Development of New Hybrid Composites for High-Temperature Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ansys Simulation

2.3. Measurements

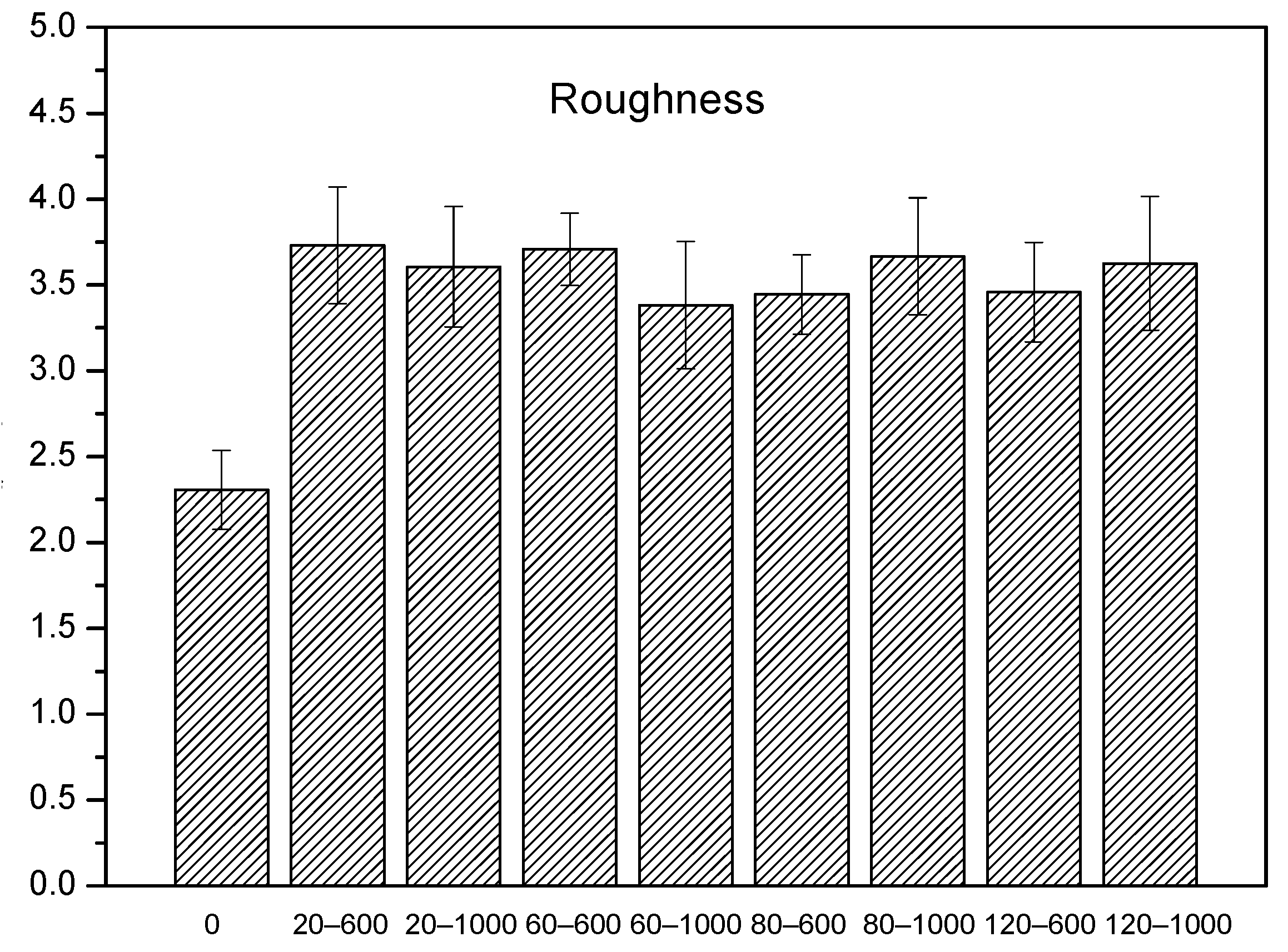

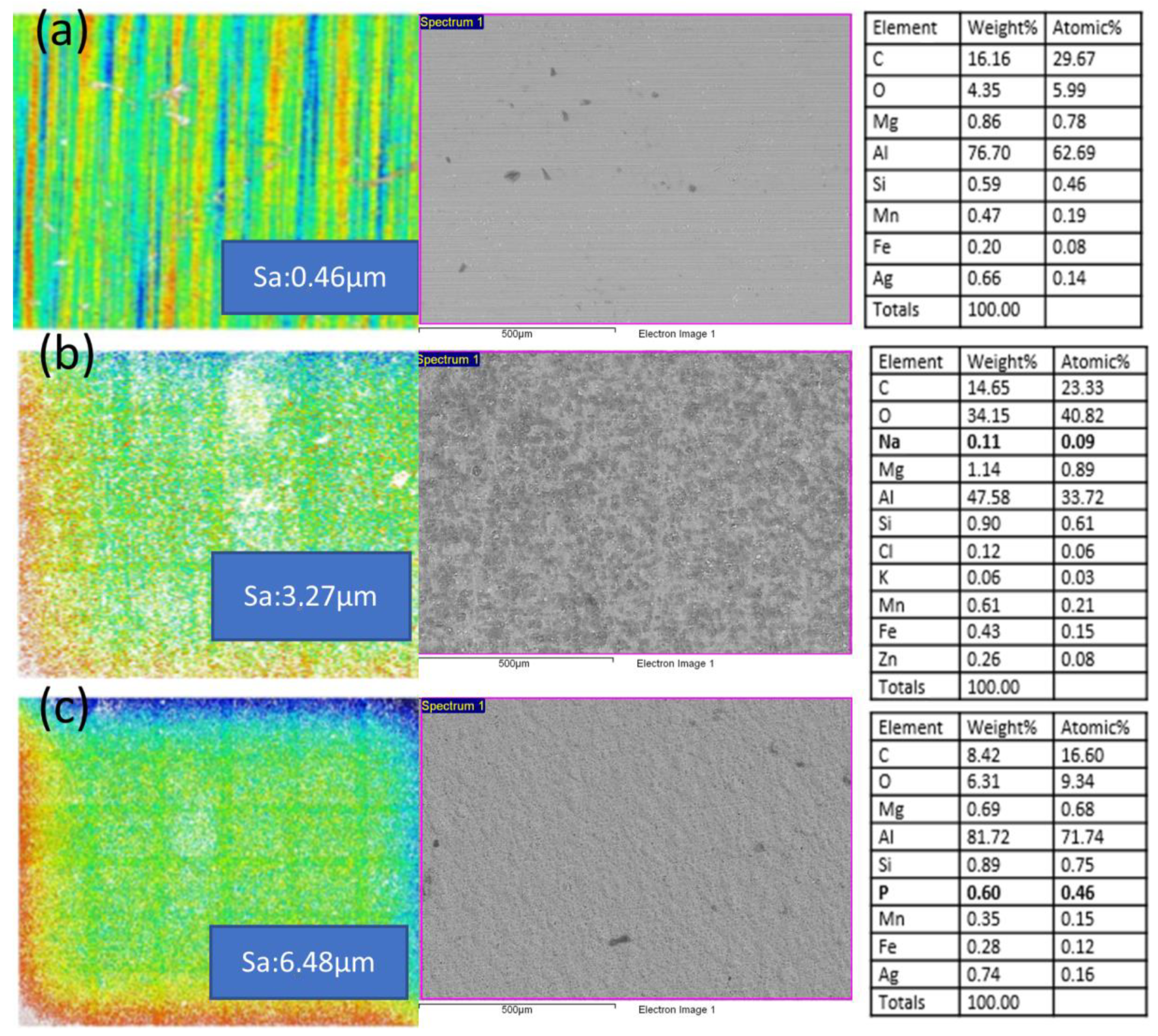

2.4. Fabrication of FML Composites

3. Results

