Method for Simulating the Anti-Damage Performance of Consolidation Soil Balls at the Roots of Seedlings during Transportation Using Consolidated Soil Columns

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Equipment

- (1)

- Experimental materials

- (2)

- Experimental equipment

2.2. Experimental Methods

- (1)

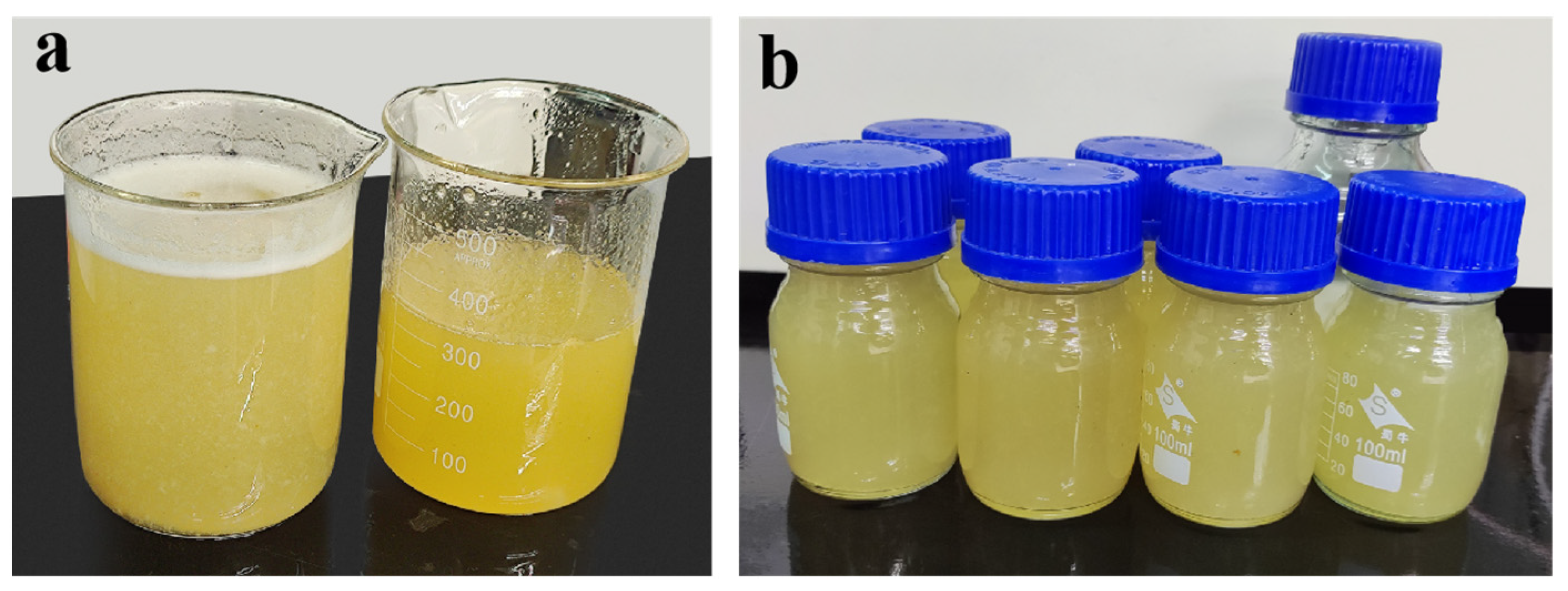

- Preparation of polymer-based soil consolidation agent

- (2)

- Preparation of soil column samples

- (3)

- Compressibility test of consolidated soil column

- (4)

- Test methods for transportation vibration resistance of consolidated soil columns

3. Results

3.1. Compressive Performance of Consolidated Soil Column

3.2. The Main Influencing Factors of Transportation Oscillation Resistance

3.2.1. Main Influencing Factors on the Transportation Oscillation Resistance of Consolidated Soil Columns in Test Method 1

- (1)

- The influence of transportation-induced vibration modes on the consolidated soil columns

- (2)

- The influence of the flowability of the consolidation adhesive on the resistance of consolidated soil columns to transportation-induced vibrations

- (3)

- The influence of the drying degree of the consolidation film on its resistance to transportation-induced vibrations

3.2.2. Main Influencing Factors on the Transport Vibration Resistance of Consolidated Soil Columns in Test Method 2

4. Discussion

4.1. Main Factors Affecting Compressibility of Consolidated Soil Column

4.1.1. Analysis of the Influence of Soil Particle Size on the Compressive Resistance of Consolidated Soil Columns

4.1.2. Analysis of the Influence of Drying Degree of Adhesive Film on the Compressive Resistance of Consolidated Soil Columns

