Approaches for Numerical Modeling and Simulation of the Filling Phase in Injection Molding: A Review

Abstract

:1. Introduction

2. Modeling of the Filling Phase

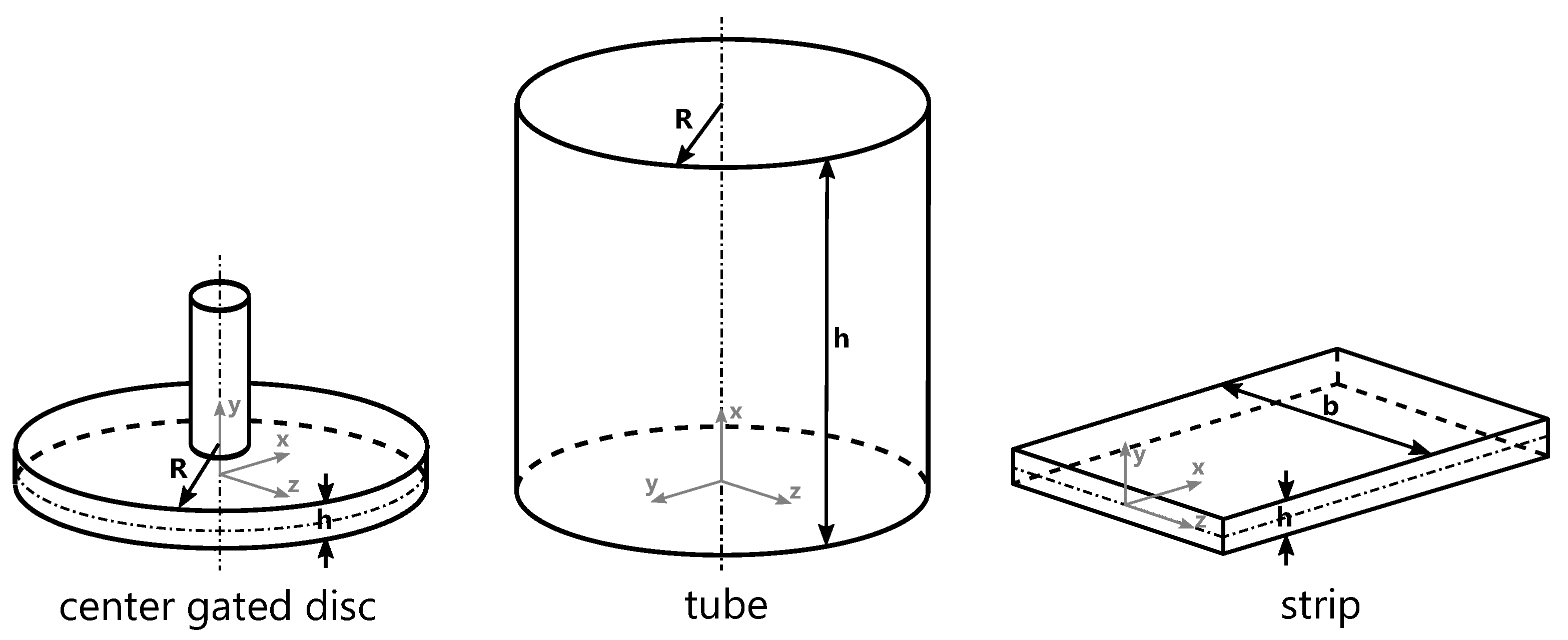

2.1. 1-Dimensional Model

2.2. 2-Dimensional Model

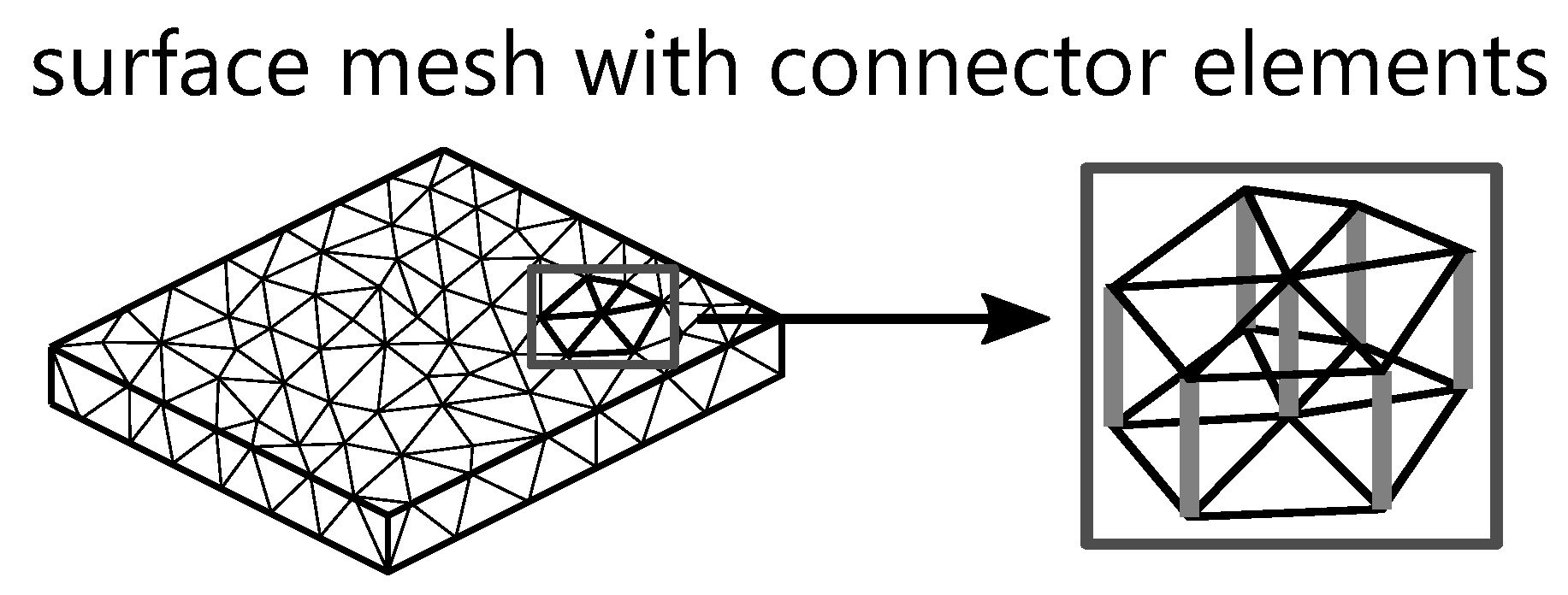

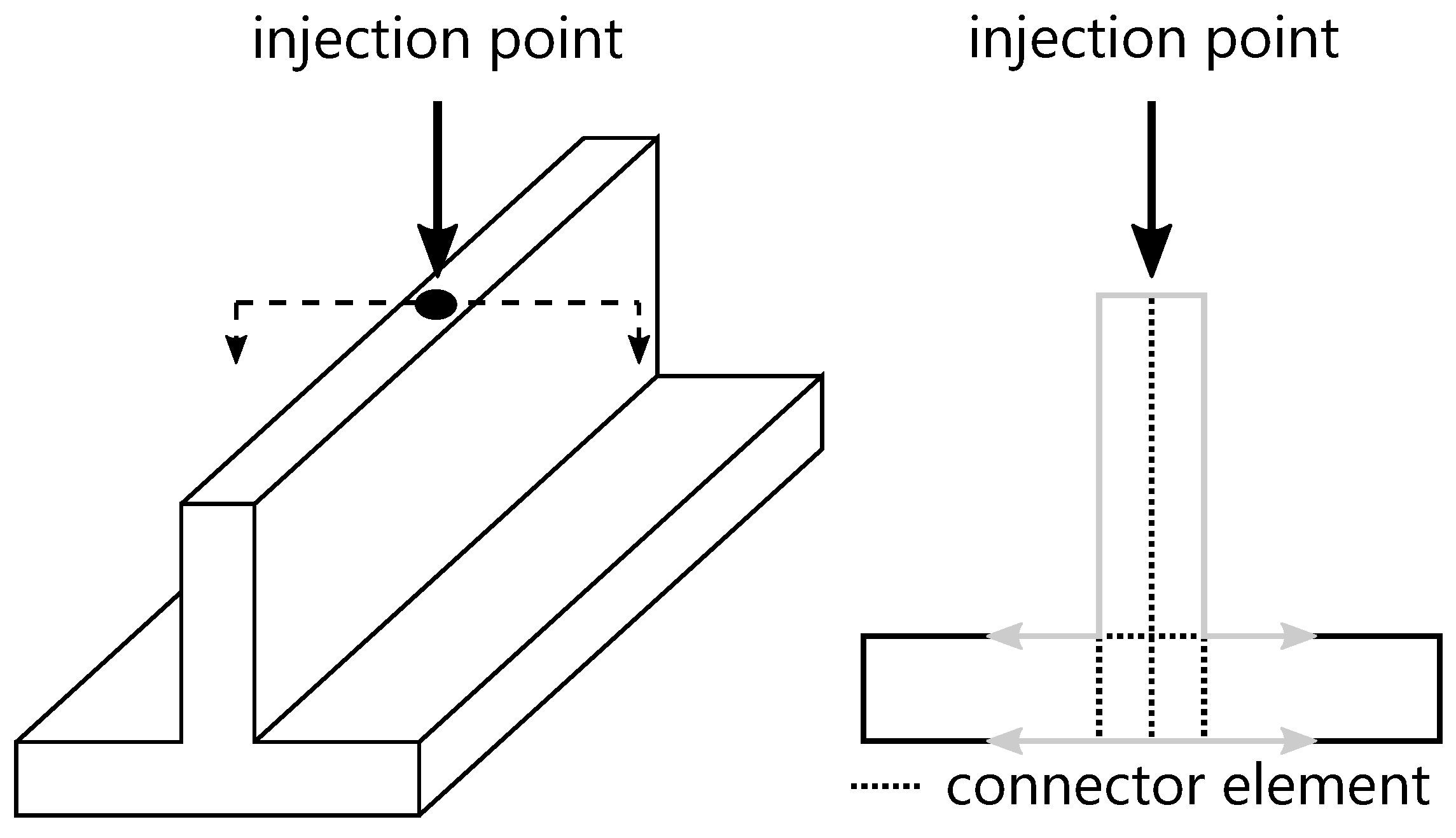

2.3. 2.5-Dimensional Model

2.4. 3-Dimensional Model

2.5. Rheological Model

2.5.1. Power-Law Model

2.5.2. Second-Order Model

2.5.3. Herschel–Bulkley Model

2.5.4. Bingham Plastic Model

2.5.5. Temperature Shift Factors

2.5.6. Carreau Model

2.5.7. Bird–Carreau Model

2.5.8. Cross Model

3. Overview

3.1. Overview of Commercial Software

3.2. Overview of Research with Commercial Software

3.3. Overview of Research Approaches

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H. Computer Modeling for Injection Molding: Simulation, Optimization, and Control; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Cardozo, D. Three Models of the 3D Filling Simulation for Injection Molding: A Brief Review. J. Reinf. Plast. Compos. 2008, 27, 1963–1974. [Google Scholar] [CrossRef]

- Cardozo, D. A brief history of the filling simulation of injection moulding. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 711–721. [Google Scholar] [CrossRef]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and Optimization of the Injection-Molding Process: A Review. Adv. Polym. Technol. 2018, 37, 429–449. [Google Scholar] [CrossRef]

- Kamal, M.R.; Isayev, A.I.; Liu, S.J.; White, J.L. (Eds.) Injection Molding: Technology and Fundamentals: Progress in Polymer Processing; Hanser: Munich, Germany, 2009. [Google Scholar]

- Osswald, T.A.; Turng, L.S.; Gramann, P.J. Injection Molding Handbook, 2nd ed.; Hanser: Cincinnati, OH, USA; Munich, Germany, 2008. [Google Scholar]

- Kamal, M.R.; Kenig, S. The injection molding of thermoplastics part I: Theoretical model. Polym. Eng. Sci. 1972, 12, 294–301. [Google Scholar] [CrossRef]

- Kamal, M.R.; Kenig, S. The injection molding of thermoplastics part II: Experimental test of the model. Polym. Eng. Sci. 1972, 12, 302–308. [Google Scholar] [CrossRef]

- Wu, P.C.; Huang, C.F.; Gogos, C.G. Simulation of the mold-filling process. Polym. Eng. Sci. 1974, 14, 223–230. [Google Scholar] [CrossRef]

- Nunn, R.E.; Fenner, R.T. Flow and heat transfer in the nozzle of an injection molding machine. Polym. Eng. Sci. 1977, 17, 811–818. [Google Scholar] [CrossRef]

- Stevenson, J.F. A simplified method for analyzing mold filling dynamics Part I: Theory. Polym. Eng. Sci. 1978, 18, 577–582. [Google Scholar] [CrossRef]

- Lord, H.A.; Williams, G. Mold-filling studies for the injection molding of thermoplastic materials. Part II: The transient flow of plastic materials in the cavities of injection-molding dies. Polym. Eng. Sci. 1975, 15, 569–582. [Google Scholar] [CrossRef]

- Williams, G.; Lord, H.A. Mold-filling studies for the injection molding of thermoplastic materials. Part I: The flow of plastic materials in hot- and cold-walled circular channels. Polym. Eng. Sci. 1975, 15, 553–568. [Google Scholar] [CrossRef]

- Harry, D.H.; Parrott, R.G. Numerical simulation of injection mold filling. Polym. Eng. Sci. 1970, 10, 209–214. [Google Scholar] [CrossRef]

