1. Introduction

Ab initio emulsion polymerizations (EPs) are complex multiphase processes composed of key ingredients: water, monomers, initiator, surfactant, chain transfer agent, inhibitor, and buffer [

1,

2]. A commercial recipe may contain more than twenty ingredients [

1]. Some relevant products of industrial EP include adhesives, styrene-butadiene rubber (SBR) for carpet backing, textile fibers, high impact strength materials, emulsion paints, bone marrow transplantations, drug delivery systems, conducting polymers, sealants, and cosmetic products [

3]. Their average polymer characteristics can be controlled using on-line monitoring techniques such as Raman, near-infrared (NIR), and photon density wave (PDW) spectroscopy [

4].

Population balance equations (PBEs) have been extensively employed to capture distinct phenomena affecting the evolution of the particle size distribution (PSD) of entities such as cells, droplets, crystals, and polymer particles [

5,

6,

7,

8]. PBEs are mathematically a set of hyperbolic partial integro-differential equations (PDEs) whose solutions can be attained by either deterministic or stochastic numerical methods [

9,

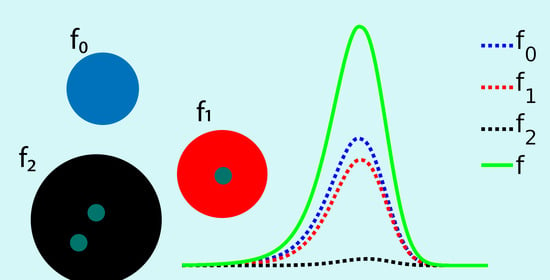

10]. In EPs, the number of radicals per polymer particle may vary from zero to a maximum number (

), eventually leading to an intractable set of PDEs. However, some simplifications are considered to keep the problem tractable. On the one hand, some approaches neglect particles with two or more radicals: the 0-1 model (polymer particles contain either zero or one radical) and the 0-1-2 model (a maximum of two radicals per particle). On the other hand, in another approach, it is assumed that all particles of the same mass (or size) contain the same average number of radicals,

. This hypothesis is used in the pseudo-bulk (PB) approach and in an implementation using the Fokker–Planck equation (FPE) [

11]. A third approach has been built considering that small particles may follow the 0-1 model, whereas large particles may obey the PB approach [

12].

A brief summary of the main features of modeling approaches for emulsion homo- and copolymerizations is presented in

Table 1.

The numerical solution of hyperbolic PDE’s is challenging due to the possible presence of steep fronts as in the case of the inviscid Burger’s equation representing shock-waves [

22]. One way to reduce the set of PDEs to a set of ordinary differential equations (ODEs) in time is using the weighted residual method (MWR) on finite elements, in which the solution in each element is approximated with either first-, second-, or third-order polynomials of the internal coordinate (mass or diameter particle) with time-dependent coefficients [

23]. Both the orthogonal collocation on finite elements method (OCFE) and the Galerkin methods, two kinds of MWR, are widely used in the estimation of PSD in EPs [

5,

24]. Increasing the number of elements will improve estimates of the PSD, especially if sharp fronts are expected [

25]. Recently, the evolution of seeded EPs was studied by a multiscale model built with kinetic Monte Carlo, the Fokker–Planck equation (FPE), and solved with the Galerkin method, in conjunction with traditional mass and energy balances [

13]. The shape of the PSD was adjusted by varying the size-dependent diffusion coefficient in the FPE. Another practical type of MWR is the method of moments (MMs), which is particularly useful for the computation of relevant average properties such as the number average particle diameter (

) and the average number of radicals per particle (

). Recently, a model based on the MMs for the 0-1-2 model has captured the effect of the number of reactors on the monomer conversion, molar mass, and copolymer composition of emulsion copolymerization of styrene-butadiene rubber and acrylonitrile-butadiene rubber in a train of CSTRs [

17].

