Improvement of the Ductility of Environmentally Friendly Poly(lactide) Composites with Posidonia oceanica Wastes Plasticized with an Ester of Cinnamic Acid

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Manufacturing of PLA–Posidonia oceanica Composites

2.3. Characterization of PLA/PO Composites

2.3.1. Chemical Characterization

2.3.2. Mechanical Characterization

2.3.3. Morphological Characterization

2.3.4. Thermal Characterization

2.3.5. Wettability

2.3.6. Dynamic Mechanical Thermal Analysis (DMTA)

3. Results and Discussion

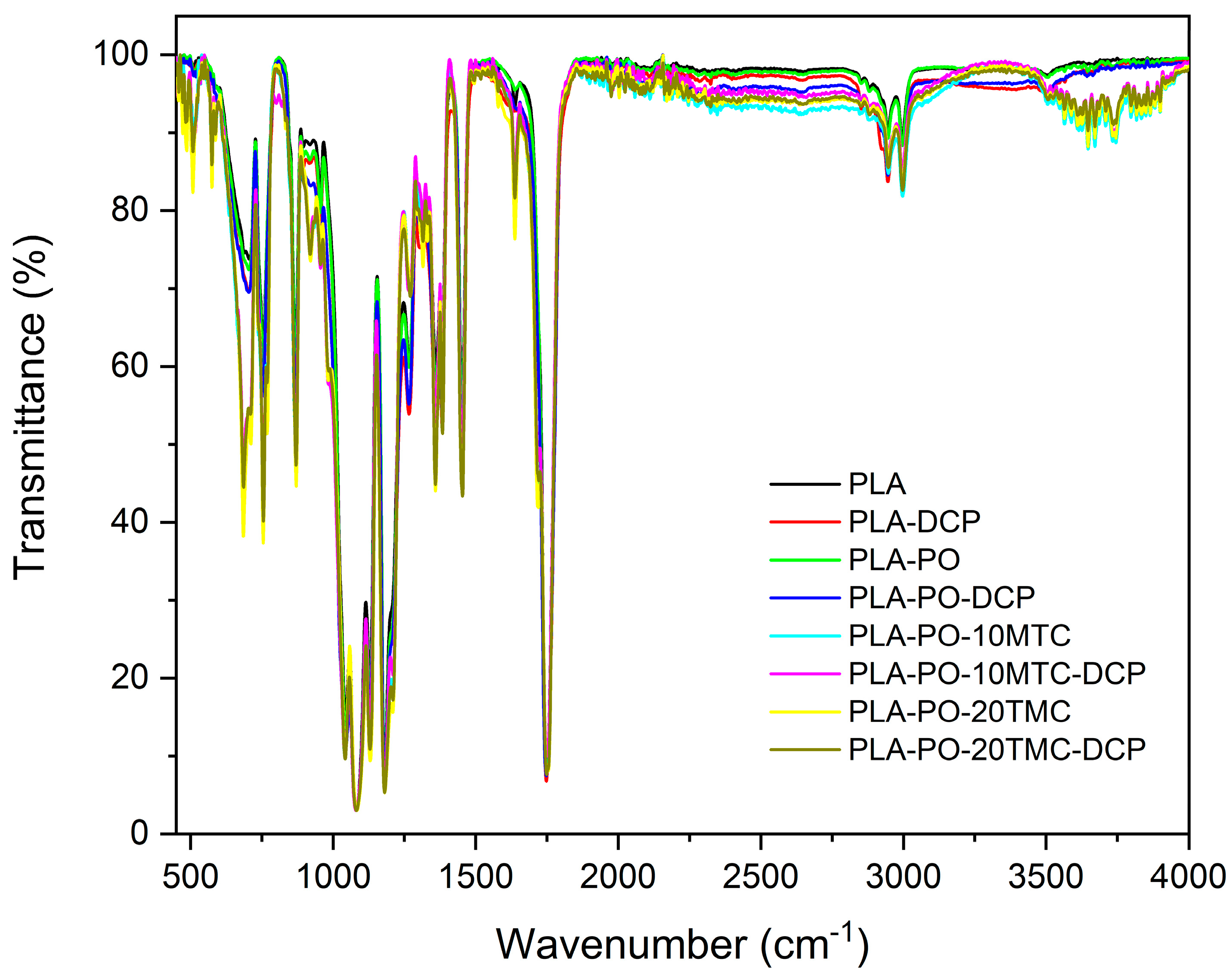

3.1. Chemical Characterization

3.2. Mechanical Properties of PLA/PO Composites

3.3. Morphological Characterization

3.4. Thermal Characterization

3.5. Wettability Characterization

3.6. Dynamic Mechanical Thermal Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Srivastava, A.; Srivasatva, A.K.; Singh, A.; Singh, P.; Verma, S.; Vats, M.; Sagadevan, S. Biopolymers as renewable polymeric materials for sustainable development-an overview. Polimery 2022, 67, 185–196. [Google Scholar] [CrossRef]

