Holographic Properties of Irgacure 784/PMMA Photopolymer Doped with SiO2 Nanoparticles

Abstract

:1. Introduction

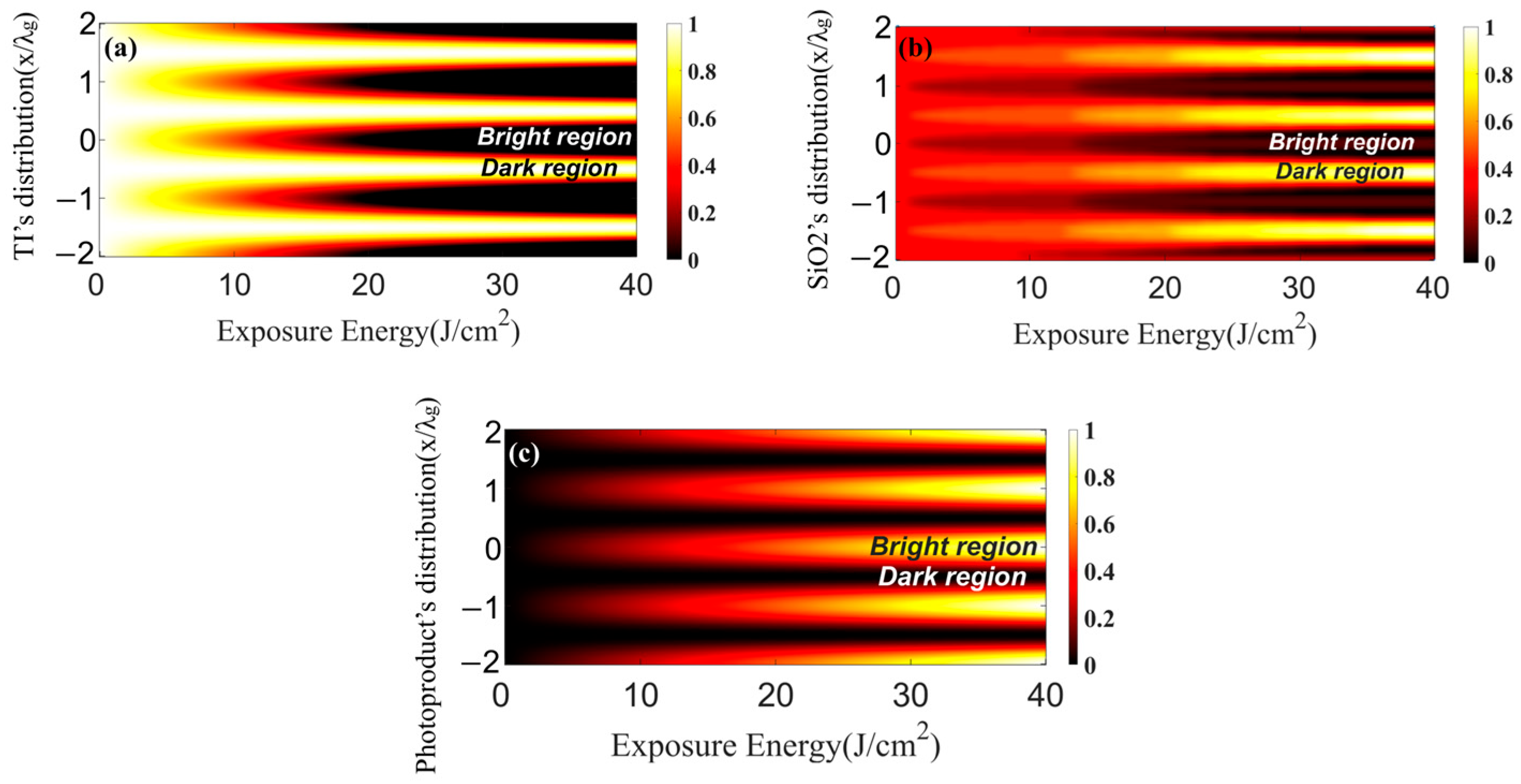

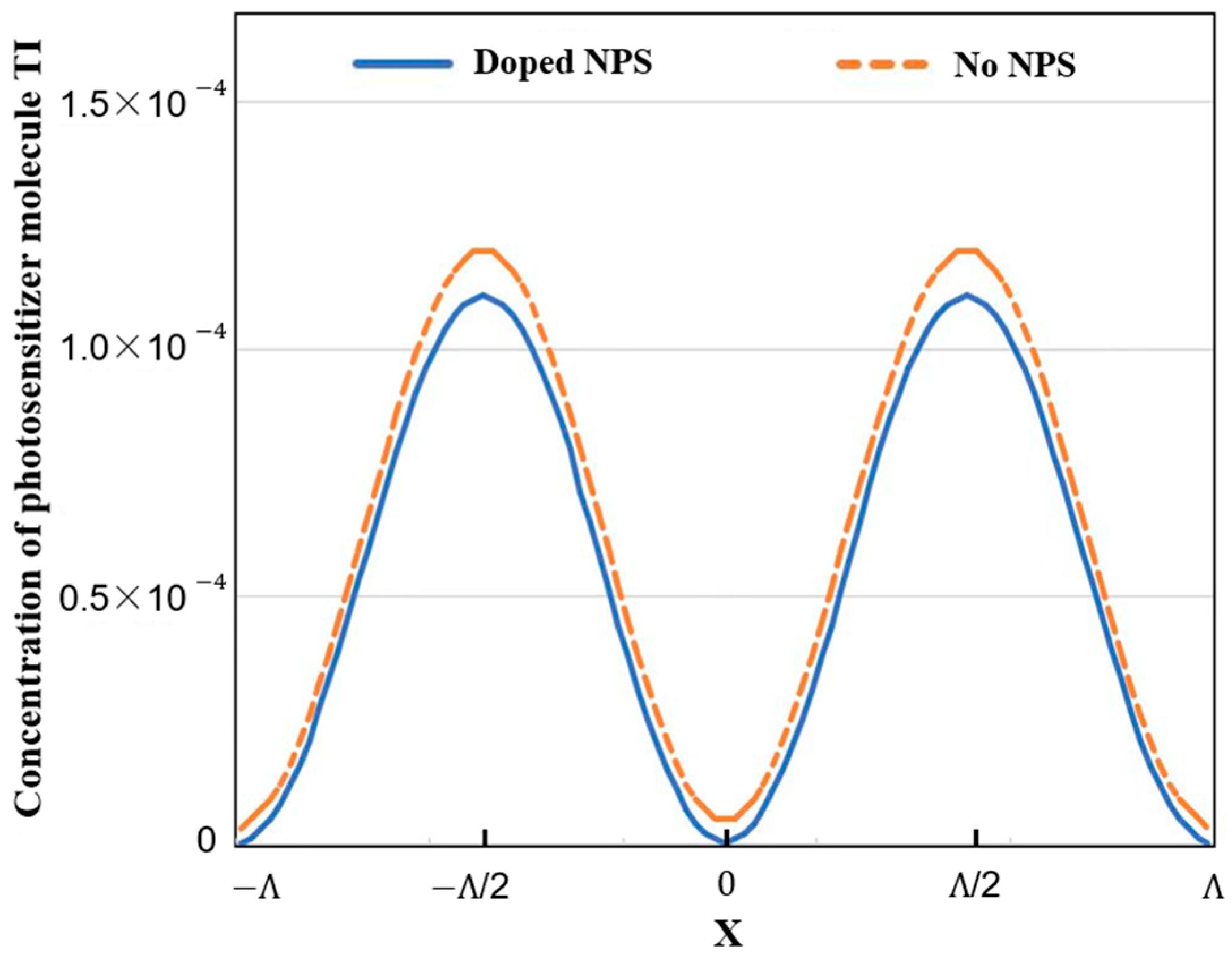

2. Mutual Diffusion Model

3. Preparation Process

4. Material Characteristics

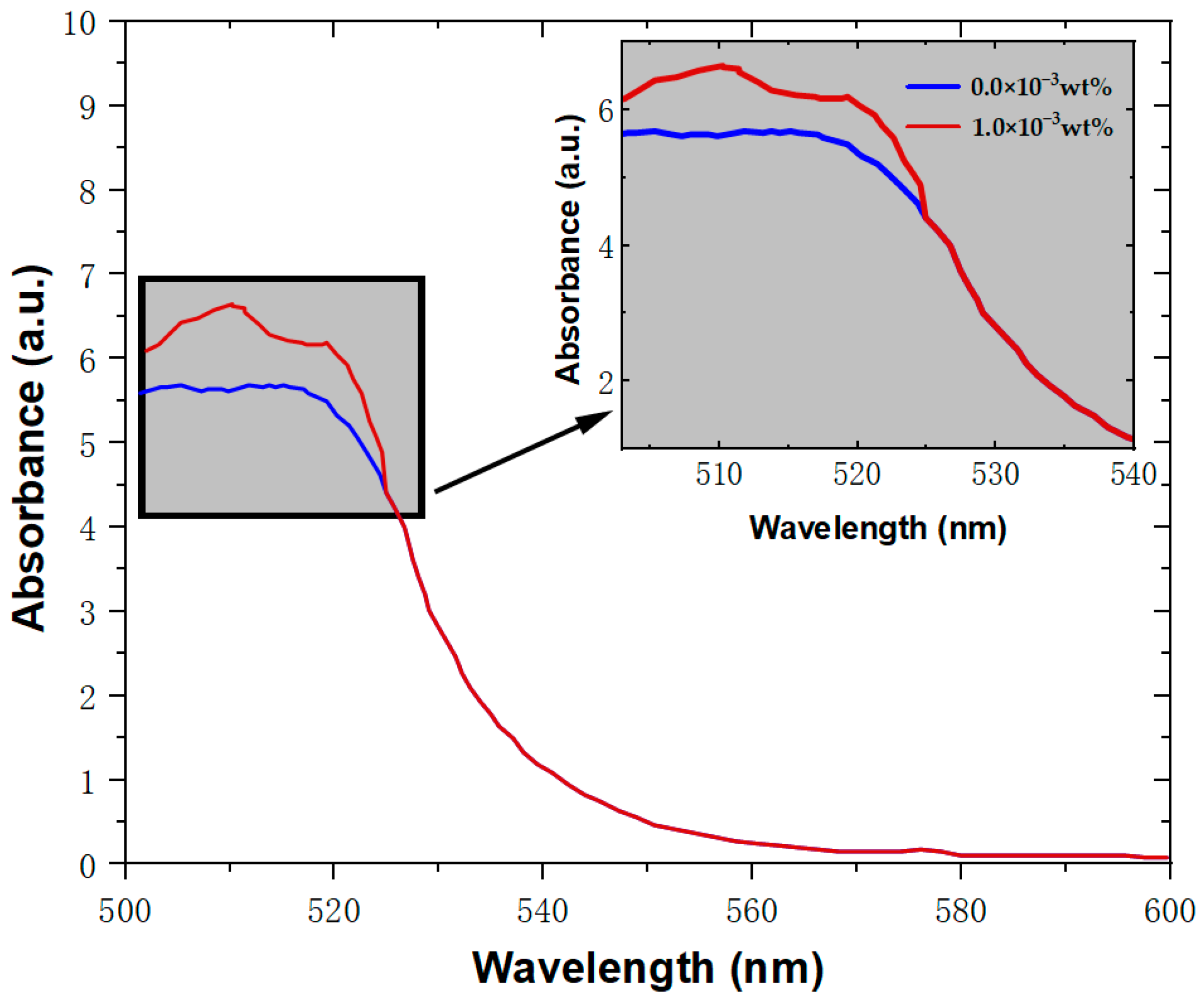

4.1. Spectra Measurements

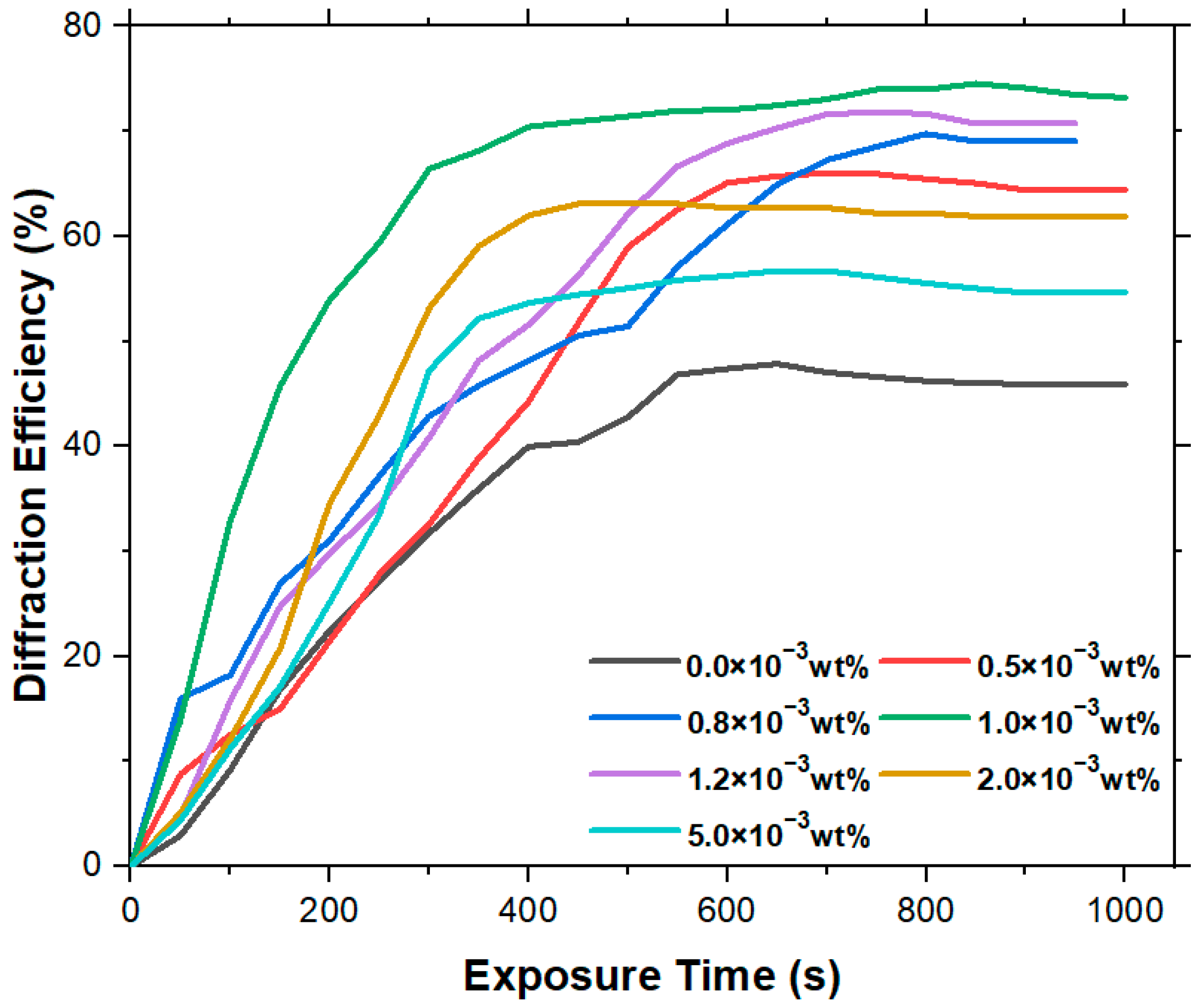

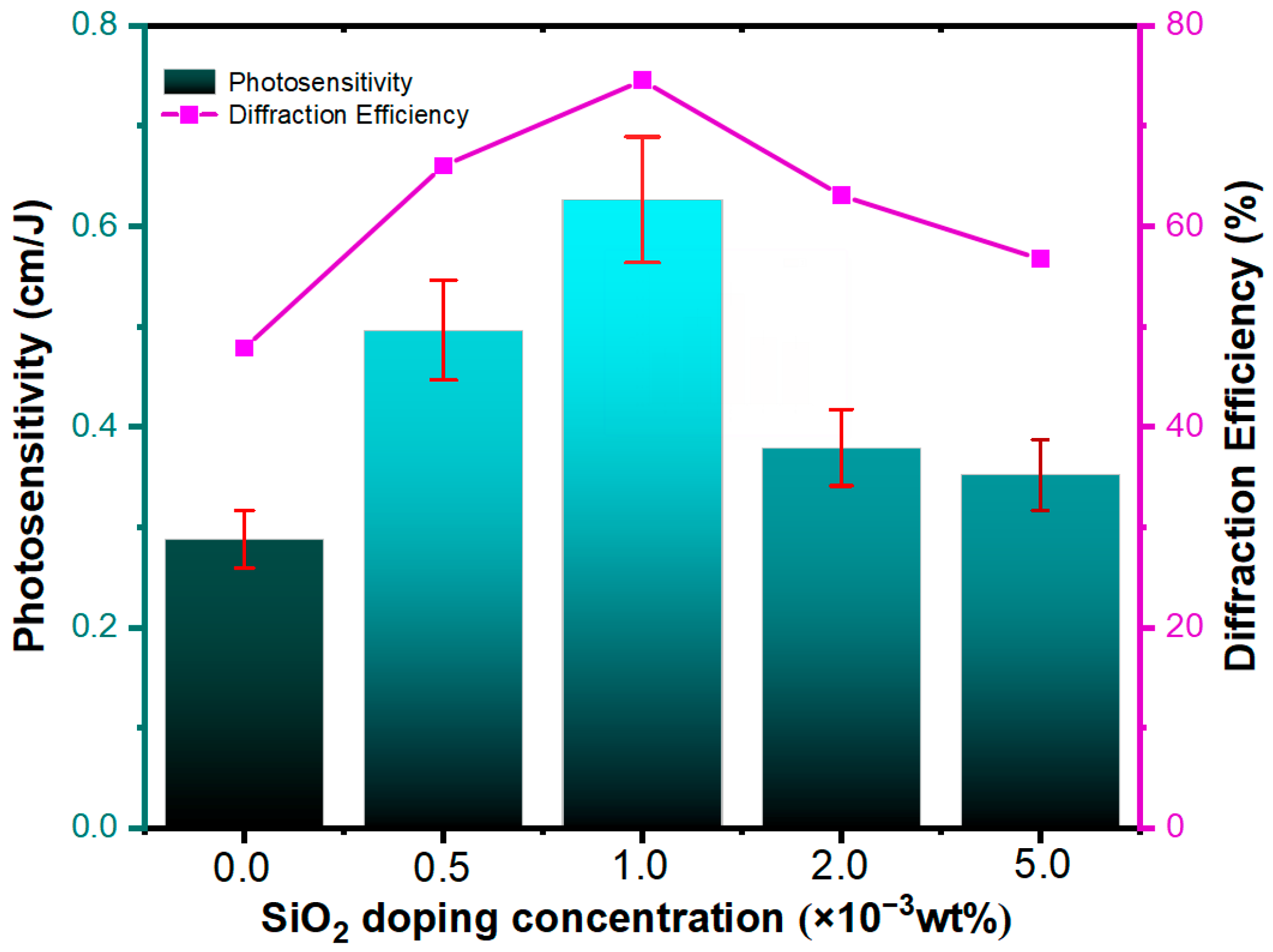

4.2. Diffraction Efficiency