4.2. Main Factors Affecting the Transport Vibration Resistance of Consolidated Soil Columns

4.2.1. Analysis of the Influence of Adhesive Film on the Transport Vibration Resistance of Consolidated Soil Columns

- (1)

- Enhanced structural integrity

- (2)

- Reduced wear and friction

- (3)

- Uniformity of protection

- (4)

- Moisture retention

- (5)

- Drying time

4.2.2. The Influence of the Testing Position of Consolidated Soil Columns on Their Resistance to Transportation Vibration

- (1)

- Surface wear and impact

- (2)

- Uniformity of stress distribution

- (3)

- Effect on consolidation film

4.2.3. The Influence of Two Different Testing Methods on the Transport Vibration Resistance Test of Consolidated Soil Columns

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aarzoo; Nidhi; Samim, M. Palladium nanoparticles as emerging pollutants from motor vehicles: An in-depth review on distribution, uptake and toxicological effects in occupational and living environment. Sci. Total Environ. 2022, 823, 153787. [Google Scholar] [CrossRef] [PubMed]

- Pei, N.; Wang, C.; Jin, J.; Jia, B.; Chen, B.; Qie, G.; Qiu, E.; Lin, G.; Sun, R.; Li, J.; et al. Long-term afforestation efforts increase bird species diversity in Beijing, China. Urban For. Urban Green. 2018, 29, 88–95. [Google Scholar] [CrossRef]

- Dahar, D.; Handayani, B.; Mardikaningsih, R. Urban Forest: The role of improving the quality of the urban environment. Bull. Sci. Technol. Soc. 2022, 1, 25–29. [Google Scholar]

- Yang, K.; Sun, W.; Luo, Y.; Zhao, L. Impact of urban expansion on vegetation: The case of China (2000–2018). J. Environ. Manag. 2021, 291, 112598. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Wang, J.; Jing, Z.; Yan, Y.; Niu, H. Response of ecological vulnerability to land use change in a resource-based city, China. Resour. Policy 2021, 74, 102324. [Google Scholar] [CrossRef]

- Lv, T.; Hu, H.; Zhang, X.; Wang, L.; Fu, S. Impact of multidimensional urbanization on carbon emissions in an ecological civilization experimental area of China. Phys. Chem. Earth Parts A/B/C 2022, 126, 103120. [Google Scholar] [CrossRef]

- Liu, Y.; Xia, C.; Ou, X.; Lv, Y.; Ai, X.; Pan, R.; Zhang, Y.; Shi, M.; Zheng, X. Quantitative structure and spatial pattern optimization of urban green space from the perspective of carbon balance: A case study in Beijing, China. Ecol. Indic. 2023, 148, 110034. [Google Scholar] [CrossRef]

- Arnold, M.A. Challenges and benefts of transplanting large trees: An introduction to the workshop. Hort Technol. 2005, 15, 115–117. [Google Scholar] [CrossRef]

- Pryor, M.; Watson, G. Mature tree transplanting: Science supports best management practice. Arboric. J. 2016, 38, 2–27. [Google Scholar] [CrossRef]

- Mathers, H.M.; Lowe, S.B.; Scagel, C.; Struve, D.K.; Case, L.T. Abiotic factors influencing root growth of woody nursery plants in containers. Hort Technol. 2007, 17, 151–162. [Google Scholar] [CrossRef]

- Watson, W.T. Influence of tree size on transplant establishment and growth. Hort Technol. 2005, 15, 118–122. [Google Scholar] [CrossRef]

- Sun, Y. Big Tree Transplanting Techniques in Urban Road Renovation: A Case Study of Big Tree Transplanting in Urban Road Renovation of Jinchang City, Gansu Province. J. Landsc. Res. 2015, 7, 1–2. [Google Scholar]

- Wang, S.; Song, S.; Yang, X.; Xiong, Z.; Luo, C.; Xia, Y.; Wei, D.; Wang, S.; Liu, L.; Wang, H.; et al. Effect of preparation conditions on application properties of environment friendly polymer soil consolidation agent. Polymers 2022, 14, 2122. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Wei, D.; Yang, X.; Song, S.; Sun, L.; Xin, X.; Zheng, G.; Wang, R.; Liu, L.; Sun, J.; et al. Study on a new type of environment-friendly polymer and its preliminary application as soil consolidation agent during tree transplanting. Sci. Rep. 2021, 11, 5575. [Google Scholar] [CrossRef]

