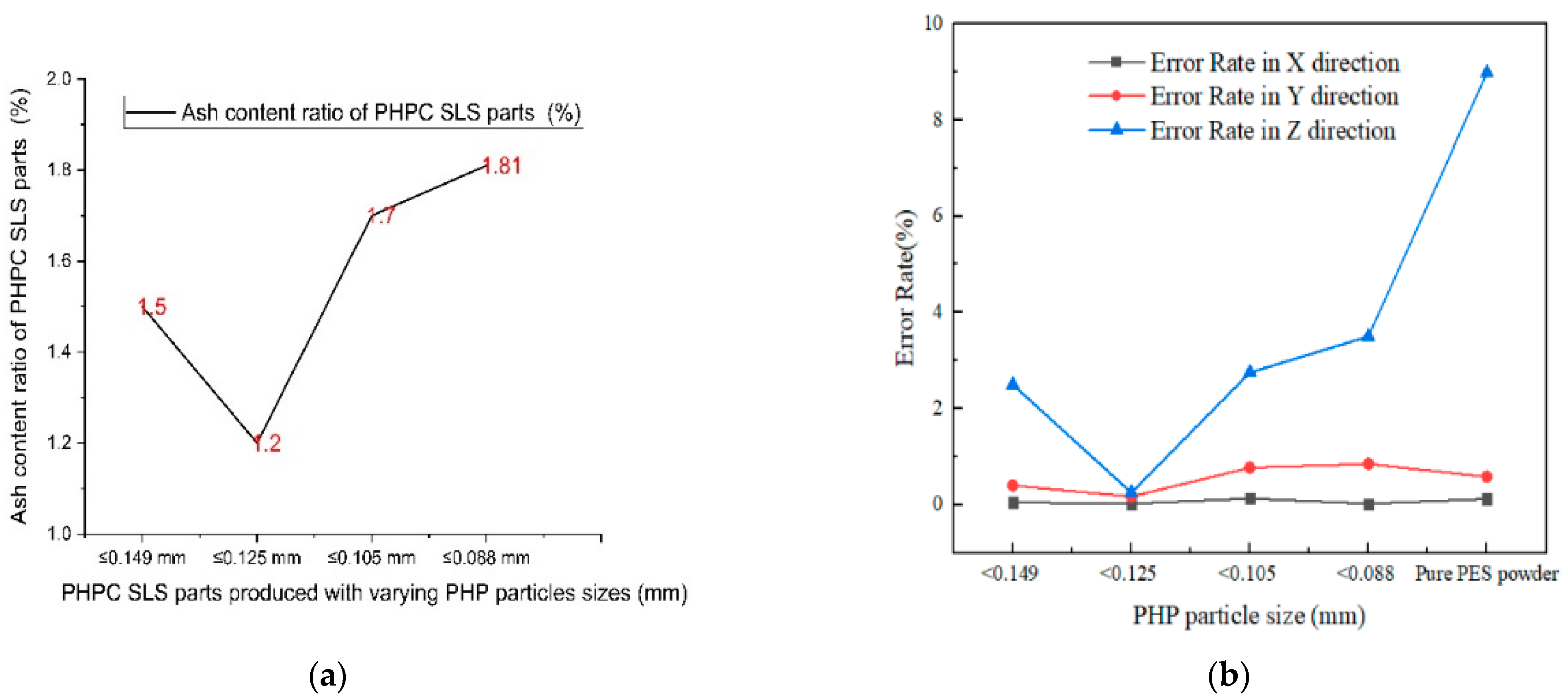

2.5. Dimensional Accuracy (DA)

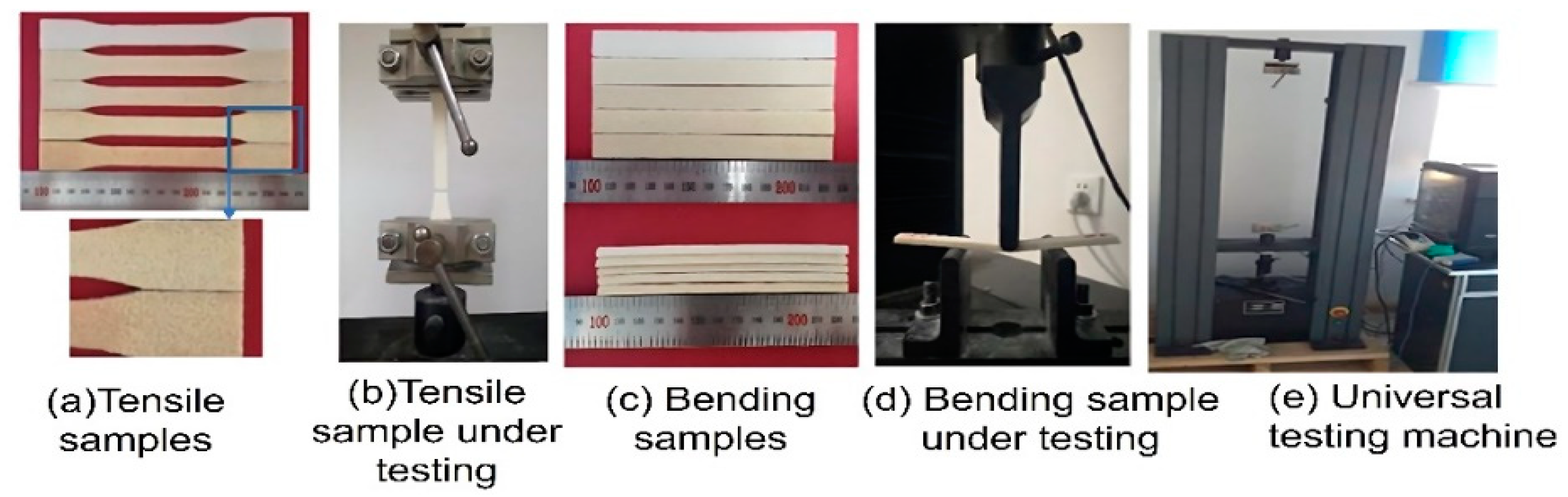

2.6. Mechanical Testing

2.7. Density

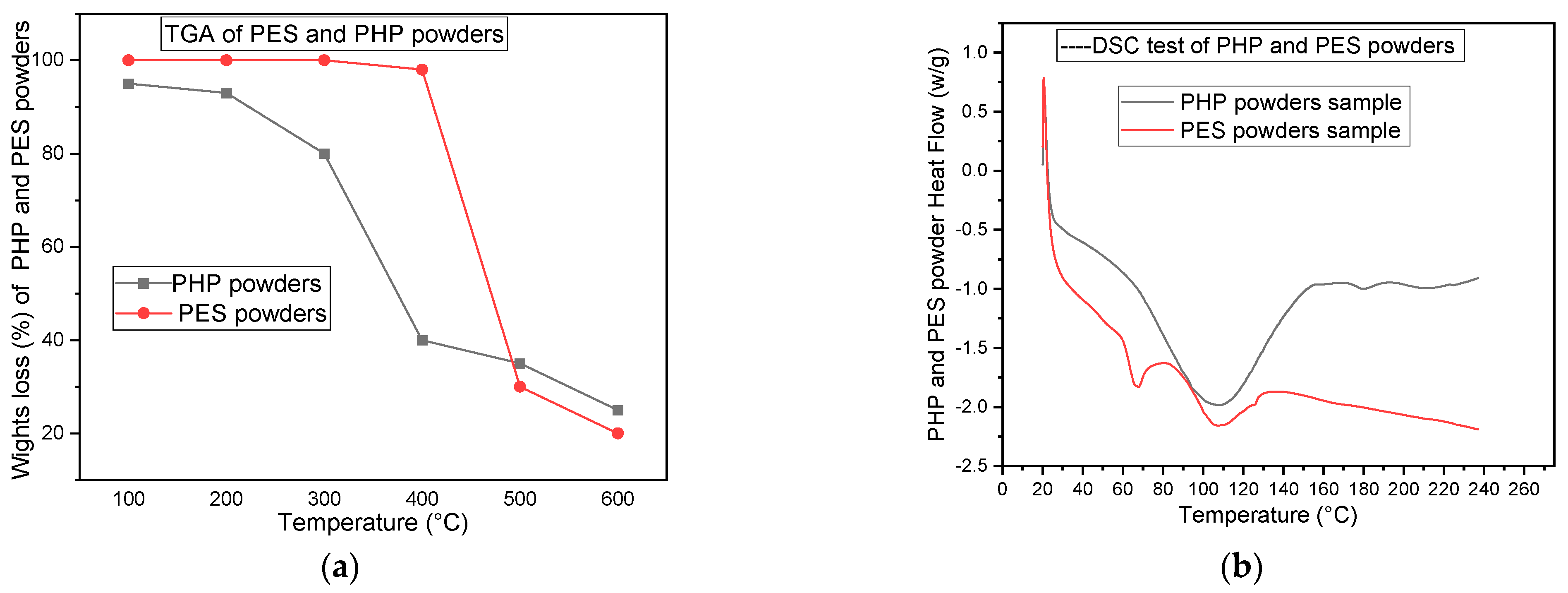

2.8. Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC) Examinations

2.9. SEM Analysis

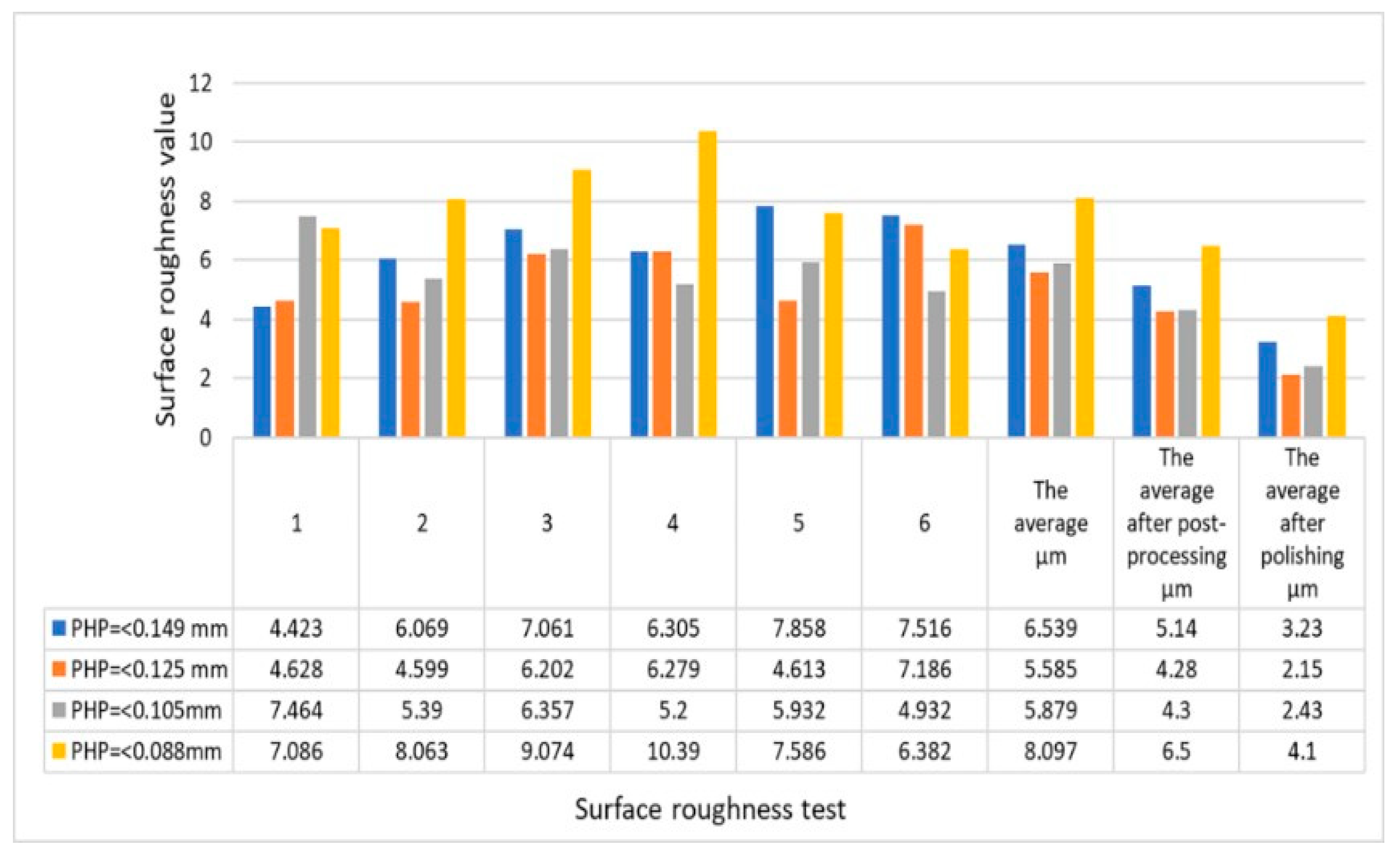

2.10. Surface Roughness Analysis

2.11. Residual Ash Content Analysis

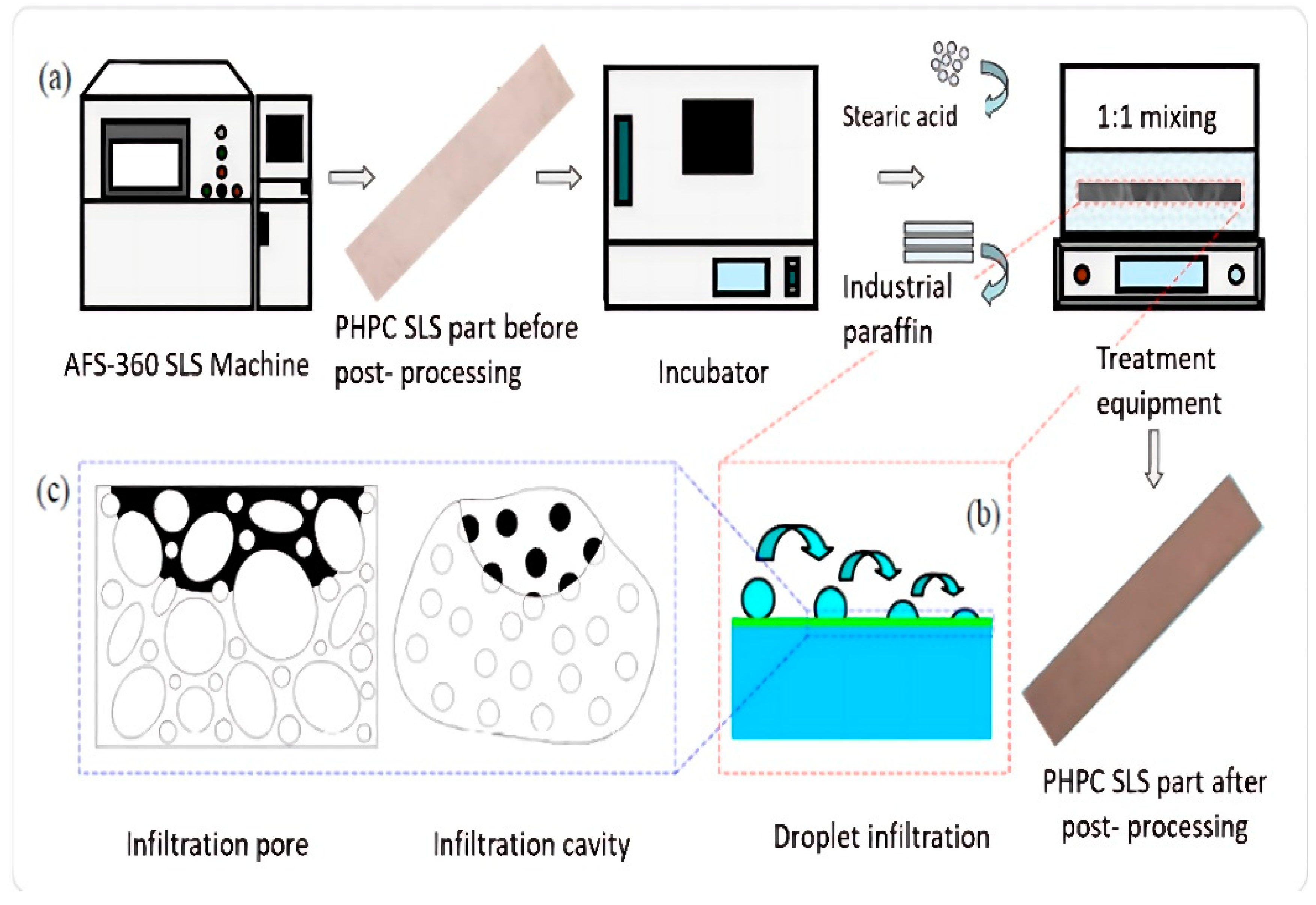