- Recio, J.M.B.; Guerrero, P.J.; Ageitos, M.G.; Narváez, R.P. Estimate of Energy Consumption and CO2 Emission Associated with the Production, Use and Final Disposal of PVC, HDPE, PP, Ductile Iron and Concrete Pipes; Universitat Politécnica de Catalunya: Barcelona, Spain, 2005. [Google Scholar]

- Yuan, J.; Ma, J.; Sun, Y.; Zhou, T.; Zhao, Y.; Yu, F. Microbial degradation and other environmental aspects of microplastics/plastics. Sci. Total Environ. 2020, 715, 136968. [Google Scholar] [CrossRef] [PubMed]

- Abbas-Abadi, M.S. The effect of process and structural parameters on the stability, thermo-mechanical and thermal degradation of polymers with hydrocarbon skeleton containing PE, PP, PS, PVC, NR, PBR and SBR. J. Therm. Anal. Calorim. 2021, 143, 2867–2882. [Google Scholar] [CrossRef]

- Tănase, E.E.; Râpă, M.; Popa, O. Biopolymers based on renewable resources—A review. Sci. Bulletin. Ser. F. Biotechnol. 2014, 18, 188–195. [Google Scholar]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Yildizhan, Ş.; Çalik, A.; Özcanli, M.; Serin, H. Bio-composite materials: A short review of recent trends, mechanical and chemical properties, and applications. Eur. Mech. Sci. 2018, 2, 83–91. [Google Scholar] [CrossRef]

- Friedrich, D. Thermoplastic moulding of Wood-Polymer Composites (WPC): A review on physical and mechanical behaviour under hot-pressing technique. Compos. Struct. 2021, 262, 113649. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Wen, J.; Yuan, S.; Zhu, Z. The effects of CaCO3 on the properties of PCL wood-plastic composites. Proc. IOP Conf. Ser. Earth Environ. Sci. 2019, 223, 022004. [Google Scholar] [CrossRef]

- Aliotta, L.; Vannozzi, A.; Canesi, I.; Cinelli, P.; Coltelli, M.-B.; Lazzeri, A. Poly (lactic acid)(PLA)/poly (butylene succinate-co-adipate)(PBSA) compatibilized binary biobased blends: Melt fluidity, morphological, thermo-mechanical and micromechanical analysis. Polymers 2021, 13, 218. [Google Scholar] [CrossRef]

- Blasi, P. Poly (lactic acid)/poly (lactic-co-glycolic acid)-based microparticles: An overview. J. Pharm. Investig. 2019, 49, 337–346. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H. Biodegradable polymers. In Biodegradation-Life of Science; Intechopen: Rijeka, Croatia, 2013; pp. 141–185. [Google Scholar]

- Nachod, B.; Keller, E.; Hassanein, A.; Lansing, S. Assessment of petroleum-based plastic and bioplastics degradation using anaerobic digestion. Sustainability 2021, 13, 13295. [Google Scholar] [CrossRef]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic acid technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Seshadri, S.A.; Devnani, G.; Sanjay, M.; Siengchin, S.; Maran, J.P.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites–A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Li, G.; Zhao, M.; Xu, F.; Yang, B.; Li, X.; Meng, X.; Teng, L.; Sun, F.; Li, Y. Synthesis and biological application of polylactic acid. Molecules 2020, 25, 5023. [Google Scholar] [CrossRef]

- Avérous, L. Polylactic acid: Synthesis, properties and applications. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 433–450. [Google Scholar]

- Yang, X.; Liu, S.; Yu, E.; Wei, Z. Toughening of Poly (L-Lactide) with branched polycaprolactone: Effect of chain length. ACS Omega 2020, 5, 29284–29291. [Google Scholar] [CrossRef] [PubMed]

- Nofar, M.; Maani, A.; Sojoudi, H.; Heuzey, M.-C.; Carreau, P. Interfacial and rheological properties of PLA/PBAT and PLA/PBSA blends and their morphological stability under shear flow. J. Rheol. 2015, 59, 317–333. [Google Scholar] [CrossRef]

