Applications of Xylan Derivatives to Improve the Functional Properties of Cellulose Foams for Noise Insulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

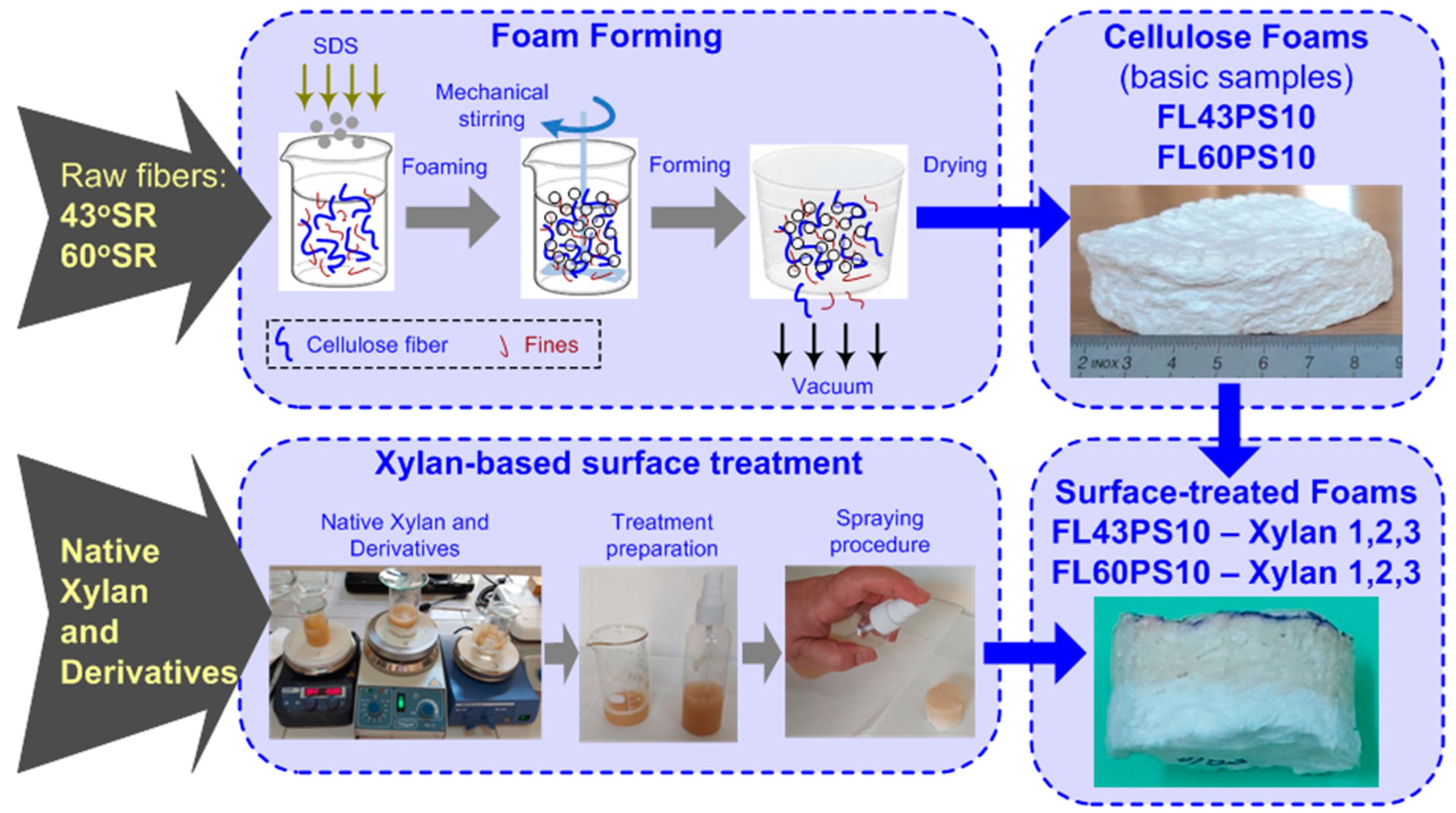

2.2. Methods within Sample Forming Procedure

2.3. Methods within Contact Angle Evaluation

2.4. Methods within FT-IR Investigations

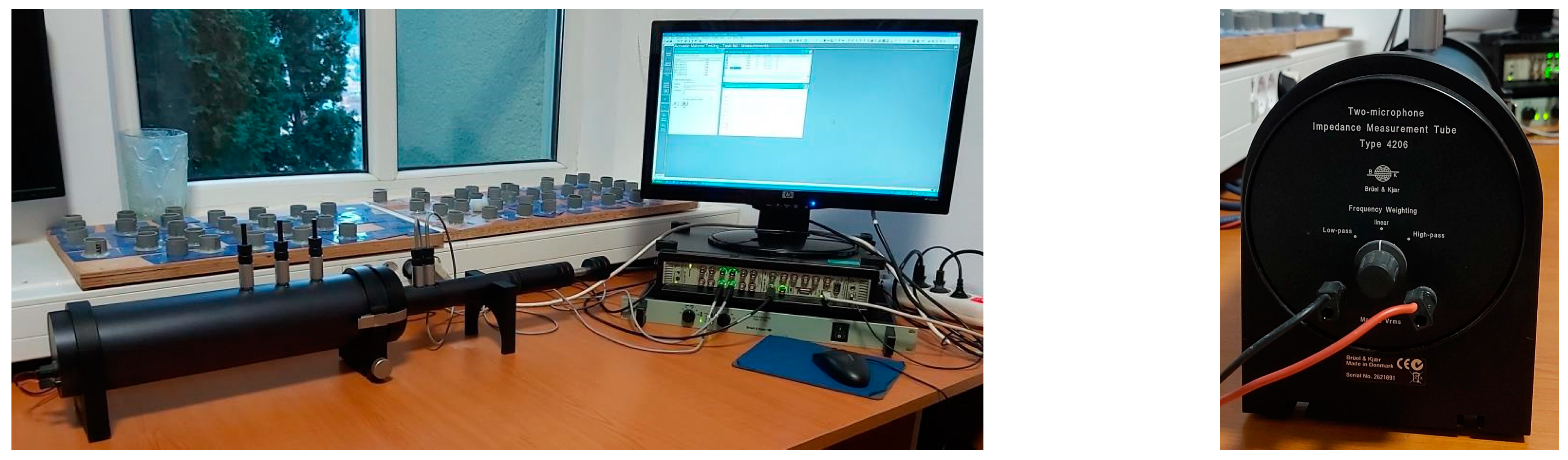

2.5. Methods within Noise Insulation Investigations

3. Results

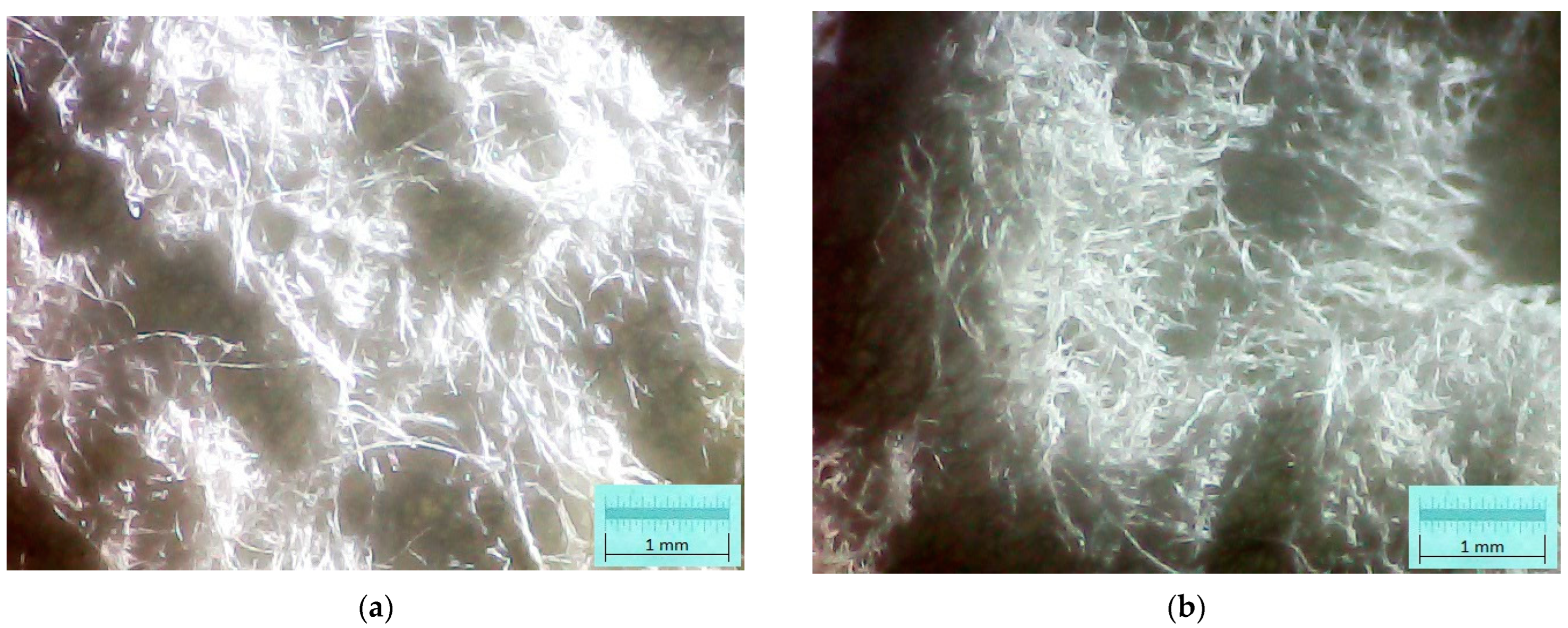

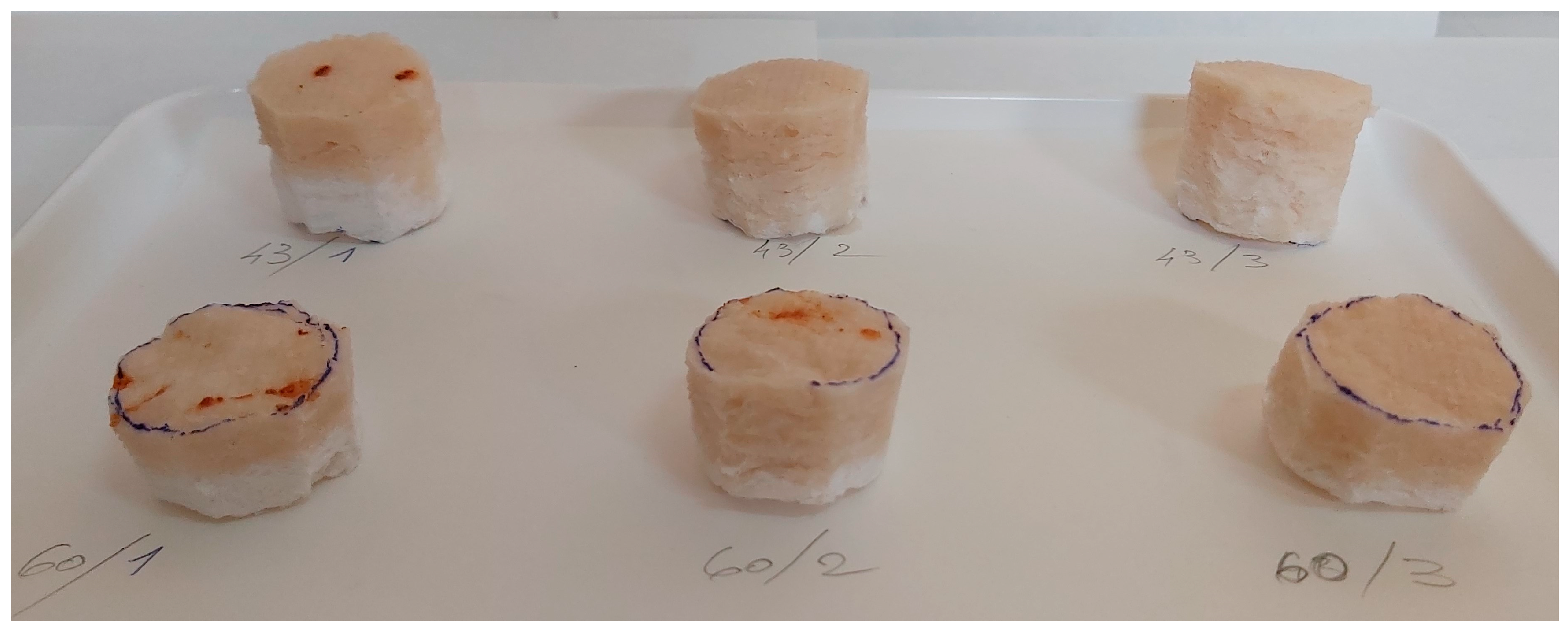

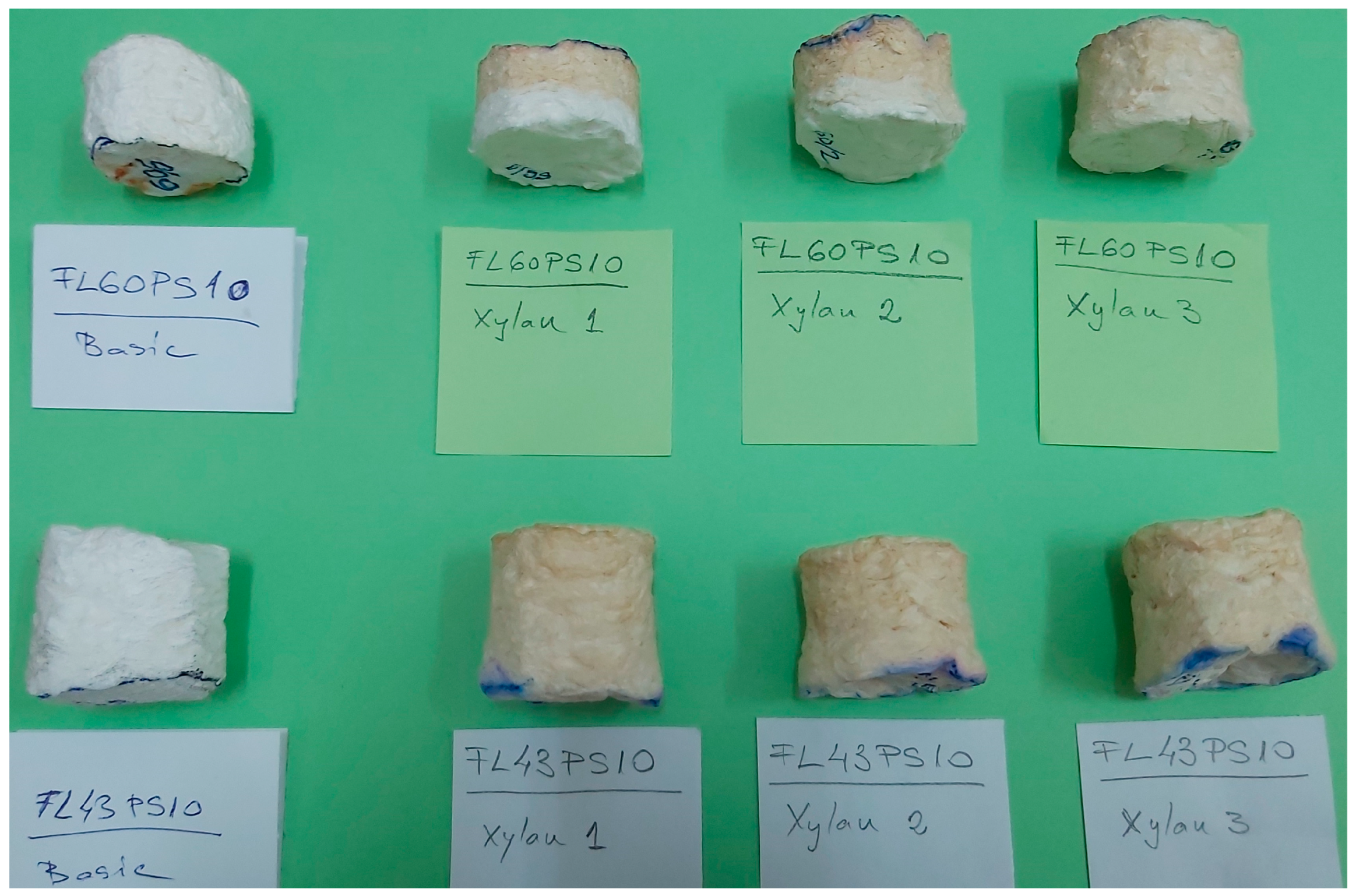