2.12. Post-Processing Treatment

3. Results and Discussion

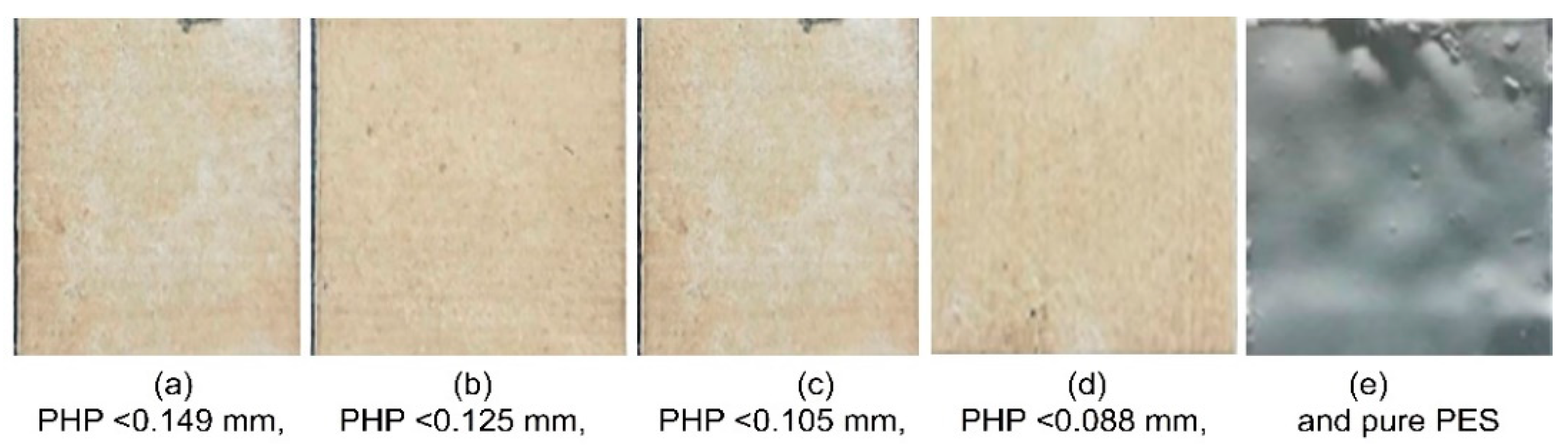

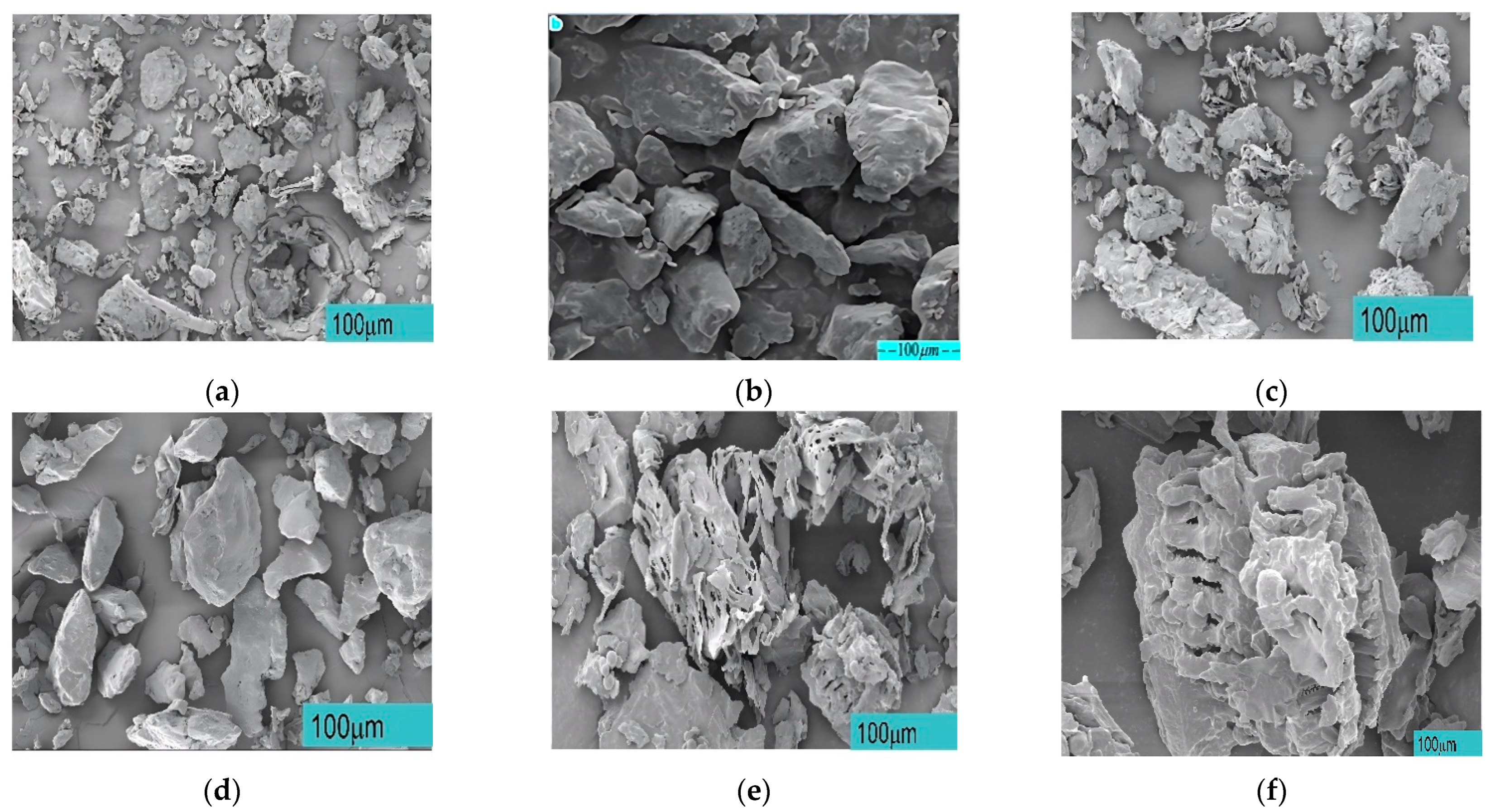

3.1. Single-Layer Sintering Analysis

3.2. Selective Laser Sintering Test Experiment

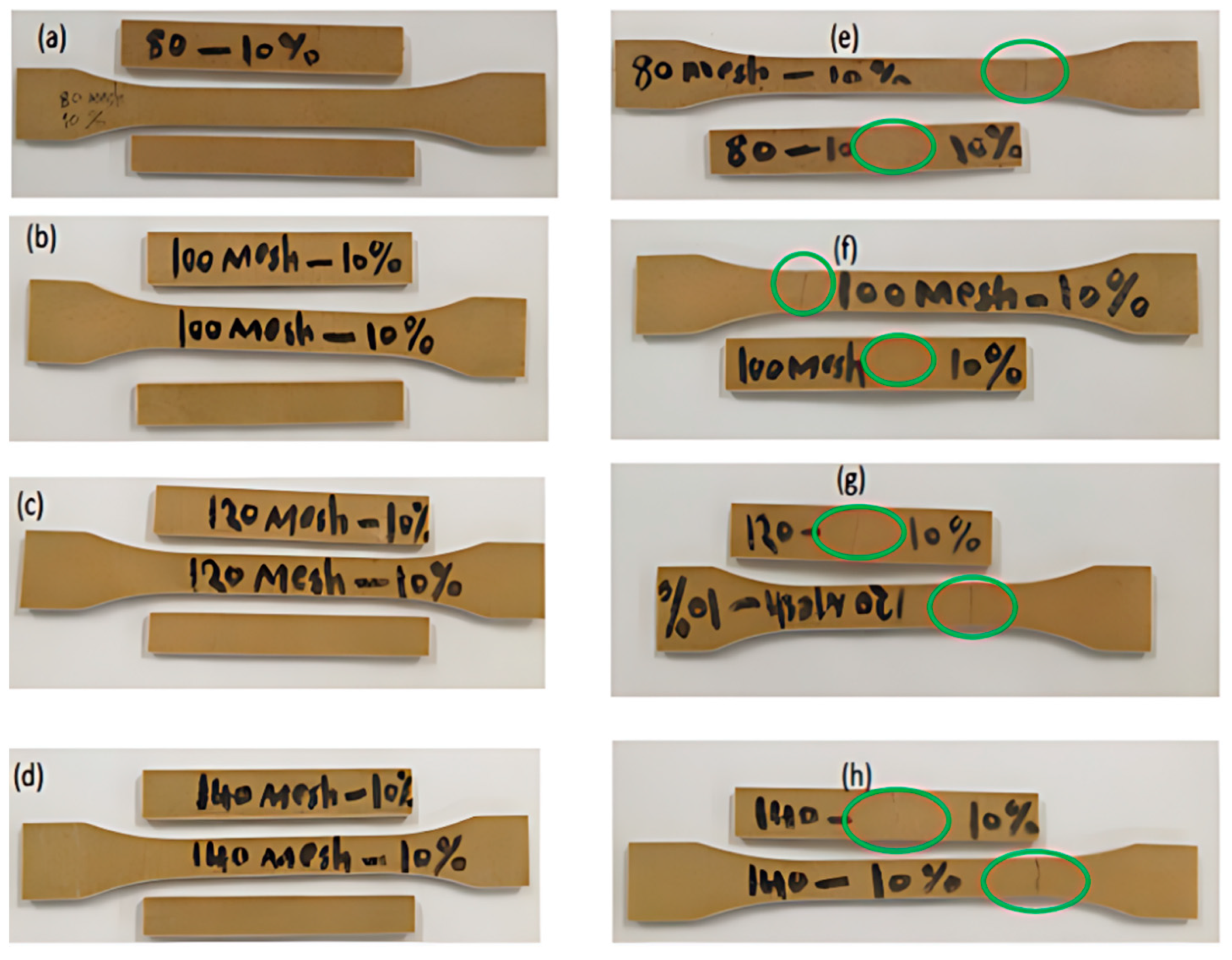

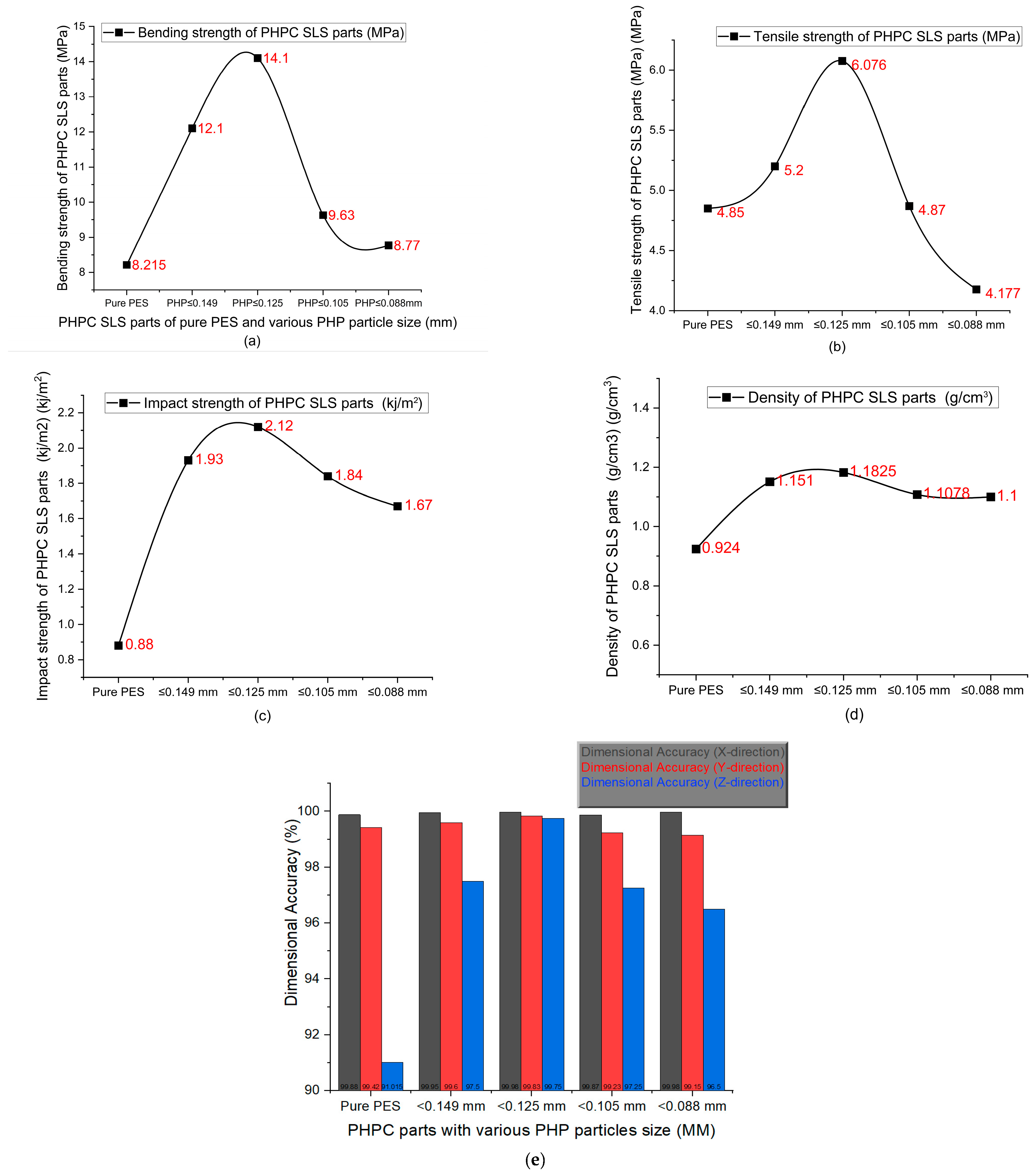

3.3. Mechanical Properties’ Analysis

3.4. Statistical Analyses

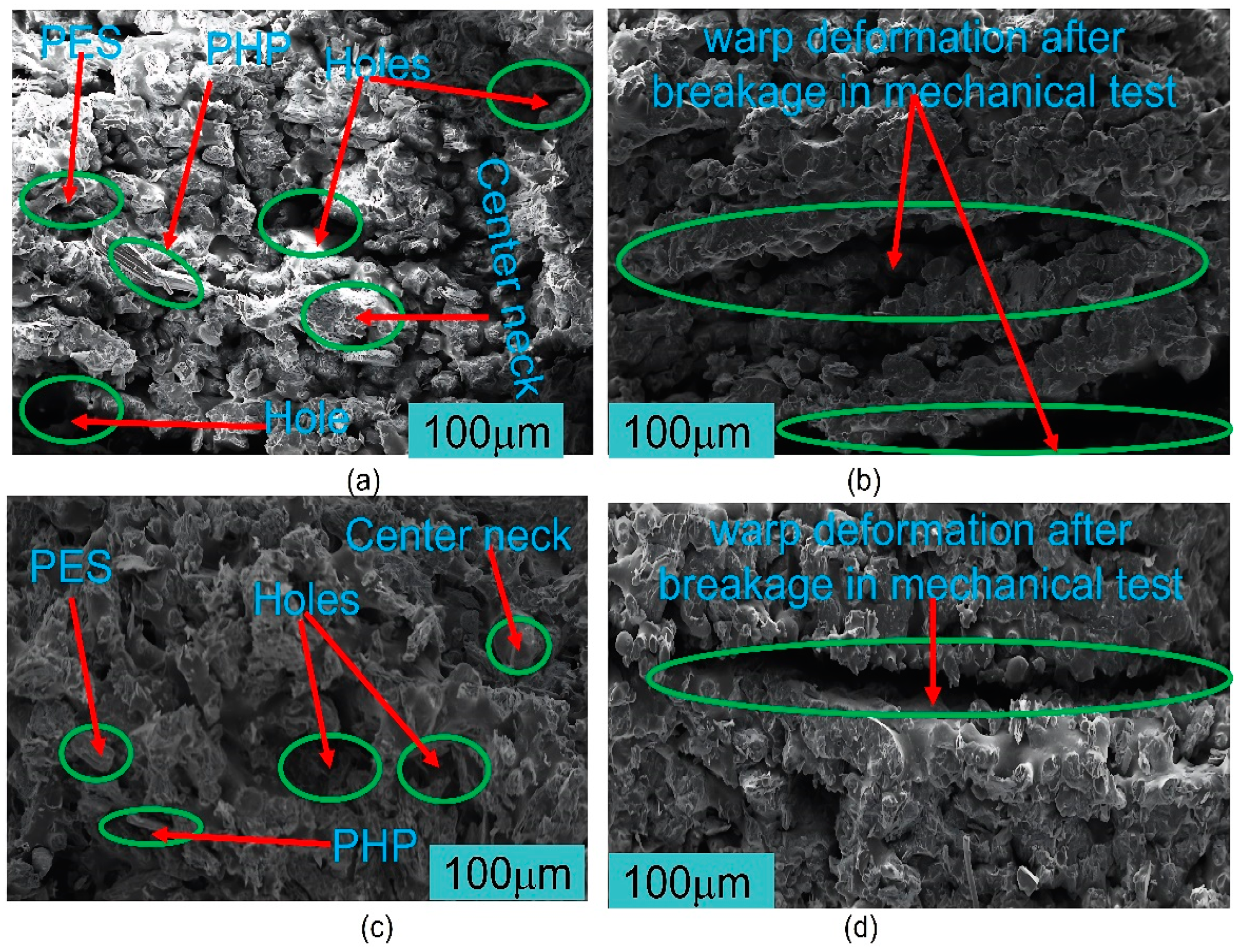

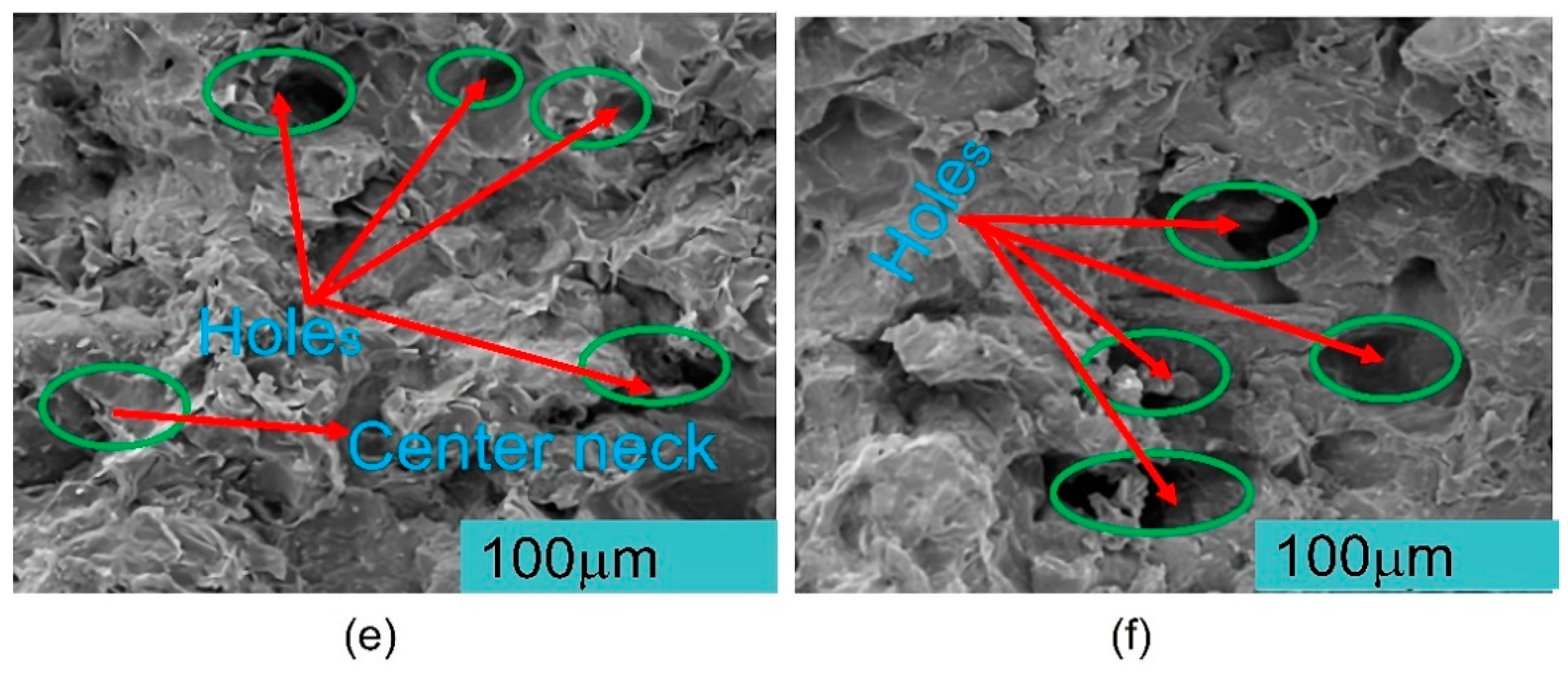

