Application of a Core-Shell Structure Nano Filtration Control Additive in Salt-Resistant Clay-Free Water-Based Drilling Fluid

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Systhesis of FATG

2.3. Characterizations

2.4. Preparation of Clay-Free WBDFs

2.5. Filtrate Loss Reduction Performance Test of Clay-Free WBDFs

2.6. Rheological Parameters

2.7. Density Measurement

2.8. Linear Swelling Test

2.9. Sticking Factor of Mud Cake Test

2.10. Evaluation Method of the Damage Degree

2.11. Formation Water Compatibility Tests on the Drilling Fluids Containing FATG

3. Results and Discussion

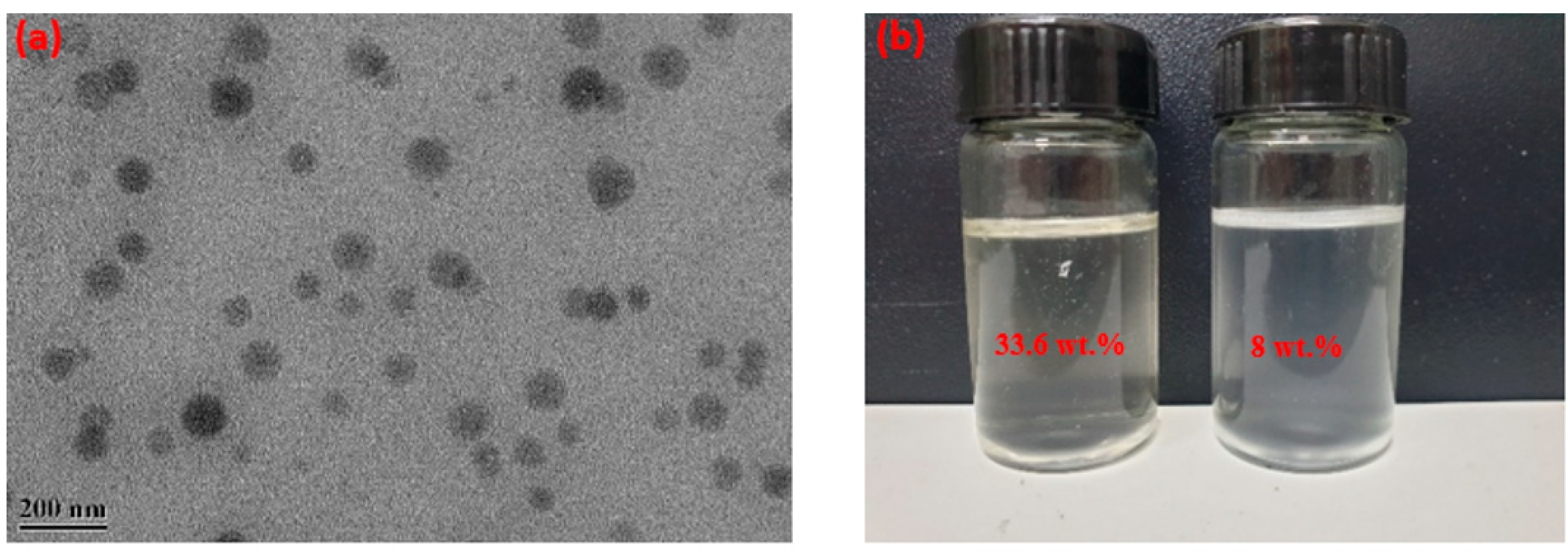

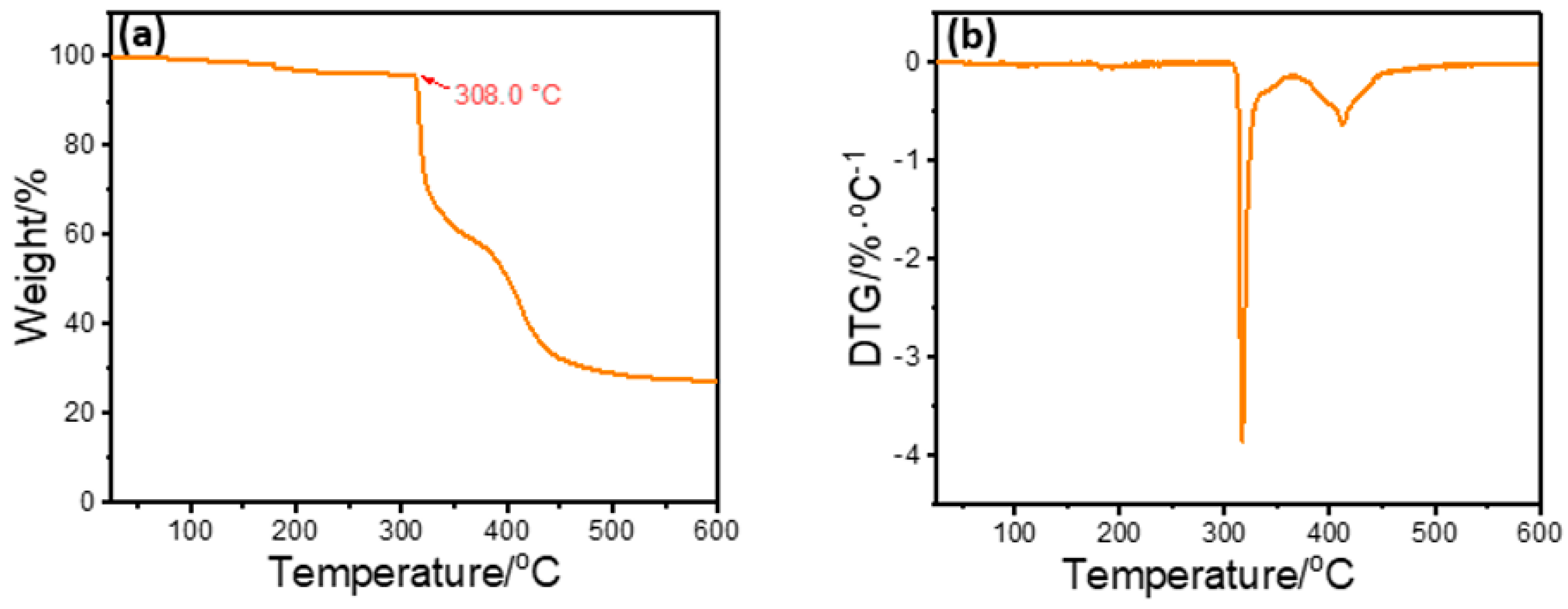

3.1. Characterization of FATG

3.2. Filtration Performance of Clay-Free WBDFs

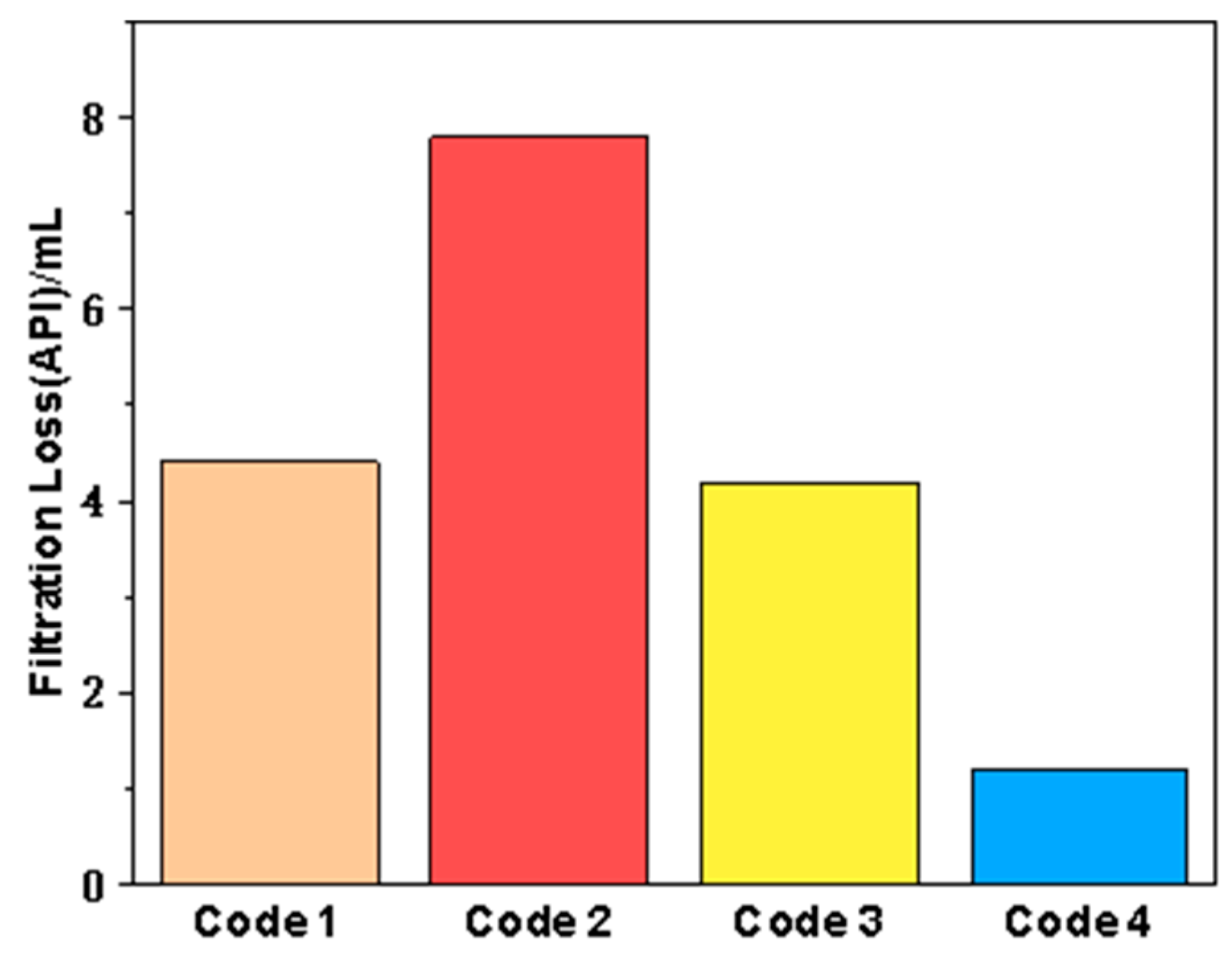

3.2.1. Performance of FATG in Non-Saline Clay-Free Drilling Fluids

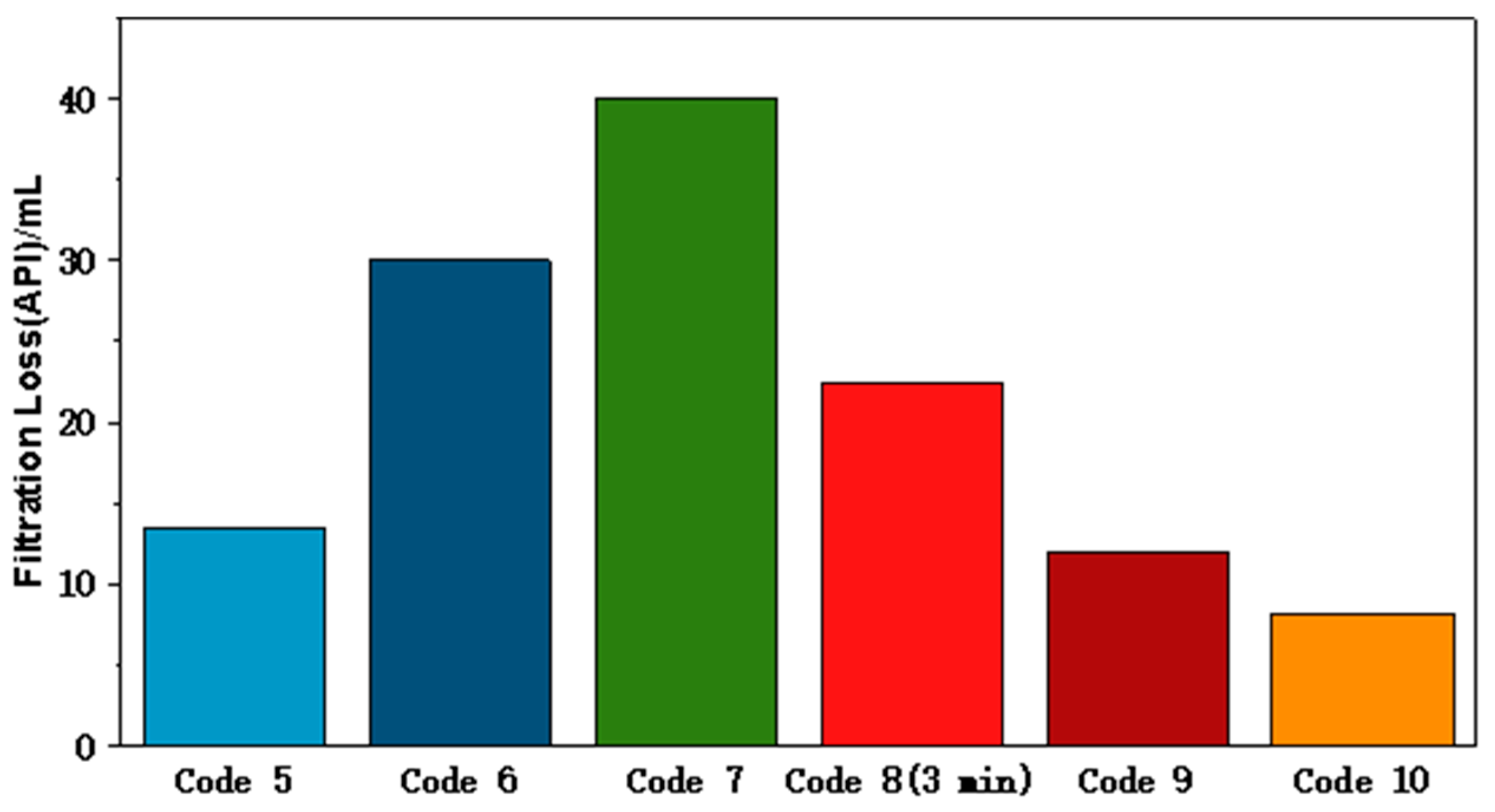

3.2.2. Performance of FATG in Saline Clay-Free WBDFs

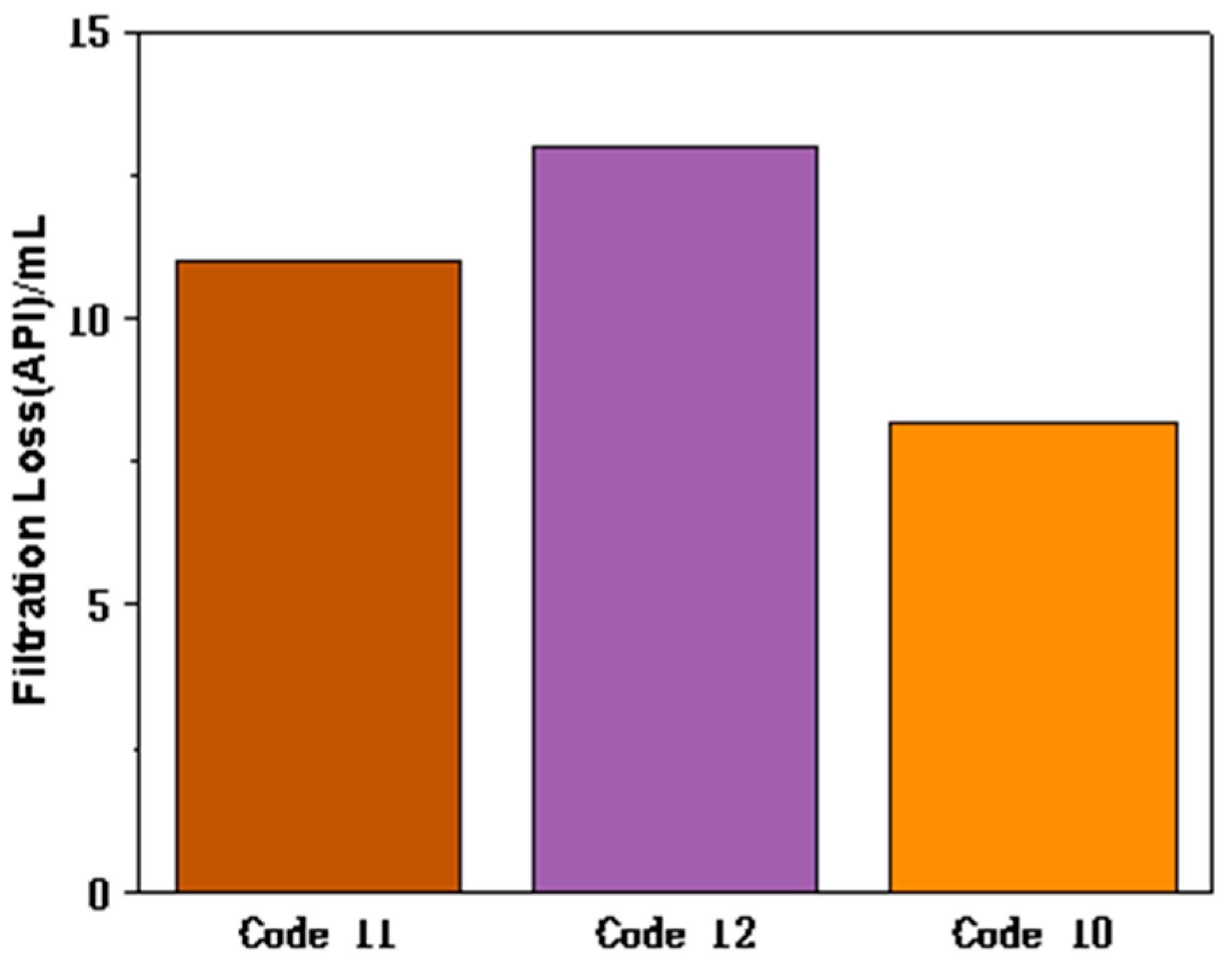

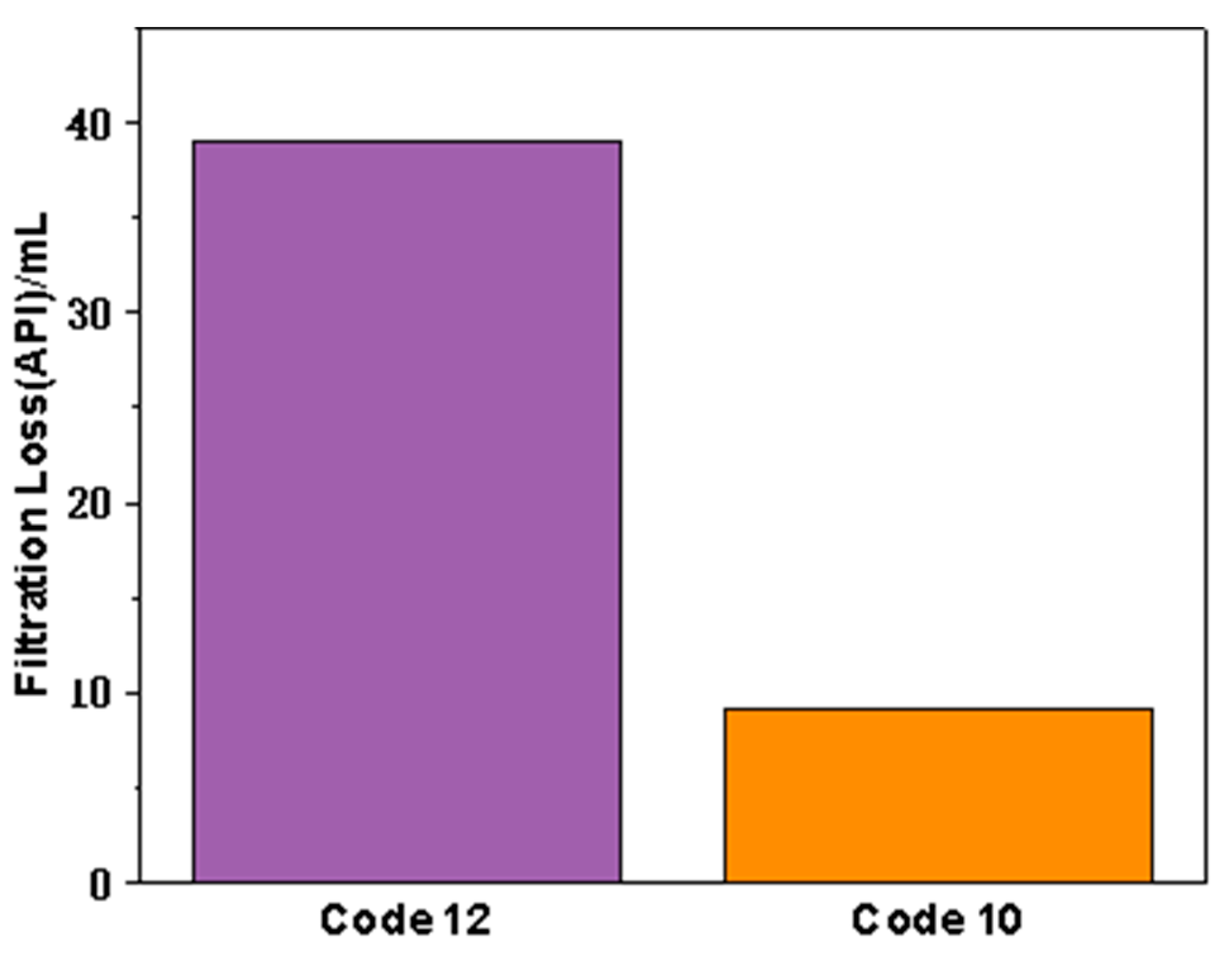

