Impact Resistance of 3D-Printed Continuous Hybrid Fiber-Reinforced Composites

Abstract

:1. Introduction

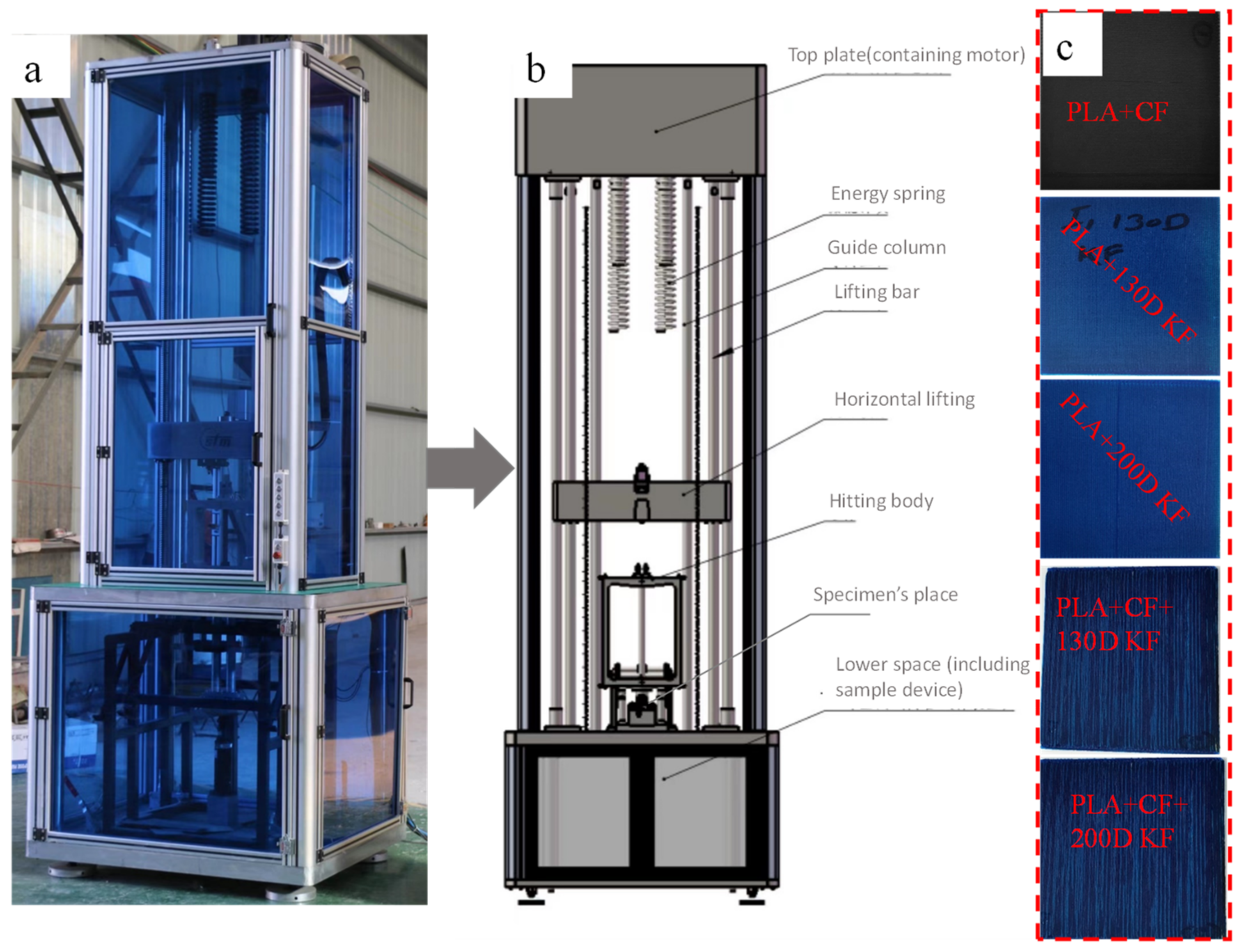

2. Experimental Methodology

2.1. Materials and Processing

2.2. Characterization

3. Results and Discussion

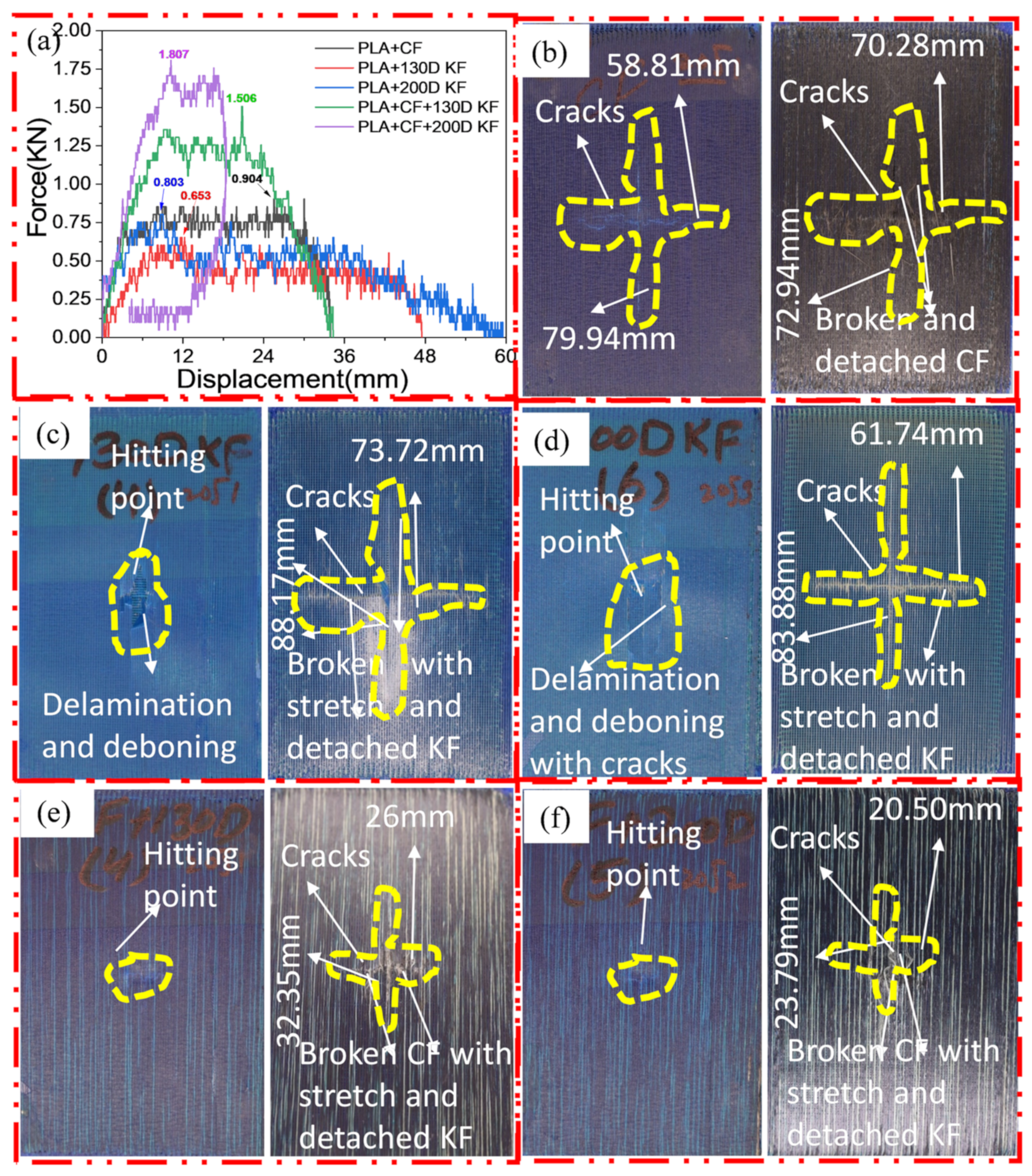

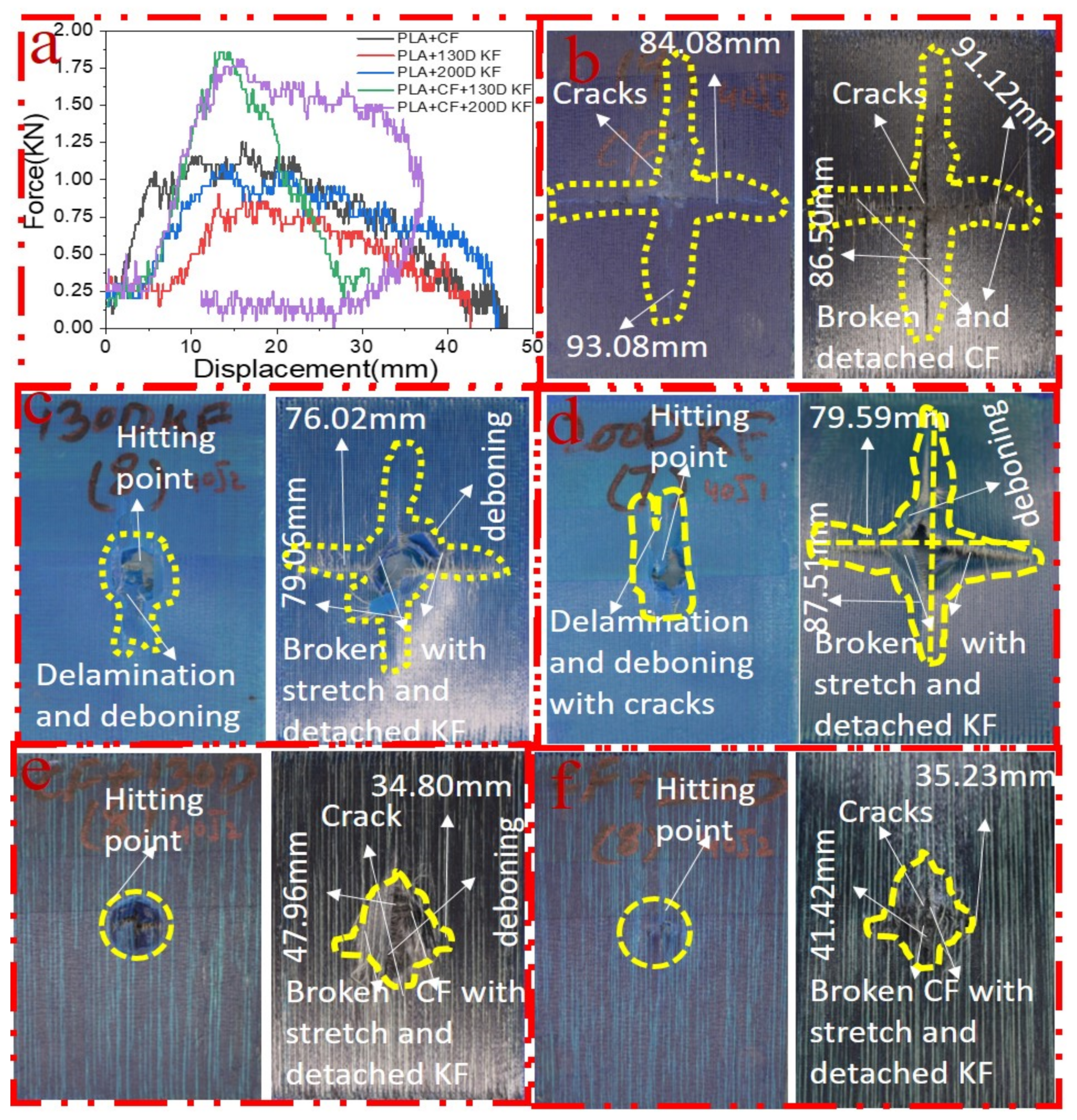

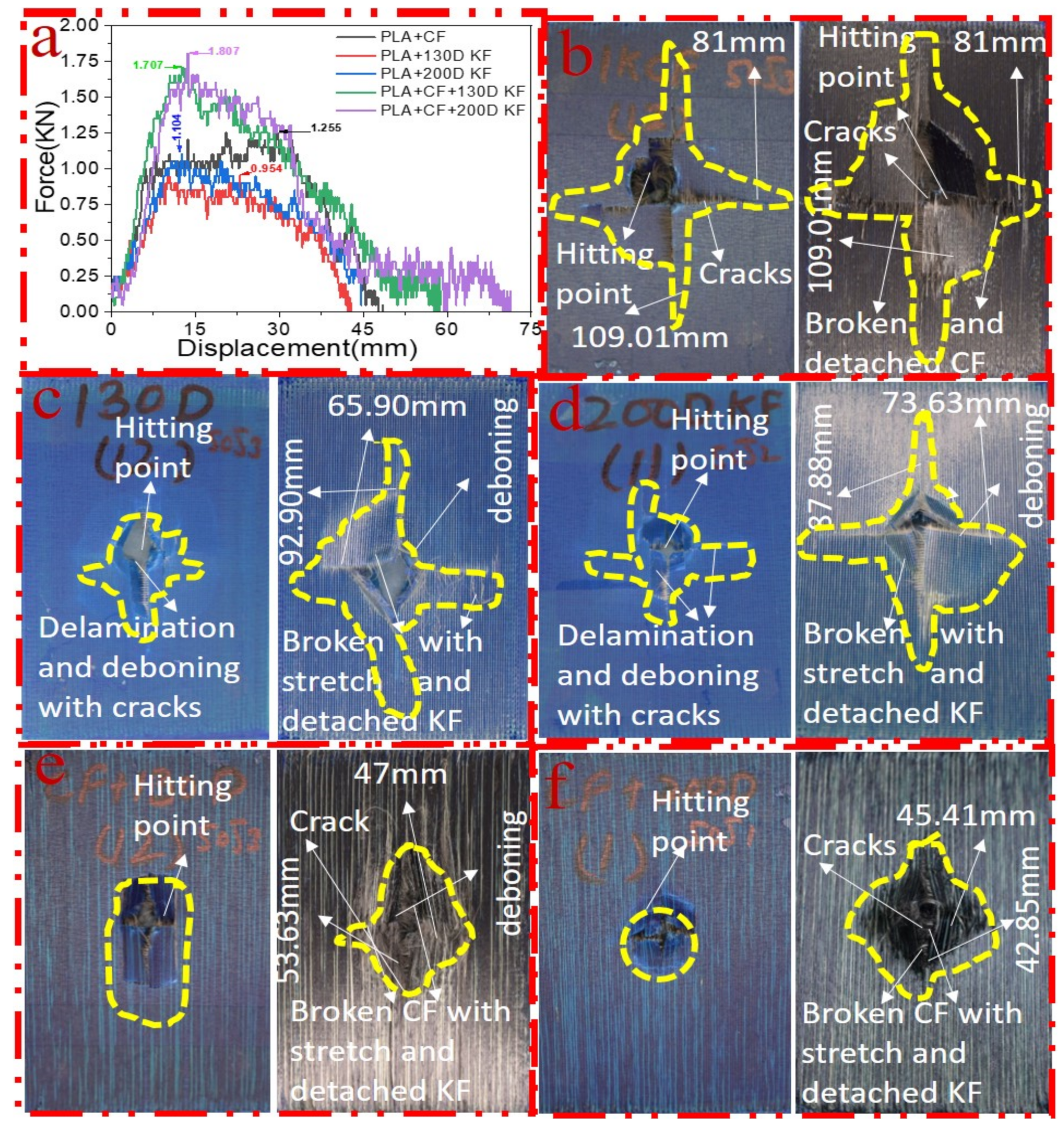

3.1. Loading Response

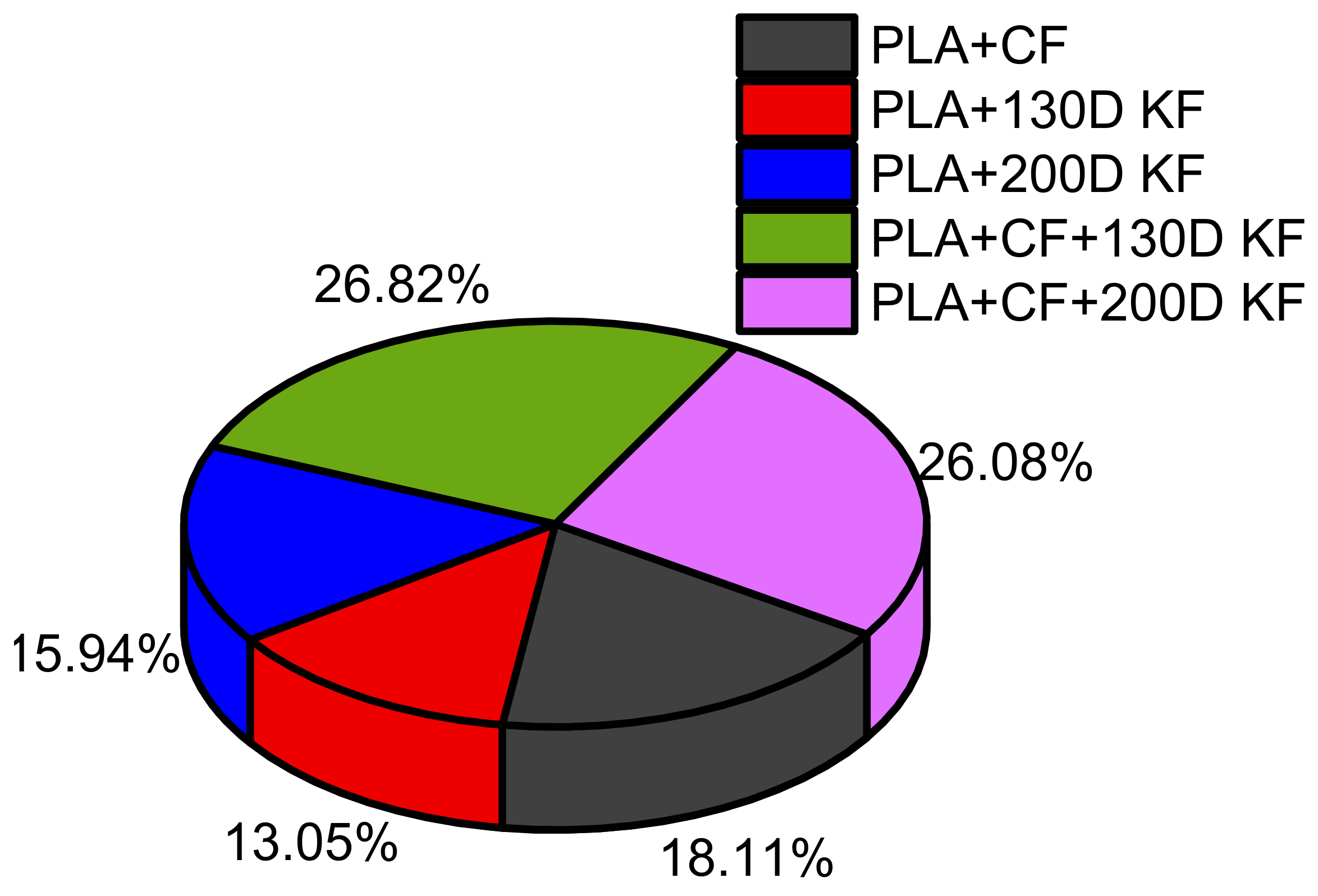

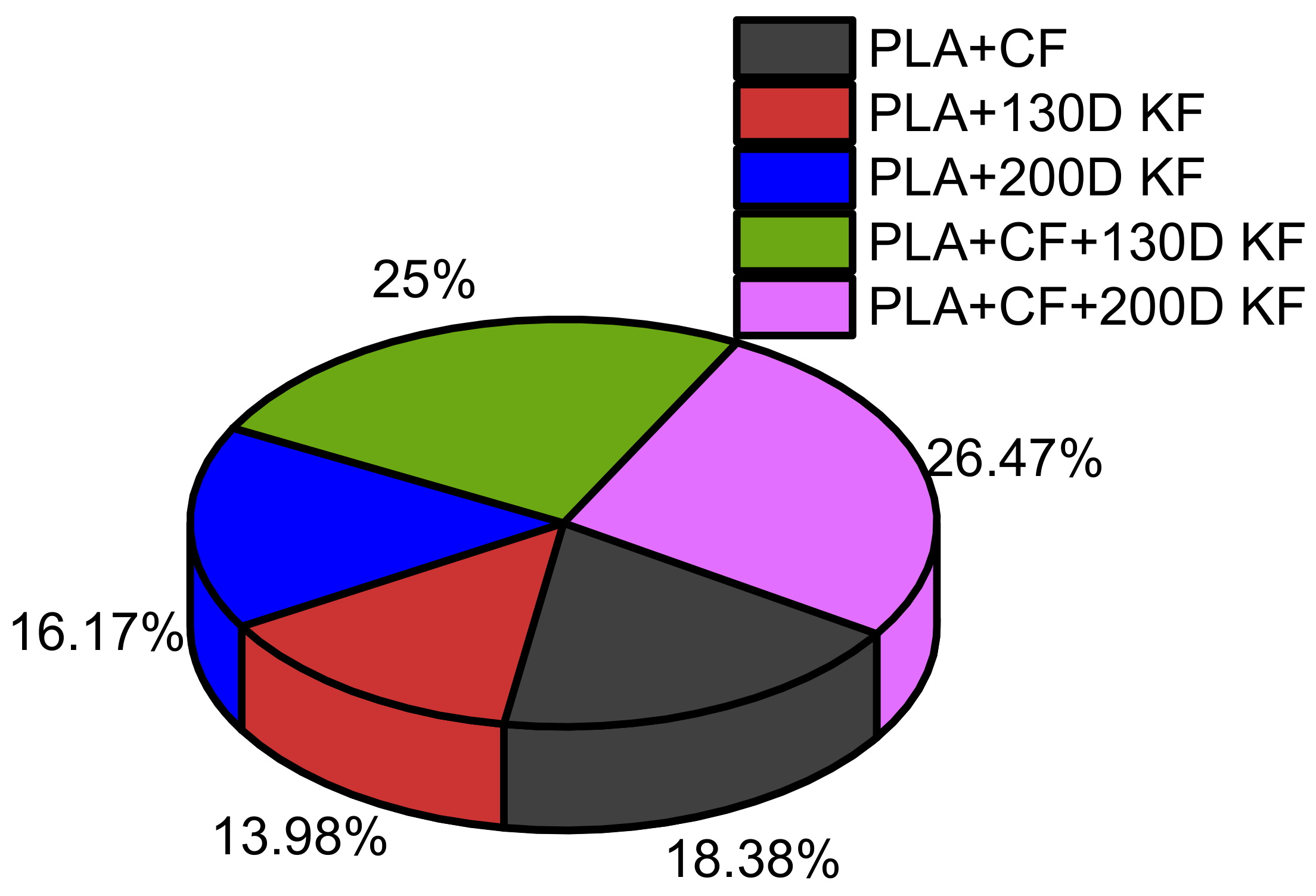

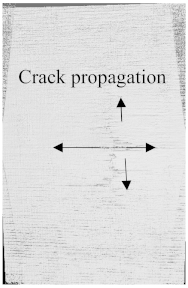

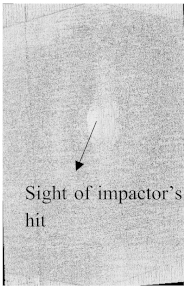

