Properties of Hyper-Elastic-Graded Triply Periodic Minimal Surfaces

Abstract

:1. Introduction

2. Method and Materials

2.1. TPMS Development

2.1.1. TPMS Solid–Void Boundary Definitions

- Schoen Gyroid

- 2.

- Schwarz Diamond

- 3.

- Schwarz Primitive

2.1.2. Modeling and Fabrication

2.2. Mechanical Tests and Characterization

- the experimental Young’s modulus and plateau stress related to predicted values by theoretical models;

- energy absorption, recovery, and dissipation extracted from σ-ε diagrams;

- and normalized energy absorption per unit volume (W/Es) vs. normalized peak stress (σp/Es).

3. Results

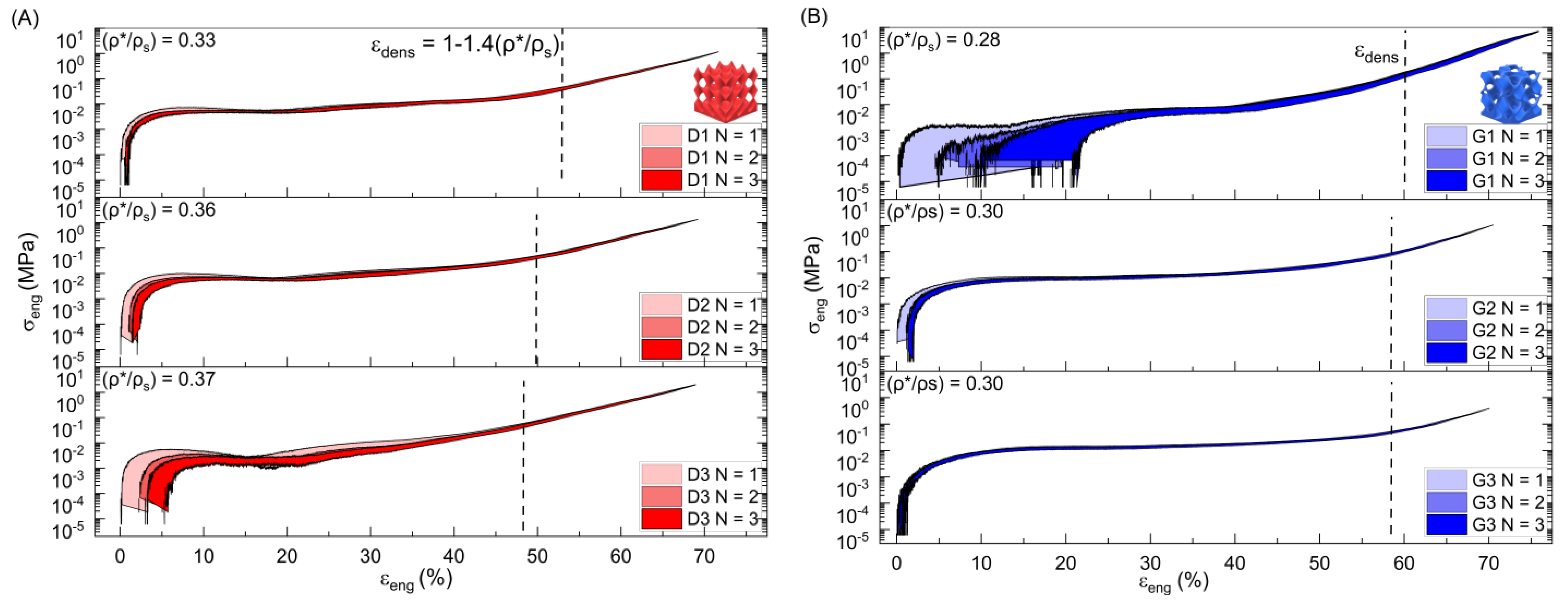

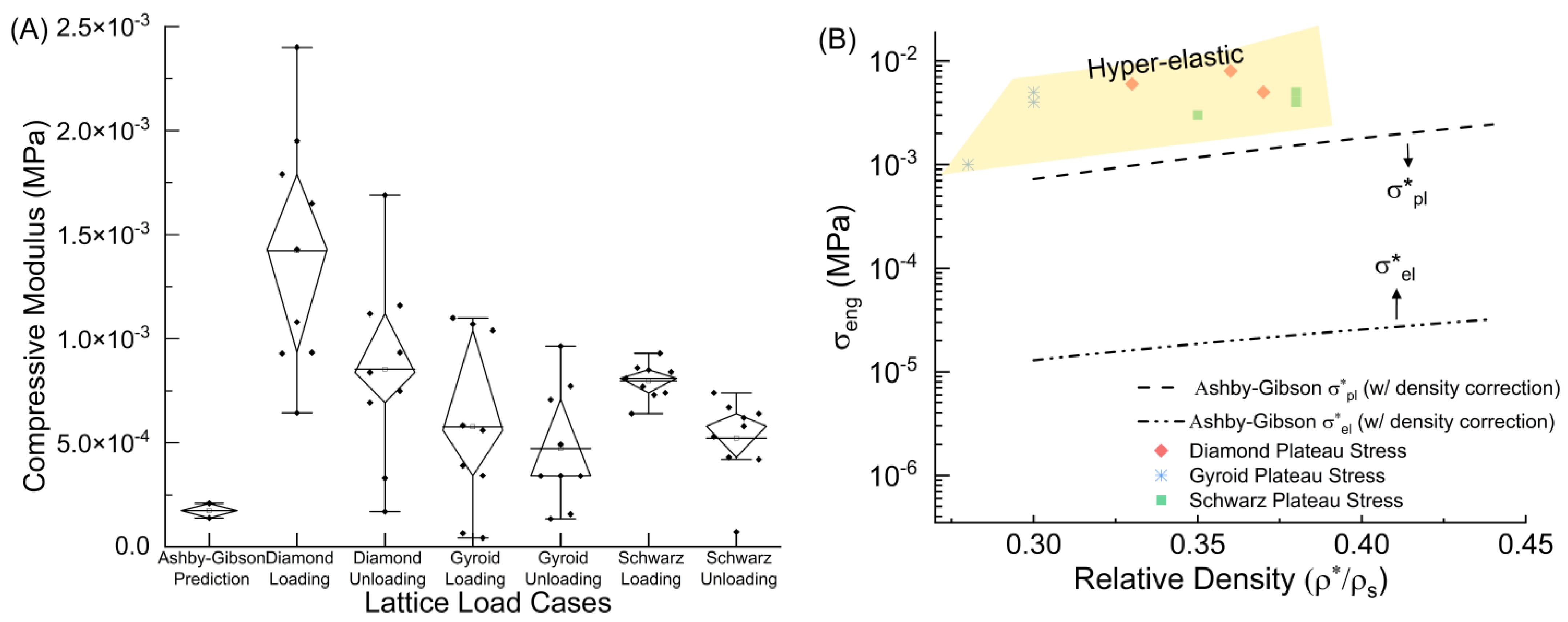