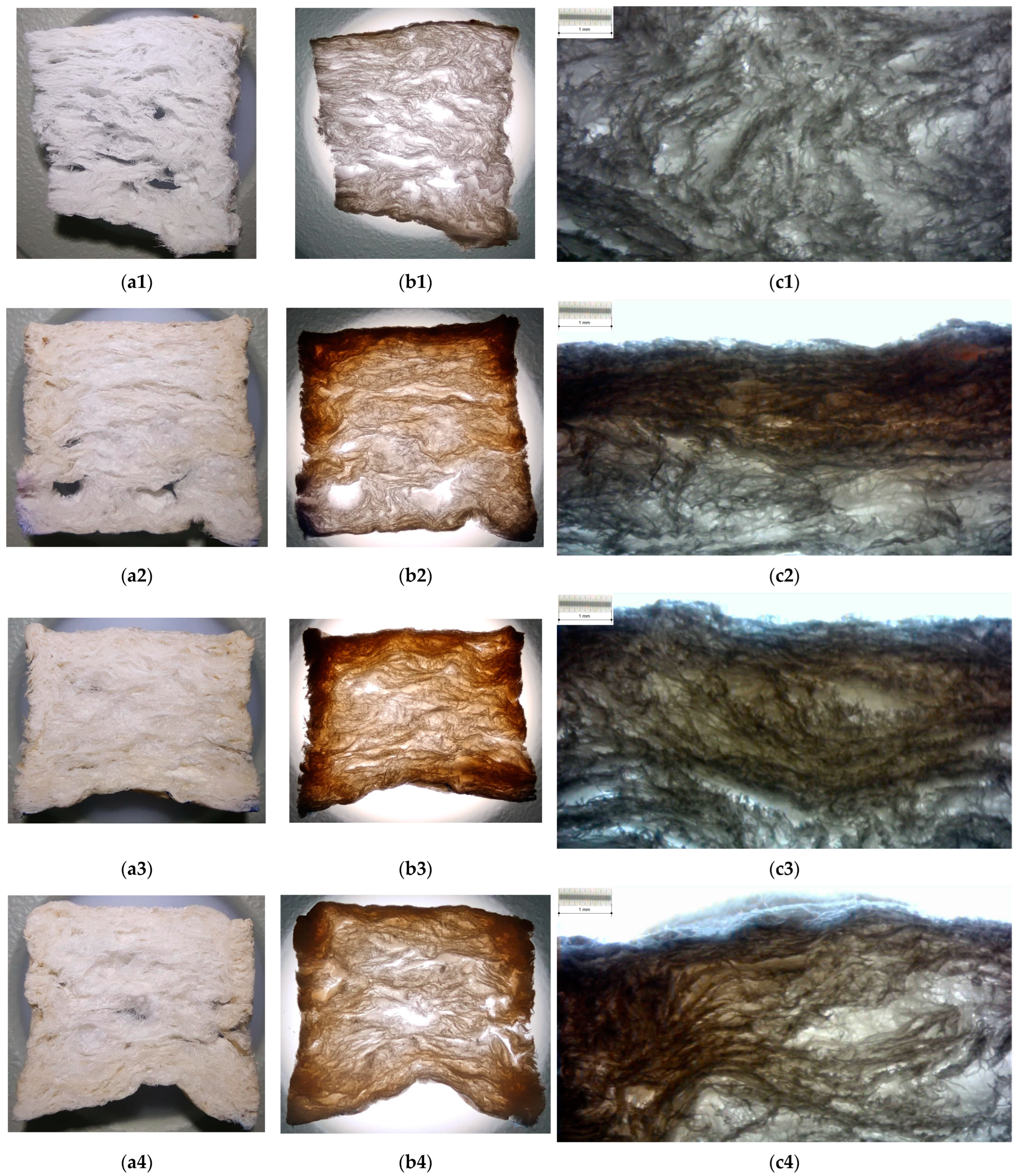

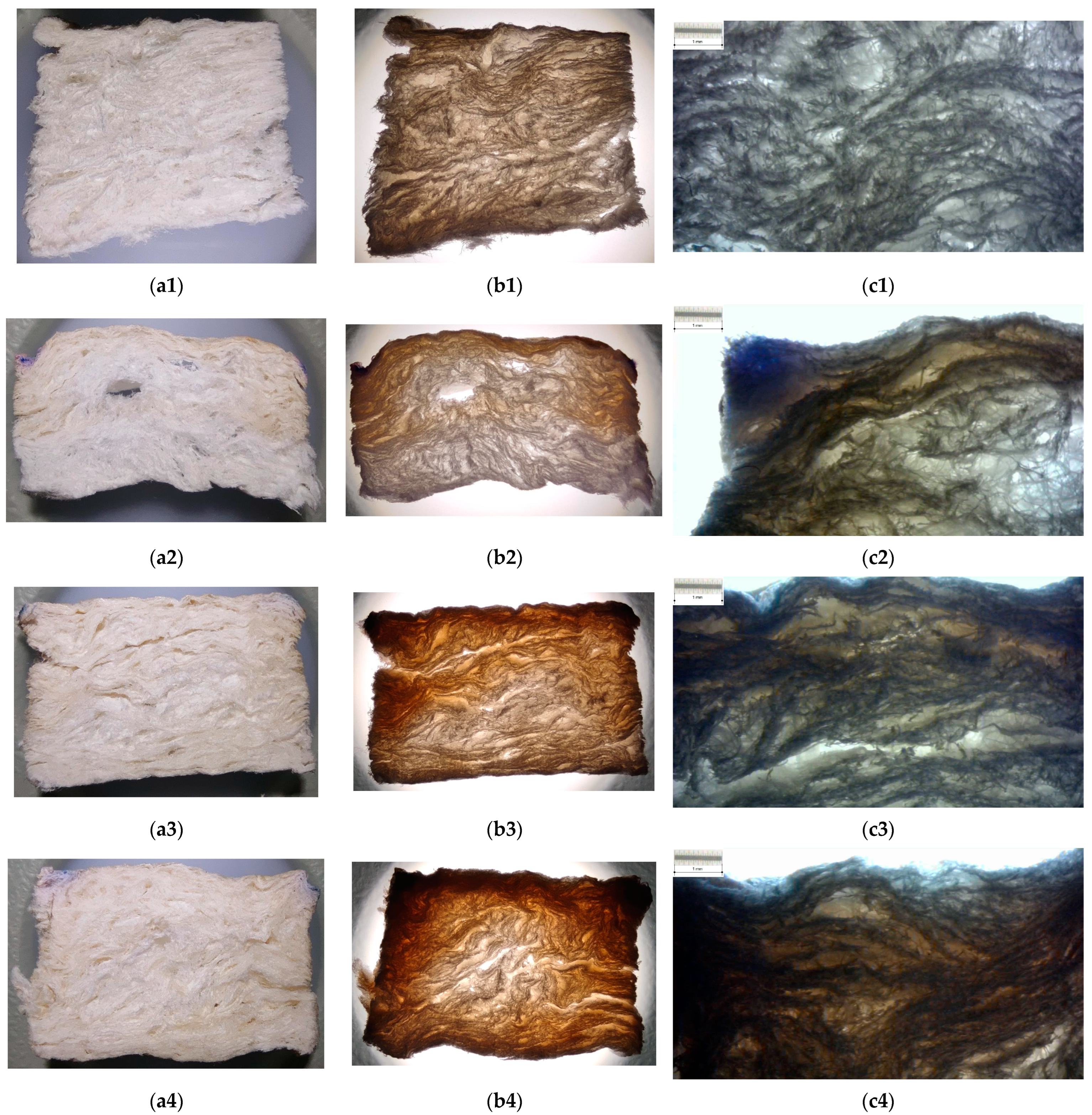

3.1. Cellulose-Based Foam Formed Samples with Xylan-Based Treatments

3.2. Static Water Contact Angle

3.3. FT-IR Analysis

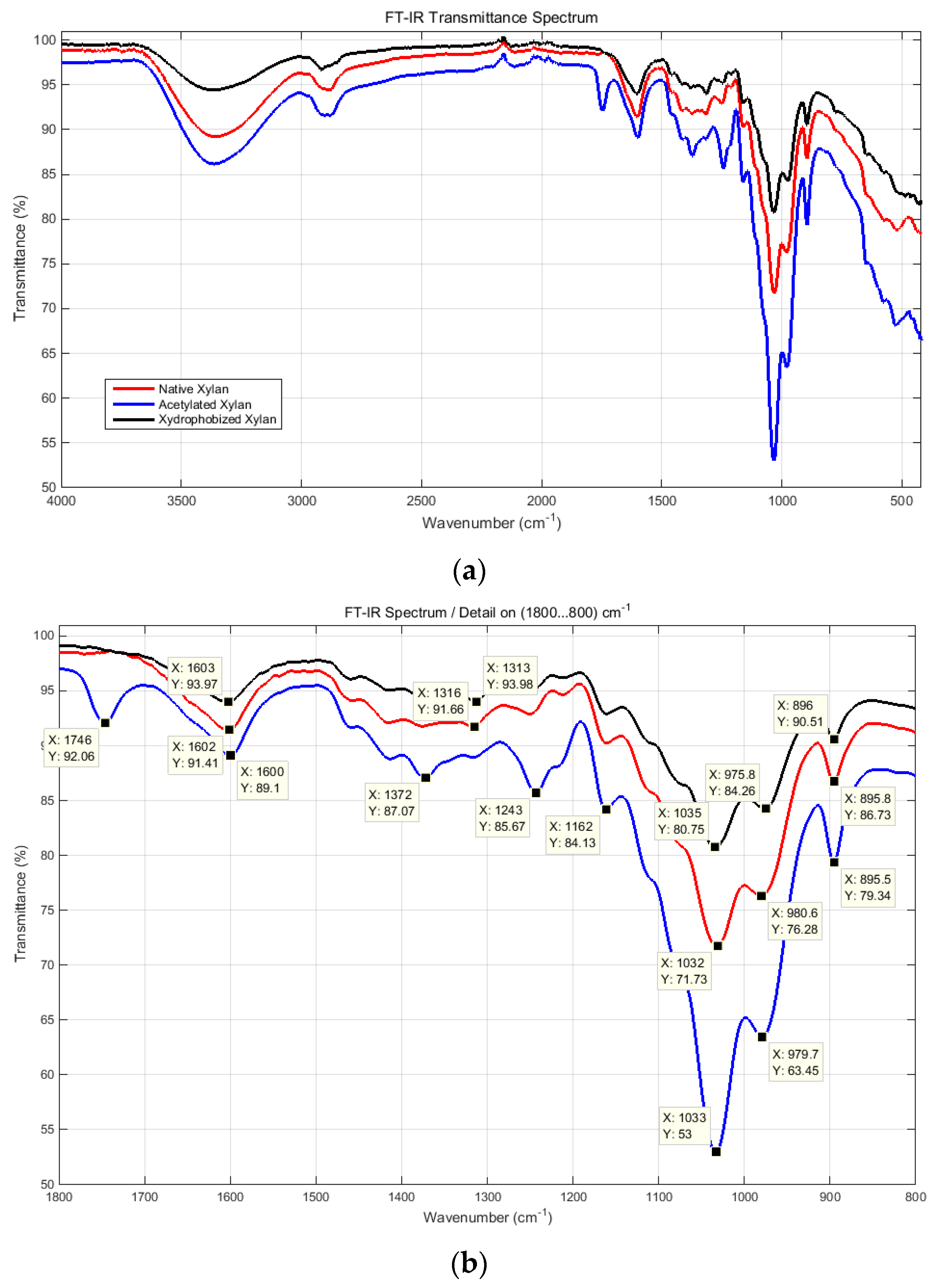

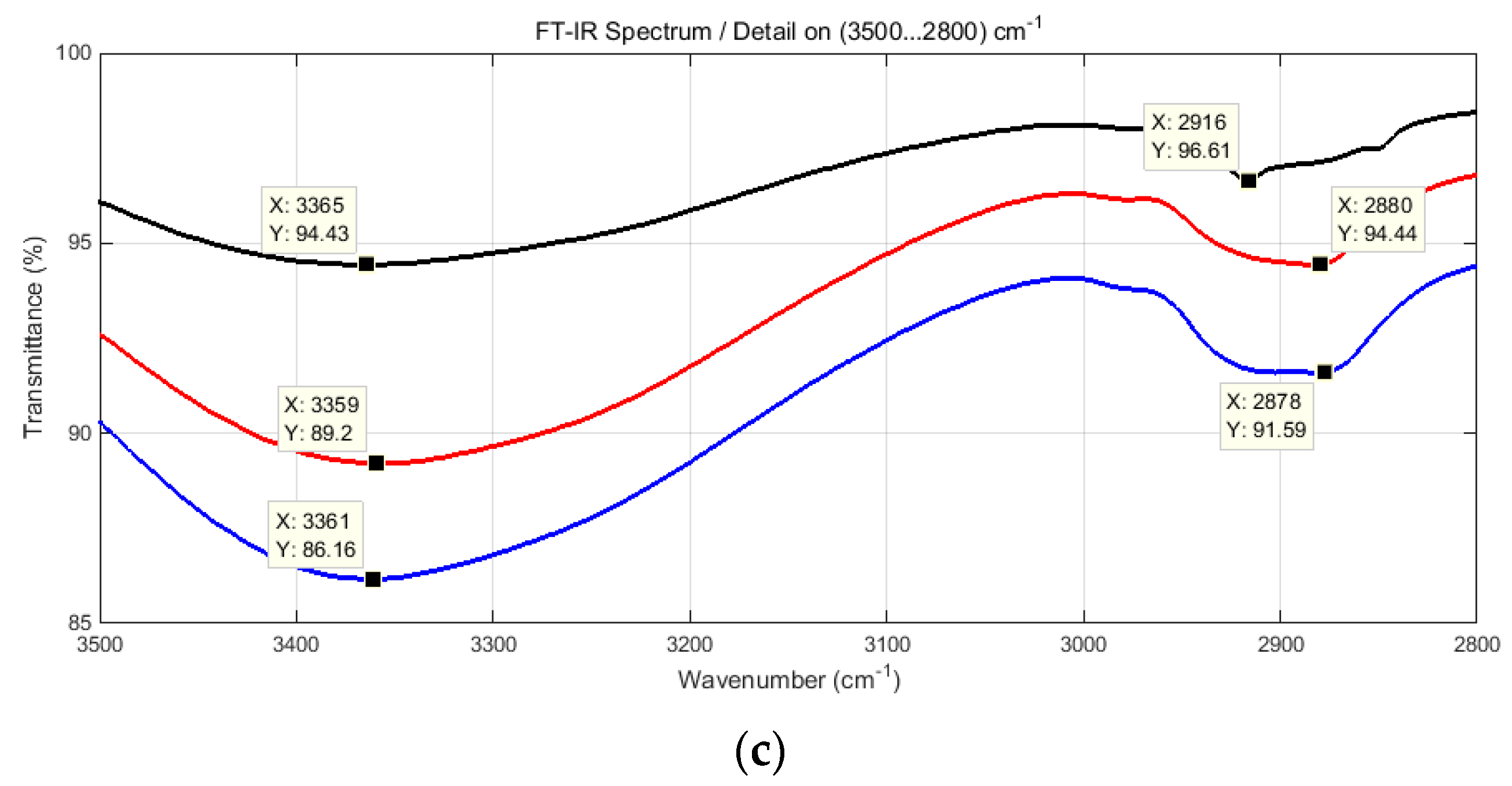

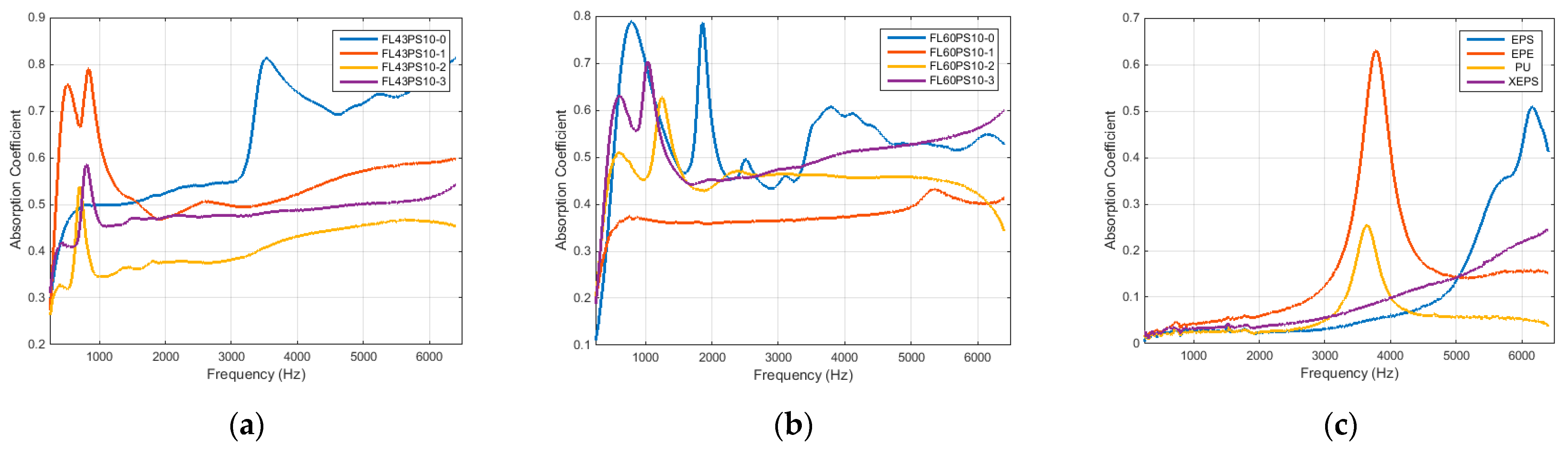

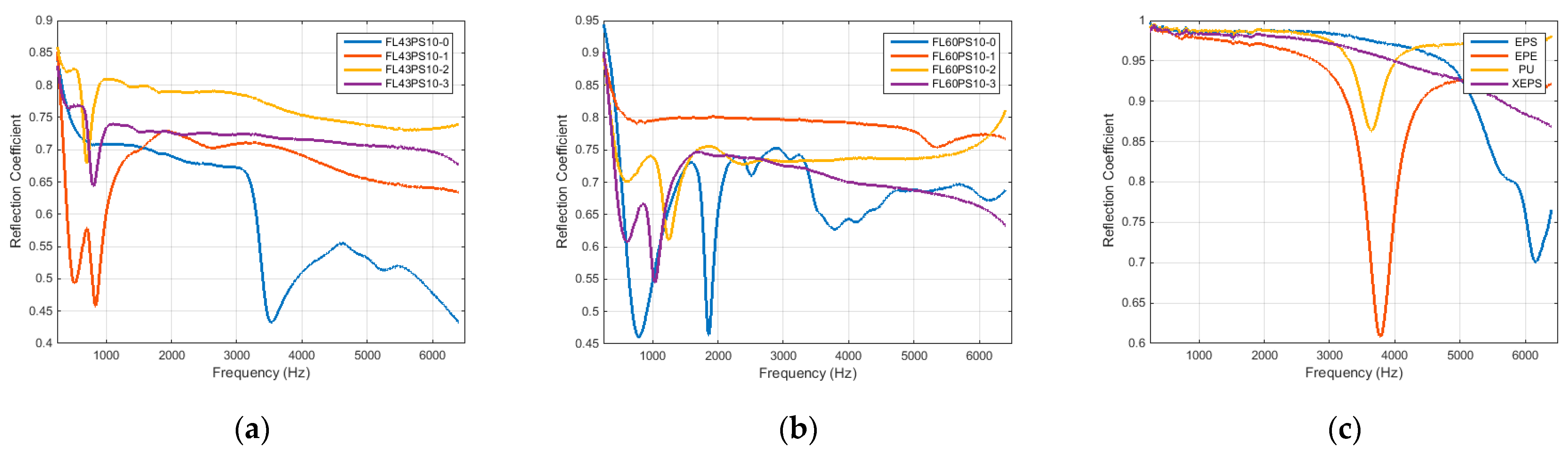

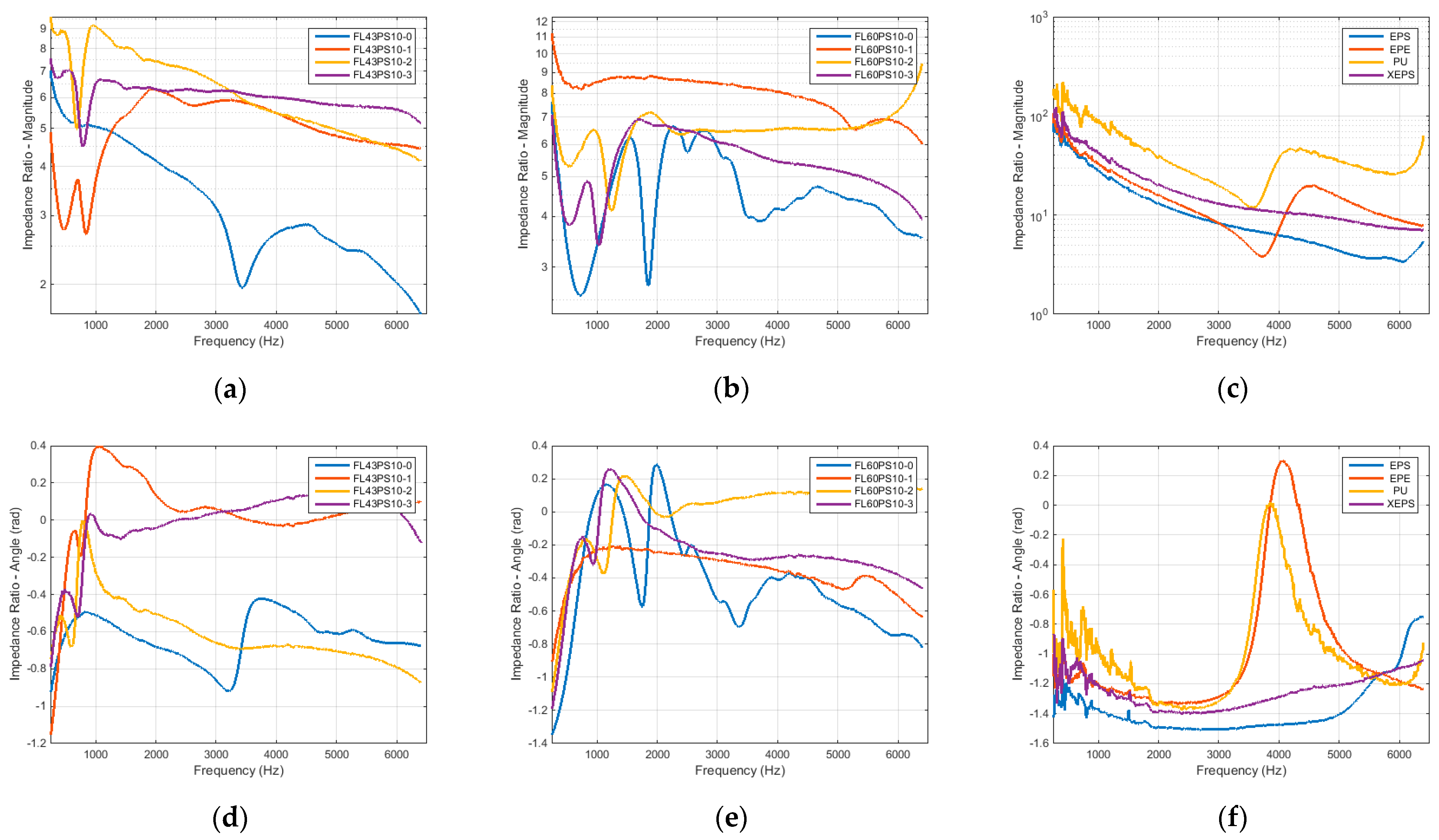

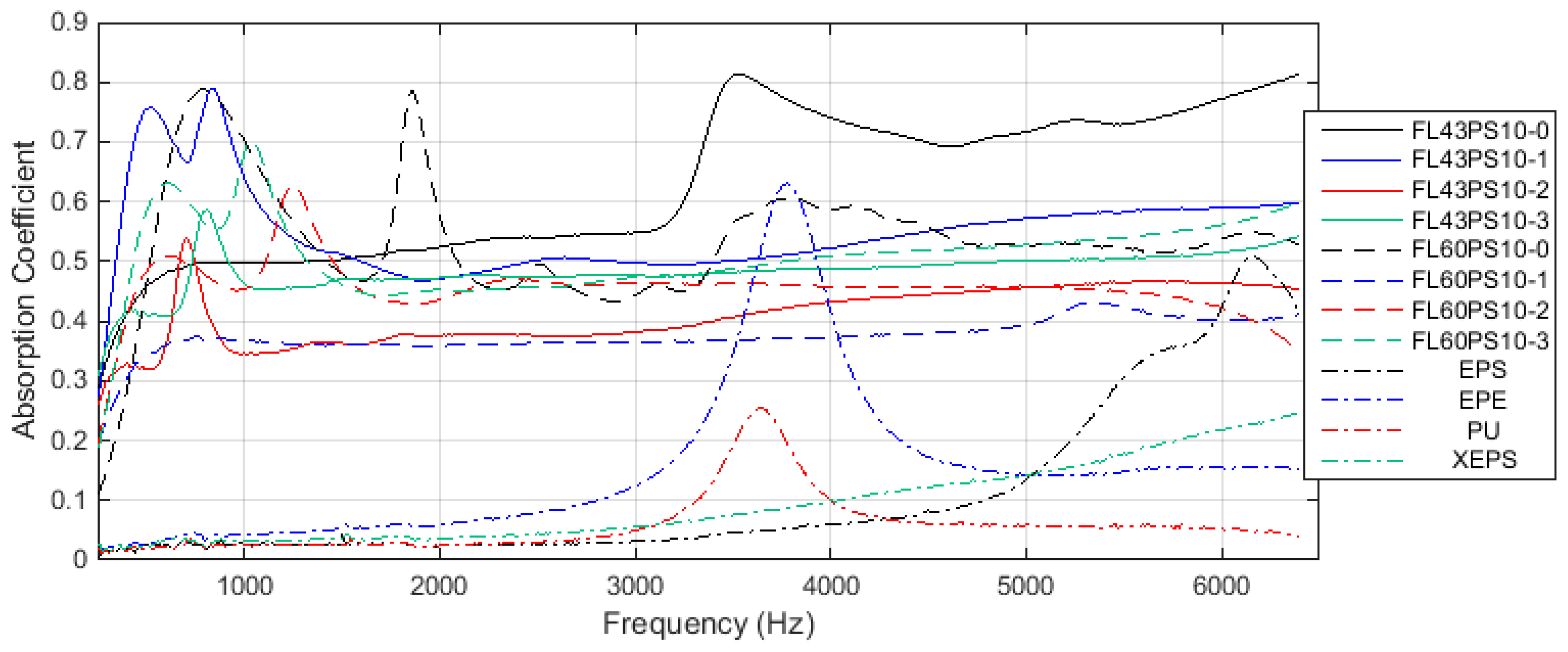

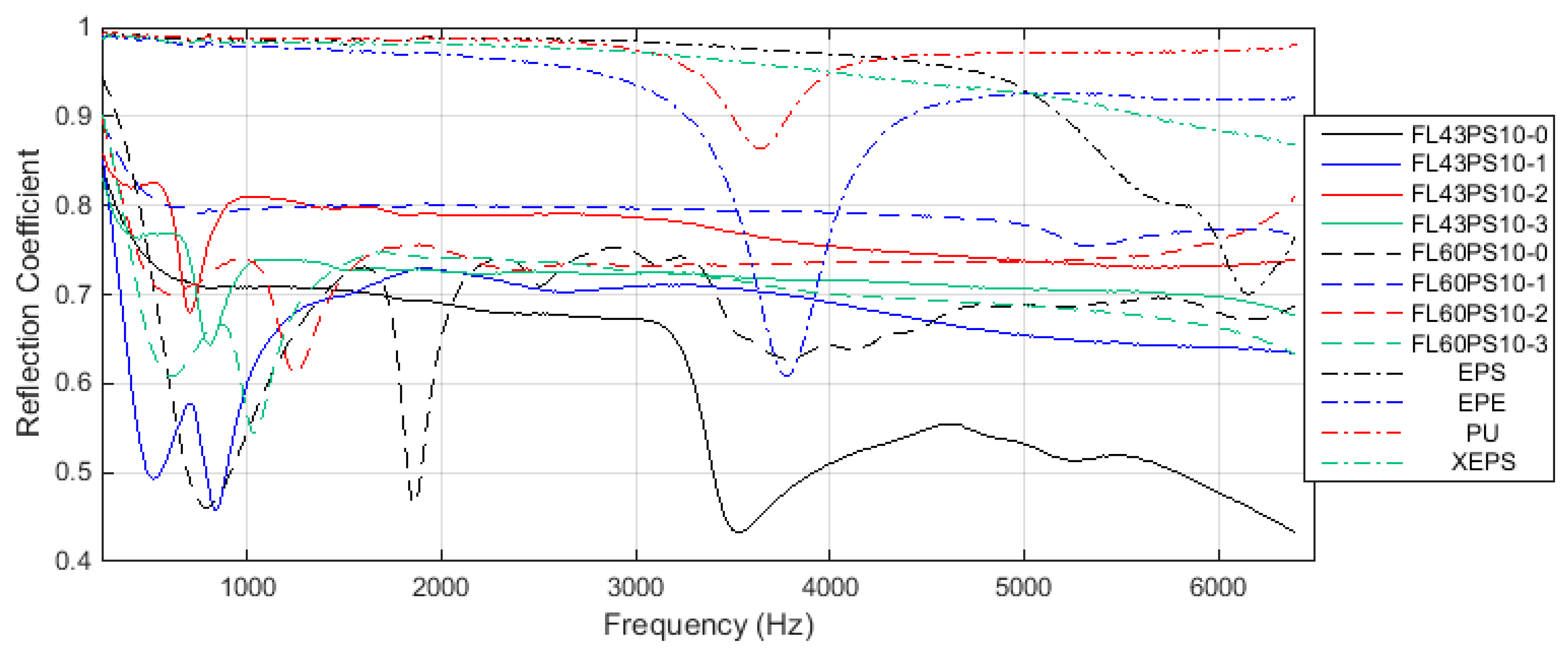

3.4. Noise Insulation Characteristics