3.2.3. Comparison of Filtration Performance of FATG and GBG in Saline WBDFs

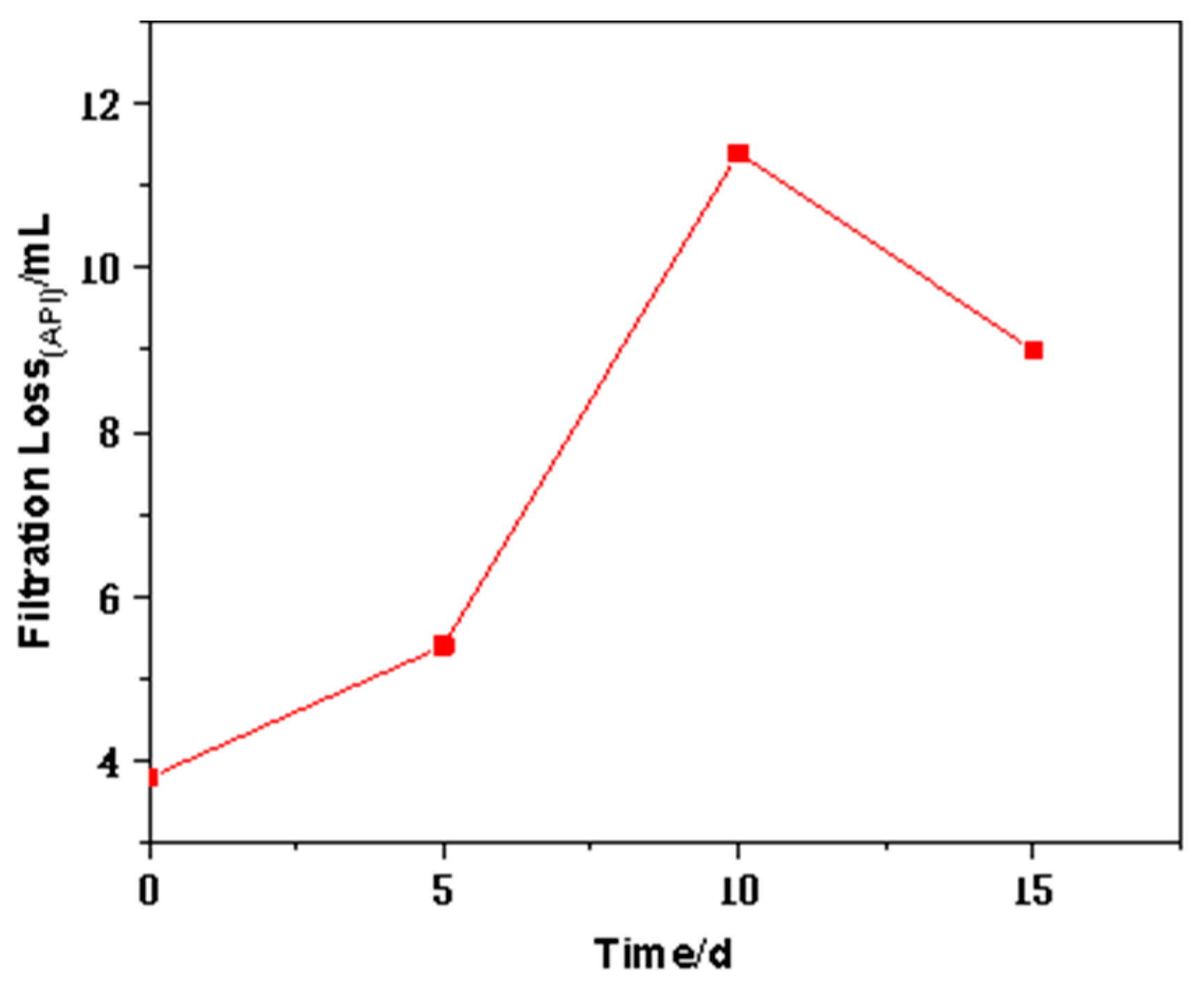

3.2.4. Effect of Hot Rolling Time on the Performance of FATG in Clay-Free WBDFs

3.2.5. The Effect of Higher-Temperature Aging on the Properties of FATG in Clay-Free WBDFs

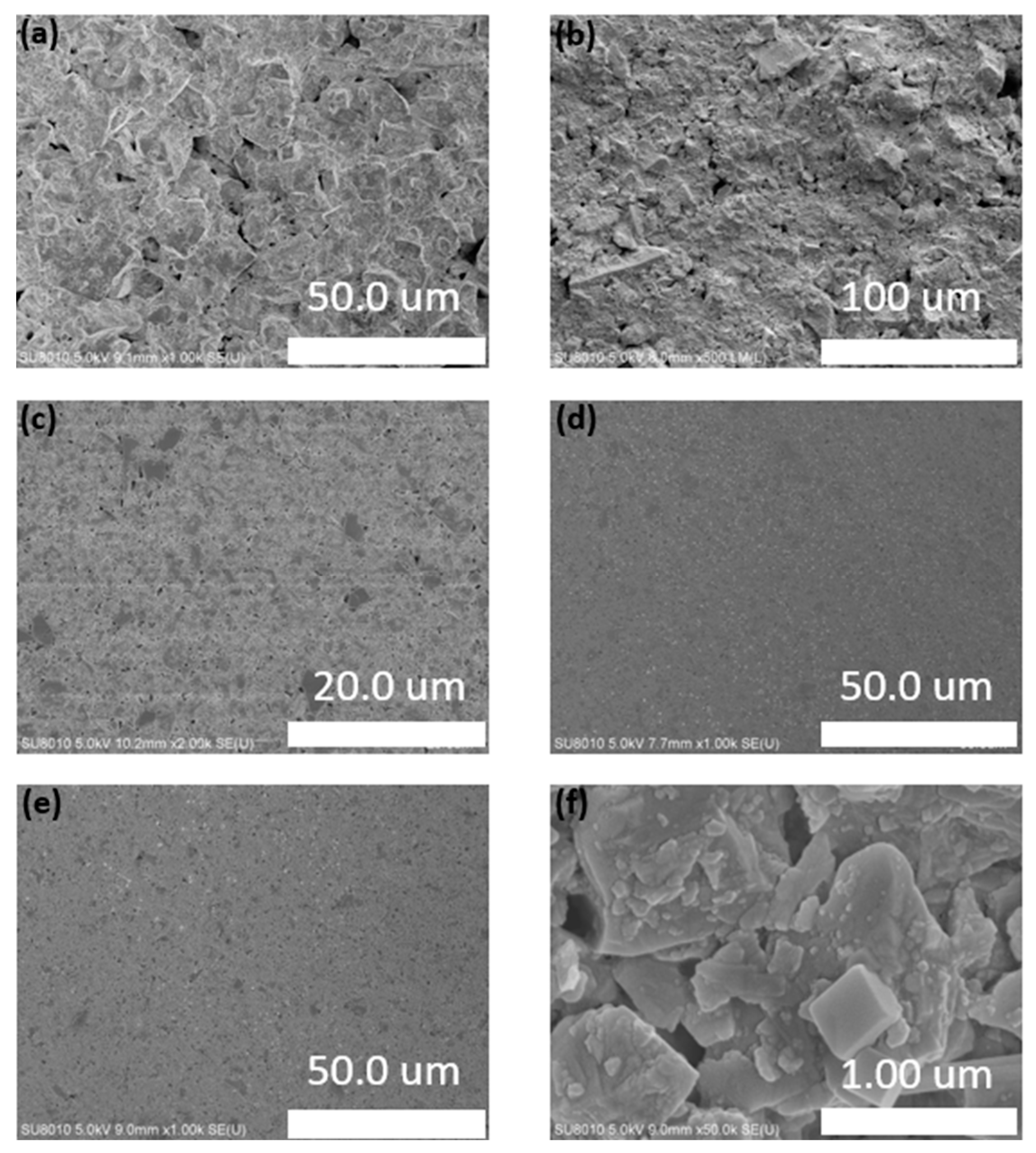

3.3. Characterization of Mud Cake of Clay-Free WBDF

3.4. Clay-Free Drilling Fluid Inhibition and Sticking Factor of Mud Cake Test

3.5. Effect of FATG Clay-Free Drilling Fluid on Core Damage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Galindo, K.A.; Zha, W.; Zhou, H.; Deville, J.P. Clay-free high performance water-based drilling fluid for extreme high temperature wells. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March 2015; p. D012S020R005. [Google Scholar]

- VasheghaniFarahani, M.; Soleimani, R.; Jamshidi, S.; Salehi, S. Development of a dynamic model for drilling fluid’s filtration: Implications to prevent formation damage. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014; p. D012S007R006. [Google Scholar]