3.1. Compressive Mechanical Properties

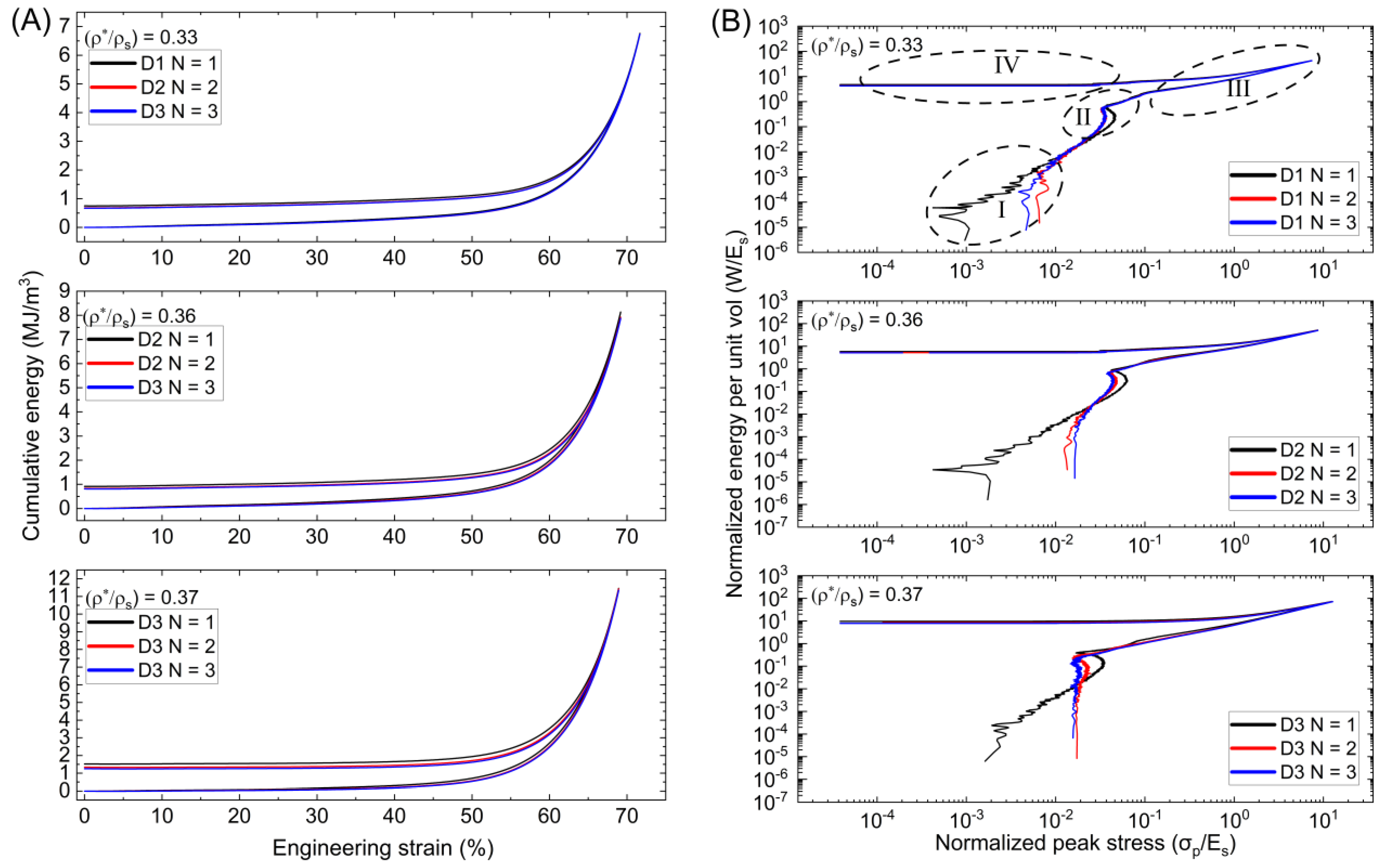

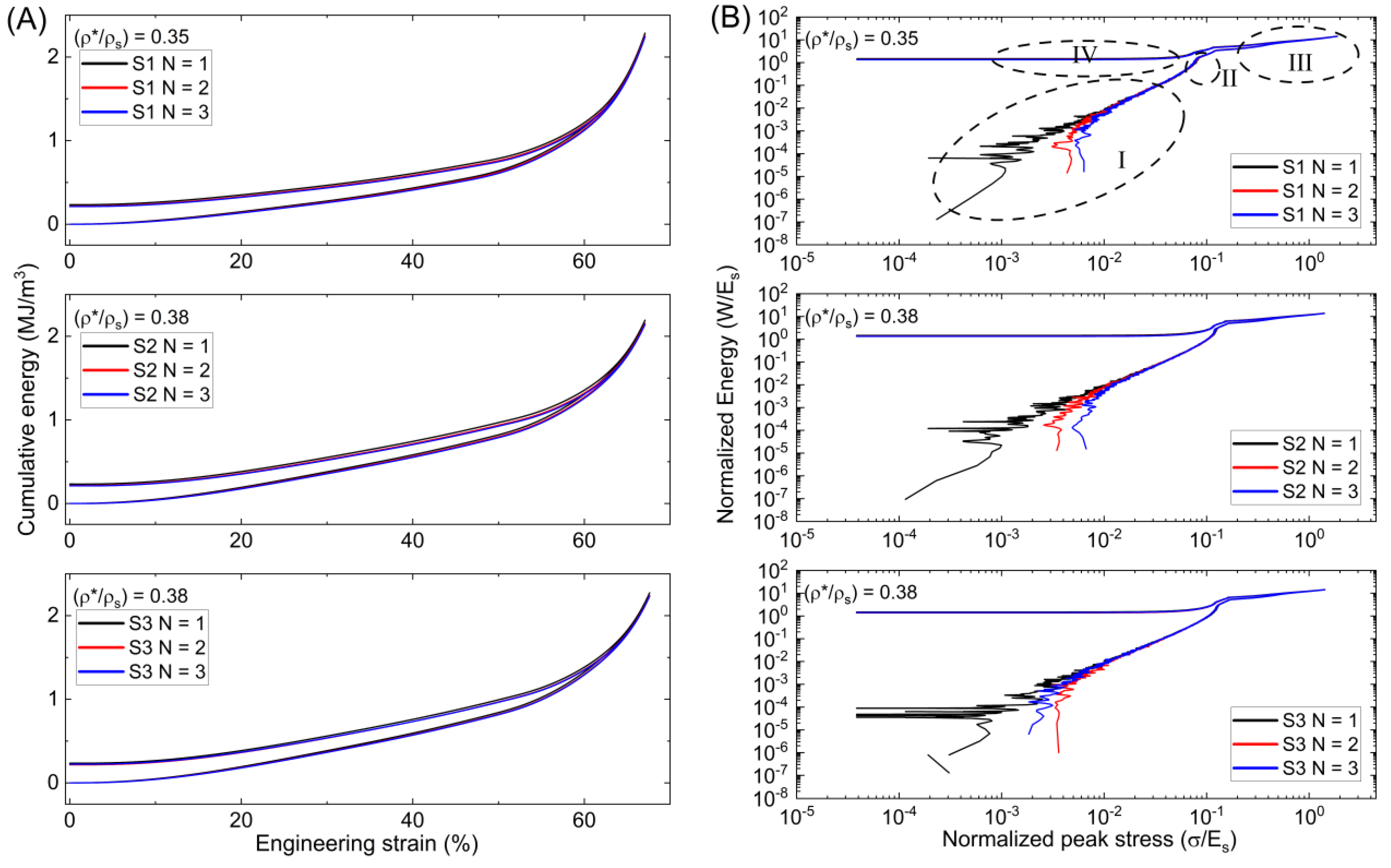

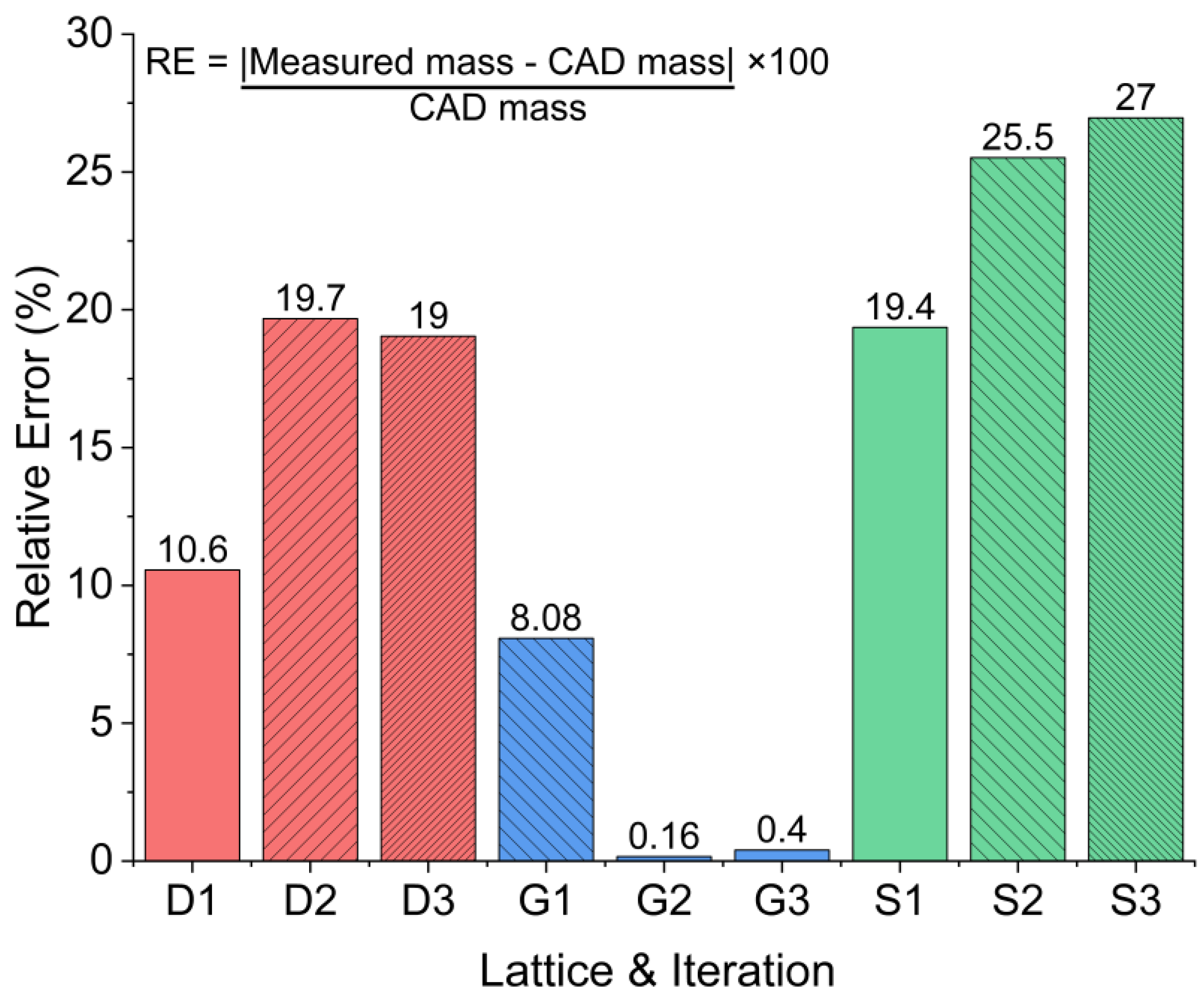

3.2. Energy Absorption Properties and Relative Error

3.2.1. Absorption, Recovery, and Dissipation

3.2.2. Normalized Energy Absorption

4. Conclusions

- Vat polymerization could produce complicated TPMS samples with adequate precision that compare favorably to the intended designs.

- In the σ-ε graphs, The Schwarz primitive sample presents a bending-dominated behavior, whereas the Diamond and Gyroid samples show stretching dominance. The Gyroid (adjusted for G1) and Schwarz Primitive lattices came in second and third, respectively, with