A Comprehensive Mechanical Examination of ABS and ABS-like Polymers Additively Manufactured by Material Extrusion and Vat Photopolymerization Processes

Abstract

:1. Introduction

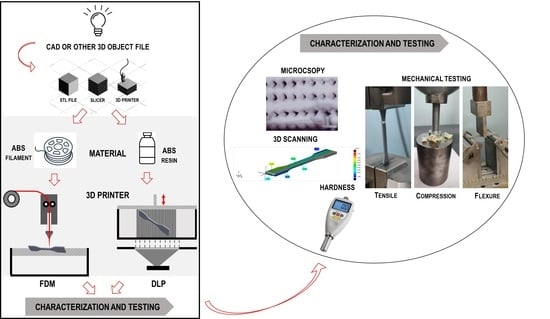

2. Methodology

2.1. Specimen Preparation

2.2. Material Examination

2.2.1. 3D Scanning

2.2.2. Mechanical Testing

2.2.3. Hardness

2.2.4. Microscopy

3. Results

3.1. Mechanical Testing

3.1.1. Tensile Testing

3.1.2. Flexural Testing

3.1.3. Compression Testing

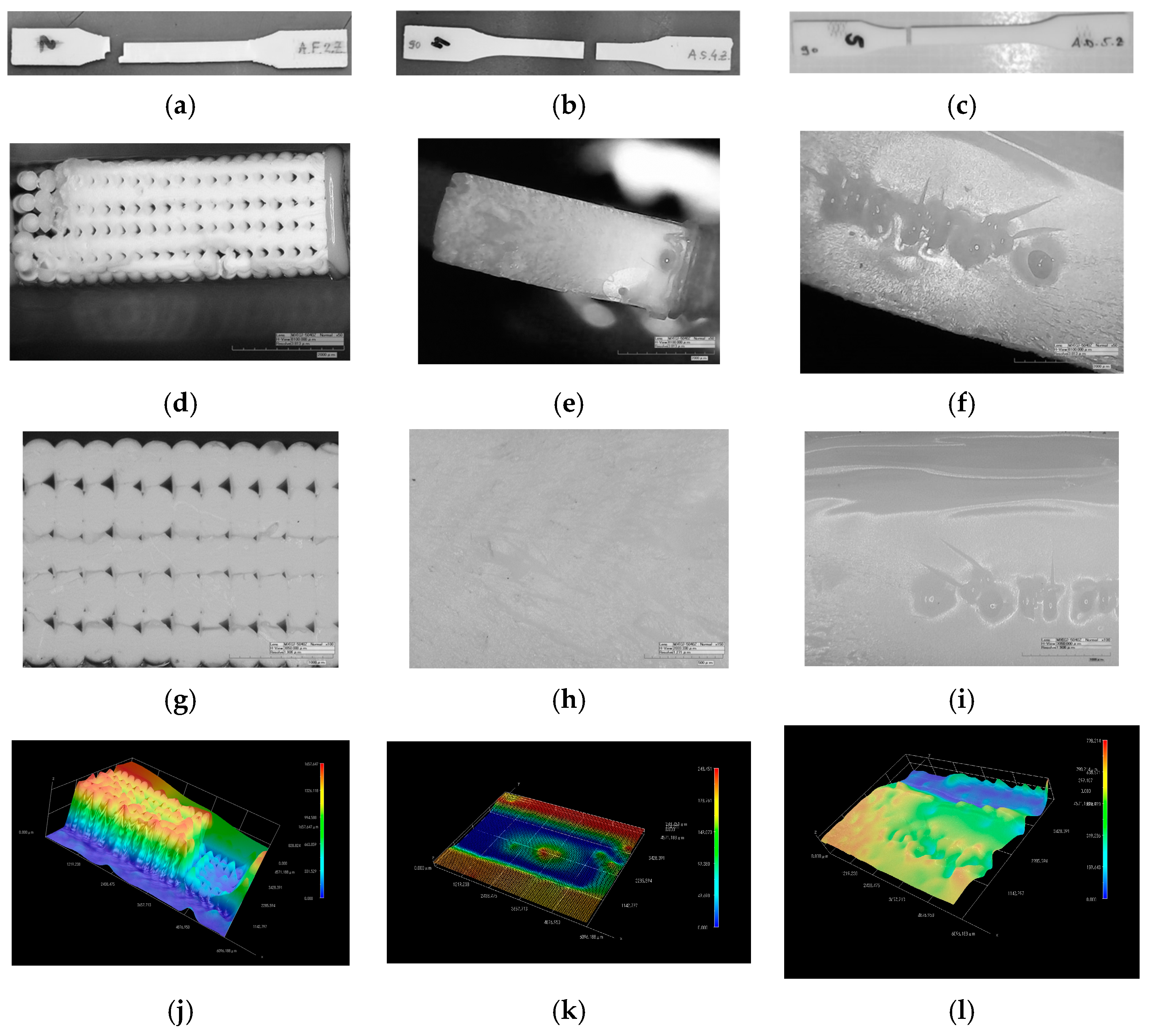

3.2. Microscopy

3.2.1. Tensile Testing

3.2.2. Flexure Testing

3.2.3. Compression Testing

3.3. 3D Scanning

3.3.1. FDM Scanned Specimens

3.3.2. SLA Scanned Specimens

3.3.3. DLP Scanned Specimens

3.4. Hardness

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thiele, A.C.S.; Tavares, M.I.B. Morphological, Biological and Physicochemical Evaluation of ABS-Based Systems Containing Graphene Obtained by 3D Printing via Solution. Mater. Sci. Appl. 2022, 13, 401–416. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Proc. Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Brighenti, R.; Marsavina, L.; Marghitas, M.P.; Cosma, M.P.; Montanari, M. Mechanical characterization of additively manufactured photopolymerized polymers. Mech. Adv. Mater. Struct. 2022, 30, 1853–1864. [Google Scholar] [CrossRef]

