Electrospun Nanofibers for Biomedical, Sensing, and Energy Harvesting Functions

Abstract

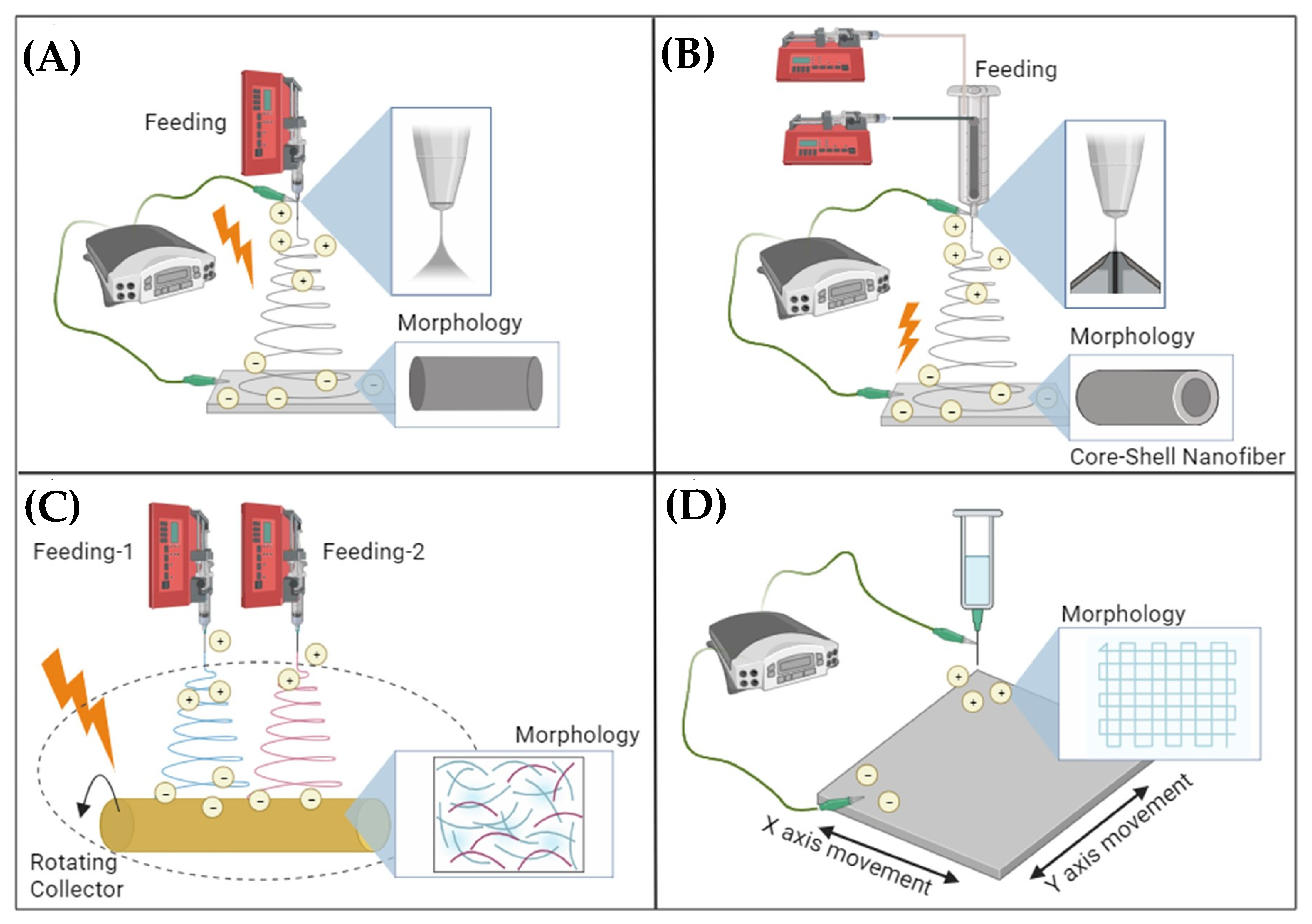

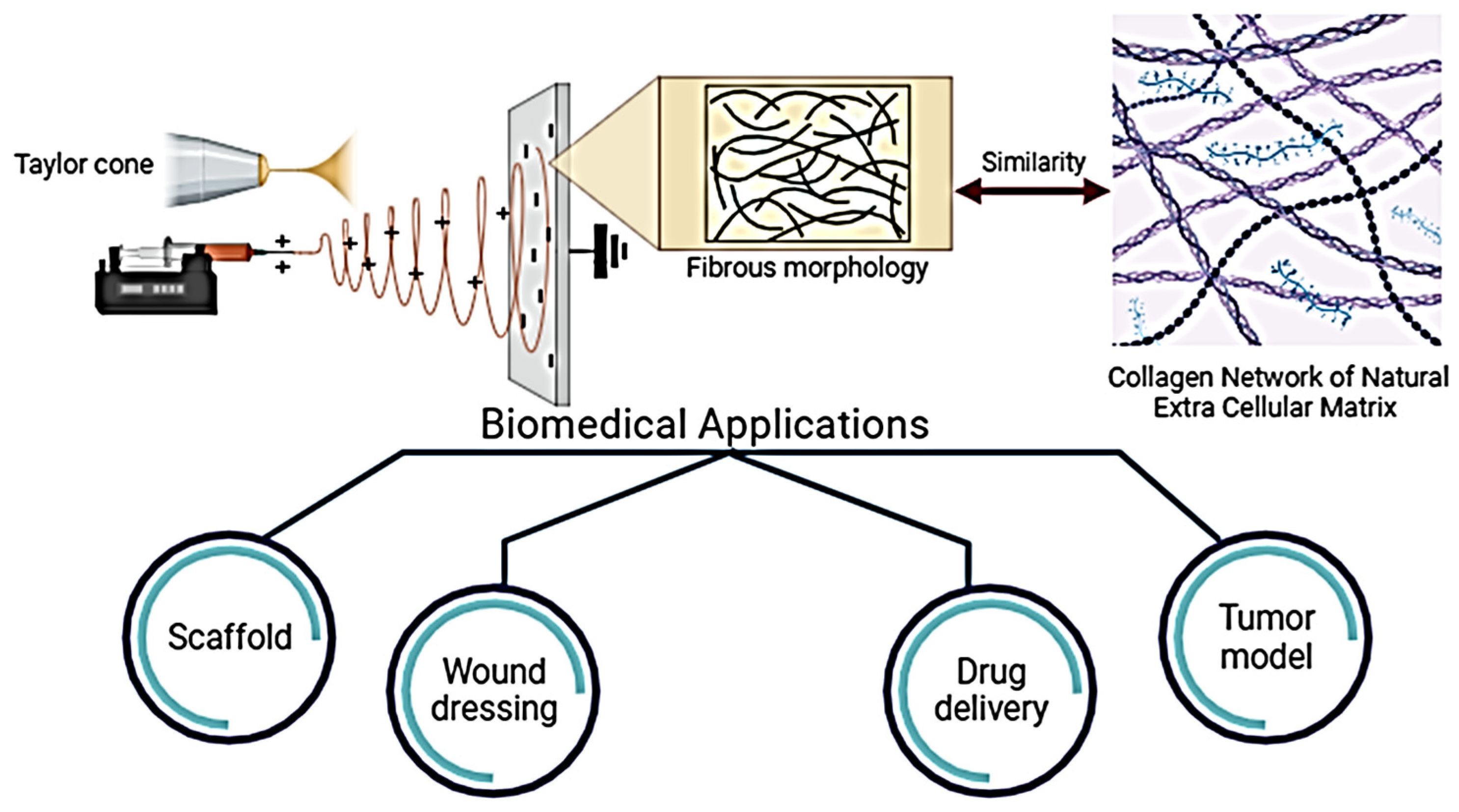

:1. Introduction to Electrospun Nanofibers

2. Electrospun Nanofibers for Biomedical Applications

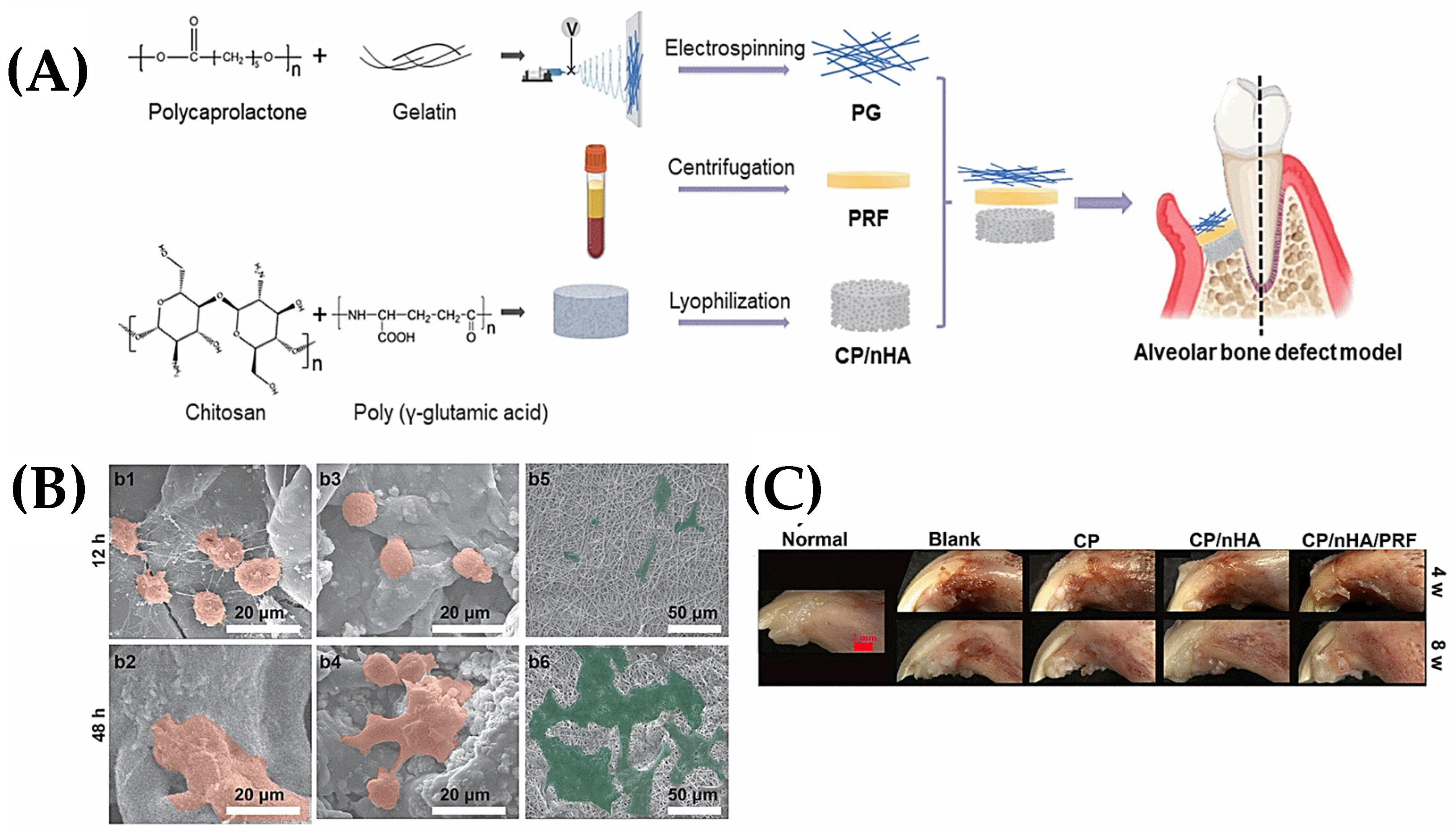

2.1. Scaffolds

2.2. Wound Dressings

2.3. Tumor Model

2.4. Drug Delivery Systems

3. Chemical Sensors and Biosensors

4. Energy Harvesting and Tactile Sensing

5. Conclusions, Recommendations, and Path Forward

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bölgen, N.; Demir, D.; Aşık, M.; Sakım, B.; Vaseashta, A. Introduction and Fundamentals of Electrospinning. In Electrospun Nanofibers Principles, Technology and Novel Applications; Springer: Cham, Switzerland, 2022; pp. 3–34. [Google Scholar] [CrossRef]

- Vaseashta, A.; Bölgen, N. Electrospun Nanofibers: Principles, Technology and Novel Applications; Springer: Cham, Switzerland, 2022; pp. 1–766. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Fujihara, K.; Teo, W.E.; Lim, T.C.; Ma, Z. An Introduction to Electrospinning and Nanofibers; World Scientific: London, UK, 2005; pp. 1–382. [Google Scholar] [CrossRef]

- Teo, W.E.; Inai, R.; Ramakrishna, S. Technological Advances in Electrospinning of Nanofibers. Sci. Technol. Adv. Mater. 2011, 12, 013002. [Google Scholar] [CrossRef]

- Bölgen, N.; Demir, D.; Vaseashta, A. Nanofibers for the Detection of VOCs. In Nanoscience Advances in CBRN Agents Detection, Information and Energy Security; Springer: Dordrecht, The Netherlands, 2015; pp. 159–165. [Google Scholar] [CrossRef]

- Gergely, A.; Kántor, J.; Bitay, E.; Biró, D. Electrospinning of Polymer Fibres Using Recycled PET. Acta Mater. Transylvanica 2019, 2, 19–26. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning Jets and Polymer Nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Vaseashta, A. Stamatin Ioan Electrospun Polymers for Controlled Release of Drugs, Vaccine Delivery, and System-on-Fibers. J. Optoelectron. Adv. Mater. 2007, 9, 1606–1613. [Google Scholar]

- Vaseashta, A. Controlled Formation of Multiple Taylor Cones in Electrospinning Process. Appl. Phys. Lett. 2007, 90, 093115. [Google Scholar] [CrossRef]