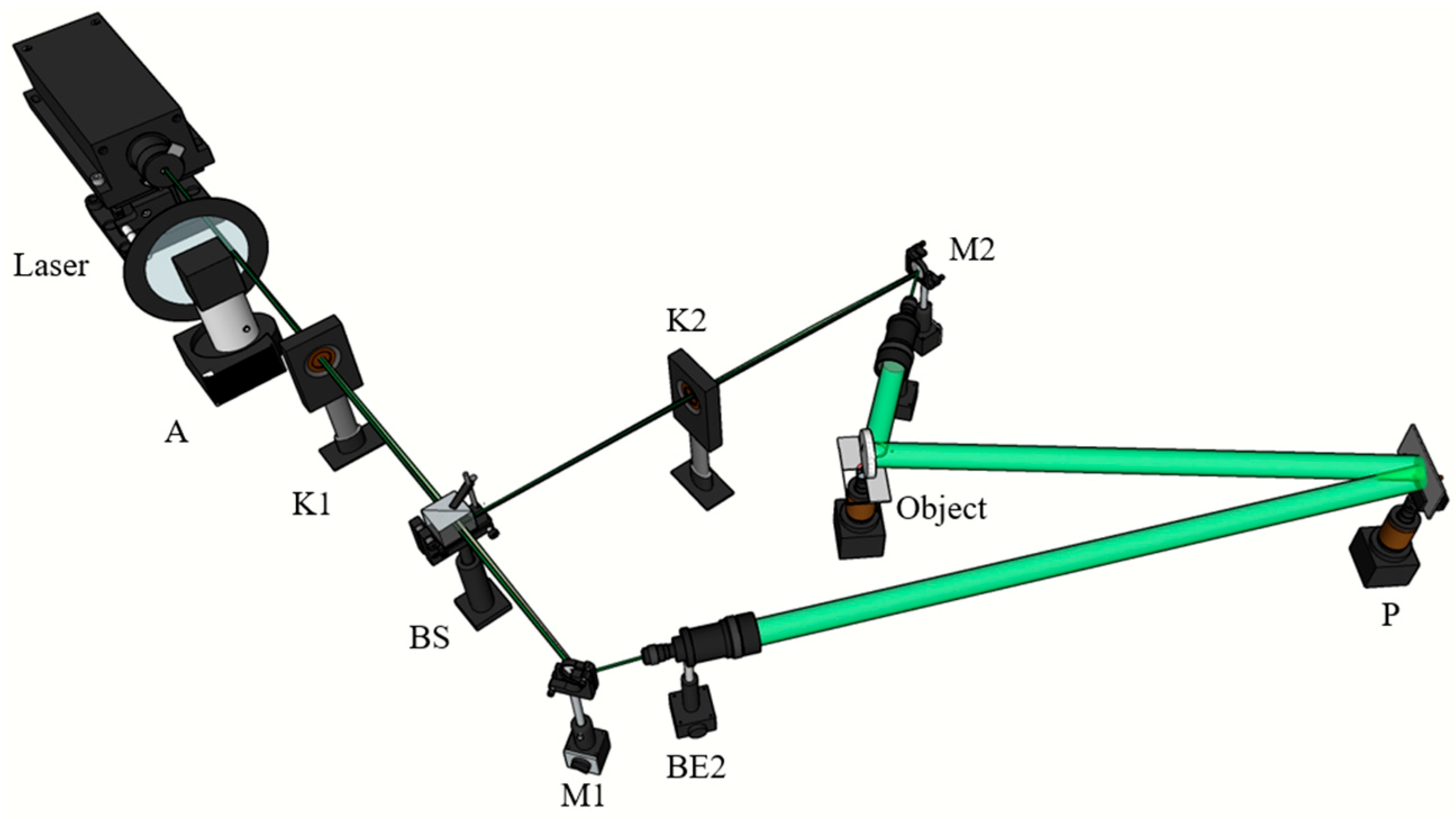

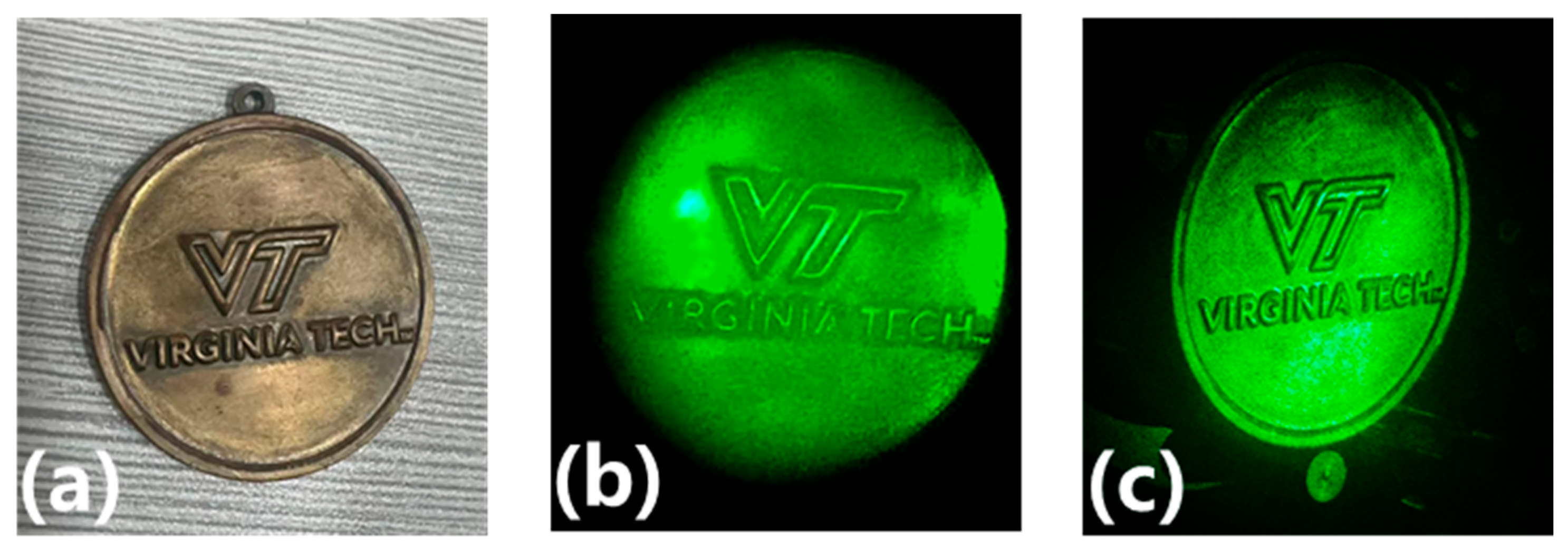

4.3. Recording and Reconstruction of Object Volume Hologram

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Heerden, P.J. Theory of optical information storage in solids. Appl. Opt. 1963, 2, 393–400. [Google Scholar] [CrossRef]

- Tan, X.; Lin, X.; Wu, A.; Zang, J. High density collinear holographic data storage system. Front. Optoelectron. 2014, 7, 443–449. [Google Scholar] [CrossRef]