- Wang, S.; Yang, X.; Luo, C.; Xiong, Z.; Wang, S.B.; Song, S.; Liu, L.; Li, S. Effects of Polymer Soil Consolidation Agent on Soil Consolidation Performance and Its Application in Seedling Transplantation. Sci. Silvae Sin. 2022, 58, 151–161. [Google Scholar]

- Wang, S.; Wang, R.; Sun, L.; Wang, H.; Xin, X.; Wei, D.; Yang, X. A Degradable Soil Consolidation Agent and Its Preparation Method and Transplantation Method of Plant Seedlings. Chinese Patent CN 108774530 A, 9 November 2018. [Google Scholar]

- Bu, F.; Liu, J.; Bai, Y.; Prasanna Kanungo, D.; Song, Z.; Kong, F.; Pan, C. Effects of the preparation conditions and reinforcement mechanism of polyvinyl acetate soil stabilizer. Polymers 2019, 11, 506. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of Problematic Soils with Bio polymer An Environmentally Friendly Soil Stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.-C. Effects of Xanthan Gum Biopolymer on Soil Strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Padhye, L.P.; Srivastava, P.; Jasemizad, T.; Bolan, S.; Hou, D.; Sabry, S.; Hou, D.; Shaheen, S.M.; Rinklebe, J.; Connor, D.O.; et al. Contaminant containment for sustainable remediation of persistent contaminants in soil and groundwater. J. Hazard. Mater. 2023, 455, 131575. [Google Scholar] [CrossRef]

- Shah, A.; Shahzad, S.; Munir, A.; Nadagouda, M.N.; Khan, G.S.; Shams, D.F.; Dionysiou, D.D.; Rana, U.A. Micelles as soil and water decontamination agents. Chem. Rev. 2016, 116, 6042–6074. [Google Scholar] [CrossRef]

- Cho, G.C.; Chang, I. Cementless soil stabilizer–biopolymer. In Proceedings of the 2018 World Congress on Advances in Civil, Environmental, & Materials Research (ACEM18) Songdo Convensia, Incheon, Republic of Korea, 27–31 August 2018; pp. 27–31. [Google Scholar]

- Cole, D.M.; Ringelberg, D.B.; Reynolds, C.M. Small-scale mechanical properties of biopolymers. J. Geotech. Geoenviron. Eng. 2012, 138, 1063–1074. [Google Scholar] [CrossRef]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Katsuraya, K.; Okuyama, K.; Hatanaka, K.; Oshima, K.; Sato, T.; Matsuzaki, K. Constitution of konjac glucomannan: Chemical analysis and 13C NMR spec-troscopy. Carbohydr. Polym. 2003, 53, 183–189. [Google Scholar] [CrossRef]

- Fang, W.X.; Wu, P.W. Variations of Konjac glucomannan (KGM) from Amorphophallus konjac and its refined powder in China. Food Hydrocoll. 2004, 18, 167–170. [Google Scholar] [CrossRef]

- Agoub, A.A.; Smith, A.M.; Giannouli, P.; Richardson, R.K.; Morris, E.R. “Melt-in-the-mouth” gels from mixtures of xanthan and konjac glucomannan under acidic conditions: A rheological and calorimetric study of the mechanism of synergistic gelation. Carbohydr. Polym. 2007, 69, 713–724. [Google Scholar] [CrossRef]

- Li, B.; Xie, B.J.; Kennedy, J.F. Studies on the molecular chain morphology of konjac glucomannan. Carbohydr. Polym. 2006, 64, 510–515. [Google Scholar] [CrossRef]

- Chua, M.; Baldwin, T.C.; Hocking, T.J.; Chan, K. Traditional uses and potential health benefits of Amorphophallus konjac K. Kochex N.E.Br. J. Ethnopharmacol. 2010, 128, 268–278. [Google Scholar] [CrossRef]

- Luo, X.; He, P.; Lin, X. The mechanism of sodium hydroxide solution promoting the gelation of Konjac glucomannan (KGM). Food Hydrocoll. 2013, 30, 92–99. [Google Scholar] [CrossRef]

- Mourya, V.K.; Inamdar, N.N. Chitosan-modifications and applications: Opportunities galore. React. Funct. Polym. 2008, 68, 1013–1051. [Google Scholar] [CrossRef]