- Fortelny, I.; Ujcic, A.; Fambri, L.; Slouf, M. Phase structure, compatibility, and toughness of PLA/PCL blends: A review. Front. Mater. 2019, 6, 206. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly (butylene succinate)(PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef]

- Iwatake, A.; Nogi, M.; Yano, H. Cellulose nanofiber-reinforced polylactic acid. Compos. Sci. Technol. 2008, 68, 2103–2106. [Google Scholar] [CrossRef]

- Ilyas, R.; Zuhri, M.; Aisyah, H.; Asyraf, M.; Hassan, S.; Zainudin, E.; Sapuan, S.; Sharma, S.; Bangar, S.; Jumaidin, R. Natural fiber-reinforced polylactic acid, polylactic acid blends and their composites for advanced applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.H.; Lee, J.Y.; Chin, I.-J. Reinforcing effects of poly (D-Lactide)-g-multiwall carbon nanotubes on polylactide nanocomposites. J. Nanosci. Nanotechnol. 2015, 15, 8086–8092. [Google Scholar] [CrossRef]

- Alias, N.F.; Ismail, H. An overview of toughening polylactic acid by an elastomer. Polym.-Plast. Technol. Mater. 2019, 58, 1399–1422. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Perdiguero, M.; Fiori, S.; Kenny, J.M.; Peponi, L. Biodegradable electrospun PLA-PHB fibers plasticized with oligomeric lactic acid. Polym. Degrad. Stab. 2020, 179, 109226. [Google Scholar] [CrossRef]

- Aragón-Gutierrez, A.; Arrieta, M.P.; López-González, M.; Fernández-García, M.; López, D. Hybrid biocomposites based on poly (lactic acid) and silica aerogel for food packaging applications. Materials 2020, 13, 4910. [Google Scholar] [CrossRef] [PubMed]

- Cobos, C.M.; Fenollar, O.; López Martinez, J.; Ferrandiz, S.; Garzón, L. Effect of maleinized linseed oil (MLO) on thermal and rheolological properties of PLA/MWCNT and PLA/HNT nanocomposites for additive manufacturing. Rapid Prototyp. J. 2020, 26, 1027–1033. [Google Scholar] [CrossRef]

- Bocqué, M.; Voirin, C.; Lapinte, V.; Caillol, S.; Robin, J.J. Petro-based and bio-based plasticizers: Chemical structures to plasticizing properties. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 11–33. [Google Scholar] [CrossRef]

- Barandiaran, A.; Gomez-Caturla, J.; Ivorra-Martinez, J.; Lascano, D.; Selles, M.A.; Moreno, V.; Fenollar, O. Esters of Cinnamic Acid as Green Plasticizers for Polylactide Formulations with Improved Ductility. Macromol. Mater. Eng. 2023, 308, 2300022. [Google Scholar] [CrossRef]

- Rayon, E.; Lopez, J.; Arrieta, M.P. Mechanical characterization of microlaminar structures extracted from cellulosic materials using nanoindentation technique. Cellul. Chem. Technol. 2013, 47, 345–351. [Google Scholar]

- Tranchina, L.; Miccichè, S.; Bartolotta, A.; Brai, M.; Mantegna, R. Posidonia oceanica as a historical monitor device of lead concentration in marine environment. Environ. Sci. Technol. 2005, 39, 3006–3012. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Quiles-Carrillo, L.; Montanes, N.; Fombuena, V.; Balart, R. Manufacturing and characterization of composite fibreboards with Posidonia oceanica wastes with an environmentally-friendly binder from epoxy resin. Materials 2017, 11, 35. [Google Scholar] [CrossRef] [PubMed]

- Calmet, D.; Boudouresque, C.F.; Meinesz, A. Memorization of nuclear atmospheric tests by rhizomes and scales of the mediteranean seagrass Posidonia oceanica (Linnaeus) Delile. Aquat. Bot. 1988, 30, 279–294. [Google Scholar] [CrossRef]

- Scaffaro, R.; Lopresti, F.; Botta, L. PLA based biocomposites reinforced with Posidonia oceanica leaves. Compos. Part B Eng. 2018, 139, 1–11. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A.; Bakar, A.A. Woven hybrid composites: Tensile and flexural properties of oil palm-woven jute fibres based epoxy composites. Mater. Sci. Eng. A 2011, 528, 5190–5195. [Google Scholar] [CrossRef]

- Birnin-Yauri, A.U.; Ibrahim, N.A.; Zainuddin, N.; Abdan, K.; Then, Y.Y.; Chieng, B.W. Effect of maleic anhydride-modified poly (lactic acid) on the properties of its hybrid fiber biocomposites. Polymers 2017, 9, 165. [Google Scholar] [CrossRef] [PubMed]