- Thienel, P.; Menges, G. Mathematical and experimental determination of temperature, velocity, and pressure fields in flat molds during the filling process in injection molding of thermoplastics. Polym. Eng. Sci. 1978, 18, 314–320. [Google Scholar] [CrossRef]

- Richardson, S. Hele Shaw flows with a free boundary produced by the injection of fluid into a narrow channel. J. Fluid Mech. 1972, 56, 609–618. [Google Scholar] [CrossRef]

- White, J.L. Fluid mechanical analysis of injection mold filling. Polym. Eng. Sci. 1975, 15, 44–50. [Google Scholar] [CrossRef]

- Kamal, M.R.; Kuo, Y.; Doan, P.H. The injection molding behavior of thermoplastics in thin rectangular cavities. Polym. Eng. Sci. 1975, 15, 863–868. [Google Scholar] [CrossRef]

- Kuo, Y.; Kamal, M.R. The fluid mechanics and heat transfer of injection mold filling of thermoplastic materials. AIChE J. 1976, 22, 661–669. [Google Scholar] [CrossRef]

- Broyer, E.; Gutfinger, C.; Tadmor, Z. A Theoretical Model for the Cavity Filling Process in Injection Molding. Trans. Soc. Rheol. 1975, 19, 423–444. [Google Scholar] [CrossRef]

- Broyer, E.; Tadmor, Z.; Gutfinge, C. Filling of a rectangular channel with a Newtonian fluid. Isr. J. Technol. 1973, 11, 189–193. [Google Scholar]

- Krueger, W.L.; Tadmor, Z. Injection molding into a rectangular cavity with inserts. Polym. Eng. Sci. 1980, 20, 426–431. [Google Scholar] [CrossRef]

- Tadmor, Z.; Broyer, E.; Gutfinger, C. Flow analysis network (FAN)—A method for solving flow problems in polymer processing. Polym. Eng. Sci. 1974, 14, 660–665. [Google Scholar] [CrossRef]

- Hieber, C.A.; Shen, S.F. Flow analysis of the nonisothermal 2-dimensional filling process in injection-molding. Isr. J. Technol. 1978, 16, 248–254. [Google Scholar]

- Hieber, C.A.; Shen, S.F. A finite-element/finite-difference simulation of the injection-molding filling process. J. Non-Newtonian Fluid Mech. 1980, 7, 1–32. [Google Scholar] [CrossRef]

- Shen, S.F. Simulation of polymeric flows in the injection moulding process. Int. J. Numer. Methods Fluids 1984, 4, 171–183. [Google Scholar] [CrossRef]

- Kennedy, P.; Zheng, R. Flow Analysis of Injection Molds, 2nd ed.; Hanser: Munich, Germany; Cincinnati, OH, USA, 2013. [Google Scholar]

- Zhou, H.; Zhang, Y.; Li, D. Injection moulding simulation of filling and post-filling stages based on a three-dimensional surface model. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2001, 215, 1459–1463. [Google Scholar] [CrossRef]

- Subbiah, S.; Trafford, D.L.; Güçeri, S.I. Non-isothermal flow of polymers into two-dimensional, thin cavity molds: A numerical grid generation approach. Int. J. Heat Mass Transf. 1989, 32, 415–434. [Google Scholar] [CrossRef]

- Altan, M.C.; Subbiah, S.; Güçeri, S.I.; Pipes, R.B. Numerical prediction of three-dimensional fiber orientation in Hele–Shaw flows. Polym. Eng. Sci. 1990, 30, 848–859. [Google Scholar] [CrossRef]

- Chiang, H.H.; Hieber, C.A.; Wang, K.K. A unified simulation of the filling and postfilling stages in injection molding. Part I: Formulation. Polym. Eng. Sci. 1991, 31, 116–124. [Google Scholar] [CrossRef]

- Chiang, H.H.; Hieber, C.A.; Wang, K.K. A unified simulation of the filling and postfilling stages in injection molding. Part II: Experimental verification. Polym. Eng. Sci. 1991, 31, 125–139. [Google Scholar] [CrossRef]

- Shen, Y.K.; Chen, S.H.; Lee, H.C. Analysis of the Mold Filling Process on Flip Chip Package. J. Reinf. Plast. Compos. 2004, 23, 407–428. [Google Scholar] [CrossRef]