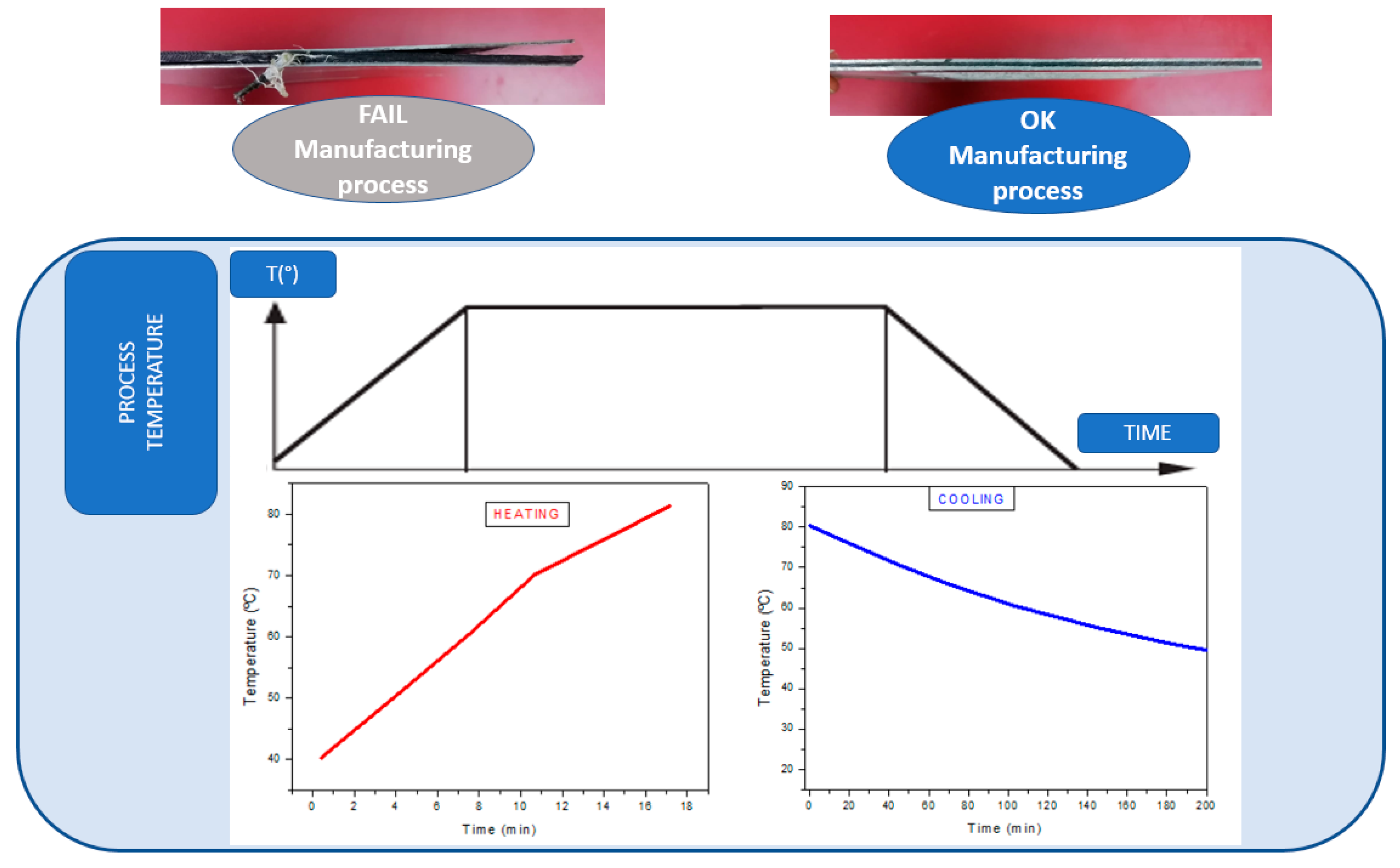

- Adjustment of vacuum temperature and times in the three process stages: heating, curing and cooling.