- Mohsenzadeh, E.; Demir, D.; Ceylan, S.; Khenoussi, N.; Schacher, L.; Adolphe, D.; Bölgen, N. A Bi-Layer Electrospun Polyurethane/Silicone Membrane Scaffold: Drug Delivery and Cytotoxicity Studies. Bull. Mater. Sci. 2023, 46, 130. [Google Scholar] [CrossRef]

- Aytac, Z.; Wang, X. Melt Electrospinning Writing. In Electrospun Nanofibers Principles, Technology and Novel Applications; Springer: Cham, Switzerland, 2022; pp. 93–119. [Google Scholar] [CrossRef]

- Salas, C. Solution Electrospinning of Nanofibers. In Electrospun Nanofibers; Elsevier: Amsterdam, The Netherlands, 2017; pp. 73–108. [Google Scholar] [CrossRef]

- Hezarkhani, M.; Aliyeva, N.; Menceloglu, Y.Z.; Okan, B.S. Fabrication Methodologies of Multi-Layered and Multi-Functional Electrospun Structures by Co-Axial and Multi-Axial Electrospinning Techniques. In Electrospun Nanofibers Principles, Technology and Novel Applications; Springer: Cham, Switzerland, 2022; pp. 35–66. [Google Scholar] [CrossRef]

- Nazemi, M.M.; Khodabandeh, A.; Hadjizadeh, A. Near-Field Electrospinning: Crucial Parameters, Challenges, and Applications. ACS Appl. Bio Mater. 2022, 5, 394–412. [Google Scholar] [CrossRef] [PubMed]

- ASTM E96/E96M-05; Standard Test Methods for Water Vapor Transmission of Materials. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Bonferoni, M.C.; Caramella, C.; Catenacci, L.; Conti, B.; Dorati, R.; Ferrari, F.; Genta, I.; Modena, T.; Perteghella, S.; Rossi, S.; et al. Biomaterials for Soft Tissue Repair and Regeneration: A Focus on Italian Research in the Field. Pharmaceutics 2021, 13, 1341. [Google Scholar] [CrossRef] [PubMed]

- Niculescu, A.G.; Grumezescu, A.M. An Up-to-Date Review of Biomaterials Application in Wound Management. Polymers 2022, 14, 421. [Google Scholar] [CrossRef]

- Su, Y.; Toftdal, M.S.; Friec, A.L.; Dong, M.; Han, X.; Chen, M. 3D Electrospun Synthetic Extracellular Matrix for Tissue Regeneration. Small Sci. 2021, 1, 2100003. [Google Scholar] [CrossRef]

- Khajavi, R.; Abbasipour, M. Electrospinning as a Versatile Method for Fabricating Coreshell, Hollow and Porous Nanofibers. Sci. Iran. 2012, 19, 2029–2034. [Google Scholar] [CrossRef]

- Syed, M.H.; Khan, M.M.R.; Zahari, M.A.K.M.; Beg, M.D.H.; Abdullah, N. A Review on Current Trends and Future Prospectives of Electrospun Biopolymeric Nanofibers for Biomedical Applications. Eur. Polym. J. 2023, 197, 112352. [Google Scholar] [CrossRef]

- Ghasemi-Mobarakeh, L.; Prabhakaran, M.P.; Morshed, M.; Nasr-Esfahani, M.H.; Ramakrishna, S. Electrospun Poly(ε-Caprolactone)/Gelatin Nanofibrous Scaffolds for Nerve Tissue Engineering. Biomaterials 2008, 29, 4532–4539. [Google Scholar] [CrossRef] [PubMed]

- Chong, E.J.; Phan, T.T.; Lim, I.J.; Zhang, Y.Z.; Bay, B.H.; Ramakrishna, S.; Lim, C.T. Evaluation of Electrospun PCL/Gelatin Nanofibrous Scaffold for Wound Healing and Layered Dermal Reconstitution. Acta Biomater. 2007, 3, 321–330. [Google Scholar] [CrossRef]

- Zhang, Y.; Venugopal, J.R.; El-Turki, A.; Ramakrishna, S.; Su, B.; Lim, C.T. Electrospun Biomimetic Nanocomposite Nanofibers of Hydroxyapatite/Chitosan for Bone Tissue Engineering. Biomaterials 2008, 29, 4314–4322. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.J.; Chen, J.; Karageorgiou, V.; Altman, G.H.; Kaplan, D.L. Human Bone Marrow Stromal Cell Responses on Electrospun Silk Fibroin Mats. Biomaterials 2004, 25, 1039–1047. [Google Scholar] [CrossRef] [PubMed]

- Buttafoco, L.; Kolkman, N.G.; Engbers-Buijtenhuijs, P.; Poot, A.A.; Dijkstra, P.J.; Vermes, I.; Feijen, J. Electrospinning of Collagen and Elastin for Tissue Engineering Applications. Biomaterials 2006, 27, 724–734. [Google Scholar] [CrossRef] [PubMed]

- Badami, A.S.; Kreke, M.R.; Thompson, M.S.; Riffle, J.S.; Goldstein, A.S. Effect of Fiber Diameter on Spreading, Proliferation, and Differentiation of Osteoblastic Cells on Electrospun Poly(Lactic Acid) Substrates. Biomaterials 2006, 27, 596–606. [Google Scholar] [CrossRef]

- Meng, Z.X.; Wang, Y.S.; Ma, C.; Zheng, W.; Li, L.; Zheng, Y.F. Electrospinning of PLGA/Gelatin Randomly-Oriented and Aligned Nanofibers as Potential Scaffold in Tissue Engineering. Mater. Sci. Eng. C 2010, 30, 1204–1210. [Google Scholar] [CrossRef]

- Ikada, Y. Challenges in Tissue Engineering. J. R. Soc. Interface 2006, 3, 589. [Google Scholar] [CrossRef]

- Owida, H.A.; Al-Nabulsi, J.I.; Alnaimat, F.; Al-Ayyad, M.; Turab, N.M.; Al Sharah, A.; Shakur, M. Recent Applications of Electrospun Nanofibrous Scaffold in Tissue Engineering. Appl. Bionics Biomech. 2022, 2022, 1953861. [Google Scholar] [CrossRef] [PubMed]

- Zulkifli, M.Z.A.; Nordin, D.; Shaari, N.; Kamarudin, S.K. Overview of Electrospinning for Tissue Engineering Applications. Polymers 2023, 15, 2418. [Google Scholar] [CrossRef] [PubMed]

- Flores-Rojas, G.G.; Gómez-Lazaro, B.; López-Saucedo, F.; Vera-Graziano, R.; Bucio, E.; Mendizábal, E. Electrospun Scaffolds for Tissue Engineering: A Review. Macromol 2023, 3, 524–553. [Google Scholar] [CrossRef]