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Miranda-Valdez, I.Y.; Coffeng, S.; Zhou, Y.; Viitanem, L.; Hu, X.; Jannuzzi, L.; Puisto, A.; Kostianien, M.A.; Makinen, T.; Kivisto, J.; et al. Foam-formed biocomposites based on cellulose products and lignin. Cellulose 2023, 30, 2253–2266. [Google Scholar] [CrossRef]

- Immonen, K.; Jetsu, P.; Keränen, J.T.; Torvinen, K. Feasibility of foam forming technology for producing wood plastic composites. J. Appl. Polym. Sci. 2020, 137, e49404. [Google Scholar] [CrossRef]

- Yan, W.; Liu, J.; Zheng, X.; Zhang, J.; Tang, K. Wood-derived high-performance cellulose structural materials. e-Polymers 2023, 23, 20230010. [Google Scholar] [CrossRef]

- Mohammadi, B.; Ershad-Langroudi, A.; Mousa, A.A.; Mazourra, A.M. Foam for Sound Insulation, Polymeric Foams: Applications of Polymeric Foams. In ACS Symposium Series, 1440; American Chemical Society: Washington, DC, USA, 2023; Volume 2, Chapter 12; pp. 253–272. [Google Scholar] [CrossRef]

- Ferreira, E.S.; Rezende, C.A. Simple Preparation of Cellulosic Lightweight Materials from Eucalyptus Pulp. ACS Sustain. Chem. Eng. 2018, 6, 14365–14373. [Google Scholar] [CrossRef]