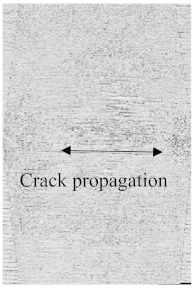

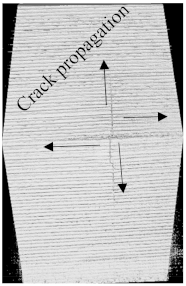

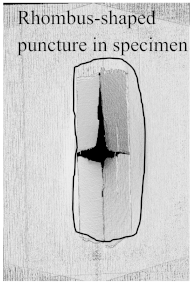

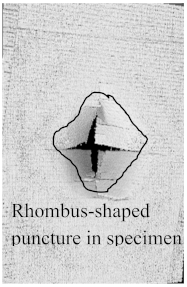

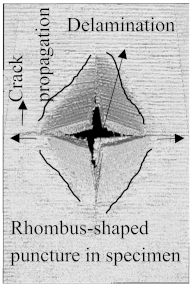

3.2. Material Damage and Impact Resistance

3.3. CT Scanning

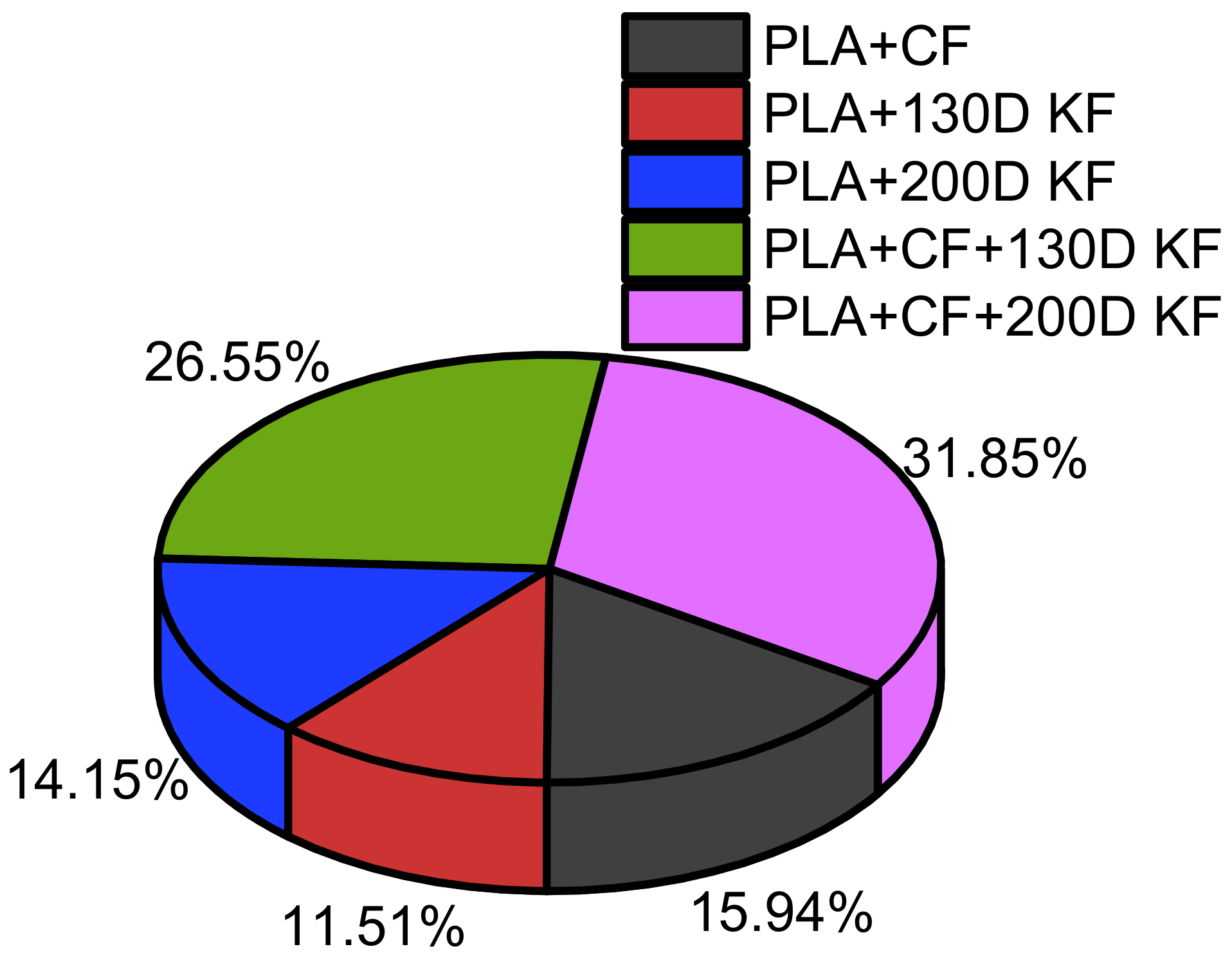

3.4. Energy Absorption Behavior

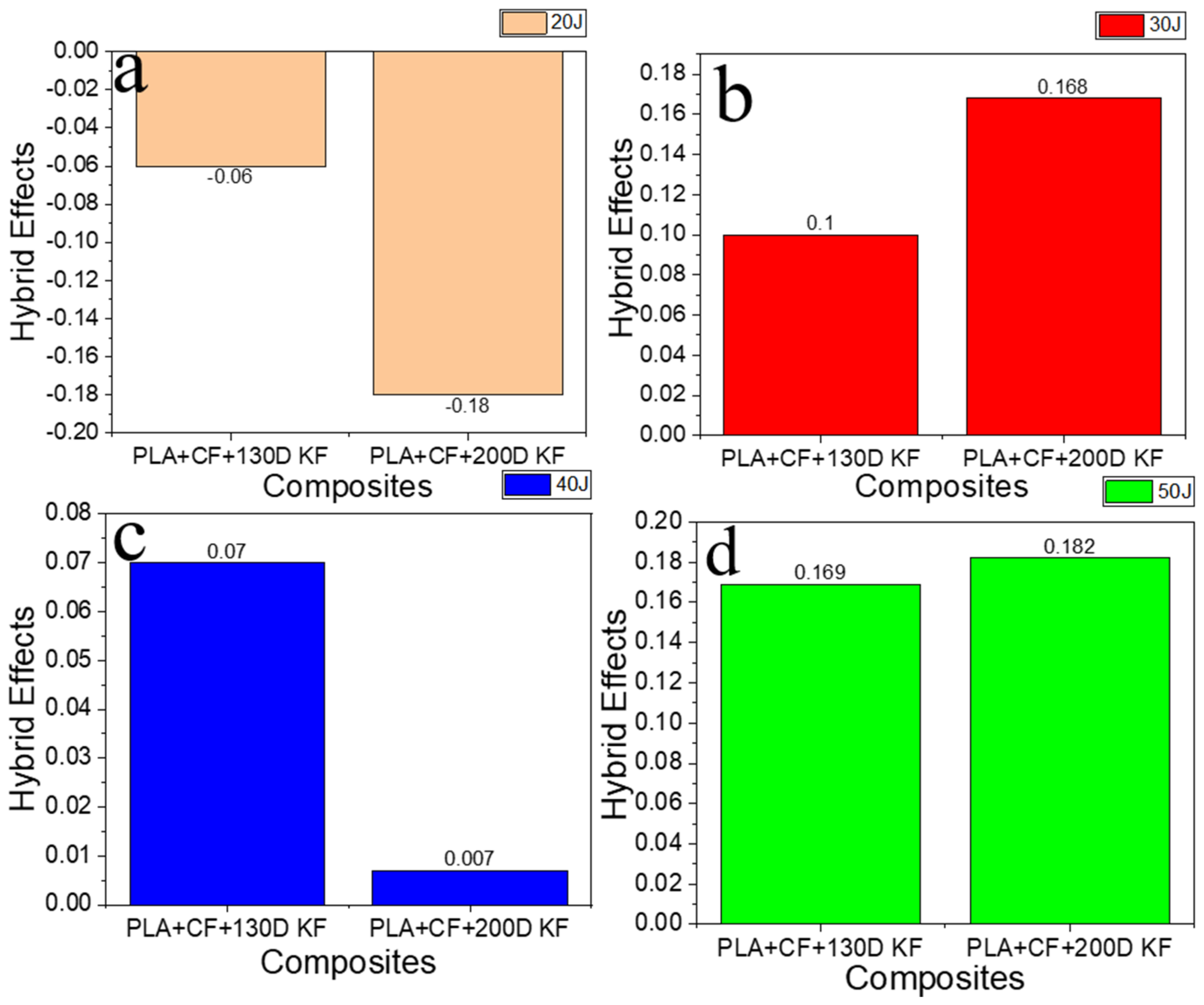

3.5. Hybrid Effect

4. Conclusions

- Specimens containing only KFs were good with absorbed energy because of their high elongation properties with low stiffness. The damage and cracks were visible