- Li, Z.; Xiang, C. Experimental investigation of a new weak-gel-type clay-free and water-based drilling fluid with high-temperature and high-salt resistance for determining its optimized formulation. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–18. [Google Scholar] [CrossRef]

- Wang, S.; Yuan, C.; Zhang, C.; Chen, L.; Liu, J. Rheological properties with temperature response characteristics and a mechanism of solid-free polymer drilling fluid at low temperatures. Appl. Sci. 2016, 7, 18. [Google Scholar] [CrossRef]

- Blinov, P.A.; Dvoynikov, M.V. Rheological and Filtration Parameters of the Polymer Salt Drilling Fluids. J. Eng. Appl. Sci. 2018, 13, 5661–5664. [Google Scholar]

- Bageri, B.S.; Adebayo, A.R.; Al Jaberi, J.; Patil, S. Effect of perlite particles on the filtration properties of high-density barite weighted water-based drilling fluid. Powder Technol. 2020, 360, 1157–1166. [Google Scholar] [CrossRef]

- Ye, Y.; An, W.H.; Yin, D.; Zhang, Q.W.; Li, L.; Ren, L.L. Application of ultrafine weighting materials in high-density oil-based drilling fluid technology. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2015; pp. 338–344. [Google Scholar]

- Galindo, K.A.; Zha, W.; Zhou, H.; Deville, J.P. High temperature, high performance water-based drilling fluid for extreme high temperature wells. In Proceedings of the SPE International Symposium On Oilfield Chemistry, The Woodlands, TX, USA, 13–15 April 2015. [Google Scholar]

- Hu, Z.; Jianwu, Z.; Zhonghua, W. Application of alkyl polyglucoside clay-free drilling fluid in well Wei 383-FP1. Petrochem. Ind. Appl. 2012, 31, 6–9. [Google Scholar]

- Zhang, X.; Jiang, G.; Xuan, Y.; Wang, L.; Huang, X. The development of a viscosifier for clay free and water based drilling fluid with high density and high temperature resistant. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition? Singapore, 22–24 August 2016; p. D021S008R005. [Google Scholar]