Another technique that has been successfully used to solve the PDE’s representing the PSD in EP is the finite volume (FV) method with a semi-discrete high-resolution scheme that has been implemented to solve the 0-1 and 0-1-2 approaches [

19,

20]. Such models accounted for homogenous nucleation and coagulation rates and were utilized, for instance, to analyze the effect of initiator and surfactant concentrations on the broadness of the PSD of poly(vinyl acetate) [

20]. In another work, it was shown that the 0-1-2 and PB models produce similar results for seeded polymerizations, whereas the 0-1 model underestimates the growth rate [

19]. As pointed out by Vale and McKenna, finite differences (FE) and FV methods are closely related, although FV may present some advantages [

26].

In the last 2–3 decades, some groups have studied and contrasted numerical and structural aspects of PSD modeling in EP, as well as their interactions. The hyperbolic nature of the PDE’s may lead to numerical oscillations and numerical dispersion (spurious dispersion added to the solution) when steep fronts arise, but their presence and severity will depend on the specific problem being solved: ab initio or seeded polymerizations and the presence or not of coagulation. Saldívar and Ray used OCFE in a moving polymer-mass frame to solve the very challenging problem of (unseeded) ab initio batch EP without coagulation terms (which smooth out the front) using a PB model; they had to add a (small) artificial numerical diffusion term to avoid numerical oscillations that otherwise would occur at the front [

14]. Unfortunately, as far as we know, no other group has attempted to solve this problem. Some other research groups have published simulation results of PSD models that did not use adequate numerical methods and therefore the simulated PSD shape generated is not reliable [

11,

27,

28,

29]; therefore, adequate numerical methods are needed to trust the solution and detect real structural deficiencies of the models used [

11]. Vale and McKenna (2005) concluded that FV/FD methods coupled with high-resolution discretization schemes are the most efficient ones in terms of computation time and provide enough precision of the solution, avoiding numerical oscillations and numerical dispersion [

26]. On the other hand, Hosseini et al. criticized deterministic PBE models arguing that they do not correctly predict the broadness of the distribution (theoretical predictions are too narrow compared with actual experimental data); however, to prove their point, they use a pseudo-bulk model and even though they mention that calculations were performed also with a 0-1 model, they do not show the results and apparently they only studied one case with this alternative model [

11]. On these bases, these authors conclude that deterministic models are structurally inadequate and fix the problem by adding a stochastic term to the PDE, turning it into the Fokker–Planck equation. Although these groups, particularly Vale and McKenna, have studied a variety of cases (pure growth, nucleation and growth, etc.) none of them have studied in detail the numerically demanding case of a batch ab initio (nucleation) EP with no seed nor coagulation that presents a sharp front prone to numerical instabilities, at least when a PB model is used [

18,

19,

26].

From these studies, there seems to be agreement on the fact that FE/FV methods with a high-resolution discretization scheme, as well as OCFE, are capable of providing sufficiently precise numerical solutions of the PBE models, but an ultimate test to further explore some limitations of these methods would be the solution of the ab initio batch EP with no coagulation terms (presence of steep fronts), labeled from here on as ABIBEPNC [

14]. It is not clear if this steep front is present only when a PB model is used and if, as one could guess, it smoothens when a 0-1 or 0-1-2 model is used.

With this panorama in mind, in this work, the following issues, aims, and related questions will be addressed: (i) to further test different numerical techniques, in particular FV/FD and OCFE methods, to assess their suitability and limitations to solve the PBEs arising in the modeling of the PSD in EP under different simulated conditions, in particular for the challenging ABIBEPNC problem; (ii) to investigate if the steep front in the ABIBEPNC problem, not experimentally observed, is a structural problem due to the use of a PB model and if using a 0-1 or 0-1-2 model the front is smoothed out; and (iii) to investigate if the apparently narrower broadness of the distribution predicted by theoretical models compared with experimental PSDs is a structural problem of the type of (deterministic) models used so far, and if the models need to incorporate stochastic terms, as suggested by Hosseini et al [

11].

