Effects of Cavity Thickness and Mold Surface Roughness on the Polymer Flow during Micro Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

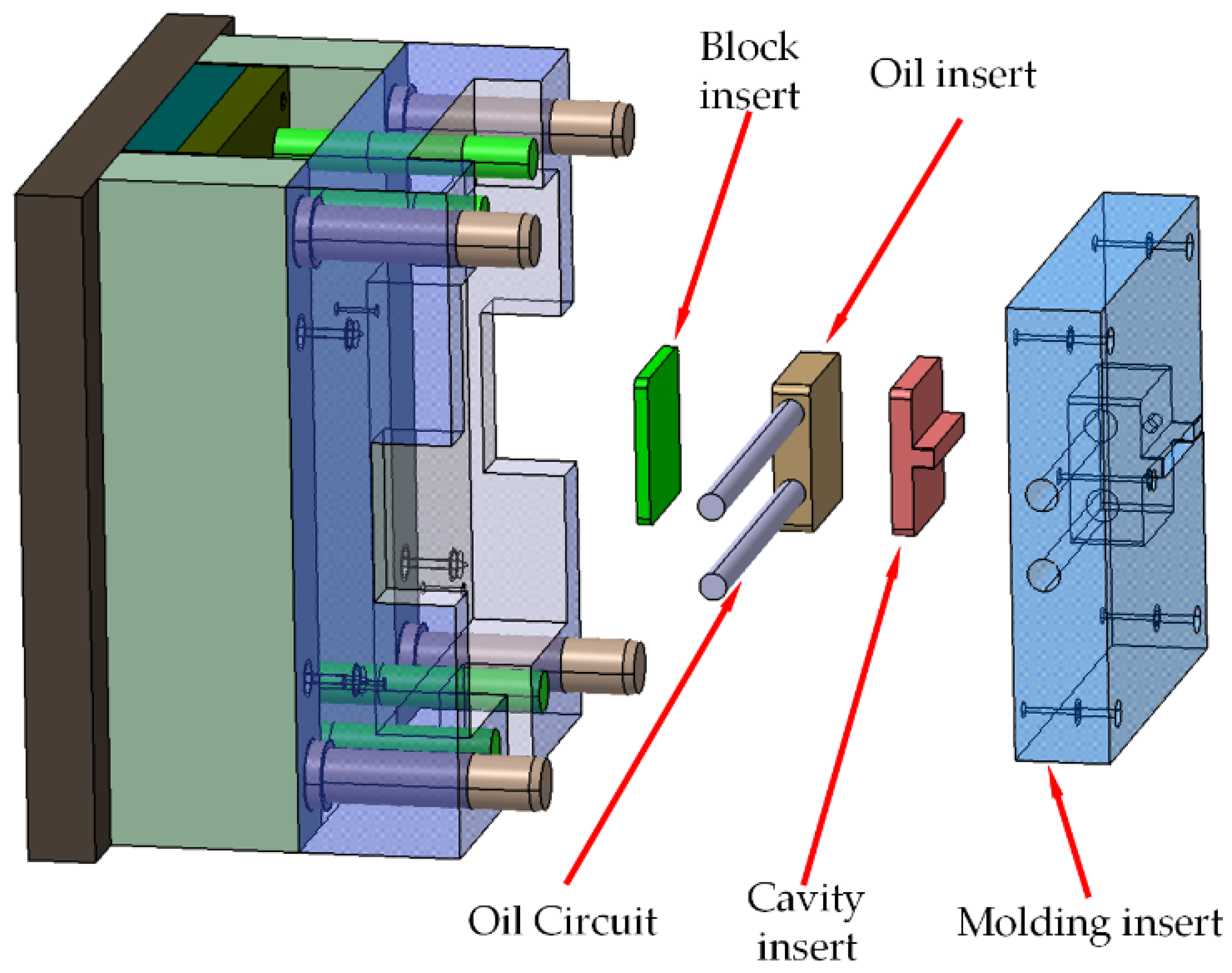

2.1. Experiment

2.2. Surface Roughness Measurement

2.3. Evaluation of Polymer Flow

2.3.1. Parts Filling Integrity

2.3.2. Roughness Replication Ratio

2.4. Full Factorial Experimental Design

3. Results and Discussion

3.1. Effects of Cavity Surface Roughness on Filling Integrity with Single Cavity Thickness

3.2. The Difference of Filling Integrity of Different Cavity Surface Roughness with Different Thicknesses

3.3. The Effects of Cavity Thickness on Filling Integrity

3.4. The Effects of Cavity Surface Roughness on Roughness Replication Ratio

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhuo, C.; Ji, K.; Xie, J.; Cheng, X.; Jiao, X.; Ye, S.; Fu, J.; Zhao, P. Non-intrusive ultrasonic measurement of tie-bar stress for molding equipment. Meas. Sci. Technol. 2022, 33, 115111. [Google Scholar] [CrossRef]