- Rakuljic, G.A.; Leyva, V.; Yariv, A. Optical data storage by using orthogonal wavelength-multiplexed volume holograms. Opt. Lett. 1992, 17, 1471–1473. [Google Scholar] [CrossRef] [PubMed]

- Colburn, W.S.; Haines, K.A. Volume hologram formation in photopolymer materials. Appl. Opt. 1971, 10, 1636–1641. [Google Scholar] [CrossRef] [PubMed]

- Steckman, G.J.; Solomatine, I.; Zhou, G.; Psaltis, D. Characterization of phenanthrenequinone-doped poly (methyl methacrylate) for holographic memory. Opt. Lett. 1998, 23, 1310–1312. [Google Scholar] [CrossRef] [PubMed]

- Mumbru, J.; Solomatine, I.; Psaltis, D.; Lin, S.H.; Hsu, K.Y.; Chen, W.-Z.; Whang, W.T. Comparison of the recording dynamics of phenanthrenequinone-doped poly (methyl methacrylate) materials. Opt. Commun. 2001, 194, 103–108. [Google Scholar] [CrossRef]

- Hsu, K.Y.; Lin, S.H.; Hsiao, Y.N.; Whang, W.T. Experimental characterization of phenanthrenequinone-doped poly (methyl methacrylate) photopolymer for volume holographic storage. Opt. Eng. 2003, 42, 1390–1396. [Google Scholar]

- Liu, P.; Chang, F.; Zhao, Y.; Li, Z.; Sun, X. Ultrafast volume holographic storage on PQ/PMMA photopolymers with nanosecond pulsed exposures. Opt. Express 2018, 26, 1072–1082. [Google Scholar] [CrossRef]

- Liu, P.; Sun, X.; Zhao, Y.; Li, Z. Ultrafast volume holographic recording with exposure reciprocity matching for TI/PMMAs application. Opt. Express 2019, 27, 19583–19595. [Google Scholar] [CrossRef]

- Tomlinson, W.J.; Chandross, E.A.; Weber, H.P.; Aumiller, G.D. Multicomponent photopolymer systems for volume phase holograms and grating devices. Appl. Opt. 1976, 15, 534–541. [Google Scholar] [CrossRef]

- Russo, J.M.; Castillo, J.E.; Kostuk, R.K. Effect of silicon dioxide nanoparticles on the characteristics of PQ/PMMA holographic filters. Int. Soc. Opt. Photonics 2007, 6653, 66530D. [Google Scholar]