To answer these questions, in this contribution, we provide a mathematical model for the ab initio EP of vinyl monomers in batch reactors by combining PBEs and kinetic and thermodynamic models. From the modeling point of view, firstly, the model can consider a maximum number of radicals per particle, , which will allow the tracking of the individual polymer particle populations, , whose evolution will render the shape of the PSD. Secondly, in order to reduce numerical dispersion and dissipation, two efficient numerical methods are implemented with fixed grids. The first method is the orthogonal collocation method on finite elements (OCFE) using third-order polynomials on each element, while the second method is the FV method with a high resolution scheme. Finally, experimental PSDs measured by dynamic light scattering (DLS) for the EP homopolymerizations of Sty and MMA at 60 °C, as well as the copolymerization of Sty-MMA (50/50; mol/mol) at 50 and 60 °C, generated by our laboratory are included for comparison with model predictions.

5. Conclusions

In this work, we built a deterministic mathematical model to analyze the polymer reaction kinetics and PSD development of ab initio EP of vinyl monomers. The model combines kinetic and thermodynamic models with population balance equations. Four experimental cases obtained from our laboratory were addressed involving homopolymerization of Sty and MMA using sodium SDS/KPS at 60 °C, as well as copolymerization of Sty-MMA at 50 and 60 °C, in a 100 mL reactor operated under batch conditions. The computation times were relatively short for the homopolymerization cases, whereas the copolymerization cases required considerably larger CPU times (4–5 h). The model quantitatively matched quite well with the experimental data of monomer conversion and Sauter average particle diameter with minimal parameter fitting. The study allowed us to make progress in answering the issues defined in the introduction of this work. Regarding the numerical techniques to solve the PBE equations, our findings confirm those of previous researchers; the FV method with a high resolution scheme provides non-oscillatory computation-time-efficient solutions for 0-1 and 0-1-2 models; however, this technique is not capable of solving the challenging ABIBEPNC problem when a PB model is used. On the other hand, OCFE on a fixed mesh with an artificial numerical diffusion term can provide non-oscillatory solutions for 0-1 and 0-1-2 models, but it cannot solve the ABIBEPNC problem with a PB model unless a moving mass domain is used. More numerical experiments are needed to have a complete map of the applicability and limitations of the available numerical techniques for this type of problems. Concerning the steep front exhibited by the solution of the ABIBEPNC problem with a PB model, which is not experimentally observed, we conclude that this is a structural problem associated with the use of a PB model consisting of a single hyperbolic PDE; when a 0-1 or 0-1-2 model is used, the front is smoothed out due to the exchange of particles among the different classes. Regarding the last issue investigated, partially challenging the conclusion of Hosseini et al., we conclude that for some problems, the broadness of the model-predicted PSD is similar to the experimental one, although for some other cases, the predicted PSD seems to be narrower than the experimental one. However, it seems premature to conclude that this discrepancy requires a stochastic term to fix the problem, especially considering the limitations of experimental PSDs estimated by DLS. Our comparisons of model-predicted and experimental PSDs have been based on distributions estimated by DLS. These will have to be confirmed by TEM measurements that are currently being conducted in our lab and will be discussed in a future publication. Although some comparisons of experimental PSDs estimated by DLS and electron microscopy (scanning and transmission) have been made [

11,

29], this is limited to a few cases, so additional comparisons between these techniques should be made to reach robust conclusions.

In general, when using 0-1 and 0-1-2 models, the PSD exhibits smooth fronts that follow the experimental trends. A value of was initially considered; however, greater values for did not improve the observed trends. If realistic PSDs are to be predicted, the use of PB models is discouraged as they suffer from a structural problem associated with the use of a single hyperbolic PDE to represent the PSD, which is more evident in some problems, e.g., the ABIBEPNC problem.