- Monitoring of material heating. Temperature deviation from the heating program.

- Temperature: 80 °C (dome and bottom plate).

- Exerted pressure: 920 millibars.

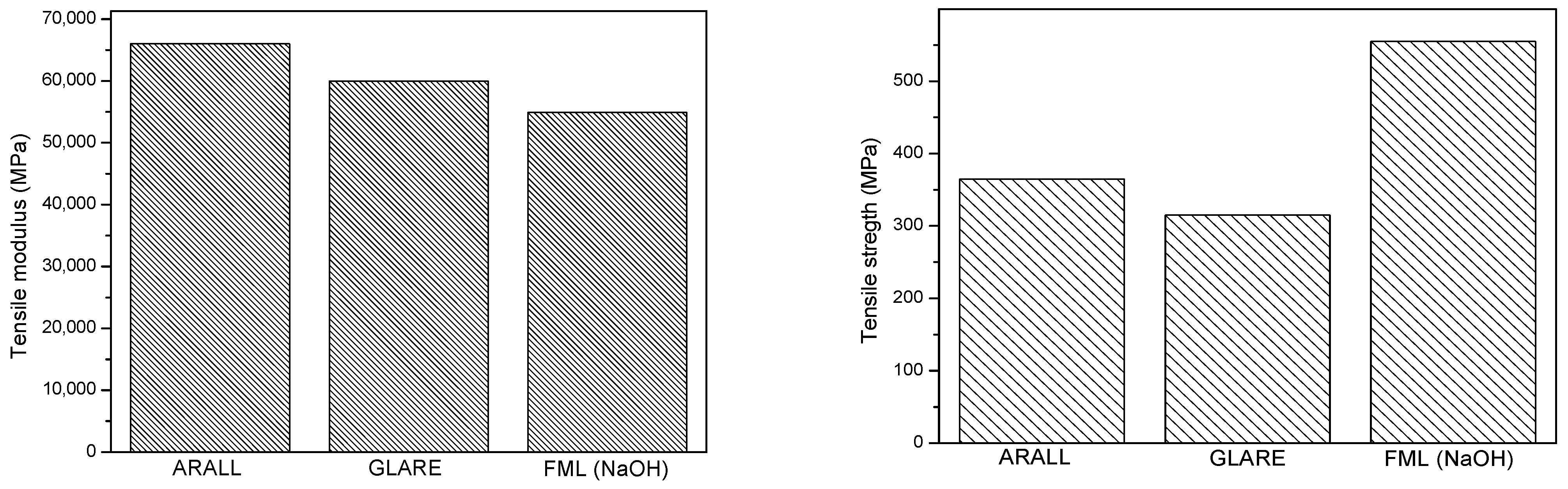

- ARALL 2: 2024-T6/UD aramid/epoxy

- GLARE 3: 2024-T3/UD R-glass/epoxy

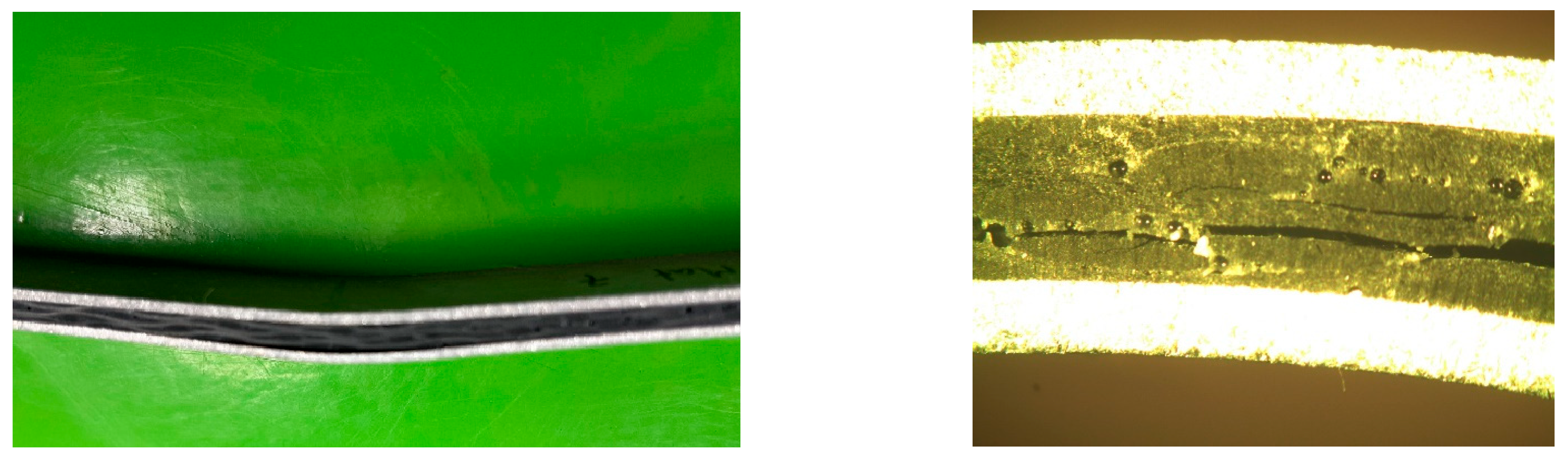

- FML (NaOH treatment): 6082/0/90 carbon/epoxy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alaaeddin, M.H.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; AL-Oqla, F.M. Lightweight and Durable PVDF-SSPF Composites for Photovoltaics Backsheet Applications: Thermal, Optical and Technical Properties. Materials 2019, 12, 2104. [Google Scholar] [CrossRef] [PubMed]

- Samyn, F.; Adanmenou, R.; Bourbigot, S.; Duquesne, S.; Jimenez, M.; Van Marle, M.; Weij, S. Flame Retardancy of Lightweight Sandwich Composites. J. Compos. Sci. 2021, 5, 274. [Google Scholar] [CrossRef]

- Gecu, R.; Karaaslan, A. Sliding Wear of the Ti-Reinforced Al Matrix Bi-metal Composite: A Potential Replacement to Conventional SiC-Reinforced Composites for Automotive Application. Inter. Metalcast. 2019, 13, 641–652. [Google Scholar] [CrossRef]