- Mavridis, H.; Hrymak, A.N.; Vlachopoulos, J. Mathematical modeling of injection mold filling: A review. Adv. Polym. Technol. 1986, 6, 457–466. [Google Scholar] [CrossRef]

- Kim, S.W.; Turng, L.S. Developments of three-dimensional computer-aided engineering simulation for injection moulding. Model. Simul. Mater. Sci. Eng. 2004, 12, S151–S173. [Google Scholar] [CrossRef]

- Nguyen-Chung, T. Strömungsanalyse der Bindenahtformation beim Spritzgieen von thermoplastischen Kunststoffen. Ph.D. Thesis, Technical University of Chemnitz, Chemnitz, Germany, 2001. [Google Scholar]

- Wang, V.W.; Hieber, C.A.; Wang, K.K. Dynamic Simulation and Graphics for the Injection Molding of Three-Dimensional Thin Parts. J. Polym. Eng. 1986, 7, 21–46. [Google Scholar] [CrossRef]

- Isayev, A.I. (Ed.) Injection and Compression Molding Fundamentals; Marcel Dekker: New York, NY, USA, 1987. [Google Scholar]

- Liang, E.W.; Tucker, C.L. A finite element method for flow in compression molding of thin and thick parts. Polym. Compos. 1995, 16, 70–82. [Google Scholar] [CrossRef]

- Smith, D.E.; Tortorelli, D.A.; Tucker, C.L. Analysis and sensitivity analysis for polymer injection and compression molding. Comput. Methods Appl. Mech. Eng. 1998, 167, 325–344. [Google Scholar] [CrossRef]

- Chung, S.T.; Kwon, T.H. Numerical simulation of fiber orientation in injection molding of short-fiber-reinforced thermoplastics. Polym. Eng. Sci. 1995, 35, 604–618. [Google Scholar] [CrossRef]

- Kabanemi, K.K.; Hétu, J.F.; Garcia-Rejon, A. Numerical Simulation of the Flow and Fiber Orientation in Reinforced Thermoplastic Injection Molded Products. Int. Polym. Process. 1997, 12, 182–191. [Google Scholar] [CrossRef]

- Himasekhar, K.; Lottey, J.; Wang, K.K. CAE of Mold Cooling in Injection Molding Using a Three-Dimensional Numerical Simulation. J. Eng. Ind. 1992, 114, 213–221. [Google Scholar] [CrossRef]

- Baaijens, F. Calculation of residual stresses in injection molded products. Rheol. Acta 1991, 30, 284–299. [Google Scholar] [CrossRef]

- Zoetelief, W.F.; Douven, L.F.A.; Housz, A.J.I. Residual thermal stresses in injection molded products. Polym. Eng. Sci. 1996, 36, 1886–1896. [Google Scholar] [CrossRef]

- Chiang, H.H.; Himasekhar, K.; Santhanam, N.; Wang, K.K. Integrated Simulation of Fluid Flow and Heat Transfer in Injection Molding for the Prediction of Shrinkage and Warpage. J. Eng. Mater. Technol. 1993, 115, 37–47. [Google Scholar] [CrossRef]

- Kabanemi, K.K.; Vaillancourt, H.; Wang, H.; Salloum, G. Residual stresses, shrinkage, and warpage of complex injection molded products: Numerical simulation and experimental validation. Polym. Eng. Sci. 1998, 38, 21–37. [Google Scholar] [CrossRef]

- Turng, L.S.; Wang, V.W.; Wang, K.K. Numerical Simulation of the Coinjection Molding Process. J. Eng. Mater. Technol. 1993, 115, 48–53. [Google Scholar] [CrossRef]

- Turng, L.S. Development and application of CAE technology for the gas-assisted injection molding process. Adv. Polym. Technol. 1995, 14, 1–13. [Google Scholar] [CrossRef]

- Phelan, F.R. Simulation of the injection process in resin transfer molding. Polym. Compos. 1997, 18, 460–476. [Google Scholar] [CrossRef]

- Han, S.; Wang, K.K.; Crouthamel, D.L. Wire-Sweep Study Using an Industrial Semiconductor-Chip-Encapsulation Operation. J. Electron. Packag. 1997, 119, 247–254. [Google Scholar] [CrossRef]

- Zhou, H.; Li, D. A numerical simulation of the filling stage in injection molding based on a surface model. Adv. Polym. Technol. 2001, 20, 125–131. [Google Scholar] [CrossRef]

- Zhou, H.; Li, D. Computer Filling Simulation of Injection Molding Based on 3D Surface Model. Polym.-Plast. Technol. Eng. 2002, 41, 91–102. [Google Scholar] [CrossRef]

- Cao, W.; Wang, R.; Shen, C. A Dual Domain Method for 3-D Flow Simulation. Polym.-Plast. Technol. Eng. 2005, 43, 1471–1486. [Google Scholar] [CrossRef]

- Jaworski, M.J. Theoretical and Experimental Comparison of Mesh Types Used in CAE Injection Molding Simulation Software. Ph.D. Thesis, University of Massachusetts, Amherst, MA, USA, 2003. [Google Scholar]

- Beaumont, J.P.; Nagel, R.L.; Sherman, R. Successful Injection Molding: Process, Design, and Simulation; Hanser Publishers: Munich, Germany, 2002. [Google Scholar]

- Yang, D.; Zhao, P.; Zhou, H.; Chen, L. Computer determination of weld lines in injection molding based on filling simulation with surface model. J. Reinf. Plast. Compos. 2014, 33, 1403–1415. [Google Scholar] [CrossRef]

- Yu, H.G.; Thomas, R. Method for Modelling Three Dimension Objects and Simulation of Fluid Flow. U.S. Patent No. US6096088A, 1 August 2000. [Google Scholar]

- Ospald, F. Numerical Simulation of Injection Molding using OpenFOAM. PAMM 2014, 14, 673–674. [Google Scholar] [CrossRef]

- Haagh, G.A.A.V.; van de Vosse, F.N. Simulation of three-dimensional polymer mould filling processes using a pseudo-concentration method. Int. J. Numer. Methods Fluids 1998, 28, 1355–1369. [Google Scholar] [CrossRef]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2006. [Google Scholar]

- Koszkul, J.; Nabialek, J. Viscosity models in simulation of the filling stage of the injection molding process. J. Mater. Process. Technol. 2004, 157–158, 183–187. [Google Scholar] [CrossRef]

- Najmi, L.A.; Lee, D. Modeling of mold filling process for powder injection molding. Polym. Eng. Sci. 1991, 31, 1137–1148. [Google Scholar] [CrossRef]

- Mavridis, H.; Hrymak, A.N.; Vlachopoulos, J. Finite element simulation of fountain flow in injection molding. Polym. Eng. Sci. 1986, 26, 449–454. [Google Scholar] [CrossRef]

- Gottlieb, M. Zero-shear-rate viscosity measurements for polymer solutions by falling ball viscometry. J. Non-Newtonian Fluid Mech. 1979, 6, 97–109. [Google Scholar] [CrossRef]

- Ilinca, F.; Hétu, J.F. Three-dimensional Filling and Post-filling Simulation of Polymer Injection Molding. Int. Polym. Process. 2001, 16, 291–301. [Google Scholar] [CrossRef]

- Chen, B.S.; Liu, W.H. Numerical simulation of the post-filling stage in injection molding with a two-phase model. Polym. Eng. Sci. 1994, 34, 835–846. [Google Scholar] [CrossRef]

- Buchmann, M.; Theriault, R.; Osswald, T.A. Polymer flow length simulation during injection mold filling. Polym. Eng. Sci. 1997, 37, 667–671. [Google Scholar] [CrossRef]

- Borzenko, E.I.; Shrager, G.R. Simulating injection molding of semi-crystalline polymers: Effect of crystallization on the dynamics of channel filling. Interfacial Phenom. Heat Transf. 2020, 8, 225–233. [Google Scholar] [CrossRef]

- Struik, L. Mechanical behaviour and physical ageing of semi-crystalline polymers: 4. Polymer 1989, 30, 815–830. [Google Scholar] [CrossRef]

- Hieber, C.A.; Chiang, H.H. Shear-rate-dependence modeling of polymer melt viscosity. Polym. Eng. Sci. 1992, 32, 931–938. [Google Scholar] [CrossRef]

- Kadijk, S.E.; van den Brule, B.H.A.A. On the pressure dependency of the viscosity of molten polymers. Polym. Eng. Sci. 1994, 34, 1535–1546. [Google Scholar] [CrossRef]

- Yao, D.; Kim, B. Scaling Issues in Miniaturization of injection-molded parts. J. Manuf. Sci. Eng. 2004, 126, 733–739. [Google Scholar] [CrossRef]

- Wang, W.; Li, X.; Han, X. Numerical simulation and experimental verification of the filling stage in injection molding. Polym. Eng. Sci. 2012, 52, 42–51. [Google Scholar] [CrossRef]

- Kennedy, P.K. Flow Analysis of Injection Molds; Hanser Gardner: Munich, Germany, 1995. [Google Scholar]

