Characterization of the Polyetheretherketone Weldment Fabricated via Rotary Friction Welding

Abstract

:1. Introduction

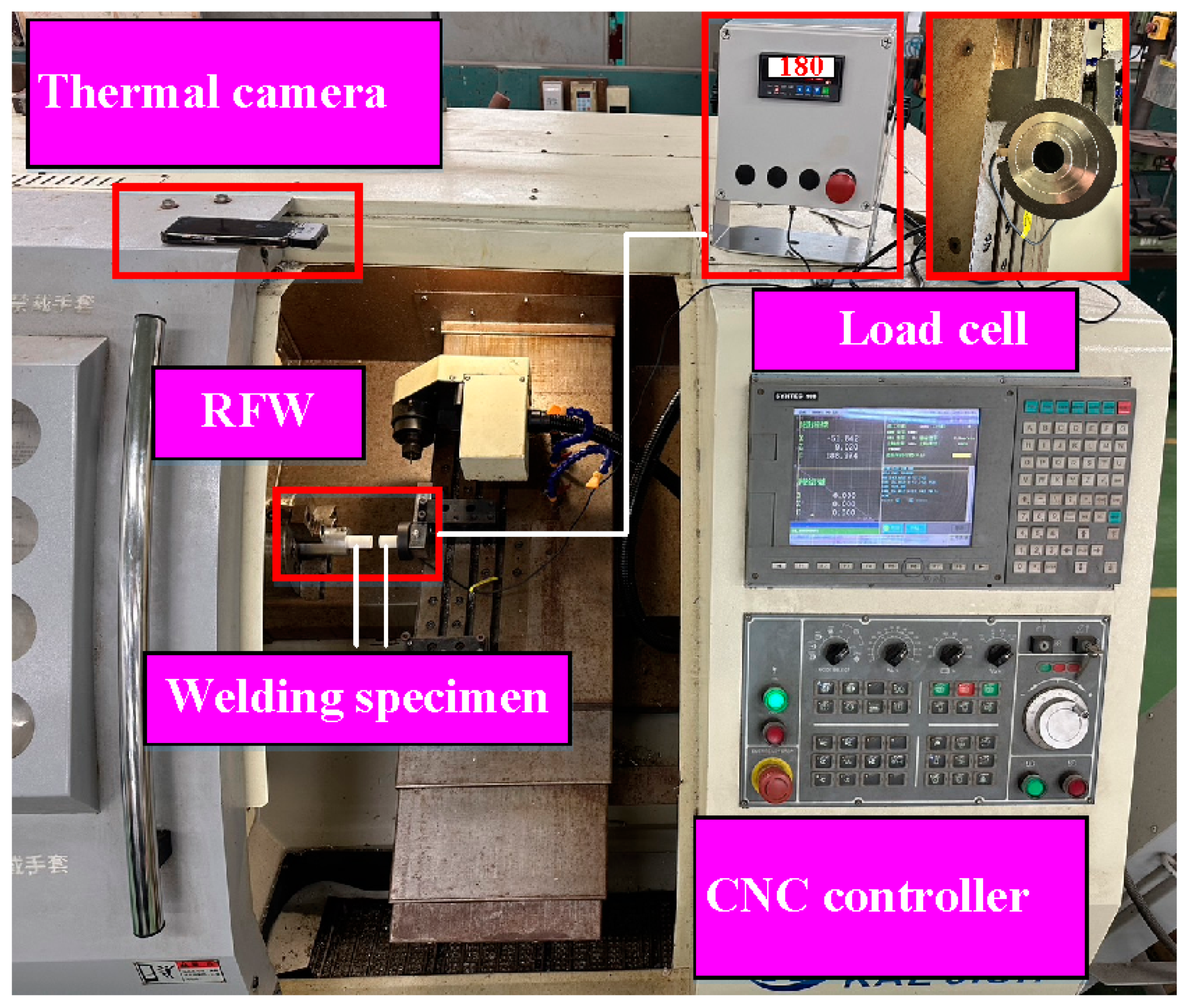