- Sachs, E.; Haggerty, J.; Cima, M.; Williams, P. Three-Dimensional Printing Techniques. U.S. Patent 5,204,055, 20 April 1993. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Lee, B.H.; Abdullah, J.; Khan, Z.A. Optimization of Rapid Prototyping Parameters for Production of Flexible ABS Object. J. Mater. Process. Technol. 2005, 169, 54–61. [Google Scholar] [CrossRef]

- Li, S.; Yuan, S.; Zhu, J.; Wang, C.; Li, J.; Zhang, W. Additive Manufacturing-Driven Design Optimization: Building Direction and Structural Topology. Addit. Manuf. 2020, 36, 101406. [Google Scholar] [CrossRef]

- Martín-Montal, J.; Pernas-Sánchez, J.; Varas, D. Experimental Characterization Framework for SLA Additive Manufacturing Materials. Polymers 2021, 13, 1147. [Google Scholar] [CrossRef]

- Vyavahare, S.; Teraiya, S.; Panghal, D.; Kumar, S. Fused deposition modelling: A review. Rapid Prototyp. J. 2020, 26, 176–201. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Zhao, J. Mechanical property modeling of photosensitive liquid resin in stereolithography additive manufacturing: Bridging degree of cure with tensile strength and hardness. Mater. Des. 2019, 162, 418–428. [Google Scholar] [CrossRef]

- Voet, V.S.D.; Tobias Strating, T.; Schnelting, G.H.M.; Dijkstra, P.; Tietema, M.; Xu, J.; Woortman, A.J.J.; Loos, K.; Jager, J.; Folkersma, R. Biobased Acrylate Photocurable Resin Formulation for Stereolithography 3D Printing. ACS Omega 2018, 3, 1403–1408. [Google Scholar] [CrossRef]

- Shah, D.M.; Morris, J.; Plaisted, T.A.; Amirkhizi, A.V.; Hansen, C.J. Highly Filled Resins for DLP-based Printing of Low Density, High Modulus Materials. Addit. Manuf. 2020, 37, 101736. [Google Scholar] [CrossRef]