- Herschel, W.H.; Bulkley, R. Konsistenzmessungen von Gummi-Benzollösungen. Kolloid-Zeitschrift 1926, 39, 291–300. [Google Scholar] [CrossRef]

- Valencia, A.; Morales, H.; Rivera, R.; Bravo, E.; Galvez, M. Blood flow dynamics in patient-specific cerebral aneurysm models: The relationship between wall shear stress and aneurysm area index. Med. Eng. Phys. 2008, 30, 329–340. [Google Scholar] [CrossRef]

- Tosello, G.; Marhöfer, D.M.; Islam, A.; Müller, T.; Plewa, K.; Piotter, V. Comprehensive characterization and material modeling for ceramic injection molding simulation performance validations. Int. J. Adv. Manuf. Technol. 2019, 102, 225–240. [Google Scholar] [CrossRef]

- Osswald, T.A.; Rudolph, N. Polymer Rheology: Fundamentals and Applications; Hanser eLibrary; Hanser: Munich, Germany, 2014. [Google Scholar] [CrossRef]

- Kutsbakh, A.A.; Muranov, A.N.; Semenov, A.B.; Semenov, B.I. The Rheological Behavior of Powder–Polymer Blends and Model Description of Feedstock Viscosity for Numerical Simulation of the Injection Molding Process. Polym. Sci. Ser. D 2022, 15, 701–708. [Google Scholar] [CrossRef]

- Rudert, A.; Schwarze, R. Numerical simulation of the filling behavior of a Non-Newtonian Fluid. PAMM 2006, 6, 585–586. [Google Scholar] [CrossRef]

- Mitsoulis, E. Fountain flow of pseudoplastic and viscoplastic fluids. J. Non-Newtonian Fluid Mech. 2010, 165, 45–55. [Google Scholar] [CrossRef]

- Ginzburg, I.; Steiner, K. A free-surface lattice Boltzmann method for modelling the filling of expanding cavities by Bingham fluids. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2002, 360, 453–466. [Google Scholar] [CrossRef] [PubMed]

- Laun, H.M. Description of the non-linear shear behaviour of a low density polyethylene melt by means of an experimentally determined strain dependent memory function. Rheol. Acta 1978, 17, 1–15. [Google Scholar] [CrossRef]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-forming Liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Fan, B.; Kazmer, D.O. Low-temperature modeling of the time-temperature shift factor for polycarbonate. Adv. Polym. Technol. 2005, 24, 278–287. [Google Scholar] [CrossRef]

- Lomellini, P. Williams-Landel-Ferry versus Arrhenius behaviour: Polystyrene melt viscoelasticity revised. Polymer 1992, 33, 4983–4989. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; John Wiley & Sons: New York, NY, USA; Chichester, UK; Brisbane, Australia; Toronto, ON, Canada; Singapore, 1980. [Google Scholar]

- Angell, C.A. Why C1 = 16–17 in the WLF equation is physical—And the fragility of polymers. Polymer 1997, 38, 6261–6266. [Google Scholar] [CrossRef]

- Van Krevelen, D.W. Properties of Polymers, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 1976. [Google Scholar]

- Rowland, H.D.; King, W.P.; Sun, A.C.; Schunk, P.R.; Cross, G.L.W. Predicting Polymer Flow during High-Temperature Atomic Force Microscope Nanoindentation. Macromolecules 2007, 40, 8096–8103. [Google Scholar] [CrossRef]

- Rowe, G.M.; Sharrock, M.J. Alternate Shift Factor Relationship for Describing Temperature Dependency of Viscoelastic Behavior of Asphalt Materials. Transp. Res. Rec. J. Transp. Res. Board 2011, 2207, 125–135. [Google Scholar] [CrossRef]

- Bird, R.B.; Carreau, P.J. A nonlinear viscoelastic model for polymer solutions and melts—I. Chem. Eng. Sci. 1968, 23, 427–434. [Google Scholar] [CrossRef]

- Carreau, P.J. Rheological Equations from Molecular Network Theories. Trans. Soc. Rheol. 1972, 16, 99–127. [Google Scholar] [CrossRef]

- Yasuda, K.; Armstrong, R.C.; Cohen, R.E. Shear flow properties of concentrated solutions of linear and star branched polystyrenes. Rheol. Acta 1981, 20, 163–178. [Google Scholar] [CrossRef]

- Geiger, K.; Khnle, H. Analytische Berechnung einfacher scherstrmungen aufgrund eines fliegesetzes vom carreauschen typ. Rheol. Acta 1984, 23, 355–367. [Google Scholar] [CrossRef]

- Menges, G.; Wortberg, J.; Michaeli, W. Estimating the Viscosity Function via the melt Flow Index. Kunstst Ger Plast 1978, 68. [Google Scholar]

- Karrenberg, G. CFD-Simulation der Kunststoffplastifizierung in einem Extruder mit durchgehend genutetem Zylinder und Barriereschnecke. Z. Kunststofftechnik 2016, 1, 205–238. [Google Scholar] [CrossRef]

- Schroeder, T. Rheologie der Kunststoffe: Theorie und Praxis; Hanser: Munich, Germany, 2018. [Google Scholar]

- Ilinca, F.; Hétu, J.F. Three-dimensional simulation of multi-material injection molding: Application to gas-assisted and co-injection molding. Polym. Eng. Sci. 2003, 43, 1415–1427. [Google Scholar] [CrossRef]

- Yavari, R.; Khorsand, H.; Sardarian, M. Simulation and modeling of macro and micro components produced by powder injection molding: A review. Polyolefins J. 2020, 7, 45–60. [Google Scholar] [CrossRef]

- Winter, H.H. Temperature-induced pressure gradient in the clearance between screw flight and barrel of a single screw extruder. Polym. Eng. Sci. 1980, 20, 406–412. [Google Scholar] [CrossRef]

- Domurath, J.; Saphiannikova, M.; Férec, J.; Ausias, G.; Heinrich, G. Stress and strain amplification in a dilute suspension of spherical particles based on a Bird–Carreau model. J. Non-Newtonian Fluid Mech. 2015, 221, 95–102. [Google Scholar] [CrossRef]

- Cross, M.M. Rheology of non-Newtonian fluids: A new flow equation for pseudoplastic systems. J. Colloid Sci. 1965, 20, 417–437. [Google Scholar] [CrossRef]

- Shi, X.Z.; Huang, M.; Zhao, Z.F.; Shen, C.Y. Nonlinear Fitting Technology of 7-Parameter Cross-WLF Viscosity Model. Manuf. Process Technol. 2011, 189–193, 2103–2106. [Google Scholar] [CrossRef]

- Mishra, A.A.; Momin, A.; Strano, M.; Rane, K. Implementation of viscosity and density models for improved numerical analysis of melt flow dynamics in the nozzle during extrusion-based additive manufacturing. Prog. Addit. Manuf. 2022, 7, 41–54. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Xiao, X.T.; Zhang, Z.H. Fitting and Verification Viscosity Parameter of ABS/Aluminum Blends. Manuf. Process. Technol. 2011, 308–310, 824–830. [Google Scholar] [CrossRef]

- de Miranda, D.A.; Rauber, W.K.; Vaz Júnior, M.; Nogueira, A.L.; Bom, R.P.; Zdanski, P.S.B. Evaluation of the Predictive Capacity of Viscosity Models in Polymer Melt Filling Simulations. J. Mater. Eng. Perform. 2022, 32, 1707–1720. [Google Scholar] [CrossRef]

- Shoemaker, J. (Ed.) Moldflow Design Guide: A Resource for Plastics Engineers; Hanser Verlag: Munich, Germany, 2006. [Google Scholar] [CrossRef]

- Austin, C. Filling of mold cavities. In Computer Aided Engineering for Injection Molding; Bernhardt, E.C., Ed.; Hanser Publishers: Munich, Germany, 1983. [Google Scholar]

- Barrie, I.T. Understanding how an injection mold fills. SPE J. 1971, 27, 64–69. [Google Scholar]

- Burton, T.E.; Rezayat, M. Polycool 2 a Three-Dimensional Transient Mold-Cooling Simulator. In Applications of Computer Aided Engineering in Injection Molding; Manzione, L.T., Ed.; Hanser: New York, NY, USA, 1987; pp. 269–294. [Google Scholar]

- Singh, K.J. Mold Cooling. In Computer Aided Engineering for Injection Molding; Bernhardt, E.C., Ed.; Hanser Publishers: Munich, Germany, 1983. [Google Scholar]

- Wang, H.P.; Lee, H.S. Numerical Techniques for Free and Moving Boundary Problems. Computer Modeling for Polymer Processing; Hanser: Munich, Germany, 1989. [Google Scholar]

- van der Werf, J.J.; Boshouwers, A.G. INJECT-3, a Simulation Code for the Filling Stage of the Injection Moulding Process of Thermoplastics. Ph.D. Thesis, Technical University of Eindhoven, Eindhoven, The Netherlands, 1988. [Google Scholar] [CrossRef]