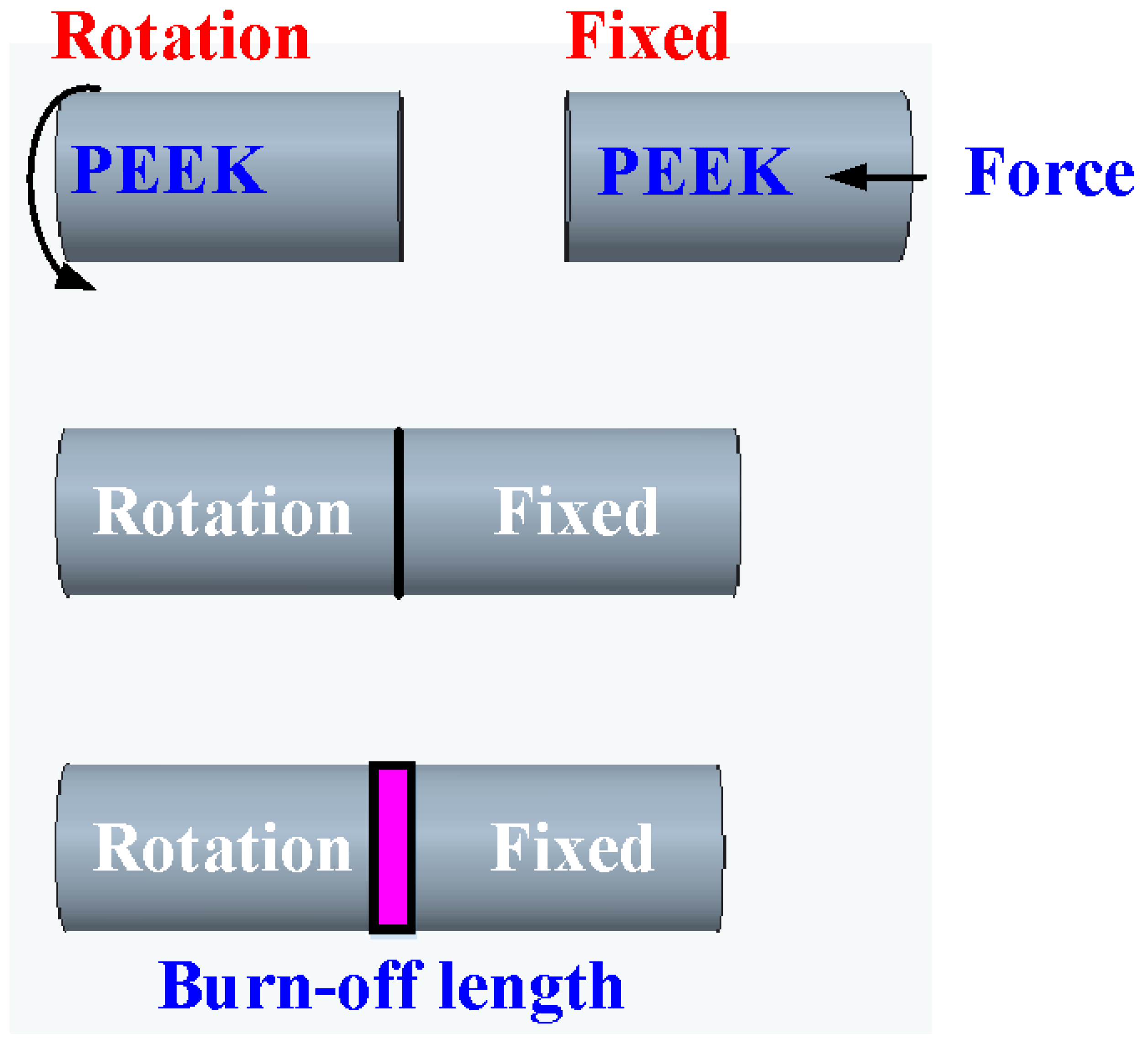

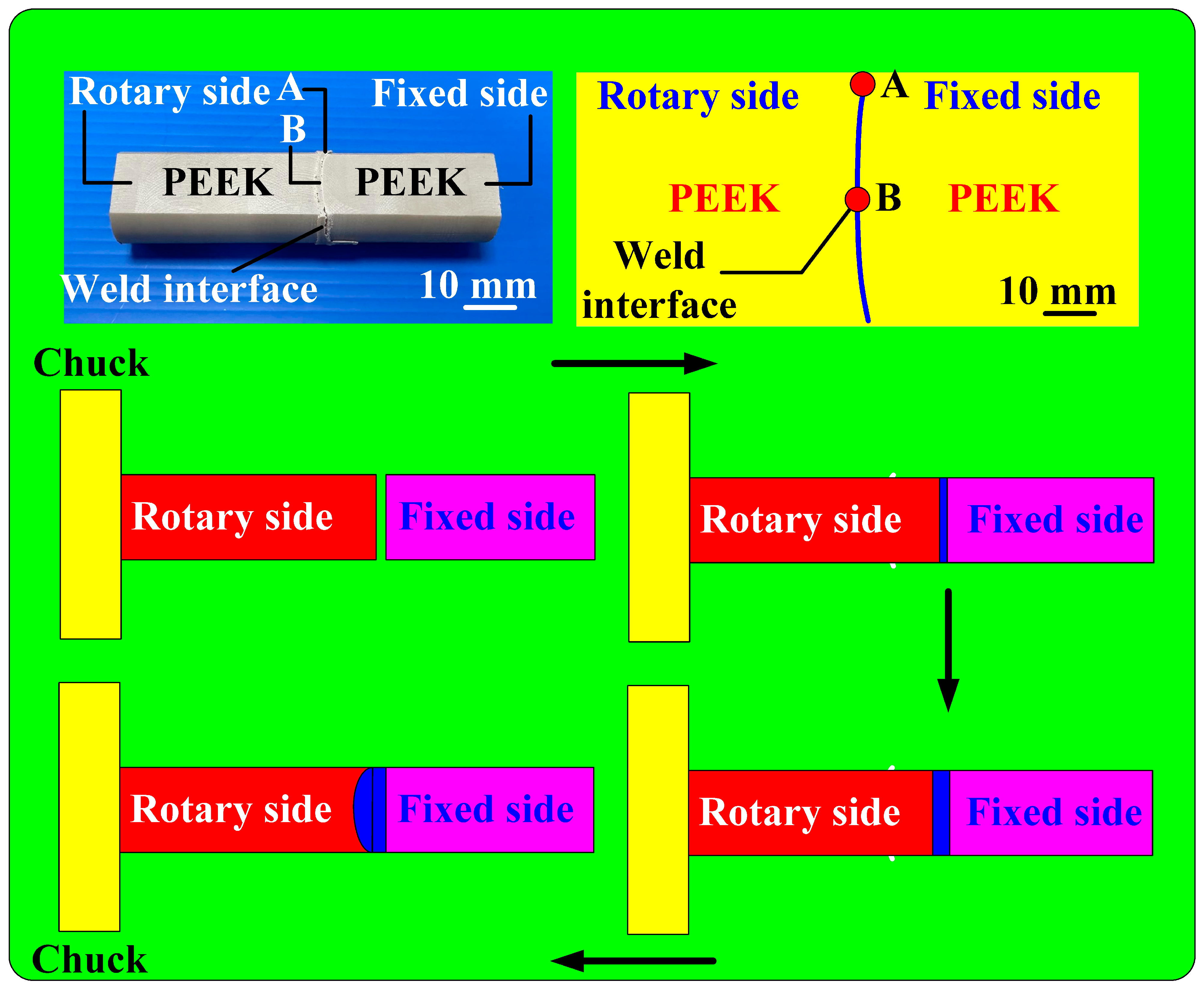

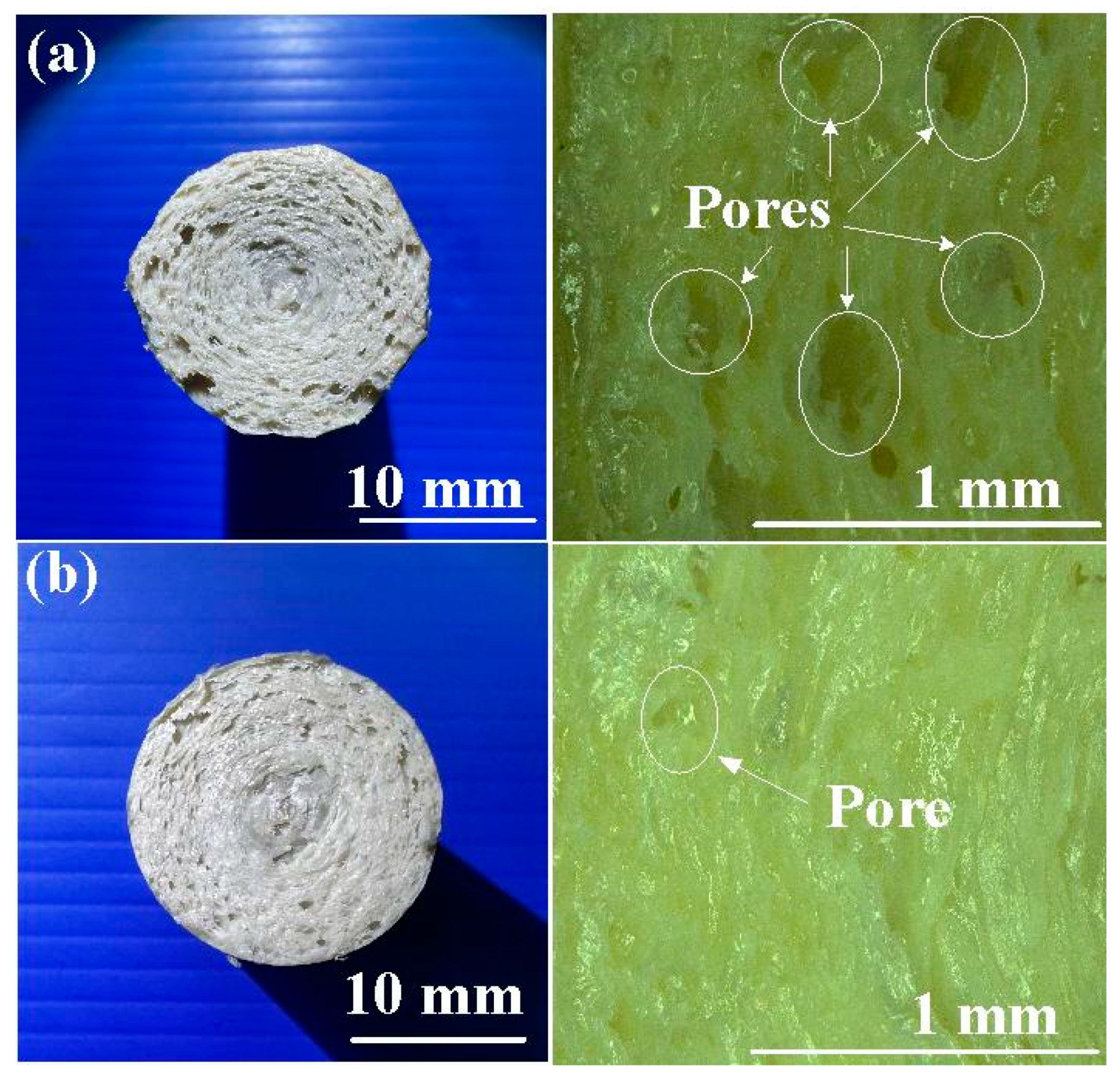

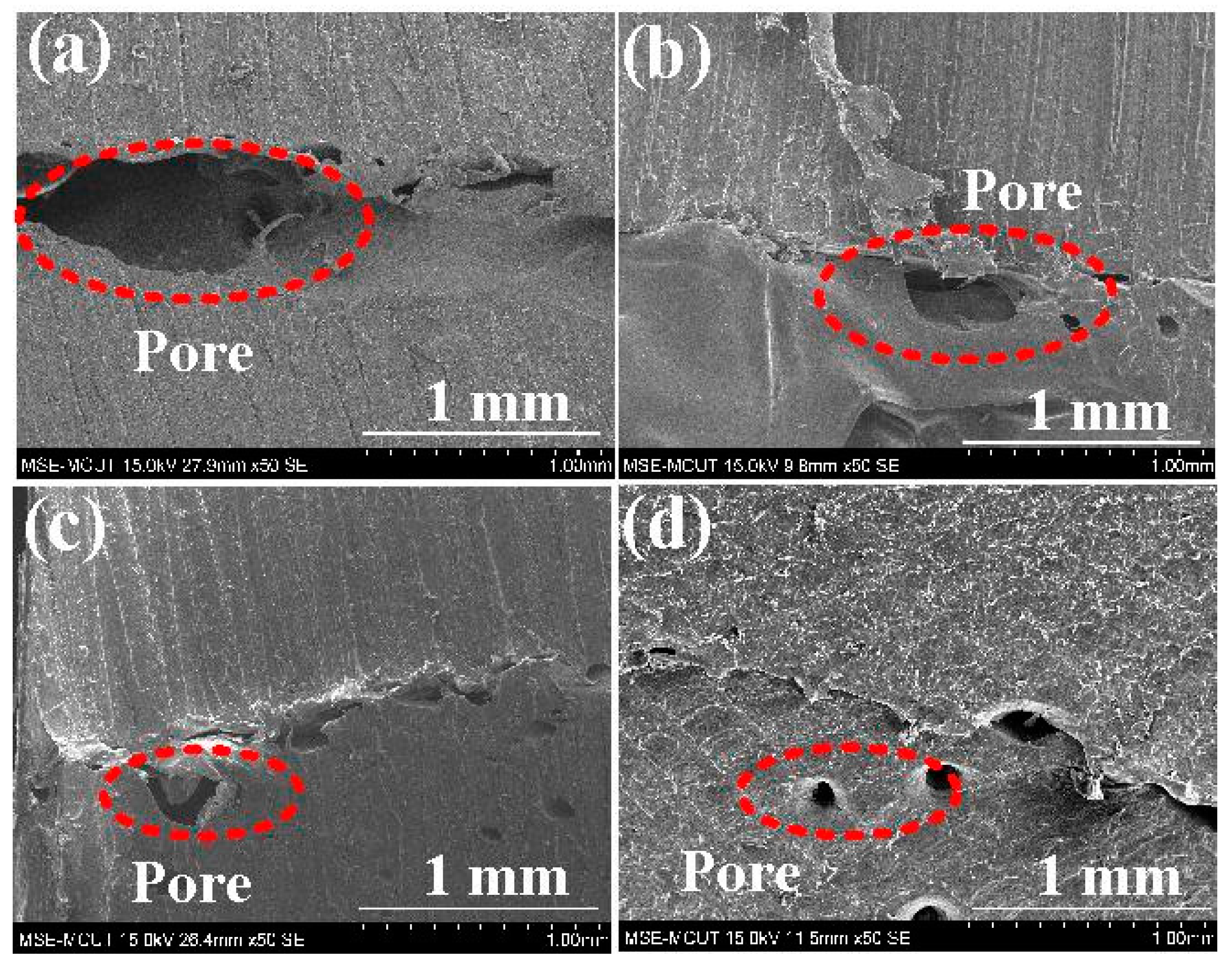