- Jiang, G.; Tengfei, D.; Kaixiao, C.; Yinbo, H.; Xiaohu, Q.; Lili, Y.; Yue, F. Research status and development directions of intelligent drilling fluid technologies. Pet. Explor. Dev. 2022, 49, 660–670. [Google Scholar] [CrossRef]

- Li, J.; Sun, J.; Lv, K.; Ji, Y.; Liu, J.; Huang, X.; Bai, Y.; Wang, J.; Jin, J.; Shi, S. Temperature-and salt-resistant micro-crosslinked polyampholyte gel as fluid-loss additive for water-based drilling fluids. Gels 2022, 8, 289. [Google Scholar] [CrossRef] [PubMed]

- Xiaoping, Z.; Jingguang, W.; Bin, Y. Development of a clay-free oil-based drilling fluid with a low shearing force and high density. Nat. Gas Ind. 2014, 34, 89–92. [Google Scholar]

- Rezaei, A.; Shadizadeh, S.R. State-of-the-art drilling fluid made of produced formation water for prevention of clay swelling: Experimental investigation. Chem. Eng. Res. Des. 2021, 170, 350–365. [Google Scholar] [CrossRef]

- Ali, M.S.M.; Khan, M.I.B.I.J.; Ezhil, A.U.S.; Sudararaj, S.; Ahmad, R. Clay-free Drilling Fluid Composition. No. PCT/US2018/061559. 16 November 2018. [Google Scholar]