3.5. SEM Microstructure Analysis

3.6. Sintering Temperature Analysis of the PHPC

4. Conclusions

- PHPC SLS parts achieved superior mechanical performance with PHP particles ≤0.125 mm.

- Reducing the PHP particle size initially improved the strength, density, DA, and surface roughness of PHPC SLS parts, along with the residual ash content. However, further reduction decreased these properties.

- PHPC SLS specimens had minimal quantities and inner hole sizes with PHP particles ≤0.125 mm, but these increased at ≤0.088 mm.

- PHP particles ≤0.125 mm had the highest impact strength (2.12 kJ/cm2), tensile strength (6.076 MPa), density (1.1825 g/cm3), and bending strength (14.1 MPa). These attributes decreased as the PHP particle size decreased from ≤0.105 mm to ≤0.088 mm. A better DA in the X, Y, and Z directions was also shown compared to pure PES SLS parts, as well as a lower residual ash content and favorable surface roughness, compared to the other parts.

- The SEM photos showed that PHP ≤ 0.125 mm is the best particle size for PHPC SLS because of the largest bonding area and the small pores observed.

- The mechanical strength and surface roughness of PHPC SLS were enhanced by post-processing with wax infiltration and polishing. Density, bending strength, impact strength, and tensile strength increased to 2.0625 g/cm3, 15.7 MPa, 2.96 kJ/cm2, and 7.476 