- Szykiedans, K.; Credo, W. Mechanical properties of FDM and SLA low-cost 3-D prints. Procedia Eng. 2016, 136, 257–262. [Google Scholar] [CrossRef]

- Milovanović, A.; Milošević, M.; Mladenović, G.; Likozar, B.; Čolić, K.; Mitrović, N. Experimental Dimensional Accuracy Analysis of Reformer Prototype Model Produced by FDM and SLA 3D Printing Technology. In Experimental and Numerical Investigations in Materials Science and Engineering; Mitrovic, N., Milosevic, M., Mladenovic, G., Eds.; CNNTech 2018; Lecture Notes in Networks and Systems; Springer: Cham, Swizterland, 2019; Volume 54. [Google Scholar] [CrossRef]

- Moldovan, C.; Cosma, C.; Berce, P.; Balc, N. Theoretical Analysis and Practical Case Studies of SLA, Polyjet and FDM Manufacturing Techniques. Acta Tech. Napoc. Appl. Math. Mech. Eng. 2018, 61, 3. [Google Scholar]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical property of FDM printed ABS: Influence of printing parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

- Orzeł, B.; Stecuła, K. Comparison of 3D Printout Quality from FDM and MSLA Technology in Unit Production. Symmetry 2022, 14, 910. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Schüürmann, J.; Berto, F.; Reinicke, T. On the post-processing of 3D-printed ABS parts. Polymers 2021, 13, 1559. [Google Scholar] [CrossRef]

- Tanoto, Y.Y.; Anggono, J.; Siahaan, J.H.; Budiman, W. The effect of orientation difference in fused deposition modeling of ABS polymer on the processing time, dimension accuracy, and strength. AIP Conf. Proc. 2017, 1788, 030051. [Google Scholar] [CrossRef]

- Vishwakarma, S.K.; Pandey, P.; Gupta, N.K. Characterization of ABS Material: A Review. J. Res. Mech. Eng. 2017, 3, 13–16. [Google Scholar]

- Jayanth, N.; Senthil, P.; Prakash, C. Effect of chemical treatment on tensile strength and surface roughness of 3D-printed ABS using the FDM process. Virtual Phys. Prototyp. 2018, 13, 155–163. [Google Scholar] [CrossRef]

- Selvamani, S.K.; Samykano, M.; Subramaniam, S.R.; Ngui, W.K.; Kadirgama, K.; Kanagaraj, G.; Idris, M.S. 3D printing: Overview of ABS evolvement. AIP Conf. Proc. 2019, 2059, 020041. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Arunprasath, K.; Vijayakumar, M.; Ramarao, M.; Arul, T.G.; Pauldoss, S.; Selwin, M.; Radhakrishnan, B.; Manikandan, V. Dynamic mechanical analysis performance of pure 3D printed polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). Mater. Today Proc. 2022, 50, 1559–1562. [Google Scholar] [CrossRef]

- Garg, A.; Bhattachary, A.; Batish, A. Chemical vapor treatment of ABS parts built by FDM: Analysis of surface finish and mechanical strength. Int. J. Adv. Manuf. Technol. 2017, 89, 2175–2191. [Google Scholar] [CrossRef]

- Górski, F.; Wichniarek, R.; Kuczko, W.; Zawadzki, P.; Bun, P. Strength of abs parts produced by fused deposition modelling technology—A critical orientation problem. Adv. Sci. Technol. Res. J. 2015, 9, 12–19. [Google Scholar] [CrossRef]

- Verma, P.; Ubaid, J.; Schiffer, A.; Jain, A.; Martínez-Pañeda, E.; Kumar, S. Essential work of fracture assessment of acrylonitrile butadiene styrene (ABS) processed via fused filament fabrication additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 771–784. [Google Scholar] [CrossRef]

- Nguyen, P.Q.K.; Zohdi, N.; Kamlade, P.; Yang, R. Predicting Material Properties of Additively Manufactured Acrylonitrile Butadiene Styrene via a Multiscale Analysis Process. Polymers 2022, 14, 4310. [Google Scholar] [CrossRef]

