Case Study on Prestressed CFRP Plates Applied for Strengthening Hollow-Section Beam Removed from an Old Bridge

Abstract

1. Introduction

2. Status of Full-Scale Hollow-Section Beam Removed from Old Bridge

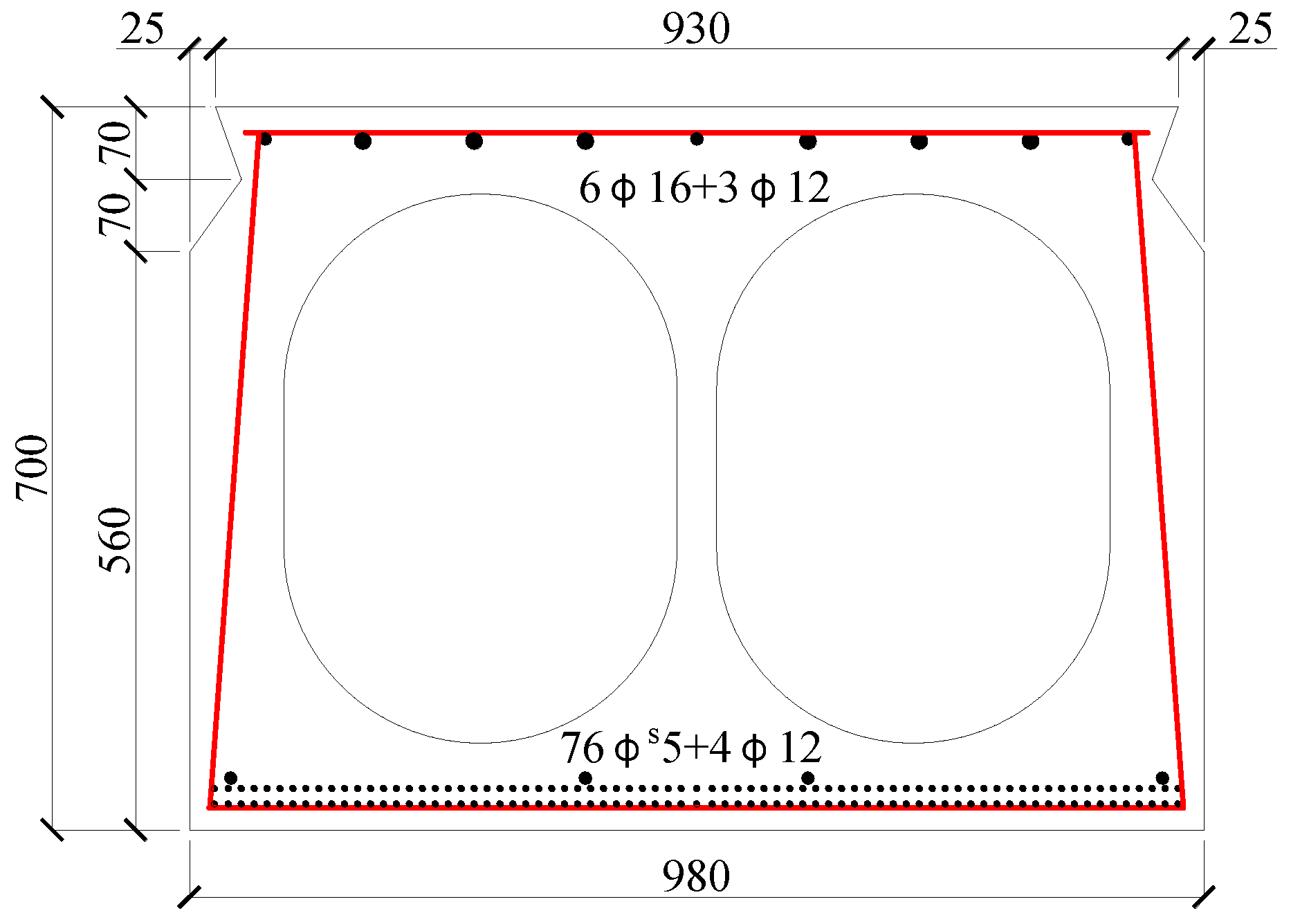

2.1. Dimension and Reinforcements of the Proto Beam

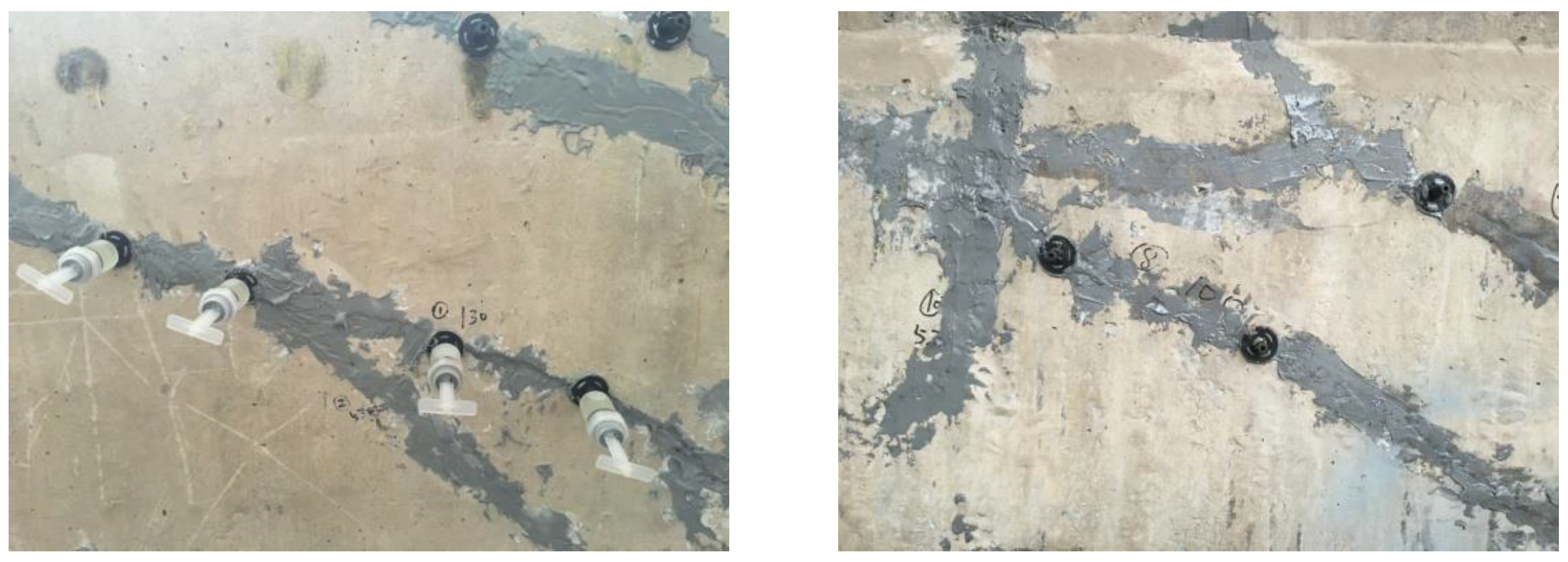