MPa, respectively. Surface roughness improved from 5.585 μm to 3.58 μm due to wax infiltration into the holes, with a slight decrease and subsequent improvement in DA after polishing.

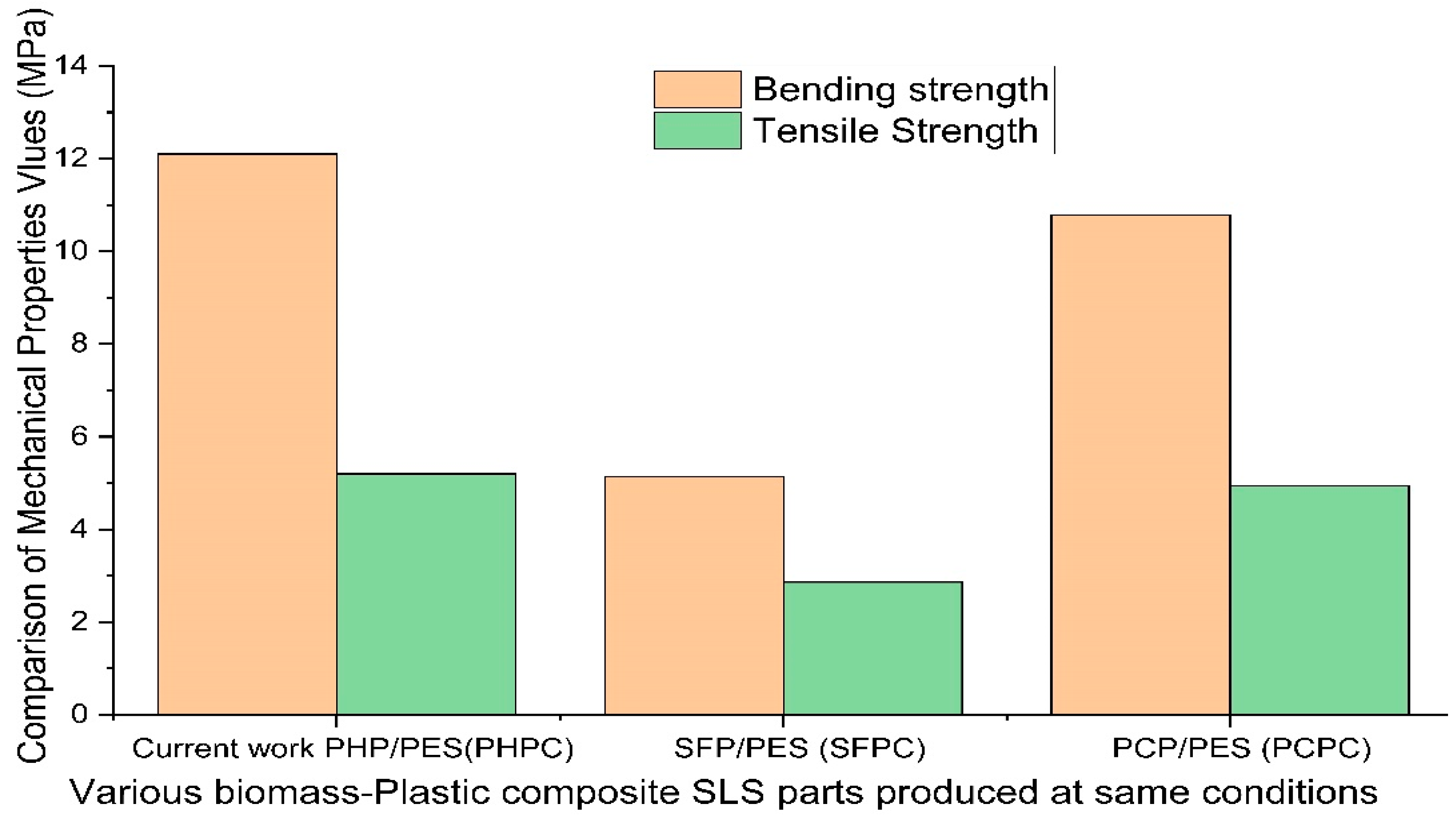

- Optimized PHPC SLS parts had superior mechanical properties compared to other biomass composites, making them suitable for applications in AM technology, such as the furniture industry and for various wooden flooring options.