- Shahriari, A.; Samei, J.; Sanjari, M.; Jahanbakht, M.; Amirkhiz, B.S.; Mohammadi, M. Plastic injection molding dies using hybrid additively manufactured 420/CX stainless steels: Electrochemical considerations. npj Mater Degrad 2022, 6, 70. [Google Scholar] [CrossRef]

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Analysis of Spring-in Deformation in L-shaped Profiles Pultruded at Different Pulling Speeds: Mathematical Simulation and Experimental Results. In Proceedings of the ESAFORM 2021. 24th International Conference on Material Forming, Liège, Belgique, 8 April 2021. [Google Scholar]

- Piccolo, L.; Puleo, K.; Sorgato, M.; Lucchetta, G.; Masato, D. Modeling the replication of submicron-structured surfaces by micro injection molding. Mater. Design 2021, 198, 109272. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Lucchetta, G. A new approach to the evaluation of ejection friction in micro injection molding. J. Manuf. Process. 2021, 62, 28–36. [Google Scholar] [CrossRef]

- Bellantone, V.; Surace, R.; Fassi, I. Quality Definition in Micro Injection Molding Process by Means of Surface Characterization Parameters. Polymers 2022, 14, 3775. [Google Scholar] [CrossRef]

- Maghsoudi, K.; Jafari, R.; Momen, G.; Farzaneh, M. Micro-nanostructured polymer surfaces using injection molding: A review. Mater. Today Commun. 2017, 13, 126–143. [Google Scholar] [CrossRef]

- Packianather, M.; Griffiths, C.; Kadir, W. Micro Injection Moulding Process Parameter Tuning. Procedia Cirp 2015, 33, 400–405. [Google Scholar] [CrossRef] [Green Version]

- Liparoti, S.; Speranza, V.; Pantani, R.; Titomanlio, G. Multi-Scale Simulation of Injection Molding Process with Micro-Features Replication: Relevance of Rheological Behaviour and Crystallization. Polymers 2021, 13, 3236. [Google Scholar] [CrossRef]

- Yang, C.; Yin, X.H.; Cheng, G.M. Microinjection molding of microsystem components: New aspects in improving performance. J. Micromech. Microeng. 2013, 23, 093001. [Google Scholar] [CrossRef]

- Vedernikov, A.; Minchenkov, K.; Gusev, S.; Sulimov, A.; Zhou, P.; Li, C.; Xian, G.; Akhatov, I.; Safonov, A. Effects of the Pre-Consolidated Materials Manufacturing Method on the Mechanical Properties of Pultruded Thermoplastic Composites. Polymers 2022, 14, 2246. [Google Scholar] [CrossRef]

- Gao, R.; Chen, H.; Hu, Z.; Cheng, X.; Gao, S.; Zhou, S.; Zhao, P. An integrated simulation method for analyzing mechanical properties of injection molded fiber-reinforced polymers. Polym. Compos. 2022, 43, 4530–4543. [Google Scholar] [CrossRef]

- Szabó, F.; Suplicz, A.; Kovács, J.G. Development of injection molding simulation algorithms that take into account segregation. Powder Technol. 2021, 389, 368–375. [Google Scholar] [CrossRef]

- Gülçür, M.; Brown, E.; Gough, T.; Romano, J.-M.; Penchev, P.; Dimov, S.; Whiteside, B. Ultrasonic micromoulding: Process characterisation using extensive in-line monitoring for micro-scaled products. J. Manuf. Process. 2020, 58, 289–301. [Google Scholar] [CrossRef]

- Regi, F.; Doest, M.; Loaldi, D.; Li, D.; Frisvad, J.R.; Tosello, G.; Zhang, Y. Functionality characterization of injection moulded micro-structured surfaces. Precis. Eng. 2019, 60, 594–601. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, L.; Li, S.; Zhang, Y.; Wang, D.; Li, Q.; Shen, C. Influence of scale effect and injection speed on morphology and structure of the microinjection molded isotactic polypropylene parts. Polym. Adv. Technol. 2020, 31, 1463–1473. [Google Scholar] [CrossRef]