- Qian, S.; Sheng, K. PLA toughened by bamboo cellulose nanowhiskers: Role of silane compatibilization on the PLA bionanocomposite properties. Compos. Sci. Technol. 2017, 148, 59–69. [Google Scholar] [CrossRef]

- Przybysz-Romatowska, M.; Haponiuk, J.; Formela, K. Reactive extrusion of biodegradable aliphatic polyesters in the presence of free-radical-initiators: A review. Polym. Degrad. Stab. 2020, 182, 109383. [Google Scholar] [CrossRef]

- Augé, M.-O.; Roncucci, D.; Bourbigot, S.; Bonnet, F.; Gaan, S.; Fontaine, G. Recent advances on reactive Extrusion of Poly (lactic acid). Eur. Polym. J. 2022, 184, 111727. [Google Scholar] [CrossRef]

- Beber, V.C.; De Barros, S.; Banea, M.D.; Brede, M.; De Carvalho, L.H.; Hoffmann, R.; Costa, A.R.M.; Bezerra, E.B.; Silva, I.D.; Haag, K. Effect of babassu natural filler on PBAT/PHB biodegradable blends: An investigation of thermal, mechanical, and morphological behavior. Materials 2018, 11, 820. [Google Scholar] [CrossRef]

- Sari, N.H.; Sanjay, M.; Arpitha, G.; Pruncu, C.I.; Siengchin, S. Synthesis and properties of pandanwangi fiber reinforced polyethylene composites: Evaluation of dicumyl peroxide (DCP) effect. Compos. Commun. 2019, 15, 53–57. [Google Scholar] [CrossRef]

- Ahmad, E.; Luyt, A. Effects of organic peroxide and polymer chain structure on morphology and thermal properties of sisal fibre reinforced polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 703–710. [Google Scholar] [CrossRef]

- Gomez-Caturla, J.; Balart, R.; Ivorra-Martinez, J.; Garcia-Garcia, D.; Dominici, F.; Puglia, D.; Torre, L. Biopolypropylene-Based Wood Plastic Composites Reinforced with Mango Peel Flour and Compatibilized with an Environmentally Friendly Copolymer from Itaconic Acid. ACS Appl. Polym. Mater. 2022, 4, 4398–4410. [Google Scholar] [CrossRef]

- Seggiani, M.; Cinelli, P.; Mallegni, N.; Balestri, E.; Puccini, M.; Vitolo, S.; Lardicci, C.; Lazzeri, A. New bio-composites based on polyhydroxyalkanoates and posidonia oceanica fibres for applications in a marine environment. Materials 2017, 10, 326. [Google Scholar] [CrossRef]

- UNE-ISO 527:2021; Plastics—Determination of tensile properties. Asociación Española de Normalizacion: Madrid, Spain, 2022.

- UNE-EN ISO 179:2021; Plastics—Determination of Charpy impact properties. Asociación Española de Normalizacion: Madrid, Spain, 2020.

- UNE-EN ISO 868:2003; Plastics and ebonite—Determination of indentation hardness by means of a durometer (Shore hardness). Asociación Española de Normalizacion: Madrid, Spain, 2003.

- Milovanovic, S.; Pajnik, J.; Lukic, I. Tailoring of advanced poly (lactic acid)-based materials: A review. J. Appl. Polym. Sci. 2022, 139, 51839. [Google Scholar] [CrossRef]

- Fonseca-García, A.; Osorio, B.H.; Aguirre-Loredo, R.Y.; Calambas, H.L.; Caicedo, C. Miscibility study of thermoplastic starch/polylactic acid blends: Thermal and superficial properties. Carbohydr. Polym. 2022, 293, 119744. [Google Scholar] [CrossRef]

- Kia, M.V.; Ehsani, M.; Hosseini, S.E.; Asadi, G.H. Fabrication and characterization of transparent nanocomposite films based on poly (lactic acid)/polyethylene glycol reinforced with nano glass flake. Int. J. Biol. Macromol. 2023, 254, 127473. [Google Scholar]

- Arany, P.; Róka, E.; Mollet, L.; Coleman, A.W.; Perret, F.; Kim, B.; Kovács, R.; Kazsoki, A.; Zelkó, R.; Gesztelyi, R. Fused deposition modeling 3D printing: Test platforms for evaluating Post-fabrication chemical modifications and in-vitro biological properties. Pharmaceutics 2019, 11, 277. [Google Scholar] [CrossRef]