the graded Diamond lattice producing the greatest modulus and plateau stress values. Energy attributes also somewhat align in this manner.

- All the tested samples show some resistance to permanent deformation; however, the Schwarz shows larger variation in early strain intervals compared to the Gyroid or Diamond, likely due to the stretching dominance, but remains the most consistent during loading. Because of this, the Diamond and Gyroid sheet TPMS are recommended, as they function well under high strains with desirable energy characteristics. The Schwarz primitive lattice demonstrated the lowest energy properties but was consistent. This could imply that, for applications where consistency is more critical than the total energy amount absorbed, the Schwarz primitive lattice may be preferred. The Schwarz primitive and Gyroid lattices show similar strain recovery rates that differ from the Diamond, likely due to the cell wall orientation. Selecting the optimal lattice structure for specific energy absorption requirements is fundamental in applications like crash-resistant structure or protective gear, where energy dissipation can be lifesaving.

- A discernible discrepancy exists between the stiffness and plateau stress as forecasted by the Ashby–Gibson models, with the Additively Manufactured (AM) materials markedly surpassing the projected parameters. This divergence could potentially be attributed to the oversimplified assumptions of the models and their consequent neglect of several pivotal factors intrinsic to AM materials. Specifically, considerations pertaining to print orientation, lattice geometry, the incorporation of fillers and additives, the formation of layer boundaries, the meticulous composition of polymers, and cross-linking dynamics are notably absent in the existing predictive frameworks, potentially contributing to the observed discrepancies in performance. This underscores the need for refining and enhancing models to align with advancing engineering technology, especially to bridge the gap between theoretical predictions and real-world performance metrics.

