Radiation Protection Device Composite of Epoxy Resin and Iodine Contrast Media for Low-Dose Radiation Protection in Diagnostic Radiology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Epoxy Resin Material Radiation Shielding

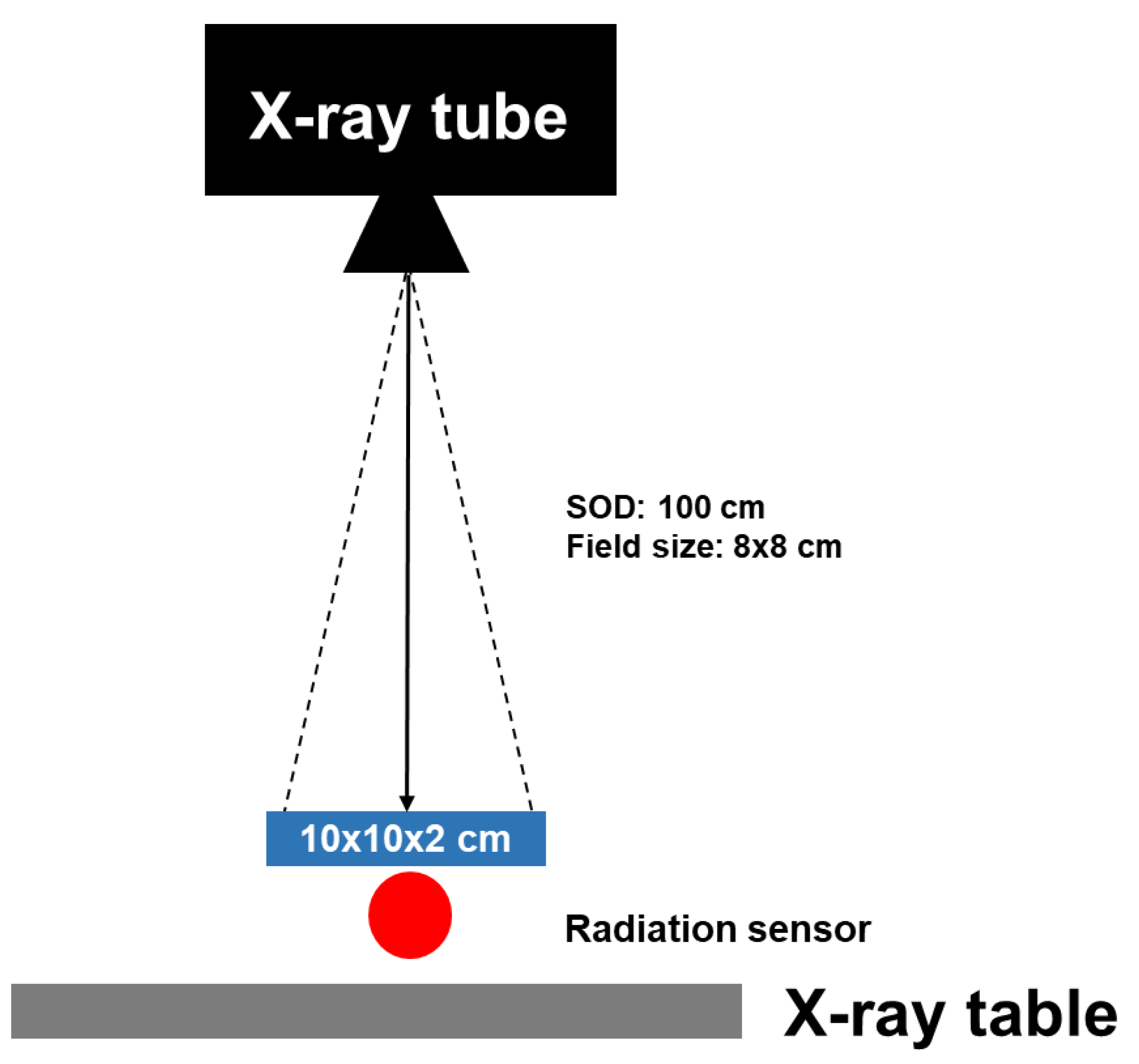

2.2. The Efficiency of Epoxy Resin Shielding Material Measurements

2.3. Materials Characterization of Epoxy Resin Shielding Material

3. Results

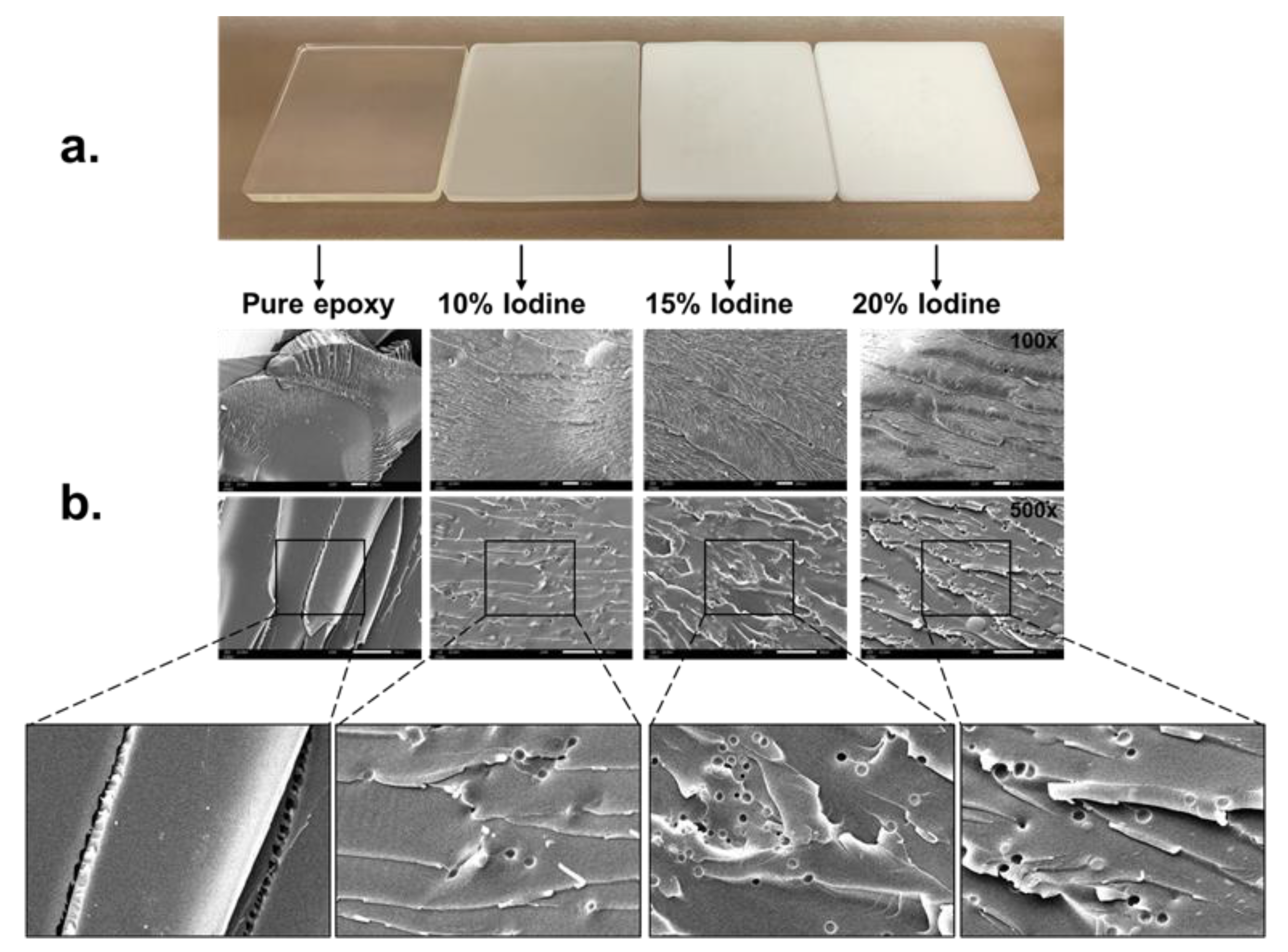

3.1. The Structural Characterization of Epoxy Resin Shielding Material

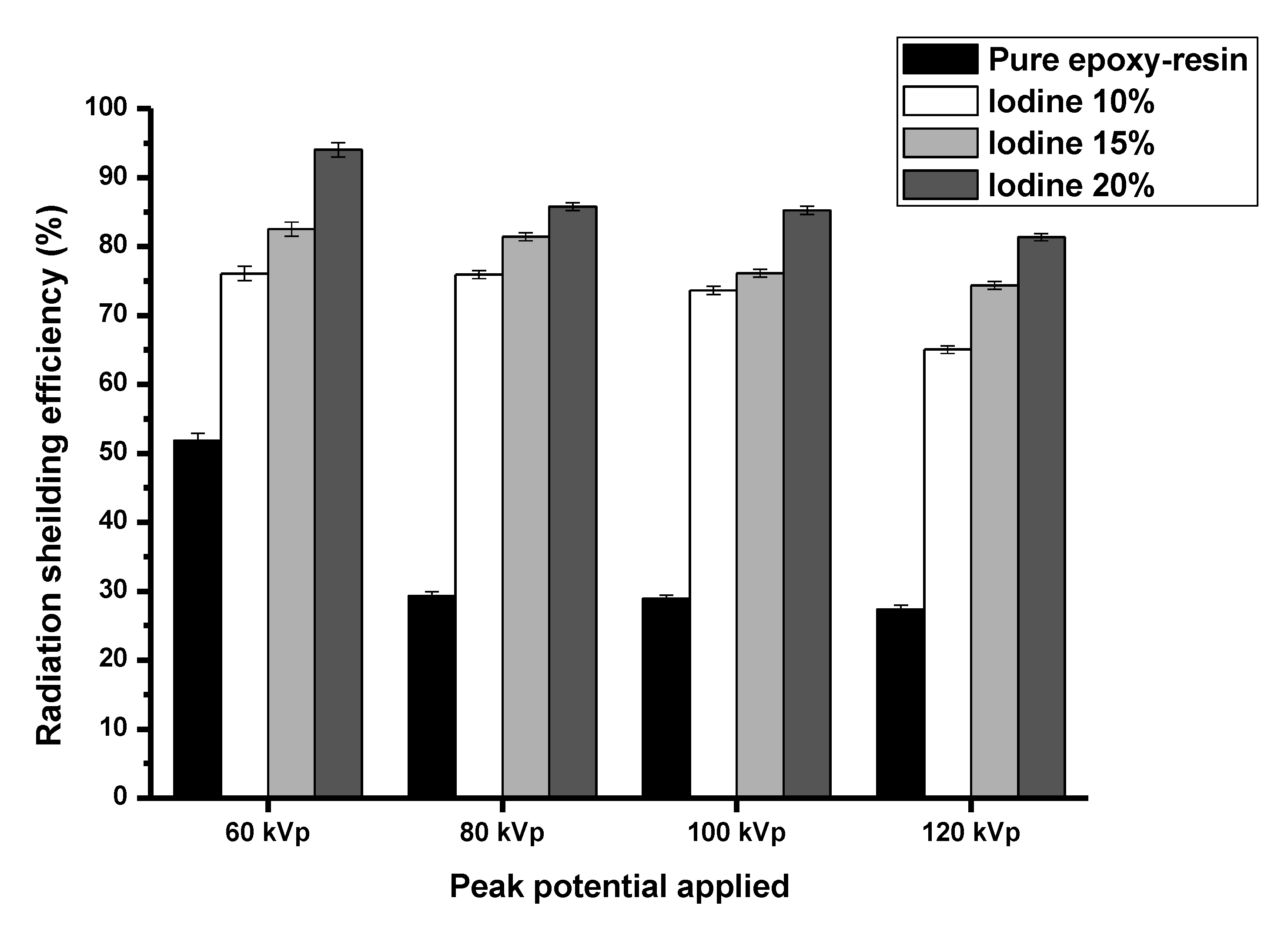

3.2. Radiation-Shielding Properties

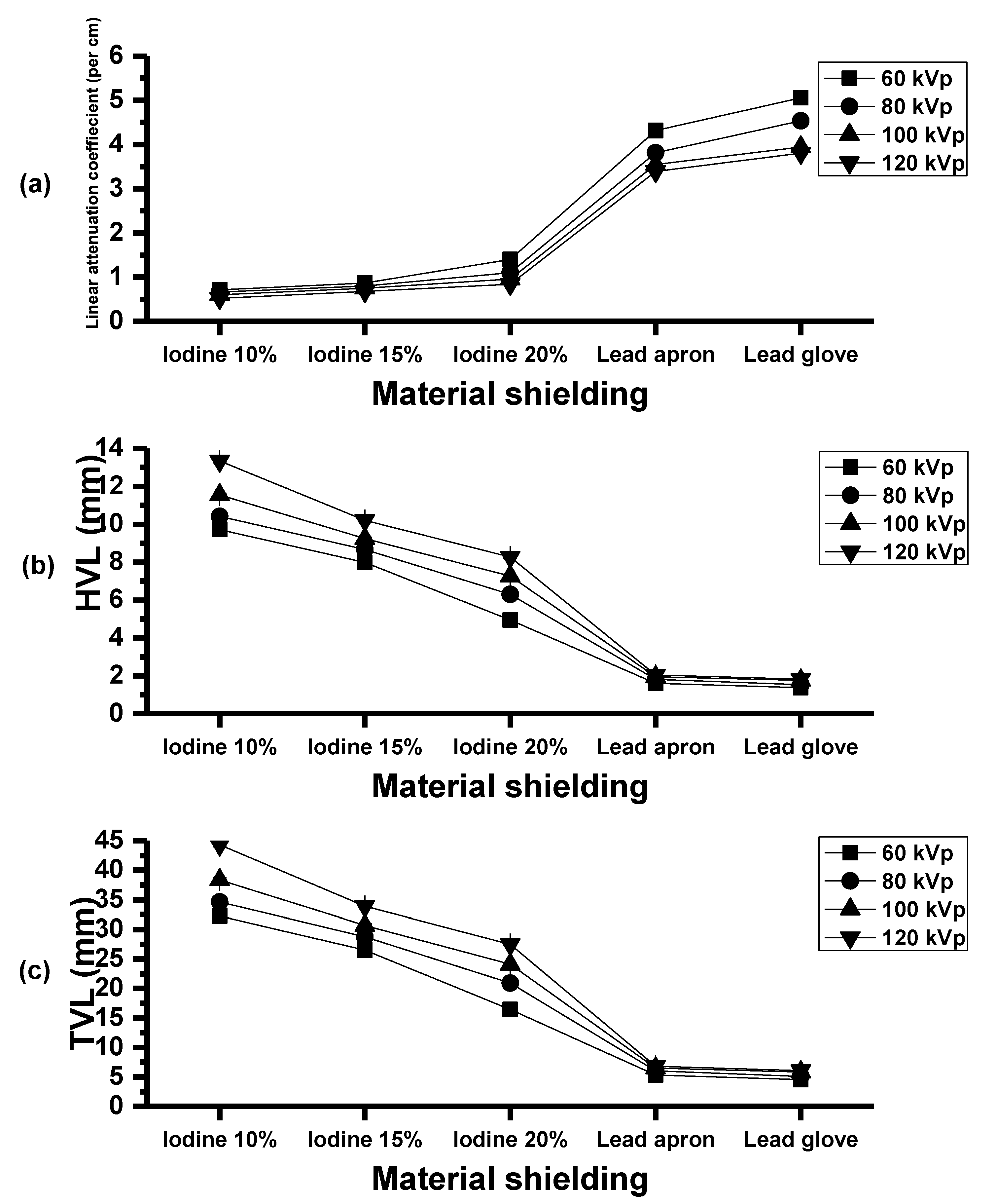

3.3. Radiation Absorption Properties

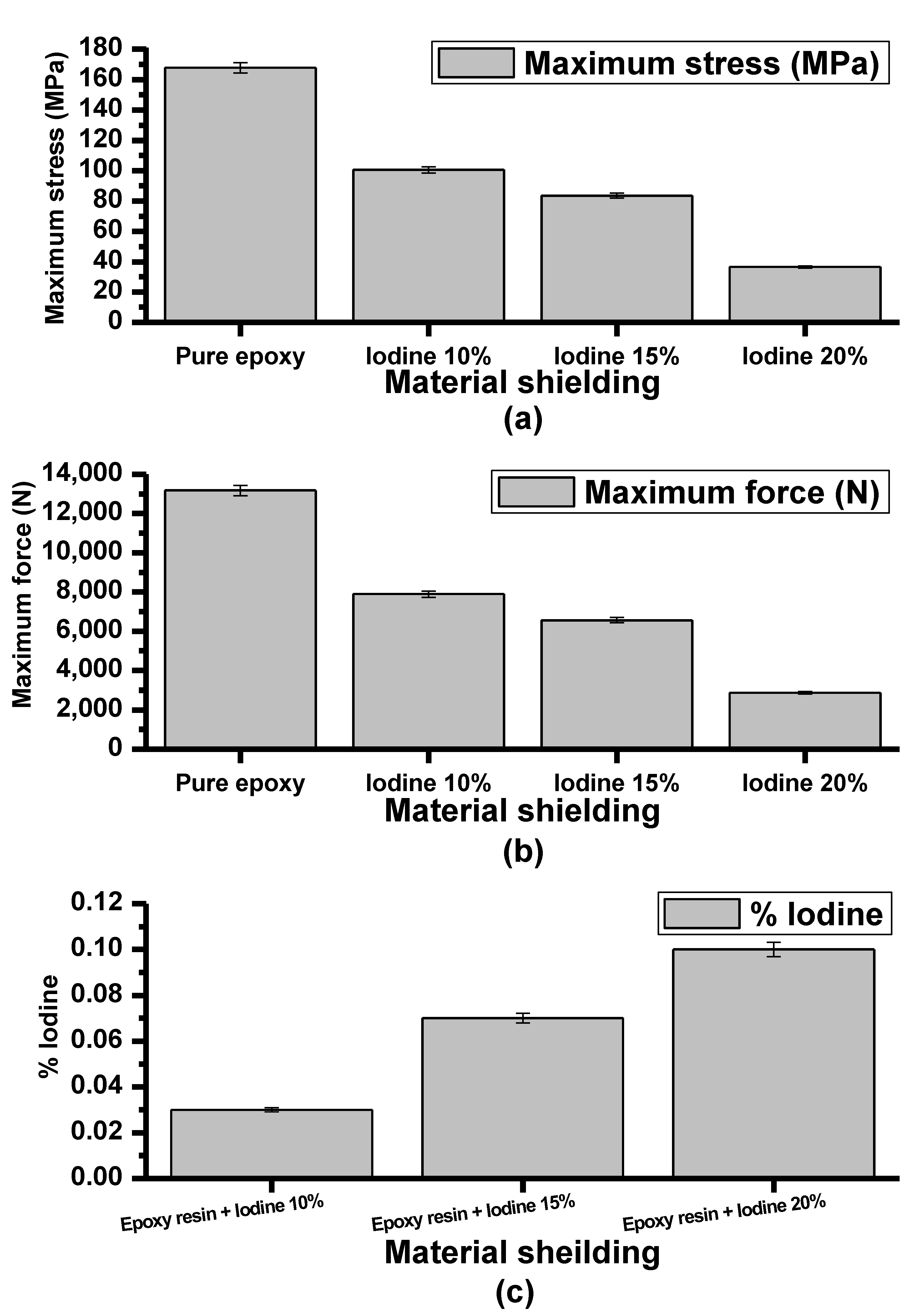