2.2. Status Detection for the Proto Beam

2.3. Repair of Concrete Cracks

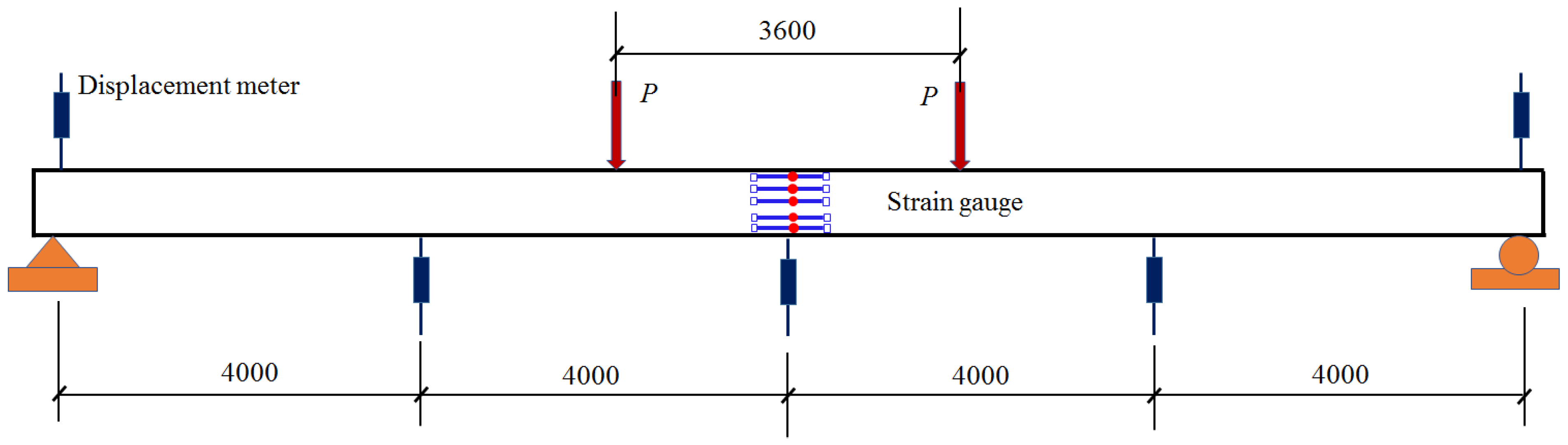

2.4. Loading Test of the Repaired Beam

3. Strengthening Method and Test of Strengthened Beam

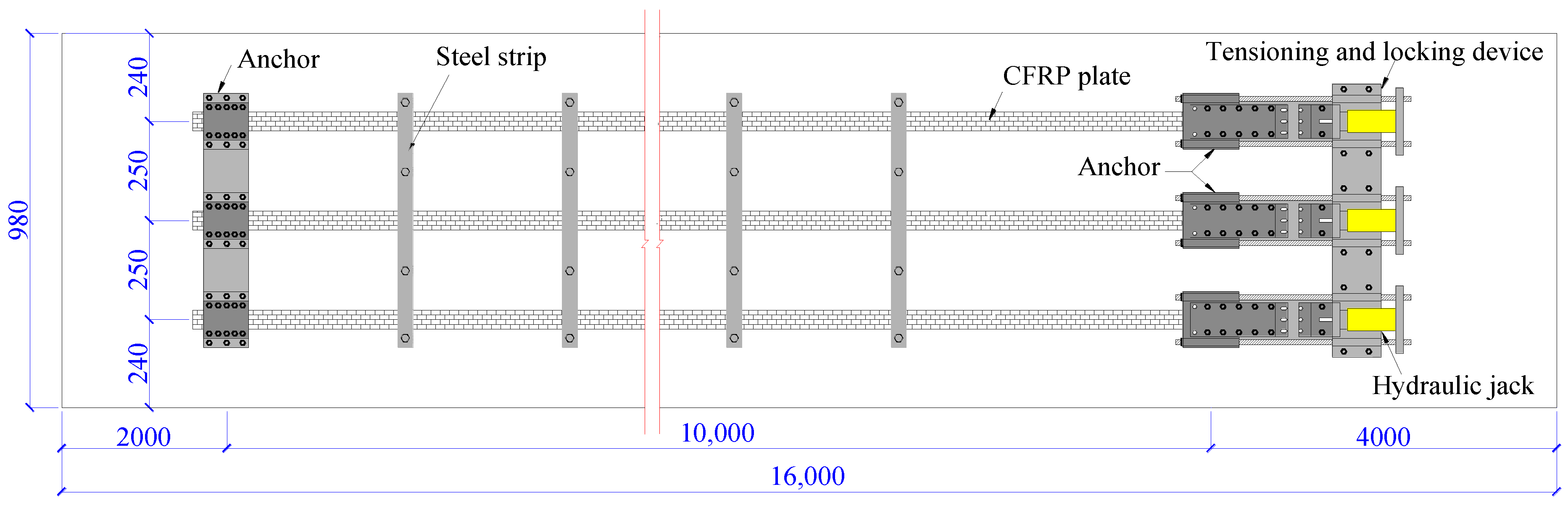

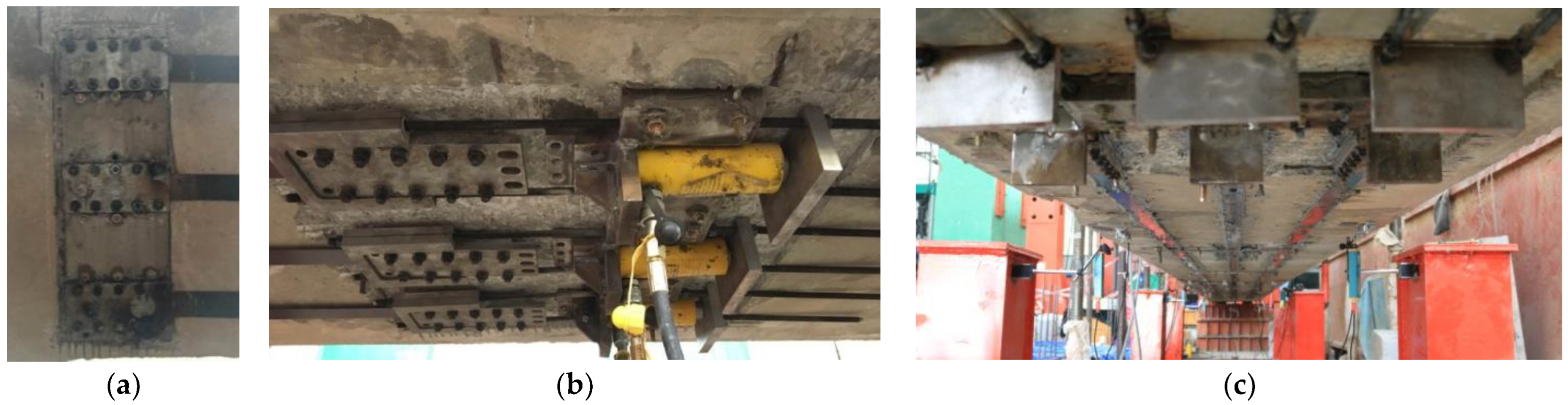

3.1. Strengthening Method of Prestressed CFRP Plates