- Garofano, A.; Acanfora, V.; Fittipaldi, F. On the Use of a Hybrid Metallic-Composite Design to Increase Mechanical Performance of an Automotive Chassis. J. Mater. Eng. Perform. 2023, 32, 3853–3870. [Google Scholar] [CrossRef]

- Samuel, R.; Ramadoss, K.N.; Gunasekaran, K.; Logesh, S.; Gnanaraj, S.J.P.; Abdul, M. Studies on mechanical properties and characterization of carbon fiber reinforced hybrid composite for aero space application. Mater. Today Proc. 2021, 47, 4438–4443. [Google Scholar] [CrossRef]

- Ramesh, G.; Gokilakrishnan, G.; Jayaraja, B.G. High-content Al-T6/pineapple fiber/brass mesh reinforcements on nanosilica-toughened epoxy hybrid natural fiber metal laminate composite for aircraft applications. Biomass Conv. Bioref. 2022, 1–9. [Google Scholar] [CrossRef]

- Sharma, P.; Khanduja, D.; Sharma, S. Tribological and mechanical behavior of particulate aluminum matrix composites. J. Reinf. Plast. Compos. 2014, 33, 2192–2202. [Google Scholar] [CrossRef]

- Ameri, B.; Moradi, M.; Talebitooti, R. Effect of Honeycomb Core on Free Vibration Analysis of Fiber Metal Laminate (FML) Beams Compared to Conventional Composites. Compos. Struct. 2020, 261, 113281. [Google Scholar] [CrossRef]