- Incorporating PHP into the PHPC composite not only enhances the SLS manufacturing sustainability but also produces strong, eco-friendly parts, making it promising for wider industrial use.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deater–Deckard, K.; Dodge, K.A.; Bates, J.E.; Pettit, G.S. Multiple risk factors in the development of externalizing behavior problems: Group and individual differences. Dev. Psychopathol. 1998, 10, 469–493. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.D.; Deckard, C.R. Advances in modeling the effects of selected parameters on the SLS process. Rapid Prototyp. J. 1998, 4, 90–100. [Google Scholar] [CrossRef]

- Yuan, S.; Shen, F.; Bai, J.; Chua, C.K.; Wei, J.; Zhou, K. 3D soft auxetic lattice structures fabricated by selective laser sintering: TPU powder evaluation and process optimization. Mater. Des. 2017, 120, 317–327. [Google Scholar] [CrossRef]

- Rahman, A.M.; Rahman, T.T.; Pei, Z.; Ufodike, C.O.; Lee, J.; Elwany, A. Additive Manufacturing Using Agriculturally Derived Biowastes: A Systematic Literature Review. Bioengineering 2023, 10, 845. [Google Scholar] [CrossRef] [PubMed]

- Hopkinson, N.; Dickens, P. Rapid prototyping for direct manufacture. Rapid Prototyp. J. 2001, 7, 197–202. [Google Scholar] [CrossRef]

- Kim, J.; Creasy, T. Selective laser sintering characteristics of nylon 6/clay-reinforced nanocomposite. Polym. Test. 2004, 23, 629–636. [Google Scholar] [CrossRef]

- Guo, Y.; Jiang, K.; Bourell, D.L. Accuracy and mechanical property analysis of LPA12 parts fabricated by laser sintering. Polym. Test. 2015, 42, 175–180. [Google Scholar] [CrossRef]

- Jiang, K.; Guo, Y.; Bourell, D.; Zeng, W.; Li, Z. Study on Selective Laser Sintering of Eucalyptus/PES Blend and Investment Casting Technology. Procedia CIRP 2013, 6, 510–514. [Google Scholar] [CrossRef][Green Version]

- Li, H.; Guo, Y.; Shuhui, T.; Jian, L.; Idriss, A.I.B. Study on selective laser sintering process and investment casting of rice husk/Co-Polyamide (Co-PA hotmelt adhesive) composite. J. Thermoplast. Compos. Mater. 2023, 36, 2311–2331. [Google Scholar] [CrossRef]

- Zhao, D.; Guo, Y.; Jiang, K.; Zhang, H. Preparation and selective laser sintering of bamboo flour/copolyester composite and post-processing. J. Thermoplast. Compos. Mater. 2017, 30, 1045–1055. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, Y.; Jiang, T.; Jiang, K.; Li, J.; Guo, S. Laser sintering and post-processing of a walnut shell/Co-PES composite. RSC Adv. 2017, 7, 23176–23181. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, Y.; Jiang, T.; Li, J.; Jiang, K.; Zhang, H. Study on Process and Parameter Optimization of Selective Laser Sintering of Walnut Shell Composite Powder. BioResources 2018, 13, 3017–3029. [Google Scholar] [CrossRef]

- Li, J.; Idriss, A.I.B.; Guo, Y.; Wang, Y.; Zhang, Z.; Zhang, H.; Elfaki, E.A. Selective laser sintering and post-processing of sisal fiber/ poly-(ether sulfone) composite powder. BioResources 2020, 15, 1338–1353. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Pande, S.; Bobade, S.M.; Kumar, S. Assessment of mechanical properties and flammability of magnesium oxide/PA12 composite material for SLS process. Rapid Prototyp. J. 2018, 25, 176–186. [Google Scholar] [CrossRef]

- Leach, R.; Bourell, D.; Carmignato, S.; Donmez, A.; Senin, N.; Dewulf, W. Geometrical metrology for metal additive manufacturing. CIRP Ann. 2019, 68, 677–700. [Google Scholar] [CrossRef]

- Gadelmoula, A.M.; Aldahash, S.A. Effects of Fabrication Parameters on the Properties of Parts Manufactured with Selective Laser Sintering: Application on Cement-Filled PA12. Adv. Mater. Sci. Eng. 2019, 2019, 8404857. [Google Scholar] [CrossRef]

- Idriss, A.I.B.; Li, J.; Wang, Y.; Guo, Y.; Elfaki, E.A.; Adam, S.A. Selective Laser Sintering (SLS) and Post-Processing of Prosopis Chilensis/Polyethersulfone Composite (PCPC). Materials 2020, 13, 3034. [Google Scholar] [CrossRef]

- Idriss, A.I.; Li, J.; Guo, Y.; Wang, Y.; Li, X.; Zhang, Z.; Elfaki, E.A. Sintering quality and parameters optimization of sisal fiber/PES composite fabricated by selective laser sintering (SLS). J. Thermoplast. Compos. Mater. 2022, 35, 1632–1646. [Google Scholar] [CrossRef]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Moshokoa, N.; Raganya, L.; Obadele, B.A.; Machaka, R.; Makhatha, M.E. Microstructural and mechanical properties of Ti-Mo alloys designed by the cluster plus glue atom model for biomedical application. Int. J. Adv. Manuf. Technol. 2020, 111, 1237–1246. [Google Scholar] [CrossRef]

- Redaelli, D.F.; Abbate, V.; Storm, F.A.; Ronca, A.; Sorrentino, A.; De Capitani, C.; Biffi, E.; Ambrosio, L.; Colombo, G.; Fraschini, P. 3D printing orthopedic scoliosis braces: A test comparing FDM with thermoforming. Int. J. Adv. Manuf. Technol. 2020, 111, 1707–1720. [Google Scholar] [CrossRef]

- Zeng, W.; Guo, Y.; Jiang, K.; Yu, Z.; Liu, Y.; Shen, Y.; Deng, J.; Wang, P. Laser intensity effect on mechanical properties of wood–plastic composite parts fabricated by selective laser sintering. J. Thermoplast. Compos. Mater. 2013, 26, 125–136. [Google Scholar] [CrossRef]

- Aldahash, S.A. Optimum manufacturing parameters in selective laser sintering of PA12 with white cement additives. Int. J. Adv. Manuf. Technol. 2018, 96, 257–270. [Google Scholar] [CrossRef]

- Idriss, A.I.; Li, J.; Guo, Y.; Wang, Y.; Elfaki, E.A.; Ahmed, E.A. Improved Sintering Quality and Mechanical Properties of Peanut Husk Powder/Polyether Sulfone Composite for Selective Laser Sintering. 3D Print. Addit. Manuf. 2023, 10, 111–123. [Google Scholar]

- Sofia, D.; Chirone, R.; Lettieri, P.; Barletta, D.; Poletto, M. Selective laser sintering of ceramic powders with bimodal particle size distribution. Chem. Eng. Res. Des. 2018, 136, 536–547. [Google Scholar] [CrossRef]

- Li, J.; Bolad, A.I.; Guo, Y.; Wang, Y.; Elfaki, E.A.; Adam, S.A.A.; Ahmed, G.A.A.M. Effects of various processing parameters on the mechanical properties and dimensional accuracies of Prosopis chilensis/PES composites produced by SLS. Rapid Prototyp. J. 2022, 28, 1144–1167. [Google Scholar] [CrossRef]

- Sun, Z.; Du, S.; Zhang, D.; Song, W. Influence of pH and loading of PANI on electrochemical and electromechanical properties for high-performance renewable soft actuator with nano-biocomposite electrode. React. Funct. Polym. 2019, 139, 102–111. [Google Scholar] [CrossRef]