3.2. Loading Test of the Strengthened Beam

4. FE Models of Proto and Strengthened Beams

4.1. Elements and FE Meshes

4.2. Modeling of Materials

4.3. Bond-Slip Relationships

4.4. Boundary Conditions

5. Verification of Test Results with FE Analytical Results

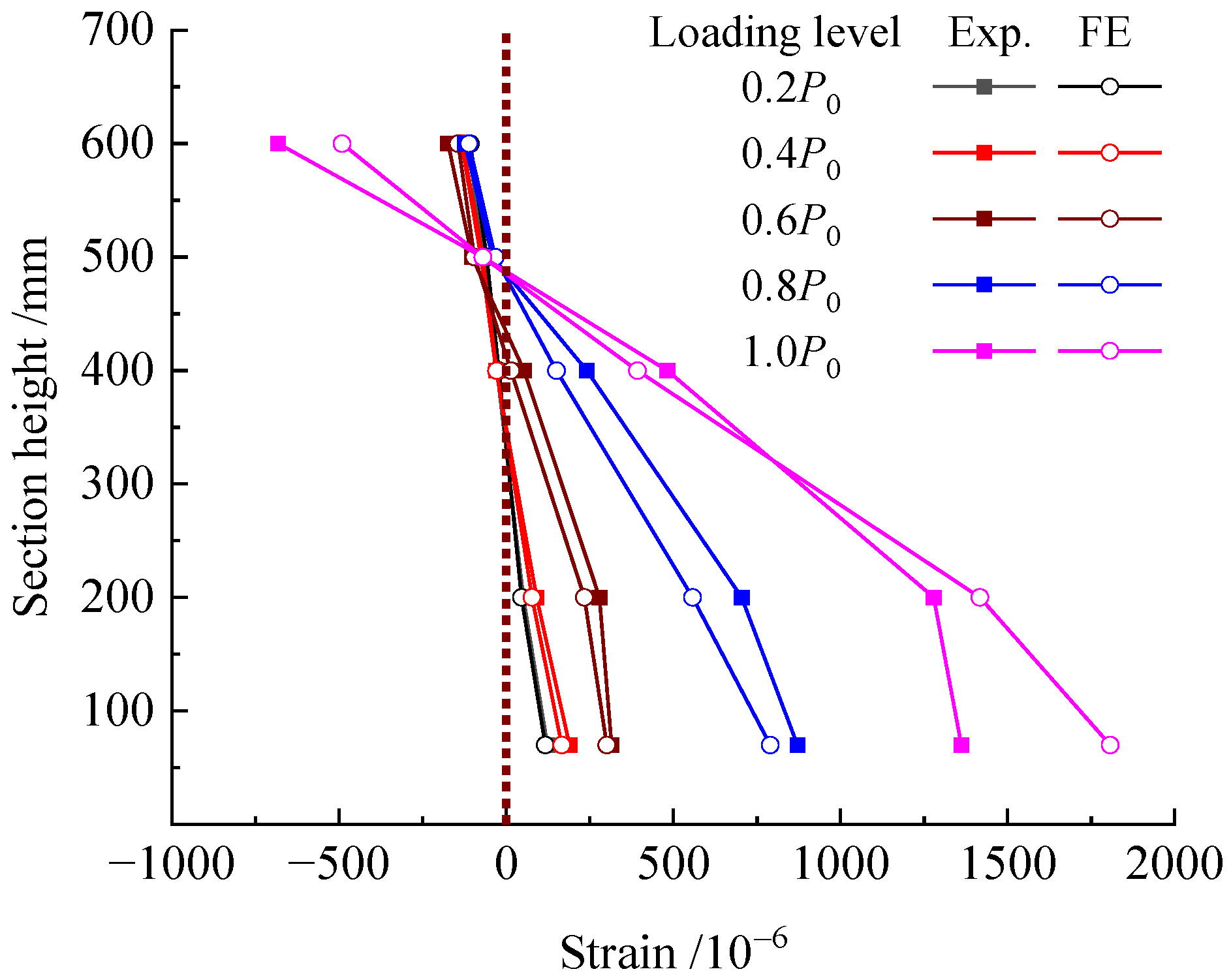

5.1. Verification of the Repaired Beam

5.1.1. Strain at Mid-Span Section