- Takamura, M.; Nakamura, T.; Kawaguchi, S.; Takahashi, T.; Koyama, K. Molecular characterization and crystallization behavior of peroxide-induced slightly crosslinked poly (L-lactide) during extrusion. Polym. J. 2010, 42, 600–608. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; de Ballesteros, O.R.; Mollica, F.; Filippone, G. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Haddar, M.; Elloumi, A.; Koubaa, A.; Bradai, C.; Migneault, S.; Elhalouani, F. Comparative study of the effects of posidonia ocranica fibres and deinking paper sludge on the thermal and mechanical properties of high density polyethylene composites. In Proceedings of the 2nd EuroMaghrébine Conference of BioComposites, Hammamet, Tunisia, 1–3 November 2018. [Google Scholar]

- Vijayasekaran, G.; Kamal, M.; Gopi, M.; Nanthakumar, S.; Girimurugan, R. Enhancement of natural fiber-reinforced plastics by polyester and seaweed waste fibers. Mater. Today Proc. 2023, in press. [Google Scholar]

- Rytlewski, P.; Moraczewski, K.; Malinowski, R.; Żenkiewicz, M. Assessment of dicumyl peroxide ability to improve adhesion between polylactide and flax or hemp fibres. Compos. Interfaces 2014, 21, 671–683. [Google Scholar] [CrossRef]

- Pickering, K.L.; Sawpan, M.A.; Jayaraman, J.; Fernyhough, A. Influence of loading rate, alkali fibre treatment and crystallinity on fracture toughness of random short hemp fibre reinforced polylactide bio-composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1148–1156. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, J.; Qian, S.; Zhu, X.; Takahashi, J. Green-plasticized poly (lactic acid)/nanofibrillated cellulose biocomposites with high strength, good toughness and excellent heat resistance. Compos. Sci. Technol. 2021, 203, 108613. [Google Scholar] [CrossRef]

- Yew, G.; Yusof, A.M.; Ishak, Z.M.; Ishiaku, U. Water absorption and enzymatic degradation of poly (lactic acid)/rice starch composites. Polym. Degrad. Stab. 2005, 90, 488–500. [Google Scholar] [CrossRef]

- Ordoñez, R.; Atarés, L.; Chiralt, A. Properties of PLA films with cinnamic acid: Effect of the processing method. Food Bioprod. Process. 2022, 133, 25–33. [Google Scholar] [CrossRef]

- Dominguez-Candela, I.; Gomez-Caturla, J.; Cardona, S.; Lora-Garcia, J.; Fombuena, V. Novel compatibilizers and plasticizers developed from epoxidized and maleinized chia oil in composites based on PLA and chia seed flour. Eur. Polym. J. 2022, 173, 111289. [Google Scholar] [CrossRef]

- Chen, T.; Wu, Y.; Qiu, J.; Fei, M.; Qiu, R.; Liu, W. Interfacial compatibilization via in-situ polymerization of epoxidized soybean oil for bamboo fibers reinforced poly (lactic acid) biocomposites. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106066. [Google Scholar] [CrossRef]

- Rojas-Lema, S.; Ivorra-Martinez, J.; Lascano, D.; Garcia-Garcia, D.; Balart, R. Improved performance of environmentally friendly blends of biobased polyethylene and kraft lignin compatibilized by reactive extrusion with dicumyl peroxide. Macromol. Mater. Eng. 2021, 306, 2100196. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the influence of the reprocessing cycles on the final properties of polylactide pieces obtained by injection molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef]

- Tábi, T.; Ageyeva, T.; Kovács, J.G. Improving the ductility and heat deflection temperature of injection molded Poly (lactic acid) products: A comprehensive review. Polym. Test. 2021, 101, 107282. [Google Scholar] [CrossRef]

- Ramos, M.; Dominici, F.; Luzi, F.; Jiménez, A.; Garrigós, M.C.; Torre, L.; Puglia, D. Effect of almond shell waste on physicochemical properties of polyester-based biocomposites. Polymers 2020, 12, 835. [Google Scholar] [CrossRef] [PubMed]

- Pawłowska, A.; Stepczyńska, M.; Walczak, M. Flax fibres modified with a natural plant agent used as a reinforcement for the polylactide-based biocomposites. Ind. Crops Prod. 2022, 184, 115061. [Google Scholar] [CrossRef]

- Murariu, M.; Da Silva Ferreira, A.; Alexandre, M.; Dubois, P. Polylactide (PLA) designed with desired end-use properties: 1. PLA compositions with low molecular weight ester-like plasticizers and related performances. Polym. Adv. Technol. 2008, 19, 636–646. [Google Scholar] [CrossRef]