- Khan, I.; Kumar, N. Fused deposition modelling process parameters influence on the mechanical properties of ABS: A review. Mater. Today Proc. 2021, 44, 4004–4008. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Zhang, N.; Wang, T.; Hao, M.Y. Short Review of Polymer Composites for 3D Printing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 758, 012046. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Wypych, G. Odor in Relation to Different Polymers; Handbook of Odors in Materials; ChemTec Publishing: Toronto, ON, Canada; Elsevier: Amsterdam, The Netherlands, 2013; pp. 73–99. [Google Scholar] [CrossRef]

- Campo, E.A. Selection of Polymeric Materials—How to Select Design Properties from Different Standards; William Andrew Inc.: Norwich, NY, USA, 2008; ISBN 978-0-8155-1551-7 (978-0-8155). [Google Scholar]

- Anastas, P.T.; Hammond, D.G. Inherent Safety at Chemical Sites—Reducing Vulnerability to Accidents and Terrorism through Green Chemistry; Elsevier Inc.: Amsterdam, The Netherlands, 2016; ISBN 978-0-12-804190-1. [Google Scholar] [CrossRef]

- Poyraz, O. Influence of Build Direction and Post Processes on the Material and Part Attributes of Hard Resins Fabricated by Photopolymerization Based Additive Manufacturing. Mater. Res. 2023, 26, e20220362. [Google Scholar] [CrossRef]

- Billings, C.; Cai, C.; Liu, Y. Utilization of Antibacterial Nanoparticles in Photocurable Additive Manufacturing of Advanced Composites for Improved Public Health. Polymers 2021, 13, 2616. [Google Scholar] [CrossRef] [PubMed]

- Markiz, N.; Horváth, E.; Ficzer, P. Influence of printing direction on 3D printed ABS specimens. Prod. Eng. Arch. 2020, 26, 127–130. [Google Scholar] [CrossRef]

- Petrov, L.; Bojović, B.; Golubović, Z.; Sedmak, A.; Mišković, Ž.; Trajković, I.; Milošević, M. Experimental Mechanical Characterization of Parts Manufactured by SLA and DLP Technologies. Struct. Integr. Life 2023, 23, 117–121, ISSN 1451-3749. [Google Scholar]

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 604:2002; Plastics—Determination of compressive properties. ISO: Geneva, Switzerland, 2002.

- ISO 178:2019; Plastics—Determination of flexural properties. ISO: Geneva, Switzerland, 2019.

- Majid, F.; Zekeriti, N.; Rhanim, R.; Lahlou, M.; Rhanima, H.; Mrani, B. Mechanical behavior and crack propagation of ABS 3D printed specimens. Procedia Struct. Integr. 2020, 28, 1719–1726. [Google Scholar] [CrossRef]

- Ramian, J.; Ramian, J.; Dziob, D. Thermal Deformations of Thermoplast during 3D Printing: Warping in the Case of ABS. Materials 2021, 14, 7070. [Google Scholar] [CrossRef]

- Torrado, A.R.; Roberson, D.A. Failure Analysis and Anisotropy Evaluation of 3D-Printed Tensile Test Specimens of Different Geometries and Print Raster Patterns. J. Fail. Anal. Prev. 2016, 16, 154–164. [Google Scholar] [CrossRef]

- ASTM D2240-15(2021); Standard Test Method for Rubber Property—Durometer Hardness. © ASTM International: West Conshohocken, PA, USA, 2021.