- Huang, X.B.; Jiang, G.C. Hydrogen Bonds-Enhanced Organoclay-Free Oil Based Drilling Fluid System. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Swizerland, 2017; pp. 227–234. [Google Scholar]

- Abbood, H.A.; Shakir, I.K. Improved Water-Based Mud Rheological Properties and Shale-Inhibition Behavior by Using Aluminum Oxide and Iron Oxide Nanoparticles. Eng. Technol. J. 2022, 40, 1171–1178. [Google Scholar] [CrossRef]

- Movahedi, H.; Farahani, M.V.; Jamshidi, S. Application of Hydrated Basil Seeds (HBS) as the herbal fiber on hole cleaning and filtration control. J. Pet. Sci. Eng. 2017, 152, 212–228. [Google Scholar] [CrossRef]

- Movahedi, H.; Jamshidi, S.; Hajipour, M. New insight into the filtration control of drilling fluids using a graphene-based nanocomposite under static and dynamic conditions. ACS Sustain. Chem. Eng. 2021, 9, 12844–12857. [Google Scholar] [CrossRef]

- Jain, R.; Mahto, V. Evaluation of polyacrylamide/clay composite as a potential drilling fluid additive in inhibitive water based drilling fluid system. J. Pet. Sci. Eng. 2015, 133, 612–621. [Google Scholar] [CrossRef]