- Sitters, C.W.M. Numerical Solution of Injection Moulding. Ph.D. Thesis, Technical University of Eindhoven, Eindhoven, The Netherlands, 1988. [Google Scholar]

- Caren, S. GRAFTEK integrated CAD/CAM/CAE system. In Applications of Computer Aided Engineering in Injection Molding; Manzione, L.T., Ed.; Hanser: New York, NY, USA, 1987. [Google Scholar]

- Wang, V.W.; Hieber, C.A. C-Flow: A CAE package with high-level interactive graphics. In Applications of Computer Aided Engineering in Injection Molding; Manzione, L.T., Ed.; Hanser: New York, NY, USA, 1987; pp. 229–246. [Google Scholar]

- Wang, V.W.; Hieber, C.A. Post Filling Simulation of Injection Molding and its Applications. SPE Tech. Pap. 1988, 34, 290–293. [Google Scholar]

- Whelan, A.; Craft, J.L. (Eds.) Developments in Plastics Technology-3; Springer: Dordrecht, The Netherlands, 1986. [Google Scholar] [CrossRef]

- Nakano, R. Apparatus and Method for Analyzing a Process of Fluid Flow, an Apparatus and Method for Analyzing an Injection Molding Process, an Injection Molded Product, and a Production Method of the Injection Molded Product. U.S. Patent 5835379, 10 November 1998. [Google Scholar]

- Nakano, R. Apparatus for Analyzing a Process of Fluid Flow, and a Production Method of an Injection Molded Product. U.S. Patent 6161057, 12 December 2000. [Google Scholar]

- CoreTech System. Moldex3D Help 2022; CoreTech System: Zhubei City, Taiwan, 2022. [Google Scholar]

- Wen, Y.H.; Wang, C.C.; Cyue, G.S.; Kuo, R.H.; Hsu, C.H.; Chang, R.Y. Retrieving Equivalent Shear Viscosity for Molten Polymers from 3-D Nonisothermal Capillary Flow Simulation. Polymers 2021, 13, 4094. [Google Scholar] [CrossRef]

- C-Soultion Inc. Simuflow 6.0 Release News; C-Soultion Inc.: St. Houston, TX, USA, 2023. [Google Scholar]

- Mannella, G.A.; La Carrubba, V.; Brucato, V.; Zoetelief, W.; Haagh, G. No-flow temperature in injection molding simulation. J. Appl. Polym. Sci. 2011, 119, 3382–3392. [Google Scholar] [CrossRef]

- Kallien, L. Optimierung des Spritzgießprozesses von Duromeren mit 3D-Simulation; Sigma Engineering GmbH: Aachen, Germany, 2002. [Google Scholar]

- Shin, H.Y.; Kim, J.H.; Jang, J.S.; Baek, S.M.; Im, J.I. FEA for Fabrication Process of PZT Preform Using CIM. J. Korean Ceram. Soc. 2009, 46, 700–707. [Google Scholar] [CrossRef]

- Silva, L.; Gruau, C.; Agassant, J.F.; Coupez, T.; Mauffrey, J. Advanced Finite Element 3D Injection Molding. Int. Polym. Process. 2005, 20, 265–273. [Google Scholar] [CrossRef]

- Zhou, H.; Yan, B.; Zhang, Y. 3D filling simulation of injection molding based on the PG method. J. Mater. Process. Technol. 2008, 204, 475–480. [Google Scholar] [CrossRef]

- Yu, W.; Ruan, S.; Li, Z.; Gu, J.; Wang, X.; Shen, C.; Chen, B. Effect of injection velocity on the filling behaviors of microinjection-molded polylactic acid micropillar array product. Int. J. Adv. Manuf. Technol. 2019, 103, 2929–2940. [Google Scholar] [CrossRef]

- Lin, W.C.; Fan, F.Y.; Huang, C.F.; Shen, Y.K.; Wang, H. Analysis of the Warpage Phenomenon of Micro-Sized Parts with Precision Injection Molding by Experiment, Numerical Simulation, and Grey Theory. Polymers 2022, 14, 1845. [Google Scholar] [CrossRef]

- Yu, W.; Gu, J.; Li, Z.; Ruan, S.; Chen, B.; Shen, C.; Lee, L.J.; Wang, X. Study on the Influence of Microinjection Molding Processing Parameters on Replication Quality of Polylactic Acid Microneedle Array Product. Polymers 2023, 15, 1199. [Google Scholar] [CrossRef] [PubMed]

- Tran, N.T.; Gehde, M. Creating material data for thermoset injection molding simulation process. Polym. Test. 2019, 73, 284–292. [Google Scholar] [CrossRef]

- Islam, A.; Li, X.; Wirska, M. Injection Moulding Simulation and Validation of Thin Wall Components for Precision Applications. In Advances in Manufacturing II; Gapiński, B., Szostak, M., Ivanov, V., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2019; pp. 96–107. [Google Scholar] [CrossRef]

- Tsai, H.H.; Wu, S.J.; Liu, J.W.; Chen, S.H.; Lin, J.J. Filling-Balance-Oriented Parameters for Multi-Cavity Molds in Polyvinyl Chloride Injection Molding. Polymers 2022, 14, 3483. [Google Scholar] [CrossRef]

- Mulser, M.; Petzoldt, F.; Lipinski, M.; Hepp, E. Influence of the injection parameters on the interface formation of co-injected PIM parts. In Proceedings of the Conference: International Powder Metallurgy Congress and Exhibition, Euro PM 2011, Barcelona, Spain, 9–12 October 2011. [Google Scholar]

- Ariff, Z.M.; Khang, T.H. Evaluation of Cadmould Software to Simulate the Filling Phase of a Natural Rubber Compound in Injection Moulding Process. Manuf. Process Technol. 2013, 747, 571–574. [Google Scholar] [CrossRef]

- Ou, H.; Sahli, M.; Barrière, T.; Gelin, J.C. Multiphysics modelling and experimental investigations of the filling and curing phases of bi-injection moulding of thermoplastic polymer/liquid silicone rubbers. Int. J. Adv. Manuf. Technol. 2017, 92, 3871–3882. [Google Scholar] [CrossRef]

- Othman, M.H.; Yusof, M.; Hasan, S.; Ibrahim, M.; Amin, S.; Marwah, O.; Shaari, M.F.; Johar, M.A.; Shahbudin, S. Development of Mould of Rheology Test Sample via CadMould 3D-F Simulation. Iop Conf. Ser. Mater. Sci. Eng. 2017, 226, 012159. [Google Scholar] [CrossRef]

- Sahli, M.; Barrière, T.; Roizard, X. Experimental and numerical investigations of bi-injection moulding of PA66/LSR peel test specimens. Polym. Test. 2020, 90, 106748. [Google Scholar] [CrossRef]

- Fang, W.; He, X.; Zhang, R.; Yang, S.; Qu, X. The effects of filling patterns on the powder–Binder separation in powder injection molding. Powder Technol. 2014, 256, 367–376. [Google Scholar] [CrossRef]

- Zhuang, X.; Ouyang, J.; Jiang, C.; Liu, Q. New approach to develop a 3D non-isothermal computational framework for injection molding process based on level set method. Chin. J. Chem. Eng. 2016, 24, 832–842. [Google Scholar] [CrossRef]

- Mukras, S.M.S.; Al-Mufadi, F.A. Simulation of HDPE Mold Filling in the Injection Molding Process with Comparison to Experiments. Arab. J. Sci. Eng. 2016, 41, 1847–1856. [Google Scholar] [CrossRef]

- Anders, D.; Baum, M.; Alken, J. A Comparative Study of Numerical Simulation Strategies in Injection Molding. In Proceedings of the 14th WCCM-ECCOMAS Congress, CIMNE, Paris, France, 11–15 January 2021. [Google Scholar] [CrossRef]

- Baum, M.; Anders, D. A numerical simulation study of mold filling in the injection molding process. Comput. Methods Mater. Sci. 2021, 21, 25–34. [Google Scholar] [CrossRef]

- Baum, M.; Jasser, F.; Stricker, M.; Anders, D.; Lake, S. Numerical simulation of the mold filling process and its experimental validation. Int. J. Adv. Manuf. Technol. 2022, 120, 3065–3076. [Google Scholar] [CrossRef]

- Rusdi, M.S.; Abdullah, M.Z.; Mahmud, A.S.; Khor, C.Y.; Abdul Aziz, M.S.; Ariff, Z.M.; Abdullah, M.K. Numerical Investigation on the Effect of Pressure and Temperature on the Melt Filling During Injection Molding Process. Arab. J. Sci. Eng. 2016, 41, 1907–1919. [Google Scholar] [CrossRef]

- Zaki, M.Z.M.; Rusdi, M.S.; Xiao, C.L.T.; Abidin, N.S.Z.; Shafee, M.A.F.M.; Tharumaalingam, V.A. The Comparison of Medical Grade PP with Common Grade PP in Injection Moulding Process. CFD Lett. 2022, 14, 1–13. [Google Scholar] [CrossRef]