- Hata, E.; Tomita, Y. Order-of-magnitude polymerization-shrinkage suppression of volume gratings recorded in nanoparticle-polymer composites. Opt. Lett. 2010, 35, 396–398. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Hu, P.; Zeng, Z.; Jin, J.; Wu, J.; Chen, X.; Liu, J.; Li, Q.; Chen, M.; Zhang, Z.; et al. Phenanthraquinone-Doped Polymethyl Methacrylate Photopolymer for Holographic Recording. Molecules 2022, 27, 6283. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Gleeson, M.R.; Guo, J.; Sheridan, J.T.; Tolstik, E.; Matusevich, V.; Kowarschik, R. Modeling the photochemical kinetics induced by holographic exposures in PQ/PMMA photopolymer material. JOSA B 2011, 28, 2833–2843. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Wang, J.; Jiang, Y.; Sun, X. Study on holographic characteristics in ZnMA doped PQ-PMMA photopolymer. Opt. Commun. 2011, 284, 2784–2788. [Google Scholar] [CrossRef]

- Liu, P.; Zhao, Y.; Li, Z.; Sun, X. Improvement of ultrafast holographic performance in silver nanoprisms dispersed photo-polymer. Opt. Express 2018, 26, 6993–7004. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, P.; Huang, Z.; Wang, J.; Song, H.; Chen, X.; Lin, X.; Wu, T.; Tan, X. Significant enhancement of the polarization holographic performance of photopolymeric materials by introducing graphene oxide. ACS Appl. Mater. Interfaces 2021, 13, 27500–27512. [Google Scholar] [CrossRef]

- Luo, Y.; Gelsinger, P.J.; Barton, J.K.; Barbastathis, G.; Kostuk, R.K. Optimization of multiplexed holographic gratings in PQ-PMMA for spectral-spatial imaging filters. Opt. Lett. 2008, 33, 566–568. [Google Scholar] [CrossRef]

- Li, C.; Cao, L.; Li, J.; He, Q.; Jin, G.; Zhang, S.; Zhang, F. Improvement of volume holographic performance by plasmon-induced holographic absorption grating. Appl. Phys. Lett. 2013, 102, 2736. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, S.; Li, C.; Zhang, Y.; Fang, W.; Lu, Y.; Guo, C.; Wang, R.; Zhang, Y.; Xu, W.; et al. Vortex beam generation from reduced graphene oxide(rGO)-polymer. Opt. Mater. Express 2019, 9, 4497. [Google Scholar] [CrossRef]

- Hu, P.; Chen, Y.; Li, J.; Wang, J.; Liu, J.; Wu, T.; Tan, X. Impact of fullerene on the holographic properties of PQ/PMMA photopolymer. Compos. Sci. Technol. 2022, 221, 109335. [Google Scholar] [CrossRef]

- Hsiao, Y.N.; Whang, W.T.; Lin, S.H. Analyses on physical mechanism of holographic recording in phenanthrenequi-none-doped poly (methyl methacrylate) hybrid materials. Opt. Eng. 2004, 43, 1993–2002. [Google Scholar] [CrossRef]

- Mahilny, U.; Trofimova, A.; Nazarov, S.; Tolstik, A.; Heintzmann, R.; Tolstik, E. Highly concentrated phenanthrenequinone–polymethylmethacrylate compo-site for thick reflection holograms recording at 532 nm. Opt. Mater. Express 2016, 6, 3427–3437. [Google Scholar] [CrossRef]

- Lin, S.H.; Hsu, K.Y.; Chen, W.Z.; Whang, W.T. Phenanthrenequinone-doped poly (methyl methacrylate) photopolymer bulk for volume holographic data storage. Opt. Lett. 2000, 25, 451–453. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Liu, Y.; Hong, Y.; Zang, J.; Kang, G.; Zhao, T.; Tan, X.; Shimura, T. Volume polarization holographic recording in phenanthrenequinone doped poly (MMA-Co-BzMA) photopolymer. Chem. Lett. 2018, 47, 520–523. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Y.; Hong, Y.; Zang, J.; Wu, A.; Zhao, T.; Kang, G.; Tan, X.; Shimura, T. Improving the polarization-holography performance of PQ/PMMA photopolymer by doping with THMFA. Opt. Express 2018, 26, 17794–17803. [Google Scholar] [CrossRef]

- Liu, P.; Sun, X.; Zhao, Y.; Li, Z. Holographic stability and storage capacity on bulk green-light sensitive TI/PMMA materials. AIP Adv. 2019, 9, 035034. [Google Scholar] [CrossRef]

- Lin, S.H.; Hsiao, Y.N.; Hsu, K.Y. Preparation and characterization of Irgacure 784 doped photopolymers for holographic data storage at 532 nm. J. Opt. A Pure Appl. Opt. 2009, 11, 024012. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, F.; Hong, Y.; Zang, J.; Kang, G.; Tan, X. Volume holographic recording in Irgacure 784-doped PMMA photopolymer. Opt. Express 2017, 25, 20654–20662. [Google Scholar] [CrossRef]

- Liu, P.; Wang, L.; Zhao, Y.; Li, Z.; Sun, X. Holographic memory performances of titanocene dispersed poly (methyl methacrylate) photopolymer with different preparation conditions. Opt. Mater. Express 2018, 8, 1441–1453. [Google Scholar] [CrossRef]