- Jenarthanan, M.P.; Karthikeyan, M.; Neeli, N. Mathematical modeling of delamination factor on drilling of ARALL composites through RSM. Multidiscip. Model. Mater. 2017, 13, 578–589. [Google Scholar] [CrossRef]

- Qaiser, H.; Umar, S.; Nasir, A. Optimization of interlaminar shear strength behavior of anodized and unanodized ARALL composites fabricated through VARTM process. Int. J. Mater. Form. 2015, 8, 481–493. [Google Scholar] [CrossRef]

- Chu, C.; Shan, L.; Al-Furjan, M.S.H.; Zarei, M.S.; Hajmohammad, M.H.; Kolahchi, R. Experimental study for the effect of hole notched in fracture mechanics of GLARE and GFRP composites subjected to quasi-static loading. Theor. Appl. Fract. Mech. 2022, 122, 103624. [Google Scholar] [CrossRef]

- Annamalai, I.; Karthik, K.; Kumar, N.; Muthuselvan, S.; Vignesh, M.; Dhanush, Y.J. Experimental investigation of mechanical properties of GLARE composite with different layup sequences. Mater. Today. Prod. 2021, 46, 1371–1375. [Google Scholar] [CrossRef]

- Böhm, M.; Głowacka, K. Fatigue Life Estimation with Mean Stress Effect Compensation for Lightweight Structures—The Case of GLARE 2 Composite. Polymers 2020, 12, 251. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Ding, X.; Niu, L.; Huang, Z.; Sun, S. Experimental Study on the Mechanical Properties and Influencing Factors of Glass Fiber-Reinforced Permeable Concrete. Materials 2023, 16, 5970. [Google Scholar] [CrossRef] [PubMed]

- Hayato, N.; Tatsuro, K.; Katsuhiko, O.; Yoshihiro, S. Damage characterization of titanium/GFRP hybrid laminates subjected to low-velocity impact. Compos. A Appl. Sci. Manuf. 2011, 42, 772–781. [Google Scholar]

- Wilk, M.; Sliwa, R.E. The Influence of Features of Aluminium Alloys 2024, 6061 and 7075 on the Properties of Glare-Type Composites. Metall. Mater 2015, 60, 3101–3108. [Google Scholar] [CrossRef]

- Asundi, A.; Chroi, A.Y.N. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 1997, 63, 384–394. [Google Scholar] [CrossRef]

- Vogelesang, L.B.; Vlot, A. Development of fibre metal laminates for advanced aerospace structures. J. Mater. Process. Technol. 2000, 103, 1–5. [Google Scholar] [CrossRef]

- Thomas, J. The A380 programme–the big task for Europe’s aerospace industry. Air Space Eur. 2001, 3, 35–39. [Google Scholar] [CrossRef]

- Wu, G.; Yang, J.M. The mechanical behavior of GLARE laminates for aircraft structures. JOM 2005, 57, 72–79. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, B.C.; Lim, S. Foreign objects impact damage characteristics of aluminum/composite hybrid drive shaft. Compos. Struct. 2004, 66, 377–389. [Google Scholar] [CrossRef]

- Yu, G.C.; Wu, L.Z.; Ma, L.; Xiong, J. Low velocity impact of carbon fiber aluminum laminates. Compos. Struct. 2015, 119, 757–766. [Google Scholar] [CrossRef]

- Sinan, M.; Mustafa, Y. Investigation of dynamic properties of GLARE and CARALL hybrid composites: Numerical and experimental results. Eng. Anal. Bound. Elem. 2023, 155, 484–499. [Google Scholar]

- Sasso, M.; Mancini, E.; Dhaliwal, G.S.; Newaz, G.M.; Amodio, D. Investigation of the mechanical behavior of CARALL FML at high strain rate. Compos. Struct. 2019, 222, 110922. [Google Scholar] [CrossRef]

- Asghar, W.; Nasir, M.A.; Qayyum, F.; Shah, M.; Azeem, M.; Nauman, S.; Khushnood, S. Investigation of fatigue crack growth rate in CARALL, ARALL and GLARE. Fatigue Fract. Engng. Mater. Struct. 2017, 40, 1086–1100. [Google Scholar] [CrossRef]