- Abdullah, M.K.; Rusdi, M.S.; Abdullah, M.Z.; Mahmud, A.S.; Mohamad Ariff, Z.; Yee, K.C.; Ali Mokhtar, M.N. Computational Analysis of Polymer Melt Filling in a Medical Mold Cavity During the Injection Molding Process. Pertanika J. Sci. Technol. 2023, 31, 33–49. [Google Scholar] [CrossRef]

- Rubin, I.I. Injection Molding: Theory and Practice; Wiley: New York, NY, USA, 1972; Volume 1. [Google Scholar]

- Gilmore, G.D.; Spencer, R.S. Role of pressure, temperature and time in the injection molding process. Mod. Plast. 1950, 37, 143–151. [Google Scholar]

- Spencer, R.S.; Gilmore, G.D. Equation of State for High Polymers. J. Appl. Phys. 1950, 21, 523–526. [Google Scholar] [CrossRef]

- Gilmore, G.D.; Spencer, R.S. Photographic study of polymer cycle in injection molding. Mod. Plast. 1951, 28, 117–124. [Google Scholar]

- Ballman, R.L.; Shusman, T.; Toor, H.L. Injection Molding—Flow of a Molten Polymer into a Cold Cavity. Ind. Eng. Chem. 1959, 51, 847–850. [Google Scholar] [CrossRef]

- Ballman, R.L.; Toor, H.L. Injection Molding: Rheological Interpretation. Mod. Plast. 1959, 31, 105–111. [Google Scholar]

- Ballman, R.L.; Toor, H.L. Orientation in injection molding. Mod. Plast. 1960, 38, 113–122. [Google Scholar]

- Toor, H.L.; Ballman, R.L.; Cooper, L. Predicting mold flow by electronic computer. Mod. Plast. 1960, 38, 117–120. [Google Scholar]

- Jackson, G.B.; Ballman, R.L. The effect of orientation on the physical properties of injection moldings. SPE J. 1960, 16, 1147–1152. [Google Scholar]

- Stevenson, J.; Hieber, C.A.; Glaskoy, A.; Wang, K.K. An experimental study simulation of disk filling by injection molding. SPE Tech. Pap. 1978, 22, 282–288. [Google Scholar]

- Afiqah Hamzah, N.; Razak, N.A.A.; Sayuti Ab Karim, M.; Gholizadeh, H. A review of history of CAD/CAM system application in the production of transtibial prosthetic socket in developing countries (from 1980 to 2019). Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2021, 235, 1359–1374. [Google Scholar] [CrossRef]

- Lichten, L. The emerging technology of CAD/CAM. In Proceedings of the 1984 Annual Conference of the ACM on The Fifth Generation Challenge, San Francisco, CA, USA, 8–14 October 1984; Muller, R.L., Ed.; ACM: New York, NY, USA, 1984; pp. 236–241. [Google Scholar] [CrossRef]

- Zheng, Y.; Lewis, R.W.; Gethin, D.T. FEView: An interactive visualization tool for finite elements. Finite Elem. Anal. Des. 1995, 19, 261–294. [Google Scholar] [CrossRef]

- Rajupalem, V.; Talwar, K.; Friedl, C. Three-Dimensional simulation of the injection molding process. In Proceedings of the SPE Annual Technical Conference—ANTEC, Toronto, ON, Canada, 27 April–2 May 1997; pp. 670–673. [Google Scholar]

- Talwar, K.; Costa, F.; Rajupalem, V.; Antanovski, L.; Friedl, C. Three-dimensional simulation of plastic injection molding. In Proceedings of the SPE Annual Technical Conference—ANTEC, Atlanta, GA, USA, 26–30 April 1998; pp. 562–566. [Google Scholar]

- Kim, S.W.; Turng, L.S. Three-dimensional numerical simulation of injection molding filling of optical lens and multiscale geometry using finite element method. Polym. Eng. Sci. 2006, 46, 1263–1274. [Google Scholar] [CrossRef]

- Zhou, H.; Geng, T.; Li, D. Numerical Filling Simulation of Injection Molding Based on 3D Finite Element Model. J. Reinf. Plast. Compos. 2005, 24, 823–830. [Google Scholar] [CrossRef]

- Haagh, G.A.A.V.; Peters, G.W.M.; van de Vosse, F.N.; Meijer, H.E.H. A 3-D finite element model for gas-assisted injection molding: Simulations and experiments. Polym. Eng. Sci. 2001, 41, 449–465. [Google Scholar] [CrossRef]

- Zhou, H.; Li, D. Further Studies of the Gas Penetration Process in Gas–Assisted Injection Molding. Polym.-Plast. Technol. Eng. 2003, 42, 911–923. [Google Scholar] [CrossRef]

- Tezduyar, T.E. Stabilized Finite Element Formulations for Incompressible Flow Computations. Adv. Appl. Mech. 1991, 28, 1–44. [Google Scholar] [CrossRef]

- Argyris, J.; Laxander, A.; Szimmat, J. Petrov-Galerkin finite element approach to coupled heat and fluid flow. Comput. Methods Appl. Mech. Eng. 1992, 94, 181–200. [Google Scholar] [CrossRef]

- Berger, R.C.; Stockstill, R.L. Finite-Element Model for High-Velocity Channels. J. Hydraul. Eng. 1995, 121, 710–716. [Google Scholar] [CrossRef]

- Ervin, V.J.; Miles, W.W. Approximation of Time-Dependent Viscoelastic Fluid Flow: SUPG Approximation. SIAM J. Numer. Anal. 2003, 41, 457–486. [Google Scholar] [CrossRef]

- Gong, Z.X.; Mujumdar, A.S. Flow and heat transfer in convection-dominated melting in a rectangular cavity heated from below. Int. J. Heat Mass Transf. 1998, 41, 2573–2580. [Google Scholar] [CrossRef]

- Wu, Y.H.; Wiwatanapataphee, B.; Yu, X. An Enthalpy Control Volume Method for Transient Mass and Heat Transport with Solidification. Int. J. Comput. Fluid Dyn. 2004, 18, 577–584. [Google Scholar] [CrossRef]

- Hétu, J.F.; Gao, D.M.; Garcia-Rejon, A.; Salloum, G. 3D finite element method for the simulation of the filling stage in injection molding. Polym. Eng. Sci. 1998, 38, 223–236. [Google Scholar] [CrossRef]

- Yan, B.; Zhou, H.; Li, D. Numerical simulation of the filling stage for plastic injection moulding based on the Petrov-Galerkin methods. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1573–1577. [Google Scholar] [CrossRef]

- Chang, R.Y.; Yang, W.H. Numerical simulation of mold filling in injection molding using a three-dimensional finite volume approach. Int. J. Numer. Methods Fluids 2001, 37, 125–148. [Google Scholar] [CrossRef]

- Yang, W.H.; Peng, A.; Liu, L.; Hsu, D.C.; Chang, R.Y. Integrated numerical simulation of injection molding using true 3D approach. In Proceedings of the SPE Annual Technical Conference—ANTEC, Chicago, IL, USA, 16–20 May 2004; pp. 486–490. [Google Scholar]

- Yang, W.H.; Peng, A.; Liu, L.; Hsu, D.C. Parallel true 3D CAE with hybrid meshing flexibity for injection molding. In Proceedings of the SPE Annual Technical Conference—ANTEC, Boston, MA, USA, 1–5 May 2005; pp. 56–60. [Google Scholar]

- Zhou, J.; Turng, L.S. Three-dimensional numerical simulation of injection mold filling with a finite-volume method and parallel computing. Adv. Polym. Technol. 2006, 25, 247–258. [Google Scholar] [CrossRef]

- Chau, S.W.; Lin, Y.W. Three-dimensional Simulation of Melt Filling and Gas Penetration in Gas-Assisted Injection Molding Process Using a Finite Volume Formulation. J. Polym. Eng. 2006, 26, 431–450. [Google Scholar] [CrossRef]

- Seo, D.; Ryoun Youn, J.; Tucker, C.L. Numerical simulation of mold filling in foam reaction injection molding. Int. J. Numer. Methods Fluids 2003, 42, 1105–1134. [Google Scholar] [CrossRef]

- Seo, D.; Youn, J.R. Numerical analysis on reaction injection molding of polyurethane foam by using a finite volume method. Polymer 2005, 46, 6482–6493. [Google Scholar] [CrossRef]

- Benitez-Rangel, J.P.; Domínguez-González, A.; Herrera-Ruiz, G.; Delgado-Rosas, M. Filling Process in Injection Mold: A Review. Polym.-Plast. Technol. Eng. 2007, 46, 721–727. [Google Scholar] [CrossRef]

- Naterer, G.F. Eulerian three-phase formulation with coupled droplet flow and multimode heat transfer. Numer. Heat Transf. Part B Fundam. 2003, 43, 331–352. [Google Scholar] [CrossRef]

- Silva, J.B.C.; Fel, L. A control-volume finite-element method (CVFEM) for unsteady, incompressible, viscous fluid flows. Numer. Heat Transf. Part B Fundam. 2001, 40, 61–82. [Google Scholar] [CrossRef]