- Suzuki, N.; Tomita, Y. Real-time phase-shift measurement during formation of a volume holographic grating in nanopar-ticle-dispersed photopolymers. Appl. Phys. Lett. 2006, 88, 011105. [Google Scholar] [CrossRef]

- Tomita, Y.; Chikama, K.; Nohara, Y.; Suzuki, N.; Furushima, K.; Endoh, Y. Two-dimensional imaging of atomic distribution morphology created by holo-graphically induced mass transfer of monomer molecules and nanoparticles in a silica-nanoparticle-dispersed pho-topolymer film. Opt. Lett. 2006, 31, 1402–1404. [Google Scholar] [CrossRef] [PubMed]

- Karpov, G.M.; Obukhovsky, V.V.; Smirnova, T.N.; Lemeshko, V. Spatial transfer of matter as a method of holographic recording in photoformers. Opt. Commun. 2000, 174, 391–404. [Google Scholar] [CrossRef]

- Yu, D.; Liu, H.; Jiang, Y.; Sun, X. Mutual diffusion dynamics with nonlocal response in SiO2 nanoparticles dispersed PQ-PMMA bulk photopolymer. Opt. Express 2011, 19, 13787–13792. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Cao, L.; He, Q.; Jin, G. Holographic kinetics for mixed volume gratings in gold nanoparticles doped photopolymer. Opt. Express 2014, 22, 5017–5028. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Yu, D.; Wang, W.; Geng, Y.; Yang, L. Mutual diffusion dynamics as matter transfer mechanism in inorganic nanoparticles dispersed photopolymer. Opt. Commun. 2014, 330, 77–84. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Liu, S.; Guo, J.; Sheridan, J.T. Non-local photo-polymerization kinetics including multiple termination mechanisms and dark reactions: Part III. Primary radical generation and inhibition. J. Opt. Soc. Am. B 2010, 27, 1804–1812. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Zhang, J.; Zhang, Y. Holographic properties and display of photopolymer with high concentration photoinitiator doped with SiO2 Nanoparticles [Invited]. In Proceedings of the OSA Imaging and Applied Optics Congress 2021 (3D, COSI, DH, ISA, pcAOP), Vancouver, BC, Canada, 19–23 July 2021. paper DTh1C–3. [Google Scholar]

| Name | Chemical Formula | Appearance | Purity (%) |

|---|---|---|---|

| MMA | C5H8O2 | Colorless liquid | 99.5 |

| AIBN | C8H12N4 | Crystalline powder | 99.0 |

| Irgacure 784 | C30H22F4N2Ti | Orange powder | 99.2 |

| MIBK | C6H12O | Colorless liquid | 99.5 |

| Quartz | SiO2 | White powder (particle diameter: 20 nm) | 99.0 |

| Components | MMA | Irgacure 784 | AIBN | Quartz |

|---|---|---|---|---|

| A1 (wt%) | 100.0 | 4.0 | 1.2 | |

| A2 (wt%) | 100.0 | 4.0 | 1.2 | |

| A3 (wt%) | 100.0 | 4.0 | 1.2 | |

| A4 (wt%) | 100.0 | 4.0 | 1.2 | |

| A5 (wt%) | 100.0 | 4.0 | 1.2 | |

| A6 (wt%) | 100.0 | 4.0 | 1.2 | |

| A7 (wt%) | 100.0 | 4.0 | 1.2 |

| Materials | Nanoparticles | S (cm/J) | (%) | Year/Ref. |

|---|---|---|---|---|

| PQ (1.0wt%)/PMMA | - | 0.027 | 3.3 | 2017 [29] |

| PQ (1.2wt%)/PMMA | SiO2 | - | 49.3 | 2011 [34] |

| PQ (1.2wt%)/PMMA | C60 | 0.59 | 72.0 | 2022 [21] |

| Irgacure 784 (5.0wt%)/PMMA | - | 0.571 | 52.0 | 2017 [29] |

| Irgacure 784 (4.0wt%)/PMMA | - | 0.288 | 47.8 | This study |

| Irgacure 784 (4.0wt%)/PMMA | SiO2 | 0.627 | 74.5 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Fu, Q.; Zhang, Y.; Zhang, B. Holographic Properties of Irgacure 784/PMMA Photopolymer Doped with SiO2 Nanoparticles. Polymers 2023, 15, 4391. https://doi.org/10.3390/polym15224391

Wang J, Fu Q, Zhang Y, Zhang B. Holographic Properties of Irgacure 784/PMMA Photopolymer Doped with SiO2 Nanoparticles. Polymers. 2023; 15(22):4391. https://doi.org/10.3390/polym15224391

Chicago/Turabian StyleWang, Jundi, Qingyang Fu, Yaping Zhang, and Bing Zhang. 2023. "Holographic Properties of Irgacure 784/PMMA Photopolymer Doped with SiO2 Nanoparticles" Polymers 15, no. 22: 4391. https://doi.org/10.3390/polym15224391