2. Materials and Methods

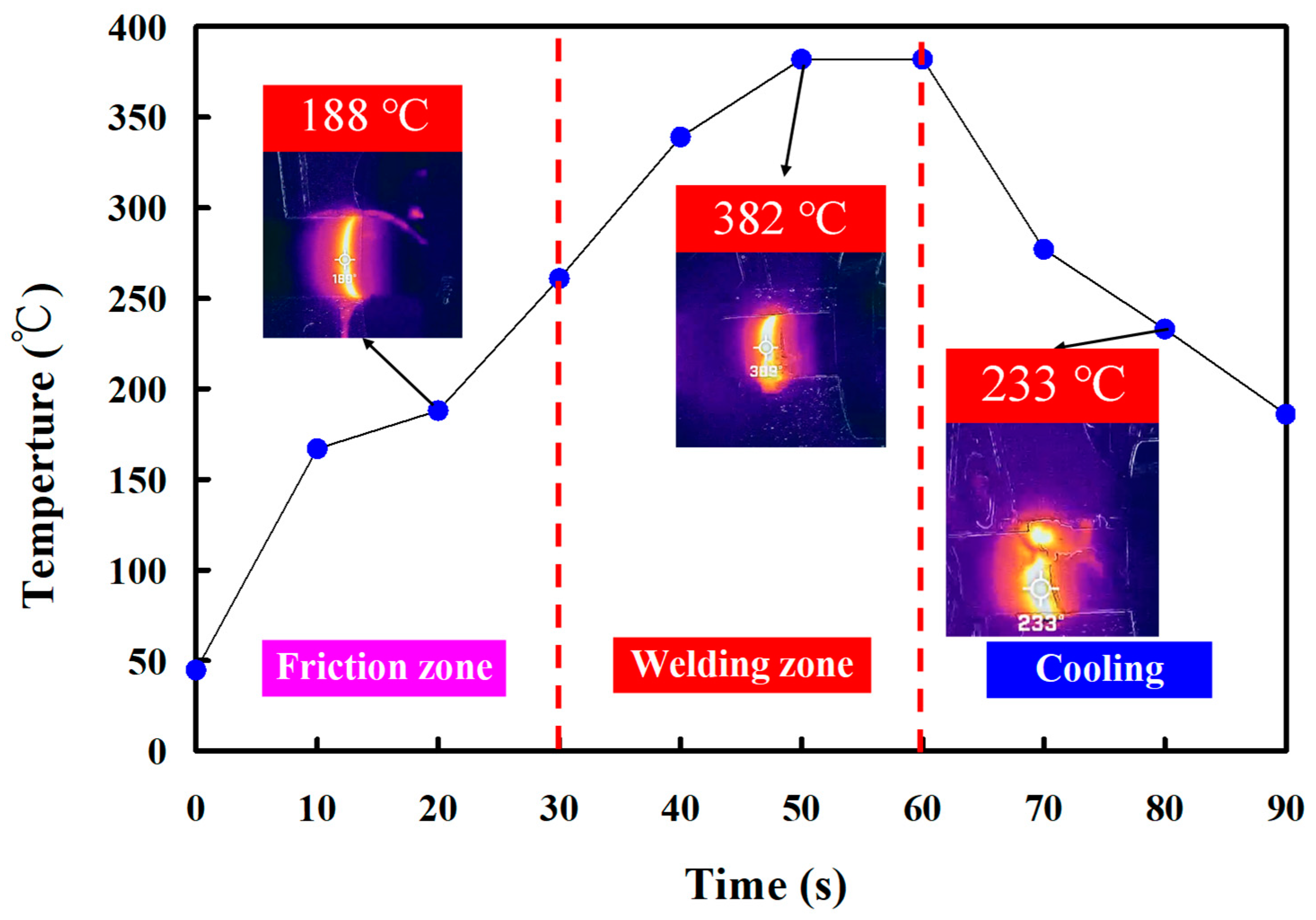

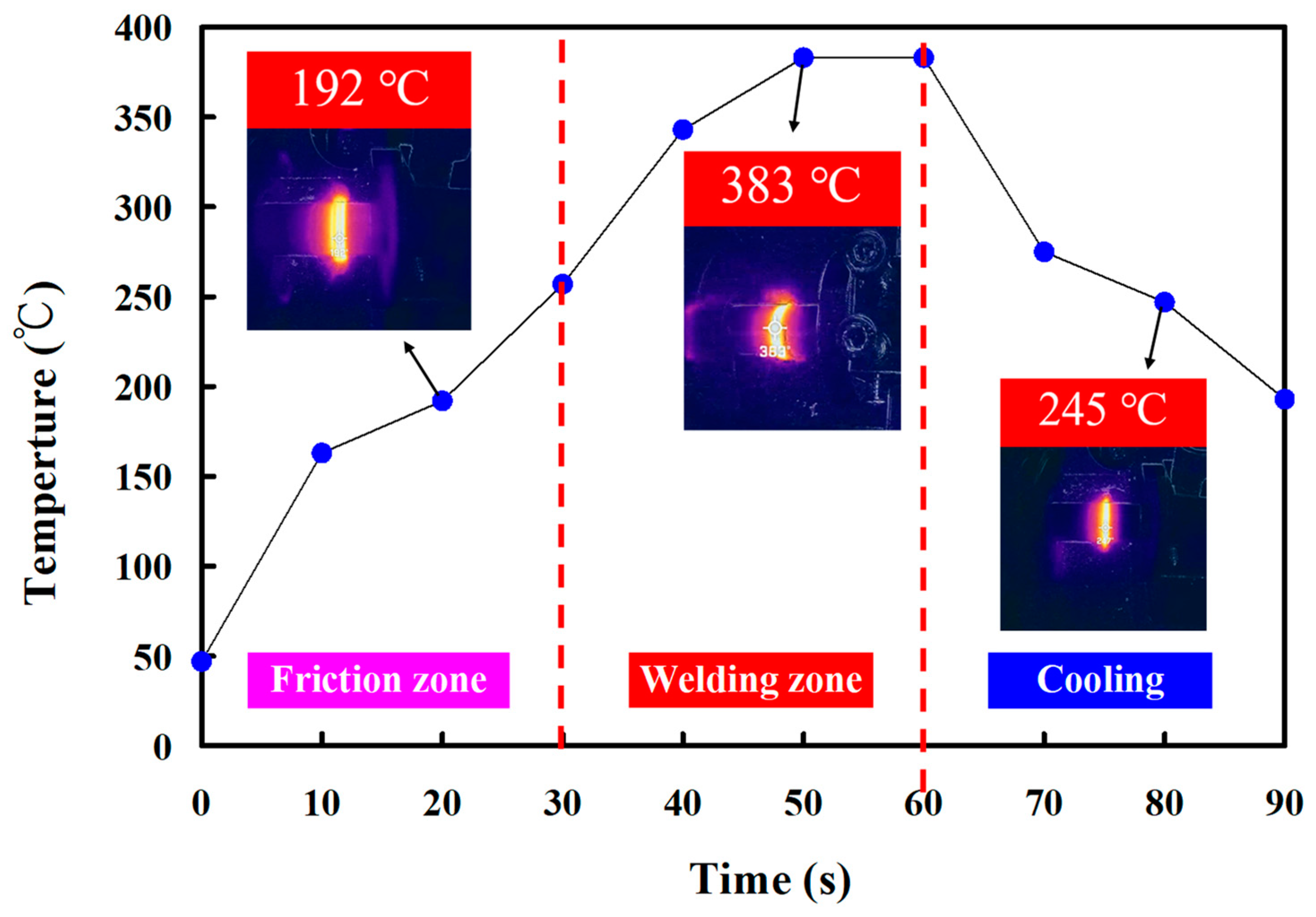

3. Results and Discussion

4. Conclusions

- The welding pressure (y) can be determined by the rotational speed (x) according to the prediction equation of y = 0.0134x + 62.762 with a correlation coefficient of 0.9753.

- The optimal burn-off length of 1.6 mm seems suitable for cylindrical rods with a length of 40 mm and a diameter of 20 mm for five rotational speeds.