- Liu, F.; Yao, H.; Liu, Q.; Wang, X.; Dai, X.; Zhou, M.; Wang, Y.; Zhang, C.; Wang, D.; Deng, Y. Nano-silica/polymer composite as filtrate reducer in water-based drilling fluids. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127168. [Google Scholar] [CrossRef]

- Wang, Q.; Dai, F.; Zhang, S.; Wang, M.; Chen, C.; Yu, Y. Design of a novel poly (aryl ether nitrile)-based composite ultrafiltration membrane with improved permeability and antifouling performance using zwitterionic modified nano-silica. RSC Adv. 2021, 11, 15231–15244. [Google Scholar] [CrossRef] [PubMed]

- Ural, N. The significance of scanning electron microscopy (SEM) analysis on the microstructure of improved clay: An overview. Open Geosci. 2021, 13, 197–218. [Google Scholar] [CrossRef]

- Xu, J.Z.; Xu, L.; Liang, Y.Y.; Zhong, G.J.; Lei, J.; Li, Z.M. Temperature dependence of molecular conformation in uniaxially deformed isotactic polypropylene investigated by combination of polarized FTIR spectroscopy and 2D correlation analysis. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 673–684. [Google Scholar] [CrossRef]

- Kagimura, F.Y.; da Cunha, M.A.A.; Theis, T.V.; Malfatti, C.R.; Dekker, R.F.; Barbosa, A.M.; Teixeira, S.D.; Salomé, K. Carboxymethylation of (1→ 6)-β-glucan (lasiodiplodan): Preparation, characterization and antioxidant evaluation. Carbohydr. Polym. 2015, 127, 390–399. [Google Scholar] [CrossRef] [PubMed]

- Deville, J.P. Drilling fluids. In Fluid Chemistry, Drilling and Completion; Elsevier: Amsterdam, The Netherlands, 2022; pp. 115–185. [Google Scholar]

- Guancheng, J.; Xueshi, W.; Jienian, Y. Study on the rheology property of water based drilling fluid at high temperature and high pressure. Drill. Fluid Complet. Fluid 1994, 1, 19–20. [Google Scholar]

- Wang, X.; Jiang, G.; Wang, G.; Yang, L.; He, Y.; Dong, T.; Chang, X.; Chen, H. Application of a biomimetic wellbore stabilizer with strong adhesion performance for hydrate reservoir exploitation. Fuel 2023, 337, 127184. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, L.; Yu, P.; Chen, Z. Experimental study on the application of an ionic liquid as a shale inhibitor and inhibitive mechanism. Appl. Clay Sci. 2017, 150, 267–274. [Google Scholar] [CrossRef]

- Chenevert, M.; Dewan, J. A model for filtration of water-base mud during drilling: Determination of mudcake parameters. Petrophys.-SPWLA J. Form. Eval. Reserv. Descr. 2001, 42. SPWLA-2001-v42n3a4. [Google Scholar]

- Sirrine, J.M.; Schexnayder, S.A.; Dennis, J.M.; Long, T.E. Urea as a monomer for isocyanate-free synthesis of segmented poly (dimethyl siloxane) polyureas. Polymer 2018, 154, 225–232. [Google Scholar] [CrossRef]

- Lei, M.; Li, N. The damage mechanism of oil-based drilling fluid for tight sandstone gas reservoir and its optimization. J. Pet. Sci. Eng. 2017, 158, 616–625. [Google Scholar] [CrossRef]

| Materials | Purity | Supplier |

|---|---|---|

| NaCl | 99.5% | Beijing InnoChem Technology Co. (Beijing, China) |

| KCl | 99.5% | Aladdin (Shanghai, China) |

| ultra-micro barite powder | 85–95% | Lingshou County Huayao Mineral Product Factory (Shijiazhuang, China) |

| sepiolite powder | 200 mesh | Aladdin (Shanghai, China) |

| dispersant | 95% | Beijing Shida Bocheng Technology Co., LTD., (Beijing, China) |

| stabilizer | 95% | Beijing Shida Bocheng Technology Co., LTD., (Beijing, China) |

| GBG | 95% | Beijing Shida Bocheng Technology Co., LTD., (Beijing, China) |

| butylbenzene latex | 95% | Beijing Shida Bocheng Technology Co., LTD., (Beijing, China) |

| 3-mercapto-1-propanesulfonic acid sodium salt | 99.5% | Aladdin (Shanghai, China) |

| aqueous ammonia | 99.5% | Aladdin (Shanghai, China) |

| SiO2 | 99.99% | Aladdin (Shanghai, China) |

| deionized water | AR | Aladdin (Shanghai, China) |

| 2-Acrylamido-2-methylpropane sulfonic acid | 99.5% | Titan (Shanghai, China) |

| diallyldimethylammonium chloride | 99.5% | Titan (Shanghai, China) |

| N-Vinyl-2-Pyrrolidinone | 99.5% | Titan (Shanghai, China) |

| K2S2O8 | Aladdin (Shanghai, China) |

| Code | Sepiolite/g | FATG/ g | AV/ mPa·s | PV/ mPa·s | YP/ Pa | Gel/ Pa | Ф6/Ф3 | ρ/ g/cm3 |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 6.72 | 14 | 11 | 3 | 1/1 | 2/1 | 2.10 |

| 2 | 8 | 0 | 9.5 | 10 | 0 | 0/0 | 0/0 | 2.09 |

| 3 | 12 | 0 | 19 | 16 | 3 | 0/0 | 1/0 | 2.35 |

| 4 | 12 | 5.38 | 71.5 | 67 | 4.5 | 4/9 | 9/8 | 2.26 |

| Code | Sepiolite/ g | Butadiene Latex/ g | GBG/ g | FATG/ g | AV/ mPa·s | PV/ mPa·s | YP/ Pa | Gel/ Pa | Ф6/Ф3 | ρ/ g/cm3 |

|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 0 | 0 | 0 | 6.72 | 38 | 26 | 12 | 10.5/35 | 11/11 | 2.29 |