in the non-hybrids from 20 J of impact energy, While the hitting sides of the hybrids had just a sign of being hit, and their blind sides had 90.486% less damage than PLA + CF.

- Damages were more obvious with the increase in impact energies. At 30 J of impact energy, the damages in these hybrids were almost 88.16% less than the non-hybrid PLA + CF, which was slightly more than the hybrids of 20 J. Moreover, the damages of these hybrids against 40 J of impact energy were 81.48% less, which was more than the hybrids of 20 J and 30 J. At 50 J of impact, the non-hybrids were almost destroyed completely, while PLA + CF + 130D KF and PLA + CF + 200D KF were only punctured because of their high perforation resistance, and still, these damages were 71.45% and 78.10% less than PLA + CF, respectively.

- There were no further microcracks found in the computed tomography (CT) scans of the hybrids, which means these specimens were crack-resistive. The energy absorptions were higher, with positive hybrid effects, suggesting its validity for structural applications.

- The breakage patterns in all the specimens were rhombus-shaped, which could be because of the 0°/90° printing orientations. In the future, different printing orientations will be applied to study further breakage patterns.

- In future studies, a system will be implemented to monitor the events of impact tests, as they occur too quickly to be observed with the naked eye. Furthermore, the structural applications of these hybrids will be defined specifically in aerospace and automobiles.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- John, M.J.; Thomas, S. Biofibres and Biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Fu, S.Y.; Xu, G.; Mai, Y.W. On the Elastic Modulus of Hybrid Particle/Short-Fiber/Polymer Composites. Compos. Part B Eng. 2002, 33, 291–299. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Durability of Bamboo-Glass Fiber Reinforced Polymer Matrix Hybrid Composites. Compos. Sci. Technol. 2003, 63, 375–387. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/Synthetic Fibre Reinforced Polymer Hybrid Composites: A Review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Environmental Effects on Bamboo-Glass/Polypropylene Hybrid Composites. J. Mater. Sci. 2003, 38, 363–376. [Google Scholar] [CrossRef]