- Li, K.; Yan, S.; Zhong, Y.; Pan, W.; Zhao, G. Multi-objective optimization of the fiber-reinforced composite injection molding process using Taguchi method, RSM, and NSGA-II. Simul. Model. Pract. Theory 2019, 91, 69–82. [Google Scholar] [CrossRef]

- Eladl, A.; Mostafa, R.; Islam, A.; Loaldi, D.; Soltan, H.; Hansen, H.N.; Tosello, G. Effect of Process Parameters on Flow Length and Flash Formation in Injection Moulding of High Aspect Ratio Polymeric Micro Features. Micromachines 2018, 9, 58. [Google Scholar] [CrossRef] [Green Version]

- Jia, J.; Song, Q.; Liu, Z.; Wang, B. Effect of wall roughness on performance of microchannel applied in microfluidic device. Microsyst. Technol. 2019, 25, 2385–2397. [Google Scholar] [CrossRef]

- Chen, Y.; Kalyon, D.M.; Bayramli, E. Effects of surface roughness and the chemical structure of materials of construction on wall slip behavior of linear low density polyethylene in capillary flow. J. Appl. Polym. Sci. 1993, 50, 1169–1177. [Google Scholar] [CrossRef]

- Griffiths, C.A.; Dimov, S.S.; Brousseau, E.B.; Hoyle, R.T. The effects of tool surface quality in micro-injection moulding. J. Mater. Process. Technol. 2007, 189, 418–427. [Google Scholar] [CrossRef]

- Surace, R.; Sorgato, M.; Bellantone, V.; Modica, F.; Fassi, I. Effect of cavity surface roughness and wettability on the filling flow in micro injection molding. J. Manuf. Process. 2019, 43, 105–111. [Google Scholar] [CrossRef]

- Bellantone, V.; Surace, R.; Modica, F.; Fassi, I. Evaluation of mold roughness influence on injected thin micro-cavities. Int. J. Adv. Manuf. Technol. 2018, 94, 4565–4575. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Batal, A.; Dimov, S.; Lucchetta, G. Thin-wall injection molding of polypropylene using molds with different laser-induced periodic surface structures. Polym. Eng. Sci. 2019, 59, 1889–1896. [Google Scholar] [CrossRef]

- Zhu, L.; Min, L.; Li, X.; Zhai, Z.; Drummer, D.; Jiang, B. Effects of process conditions on the heat transfer coefficient at the polymer-mold interface and tensile strength of thin-wall injection molding parts. Polym. Plast. Technol. Eng. 2019, 39, 493–500. [Google Scholar] [CrossRef]

- Liu, Y.; Gehde, M. Evaluation of heat transfer coefficient between polymer and cavity wall for improving cooling and crystallinity results in injection molding simulation. Appl. Therm. Eng. 2015, 80, 238–246. [Google Scholar] [CrossRef]

- Zhang, H.L.; Ong, N.S.; Lam, Y.C. Mold surface roughness effects on cavity filling of polymer melt in micro injection molding. Int. J. Adv. Manuf. Technol. 2008, 37, 1105–1112. [Google Scholar] [CrossRef]

- Stanek, M.; Manas, M.; Ovsik, M.; Reznicek, M.; Senkerik, V.; Janostik, V. Polymer Flow Influenced by Mold Cavity Surface Roughness. Manuf. Technol. 2019, 19, 327–331. [Google Scholar] [CrossRef]

- Chen, C.S.; Chen, S.C.; Liao, W.H.; Chien, R.D.; Lin, S.H. Micro injection molding of a micro-fluidic platform. Int. Commun. Heat Mass Transf. 2010, 37, 1290–1294. [Google Scholar] [CrossRef]

- Xu, B.; An, X.Y.; Li, L.C.; Li, G.M. Viscous Dissipation of Polymer Melt in Micro Channels and Macro Channels. Key Eng. Mater. 2014, 609–610, 521–525. [Google Scholar]

- Quadrini, F.; Bellisario, D.; Santo, L.; Bottini, L.; Boschetto, A. Mold replication in injection molding of high density polyethylene. Polym. Eng. Sci. 2020, 60, 2459–2469. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, F.; Wu, X.; Zhou, C.; Lou, Y.; Li, L. Fabrication of Micro-Structured Polymer by Micro Injection Molding Based on Precise Micro-Ground Mold Core. Micromachines 2019, 10, 253. [Google Scholar] [CrossRef] [PubMed]