| 6 | 8 | 0 | 0 | 0 | 25 | 19 | 6 | 8/20.5 | 5/4 | 2.09 |

| 7 | 12 | 0 | 0 | 0 | 65 | 40 | 25 | / | 38/37 | 2.35 |

| 8 | 0 | 12 | 0 | 0 | 33 | 26 | 7 | 10.5/20 | 6/5 | 2.16 |

| 9 | 0 | 0 | 12 | 0 | 22.5 | 18 | 4.5 | 2.5/8 | 4/3 | 2.00 |

| 10 | 0 | 0 | 0 | 4.03 | 22 | 16 | 6 | 6.5/18 | 7/6 | 2.11 |

| Code | Sepiolite/ g | GBG/ g | FATG/ g | AV/ mPa·s | PV/ mPa·s | YP/ Pa | Gel/ Pa | Ф6/Ф3 | ρ/ g/cm3 |

|---|---|---|---|---|---|---|---|---|---|

| 11 | 0 | 24 | 0 | 45.5 | 39 | 6.5 | 3/8 | 6/5 | 2.00 |

| 12 | 12 | 12 | 0 | 27 | 20 | 7 | 3.5/8 | 6/5 | 2.00 |

| 10 | 0 | 0 | 4.03 | 22 | 16 | 6 | 6.5/18 | 7/6 | 2.11 |

| Code | AV/ mPa·s | PV/ mPa·s | YP/ Pa | Gel/ Pa | Ф6/Ф3 | ρ/ g/cm3 |

|---|---|---|---|---|---|---|

| 12 | 23 | 9 | 14 | 3/7.5 | 8/7 | 2.00 |

| 10 | 17.5 | 14 | 3.5 | 2/9.5 | 3/2 | 2.11 |

| Code | Sepiolite/ g | FATG/ g | Aging Time/ d | AV/ mPa·s | PV/ mPa·s | YP/ Pa | Gel/ Pa | Ф6/Ф3 | ρ/ g/cm3 |

|---|---|---|---|---|---|---|---|---|---|

| 13 | 0 | 6.72 | 0 | 30 | 20 | 10 | 6.5/37 | 8/7 | 2.08 |

| 5 | 35 | 27 | 8 | 2/7 | 5/4 | 2.08 | |||

| 10 | 39 | 33 | 6 | 3.5/14 | 7/6 | 2.08 | |||

| 15 | 35.5 | 29 | 6.5 | 3.5/12 | 7/6 | 2.08 | |||

| 14 | 12 | 5.38 | 0 | 48.5 | 33 | 15.5 | 13.5/36 | 14/13 | 2.09 |

| 5 | 36.5 | 31 | 5.5 | 3.5/14 | 6/5 | 2.09 | |||

| 10 | 47 | 38 | 9 | 2.5/4 | 6/5 | 2.09 | |||

| 15 | 44 | 31 | 13 | 3.5/4.5 | 9/7 | 2.09 |

| Code | Sepiolite/ g | FATG/ g | Aging Time/ d | AV/ mPa·s | PV/ mPa·s | YP/ Pa | Gel/ Pa | Ф6/Ф3 | ρ/ g/cm3 |

|---|---|---|---|---|---|---|---|---|---|

| 15 | 12 | 5.38 | 0 | 90 | 71 | 19 | 25.5/59 | 25/22 | 2.26 |

| 5 | 49 | 39 | 10 | 4/14.5 | 10/9 | 2.26 | |||

| 10 | 65 | 54 | 9 | 7/16 | 13/11 | 2.26 | |||

| 15 | 61 | 49 | 12 | 6.5/16 | 13/11 | 2.11 |

| Code | Core Permeability (mD) | Permeability Recovery Rate (%) | |

|---|---|---|---|

| Before the Contamination | After the Contamination | ||

| 15 | 120.42 | 93.85 | 77.9 |

| 15 without FATG | 148.01 | 100.87 | 68.1 |

| Density (g/cm3) | Major Ion (mg/L) | Mineralization of Water (mg/L) | Water Type | |||||

|---|---|---|---|---|---|---|---|---|

| K+, Na+ | Mg2+ | Ca2+ | SO42− | Cl− | HCO3− | |||

| 1.0285 | 3430.22 | 31.75 | 1919.59 | 43.63 | 8292.66 | 775.52 | 14,493.37 | CaCl2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Li, W.; Qiu, S.; Liu, J.; Ou, Z.; Li, X.; Ji, F.; Zhang, L.; Liu, S.; Yang, L.; et al. Application of a Core-Shell Structure Nano Filtration Control Additive in Salt-Resistant Clay-Free Water-Based Drilling Fluid. Polymers 2023, 15, 4331. https://doi.org/10.3390/polym15214331

Wang G, Li W, Qiu S, Liu J, Ou Z, Li X, Ji F, Zhang L, Liu S, Yang L, et al. Application of a Core-Shell Structure Nano Filtration Control Additive in Salt-Resistant Clay-Free Water-Based Drilling Fluid. Polymers. 2023; 15(21):4331. https://doi.org/10.3390/polym15214331

Chicago/Turabian StyleWang, Gang, Wanjun Li, Shixin Qiu, Jitong Liu, Zhiting Ou, Xiaogang Li, Fei Ji, Liang Zhang, Shanshan Liu, Lili Yang, and et al. 2023. "Application of a Core-Shell Structure Nano Filtration Control Additive in Salt-Resistant Clay-Free Water-Based Drilling Fluid" Polymers 15, no. 21: 4331. https://doi.org/10.3390/polym15214331

APA StyleWang, G., Li, W., Qiu, S., Liu, J., Ou, Z., Li, X., Ji, F., Zhang, L., Liu, S., Yang, L., & Jiang, G. (2023). Application of a Core-Shell Structure Nano Filtration Control Additive in Salt-Resistant Clay-Free Water-Based Drilling Fluid. Polymers, 15(21), 4331. https://doi.org/10.3390/polym15214331