- Vargas-Molinero, H.Y.; Serrano-Medina, A.; Palomino-Vizcaino, K.; López-Maldonado, E.A.; Villarreal-Gómez, L.J.; Pérez-González, G.L.; Cornejo-Bravo, J.M. Hybrid Systems of Nanofibers and Polymeric Nanoparticles for Biological Application and Delivery Systems. Micromachines 2023, 14, 208. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Parveen, R.; Chatterji, B.P. Toxicology of Nanoparticles in Drug Delivery. Curr. Pathobiol. Rep. 2021, 9, 133–144. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Chen, Z.; Xiao, L.; Xu, Y.; Xiao, N.; Jin, W.; Chen, Y.; Li, Y.; Luo, K. Nanosilicate-Functionalized Nanofibrous Membrane Facilitated Periodontal Regeneration Potential by Harnessing Periodontal Ligament Cell-Mediated Osteogenesis and Immunomodulation. J. Nanobiotechnol. 2023, 21, 223. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Xia, Y.; Song, H.; Wang, L.; Zhang, X.; Lian, J.; Zhang, Y.; Li, X.; Li, Y.; Kang, J.; et al. Electrospun the Oriented Silk Fibroin/ Bioactive Glass @ Silk Fibroin/ Polycaprolactone Composite Bi-Layered Membranes for Guided Bone Regeneration. Colloids Surfaces A Physicochem. Eng. Asp. 2023, 676, 132224. [Google Scholar] [CrossRef]

- Li, X.; He, N.; Li, X.; Wang, X.; Zhan, L.; Yuan, W.E.; Song, J.; Ouyang, Y. Graphdiyne-Loaded Polycaprolactone Nanofiber Scaffold for Peripheral Nerve Regeneration. J. Colloid Interface Sci. 2023, 646, 399–412. [Google Scholar] [CrossRef]

- Tang, H.; Qi, C.; Bai, Y.; Niu, X.; Gu, X.; Fan, Y. Incorporation of Magnesium and Zinc Metallic Particles in PLGA Bi-Layered Membranes with Sequential Ion Release for Guided Bone Regeneration. ACS Biomater. Sci. Eng. 2023, 9, 3239–3252. [Google Scholar] [CrossRef]

- Tomasina, C.; Montalbano, G.; Fiorilli, S.; Quadros, P.; Azevedo, A.; Coelho, C.; Vitale-Brovarone, C.; Camarero-Espinosa, S.; Moroni, L. Incorporation of Strontium-Containing Bioactive Particles into PEOT/PBT Electrospun Scaffolds for Bone Tissue Regeneration. Biomater. Adv. 2023, 149, 213406. [Google Scholar] [CrossRef]

- Zhang, K.; Bhutto, M.A.; Wang, L.; Wang, K.; Liu, J.; Li, W.; Cui, W.; Fu, Q. Double-Layer Nanofibrous Sponge Tube via Electrospun Fiber and Yarn for Promoting Urethral Regeneration. Adv. Fiber Mater. 2023, 5, 662–680. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Z.; Zhang, A.; Liu, L.; Mithieux, S.M.; Bilek, M.M.M.; Weiss, A.S. Development of Tropoelastin-Functionalized Anisotropic PCL Scaffolds for Musculoskeletal Tissue Engineering. Regen. Biomater. 2023, 10, rbac087. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Yu, F.; Chen, J.; Yan, D.; Gong, D.; Chen, L.; Chen, J.; Yao, Q. A Thin Film Comprising Silk Peptide and Cellulose Nanofibrils Implanting on the Electrospun Poly(Lactic Acid) Fibrous Scaffolds for Biomedical Reconstruction. Int. J. Biol. Macromol. 2023, 251, 126209. [Google Scholar] [CrossRef] [PubMed]

- Garcia Garcia, C.E.; Bossard, F.; Rinaudo, M. Electrospun Biomaterials from Chitosan Blends Applied as Scaffold for Tissue Regeneration. Polymers 2021, 13, 1037. [Google Scholar] [CrossRef] [PubMed]

- Movahedi, M.; Karbasi, S. A Core-Shell Electrospun Scaffold of Polyhydroxybutyrate-Starch/Halloysite Nanotubes Containing Extracellular Matrix and Chitosan for Articular Cartilage Tissue Engineering Application. J. Polym. Environ. 2023, 31, 3052–3069. [Google Scholar] [CrossRef]

- Luo, J.; Zhu, J.; Wang, L.; Kang, J.; Wang, X.; Xiong, J. Co-Electrospun Nano-/Microfibrous Composite Scaffolds with Structural and Chemical Gradients for Bone Tissue Engineering. Mater. Sci. Eng. C 2021, 119, 111622. [Google Scholar] [CrossRef] [PubMed]

- Bongiovanni Abel, S.; Montini Ballarin, F.; Abraham, G.A. Combination of Electrospinning with Other Techniques for the Fabrication of 3D Polymeric and Composite Nanofibrous Scaffolds with Improved Cellular Interactions. Nanotechnology 2020, 31, 172002. [Google Scholar] [CrossRef]

- Keirouz, A.; Chung, M.; Kwon, J.; Fortunato, G.; Radacsi, N. 2D and 3D Electrospinning Technologies for the Fabrication of Nanofibrous Scaffolds for Skin Tissue Engineering: A Review. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2020, 12, e1626. [Google Scholar] [CrossRef]

- Hakimi, F.; Jafari, H.; Hashemikia, S.; Shabani, S.; Ramazani, A. Chitosan-Polyethylene Oxide/Clay-Alginate Nanofiber Hydrogel Scaffold for Bone Tissue Engineering: Preparation, Physical Characterization, and Biomimetic Mineralization. Int. J. Biol. Macromol. 2023, 233, 123453. [Google Scholar] [CrossRef]

- Caracciolo, P.C.; Abraham, G.A.; Battaglia, E.S.; Bongiovanni Abel, S. Recent Progress and Trends in the Development of Electrospun and 3D Printed Polymeric-Based Materials to Overcome Antimicrobial Resistance (AMR). Pharmaceutics 2023, 15, 1964. [Google Scholar] [CrossRef]

- Rosales-Ibáñez, R.; Viera-Ruiz, A.E.; Cauich-Rodríguez, J.V.; Carrillo-Escalante, H.J.; González-González, A.; Rodríguez-Martínez, J.J.; Hernández-Sánchez, F. Electrospun/3D-Printed PCL Bioactive Scaffold for Bone Regeneration. Polym. Bull. 2023, 80, 2533–2552. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, Y.; Liu, Y.; Liu, X.; Wang, Z.; Wan, J.; Yu, X.; Wang, S. Multifunctional Hydrogel/Platelet-Rich Fibrin/Nanofibers Scaffolds with Cell Barrier and Osteogenesis for Guided Tissue Regeneration/Guided Bone Regeneration Applications. Int. J. Biol. Macromol. 2023, 253, 126960. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Hu, H.; Zeng, Y.; Pan, H.; Wang, S.; Zhang, Y.; Shi, L.; Tan, G.; Pan, W.; Liu, H. Recent Advances in Electrospun Nanofibers for Wound Dressing. Eur. Polym. J. 2022, 178, 111490. [Google Scholar] [CrossRef]