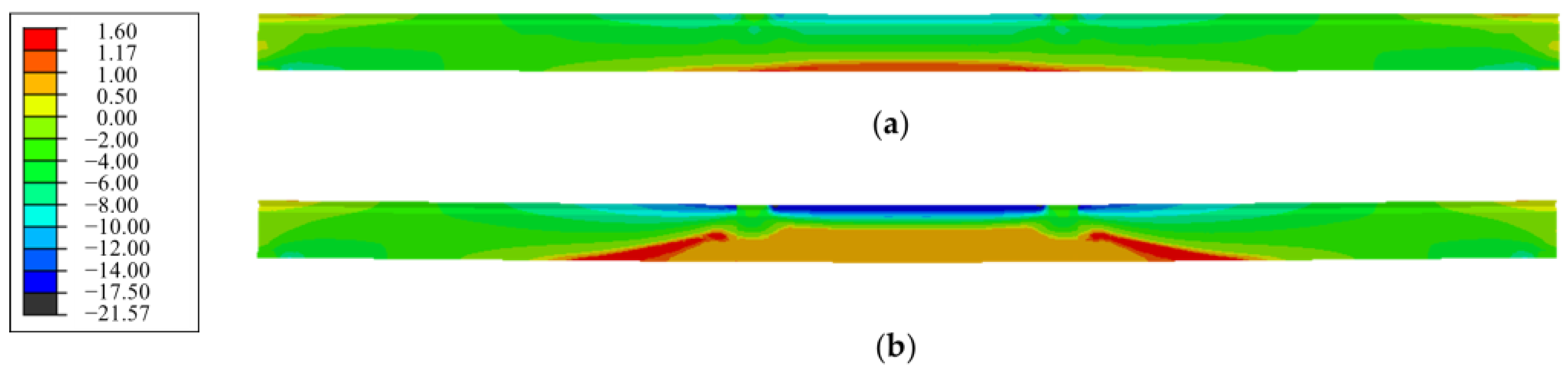

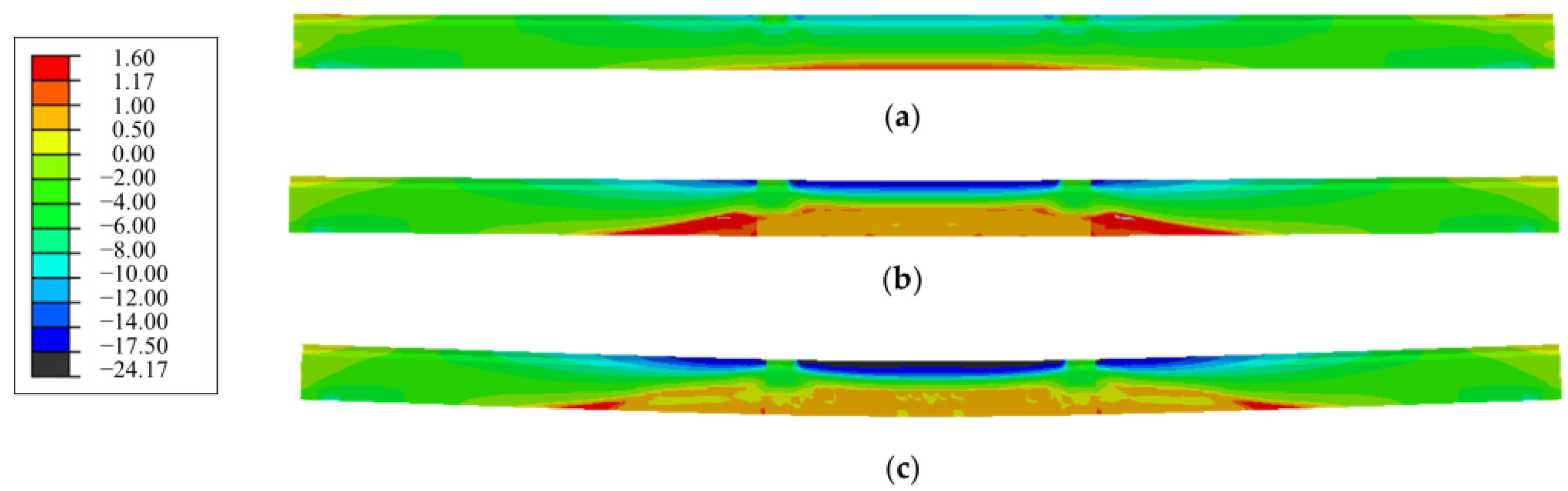

5.1.2. Concrete Stress

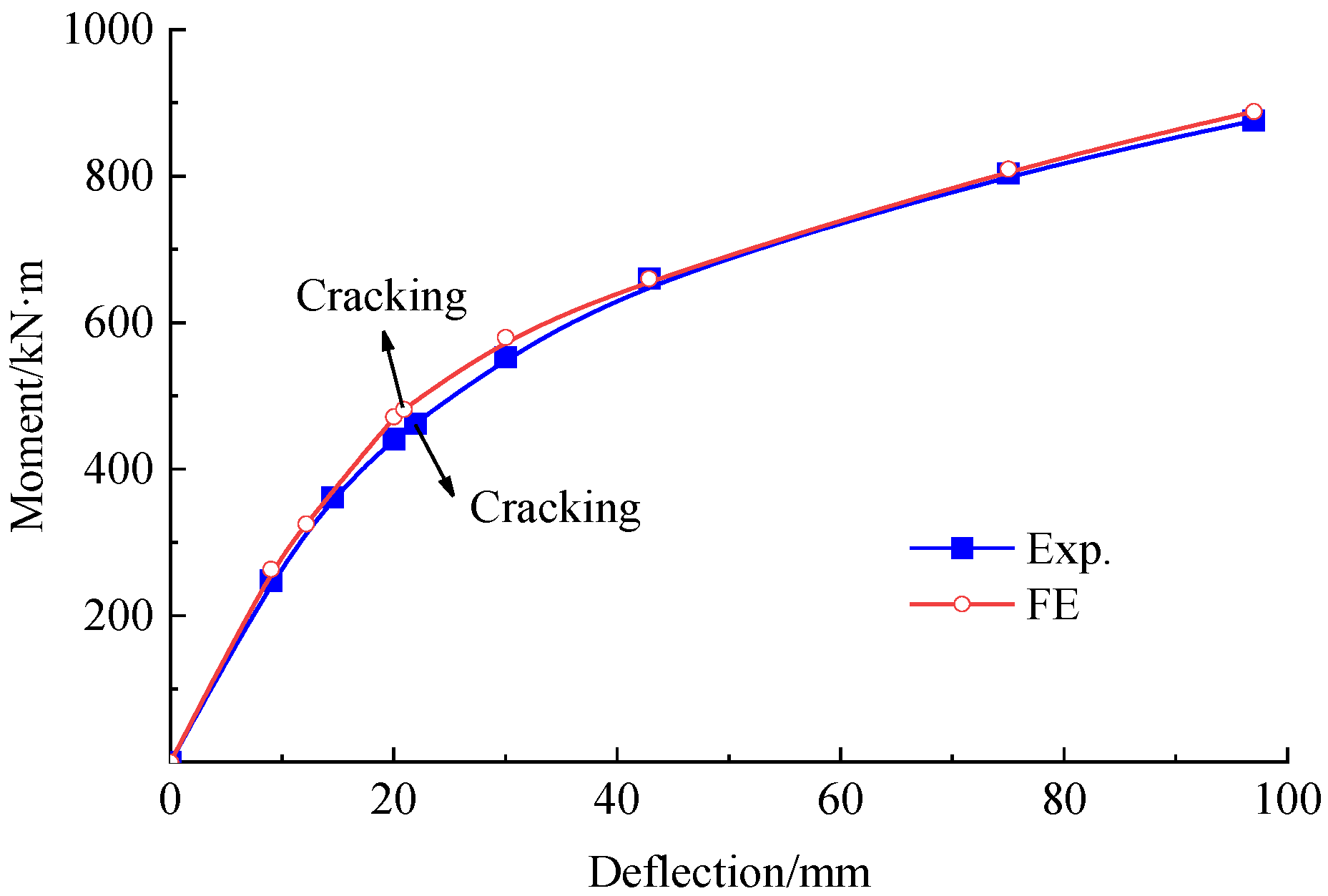

5.1.3. Mid-Span Deflection

5.2. Verification of the Strengthened Beam

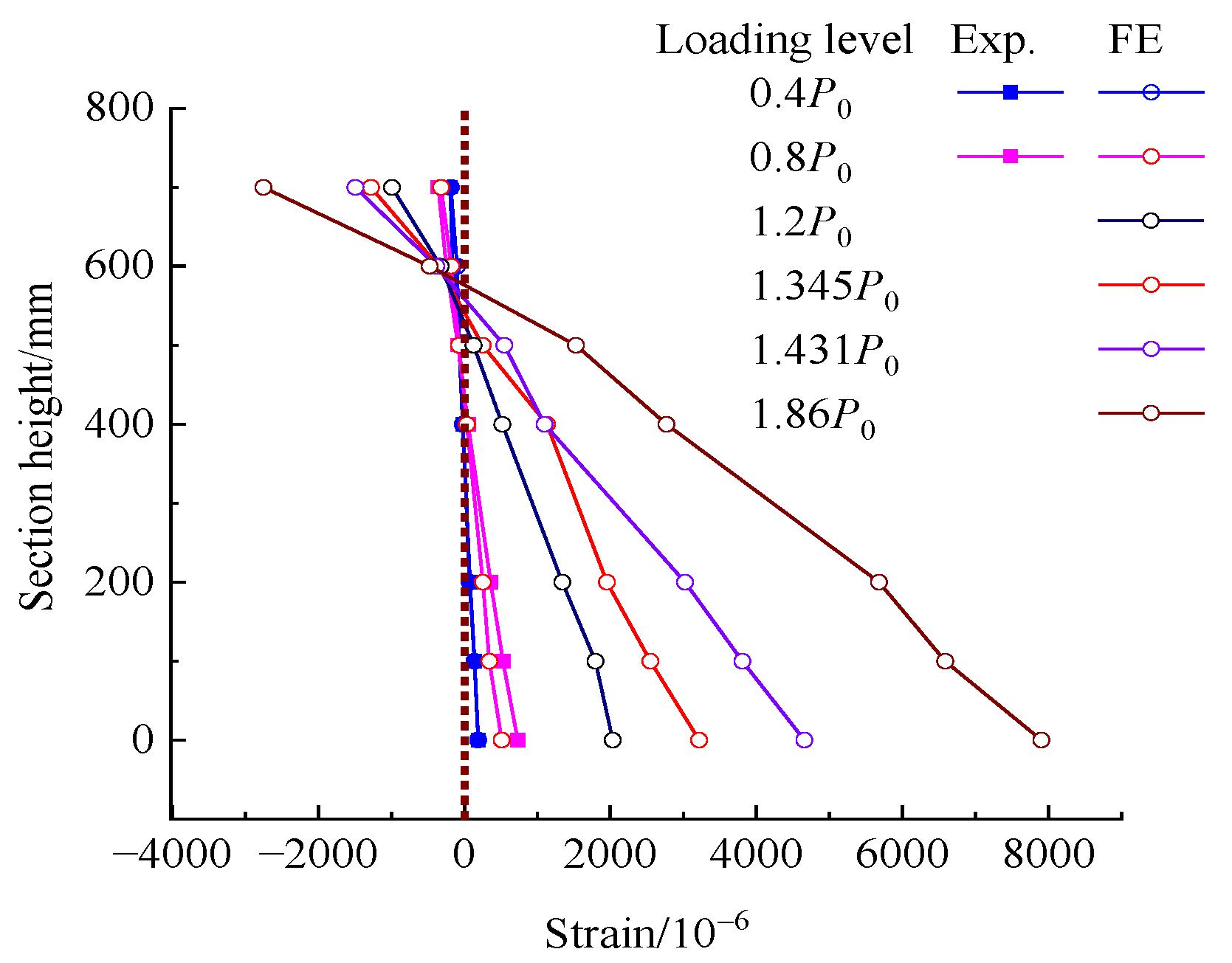

5.2.1. Strain at Mid-Span Section

5.2.2. Concrete Stress

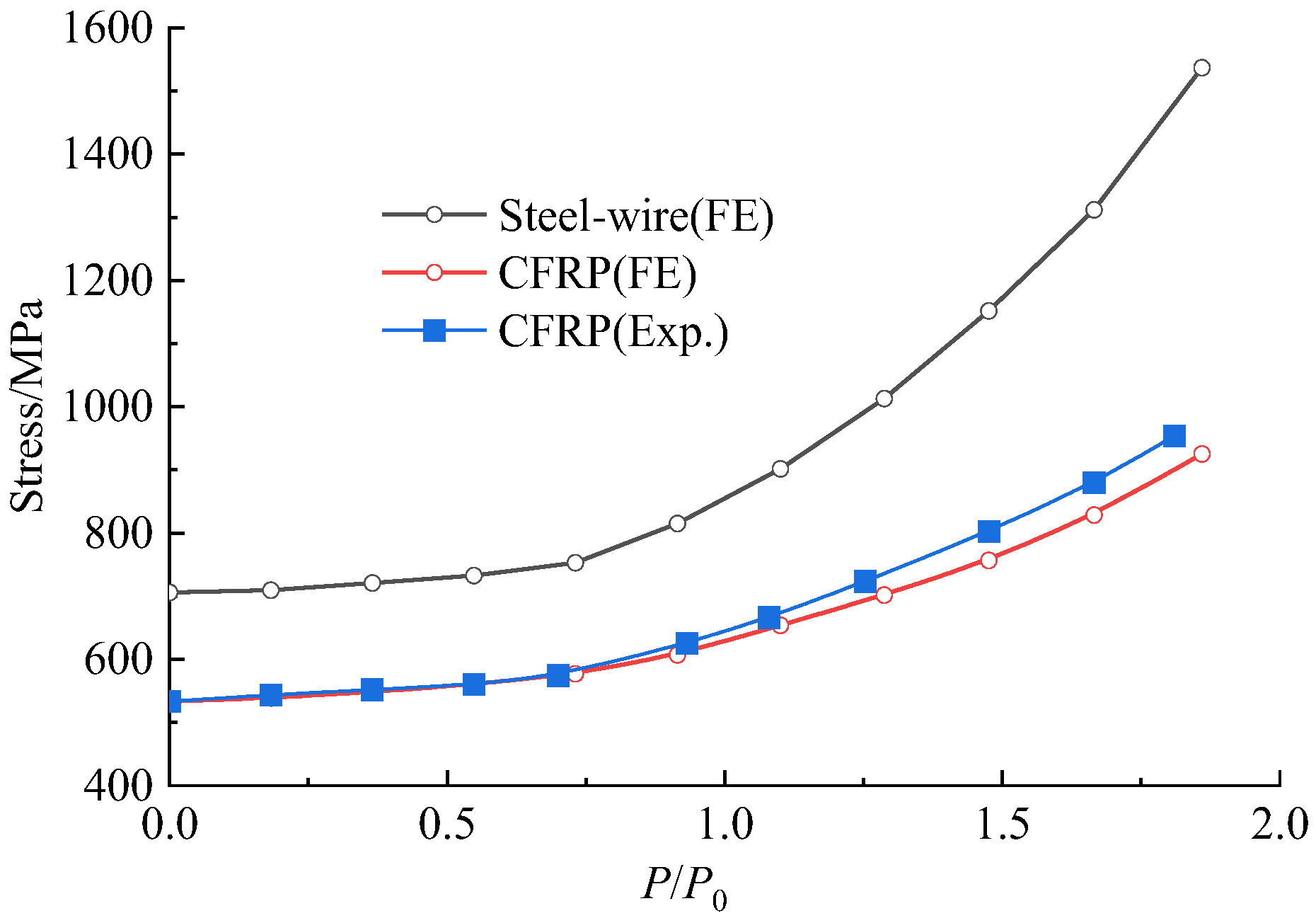