- Sreekala, M.S.; George, J.; Kumaran, M.G.; Thomas, S. The Mechanical Performance of Hybrid Phenol-Formaldehyde-Based Composites Reinforced with Glass and Oil Palm Fibres. Compos. Sci. Technol. 2002, 62, 339–353. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Steinbach, J.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Experimental Study on Mechanical Properties of Material Extrusion Additive Manufactured Parts from Recycled Glass Fibre-Reinforced Polypropylene Composite. Compos. Sci. Technol. 2023, 241, 110125. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Mechanical and Thermal Study of 3D Printing Composite Filaments from Wind Turbine Waste. Polym. Compos. 2021, 42, 2305–2316. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of Fiberglass Wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Selmy, A.I.; Elsesi, A.R.; Azab, N.A.; Abd El-Baky, M.A. In-Plane Shear Properties of Unidirectional Glass Fiber (U)/Random Glass Fiber (R)/Epoxy Hybrid and Non-Hybrid Composites. Compos. Part B Eng. 2012, 43, 431–438. [Google Scholar] [CrossRef]

- Sayer, M.; Bektaş, N.B.; Demir, E.; Çallioǧlu, H. The Effect of Temperatures on Hybrid Composite Laminates under Impact Loading. Compos. Part B Eng. 2012, 43, 2152–2160. [Google Scholar] [CrossRef]

- Idicula, M.; Malhotra, S.K.; Joseph, K.; Thomas, S. Dynamic Mechanical Analysis of Randomly Oriented Intimately Mixed Short Banana/Sisal Hybrid Fibre Reinforced Polyester Composites. Compos. Sci. Technol. 2005, 65, 1077–1087. [Google Scholar] [CrossRef]

- Shi, Y.; Swait, T.; Soutis, C. Modelling Damage Evolution in Composite Laminates Subjected to Low Velocity Impact. Compos. Struct. 2012, 94, 2902–2913. [Google Scholar] [CrossRef]

- Olsson, R. Modelling of Impact Damage Zones in Composite Laminates for Strength after Impact. Aeronaut. J. 2012, 116, 1349–1365. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Y.; Chen, L.; Pan, N. A Comparative Study on Low-Velocity Impact Response of Fabric Composite Laminates. Mater. Des. 2013, 50, 750–756. [Google Scholar] [CrossRef]

- Langkamp, A. Theoretical and experimental investigation of anisotropic damage in textile-reinforced composite structures. Mech. Compos. Mater. 2004, 40, 519–532. [Google Scholar]

- Nirbhay, M.; Misra, R.K.; Dixit, A. Finite-Element Analysis of Jute- and Coir-Fiber-Reinforced Hybrid Composite Multipanel Plates. Mech. Compos. Mater. 2015, 51, 505–520. [Google Scholar] [CrossRef]

- Akmal, A.; Tian, X.; Liu, T.; Zhou, J.; Azeem, M.; Yun, J.; Li, W.; Zhang, M.; Li, D.; Malakhov, A. V Mechanical and Energy Absorption Behaviors of 3D Printed Continuous Carbon/Kevlar Hybrid Thread Reinforced PLA Composites. Compos. Struct. 2023, 303, 116386. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre Hybridisation in Polymer Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.F.M. A Critical Review on 3D Printed Continuous Fiber-Reinforced Composites: History, Mechanism, Materials and Properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact Damage Resistance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Chen, D.; Luo, Q.; Meng, M.; Sun, G. Low Velocity Impact Behavior of Interlayer Hybrid Composite Laminates with Carbon/Glass/Basalt Fibres. Compos. Part B Eng. 2019, 176, 107191. [Google Scholar] [CrossRef]

- Scrocco, M. Impact Testing of 3D Printed Kevlar-Reinforced Onyx Material. In Proceedings of the 2018 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Chabaud, G.; Castro, M.; Denoual, C.; Le Duigou, A. Hygromechanical Properties of 3D Printed Continuous Carbon and Glass Fibre Reinforced Polyamide Composite for Outdoor Structural Applications. Addit. Manuf. 2019, 26, 94–105. [Google Scholar] [CrossRef]

- Dou, H.; Ye, W.; Zhang, D.; Cheng, Y.; Huang, K.; Yang, F.; Rudykh, S. Research on Drop-Weight Impact of Continuous Carbon Fiber Reinforced 3D Printed Honeycomb Structure. Mater. Today Commun. 2021, 29, 102869. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 4D Printing of PLA-TPU Blends: Effect of PLA Concentration, Loading Mode, and Programming Temperature on the Shape Memory Effect. J. Mater. Sci. 2023, 58, 7227–7243. [Google Scholar] [CrossRef]

- ISO 6603; Plastics-Determination of Puncture Impact Behavior of Rigid Ilastics. ISO: Geneva, Switzerland, 2023.

- Cao, M.; Cui, T.; Yue, Y.; Li, C.; Guo, X.; Jia, X.; Wang, B. Preparation and Characterization for the Thermal Stability and Mechanical Property of PLA and PLA/CF Samples Built by FFF Approach. Materials 2023, 16, 5023. [Google Scholar] [CrossRef]

- Guillermo, J.; Pertuz-Comas, A.D. Impact Strength for 3D-Printed PA6 Polymer Composites under Temperature Changes. J. Manuf. Mater. Process. 2023, 7, 178. [Google Scholar]

- Wang, K.; Li, S.; Wu, Y.; Rao, Y.; Peng, Y. Simultaneous Reinforcement of Both Rigidity and Energy Absorption of Polyamide-Based Composites with Hybrid Continuous Fibers by 3D Printing. Compos. Struct. 2021, 267, 113854. [Google Scholar] [CrossRef]