- Wang, J.; Zhuang, S. Chitosan-based materials: Preparation, modification and application. J. Clean. Prod. 2022, 355, 131825. [Google Scholar] [CrossRef]

- Aranaz, I.; Alcántara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Heras Caballero, A.; Acosta, N. Chitosan: An overview of its properties and applications. Polymers 2021, 13, 3256. [Google Scholar] [CrossRef] [PubMed]

- Kou, S.G.; Peters, L.M.; Mucalo, M.R. Chitosan: A review of sources and preparation methods. Int. J. Biol. Macromol. 2021, 169, 85–94. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Du, L.; Yang, Y.; Wang, L. Rheology of film-forming solutions and physical properties of tara gum film reinforced with polyvinyl alcohol (PVA). Food Hydrocoll. 2017, 63, 677–684. [Google Scholar] [CrossRef]

- Abral, H.; Atmajaya, A.; Mahardika, M.; Hafizulhaq, F.; Handayani, D.; Sapuan, S.M.; Ilyas, R.A. Effect of ultrasonication duration of polyvinyl alcohol (PVA) gel on characterizations of PVA film. J. Mater. Res. Technol. 2020, 9, 2477–2486. [Google Scholar] [CrossRef]

- ASTM D2266-23; Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method). ASTM: West Conshohocken, PA, USA, 2023.

- ASTM D3080-98; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM: West Conshohocken, PA, USA, 1998.

- GJB 150.16A-2009; Laboratory Environmental Test Methods for Military Materiel-Part 16: Vibration Test. The National Standards of the People’s Republic of China: Beijing, China, 2009.

| Frequency of Turning Point (Hz) | Power Spectrum Density (g2/Hz) | Root Mean Square Acceleration | Test Time | Test Directions |

|---|---|---|---|---|

| 2 | 0.01500 | 1.10 g | 30 min/direction | Longitudinal Direction, Transverse Direction, Vertical Direction |

| 40 | 0.01500 | |||

| 500 | 0.00015 |

| Vibration Condition of Combined Wheeled Vehicle | |||||

|---|---|---|---|---|---|

| Vertical Direction | Transverse Direction | Longitudinal Direction | |||

| Hz | g2/Hz | Hz | g2/Hz | Hz | g2/Hz |

| 5 | 0.2366 | 5 | 0.1344 | 5 | 0.0593 |

| 8 | 0.6889 | 7 | 0.1075 | 8 | 0.0499 |

| 12 | 0.0507 | 8 | 0.1279 | 15 | 0.0255 |

| 21 | 0.0202 | 14 | 0.0366 | 16 | 0.0344 |

| 23 | 0.0301 | 16 | 0.0485 | 20 | 0.0134 |

| 24 | 0.0109 | 17 | 0.0326 | 23 | 0.0108 |

| 26 | 0.0150 | 19 | 0.0836 | 25 | 0.0148 |

| 49 | 0.0038 | 23 | 0.0147 | 37 | 0.0040 |

| 51 | 0.0054 | 116 | 0.0008 | 41 | 0.0059 |

| 61 | 0.0023 | 145 | 0.0013 | 49 | 0.0016 |

| 69 | 0.0111 | 164 | 0.0009 | 63 | 0.0011 |

| 74 | 0.0029 | 201 | 0.0009 | 69 | 0.0040 |

| 78 | 0.0048 | 270 | 0.0051 | 78 | 0.0008 |

| 84 | 0.0033 | 298 | 0.0021 | 94 | 0.0020 |

| 90 | 0.0052 | 364 | 0.0099 | 98 | 0.0013 |

| 93 | 0.0034 | 375 | 0.0019 | 101 | 0.0025 |

| 123 | 0.0083 | 394 | 0.0073 | 104 | 0.0014 |

| 160 | 0.0041 | 418 | 0.0027 | 111 | 0.0024 |

| 207 | 0.0055 | 500 | 0.0016 | 114 | 0.0014 |

| 224 | 0.0139 | 1.62 g | 117 | 0.0020 | |

| 245 | 0.0031 | 121 | 0.0012 | ||

| 276 | 0.0129 | 139 | 0.0024 | ||

| 287 | 0.0036 | 155 | 0.0021 | ||

| 353 | 0.0027 | 161 | 0.0034 | ||

| 375 | 0.0049 | 205 | 0.0042 | ||

| 500 | 0.0010 | 247 | 0.0303 | ||

| 2.20 g | 257 | 0.0027 | |||

| 293 | 0.0092 | ||||

| 330 | 0.0116 | ||||

| 353 | 0.0231 | ||||

| 379 | 0.0083 | ||||

| 427 | 0.0220 | ||||

| 500 | 0.0014 | ||||

| 2.05 g | |||||

| Wave Form | Acceleration Peak | Pulse Width | Numbers of Impact | Test Directions |