3.4. Tensile Strength, Maximum Force (N) and X-ray Fluorescence (XRF)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fazel, R.; Krumholz, H.M.; Wang, Y.; Ross, J.S.; Chen, J.; Ting, H.H.; Shah, N.D.; Nasir, K.; Einstein, A.J.; Nallamothu, B.K. Exposure to low-dose ionizing radiation from medical imaging procedures. N. Engl. J. Med. 2009, 361, 849–857. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sherer, M.A.S.; Visconti, P.J.; Ritenour, E.R.; Kelli Haynes, M. Radiation Protection in Medical Radiography; Elsevier Health Sciences: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Ron, E. Cancer risks from medical radiation. Health Phys. 2003, 85, 47–59. [Google Scholar] [CrossRef] [PubMed]

- Cool, D.; Kase, K.; Boice, J. NCRP report no. 180—Management of exposure to ionizing radiation: NCRP radiation protection guidance for the United States. J. Radiol. Prot. 2019, 39, 966. [Google Scholar] [CrossRef] [PubMed]

- Lin, E.C. Radiation risk from medical imaging. Mayo Clin. Proc. 2010, 85, 1142–1146. [Google Scholar] [CrossRef] [Green Version]

- Brusseau, M.L.; Artiola, J. Chemical contaminants. In Environmental and Pollution Science; Elsevier: Amsterdam, The Netherlands, 2019; pp. 175–190. [Google Scholar]

- Tochaikul, G.; Phattanasub, A.; Khemkham, P.; Saengthamthawee, K.; Danthanavat, N.; Moonkum, N. Radioactive waste treatment technology: A review. Kerntechnik 2022, 87, 208–225. [Google Scholar] [CrossRef]