- Pluta, M. Morphology and properties of polylactide modified by thermal treatment, filling with layered silicates and plasticization. Polymer 2004, 45, 8239–8251. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, A.A.; Majumdar, A.; Butola, B.S. Harnessing the ductility of polylactic acid/halloysite nanocomposites by synergistic effects of impact modifier and plasticiser. Compos. Part B Eng. 2020, 188, 107845. [Google Scholar] [CrossRef]

- Chaos, A.; Sangroniz, A.; Gonzalez, A.; Iriarte, M.; Sarasua, J.R.; del Río, J.; Etxeberria, A. Tributyl citrate as an effective plasticizer for biodegradable polymers: Effect of plasticizer on free volume and transport and mechanical properties. Polym. Int. 2019, 68, 125–133. [Google Scholar] [CrossRef]

- Johari, A.P.; Kurmvanshi, S.; Mohanty, S.; Nayak, S. Influence of surface modified cellulose microfibrils on the improved mechanical properties of poly (lactic acid). Int. J. Biol. Macromol. 2016, 84, 329–339. [Google Scholar] [CrossRef]

- Simmons, H.; Kontopoulou, M. Hydrolytic degradation of branched PLA produced by reactive extrusion. Polym. Degrad. Stab. 2018, 158, 228–237. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Arrieta, M.; López-Martínez, J.; Samper, M. Improvement of PLA film ductility by plasticization with epoxidized karanja oil. Polym. Degrad. Stab. 2020, 179, 109259. [Google Scholar] [CrossRef]

- Aguero, A.; Quiles-Carrillo, L.; Jorda-Vilaplana, A.; Fenollar, O.; Montanes, N. Effect of different compatibilizers on environmentally friendly composites from poly (lactic acid) and diatomaceous earth. Polym. Int. 2019, 68, 893–903. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Montanes, N.; Boronat, T.; Quiles-Carrillo, L.; Balart, R. Melt grafting of sepiolite nanoclay onto poly (3-hydroxybutyrate-co-4-hydroxybutyrate) by reactive extrusion with multi-functional epoxy-based styrene-acrylic oligomer. Eur. Polym. J. 2016, 84, 693–707. [Google Scholar] [CrossRef]

- Rojas-Lema, S.; Lascano, D.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Balart, R.; Garcia-Garcia, D. Manufacturing and Characterization of High-Density Polyethylene Composites with Active Fillers from Persimmon Peel Flour with Improved Antioxidant Activity and Hydrophobicity. Macromol. Mater. Eng. 2021, 306, 2100430. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J.M. Multifunctional PLA–PHB/cellulose nanocrystal films: Processing, structural and thermal properties. Carbohydr. Polym. 2014, 107, 16–24. [Google Scholar] [CrossRef]

- Khonakdar, H.; Morshedian, J.; Wagenknecht, U.; Jafari, S. An investigation of chemical crosslinking effect on properties of high-density polyethylene. Polymer 2003, 44, 4301–4309. [Google Scholar] [CrossRef]

- Yamoum, C.; Maia, J.; Magaraphan, R. Rheological and thermal behavior of PLA modified by chemical crosslinking in the presence of ethoxylated bisphenol A dimethacrylates. Polym. Adv. Technol. 2017, 28, 102–112. [Google Scholar] [CrossRef]

- Essabir, H.; Nekhlaoui, S.; Malha, M.; Bensalah, M.; Arrakhiz, F.; Qaiss, A.; Bouhfid, R. Bio-composites based on polypropylene reinforced with Almond Shells particles: Mechanical and thermal properties. Mater. Des. 2013, 51, 225–230. [Google Scholar] [CrossRef]

- Ortiz-Barajas, D.L.; Arévalo-Prada, J.A.; Fenollar, O.; Rueda-Ordóñez, Y.J.; Torres-Giner, S. Torrefaction of coffee husk flour for the development of injection-molded green composite pieces of polylactide with high sustainability. Appl. Sci. 2020, 10, 6468. [Google Scholar] [CrossRef]

- Kodal, M.; Sirin, H.; Ozkoc, G. Long-and short-term stability of plasticized poly (lactic acid): Effects of plasticizers type on thermal, mechanical and morphological properties. Polym. Bull. 2019, 76, 423–445. [Google Scholar] [CrossRef]

- Ivorra-Martinez, J.; Peydro, M.A.; Gomez-Caturla, J.; Boronat, T.; Balart, R. The Potential of an Itaconic Acid Diester as Environmentally Friendly Plasticizer for Injection-Molded Polylactide Parts. Macromol. Mater. Eng. 2022, 307, 2200360. [Google Scholar] [CrossRef]