|---|---|---|---|---|

| Final peak saw tooth wave | 20 g | 11 ms | 3 times/direction | Three-axis |

| Vibration Test Sequence | Test Speed (r/min) | Corresponding Frequency (Hz) | Test Time (min) |

|---|---|---|---|

| Test 1 | 150 | 2.5 | 95 |

| Test 2 | 180 | 3.0 | 79 |

| Test 3 | 210 | 3.5 | 66 |

| Test 4 | 240 | 4.0 | 60 |

| Type of Soil Columns | Particle Size of Soil (mm)/Sample No. | |||||

|---|---|---|---|---|---|---|

| Model 1 | 1 Sample 1 | 2 Sample 2 | 3 Sample 3 | 4 Sample 4 | 5 Sample 5 | Mixed Sample 6 |

| Model 2 | 1 Sample 7 | 2 Sample 8 | 3 Sample 9 | 4 Sample 10 | 5 Sample 11 | Mixed Sample 12 |

| Type | Preparation Conditions of the Main Agent of Consolidation Adhesive Used for Sample Treatment | Particle Size of Soil | pH of Soil |

|---|---|---|---|

| Type1 | 50 °C; KGM, CA, PVA (4.0%, 4.0%, 2.0%); pH 4.5 | 2 mm | 8.5 |

| Type 2 | 60 °C; KGM, CA, PVA (4.5%, 4. 5%, 3.0%); pH 4.5 | 2 mm | 8.5 |

| Type 3 | 65 °C; KGM, CA, PVA (5.0%, 5.0%, 5.0%); pH 4.5 | 1–5 mm | 8.5 |

| Sample Number | Preparation Conditions of the Main Agent of Consolidation Glue Used for Sample Treatment | Particle Size of Soil | pH of Soil |

|---|---|---|---|

| Sample 1 | Blank Control, Not Consolidated with Adhesive | 3 mm | 8.5 |

| Sample 2 | 30 °C; KGM, CA, PVA(4.5%, 4.5%, 3.0%); pH 4.5 | 3 mm | 8.5 |

| Sample 3 | 40 °C; KGM, CA, PVA(4.5%, 4.5%, 3.0%); pH 4.5 | 3 mm | 8.5 |

| Sample 4 | 50 °C; KGM, CA, PVA(4.5%, 4. 5%, 3.0%); pH 4.5 | 3 mm | 8.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Song, S.; Yang, X.; Xiong, Z.; Luo, C.; Wei, D.; Wang, H.; Liu, L.; Yang, X.; Li, S.; et al. Method for Simulating the Anti-Damage Performance of Consolidation Soil Balls at the Roots of Seedlings during Transportation Using Consolidated Soil Columns. Polymers 2023, 15, 4083. https://doi.org/10.3390/polym15204083

Wang S, Song S, Yang X, Xiong Z, Luo C, Wei D, Wang H, Liu L, Yang X, Li S, et al. Method for Simulating the Anti-Damage Performance of Consolidation Soil Balls at the Roots of Seedlings during Transportation Using Consolidated Soil Columns. Polymers. 2023; 15(20):4083. https://doi.org/10.3390/polym15204083

Chicago/Turabian StyleWang, Shaoli, Shengju Song, Xuping Yang, Zhengqi Xiong, Chaoxing Luo, Donglu Wei, Hong Wang, Lili Liu, Xinxin Yang, Shaofeng Li, and et al. 2023. "Method for Simulating the Anti-Damage Performance of Consolidation Soil Balls at the Roots of Seedlings during Transportation Using Consolidated Soil Columns" Polymers 15, no. 20: 4083. https://doi.org/10.3390/polym15204083

APA StyleWang, S., Song, S., Yang, X., Xiong, Z., Luo, C., Wei, D., Wang, H., Liu, L., Yang, X., Li, S., & Xia, Y. (2023). Method for Simulating the Anti-Damage Performance of Consolidation Soil Balls at the Roots of Seedlings during Transportation Using Consolidated Soil Columns. Polymers, 15(20), 4083. https://doi.org/10.3390/polym15204083