- Morelli, A.C.; Croce, J.A.G.; Caminaga, C.; Letícia, R. Timarco Development of Hybrids Composites of Carbon and Aramid Fibers to Reinforce Matrix of Epoxy Resins Part I. J. Mater. Sci. Eng. B 2018, 8, 86–89. [Google Scholar] [CrossRef]

| Specimens | Matrix Volume Fraction (vol. %) | Matrix Weight Fraction (wt. %) | Fiber Volume Fraction (vol. %) | Fiber Weight Fraction (wt. %) |

|---|---|---|---|---|

| PLA + 1K CF | 88 ± 3 | 83 ± 5 | 12 ± 3 | 17 ± 5 |

| PLA + 130D KF | 88 ± 3 | 83 ± 5 | 12 ± 3 | 17 ± 5 |

| PLA + 200D KF | 88 ± 3 | 83 ± 5 | 12 ± 3 | 17 ± 5 |

| PLA + 1K CF + 130D KF | 88 ± 3 | 83 ± 5 | 12 ± 3 | 17 ± 5 |

| Specimens | Puncture Force (kN) | Energy (J) | Type of Deformation | Deformed Area (mm2) | Deformed Area % w.r.t PLA + CF | Absorbed Engery % w.r.t PLA + CF |

|---|---|---|---|---|---|---|

| PLA + CF | 0.904 | 17.5078 | Ductile with complex tearing | As a reference | As a reference | |

| PLA + 130D KF | 0.653 | 17.187 | - | 26.796% less | 1.8% less | |

| PLA + 200D KF | 0.803 | 19 | - | 1.02% more | 8.52% more | |

| PLA + CF + 130D KF | 1.506 | 16.588 | initially brittle with arrested complex structure | 841.1 mm2 | 83.592% less | 5.25% less |

| PLA + CF + 200D KF | 1.807 | 14.455 | initially brittle with arrested complex structure | 487.695 mm2 | 90.486% less | 17.43% less |

| Specimens | Puncture Force (kN) | Energy (J) | Type of Deformation | Deformed Area (mm2) | Deformed Area % w.r.t PLA + CF | Absorbed Engery % w.r.t PLA + CF |

|---|---|---|---|---|---|---|

| PLA + CF | 1.004 | 22.438 | Ductile with complex tearing | As a reference | As a reference | |

| PLA + 130D KF | 0.653 | 15.855 | - | 7.96% less | 29.33% less | |

| PLA + 200D KF | 0.753 | 21.494 | - | 1.15% more | 4.20% less | |

| PLA + CF + 130D KF | 1.456 | 23.712 | initially brittle with arrested complex structure | 1278.87 mm2 | 79.69% less | 5.72% more |

| PLA + CF + 200D KF | 1.506 | 23.809 | initially brittle with arrested complex structure | 745.02 mm2 | 88.16% less | 6.11% more |

| Specimens | Puncture Force (kN) | Energy (J) | Type of Deformation | Deformed Area (mm2) | Deformed Area % w.r.t PLA + 1k CF | Absorbed Engery % w.r.t PLA + CF |

|---|---|---|---|---|---|---|

| PLA + CF | 1.255 | 27.291 | Ductile with complex tearing | As a reference | As a reference | |

| PLA + 130D KF | 0.904 | 27.227 | - | 23.74% less | 0.2% less | |

| PLA + 200D KF | 1.104 | 28.409 | - | 11.63% more | 4.09% more | |

| PLA + CF + 130D KF | 1.858 | 28.799 | initially brittle with arrested complex structure | 1669.0 mm2 | 78.82% less | 5.52% more |

| PLA + CF + 200D KF | 1.807 | 28.8 | initially brittle with arrested complex structure | 1459.22 mm2 | 81.48% less | 5.52% more |

| Specimens | Puncture Force (kN) | Energy (J) | Type of Deformation | Deformed Area (mm2) | Deformed Area % w.r.t PLA + 1k CF | Absorbed Engery % w.r.t PLA + CF |

|---|---|---|---|---|---|---|

| PLA + CF | 1.255 | 34.65 | Ductile with complex tearing | As a reference | As a reference | |

| PLA + 130D KF | 0.954 | 27.326 | - | 30.66% less | 21.13% less | |

| PLA + 200D KF | 1.104 | 36.283 | - | 26.71% more | 4.71% more | |

| PLA + CF + 130D KF | 1.707 | 38.272 | initially brittle with arrested complex structure | 2520.61 mm2 | 71.45% less | 10.45% more |

| PLA + CF + 200D KF | 1.807 | 38.684 | initially brittle with arrested complex structure | 1933.55 mm2 | 78.10% less | 11.64% more |

| PLA + CF + 130D KF | PLA + CF + 130D KF | |||

|---|---|---|---|---|

| Front | Back | Front | Back | |

| 20 J |  |  |  |  |

| 30 J |  |  |  |  |

| 40 J |  |  |  |  |

| 50 J |  |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akmal Zia, A.; Tian, X.; Jawad Ahmad, M.; Tao, Z.; Meng, L.; Zhou, J.; Zhang, D.; Zhang, W.; Qi, J.; Li, D. Impact Resistance of 3D-Printed Continuous Hybrid Fiber-Reinforced Composites. Polymers 2023, 15, 4209. https://doi.org/10.3390/polym15214209

Akmal Zia A, Tian X, Jawad Ahmad M, Tao Z, Meng L, Zhou J, Zhang D, Zhang W, Qi J, Li D. Impact Resistance of 3D-Printed Continuous Hybrid Fiber-Reinforced Composites. Polymers. 2023; 15(21):4209. https://doi.org/10.3390/polym15214209

Chicago/Turabian StyleAkmal Zia, Ali, Xiaoyong Tian, Muhammad Jawad Ahmad, Zhou Tao, Luo Meng, Jin Zhou, Daokang Zhang, Wenxin Zhang, Jiangwei Qi, and Dichen Li. 2023. "Impact Resistance of 3D-Printed Continuous Hybrid Fiber-Reinforced Composites" Polymers 15, no. 21: 4209. https://doi.org/10.3390/polym15214209

APA StyleAkmal Zia, A., Tian, X., Jawad Ahmad, M., Tao, Z., Meng, L., Zhou, J., Zhang, D., Zhang, W., Qi, J., & Li, D. (2023). Impact Resistance of 3D-Printed Continuous Hybrid Fiber-Reinforced Composites. Polymers, 15(21), 4209. https://doi.org/10.3390/polym15214209