- Su, J.; Li, J.; Liang, J.; Zhang, K.; Li, J. Hydrogel Preparation Methods and Biomaterials for Wound Dressing. Life 2021, 11, 1016. [Google Scholar] [CrossRef] [PubMed]

- Chanu, N.R.; Bhattacharya, K.; Marbaniang, D.; Pal, P.; Ray, S.; Mazumder, B. Evaluation of a Novel Melatonin-Loaded Gelatin Sponge as a Wound Dressing. J. Vasc. Nurs. 2022, 40, 2–10. [Google Scholar] [CrossRef] [PubMed]

- Lee, O.J.; Kim, J.H.; Moon, B.M.; Chao, J.R.; Yoon, J.; Ju, H.W.; Lee, J.M.; Park, H.J.; Kim, D.W.; Kim, S.J.; et al. Fabrication and Characterization of Hydrocolloid Dressing with Silk Fibroin Nanoparticles for Wound Healing. Tissue Eng. Regen. Med. 2016, 13, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Borbolla-Jiménez, F.V.; Peña-Corona, S.I.; Farah, S.J.; Jiménez-Valdés, M.T.; Pineda-Pérez, E.; Romero-Montero, A.; Del Prado-Audelo, M.L.; Bernal-Chávez, S.A.; Magaña, J.J.; Leyva-Gómez, G. Films for Wound Healing Fabricated Using a Solvent Casting Technique. Pharmaceutics 2023, 15, 1914. [Google Scholar] [CrossRef] [PubMed]

- Merzougui, C.; Miao, F.; Liao, Z.; Wang, L.; Wei, Y.; Huang, D. Electrospun Nanofibers with Antibacterial Properties for Wound Dressings. J. Biomater. Sci. Polym. Ed. 2022, 33, 2165–2183. [Google Scholar] [CrossRef]

- Parham, S.; Kharazi, A.Z.; Bakhsheshi-Rad, H.R.; Kharaziha, M.; Ismail, A.F.; Sharif, S.; Razzaghi, M.; RamaKrishna, S.; Berto, F. Antimicrobial Synthetic and Natural Polymeric Nanofibers as Wound Dressing: A Review. Adv. Eng. Mater. 2022, 24, 2101460. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, D.; Sønderskov, S.M.; Xia, D.; Wu, X.; Liang, C.; Dong, M. Tannic Acid-Functionalized 3D Porous Nanofiber Sponge for Antibiotic-Free Wound Healing with Enhanced Hemostasis, Antibacterial, and Antioxidant Properties. J. Nanobiotechnol. 2023, 21, 190. [Google Scholar] [CrossRef]

- Maliszewska, I.; Czapka, T. Electrospun Polymer Nanofibers with Antimicrobial Activity. Polymers 2022, 14, 1661. [Google Scholar] [CrossRef] [PubMed]

- Terezaki, A.; Kikionis, S.; Ioannou, E.; Sfiniadakis, I.; Tziveleka, L.A.; Vitsos, A.; Roussis, V.; Rallis, M. Ulvan/Gelatin-Based Nanofibrous Patches as a Promising Treatment for Burn Wounds. J. Drug Deliv. Sci. Technol. 2022, 74, 103535. [Google Scholar] [CrossRef]

- Yu, J.; Xu, Y.; Zhang, Z.; Zeng, Z.; Chen, D.; Wei, Z.; Wang, E.; Zhou, Y.; Yang, C.; Chang, J. Strontium Zinc Silicate Bioceramic Composite Electrospun Fiber Membrane for Hair Follicle Regeneration in Burn Wounds. Compos. Part B Eng. 2023, 266, 110953. [Google Scholar] [CrossRef]

- Grizzo, A.; dos Santos, D.M.; da Costa, V.P.V.; Lopes, R.G.; Inada, N.M.; Correa, D.S.; Campana-Filho, S.P. Multifunctional Bilayer Membranes Composed of Poly(Lactic Acid), Beta-Chitin Whiskers and Silver Nanoparticles for Wound Dressing Applications. Int. J. Biol. Macromol. 2023, 251, 126314. [Google Scholar] [CrossRef] [PubMed]

- Alvandi, H.; Jaymand, M.; Eskandari, M.; Aghaz, F.; Hosseinzadeh, L.; Heydari, M.; Arkan, E. A Sandwich Electrospun Nanofibers/Tragacanth Hydrogel Composite Containing Aloe Vera Extract and Silver Sulfadiazine as a Wound Dressing. Polym. Bull. 2022, 80, 11235–11248. [Google Scholar] [CrossRef]

- Saghafi, Y.; Baharifar, H.; Najmoddin, N.; Asefnejad, A.; Maleki, H.; Sajjadi-Jazi, S.M.; Bonkdar, A.; Shams, F.; Khoshnevisan, K. Bromelain- and Silver Nanoparticle-Loaded Polycaprolactone/Chitosan Nanofibrous Dressings for Skin Wound Healing. Gels 2023, 9, 672. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Yin, H.; Wei, J.; Wu, J.; Ping, D.; Zhang, X. A Bilayer Biocompatible Polycaprolactone/Zinc Oxide/Capparis Spinosa L. Ethyl Acetate Extract/Polylactic Acid Nanofibrous Composite Scaffold for Novel Wound Dressing Applications. Int. J. Biol. Macromol. 2023, 242, 125093. [Google Scholar] [CrossRef]

- Akturk, A.; Kasikci, F.N.; Dikmetas, D.N.; Karbancioglu-Guler, F.; Erol-Taygun, M. Hypericum Perforatum Oil and Vitamin A Palmitate-Loaded Gelatin Nanofibers Cross-Linked by Tannic Acid as Wound Dressings. ACS Omega 2023, 8, 24023–24031. [Google Scholar] [CrossRef]

- Saghebasl, S.; Amini, H.; Nobakht, A.; Haiaty, S.; Bagheri, H.S.; Hasanpour, P.; Milani, M.; Saghati, S.; Naturi, O.; Farhadi, M.; et al. Polyurethane-Based Nanofibrous Mat Containing Porphyrin with Photosensitivity and Bactericidal Properties Can Promote Cutaneous Tissue Healing in Rats. J. Nanobiotechnol. 2023, 21, 313. [Google Scholar] [CrossRef]

- Kaliaperumal, C.; Thulasisingh, A. Electrospun Polycaprolactone/Chitosan/Pectin Composite Nanofibre: A Novel Wound Dressing Scaffold. Bull. Mater. Sci. 2023, 46, 23. [Google Scholar] [CrossRef]

- Fiorentini, F.; Suarato, G.; Summa, M.; Miele, D.; Sandri, G.; Bertorelli, R.; Athanassiou, A. Plant-Based, Hydrogel-like Microfibers as an Antioxidant Platform for Skin Burn Healing. ACS Appl. Bio Mater. 2023, 6, 3103–3116. [Google Scholar] [CrossRef] [PubMed]