- Gomez-Caturla, J.; Dominguez-Candela, I.; Medina-Casas, M.P.; Ivorra-Martinez, J.; Moreno, V.; Balart, R.; Garcia-Garcia, D. Improvement of Poly (lactide) Ductile Properties by Plasticization with Biobased Tartaric Acid Ester. Macromol. Mater. Eng. 2023, 308, 2200694. [Google Scholar] [CrossRef]

- Vogler, E.A. Structure and reactivity of water at biomaterial surfaces. Adv. Colloid Interface Sci. 1998, 74, 69–117. [Google Scholar] [CrossRef]

- Jordá-Vilaplana, A.; Fombuena, V.; García-García, D.; Samper, M.; Sánchez-Nácher, L. Surface modification of polylactic acid (PLA) by air atmospheric plasma treatment. Eur. Polym. J. 2014, 58, 23–33. [Google Scholar] [CrossRef]

- Silva, C.G.; Campini, P.A.; Rocha, D.B.; Rosa, D.S. The influence of treated eucalyptus microfibers on the properties of PLA biocomposites. Compos. Sci. Technol. 2019, 179, 54–62. [Google Scholar] [CrossRef]

- Ferri, J.M.; Aldas, M.; Rayon, E.; Samper, M.D.; Lozano-Pérez, A.A. The Influence of Different Sustainable Silk-Based Fillers on the Thermal and Mechanical Properties of Polylactic Acid Composites. Polymers 2022, 14, 5016. [Google Scholar] [CrossRef]

- Loganathan, K.; Giri, R.; Srinivasan, S.; Vimalanathan, P. Experimental investigation on mechanical, thermal, DMA, and dielectric analysis of Cordia dichotoma with PLA composites. Biomass Convers. Biorefinery 2023, 1–16. [Google Scholar] [CrossRef]

- Harte, I.; Birkinshaw, C.; Jones, E.; Kennedy, J.; DeBarra, E. The effect of citrate ester plasticizers on the thermal and mechanical properties of poly (DL-lactide). J. Appl. Polym. Sci. 2013, 127, 1997–2003. [Google Scholar] [CrossRef]

- Erdem, A.; Doğan, M. Development of ductile green flame retardant poly (lactic acid) composites using hydromagnesite&huntite and bio-based plasticizer. J. Vinyl Addit. Technol. 2023, 29, 978–990. [Google Scholar] [CrossRef]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing Polylactic acid (PLA). Polimeros 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Christopoulos, A.; Koutsoumpis, S.; Kontou, E. The effect of surface treatment on the performance of flax/biodegradable composites. Compos. Part B Eng. 2016, 106, 88–98. [Google Scholar] [CrossRef]

| Code | Tensile | Shore D Hardness | Impact Strength (kJ m−2) | ||

|---|---|---|---|---|---|

| Elastic Modulus, Et (MPa) | Strength, σt (MPa) | Elongation at Break, εb (%) | |||