- Zhang, H.; Bourell, D.; Guo, Y.; Zhang, X.; Zhuang, Y.; Yu, Y.; Jiang, K.; Helal, W.M.K. Study on laser sintering of pine/co-PES composites and the investment casting process. Rapid Prototyp. J. 2019, 25, 1349–1358. [Google Scholar] [CrossRef]

- Zeng, W.; Guo, Y.; Jiang, K.; Yu, Z.; Liu, Y. Preparation and selective laser sintering of rice husk-plastic composite powder and post processing. Dig. J. Nanomater. Biostructures 2012, 7, 1063–1070. [Google Scholar]

- Yu, Y.; Jiang, M.; Wang, S.; Guo, Y.; Jiang, T.; Zeng, W.; Zhuang, Y. Impact of Particle Size on Performance of Selective Laser Sintering Walnut Shell/Co-PES Powder. Materials 2021, 14, 448. [Google Scholar] [CrossRef]

- Idriss, A.I.B.; Li, J.; Guo, Y.; Shuhui, T.; Wang, Y.; Elfaki, E.A.; Ahmed, G.A. Selective laser sintering parameter optimization of prosopis chilensis/polyethersulfone composite fabricated by AFS-360 SLS. 3d Print. Addit. Manuf. 2023, 10, 697–710. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Ma, P.; Fang, Y.; Yang, Z.; Zhang, N.; Prashanth, K.G.; Jia, Y. Effect of NiCoFeAlTi high entropy intermetallic reinforcement particle size on the microstructure and mechanical properties of CoCrFeMnNi high-entropy alloy composites fabricated by selective laser melting. J. Alloys Compd. 2023, 947, 169417. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, T.; Wang, S.; Jiang, M.; Guo, Y.; Jiang, T.; Huang, S.; Zheng, Z.; Yan, B.; Lv, J. Simulation Analysis of Stress Field of Walnut Shell Composite Powder in Laser Additive Manufacturing Forming. J. Renew. Mater. 2023, 11, 333–347. [Google Scholar] [CrossRef]

- Le, D.; Nguyen, C.H.; Pham, T.H.N.; Nguyen, V.T.; Pham, S.M.; Le, M.T.; Nguyen, T.T. Optimizing 3D Printing Process Parameters for the Tensile Strength of Thermoplastic Polyurethane Plastic. J. Mater. Eng. Perform. 2023, 1–12. [Google Scholar] [CrossRef]

- GB/T 1040-1992; Plastics—Determination of Tensile Properties. Standardization Administration of China (SAC): Beijing, China, 1992.

- GB/T 9341-2008; Plastics Determination of Bending Properties. Standardization Administration of China (SAC): Beijing, China, 2008.

- ISO 179-2000; Plastics—Determination of Charpy Impact Properties. International Organization for Standardization (ISO): Geneva, Switzerland, 2000.

| PHPC SLS Parts | Width (mm) | Thickness (mm) | Length (mm) |

|---|---|---|---|

| PHP ≤ 0.149 mm | 13.052 | 4.1 | 80.04 |

| PHP ≤ 0.125 mm | 13.1 | 4.01 | 80.01 |

| PHP ≤ 0.105 mm | 13.1 | 4.11 | 79.9 |

| PHP ≤ 0.088 mm | 13.12 | 4.14 | 80.014 |

| Parts at 10/90 | Bending Strength Test Repeatability | Mean | 95% Confidence Intervals for the Means | Tensile Strength Test Repeatability | Mean | 95% Confidence Intervals for the Means | Standard Deviation (SD) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test 1 | Test 2 | Test 3 | Test 1 | Test 2 | Test 3 | Bending | Tensile | |||||

| PES | 8.15 | 8.28 | 8.23 | 8.215 | Lower = 7.22 Upper = 9.22 | 4.83 | 4.9 | 4.81 | 4.85 | Lower = 4.27 Upper = 5.43 | 0.065574385 | 0.047258156 |

| ≤0.149 mm | 12.6 | 11.9 | 11.8 | 12.1 | Lower = 11.52 Upper = 12.68 | 5.1 | 5.15 | 5.36 | 5.2 | Lower = 4.62 Upper = 5.78 | 0.34588989 | 0.13796135 |

| ≤0.125 mm | 14 | 14.1 | 14.2 | 14.1 | Lower = 13.52 Upper = 14.68 | 5.93 | 6.1 | 6.2 | 6.076 | Lower = 5.49 Upper = 6.66 | 0.1 | 0.13650397 |

| ≤0.105 mm | 9.8 | 9.9 | 9.2 | 9.63 | Lower = 9.05 Upper = 10.21 | 4.8 | 4.8 | 5 | 4.87 | Lower = 4.29 Upper = 5.45 | 0.37859389 | 0.11547005 |

| ≤0.088 mm | 9.4 | 8.8 | 8.3 | 8.77 | Lower = 8.19 Upper = 9.4 | 4.3 | 4.06 | 4.17 | 4.177 | Lower = 3.6 Upper = 4.76 | 0.55075705 | 0.12013881 |

| SLS Parts | Bending Strength (MPa) | The Related Tensile Force Loading (N) | Tensile Strength (MPa) | The Related Tensile Force Loading (N) |

|---|---|---|---|---|

| PES | 8.215 | 138 | 4.85 | 102 |

| ≤0.149 mm | 12.1 | 152.5 | 5.2 | 109 |

| ≤0.125 mm | 14.1 | 158 | 6.076 | 115.7 |

| ≤0.105 mm | 9.63 | 146 | 4.87 | 102.6 |

| ≤0.088 mm | 8.77 | 140 | 4.177 | 99.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Idriss, A.I.B.; Yang, C.-M.; Li, J.; Guo, Y.; Liu, J.; Abdelmagid, A.A.A.; Ahmed, G.A.; Zhang, H. Influence of Particle Size on the Mechanical Performance and Sintering Quality of Peanut Husk Powder/PES Composites Fabricated through Selective Laser Sintering. Polymers 2023, 15, 3913. https://doi.org/10.3390/polym15193913

Idriss AIB, Yang C-M, Li J, Guo Y, Liu J, Abdelmagid AAA, Ahmed GA, Zhang H. Influence of Particle Size on the Mechanical Performance and Sintering Quality of Peanut Husk Powder/PES Composites Fabricated through Selective Laser Sintering. Polymers. 2023; 15(19):3913. https://doi.org/10.3390/polym15193913

Chicago/Turabian StyleIdriss, Aboubaker I. B., Chun-Mei Yang, Jian Li, Yanling Guo, Jiuqing Liu, Alaaeldin A. A. Abdelmagid, Gafer A. Ahmed, and Hao Zhang. 2023. "Influence of Particle Size on the Mechanical Performance and Sintering Quality of Peanut Husk Powder/PES Composites Fabricated through Selective Laser Sintering" Polymers 15, no. 19: 3913. https://doi.org/10.3390/polym15193913

APA StyleIdriss, A. I. B., Yang, C.-M., Li, J., Guo, Y., Liu, J., Abdelmagid, A. A. A., Ahmed, G. A., & Zhang, H. (2023). Influence of Particle Size on the Mechanical Performance and Sintering Quality of Peanut Husk Powder/PES Composites Fabricated through Selective Laser Sintering. Polymers, 15(19), 3913. https://doi.org/10.3390/polym15193913