- Large variations in σ-ε diagrams reveal variations in material properties for different lattice structures through consecutive loadings. This infers that lattice structures exhibit varied mechanical responses. This results in a demand for engineering design to consider these variations for the structural integrity of prolonged periods. Careful consideration of manufacturing parameters and procedures is crucial for leveraging the full potential of AM technology.

- Densification and thickness of lattices influences the deformation and collapse of the cell walls and the strain where opposing walls meet. This can impact structural integrity and performance. Designing lattices with appropriate relative density and wall thickness can provide enhanced structural stability and resilience against collapse while removing excess weight. The results obtained can guide the design and manufacturing process, enhancing the performance of samples in real-world applications.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Metric | Imperial | Method | |||

|---|---|---|---|---|---|

| Green | Post-Cured | Green | Post-Cured | ||

| UTS | 1.61 MPa | 3.23 MPa | 234 psi | 468 psi | ASTM D412-06 (A) [37] |

| σ at 50% Elongation | 0.92 MPa | 0.94 MPa | 133 psi | 136 psi | ASTM D412-06 (A) |

| σ at 100% Elongation | 1.54 MPa | 1.59 MPa | 223 psi | 231 psi | ASTM D412-06 (A) |

| Elongation @ Failure | 100% | 160% | 100% | 160% | ASTM D412-06 (A) |

| Compression set 23 °C for 22 h. | 2% | 2% | 2% | 2% | ASTM D395-03 (B) [38] |

| Compression set for 70 °C for 22 h. | 3% | 9% | 3% | 9% | ASTM D395-03 (B) |

| Tear strength | 8.9 kN/m | 19.1 kN/m | 51 lbf/in | 109 lbf/in | ASTM D624-00 [39] |

| Shore Hardness | 40 A | 50 A | 40 A | 50 A | ASTM 2240 [40] |

References

- Regis, J.E.; Renteria, A.; Hall, S.E.; Hassan, S.; Marquez, C.; Lin, Y. Soft Functional Materials. Materials 2021, 14, 4521. [Google Scholar] [CrossRef]

- Rahman, H.; Yarali, E.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. Energy absorption and mechanical performance of functionally graded soft–hard lattice structures. Materials 2021, 14, 1366. [Google Scholar] [CrossRef]

- Boyraz, P.; Runge, G.; Raatz, A. An overview of novel actuators for soft robotics. Actuators 2018, 7, 48. [Google Scholar] [CrossRef]

- Du, K.; Basuki, J.; Glattauer, V.; Mesnard, C.; Nguyen, A.T.; Alexander, D.L.J.; Hughes, T.C. Digital Light Processing 3D Printing of PDMS-Based Soft and Elastic Materials with Tunable Mechanical Properties. ACS Appl. Polym. Mater. 2021, 3, 3049–3059. [Google Scholar] [CrossRef]

- Zhang, M.; Tao, X.; Yu, R.; He, Y.; Li, X.; Chen, X.; Huang, W. Self-healing, mechanically robust, 3D printable ionogel for highly sensitive and long-term reliable ionotronics. J. Mater. Chem. A 2021, 10, 12005–12015. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Ren, J.; Rong, L.; Cao, P.F.; Advincula, R.C. 3D Printed Multifunctional, Hyperelastic Silicone Rubber Foam. Adv. Funct. Mater. 2019, 29, 1900469. [Google Scholar] [CrossRef]

- Shanmugasundaram, S.A.; Razmi, J.; Mian, M.J.; Ladani, L. Mechanical anisotropy and surface roughness in additively manufactured parts fabricated by stereolithography (SLA) using statistical analysis. Materials 2020, 13, 2496. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, Z.; Zhao, L.; Guo, W.; Jiang, Z.; Li, X.; Chen, G. Mechanical characteristics and deformation mechanism of functionally graded triply periodic minimal surface structures fabricated using stereolithography. Int. J. Mech. Sci. 2021, 208, 106679. [Google Scholar] [CrossRef]