- Estacio, K.C.; Mangiavacchi, N. Simplified model for mould filling simulations using CVFEM and unstructured meshes. Commun. Numer. Methods Eng. 2007, 23, 345–361. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, Z.; Zhou, G.; Yang, W. An implicit control-volume finite element method and its time step strategies for injection molding simulation. Comput. Chem. Eng. 2007, 31, 1407–1418. [Google Scholar] [CrossRef]

- Khayat, R.; Derdouri, A.; Hebert, L. A three-dimensional boundary-element approach to gas-assisted injection molding. J. Non-Newtonian Fluid Mech. 1995, 57, 253–270. [Google Scholar] [CrossRef]

- Khayat, R.E.; Elsin, W.; Kim, K. An adaptive boundary element approach to transient free surface flow as applied to injection molding. Int. J. Numer. Methods Fluids 2000, 33, 847–868. [Google Scholar] [CrossRef]

- Khayat, R.E.; Plaskos, C.; Genouvrier, D. An adaptive boundary-element approach for 3D transient free surface cavity flow, as applied to polymer processing. Int. J. Numer. Methods Eng. 2001, 50, 1347–1368. [Google Scholar] [CrossRef]

- Muttin, F.; Coupez, T.; Bellet, M.; Chenot, J.L. Lagrangian finite-element analysis of time-dependent viscous free-surface flow using an automatic remeshing technique: Application to metal casting flow. Int. J. Numer. Methods Eng. 1993, 36, 2001–2015. [Google Scholar] [CrossRef]

- Feng, Y.T.; Perić, D. A time-adaptive space-time finite element method for incompressible Lagrangian flows with free surfaces: Computational issues. Comput. Methods Appl. Mech. Eng. 2000, 190, 499–518. [Google Scholar] [CrossRef]

- Hyman, J.M. Numerical methods for tracking interfaces. Phys. D Nonlinear Phenom. 1984, 12, 396–407. [Google Scholar] [CrossRef]

- Holm, E.J.; Langtangen, H.P. A unified finite element model for the injection molding process. Comput. Methods Appl. Mech. Eng. 1999, 178, 413–429. [Google Scholar] [CrossRef]

- Luoma, J.A.; Voller, V.R. An explicit scheme for tracking the filling front during polymer mold filling. Appl. Math. Model. 2000, 24, 575–590. [Google Scholar] [CrossRef]

- Soukane, S.; Trochu, F. Application of the level set method to the simulation of resin transfer molding. Compos. Sci. Technol. 2006, 66, 1067–1080. [Google Scholar] [CrossRef]

- Harlow, F.H. Numerical Study of Large-Amplitude Free-Surface Motions. Phys. Fluids 1966, 9, 842. [Google Scholar] [CrossRef]

- Hirt, C.; Nichols, B. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Ayad, R.; Rigolot, A. The VOF-G/FEV Model For Tracking a Polymer-Air Interface in the Injection Moulding Process. J. Mech. Des. 2002, 124, 813–821. [Google Scholar] [CrossRef]

- Tie, G.; Dequn, L.; Huamin, Z. Three-dimensional finite element method for the filling simulation of injection molding. Eng. Comput. 2006, 21, 289–295. [Google Scholar] [CrossRef]

- Kim, M.S.; Lee, W.I. A new VOF-based numerical scheme for the simulation of fluid flow with free surface. Part I: New free surface-tracking algorithm and its verification. Int. J. Numer. Methods Fluids 2003, 42, 765–790. [Google Scholar] [CrossRef]

- Kim, M.S.; Park, J.S.; Lee, W.I. A new VOF-based numerical scheme for the simulation of fluid flow with free surface. Part II: Application to the cavity filling and sloshing problems. Int. J. Numer. Methods Fluids 2003, 42, 791–812. [Google Scholar] [CrossRef]

- Berger, J.L.; Gogos, C.G. A numerical simulation of the cavity filling process with PVC in injection molding. Polym. Eng. Sci. 1973, 13, 102–112. [Google Scholar] [CrossRef]

- Stevenson, J.F.; Chuck, W. A simplified method for analyzing mold filling dynamics. Part II: Extensions and comparisons with experiment. Polym. Eng. Sci. 1979, 19, 849–857. [Google Scholar] [CrossRef]

- Chung, S.T.; Kwon, T.H. Coupled analysis of injection molding filling and fiber orientation, including in-plane velocity gradient effect. Polym. Compos. 1996, 17, 859–872. [Google Scholar] [CrossRef]

- Han, K.H.; Im, Y.T. Compressible flow analysis of filling and postfilling in injection molding with phase-change effect. Compos. Struct. 1997, 38, 179–190. [Google Scholar] [CrossRef]

- Wang, J.; Silva, C.A.; Viana, J.C.; van Hattum, F.; Cunha, A.M.; Tucker, C.L. Prediction of fiber orientation in a rotating compressing and expanding mold. Polym. Eng. Sci. 2008, 48, 1405–1413. [Google Scholar] [CrossRef]

- Xu, X.; Yu, P. Modeling and simulation of injection molding process of polymer melt by a robust SPH method. Appl. Math. Model. 2017, 48, 384–409. [Google Scholar] [CrossRef]

- Kwon, T.H.; Ahn, S.Y. Slip characterization of powder/binder mixtures and its significance in the filling process analysis of powder injection molding. Powder Technol. 1995, 85, 45–55. [Google Scholar] [CrossRef]

- Pichelin, E.; Coupez, T. Finite element solution of the 3D mold filling problem for viscous incompressible fluid. Comput. Methods Appl. Mech. Eng. 1998, 163, 359–371. [Google Scholar] [CrossRef]

- Pichelin, E.; Coupez, T. A Taylor discontinuous Galerkin method for the thermal solution in 3D mold filling. Comput. Methods Appl. Mech. Eng. 1999, 178, 153–169. [Google Scholar] [CrossRef]

- Zheng, R.; Kennedy, P.; Phan-Thien, N.; Fan, X.J. Thermoviscoelastic simulation of thermally and pressure-induced stresses in injection moulding for the prediction of shrinkage and warpage for fibre-reinforced thermoplastics. J. Non-Newtonian Fluid Mech. 1999, 84, 159–190. [Google Scholar] [CrossRef]

- Ilinca, F.; Hétu, J.F. 3D Simulation of the Packing-Cooling Stage in Polymer lnjection Molding. In Proceedings of the SPE Annual Technical Conference—ANTEC, Orlando, FL, USA, 7–11 May 2005; Volume 46, pp. 727–731. [Google Scholar]

- Hwang, C.J.; Kwon, T.H. A full 3D finite element analysis of the powder injection molding filling process including slip phenomena. Polym. Eng. Sci. 2002, 42, 33–50. [Google Scholar] [CrossRef]

- Cao, W.; Shen, C.; Wang, R. 3D Flow Simulation for Viscous Nonisothermal Incompressible Fluid in Injection Molding. Polym.-Plast. Technol. Eng. 2005, 44, 901–917. [Google Scholar] [CrossRef]

- Liang, J.; Luo, W.; Huang, Z.; Zhou, H.; Zhang, Y.; Zhang, Y.; Fu, Y. A robust finite volume method for three-dimensional filling simulation of plastic injection molding. Eng. Comput. 2017, 34, 814–831. [Google Scholar] [CrossRef]

- He, L.; Lu, G.; Chen, D.; Li, W.; Lu, C. Three-dimensional smoothed particle hydrodynamics simulation for injection molding flow of short fiber-reinforced polymer composites. Model. Simul. Mater. Sci. Eng. 2017, 25, 055007. [Google Scholar] [CrossRef]