- Dewar, C. Occupational radiation safety. Radiol. Technol. 2013, 84, 467–489. [Google Scholar]

- McCaffrey, J.; Shen, H.; Downton, B.; Mainegra-Hing, E. Radiation attenuation by lead and nonlead materials used in radiation shielding garments. Med. Phys. 2007, 34, 530–537. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-W.; Choi, H.; Hwang, U.-K.; Kang, J.-C.; Kang, Y.J.; Kim, K.I.; Kim, J.-H. Toxic effects of lead exposure on bioaccumulation, oxidative stress, neurotoxicity, and immune responses in fish: A review. Environ. Toxicol. Pharmacol. 2019, 68, 101–108. [Google Scholar] [CrossRef]

- Kim, S.-C.; Cho, S.-H. Analysis of the correlation between shielding material blending characteristics and porosity for radiation shielding films. Appl. Sci. 2019, 9, 1765. [Google Scholar] [CrossRef] [Green Version]

- Danthanavat, N.; Mongkolsuk, M.; Tochaikul, G.; Sriwongta, S.; Piyajaroenporn, A.; Lithreungnam, C.; Moonkum, N. Study of epoxy shielding material with barium sulphate for development of radiation protection materials in low-dose diagnostic X-ray. Radiat. Eff. Defects Solids 2021, 176, 887–895. [Google Scholar] [CrossRef]

- Halimah, M.; Azuraida, A.; Ishak, M.; Hasnimulyati, L. Influence of bismuth oxide on gamma radiation shielding properties of boro-tellurite glass. J. Non-Cryst. Solids 2019, 512, 140–147. [Google Scholar] [CrossRef]

- Moonkum, N.; Pilapong, C.; Daowtak, K.; Tochaikul, G. Evaluation of silicone rubber shielding material composites enriched with BaSO4 and Bi2O3 particles for radiation shielding properties. Mater. Res. Innov. 2022. [Google Scholar] [CrossRef]

- Alajerami, Y.; Morsy, M.A.; Mhareb, M.; Sayyed, M.; Imheidat, M.A.; Hamad, M.K.; Karim, M.K. Structural, optical, and radiation shielding features for a series of borate glassy system modified by molybdenum oxide. Eur. Phys. J. Plus 2021, 136, 583. [Google Scholar] [CrossRef]

- Ali, K.M.; Mohammad, K.K.; Atallah, F.S. Calculation of radiation doses using shields for nanoparticles tungsten oxide WO3 mixed with epoxy. J. Radiat. Nucl. Appl. 2018, 3, 191–197. [Google Scholar] [CrossRef]