- Rabie, A.M.I.; Ali, A.S.M.; Al-Zeer, M.A.; Barhoum, A.; El-Hallouty, S.; Shousha, W.G.; Berg, J.; Kurreck, J.; Khalil, A.S.G. Spontaneous Formation of 3D Breast Cancer Tissues on Electrospun Chitosan/Poly(Ethylene Oxide) Nanofibrous Scaffolds. ACS Omega 2022, 7, 2114–2126. [Google Scholar] [CrossRef]

- Cavo, M.; Serio, F.; Kale, N.R.; D’Amone, E.; Gigli, G.; Del Mercato, L.L. Electrospun Nanofibers in Cancer Research: From Engineering of: From Vitro 3D Cancer Models to Therapy. Biomater. Sci. 2020, 8, 4887–4905. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Cui, T.; Gan, D.; Gama, M.; Zhang, Q.; Wan, Y. Fabrication of a Novel Hierarchical Fibrous Scaffold for Breast Cancer Cell Culture. Polym. Test. 2019, 80, 106107. [Google Scholar] [CrossRef]

- Ricci, C.; Azimi, B.; Panariello, L.; Antognoli, B.; Cecchini, B.; Rovelli, R.; Rustembek, M.; Cinelli, P.; Milazzo, M.; Danti, S.; et al. Assessment of Electrospun Poly(ε-Caprolactone) and Poly(lactic acid) Fiber Scaffolds to Generate 3D In Vitro Models of Colorectal Adenocarcinoma: A Preliminary Study. Int. J. Mol. Sci. 2023, 24, 9443. [Google Scholar] [CrossRef]

- Redmond, J.; McCarthy, H.; Buchanan, P.; Levingstone, T.J.; Dunne, N.J. Advances in Biofabrication Techniques for Collagen-Based 3D in Vitro Culture Models for Breast Cancer Research. Mater. Sci. Eng. C 2021, 122, 111944. [Google Scholar] [CrossRef] [PubMed]

- Arumugam, M.; Murugesan, B.; Pandiyan, N.; Chinnalagu, D.K.; Rangasamy, G.; Mahalingam, S. Electrospinning Cellulose Acetate/Silk Fibroin/Au-Ag Hybrid Composite Nanofiber for Enhanced Biocidal Activity against MCF-7 Breast Cancer Cell. Mater. Sci. Eng. C 2021, 123, 112019. [Google Scholar] [CrossRef]

- Vashisth, P.; Sharma, M.; Nikhil, K.; Singh, H.; Panwar, R.; Pruthi, P.A.; Pruthi, V. Antiproliferative Activity of Ferulic Acid-Encapsulated Electrospun PLGA/PEO Nanofibers against MCF-7 Human Breast Carcinoma Cells. 3 Biotech 2015, 5, 303–315. [Google Scholar] [CrossRef]

- Chou, S.-F.; Daniel, C.; Woodrow, K.A. Current Strategies for Sustaining Drug Release from Electrospun Nanofibers. J. Control. Release 2015, 220, 584–591. [Google Scholar] [CrossRef]

- Li, L.; Hao, R.; Qin, J.; Song, J.; Chen, X.; Rao, F.; Zhai, J.; Zhao, Y.; Zhang, L.; Xue, J. Electrospun Fibers Control Drug Delivery for Tissue Regeneration and Cancer Therapy. Adv. Fiber Mater. 2022, 4, 1375–1413. [Google Scholar] [CrossRef]

- Torres-Martinez, E.J.; Cornejo Bravo, J.M.; Serrano Medina, A.; Pérez González, G.L.; Villarreal Gómez, L.J. A Summary of Electrospun Nanofibers as Drug Delivery System: Drugs Loaded and Biopolymers Used as Matrices. Curr. Drug Deliv. 2018, 15, 1360–1374. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yu, D.G.; Liu, Y.; Liu, Y.N. Progress of Electrospun Nanofibrous Carriers for Modifications to Drug Release Profiles. J. Funct. Biomater. 2022, 13, 289. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hu, C.; Hu, B.; Tian, J.; Zhao, G.; Cai, C.; Li, Y.; Sun, Z.; Wang, S.; Pang, S.; et al. Sustained Release of Dicumarol via Novel Grafted Polymer in Electrospun Nanofiber Membrane for Treatment of Peritendinous Adhesion. Adv. Healthc. Mater. 2023, 12, 202203078. [Google Scholar] [CrossRef]

- Chao, S.; Zhang, Y.; Cheng, S.; Shao, X.; Liu, S.; Lu, W.; Wang, Y.; Zhang, P.; Yao, Q. Ibuprofen-Loaded ZnO Nanoparticle/Polyacrylonitrile Nanofibers for Dual-Stimulus Sustained Release of Drugs. ACS Appl. Nano Mater. 2023, 6, 5535–5544. [Google Scholar] [CrossRef]

- Jiang, B.; Yang, Z.; Shi, H.; Turki Jalil, A.; Mahmood Saleh, M.; Mi, W. Potentiation of Curcumin-Loaded Zeolite Y Nanoparticles/PCL-Gelatin Electrospun Nanofibers for Postsurgical Glioblastoma Treatment. J. Drug Deliv. Sci. Technol. 2023, 80, 104105. [Google Scholar] [CrossRef]

- Reise, M.; Kranz, S.; Guellmar, A.; Wyrwa, R.; Rosenbaum, T.; Weisser, J.; Jurke, A.; Schnabelrauch, M.; Heyder, M.; Watts, D.C.; et al. Coaxial Electrospun Nanofibers as Drug Delivery System for Local Treatment of Periodontitis. Dent. Mater. 2023, 39, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Zhang, M.; Bai, R.; Kong, L.; Yang, H.; Zhang, A.; Dong, S.; Chen, M.; Ramakrishna, S.; Yang, F. Electrospun Coaxial Nanofibers Loading with Perovskite and Icariin to Enhance the Bone Scaffold-Mediated Osteogenesis. Mater. Today Chem. 2022, 26, 101246. [Google Scholar] [CrossRef]

- Liu, Z.; Luo, X.; Mo, Y.; Zhao, P.; Wang, H.; Fang, Y.; Xu, Y. Enzyme-Enhanced Codelivery of Doxorubicin and Bcl-2 Inhibitor by Electrospun Nanofibers for Synergistic Inhibition of Prostate Cancer Recurrence. Pharmaceuticals 2022, 15, 1244. [Google Scholar] [CrossRef]

- Ajalloueian, F.; Asgari, S.; Guerra, P.R.; Chamorro, C.I.; Ilchenco, O.; Piqueras, S.; Fossum, M.; Boisen, A. Amoxicillin-Loaded Multilayer Pullulan-Based Nanofibers Maintain Long-Term Antibacterial Properties with Tunable Release Profile for Topical Skin Delivery Applications. Int. J. Biol. Macromol. 2022, 215, 413–423. [Google Scholar] [CrossRef]