5.2.3. Stress in Prestressed Wires and CFRP Plates

5.2.4. Mid-Span Deflection

6. Parametric Analyses of FE Model of Strengthened Beam

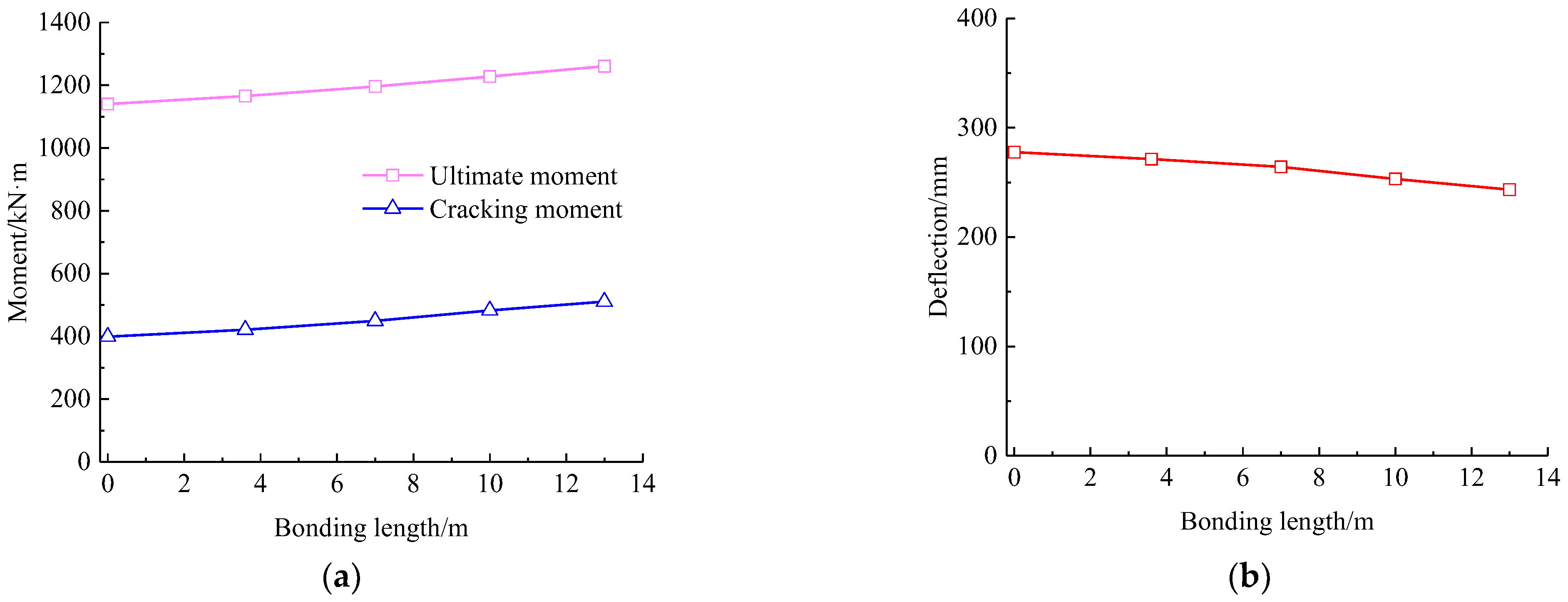

6.1. Effect of the Length of Prestressed CFRP Plates

6.2. Effect of the Amount of Prestressed CFRP Plates

7. Conclusions

- (1)

- Although several concrete cracks appeared on the proto beam, the concrete and the prestressed steel wire worked well without obvious degradation and steel erosion. After the concrete cracks were repaired with epoxy adhesive, the degradation coefficient of flexural stiffness was determined as 0.73, based on the experimental study of the repaired beam by four-point bending test.