- Patil, N.A.; Mulik, S.S.; Wangikar, K.S.; Kulkarni, A.P. Characterization of glass laminate aluminium reinforced epoxy–A review. Procedia Manuf. 2018, 20, 554–562. [Google Scholar] [CrossRef]

- Bieniaś, J.; Jakubczak, P. Impact damage growth in carbon fibre aluminium laminates. Compos. Struct. 2017, 17, 147–154. [Google Scholar] [CrossRef]

- Venkategowda, C.; Rajanna, S.; Udupa, N.G.S.; Keshavamurthy, R. Experimental Investigation of Glass-Carbon/Epoxy Hybrid Composites Subjected to Low Velocity Impact Test. FME Trans. 2018, 46, 595–602. [Google Scholar] [CrossRef]

- Sathiyamurthy, R.; Duraiselvam, M.; Sevvel, P. Acoustic Emission Based Deep Learning Technique to Predict Adhesive Bond Strength of Laser Processed CFRP Composites. FME Trans. 2020, 48, 611–619. [Google Scholar] [CrossRef]

- Kuo, C.; Li, Z.; Wang, C. Multi-objective optimisation in vibration-assisted drilling of CFRP/Al stacks. Compos. Struct. 2017, 173, 196–209. [Google Scholar] [CrossRef]

- Giasin, K.; Gorey, G.; Byrne, C.; Sinke, J.; Brousseau, E. Effect of machining parameters and cutting tool coating on hole quality in dry drilling of fibre metal laminates. Compos. Struct. 2019, 212, 159–174. [Google Scholar] [CrossRef]

- Shaker, K.; Adnan, M.; Nawab, Y.; Umair, M.; Jabbar, M.; Siddique, A.; Ahmad, A. Mechanical Performance of Glass/Epoxy Composites Loaded with Silane-Treated Aluminum Hydroxide Fillers. Polymers 2023, 15, 3514. [Google Scholar] [CrossRef]

- Nadeem, M.M.D.; Chethan, S.; Srinivasa, K.; Karthik Kumar, M.; Yathisha, N. Effect of glass fibers and multi walled carbon nano tubes (MWCNT’s) on mechanical properties of epoxy hybrid composites at elevated temperature. Mater. Today Prod. 2021, 44, 2013–2018. [Google Scholar] [CrossRef]

- Dhanaraj, R.; Venkateshwaran, N.; Chenthil, M.; Natarajan, M.S.; Santhanam, V.; Baskar, S. Experimental investigation on the mechanical properties of glass fiber with perforated aluminum sheet reinforced epoxy composite. Mater. Today. Prod. 2021, 37, 1880–1883. [Google Scholar] [CrossRef]

- Franz, M.H.; Neda, I.; Maftei, C.V. Studies of chemical and mechanical properties of hybrid composites based on natural resin Dammar formulated by epoxy resin. Polym. Bull. 2021, 78, 2427–2438. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, W.; Drummer, D.; Liu, C.; Tomiak, F.; Schneider, K. Improvement of thermal conductivity and mechanical properties for polybenzoxazine composites via incorporation of epoxy resin and segregated structure. Mater. Res. Express. 2020, 7, 095301. [Google Scholar] [CrossRef]

- Phaneendra, A.; Sankaraiah, G.; Reddy, V.; Reddy, R.M. Assimilation of Mechanical properties of reinforced aluminum, stainless steel wire mesh with glass fiber epoxy hybrid composites for aircraft application. Adv. Mater. Process. Technol. 2020, 7, 288–303. [Google Scholar]

- Lim, S.; Choi, W.; Park, H. A Study on Design of S-Duct Structures and Air Intake for Small Aircraft Applied to High Strength Carbon–Epoxy Composite Materials. Materials 2022, 15, 3001. [Google Scholar] [CrossRef]