- Chen, H.; Wu, J.; Rahman, M.S.U.; Li, S.; Wang, J.; Li, S.; Wu, Y.; Liu, Y.; Xu, S. Dual Drug-Loaded PLGA Fibrous Scaffolds for Effective Treatment of Breast Cancer in Situ. Biomater. Adv. 2023, 148, 213358. [Google Scholar] [CrossRef]

- Ghasemvand, F.; Kabiri, M.; Hassan-Zadeh, V.; Simchi, A. Chitosan, Polyethylene Oxide/Polycaprolactone Electrospun Core/Shell Nanofibrous Mat Containing Rosuvastatin as a Novel Drug Delivery System for Enhancing Human Mesenchymal Stem Cell Osteogenesis. Front. Mol. Biosci. 2023, 10, 1220357. [Google Scholar] [CrossRef]

- Mirhaj, M.; Varshosaz, J.; Labbaf, S.; Emadi, R.; Seifalian, A.M.; Sharifianjazi, F.; Tavakoli, M. Mupirocin Loaded Core-Shell Pluronic-Pectin-Keratin Nanofibers Improve Human Keratinocytes Behavior, Angiogenic Activity and Wound Healing. Int. J. Biol. Macromol. 2023, 253, 126700. [Google Scholar] [CrossRef] [PubMed]

- Luraghi, A.; Peri, F.; Moroni, L. Electrospinning for Drug Delivery Applications: A Review. J. Control. Release 2021, 334, 463–484. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J. Electrospinning for the Manufacture of Biosensor Components: A Mini-Review. Med. Devices Sens. 2021, 4, e10136. [Google Scholar] [CrossRef]

- Halicka, K.; Cabaj, J. Electrospun Nanofibers for Sensing and Biosensing Applications—A Review. Int. J. Mol. Sci. 2021, 22, 6357. [Google Scholar] [CrossRef] [PubMed]

- Ji, G.; Chen, Z.; Li, H.; Awuye, D.E.; Guan, M.; Zhu, Y. Electrospinning-Based Biosensors for Health Monitoring. Biosensors 2022, 12, 876. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Hao, M.; Chen, Z.; Liu, L.; Liu, Y.; Yang, W.; Ramakrishna, S. A Review on Recent Advances in Application of Electrospun Nanofiber Materials as Biosensors. Curr. Opin. Biomed. Eng. 2020, 13, 174–189. [Google Scholar] [CrossRef]

- Xu, T.; Ji, G.; Li, H.; Li, J.; Chen, Z.; Awuye, D.E.; Huang, J. Preparation and Applications of Electrospun Nanofibers for Wearable Biosensors. Biosensors 2022, 12, 177. [Google Scholar] [CrossRef]

- Rezaei, Z.; Alemzadeh, I.; Vossoughi, M. Design and Fabrication of an Electrochemical-Based Nanofibrous Immunosensor for Detection of Prostate Cancer Biomarker, PSMA. Polym. Adv. Technol. 2022, 33, 1967–1977. [Google Scholar] [CrossRef]

- Iftikhar, F.J.; Shah, A.; Wali, Q.; Kokab, T. Advancements in Nanofiber-Based Electrochemical Biosensors for Diagnostic Applications. Biosensors 2023, 13, 416. [Google Scholar] [CrossRef]

- Chen, K.; Chou, W.; Liu, L.; Cui, Y.; Xue, P.; Jia, M. Electrochemical Sensors Fabricated by Electrospinning Technology: An Overview. Sensors 2019, 19, 3676. [Google Scholar] [CrossRef] [PubMed]

- Vaseashta, A.; Demir, D.; Sakım, B.; Aşik, M.; Bölgen, N. Hierarchical Integration of 3D Printing and Electrospinning of Nanofibers for Rapid Prototyping. In Electrospun Nanofibers Principles, Technology and Novel Applications; Springer: Cham, Switzerland, 2022; pp. 631–655. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Peng, X.; Zhang, X.; Wang, Y.; Yu, B.; Tian, M.; Zhang, L.; Xue, J.; Dai, Y. Integration of Electrospinning and 3D Printing Technology. In Electrospun Nanofibers Principles, Technology and Novel Applications; Springer: Cham, Switzerland, 2022; pp. 657–691. [Google Scholar] [CrossRef]

- Vaseashta, A. Ecosystem of Innovations in Nanomaterials Based CBRNE Sensors and Threat Mitigation. In Advanced Sensors for Safety and Security Advanced Sensors for Safety and Security; Vaseashta, A., Khudaverdyan, S., Eds.; NATO Science for Peace and Security Series B: Physics and Biophysics; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Batra, A.; Sampson, J.; Davis, A.; Currie, J.; Vaseashta, A. Electrospun Nanofibers Doped with PVDF and PLZT Nanoparticles for Potential Biomedical and Energy Harvesting Applications. J. Mater. Sci. Mater. Electron. 2023, 34, 1654. [Google Scholar] [CrossRef]

- Palwai, S.; Batra, A.; Kotru, S.; Vaseashta, A. Electrospun Polyvinylidene Fluoride Nanofiber Membrane-Based Flexible Capacitive Tactile Sensors for Biomedical Applications. Surf. Eng. Appl. Electrochem. 2022, 58, 194–201. [Google Scholar] [CrossRef]

- He, Z.; Rault, F.; Lewandowski, M.; Mohsenzadeh, E.; Salaün, F. Electrospun PVDF Nanofibers for Piezoelectric Applications: A Review of the Influence of Electrospinning Parameters on the β Phase and Crystallinity Enhancement. Polymers 2021, 13, 174. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Gradys, A.; Kim, S.K.; Persano, L.; Marzec, M.; Kryshtal, A.; Busolo, T.; Toncelli, A.; Pisignano, D.; Bernasik, A.; et al. Enhanced Piezoelectricity of Electrospun Polyvinylidene Fluoride Fibers for Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 13575–13583. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Qu, M.; Carlos, C.; Gu, L.; Jin, F.; Yuan, T.; Wu, X.; Xiao, J.; Wang, T.; Dong, W.; et al. High-Performance Poly(Vinylidene Difluoride)/Dopamine Core/Shell Piezoelectric Nanofiber and Its Application for Biomedical Sensors. Adv. Mater. 2021, 33, 202006093. [Google Scholar] [CrossRef]

- Zhang, J.H.; Sun, X.; Wang, H.; Li, J.; Guo, X.; Li, S.; Wang, Y.; Cheng, W.; Qiu, H.; Shi, Y.; et al. From 1D to 2D to 3D: Electrospun Microstructures towards Wearable Sensing. Chemosensors 2023, 11, 295. [Google Scholar] [CrossRef]

- Sengupta, D.; Romano, J.; Kottapalli, A.G.P. Electrospun Bundled Carbon Nanofibers for Skin-Inspired Tactile Sensing, Proprioception and Gesture Tracking Applications. NPJ Flex. Electron. 2021, 5, 29. [Google Scholar] [CrossRef]