- (2)

- FE models are built for the analyses of the repaired beam and the strengthened beam, including the concrete strain at mid-span section, the stress of the concrete and the prestressed steel wire, and the stress of prestressed CFRP plates, as well as mid-span deflection. Good agreement between the test and FE analytical results of the loading response demonstrates the validity of the FE model for simulating the strengthened beam with prestressed CFRP plates.

- (3)

- A parametric analysis indicates that the increase in length and amount of prestressed CFRP plates improves the serviceability and the ultimate bearing capacity of the strengthened beam. Additional benefits to improve the flexural stiffness come from the confinements of prestressed CFRP plates to the existed concrete cracks and by increasing the length of prestressed CFRP plates to the newly appeared concrete cracks, and the improvement of concrete cracking resistance by increasing the amount of prestressed CFRP plates.

- (4)

- It should be noticed that with the increased amount of prestressed CFRP plates, the failure mode of the strengthened beam can be transferred from the under-reinforcement to the over-reinforcement. This leads to an expense of deformation ductility of the strengthened beam.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Editorial Board of Chinese Journal of Highways. Review of academic research on bridge engineering in China-2021. China J. Highw. 2021, 34, 1–97. [Google Scholar]

- Li, C.; Wang, H.; Ren, J.; Zhao, S. Research and Application of High-Performance Prestressed Concrete Hollow Plate Bridges, 1st ed.; China Electric Power Press: Beijing, China, 2017; pp. 2–4. [Google Scholar]

- Qin, S.; Gao, Z. Developments and prospects of long-span high-speed railway bridge technologies in China. Engineering 2017, 3, 787–794. [Google Scholar] [CrossRef]

- He, X.; Wu, T.; Zou, Y.; Chen, F.; Guo, H.; Yu, Z. Recent developments of high-speed railway bridges in China. Struct. Infrastruct. Eng. 2017, 13, 1584–1595. [Google Scholar] [CrossRef]

- Connor, J.T.; Huh, Y. Crew production rates for contract time estimation: Beam erection, deck, and rail of highway bridges. J. Constr. Eng. Machan. 2006, 132, 408–415. [Google Scholar]

- Chen, J.; Bai, L.; Zhao, S.; Yu, X.; Chen, C. Construction technology of transverse bonded structural steel for strengthening PPC hollow slab bridge. Appl. Mech. Mater. 2012, 238, 697–700. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, S.; Yao, J. Method of calculating live load transverse distribution in design of the existing PPC hollow slab bridge widening. Eng. Mech. 2012, 29, 265–271. [Google Scholar]

- Mugahed, A.Y.; Alyousef, R.; Rashid, R.; Alabduljabbar, H.; Hung, C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- GB 50367-2013; Code for Design of Strengthening Concrete Structure. China Building Industry Press: Beijing, China, 2013.

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Hollaway, L.C. A review of the present and future utilization of FRP composites in the civil infrastructure with reference to their important in service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A review on FRP composites applications and durability concerns in the construction sector. J. Reinf. Plast. Comp. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Hawileh, R.; Rasheed, H.; Abdalla, J.; Al-Tamimi, A. Behavior of reinforced concrete beams strengthened with externally bonded hybrid fiber reinforced polymer systems. Mater. Des. 2014, 53, 972–982. [Google Scholar] [CrossRef]

- Chan, T.; Mackie, K. Flexural strengthening of reinforced concrete beams using externally bonded polyurethane-carbon fiber-reinforced polymer composite systems. ACI Struct. J. 2020, 117, 311–324. [Google Scholar]

- Ahmad, S.; Elahi, A.; Tufail, R.; Zahid, M.; Tariq, S. Experimental investigation and strength model of RC deep beams externally bonded by CFRP. Adv. Struct. Eng. 2021, 24, 3645–3657. [Google Scholar] [CrossRef]

- Smith, S.; Teng, J. FRP-strengthened RC beams. I: Review of debonding strength models. Eng. Struct. 2002, 24, 385–395. [Google Scholar] [CrossRef]

- Teng, J.; Smith, S.; Yao, J.; Chen, J. Intermediate crack-induced debonding in RC beams and slabs. Constr. Build. Mater. 2003, 17, 447–462. [Google Scholar] [CrossRef]

- Pan, L.; Chen, S.; Zhao, S.; Li, C. Experimental study of cyclic loading behaviors of reinforced concrete beams strengthening with CFRP sheets. Appl. Mech. Mater. 2012, 201–202, 483–486. [Google Scholar] [CrossRef]

- Fu, B.; Chen, G.; Teng, J. Mitigation of intermediate crack debonding in FRP-plated RC beams using FRP U-jackets. Compos. Struct. 2017, 176, 883–897. [Google Scholar] [CrossRef]

- Zhang, S.; Ke, Y.; Chen, E.; Biscaia, H.; Li, W. Effect of load distribution on the behaviour of RC beams strengthened in flexure with Near-Surface Mounted (NSM) FRP. Compos. Struct. 2022, 279, 114782. [Google Scholar] [CrossRef]

- Lorenzis, L.; Teng, J. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos. Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Al-Zúbi, H.; Abdel-Jaber, M.; Katkhuda, H. Flexural strengthening of reinforced concrete beams with variable compressive strength using near-surface mounted carbon-fiber-reinforced polymer strips [NSM-CFRP]. Fibers 2022, 10, 86. [Google Scholar] [CrossRef]

- Abdel-Jaber, M.; Abdel-Jaber, M.; Katkhuda, H.; Shatarat, N.; Sulaiman, A.; El-Nimri, R. Influence of stirrup spacing on the strengthening and rehabilitating of RC T-beams using near-surface mounted carbon-fiber-reinforced polymer strips. Fibers 2022, 10, 103. [Google Scholar] [CrossRef]

- Pitek, B.; Siwowski, T. Experimental study on flexural behaviour of reinforced concrete beams strengthened with passive and active CFRP strips using a novel anchorage system. Arch. Civ. Mech. Eng. 2022, 22, 1–17. [Google Scholar] [CrossRef]

- Bengar, H.; Shahmansouri, A. A new anchorage system for CFRP strips in externally strengthened RC continuous beams. J. Build. Eng. 2020, 30, 101230. [Google Scholar] [CrossRef]

- Elsayed, W.; Ebead, U.; Neale, K. Studies on mechanically fastened fiber-reinforced polymer strengthening systems. ACI Struct. J. 2009, 106, 49–59. [Google Scholar]

- Sun, W.; Jirsa, J.; Ghannoum, W. Behavior of anchored carbon fiber reinforced polymer strips used for strengthening concrete structures. ACI Mater. J. 2016, 113, 163–172. [Google Scholar] [CrossRef]