- Guan, B.; Cherrill, M.; Pai, J.H.; Priest, C. Effect of mould roughness on injection moulded poly (methyl methacrylate) surfaces: Roughness and wettability. J. Manuf. Process. 2019, 48, 313–319. [Google Scholar] [CrossRef]

- Liu, Y.; Gehde, M. Effects of surface roughness and processing parameters on heat transfer coefficient between polymer and cavity wall during injection molding. Int. J. Adv. Manuf. Technol. 2016, 84, 1325–1333. [Google Scholar] [CrossRef]

- Trotta, G.; Stampone, B.; Fassi, I.; Tricarico, L. Study of rheological behaviour of polymer melt in micro injection moulding with a miniaturized parallel plate rheometer. Polym. Test. 2021, 96, 107068. [Google Scholar] [CrossRef]

- Zhang, H.L.; Ong, N.S.; Lam, Y.C. Experimental investigation of key parameters on the effects of cavity surface roughness in microinjection molding. Polym. Eng. Sci. 2008, 48, 490–495. [Google Scholar] [CrossRef]

- Li, J.; Liu, W.; Xia, X.; Zhou, H.; Jing, L.; Peng, X.; Jiang, S. Reducing the Burn Marks on Injection-Molded Parts by External Gas-Assisted Injection Molding. Polymers 2021, 13, 4087. [Google Scholar] [CrossRef]

- Wang, L.; Li, Q.; Zhu, W.; Shen, C. Scale effect on filling stage in micro-injection molding for thin slit cavities. Microsyst Technol. 2012, 18, 2085–2091. [Google Scholar] [CrossRef]

| Cavity Insert Number | Polishing Method |

|---|---|

| 1 | None |

| 2 | Polished by 60 Cw abrasive paper |

| 3 | Polished by 400 Cw abrasive paper |

| 4 | Polished by 1500 Cw abrasive paper |

| 5 | Polished by polishing paste |

| Processing Parameters | Values |

|---|---|

| Melt temperature (°C) | 255 |

| Mold temperature (°C) | 100 |

| Injection speed (mm/s) | 280 |

| Injection pressure (MPa) | 160 |

| Holding pressure (MPa) | 128 |

| Holding time (s) | 7 |

| Cooling time (s) | 35 |

| Cavity Insert No. | Ra (nm) | Ra Stand Deviation (nm) | Rq (nm) | Rq Stand Deviation (nm) | Rz (nm) | Rz Stand Deviation (nm) |

|---|---|---|---|---|---|---|

| R1 | 46.55 | 12.42 | 88.68 | 43.98 | 370.08 | 173.03 |

| R2 | 71.27 | 13.72 | 132.50 | 49.73 | 802.26 | 242.41 |

| R3 | 180.05 | 21.03 | 227.06 | 21.01 | 1114.77 | 68.24 |

| R4 | 286.89 | 31.33 | 363.26 | 29.88 | 1701.14 | 40.71 |

| R5 | 462.57 | 101.80 | 591.31 | 135.36 | 2793.20 | 690.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Ma, H.; Liu, W.; Jiang, S.; Pan, B. Effects of Cavity Thickness and Mold Surface Roughness on the Polymer Flow during Micro Injection Molding. Polymers 2023, 15, 326. https://doi.org/10.3390/polym15020326

Li J, Ma H, Liu W, Jiang S, Pan B. Effects of Cavity Thickness and Mold Surface Roughness on the Polymer Flow during Micro Injection Molding. Polymers. 2023; 15(2):326. https://doi.org/10.3390/polym15020326

Chicago/Turabian StyleLi, Jiquan, Haowei Ma, Wenyong Liu, Shaofei Jiang, and Baisong Pan. 2023. "Effects of Cavity Thickness and Mold Surface Roughness on the Polymer Flow during Micro Injection Molding" Polymers 15, no. 2: 326. https://doi.org/10.3390/polym15020326

APA StyleLi, J., Ma, H., Liu, W., Jiang, S., & Pan, B. (2023). Effects of Cavity Thickness and Mold Surface Roughness on the Polymer Flow during Micro Injection Molding. Polymers, 15(2), 326. https://doi.org/10.3390/polym15020326