- Ramadoss, T.S.; Ishii, Y.; Chinnappan, A.; Ang, M.H.; Ramakrishna, S. Fabrication of Pressure Sensor Using Electrospinning Method for Robotic Tactile Sensing Application. Nanomaterials 2021, 11, 1320. [Google Scholar] [CrossRef]

- Vaseashta, A.; Dektyar, Y.; Ivanov, V.; Klavins, M.; Demir, D.; Bolgen, N. Nexus of Electrospun Nanofibers and Additive Processing—Overview of Wearable Tactical Gears for CBRNE Defense. Smart Innov. Syst. Technol. 2022, 255, 133–145. [Google Scholar] [CrossRef]

- Vaseashta, A. Life Cycle Analysis of Nanoparticles-Risk, Assessment, and Sustainability; Destech Publications: Lancaster, PA, USA, 2015; ISBN 978-1-60595-023-5. Available online: http://www.destechpub.com (accessed on 5 May 2023).

| Electrospun Polymer | Additives | Morphology | Application | Ref. |

|---|---|---|---|---|

| PCL | nanosilicate, laponit | randomly oriented filamentous architecture | periodontal regeneration | [34] |

| silk fibroin PCL | bioactive glass nanoparticles | double-layer scaffold with an oriented fiber topology | guided bone regeneration | [35] |

| PCL | graphdiyne nanoparticles | rough surface with a multilayer structure by rolling into the nerve guide conduits | peripheral nerve regeneration | [36] |

| PLGA | magnesium and zinc metallic particles | bi-layered membrane with both dense and porous structure | periodontal tissue regeneration | [37] |

| PEOT PBT | hydroxyapatite and mesoporous bioactive glasses | porous structure with random fiber orientation | bone tissue regeneration | [38] |

| PLLA-PCL | silk fibroin vitamin B5 | double-layer sponge tube including both nanofiber and nano yarn | urethral regeneration | [39] |

| PCL | tropoelastin | wave-like fibers aligned in the stretch direction | musculoskeletal tissue mimicking | [40] |

| PLA | silk peptide cellulose nanofibrils Ag nanoparticles | randomly aligned, ultra-fine fibers covered with relatively smooth film | scaffolds for biomedical reconstruction | [41] |

| chitosan PEO | - | increased fiber diameters when using PEO | potential for cartilage repair applications | [42] |

| PHB-starch Chitosan-ECM | halloysite nanotubes | nanofibers in core–shell structure | potential for articular cartilage tissue regeneration | [43] |

| Electrospun Polymer | Additive | Morphology | Acquired Property | Ref. |

|---|---|---|---|---|

| gelatin PEO ulvan | ulvan-stabilized silver nanoparticles | co-electrospun nanofibers | faster wound contraction during the early stages of the burn wound healing process | [60] |

| chitosan PVA | tannic acid | 3D nanofiber sponge | antioxidant properties and antibacterial ability | [58] |

| PCL gelatin | strontium zinc silicon bioceramics | bioceramic-nanoparticle-loaded 2D fiber membrane | activation of hair follicle stem cells around the burn wound with ion release | [61] |

| PLA | beta-chitin whiskers, silver nanoparticles | bilayer membrane | hydrophilicity: moist environment, hydrophobicity: mechanical properties, antimicrobial activity: preventing skin wound infections | [62] |

| PAN | aloe vera extract and silver sulfadiazine tragacanth | sandwich electrospun nanofibers/tragacanth hydrogel composite | improved properties by adding hydrogel as a second layer to make a sandwich wound dressing | [63] |

| PCL chitosan | bromelain and silver nanoparticles | 2D membrane with uniform and homogeneous fibers | additives improved the wound-healing process within one week compared to other groups | [64] |

| PCL PLA | Capparis spinosa L. zinc oxide nanoparticles | double-layer nanofiber membrane | additives enhanced the mechanical strength and good antibacterial effect | [65] |

| gelatin | Hypericum perforatum oil Vitamin A palmitate | active agents incorporated relatively uniform fibers | improved the properties of gelatin nanofiber | [66] |

| PU PCEC chitosan | TMP | 2D membrane with homogeneous and smooth surface morphology | photosensitivity and bactericidal properties for cutaneous tissue healing | [67] |

| PCL chitosan pectin | - | 2D membrane with uniform morphology | effective against a wide range of microbial organisms which aids in wound healing | [68] |

| zein pectin soy lecithin | vitamin C | continuous and smooth ribbon-like structure | promoting the healing and reducing inflammation in the created burn wound | [69] |

| Electrospun Polymer | Drug | Strategy | Application | Ref. |

|---|---|---|---|---|

| PLA | dicumarol | Before electrospinning, drug was linked to polymer by esterification reaction | Treatment of Peritendinous Adhesion | [81] |

| PAN | ibuprofen | Before electrospinning, ibuprofen was encapsulated in zinc oxide nanoparticles | Transdermal drug delivery carrier | [82] |

| PCL gelatin | curcumin | Before electrospinning, curcumin was encapsulated in zeolite Y nanoparticles | Postsurgical glioblastoma treatment | [83] |

| PDLLA | metronidazole | Co-electrospinning: the core was enriched with drug, while the sheath of the fiber consisted of polymer | Local drug delivery systems for the treatment of periodontitis | [84] |

| hyaluronic acid PHBV | icariin | Co-electrospinning: the core was made with icariin-loaded hyaluronic acid while the sheath was made from perovskite nanoparticle-loaded PHBV | Long-term osteogenesis-promoting application | [85] |

| PLGA | doxorubicin venetoclax | Directly adding to polymer solution before electrospinning | Synergistic inhibition of prostate cancer recurrence | [86] |

| pullulan PLGA | amoxicillin | Directly adding to polymer solution before electrospinning | Topical skin delivery applications | [87] |

| PLGA | doxorubicin paclitaxel | Sequential electrospinning of drug-containing polymer solutions | Inhibition of breast tumor in situ | [88] |

| chitosan PEO PCL | rosuvastatin | Co-electrospinning: the drug was electrospun together with the polymer solution to be found in the core of the fibers | Bone tissue engineering such as guided bone regeneration, bone fracture healing, and localized drug delivery to the damaged bone site | [89] |

| pluronic pectin keratin | mupirocin | Co-electrospinning: directly adding to the core polymer solution | Potential in wound healing applications | [90] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demir, D.; Bolgen, N.; Vaseashta, A. Electrospun Nanofibers for Biomedical, Sensing, and Energy Harvesting Functions. Polymers 2023, 15, 4253. https://doi.org/10.3390/polym15214253

Demir D, Bolgen N, Vaseashta A. Electrospun Nanofibers for Biomedical, Sensing, and Energy Harvesting Functions. Polymers. 2023; 15(21):4253. https://doi.org/10.3390/polym15214253

Chicago/Turabian StyleDemir, Didem, Nimet Bolgen, and Ashok Vaseashta. 2023. "Electrospun Nanofibers for Biomedical, Sensing, and Energy Harvesting Functions" Polymers 15, no. 21: 4253. https://doi.org/10.3390/polym15214253