- Garden, H.; Hollaway, L. An experimental study of the failure modes of reinforced concrete beams strengthened with prestressed carbon composite plates. Compos. Part B Eng. 1998, 29, 411–424. [Google Scholar] [CrossRef]

- Yang, D.; Park, S.; Neale, K. Flexural behaviour of reinforced concrete beams strengthened with prestressed carbon composites. Compos. Struct. 2009, 88, 497–508. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.; Shah, S. Strengthening of RC beams using prestressed fiber reinforced polymers—A review. Constr. Build. Mater. 2015, 82, 235–256. [Google Scholar] [CrossRef]

- Slaitas, J.; Valivonis, J. Technological peculiarities of strengthening RC members with prestressed FRP laminates. Compos. Struct. 2022, 15, 115526. [Google Scholar] [CrossRef]

- Yang, J.; Johansson, M.; Al-Emrani, M.; Haghani, R. Innovative flexural strengthening of RC beams using self-anchored prestressed CFRP plates: Experimental and numerical investigations. Eng. Struct. 2021, 243, 112687. [Google Scholar] [CrossRef]

- Xie, J.; Li, J.; Lu, Z.; Liu, D.; Huang, P. Effects of pre-existing damage and cyclic overloading on the flexural behaviour of RC beams strengthened with prestressed CFRP plates. Eng. Struct. 2021, 247, 113078. [Google Scholar] [CrossRef]

- Yang, J.; Feng, P.; Liu, B.; Wang, H.; Zhao, W.; Hu, L. Strengthening RC beams with mid-span supporting prestressed CFRP plates: An experimental investigation. Eng. Struct. 2022, 272, 115022. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, C.; Xiong, H.; Xu, G. Experimental study on the flexural behavior of large-scale reinforced concrete beams strengthened with prestressed CFRP plates. J. Compos. Constr. 2022, 26, 04022076. [Google Scholar] [CrossRef]

- Li, B.; Zeng, L.; Guo, X.; Wang, Y.; Deng, Z. Flexural behavior of full-scale damaged hollow RC beams strengthened with prestressed SCFRP plate under four-point bending. Polymers 2022, 14, 2939. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Li, Q.; Li, X.; Zhang, X.; Zhao, S. Elasto-plastic bending behaviors of reinforced SFRELC beams analyzed by nonlinear finite-element method. Case Stud. Constr. Mater. 2020, 13, e00372. [Google Scholar]

- Chen, Z.; Li, X.; Yang, Y.; Zhao, S.; Fu, Z. Experimental and numerical investigation of the effect of temperature patterns on behaviour of large scale silo. Eng. Fail. Anal. 2018, 91, 543–553. [Google Scholar] [CrossRef]

- JTG D 62-85; Code for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. China Communications Press: Beijing, China, 1985.

- JTG D 62-2004; Code for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. China Communications Press: Beijing, China, 2004.

- JTG 3362-2018; Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. China Communications Press: Beijing, China, 2018.

- JGJ/T 23-2011; Technical Specification for Inspecting of Concrete Compressive Strength by Rebound Method. China Building Industry Press: Beijing, China, 2011.

- GB 50010-2010; Code for Design of Concrete Structures. China Building Industry Press: Beijing, China, 2015.

- JGJ/T 152-2019; Technical Standard for Testing of Reinforcing Steel Bar in Concrete. China Building Industry Press: Beijing, China, 2019.

- JGJ/T 411-2017; Technical Specification for Testing of Concrete Defects by Impact Echo Method. China Building Industry Press: Beijing, China, 2017.

- Wang, Z.; Fan, H.; Liu, Z.; Zhao, S. Experimental study on anchoring performance of flat anchorage with circular tooth for prestressed CFRP plate. Sci. Technol. Eng. 2017, 17, 279–283. [Google Scholar]

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A Plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G. A Plastic-damage concrete model for earthquake analysis of dams. Earthq. Eng. Struct. D 1998, 27, 937–956. [Google Scholar] [CrossRef]

- Zeng, J.; Guo, Y.; Li, L.; Chen, W. Behavior and three-dimensional finite element modeling of circular concrete columns partially wrapped with FRP strips. Polymers 2018, 10, 253. [Google Scholar] [CrossRef]

- Mosallam, A.; Allam, K.; Salama, M. Analytical and numerical modeling of RC beam-column joints retrofitted with FRP laminates and hybrid composite connectors. Compos. Struct. 2019, 214, 486–503. [Google Scholar] [CrossRef]

- Geng, H.; Mu, Z.; Yu, X. Bond-Slip Constitutive model of the interface between plain bar and concrete. Bull. Chin. Ceram. Soc. 2017, 36, 3064–3069. [Google Scholar]

- Xie, C. Study on the Interface Bond Slip Constitutive Relationship and Influencing Factors of CFRP-Concrete. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2014. [Google Scholar]

| E1 (GPa) | E2 (GPa) | Nu12 | G12 (MPa) | G13 (MPa) | G23 (MPa) |

|---|---|---|---|---|---|

| 160 | 9 | 0.34 | 4800 | 4800 | 4500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Li, B.; Bao, J.; Cheng, S.; Meng, Q.; Zhao, S. Case Study on Prestressed CFRP Plates Applied for Strengthening Hollow-Section Beam Removed from an Old Bridge. Polymers 2023, 15, 549. https://doi.org/10.3390/polym15030549

Liu G, Li B, Bao J, Cheng S, Meng Q, Zhao S. Case Study on Prestressed CFRP Plates Applied for Strengthening Hollow-Section Beam Removed from an Old Bridge. Polymers. 2023; 15(3):549. https://doi.org/10.3390/polym15030549

Chicago/Turabian StyleLiu, Guirong, Bingchen Li, Jiasheng Bao, Shengzhao Cheng, Qingxin Meng, and Shunbo Zhao. 2023. "Case Study on Prestressed CFRP Plates Applied for Strengthening Hollow-Section Beam Removed from an Old Bridge" Polymers 15, no. 3: 549. https://doi.org/10.3390/polym15030549

APA StyleLiu, G., Li, B., Bao, J., Cheng, S., Meng, Q., & Zhao, S. (2023). Case Study on Prestressed CFRP Plates Applied for Strengthening Hollow-Section Beam Removed from an Old Bridge. Polymers, 15(3), 549. https://doi.org/10.3390/polym15030549