- Al-Qararah, A.M.; Hjelt, T.; Kinnunen, K.; Beletski, N.; Ketoja, J.A. Exceptional pore size distribution in foam-formed fibre networks. Nord. Pulp Pap. Res. J. 2012, 27, 226–230. [Google Scholar] [CrossRef]

- Cervin, N.T.; Andersson, L.; Ng, J.B.S.; Olin, P.; Bergstorm, L.; Wagberg, L. Lightweight and strong cellulose materials made from aqueous foams stabilized by nano-fibrillated cellulose. Biomacromolecules 2013, 14, 503–511. [Google Scholar] [CrossRef]

- Ferreira, E.S.; Dobrzanski, E.; Tiwary, P.; Agrawal, P.; Chen, R.; Cranston, E.D. Insulative wood materials templated by wet foams. Mater. Adv. 2023, 4, 641–650. [Google Scholar] [CrossRef]

- Keranen, J.T.; Jetsu, P.; Turpeinen, T.; Koponen, A.I. Dewatering and Structural Analysis of Foam-Formed, Lightweight Fibrous Materials. BioResources 2023, 18, 531–549. [Google Scholar] [CrossRef]

- Hurtado, P.L.; Rouilly, A.; Maréchal, V.V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef]

- Zhou, Y.; Yin, W.; Guo, Y.; Qin, C.; Qin, Y.; Liu, Y. Green. Preparation of Lightweight, High-Strength Cellulose-Based Foam and Evaluation of Its Adsorption Properties. Polymers 2023, 15, 1879. [Google Scholar] [CrossRef] [PubMed]