- Yılmaz, D.; Aktaş, B.; Yalçın, Ş.; Albaşkara, M. Erbium oxide and cerium oxide-doped borosilicate glasses as radiation shielding material. Radiat. Eff. Defects Solids 2020, 175, 458–471. [Google Scholar] [CrossRef]

- Yu, L.; Yap, P.L.; Santos, A.; Tran, D.; Losic, D. Lightweight bismuth titanate (Bi4Ti3O12) nanoparticle-epoxy composite for advanced lead-free X-ray radiation shielding. ACS Appl. Nano Mater. 2021, 4, 7471–7478. [Google Scholar] [CrossRef]

- Ozdogan, H.; Kilicoglu, O.; Akman, F.; Agar, O. Comparison of Monte Carlo simulations and theoretical calculations of nuclear shielding characteristics of various borate glasses including Bi, V, Fe, and Cd. Appl. Radiat. Isot. 2022, 189, 110454. [Google Scholar] [CrossRef]

- Kilicoglu, O.; Akman, F.; Oğul, H.; Agar, O.; Kara, U. Nuclear radiation shielding performance of borosilicate glasses: Numerical simulations and theoretical analyses. Radiat. Phys. Chem. 2022, 204, 110676. [Google Scholar] [CrossRef]

- Alotaibi, B.; Alotiby, M.; Kumar, A.; Mahmoud, K.; Sayyed, M.; Al-Yousef, H.A.; Al-Hadeethi, Y. Gamma-ray shielding, physical, and structural characteristics of TeO2–CdO–PbO–B2O3 glasses. Opt. Mater. 2021, 119, 111333. [Google Scholar] [CrossRef]

- Kim, S.-C. Development of Shielding using Medical Radiological Contrast Media; Comparison Analysis of Barium Sulfate Iodine Shielding ability by Monte Carlo Simulation. J. Korean Soc. Radiol. 2017, 11, 329–334. [Google Scholar]

- Gang, H.-H.; Kim, D.-H. Study on shielding using CT contrast medium. J. Korean Soc. Radiol. 2018, 12, 693–698. [Google Scholar]

- Çetin, H.; Yurt, A.; Yüksel, S.H. The absorption properties of lead-free garments for use in radiation protection. Radiat. Prot. Dosim. 2017, 173, 345–350. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, E.L.; Furey, P. Prevention of radiation injury from medical imaging. J. Vasc. Surg. 2011, 53, 22S–27S. [Google Scholar] [CrossRef]

- Penn, L.S.; Chiao, T. Epoxy resins. In Handbook of Composites; Springer: Boston, MA, USA, 1982; pp. 57–88. [Google Scholar]

- Dai, J.; Peng, Y.; Teng, N.; Liu, Y.; Liu, C.; Shen, X.; Mahmud, S.; Zhu, J.; Liu, X. High-performing and fire-resistant biobased epoxy resin from renewable sources. ACS Sustain. Chem. Eng. 2018, 6, 7589–7599. [Google Scholar] [CrossRef]

- Ahmadi, Z. Nanostructured epoxy adhesives: A review. Prog. Org. Coat. 2019, 135, 449–453. [Google Scholar] [CrossRef]

- Hmeidat, N.S.; Kemp, J.W.; Compton, B.G. High-strength epoxy nanocomposites for 3D printing. Compos. Sci. Technol. 2018, 160, 9–20. [Google Scholar] [CrossRef]

- Pitt, C.; Barth, B.; Godard, B. Electrical properties of epoxy resins. IRE Trans. Compon. Parts 1957, 4, 110–113. [Google Scholar] [CrossRef]

- Pham, H.Q.; Marks, M.J. Epoxy Resins; Wiley-VCH: Weinheim, Germany, 2000. [Google Scholar]

- Al-Buriahi, M.S.; Tonguc, B.T. Mass attenuation coefficients, effective atomic numbers and electron densities of some contrast agents for computed tomography. Radiat. Phys. Chem. 2020, 166, 108507. [Google Scholar] [CrossRef]