- Tan, B.; Gan, S.; Wang, X.; Liu, W.; Li, X. Applications of 3D bioprinting in tissue engineering: Advantages, deficiencies, improvements, and future perspectives. J. Mater. Chem. B 2021, 9, 5385–5413. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Vosooghnia, A.; Dehghanghadikolaei, A.; Fotovvati, B. The benefits of additive manufacturing for sustainable design and production. In Sustainable Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Veloso, F.; Gomes-Fonseca, J.; Morais, P.; Correia-Pinto, J.; Pinho, A.C.M.; Vilaça, J.L. Overview of Methods and Software for the Design of Functionally Graded Lattice Structures. Adv. Eng. Mater. 2022, 24, 2200483. [Google Scholar] [CrossRef]

- Mostafa, K.G.; Momesso, G.A.; Li, X.; Nobes, D.S.; Qureshi, A.J. Dual graded lattice structures: Generation framework and mechanical properties characterization. Polymers 2021, 13, 1528. [Google Scholar] [CrossRef]

- Keshavarzan, M.; Kadkhodaei, M.; Forooghi, F. An investigation into compressive responses of shape memory polymeric cellular lattice structures fabricated by vat polymerization additive manufacturing. Polym. Test. 2020, 91, 106832. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Parry, L.; Wildman, R.D.; Tuck, C.J.; Ashcroft, I.A. Effective design and simulation of surface-based lattice structures featuring volume fraction and cell type grading. Mater. Des. 2018, 155, 220–232. [Google Scholar] [CrossRef]

- Plessis, A.D.; Yadroitsava, I.; Yadroitsev, I.; le Roux, S.G.; Blaine, D.C. Numerical comparison of lattice unit cell designs for medical implants by additive manufacturing. Virtual Phys. Prototyp. 2018, 13, 266–281. [Google Scholar] [CrossRef]

- Melancon, D.; Bagheri, Z.S.; Johnston, R.B.; Liu, L.; Tanzer, M.; Pasini, D. Mechanical characterization of structurally porous biomaterials built via additive manufacturing: Experiments, predictive models, and design maps for load-bearing bone replacement implants. Acta Biomater. 2017, 63, 350–368. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, H.; Zhou, Z.; Zeng, H.; Zhang, X.; Yang, J.; Lei, H.; Han, F. Energy absorption diagram characteristic of metallic self-supporting 3D lattices fabricated by additive manufacturing and design method of energy absorption structure. Int. J. Solids Struct. 2021, 226–227, 111082. [Google Scholar] [CrossRef]

- Hatamleh, M.I.; Barrios, C.A.; Ren, Y.; Zhang, R.; Nambiar, V.V.; Williams, A.; Shah, P.; Guyan, A.; Lund, B.; Lu, H.; et al. Structural response of 3D-printed rubber lattice structures under compressive fatigue. MRS Commun. 2021, 11, 168–172. [Google Scholar] [CrossRef]

- Pepelnjak, T.; Karimi, A.; Maček, A.; Mole, N. Altering the elastic properties of 3D printed poly-lactic acid (Pla) parts by compressive cyclic loading. Materials 2020, 13, 4456. [Google Scholar] [CrossRef]

- Yuan, X.; Chen, M.; Yao, Y.; Guo, X.; Huang, Y.; Peng, Z.; Xu, B.; Lv, B.; Tao, R.; Duan, S.; et al. Recent progress in the design and fabrication of multifunctional structures based on metamaterials. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100883. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids Structure and Properties, 2nd ed.; Press Syndicate of The University of Cambridge: Cambridge, UK, 1999. [Google Scholar]

- Yu, S.; Sun, J.; Bai, J. Investigation of functionally graded TPMS structures fabricated by additive manufacturing. Mater. Des. 2019, 182, 108021. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Lee, D.W.; Rowshan, R.; Al-Rub, R.K.A. Functionally graded and multi-morphology sheet TPMS lattices: Design, manufacturing, and mechanical properties. J. Mech. Behav. Biomed. Mater. 2020, 102, 103520. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, D.Z.; Zhao, M.; Jiang, J.; Luo, F.; Zhou, H. Mechanical and energy absorption properties of functionally graded lattice structures based on minimal curved surfaces. Int. J. Adv. Manuf. Technol. 2022, 118, 995–1008. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Al-Rub, R.K.A. Multifunctional Mechanical Metamaterials Based on Triply Periodic Minimal Surface Lattices. Adv. Eng. Mater. 2019, 21, 1900524. [Google Scholar] [CrossRef]