- Silviana, S.; Prastiti, E.C.; Hermawan, F.; Setyawan, A. Optimization of the Sound Absorption Coefficient (SAC) from Cellu-lose–Silica Aerogel Using the Box–Behnken Design. ACS Omega 2022, 7, 41968–41980. [Google Scholar] [CrossRef] [PubMed]

- Akıncı, T.C. Evaluation of sound absorption properties of natural fiber materials. J. Nat. Fibers 2018, 15, 336–349. [Google Scholar]

- Taiwo, E.M.; Yahya, K.; Haron, Z. Potential of Using Natural Fiber for Building Acoustic Absorber: A Review. J. Phys. Conf. Ser. 2019, 1262, 012017. [Google Scholar] [CrossRef]

- Arenas, J.P.; Rebolledo, J.; del Rey, R.; Alba, J. Sound absorption properties of unbleached cellulose loose-fill insulation material. BioResources 2014, 9, 6227–6240. [Google Scholar] [CrossRef]

- Cucharero, J.; Ceccherini, S.; Maloney, T.; Lokki, R.; Hannien, T. Sound absorption properties of wood-based pulp fibre foams. Cellulose 2021, 28, 4267–4279. [Google Scholar] [CrossRef]

- Jahangiri, P. Novel Cellulose based Foam-Formed Products: Applications and Numerical Studies. Ph.D. Thesis, University of Vancouver, Vancouver, BC, Canada, 2013. [Google Scholar]

- Jahangiri, P.; Madani, A.; Korehei, R.; Zeinoddini, S.S.; Madani, A.; Sharma, A.; Phillion, A.; Martinez, M.D.; Olson, J.A. On filtration and heat insulation properties of foam formed cellulose based materials. Nord. Pulp Pap. 2014, 29, 584–591. [Google Scholar] [CrossRef]

- Jahangiri, P.; Logawa, B.; Korehei, R.; Hodgson, M.; Martinez, D.M.; Olson, J.A. On acoustical properties of novel foam-formed cellulose-based material. Nord. Pulp Pap. Res. J. 2016, 31, 14–19. [Google Scholar] [CrossRef]

- Stanciu, M.D.; Savin, A.; Nastac, S.M. Mechanical and surface properties of lignocellulosicfibres reinforced composites. Stroj. Vestn 2018, 64, 698–705. [Google Scholar]

- Seciureanu, M.; Nastac, S.-M.; Guiman, M.-V.; Nechita, P. Cellulose Fibers-Based Porous Lightweight Foams for Noise Insulation. Polymers 2023, 15, 3796. [Google Scholar] [CrossRef]

- Nechita, P.; Nastac, S. Foam-formed cellulose composite materials with potential applications in sound insulation. J. Compos. Mater. 2018, 52, 747–754. [Google Scholar] [CrossRef]

- Debeleac, C.; Nechita, P.; Nastac, S. Computational investigations on soundproof applications of foam-formed cellulose materials. Polymers 2019, 11, 1223. [Google Scholar] [CrossRef]

- Nastac, S.; Nechita, P.; Debeleac, C.; Simionescu, C.; Seciureanu, M. The Acoustic Performance of Expanded Perlite Composites Reinforced with Rapeseed Waste and Natural Polymers. Sustainability 2022, 14, 103. [Google Scholar] [CrossRef]

- Ionescu, S.; Nechita, P. Thermo-Insulating Panels Based on Composite Structures from Vegetal Fibres and Polymeric Matrix. Adv. Mater. Res. 2017, 1143, 154–159. [Google Scholar]

- Nechita, P.; Roman, M.; Nastac, S.M. Green Approaches on Modification of Xylan Hemicellulose to Enhance the Functional Properties for Food Packaging Materials—A Review. Polymers 2023, 15, 2088. [Google Scholar] [CrossRef] [PubMed]

- Nastac, S.; Debeleac, C.; Nechita, P. Assessments On Shock Absorption Properties Of Foam-Formed Low Density Cellulose Composites. Acta Tech. Napoc. Ser. -Appl. Math. Mech. Eng. 2017, 60, 565–572. [Google Scholar]

- Radvan, B.; Gatward, A. Formation of wet-laid webs by a foaming process. Tappi 1972, 55, 748. [Google Scholar]

- Xiang, W.; Filpponen, I.; Saharinen, E.; Lappalainen, T.; Salminen, K.; Rojas, O.J. Foam Processing of Fibers As a Sustainable Alternative to Wet-Laying: Fiber Web Properties and Cause–Effect Relations. ACS Sustain. Chem. Eng. 2018, 6, 14423–14431. [Google Scholar] [CrossRef]

- Madani, A.; Zeinoddini, S.; Varahmi, S.; Turnbull, H.; Phillion, A.B.; Martinez, M.D. Ultra-lightweight paper foams: Processing and properties. Cellulose 2014, 21, 2023–2031. [Google Scholar] [CrossRef]

- Hasan, A.; Rabbi, M.S.; Billah, M. Making the lignocellulosic fibers chemically compatible for composite: A comprehensive review. Clean. Mater. 2022, 4, 100078. [Google Scholar] [CrossRef]

- Tauhiduzzaman, M.; Hafez, I.; Bousfield, D.; Tajvidi, M. Multiscale modeling of lignocellulosic foams under compression. Mater. Des. 2023, 225, 111471. [Google Scholar] [CrossRef]

- Leppänen, M.; Väätäinen, P. Environmental impact of cellulose-based insulation materials. Energy Build. 2018, 166, 246–254. [Google Scholar]

- Hjelt, T.; Ketoja, J.A.; Kiiskinen, H.; Koponen, A.I.; Paakkonen, E. Foam forming of fiber products: A review. J. Dispers. Sci. Technol. 2022, 43, 1462–1497. [Google Scholar] [CrossRef]

- Nechita, P.; Nastac, S.M. Overview on Foam Forming Cellulose Materials for Cushioning Packaging Applications. Polymers 2022, 14, 1963. [Google Scholar] [CrossRef]

- Abd El-Sayed, E.; El-Sakhawy, M.; El-Sakhawy, M. Non-wood fibers as raw material for pulp and paper industry. Nord. Pulp Pap. Res. J. 2020, 35, 215–230. [Google Scholar] [CrossRef]

- Cheng, F.; Lu, P.; Ren, P.; Chen, J.; Ou, Y.; Lin, M.; Liu, D. Preparation and properties of foamed cellulose-polymer microsphere hybrid materials for sound absorption. BioResources 2016, 11, 7394–7405. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R. Characterizing and modelling the sound absorption of the cellulose acetate fibers coming from cigarette butts. J. Environ. Health Sci. Eng. 2021, 19, 1075–1086. [Google Scholar] [CrossRef]

- Reichler, M.; Rabensteiner, S.; Törnblom, L.; Coffeng, S.; Viitanen, L.; Jannuzzi, L.; Makinen, T.; Mac Intyne, J.R.; Koivisto, J.; Puisto, A.; et al. Scalable method for bio-based solid foams that mimic wood. Sci. Rep. 2021, 11, 24306. [Google Scholar] [CrossRef] [PubMed]

- Miranda-Valdez, I.Y.; Yazdani, M.R.; Mäkinen, T.; Coffeng, S.; Viitanen, L.; Koivisto, J.; Alava, M.J. Cellulose foams as scalable templates for phase change materials. J. Energy Storage 2023, 73 Pt B, 109036. [Google Scholar] [CrossRef]

- Ketola, A.E.; Song, W.; Lappalainen, T.; Salminen, K.; Viitala, J.; Turpinen, T.; Lee, K.-Y.; Ketoja, J.A. Changing the Structural and Mechanical Anisotropy of Foam-Formed Cellulose Materials by Affecting Bubble−Fiber Interaction with Surfactant. ACS Appl. Polym. Mater. 2022, 4, 7685–7698. [Google Scholar] [CrossRef]

- Neri, M.; Levi, E.; Cuerva, E.; Pardo-Bosch, F.; Zabaleta, A.G.; Pujadas, P. Sound Absorbing and Insulating Low-Cost Panels from End-of-Life Household Materials for the Development of Vulnerable Contexts in Circular Economy Perspective. Appl. Sci. 2021, 11, 5372. [Google Scholar] [CrossRef]