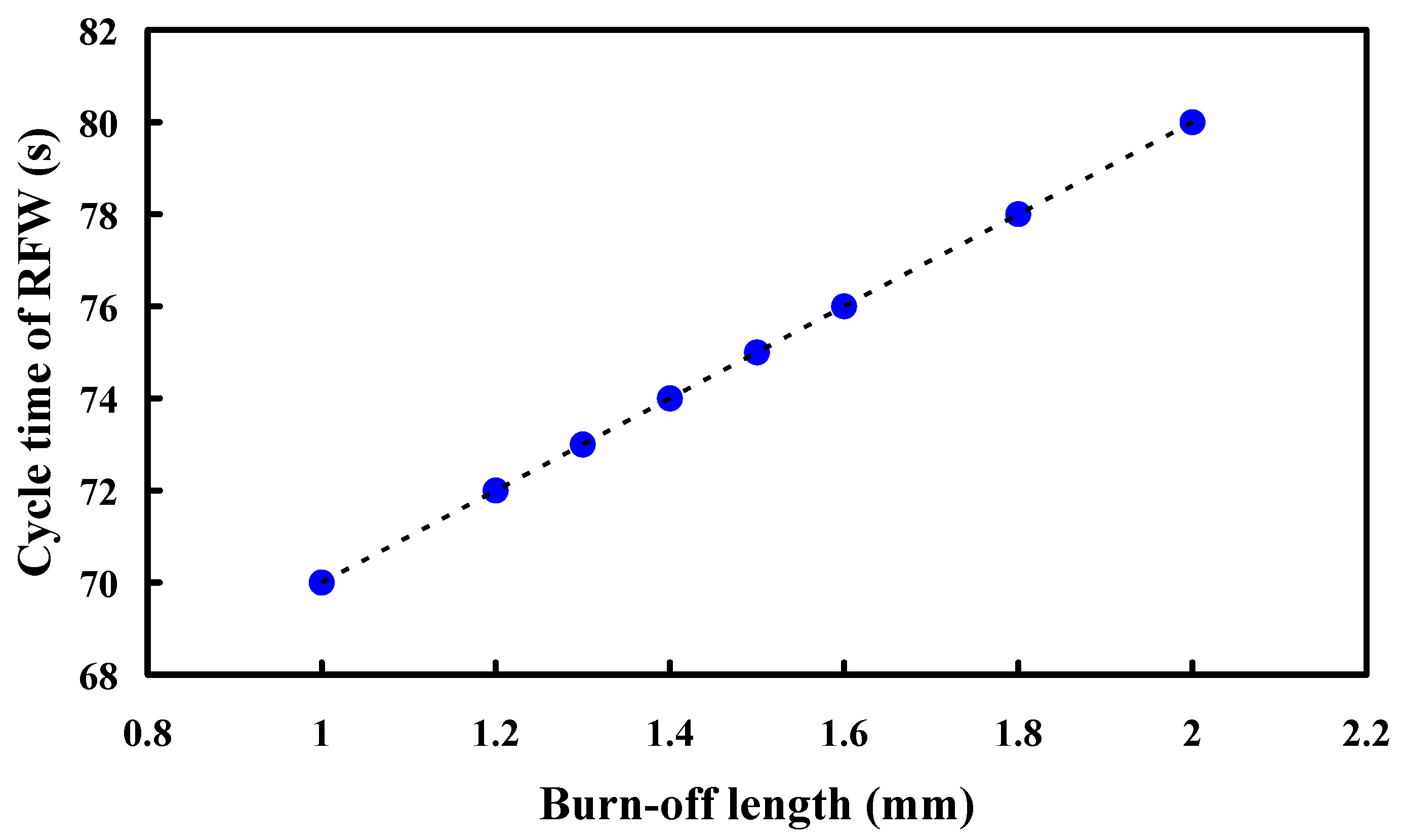

- For the rotational speed of 1000 rpm, the average bending strength of the welded parts increased from 108 MPa to 160 MPa when the burn-off length increased from 1 mm to 1.6 mm, and a saving in the cycle time of RFW about 5% can be obtained since the cycle time of RFW was reduced from 80 s to 76 s.

- The peak temperature in the weld interface for a rotational speed of 4000 rpm is only about 363 °C, which was attributed to the friction coefficient of the material being different due to the high rotation speed.

- The bending strength of the welded component through laser welding is inferior compared to that achieved using RFW. This discrepancy arises from the fact that the fiber laser only melts the peripheral material of the PEEK cylinder during the laser welding process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Chen, F.; Gatea, S.; Ou, H. Design of the novel hot incremental sheet forming experimental setup, characterization of formability behavior of polyether-ether-ketone (PEEK). Int. J. Adv. Manuf. Technol. 2020, 106, 5365–5381. [Google Scholar] [CrossRef]

- Rashed, K.; Kafi, A.; Simons, R.; Bateman, S. Effects of fused filament fabrication process parameters on tensile properties of polyether ketone ketone (PEKK). Int. J. Adv. Manuf. Technol. 2022, 122, 3607–3621. [Google Scholar] [CrossRef]

- Rashed, K.; Kafi, A.; Simons, R.; Bateman, S. Optimization of material extrusion additive manufacturing process parameters for polyether ketone ketone (PEKK). Int. J. Adv. Manuf. Technol. 2023, 126, 1067–1091. [Google Scholar] [CrossRef]

- Khoran, M.; Azarhoushang, B.; Amirabadi, H. Evaluating the influence of reinforcing fiber type on the grinding process of PEEK’s composites. Int. J. Adv. Manuf. Technol. 2021, 119, 2187–2200. [Google Scholar] [CrossRef]

- Lee, P.-C.; Peng, T.-Y.; Ma, T.-L.; Chiang, K.-Y.; Mine, Y.; Lee, I.-T.; Yu, C.-C.; Chen, S.-F.; Yu, J.-H. Effect of Various Airborne Particle Abrasion Conditions on Bonding between Polyether-Ether-Ketone (PEEK) and Dental Resin Cement. Polymers 2023, 15, 2114. [Google Scholar] [CrossRef]

- Miura, D.; Ishida, Y.; Shinya, A. The Effects of Different Molding Orientations, Highly Accelerated Aging, and Water Absorption on the Flexural Strength of Polyether Ether Ketone (PEEK) Fabricated by Fused Deposition Modeling. Polymers 2023, 15, 1602. [Google Scholar] [CrossRef]

- Vaddamanu, S.K.; Alhamoudi, F.H.; Chaturvedi, S.; Alqahtani, N.M.; Addas, M.K.; Alfarsi, M.A.; Vyas, R.; Kanji, M.A.; Zarbah, M.A.; Alqahtani, W.M.S.; et al. Retentive Forces and Deformation of Fitting Surface in RPD Clasp Made of Polyether-Ether-Ketone (PEEK). Polymers 2023, 15, 956. [Google Scholar] [CrossRef]

- Bontempi, M.; Capozza, R.; Visani, A.; Fini, M.; Giavaresi, G.; Gambardella, A. Near-Surface Nanomechanics of Medical-Grade PEEK Measured by Atomic Force Microscopy. Polymers 2023, 15, 718. [Google Scholar] [CrossRef]

- Yang, X.; Yokokura, S.; Nagahama, T.; Yamaguchi, M.; Shimada, T. Molecular Dynamics Simulation of Poly(Ether Ether Ketone) (PEEK) Polymer to Analyze Intermolecular Ordering by Low Wavenumber Raman Spectroscopy and X-ray Diffraction. Polymers 2022, 14, 5406. [Google Scholar] [CrossRef]

- Naghavi, S.A.; Lin, C.; Sun, C.; Tamaddon, M.; Basiouny, M.; Garcia-Souto, P.; Taylor, S.; Hua, J.; Li, D.; Wang, L.; et al. Stress Shielding and Bone Resorption of Press-Fit Polyether–Ether–Ketone (PEEK) Hip Prosthesis: A Sawbone Model Study. Polymers 2022, 14, 4600. [Google Scholar] [CrossRef]