- Margoy, D.; Gouzman, I.; Grossman, E.; Bolker, A.; Eliaz, N.; Verker, R. Epoxy-based shape memory composite for space applications. Acta Astronaut. 2021, 178, 908–919. [Google Scholar] [CrossRef]

- He, Y.; Suliga, A.; Brinkmeyer, A.; Schenk, M.; Hamerton, I. Atomic oxygen degradation mechanisms of epoxy composites for space applications. Polym. Degrad. Stab. 2019, 166, 108–120. [Google Scholar] [CrossRef]

- SN-CEN/TR 17603-32-07:2022; Space Engineering Structural Materials Handbook––Part 7: Thermal and Environmental Integrity, Manufacturing Aspects, in-Orbit and Health Monitoring, Soft Materials, Hybrid Materials and Nanotechnologies. ESA Requirements and Standards Division: Noordwijk, The Netherlands, 2011; pp. 336–337.

| Property | Temperature | Aluminum | Epoxy Carbon Prepreg | |

|---|---|---|---|---|

| Plane | Perpendicular to the Plane | |||

| Density (kg·m3) | RT | 2770 | 1420 | |

| Coefficient of thermal expansion (°C−1) | RT | 23 × 10−6 | 2.2 × 10−6 | 10 × 10−6 |

| Young’s modulus (MPa) | RT | 71000 | 61300 | 6900 |

| Poisson’s ratio | RT | 0.33 | 0.04 | 0.3 |

| Aluminum (Mpa) | Composite (Mpa) | |

|---|---|---|

| 175 °C Tensile stresses (simulation) | 70 | 245 |

| 175 °C Tensile strength | 241 | 578 |

| Tensile Strength/Mpa | Tensile Modulus/Gpa | Tensile Strain/% | ||||

|---|---|---|---|---|---|---|

| Ambient temperature | 175 °C temperature | Ambient temperature | 175 °C temperature | Ambient temperature | 175 °C temperature | |

| FML NaOH treatment | 530 ± 36 | 472 ± 29 | 52.7 ± 1.7 | 37.8 ± 9.4 | 4.0 ± 0.4 | 4.1 ± 0.5 |

| FML Silane treatment | 467 ± 77 | 333 ± 47 | 55.3 ± 4.2 | 52.7 ± 11.2 | 4.3 ± 0.1 | 4.4 ± 0.3 |

| Flexural Strength/MPa | Flexural Modulus/GPa | Flexural Deflection/mm | ||||

|---|---|---|---|---|---|---|

| Ambient temperature | 175 °C temperature | Ambient temperature | 175 °C temperature | Ambient temperature | 175 °C temperature | |

| FML NaOH treatment | 571 ± 13 | 132 ± 21 | 50.5 ± 1.6 | 15.1 ± 1.6 | 3.4 ± 0.3 | 3.5 ± 0.6 |

| FML Silane treatment | 586 ± 15 | 104 ± 15 | 48.9 ± 3.1 | 17.1 ± 7.6 | 3.5 ± 0.5 | 3.6 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seoane-Rivero, R.; Germán, L.; Santos, F.; Gondra, K. Development of New Hybrid Composites for High-Temperature Applications. Polymers 2023, 15, 4380. https://doi.org/10.3390/polym15224380

Seoane-Rivero R, Germán L, Santos F, Gondra K. Development of New Hybrid Composites for High-Temperature Applications. Polymers. 2023; 15(22):4380. https://doi.org/10.3390/polym15224380

Chicago/Turabian StyleSeoane-Rivero, Rubén, Lorena Germán, Fernando Santos, and Koldo Gondra. 2023. "Development of New Hybrid Composites for High-Temperature Applications" Polymers 15, no. 22: 4380. https://doi.org/10.3390/polym15224380

APA StyleSeoane-Rivero, R., Germán, L., Santos, F., & Gondra, K. (2023). Development of New Hybrid Composites for High-Temperature Applications. Polymers, 15(22), 4380. https://doi.org/10.3390/polym15224380