- Aygün, H.H. Epoxy Composites for radiation shielding. In Epoxy-Based Composites; Intech Open: London, UK, 2022; p. 105. [Google Scholar]

- Dong, Y.; Chang, S.-Q.; Zhang, H.-X.; Ren, C.; Kang, B.; Dai, M.-Z.; Dai, Y.-D. Effects of WO3 particle size in WO3/epoxy resin radiation shielding material. Chin. Phys. Lett. 2012, 29, 108102. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Wang, Y.; Yang, Z.; Li, M.; Zhang, Z. Effect of particle size on gamma radiation shielding property of gadolinium oxide dispersed epoxy resin matrix composite. Mater. Res. Express 2017, 4, 035035. [Google Scholar] [CrossRef]

- Kurudirek, M. Radiation shielding and effective atomic number studies in different types of shielding concretes, lead base and non-lead base glass systems for total electron interaction: A comparative study. Nucl. Eng. Des. 2014, 280, 440–448. [Google Scholar] [CrossRef]

- Oto, B.; Yıldız, N.; Akdemir, F.; Kavaz, E. Investigation of gamma radiation shielding properties of various ores. Prog. Nucl. Energy 2015, 85, 391–403. [Google Scholar] [CrossRef]

- Al-Sarray, E.; Akkurt, I.; Günoğlu, K.; Evcin, A.; Bezir, N.Ç. Radiation shielding properties of some composite panel. Acta Phys. Pol. 2017, 132, 490–492. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T. Polymer-composite materials for radiation protection. ACS Appl. Mater. Interfaces 2012, 4, 5717–5726. [Google Scholar] [CrossRef]

- Abunahel, B.M.; Mustafa, I.S.; Noor Azman, N.Z. Characteristics of X-ray attenuation in nano-sized bismuth oxide/epoxy-polyvinyl alcohol (PVA) matrix composites. Appl. Phys. A 2018, 124, 1–7. [Google Scholar] [CrossRef]

- Azman, N.N.; Siddiqui, S.; Hart, R.; Low, I.-M. Effect of particle size, filler loadings and X-ray tube voltage on the transmitted X-ray transmission in tungsten oxide—Epoxy composites. Appl. Radiat. Isot. 2013, 71, 62–67. [Google Scholar] [CrossRef] [PubMed]

| Formula Number | Iodine Contrast Media (%) | Epoxy Resin (%) |

|---|---|---|

| No.1 | - | 100 |

| No.2 | 10 | 90 |

| No.3 | 15 | 85 |

| No.4 | 20 | 80 |

| Shielding Material: Iodine Contrast Media (%) | Weight (g) | Density (g/cm3) | Light Transmission |

|---|---|---|---|

| Pure epoxy resin | 174 | 1.21 | Transparent |

| 10% Iodine contrast media | 180 | 1.23 | Opaque |

| 15% Iodine contrast media | 184 | 1.24 | Opaque |

| 20% Iodine contrast media | 188 | 1.25 | Opaque |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moonkum, N.; Pilapong, C.; Daowtak, K.; Tochaikul, G. Radiation Protection Device Composite of Epoxy Resin and Iodine Contrast Media for Low-Dose Radiation Protection in Diagnostic Radiology. Polymers 2023, 15, 430. https://doi.org/10.3390/polym15020430

Moonkum N, Pilapong C, Daowtak K, Tochaikul G. Radiation Protection Device Composite of Epoxy Resin and Iodine Contrast Media for Low-Dose Radiation Protection in Diagnostic Radiology. Polymers. 2023; 15(2):430. https://doi.org/10.3390/polym15020430

Chicago/Turabian StyleMoonkum, Nutthapong, Chalermchai Pilapong, Krai Daowtak, and Gunjanaporn Tochaikul. 2023. "Radiation Protection Device Composite of Epoxy Resin and Iodine Contrast Media for Low-Dose Radiation Protection in Diagnostic Radiology" Polymers 15, no. 2: 430. https://doi.org/10.3390/polym15020430