- Zhou, Y.; Ren, L.; Zang, J.; Zhang, Z. The Shape Memory Properties and Actuation Performances of 4D Printing Poly (Ether-Ether-Ketone). Polymers 2022, 14, 3800. [Google Scholar] [CrossRef] [PubMed]

- Baltag, L.; Cojocaru, C.; Enache, A.-C.; Samoila, P.; Harabagiu, V. Ultrasonic-Assisted Rapid Preparation of Sulfonated Polyether Ether Ketone (PEEK) and Its Testing in Adsorption of Cationic Species from Aqueous Solutions. Materials 2022, 15, 7558. [Google Scholar] [CrossRef] [PubMed]

- Saravi, B.; Flohr, A.; Patzelt, S.B.; Spies, B.C.; Hazard, D.; Kohal, R.J. Fatigue and Fracture Resistance Testing of Polyether Ether Ketone (PEEK) Implant Abutments in an Ex Vivo Chewing Simulator Model. Materials 2022, 15, 6927. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yu, G.; Tian, C.; Li, Z.; Shao, J.; Li, S.; He, X. Hole Morphology and Keyhole Evolution during Single Pulse Laser Drilling on Polyether-Ether-Ketone (PEEK). Materials 2022, 15, 2457. [Google Scholar] [CrossRef] [PubMed]

- Bialas, O.; Lis, M.; Woźniak, A.; Adamiak, M. Laser Superficial Fusion of Gold Nanoparticles with PEEK Polymer for Cardiovascular Application. Materials 2021, 14, 971. [Google Scholar] [CrossRef] [PubMed]

- Pedroso, J.M.; Enger, M.; Bandeira, P.; Magalhães, F.D. Comparative Study of Friction and Wear Performance of PEK, PEEK and PEKK Binders in Tribological Coatings. Polymers 2022, 14, 4008. [Google Scholar] [CrossRef] [PubMed]

- Belkahla, Y.; Mazouzi, A.; Lebouachera, S.E.I.; Hassan, A.J.; Fides, M.; Hvizdoš, P.; Cheniti, B.; Miroud, D. Rotary friction welded C45 to 16NiCr6 steel rods: Statistical optimization coupled to mechanical and microstructure approaches. Int. J. Adv. Manuf. Technol. 2021, 116, 2285–2298. [Google Scholar] [CrossRef]

- Rinaldi, M.; Cecchini, F.; Pigliaru, L.; Ghidini, T.; Lumaca, F.; Nanni, F. Additive Manufacturing of Polyether Ether Ketone (PEEK) for Space Applications: A Nanosat Polymeric Structure. Polymers 2021, 13, 11. [Google Scholar] [CrossRef]

- Liu, C.; Chan, K.W.; Shen, J.; Liao, C.Z.; Yeung, K.W.K.; Tjong, S.C. Polyetheretherketone Hybrid Composites with Bioactive Nanohydroxyapatite and Multiwalled Carbon Nanotube Fillers. Polymers 2016, 8, 425. [Google Scholar] [CrossRef]

- Zhang, Y.; Hansen, H.N.; Sørensen, S. Replication of micro-pillars by PEEK injection moulding with CrN-coated Ni tool. Int. J. Adv. Manuf. Technol. 2015, 80, 383–388. [Google Scholar] [CrossRef]

- Griffiths, C.A.; Bigot, S.; Brousseau, E.; Worgull, M.; Heckele, M.; Nestler, J.; Auerswald, J. Investigation of polymer inserts as prototyping tooling for micro injection moulding. Int. J. Adv. Manuf. Technol. 2009, 47, 111–123. [Google Scholar] [CrossRef]

- Deringer, T.; Drummer, D. In situ curing and bonding of epoxy prepregs in epoxy thermoset injection molding. Int. J. Adv. Manuf. Technol. 2021, 117, 2667–2677. [Google Scholar] [CrossRef]

- Su, C.; Lv, S.; Wang, R.; Lv, Y.; Lou, S.; Wang, Q.; Guo, S. Effects of forming parameters on the forming limit of single-point incremental forming of sheet metal. Int. J. Adv. Manuf. Technol. 2021, 113, 483–501. [Google Scholar] [CrossRef]

- Khatri, B.; Roth, M.F.; Balle, F. Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors. J. Manuf. Mater. Process. 2023, 7, 2. [Google Scholar] [CrossRef]

- Alexenko, V.O.; Panin, S.V.; Stepanov, D.Y.; Byakov, A.V.; Bogdanov, A.A.; Buslovich, D.G.; Panin, K.S.; Tian, D. Ultrasonic Welding of PEEK Plates with CF Fabric Reinforcement—The Optimization of the Process by Neural Network Simulation. Materials 2023, 16, 2115. [Google Scholar] [CrossRef] [PubMed]

- Bonmatin, M.; Chabert, F.; Bernhart, G.; Cutard, T.; Djilali, T. Ultrasonic welding of CF/PEEK composites: Influence of welding parameters on interfacial temperature profiles and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107074. [Google Scholar] [CrossRef]

- Kunhirunbawon, S.; Suwichien, N.; Jantarasricha, T. Friction welding parameter for AA6063 using ANFIS prediction. Int. J. Adv. Manuf. Technol. 2023, 128, 2589–2597. [Google Scholar] [CrossRef]

- Naganaboyina, H.P.S.; Nagaraju, P.; Sonaye, S.Y.; Bokam, V.K.; Sikder, P. In-house processing of carbon fiber-reinforced polyetheretherketone (CFR-PEEK) 3D printable filaments and fused filament fabrication-3D printing of CFR-PEEK parts. Int. J. Adv. Manuf. Technol. 2023, 128, 5011–5024. [Google Scholar] [CrossRef]