| PLA | 3242.3 ± 89.9 | 64.2 ± 3.7 | 7.1 ± 0.3 | 82.6 ± 1.0 | 38.9 ± 6.1 |

| PLA–DCP | 3576.4 ± 71.3 | 62.8 ± 2.9 | 7.8 ± 0.9 | 82.1 ± 1.5 | 49.8 ± 4.6 |

| PLA–PO | 4231.5 ± 27.0 | 53.5 ± 1.4 | 4.5 ± 0.4 | 83.9 ± 1.6 | 26.5 ± 4.7 |

| PLA–PO–DCP | 3118.1 ± 90.4 | 53.9 ± 1.5 | 4.1 ± 0.2 | 84.4 ± 1.0 | 34.3 ± 2.6 |

| PLA–PO–10MTC | 3292.0 ± 78.2 | 39.6 ± 0.4 | 4.4 ± 0.2 | 82.5 ± 0.8 | 31.3 ± 2.6 |

| PLA–PO–10MTC–DCP | 3619.8 ± 80.1 | 39.9 ± 0.8 | 4.8 ± 0.5 | 81.5 ± 1.6 | 18.1 ± 1.6 |

| PLA–PO–20MTC | 1092.7 ± 29.6 | 16.4 ± 1.2 | 21.6 ± 2.3 | 79.0 ± 2.8 | 30.9 ± 8.7 |

| PLA–PO–20MTC–DCP | 2961.4 ± 78.5 | 5.1 ± 0.5 | 31.1 ± 12.1 | 80.3 ± 2.9 | 17.0± 2.1 |

| Code | Tg (°C) | Tcc (°C) | ΔHcc (J g−1) | Tm (°C) | ΔHm (J g−1) | χc (%) |

|---|---|---|---|---|---|---|

| PLA | 61.6 ± 1.2 | 103.1 ± 1.2 | 27.9 ± 0.5 | 174.2 ± 4.5 | 49.3 ± 1.0 | 22.9 ± 0.3 |

| PLA–DCP | 60.9 ± 1.0 | 100.8 ± 1.8 | 14.8 ± 0.3 | 173.0 ± 2.4 | 54.4 ± 0.9 | 42.6 ± 0.9 |

| PLA–PO | 61.4 ± 1.1 | 96.3 ± 1.4 | 5,3 ± 0.1 | 173.5 ± 3.1 | 47.3 ± 0.7 | 64.6 ± 1.3 |

| PLA–PO–DCP | 61.4 ± 1.1 | - | - | 173.1 ± 3.5 | 31.9 ± 0.5 | 48.9 ± 0.8 |

| PLA–PO–10MTC | 39.6 ± 0.8 | 81.6 ± 1.6 | 5.2 ± 0.1 | 168.2 ± 3.2 | 34.8 ± 0.7 | 45.4 ± 0.8 |

| PLA–PO–10MTC–DCP | 39.3 ± 0.6 | 85.0 ± 1.4 | 14.5 ± 0.2 | 165.5 ± 3.1 | 34.9 ± 0.6 | 31.4 ± 0.6 |

| PLA–PO–20MTC | 37.3 ± 0.7 | 83.2 ± 1.4 | 12.9 ± 0.2 | 174.3 ± 3.0 | 31.4 ± 0.6 | 28.4 ± 0.5 |

| PLA–PO–20MTC–DCP | 41.6 ± 0.7 | 85.3 ± 1.5 | 10.4 ± 0.2 | 168.2 ± 3.2 | 36.6 ± 0.9 | 40.2 ± 0.8 |

| Code | T5% (°C) | Tdeg (°C) | %mass |

|---|---|---|---|

| PLA | 374.3 ± 7.5 | 417 ± 6.3 | 0.0 ± 0.1 |

| PLA–DCP | 342.3 ± 5.1 | 374.3 ± 5.6 | 0.0 ± 0.1 |

| PLA–PO | 307.7 ± 4.9 | 355.7 ± 5.7 | 5.12 ± 0.1 |

| PLA–PO–DCP | 307.7 ± 4.3 | 353 ± 5.1 | 5.13 ± 0.1 |

| PLA–PO–10MTC | 169.0 ± 2.3 | 355.7 ± 4.9 | 1.96 ± 0.1 |

| PLA–PO–10MTC–DCP | 147.7 ± 2.8 | 355.7 ± 7.1 | 0.0 ± 0.1 |

| PLA–PO–20MTC | 163.7 ± 2.6 | 358.3 ± 6.8 | 2.26 ± 0.1 |

| PLA–PO–20MTC–DCP | 166.3 ± 2.5 | 358.3 ± 5.7 | 2.36 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barandiaran, A.; Lascano, D.; Montanes, N.; Balart, R.; Selles, M.A.; Moreno, V. Improvement of the Ductility of Environmentally Friendly Poly(lactide) Composites with Posidonia oceanica Wastes Plasticized with an Ester of Cinnamic Acid. Polymers 2023, 15, 4534. https://doi.org/10.3390/polym15234534

Barandiaran A, Lascano D, Montanes N, Balart R, Selles MA, Moreno V. Improvement of the Ductility of Environmentally Friendly Poly(lactide) Composites with Posidonia oceanica Wastes Plasticized with an Ester of Cinnamic Acid. Polymers. 2023; 15(23):4534. https://doi.org/10.3390/polym15234534

Chicago/Turabian StyleBarandiaran, Alejandro, Diego Lascano, Nestor Montanes, Rafael Balart, Miguel Angel Selles, and Virginia Moreno. 2023. "Improvement of the Ductility of Environmentally Friendly Poly(lactide) Composites with Posidonia oceanica Wastes Plasticized with an Ester of Cinnamic Acid" Polymers 15, no. 23: 4534. https://doi.org/10.3390/polym15234534

APA StyleBarandiaran, A., Lascano, D., Montanes, N., Balart, R., Selles, M. A., & Moreno, V. (2023). Improvement of the Ductility of Environmentally Friendly Poly(lactide) Composites with Posidonia oceanica Wastes Plasticized with an Ester of Cinnamic Acid. Polymers, 15(23), 4534. https://doi.org/10.3390/polym15234534