- Singh, R.; Trivedi, A.; Singh, S. Experimental investigation on shore hardness of barrel-finished FDM patterns. Sādhanā 2017, 42, 1579–1584. [Google Scholar] [CrossRef]

- Son, J.; Lee, H. Preliminary Study on Polishing SLA 3D-Printed ABS-Like Resins for Surface Roughness and Glossiness Reduction. Micromachines 2020, 11, 843. [Google Scholar] [CrossRef]

- Mwema, F.M.; Akinlabi, E.T. Basics of Fused Deposition Modelling (FDM). In Fused Deposition Modeling; Springer: Cham, Switzerland, 2020; pp. 1–15. [Google Scholar] [CrossRef]

- Pop, M.A.; Croitoru, C.; Bedo, T.; Geamăn, V.; Radomir, I.; Zaharia, S.M.; Chicoș, L.A. Influence of Internal Innovative Architecture on the Mechanical Properties of 3D Polymer Printed Parts. Polymers 2020, 12, 1129. [Google Scholar] [CrossRef]

- Eng, H.; Maleksaeedi, S.; Yu, S. Development of CNTs-filled photopolymer for projection stereolithography. Rapid Prototyp. J. 2017, 23, 129–136. [Google Scholar] [CrossRef]

- Pilipović, A.; Baršić, G.; Katić, M.; Rujnić Havstad, M. Repeatability and Reproducibility Assessment of a PolyJet Technology Using X-ray Computed Tomography. Appl. Sci. 2020, 10, 7040. [Google Scholar] [CrossRef]

- Dowling, L.; Kennedy, J.; O’Shaughnessy, S.; Trimble, D. A review of critical repeatability and reproducibility issues in powder bed fusion. Mater. Des. 2020, 186, 108346. [Google Scholar] [CrossRef]

| Material | 3D Printing Process | Tensile | Flexure | Compression | ∑ |

|---|---|---|---|---|---|

| ABS | FDM | 5 | 5 | 5 | 15 |

| ABS-like | DLP | 5 | 5 | 5 | 15 |

| SLA | 5 | 5 | 5 | 15 | |

| 45 |

| Description | FDM | Description | SLA | Description | DLP |

|---|---|---|---|---|---|

| Material | ABS filament | Material | ABS resin | Material | ABS resin |

| Layer thickness | 0.24 mm | Layer thickness | 0.05 mm | Layer thickness | 0.05 mm |

| Nozzle diameter | 0.4 mm | Laser beam size | 0.08 mm | Bottom layer count | 10 |

| Filament diameter | 1.75 mm | Scanning speed | 1.5 m/s | Exposure time | 8 s |

| Printing temperature | 250 °C | Wavelength | 355 nm | Wavelength | 405 nm |

| Build platform temperature | 90 °C | Bottom exposure time | 80 s | ||

| Printing speed | 60 mm/s | Bottom lift speed | 100 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golubović, Z.; Danilov, I.; Bojović, B.; Petrov, L.; Sedmak, A.; Mišković, Ž.; Mitrović, N. A Comprehensive Mechanical Examination of ABS and ABS-like Polymers Additively Manufactured by Material Extrusion and Vat Photopolymerization Processes. Polymers 2023, 15, 4197. https://doi.org/10.3390/polym15214197

Golubović Z, Danilov I, Bojović B, Petrov L, Sedmak A, Mišković Ž, Mitrović N. A Comprehensive Mechanical Examination of ABS and ABS-like Polymers Additively Manufactured by Material Extrusion and Vat Photopolymerization Processes. Polymers. 2023; 15(21):4197. https://doi.org/10.3390/polym15214197

Chicago/Turabian StyleGolubović, Zorana, Ivan Danilov, Božica Bojović, Ljubiša Petrov, Aleksandar Sedmak, Žarko Mišković, and Nenad Mitrović. 2023. "A Comprehensive Mechanical Examination of ABS and ABS-like Polymers Additively Manufactured by Material Extrusion and Vat Photopolymerization Processes" Polymers 15, no. 21: 4197. https://doi.org/10.3390/polym15214197

APA StyleGolubović, Z., Danilov, I., Bojović, B., Petrov, L., Sedmak, A., Mišković, Ž., & Mitrović, N. (2023). A Comprehensive Mechanical Examination of ABS and ABS-like Polymers Additively Manufactured by Material Extrusion and Vat Photopolymerization Processes. Polymers, 15(21), 4197. https://doi.org/10.3390/polym15214197