- Assawakawintip, T.; Santiwong, P.; Khantachawana, A.; Sipiyaruk, K.; Chintavalakorn, R. The Effects of Temperature and Time of Heat Treatment on Thermo-Mechanical Properties of Custom-Made NiTi Orthodontic Closed Coil Springs. Materials 2022, 15, 3121. [Google Scholar] [CrossRef]

- El-Geassy, A.A.; Halim, K.S.A.; Alghamdi, A.S. A Novel Hydro-Thermal Synthesis of Nano-Structured Molybdenum-Iron Intermetallic Alloys at Relatively Low Temperatures. Materials 2023, 16, 2736. [Google Scholar] [CrossRef]

- Koniorczyk, P.; Zieliński, M.; Sienkiewicz, J.; Zmywaczyk, J.; Dębski, A. Experimental Studies of Thermophysical Properties and Microstructure of X37CrMoV5-1 Hot-Work Tool Steel and Maraging 350 Steel. Materials 2023, 16, 1206. [Google Scholar] [CrossRef] [PubMed]

- Elkolali, M.; Nogueira, L.P.; Rønning, P.O.; Alcocer, A. Void Content Determination of Carbon Fiber Reinforced Polymers: A Comparison between Destructive and Non-Destructive Methods. Polymers 2022, 14, 1212. [Google Scholar] [CrossRef] [PubMed]

- Misra, D.; Mitra, S.; Meena, H.L.; Datta, S.N.; Nayak, J.; Kalvettukaran, P.; Paul, S. Study of experimental and numerical simulation of high-energy laser processing on carbon fiber reinforced polymer. Int. J. Adv. Manuf. Technol. 2023, 129, 429–444. [Google Scholar] [CrossRef]

- Liu, H.; Wang, C.; Liu, Z.; Liu, K.; Jiang, S.; Wang, Y. Numerical prediction of machining-induced surface residual stress for TC4 cryogenic turning. Int. J. Adv. Manuf. Technol. 2021, 114, 131–144. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X. Machine learning surface roughnesses in turning processes of brass metals. Int. J. Adv. Manuf. Technol. 2022, 121, 2437–2444. [Google Scholar] [CrossRef]

- Bagga, P.J.; Makhesana, M.A.; Darji, P.P.; Patel, K.M.; Pimenov, D.Y.; Giasin, K.; Khanna, N. Tool life prognostics in CNC turning of AISI 4140 steel using neural network based on computer vision. Int. J. Adv. Manuf. Technol. 2022, 123, 3553–3570. [Google Scholar] [CrossRef]

- Miao, J.; Li, Y.; Ren, B.; Dong, Z.; Zou, W.; Chang, C.; Chang, Y. Current status of research on numerical simulation of droplet transfer in CO2 gas–shielded welding. Int. J. Adv. Manuf. Technol. 2023, 128, 1–15. [Google Scholar] [CrossRef]

- Abdul-Rashid, S.H.; Mohamad, M.N.; Sakundarini, N.; Ghazilla, R.A.R.; Thurasamy, R. Modelling sustainable manufacturing practices effects on sustainable performance: The contingent role of ownership. Int. J. Adv. Manuf. Technol. 2022, 122, 3997–4012. [Google Scholar] [CrossRef]

- Tian, S.; Xie, X.; Xu, W.; Liu, J.; Zhang, X. Dynamic assessment of sustainable manufacturing capability based on correlation relationship for industrial cloud robotics. Int. J. Adv. Manuf. Technol. 2021, 124, 3113–3135. [Google Scholar] [CrossRef]

- Klimant, P.; Koriath, H.J.; Schumann, M.; Winkler, S. Investigations on digitalization for sustainable machine tools and forming technologies. Int. J. Adv. Manuf. Technol. 2021, 117, 2269–2277. [Google Scholar] [CrossRef]

- Ribeiro, C.A.C.; Ferreira, J.R.; Lima e Silva, S.M. Thermal influence analysis of coatings and contact resistance in turning cutting tool using COMSOL. Int. J. Adv. Manuf. Technol. 2022, 118, 275–289. [Google Scholar] [CrossRef]

- Schorr, L.; Johnson, B.; McFall, J.; Shepherd, D.; Hadimani, R.L. High-temperature gripper for collaborative robots in additive manufacturing. Int. J. Adv. Manuf. Technol. 2023, 128, 1291–1303. [Google Scholar] [CrossRef]

- Erkol, H.O.; Bailey, M.; Palardy, G.; Barbalata, C. Predicting composite laminates roughness: Data-driven modeling approaches using force sensor data from robotic manipulators. Int. J. Adv. Manuf. Technol. 2023, 128, 1801–1813. [Google Scholar] [CrossRef]

- Feddoul, Y.; Ragot, N.; Duval, F.; Havard, V.; Baudry, D.; Assila, A. Exploring human-machine collaboration in industry: A systematic literature review of digital twin and robotics interfaced with extended reality technologies. Int. J. Adv. Manuf. Technol. 2023, 129, 1917–1932. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, C.-C.; Liang, H.-X.; Huang, S.-H. Characterization of the Polyetheretherketone Weldment Fabricated via Rotary Friction Welding. Polymers 2023, 15, 4552. https://doi.org/10.3390/polym15234552

Kuo C-C, Liang H-X, Huang S-H. Characterization of the Polyetheretherketone Weldment Fabricated via Rotary Friction Welding. Polymers. 2023; 15(23):4552. https://doi.org/10.3390/polym15234552

Chicago/Turabian StyleKuo, Chil-Chyuan, Hua-Xhin Liang, and Song-Hua Huang. 2023. "Characterization of the Polyetheretherketone Weldment Fabricated via Rotary Friction Welding" Polymers 15, no. 23: 4552. https://doi.org/10.3390/polym15234552

APA StyleKuo, C.-C., Liang, H.-X., & Huang, S.-H. (2023). Characterization of the Polyetheretherketone Weldment Fabricated via Rotary Friction Welding. Polymers, 15(23), 4552. https://doi.org/10.3390/polym15234552