- Deng, L.; Fan, S.; Zhang, Y.; Huang, Z.; Zhou, H.; Jiang, S.; Li, J. Multiscale Modeling and Simulation of Polymer Blends in Injection Molding: A Review. Polymers 2021, 13, 3783. [Google Scholar] [CrossRef]

| Center Gated Disc | Tube | Strip | |

|---|---|---|---|

| Volume flow | |||

| Shear rate | |||

| Pressure gradient | |||

| Fluidity S |

| Supplier | Software | Type of Model Approach | Rheological Model | References |

|---|---|---|---|---|

| Autodesk, Inc. (San Fransico, CA, USA) | Moldflow | 2.5D, 3D | Cross-WLF, second-order | [101] |

| CoreTech System Co., Ltd. (Zhubei City, Taiwan) | Moldex3D | 2D, 3D | Power-Law, Cross-WLF, Carreau, Herschel–Bulkley | [5,101,123,124] |

| C-Solution, Inc. (Boulder, CO, USA) | Simuflow | 2D | Carreau | [5,125] |

| Hexagon AB (Stockholm, Sweden) | VISI-Flow | 2.5D (only surface) | Cross-WLF | [5,126] |

| SIGMA Engineering GmbH (Aachen, Germany) | Sigmasoft | 3D | Cross-WLF, Herschel–Bulkley | [5,101,127] |

| Simcon kunststofftechnische Software GmbH (Würselen, Germany) | Cadmould 3D-F/3D-V | advanced 2.5D, 3D | Carreau-WLF, Cross-WLF | [5,101] |

| Toray Engineering Co., Ltd. (Tokyo, Japan) | 3D TIMON | pseudo 3D | Cross-WLF | [1,5,27,128] |

| Tanslavor S.A. (Biot, France) | Rem3D | 3D | Cross-WLF, Cross-Arrhenius | [1,5,27,129] |

| Year | Author | Commercial Software | Rheological Model | References |

|---|---|---|---|---|

| 2008 | Zhou et al. | Moldflow | Cross-WLF | [130] |

| 2019 | Yu et al. | Moldflow | Cross-WLF | [131] |

| 2022 | Lin et al. | Moldflow | Cross-WLF | [132] |

| 2023 | Yu et al. | Moldflow | Cross-WLF | [133] |

| 2019 | Tran and Gehde | Moldex3D | Cross-WLF | [134] |

| 2019 | Islam et al. | Moldex3D | Cross-WLF | [135] |

| 2022 | Tsai et al. | Moldex3D | Cross-WLF | [136] |

| 2011 | Mannella et al. | VISI-Flow, Moldflow | Cross-WLF | [126] |

| 2011 | Mulser et al. | Sigmasoft | Cross-WLF | [137] |

| 2013 | Ariff and Khang | Cadmould 3D-F | Carreau-WLF | [138] |

| 2017 | Ou et al. | Cadmould 3D-F | Carreau-WLF | [139] |

| 2017 | Othman et al. | Cadmould 3D-F | N/A | [140] |

| 2020 | Sahli et al. | Cadmould 3D-F | Carreau-WLF | [141] |

| 2009 | Shin et al. | 3D Timon | Cross-WLF | [128] |

| 2005 | Silva et al. | Rem3D | Cross-WLF | [129] |

| 2014 | Fang et al. | ANSYS CFX | Power-Law-Arrhenius | [142] |

| 2016 | Zhuang et al. | ANSYS CFX, Moldflow | Cross-WLF | [143] |

| 2016 | Mukras and Al-Mufadi | ANSYS CFX | Newtonian | [144] |

| 2021 | Anders et al. | ANSYS CFX, Cadmould 3D-F | Carreau-WLF | [145] |

| 2021 | Baum and Anders | ANSYS CFX, Cadmould 3D-F | Carreau-WLF | [146] |

| 2022 | Baum et al. | ANSYS CFX | Carreau, Carreau-WLF | [147] |

| 2016 | Rusdi et al. | ANSYS Fluent | Cross-Arrhenius | [148] |

| 2022 | Zaki et al. | ANSYS Fluent | Cross | [149] |

| 2023 | Abdullah et al. | ANSYS Fluent | Cross-Arrhenius | [150] |

| Year | Author | Model Approach | Rheological Model | References |

|---|---|---|---|---|

| 1971 | Barie | 1D | Power-Law | [111] |

| 1972 | Kamal and Kenig | 1D | Power-Law | [7,8] |

| 1973 | Berger and Gogos | 1D | Power-Law | [205] |

| 1973 | Broyer et al. | 1D | Newtonian | [21] |

| 1974 | Wu et al. | 1D | Power-Law | [9] |

| 1975 | Lord and Williams | 1D | second-order | [12] |

| 1975 | Williams and Lord | 1D | second-order | [13] |

| 1977 | Nunn and Fenner | 1D | Power-Law | [10] |

| 1978 | Stevenson | 1D | Power-Law | [11] |

| 1979 | Stevenson and Chuck | 1D | Power-Law | [206] |

| 1974 | Tadmor et al. | 2D | Power-Law | [23] |

| 1978 | Hieber and Shen | 2D | Power-Law | [24] |

| 1980 | Hieber and Shen | 2D | Power-Law | [25] |

| 1986 | Wang et al. | 2D | Cross-Arrhenius | [37] |

| 1991 | Chiang et al. | 2D | Cross-WLF | [31,32] |

| 1993 | Chiang et al. | 2D | Cross-WLF | [46] |

| 1994 | Chen and Liu | 2D | Cross-Arrhenius, Cross-WLF | [67] |

| 1995 | Chung and Kwon | 2D | Cross | [41] |

| 1996 | Chung and Kwon | 2D | Cross | [207] |

| 1997 | Han and Im | 2D | Cross-WLF | [208] |

| 1999 | Holm and Langtangen | 2D | Power-Law | [196] |

| 2007 | Estacio and Mangiavacchi | 2D | Cross-Arrhenius | [188] |

| 2008 | Wang et al. | 2D | Cross-WLF | [209] |

| 2017 | Xu and Yu | 2D, 3D | Newtonian, Cross | [210] |

| 1995 | Kwon and Ahn | 2.5D | Cross | [211] |

| 1997 | Rajupalem et al. | 2.5D | N/A | [164] |

| 1998 | Talwar et al. | 2.5D | N/A | [165] |

| 2001 | Zhou and Li | 2.5D | Cross-Arrhenius | [52] |

| 2001 | Zhou et al. | 2.5D | Cross-Arrhenius | [28] |

| 2001 | Chang and Yang | 2.5D, 3D | Newtonian | [178] |

| 2002 | Zhou and Li | 2.5D | Cross-Arrhenius | [53] |

| 1998 | Hétu et al. | 3D | Newtonian, Bird–Carreau, Bird–Carreau–Arrhenius | [176] |

| 1998 | Pichelin and Coupez | 3D | Bird–Carreau | [212] |

| 1999 | Pichelin and Coupez | 3D | Bird–Carreau | [213] |

| 1999 | Zheng et al. | 3D | Cross | [214] |

| 2000 | Ilinca and Hétu | 3D | Cross-WLF | [215] |

| 2001 | Haag et al. | 3D | Cross-WLF | [168] |

| 2001 | Khayat et al. | 3D | Newtonian | [192] |

| 2002 | Hwang and Kwon | 3D | Cross | [216] |

| 2003 | Ilinca and Hétu | 3D | Carreau-WLF | [100] |

| 2004 | Yang et al. | 3D | Cross-Arrhenius | [179] |

| 2005 | Cao et al. | 3D | Cross-WLF | [217] |

| 2005 | Zhou et al. | 3D | Cross-Arrhenius | [167] |

| 2006 | Kim and Turng | 3D | Power-Law, Cross-WLF | [166] |

| 2006 | Zhou and Turng | 3D | Power-Law | [181] |

| 2012 | Wang et al. | 3D | Cross-Arrhenius, second-order | [74] |

| 2017 | Liang et al. | 3D | Cross-WLF | [218] |

| 2017 | He et al. | 3D | Power-Law | [219] |

| 1D Model | 2D Model | 2.5D Model | 3D Model | |

|---|---|---|---|---|

| Assumptions for a thin-walled laminar flow (Hele–Shaw) | X | √ | √ | X |

| Assumption of incompressibility | √ | √ | √ | √ |

| Heat transfer in flow direction | X | √ | √ | √ |

| Constant physical variables | √ | √ | √ | √ |

| Planar flow front | X | √ | √ | X |

| Mesh Size | Coarse | Medium | Fine | Ultrafine |

| Complexity of numerical model | Very simple | Simple | Complex | Very complex |

| Solution time | Very short | Short | Moderate | Long |

| Viscosity Model | Shear Rate | Temperature | Pressure |

|---|---|---|---|

| Power-Law | √ | X | X |

| Second-order | √ | √ | X |

| Herschel–Bulkley | √ | X | X |

| Bingham | √ | X | X |

| Carreau | √ | X | X |

| Bird–Carreau | √ | X | X |

| Cross | √ | X | X |

| Power-Law-Arrhenius | √ | √ | √ |

| Carreau-WLF | √ | √ | √ |

| Bird–Carreau–Arrhenius | √ | √ | X |

| Cross-WLF | √ | √ | √ |

| Cross-Arrhenius | √ | √ | √ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baum, M.; Anders, D.; Reinicke, T. Approaches for Numerical Modeling and Simulation of the Filling Phase in Injection Molding: A Review. Polymers 2023, 15, 4220. https://doi.org/10.3390/polym15214220

Baum M, Anders D, Reinicke T. Approaches for Numerical Modeling and Simulation of the Filling Phase in Injection Molding: A Review. Polymers. 2023; 15(21):4220. https://doi.org/10.3390/polym15214220

Chicago/Turabian StyleBaum, Markus, Denis Anders, and Tamara Reinicke. 2023. "Approaches for Numerical Modeling and Simulation of the Filling Phase in Injection Molding: A Review" Polymers 15, no. 21: 4220. https://doi.org/10.3390/polym15214220

APA StyleBaum, M., Anders, D., & Reinicke, T. (2023). Approaches for Numerical Modeling and Simulation of the Filling Phase in Injection Molding: A Review. Polymers, 15(21), 4220. https://doi.org/10.3390/polym15214220

_Yang.png)