- Ruan, J.; Tang, S.; Dai, J. Research on sound absorption property of natural cellulose fiber. In Proceedings of the 2018 2nd International Conference on Composite Material, Polymer Science and Engineering (CMPSE), Osaka, Japan, 21–22 September 2018; pp. 242–245. [Google Scholar]

- Sombatsompop, N.; Niamsuwan, V. Acoustical properties of wood-based materials. In Wood in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2012; pp. 153–177. [Google Scholar]

- Joutsimo, O.P.; Tyrväinen, P. The effect of fiber properties on sound absorption of soft fiberboards. Appl. Acoust. 2014, 77, 17–24. [Google Scholar]

- Sahin, T.; Yılmaz, H. Sound absorption properties of wood-based insulation materials. J. Acoust. Soc. Am. 2016, 140, 3043. [Google Scholar]

- Malekzadeh, H.; MdZaid, N.S.B.; Bele, E. Characterization and structural properties of bamboo fibre solid foams. Cellulose 2021, 28, 703–714. [Google Scholar] [CrossRef]

- Sari, K.; Isnen, Y.Z.; Utomo, A.B.S.; Sunardi, S. Properties of pineapple leaf fibers with paper waste as an absorbing-composite to reduce noise. J. Ilm. Pendidik. Fis. Al-Biruni 2022, 11, 175–184. [Google Scholar] [CrossRef]

- Li, R.; Du, J.; Zheng, Y.; Wen, Y.; Zhang, X.; Yang, Y.; Lue, A.; Zhang, L. Ultra-lightweight cellulose foam material: Preparation and properties. Cellulose 2017, 24, 1417–1426. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G.; Guerriero, L.; Trematerra, A. Use of Cork Sheets for Room Acoustic Correction. J. Green Build. 2020, 15, 45–55. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Membrane-type acoustic metamaterial using cork sheets and attached masses based on reused materials. Appl. Acoust. 2022, 189, 108605. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A Review of Sustainable Materials for Acoustic Applications. Build. Acoust. 2012, 19, 283–311. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G. Modelling sound absorption properties for recycled polyethylene terephthalate-based material using Gaussian regression. Build. Acoust. 2021, 28, 185–196. [Google Scholar] [CrossRef]

- Ciaburro, G.; Puyana-Romero, V.; Iannace, G.; Jaramillo-Cevallos, W.A. Characterization and Modeling of Corn Stalk Fibers tied with Clay using Support Vector Regression Algorithms. J. Nat. Fibers 2022, 19, 7141–7156. [Google Scholar] [CrossRef]

- Paunonen, S.; Timofeev, O.; Torvinen, K.; Turpeinen, T.; Ketoja, J.A. Improving compression recovery of foam-formed fiber materials. BioResources 2018, 13, 4058–4074. [Google Scholar] [CrossRef]

- Wu, M.; Yu, G.; Chen, W.; Dong, S.; Wang, Y.; Liu, C.; Li, B. A pulp foam with highly improved physical strength, fire-resistance and antibiosis by incorporation of chitosan and CPAM. Carbohydr. Polym. 2022, 278, 118963. [Google Scholar] [CrossRef] [PubMed]

- Ergun, M.E. Activated Carbon and Cellulose-reinforced Biodegradable Chitosan Foams. BioResources 2023, 18, 1215–1231. [Google Scholar] [CrossRef]

- Ottenhall, A.; Seppänen, T.; Ek, M. Water-stable cellulose fiber foam with antimicrobial properties for bio based low-density materials. Cellulose 2018, 25, 2599–2613. [Google Scholar] [CrossRef]

- Seppänen, T.; Ketoja, J.; Pöhler, T.; Pääkkönen, E. Wet strength properties of foam formed fiber materials. In Progress in Paper Physics Seminar: Abstract Book of the PPPS2020 Seminar (281–283); Kouko, J., Lehto, J., Tuovinen, T., Eds.; VTT Technical Research Centre of Finland: Espoo, Finland, 2020; Available online: https://publications.vtt.fi/pdf/technology/2020/T378.pdf (accessed on 7 November 2023).

- Pöhler, T.; Ketoja, J.A.; Lappalainen, T.; Luukkainen, V.; Nurminen, I.; Lahtinen, P.; Torvinen, K. On the strength improvement of lightweight fibre networks by polymers, fibrils and fines. Cellulose 2020, 27, 6961–6976. [Google Scholar] [CrossRef]

- Ramos, A.; Sousa, S.; Evtuguin, D.; Gamelas, J. Functionalized xylans in the production of xylan-coated paper laminates. React. Funct. Polym. 2017, 117, 89–96. [Google Scholar] [CrossRef]

- Ebringerová, A.; Hromádková, Z.; Heinze, T. Hemicellulose, Polysaccharides I: Structure, Characterization and Use, Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1–7. [Google Scholar] [CrossRef]

- Petzold-Welcke, K.; Schwikal, K.; Daus, S.; Heinze, T. Xylan derivatives and their application potential—Mini-review of own results. Carbohydr. Polym. 2014, 100, 80–88. [Google Scholar] [CrossRef]

- Zongquan, L.; Xuejun, P. Strategies to modify physicochemical properties of hemicelluloses from biorefinery and paper industry for packaging material. Rev. Environ. SciBiotechnol. 2018, 17, 47. [Google Scholar] [CrossRef]

- Roman, M.; Nechita, P.; Simionescu, C.S. Evaluation of Barrier Properties of Food Packaging Papers Coated with Hemicellulose Biopolymers. Bul. Inst. Polit. Iaşi 2023, 69, 1–11. [Google Scholar] [CrossRef]

- T-458 cm-04; Surface Wettability of Paper (Angle of Contact Method). TAPPI: Atlanta, GA, USA, 2004.

- ISO 10534-2; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Two-microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. ISO: Geneva, Switzerland, 2023.

- ASTM E1050-12; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. ASTM International: West Conshohocken, PA, USA, 2012.

| Sample * | Left Angle (°) | Right Angle (°) | Average Angle (°) | Left RMSE ** | Right RMSE ** |

|---|---|---|---|---|---|

| FL43PS10/xylan 1 | 47.46 | 43.34 | 45.4 | 0.89234076 | 0.968734416 |

| FL60PS10/xylan 1 | 45.98 | 48.67 | 47.32 | 0.45422208 | 0.476735329 |

| FL43PS10/xylan 2 | 49.47 | 53.17 | 51.32 | 0.81973641 | 0.772447342 |

| FL60PS10/xylan 2 | 56.17 | 55.06 | 55.61 | 0.58340201 | 0.430664096 |

| FL43PS10/xylan 3 | 59.61 | 57.3 | 58.45 | 0.52365381 | 0.441699407 |

| FL60PS10/xylan 3 | 59.02 | 62.16 | 60.59 | 0.69721882 | 0.628683974 |

| CF Material * | Parameter | Surface Treatment | |||

|---|---|---|---|---|---|

| No Xylan | Xylan 1 * | Xylan 2 * | Xylan 3 * | ||

| FL43PS10 | Freq. (Hz) | 3528 | 840 | 704 | 808 |

| α | 0.8131 | 0.7902 | 0.5384 | 0.5856 | |

| FL60PS10 | Freq. (Hz) | 792 | 5368 | 1248 | 1040 |

| α | 0.7887 | 0.4325 | 0.6277 | 0.7029 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nastac, S.M.; Nechita, P.; Guiman, M.V.; Roman, M.; Rosca, I.C. Applications of Xylan Derivatives to Improve the Functional Properties of Cellulose Foams for Noise Insulation. Polymers 2023, 15, 4648. https://doi.org/10.3390/polym15244648

Nastac SM, Nechita P, Guiman MV, Roman M, Rosca IC. Applications of Xylan Derivatives to Improve the Functional Properties of Cellulose Foams for Noise Insulation. Polymers. 2023; 15(24):4648. https://doi.org/10.3390/polym15244648

Chicago/Turabian StyleNastac, Silviu Marian, Petronela Nechita, Maria Violeta Guiman, Mirela Roman, and Ioan Calin Rosca. 2023. "Applications of Xylan Derivatives to Improve the Functional Properties of Cellulose Foams for Noise Insulation" Polymers 15, no. 24: 4648. https://doi.org/10.3390/polym15244648

APA StyleNastac, S. M., Nechita, P., Guiman, M. V., Roman, M., & Rosca, I. C. (2023). Applications of Xylan Derivatives to Improve the Functional Properties of Cellulose Foams for Noise Insulation. Polymers, 15(24), 4648. https://doi.org/10.3390/polym15244648