- Park, S.Y.; Kim, K.S.; AlMangour, B.; Grzesiak, D.; Lee, K.A. Compressive deformation behavior and energy absorption characteristic of additively manufactured sheet CoCrMo triply periodic minimal surface lattices. J. Mater. Res. Technol. 2022, 18, 171–184. [Google Scholar] [CrossRef]

- Wu, M.W.; Chen, J.K.; Lin, B.H.; Chiang, P.H.; Tsai, M.K. Compressive fatigue properties of additive-manufactured Ti-6Al-4V cellular material with different porosities. Mater. Sci. Eng. A 2020, 790, 139695. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Liang, S.-X.; Liu, Y.; Zhang, L.-C. Additive manufacturing of metallic lattice structures: Unconstrained design, accurate fabrication, fascinated performances, and challenges. Mater. Sci. Eng. R Rep. 2021, 146, 100648. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Montazerian, H.; Raeisi, S. Investigating internal architecture effect in plastic deformation and failure for TPMS-based scaffolds using simulation methods and experimental procedure. Mater. Sci. Eng. C 2014, 43, 587–597. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Maskery, I.; Parry, L.A.; Padrão, D.; Hague, R.J.M.; Ashcroft, I.A. FLatt Pack: A research-focussed lattice design program. Addit. Manuf. 2022, 49, 102510. [Google Scholar] [CrossRef]

- Maskery, I.; Sturm, L.; Aremu, A.O.; Panesar, A.; Williams, C.B.; Tuck, C.J.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Al-Rub, R.K.A. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Haney, C.W.; Siller, H.R. Anthropo-fidelic behavior of elastic-plastic lattice structures. Polym. Test. 2023, 120, 107970. [Google Scholar] [CrossRef]

- Sokollu, B.; Gulcan, O.; Konukseven, E.I. Mechanical properties comparison of strut-based and triply periodic minimal surface lattice structures produced by electron beam melting. Addit. Manuf. 2022, 60, 103199. [Google Scholar] [CrossRef]

- Maiti, S.K.; Gibson, L.J.; Ashby, M.F. Deformation and energy absorption diagrams for cellular solids. Acta Metall. 1984, 32, 1963–1975. [Google Scholar] [CrossRef]

- ASTM D412-06; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers-Tension. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D395-03; Standard Test Methods for Rubber Property—Compression Set. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D624-00; Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM 2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2021.

| Sample | Diamond (g) | Gyroid (g) | Schwarz (g) |

|---|---|---|---|

| 1 | 1.382 | 1.149 | 1.492 |

| 2 | 1.496 | 1.248 | 1.569 |

| 3 | 1.488 | 1.255 | 1.587 |

| Theoretical mass (g) | 1.25 | 1.25 | 1.25 |

| STL file size (MB) | 44.65 | 43.75 | 29.81 |

| X, Y, Z Cell Size (mm) | 11 | 11 | 9.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haney, C.W.; Siller, H.R. Properties of Hyper-Elastic-Graded Triply Periodic Minimal Surfaces. Polymers 2023, 15, 4475. https://doi.org/10.3390/polym15234475

Haney CW, Siller HR. Properties of Hyper-Elastic-Graded Triply Periodic Minimal Surfaces. Polymers. 2023; 15(23):4475. https://doi.org/10.3390/polym15234475

Chicago/Turabian StyleHaney, Christopher W., and Hector R. Siller. 2023. "Properties of Hyper-Elastic-Graded Triply Periodic Minimal Surfaces" Polymers 15, no. 23: 4475. https://doi.org/10.3390/polym15234475

APA StyleHaney, C. W., & Siller, H. R. (2023). Properties of Hyper-Elastic-Graded Triply Periodic Minimal Surfaces. Polymers, 15(23), 4475. https://doi.org/10.3390/polym15234475