Effect of Surface Polishing on Physical Properties of an Occlusal Splint Material for Additive Manufacturing under Protection Gas Post-Curing Condition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Fabrication

2.2. Flexural Strength and Modulus Testing

2.3. Surface Microhardness (Vickers Hardness)

2.4. Degree of Carbon Double Bond Conversion (DC)

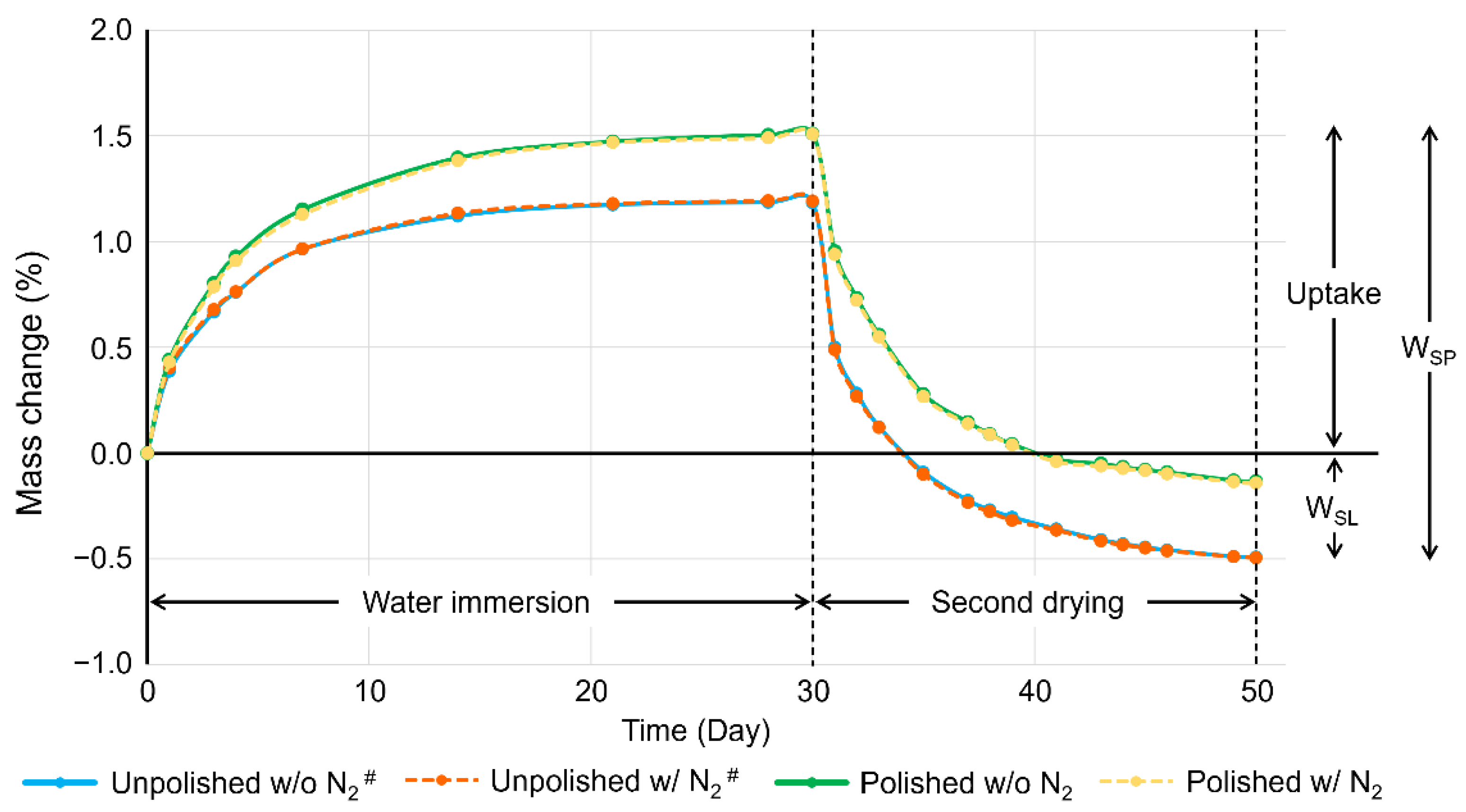

2.5. Water Sorption and Solubility

2.6. Optical Observation of Surface Condition

2.7. Statistical Analysis

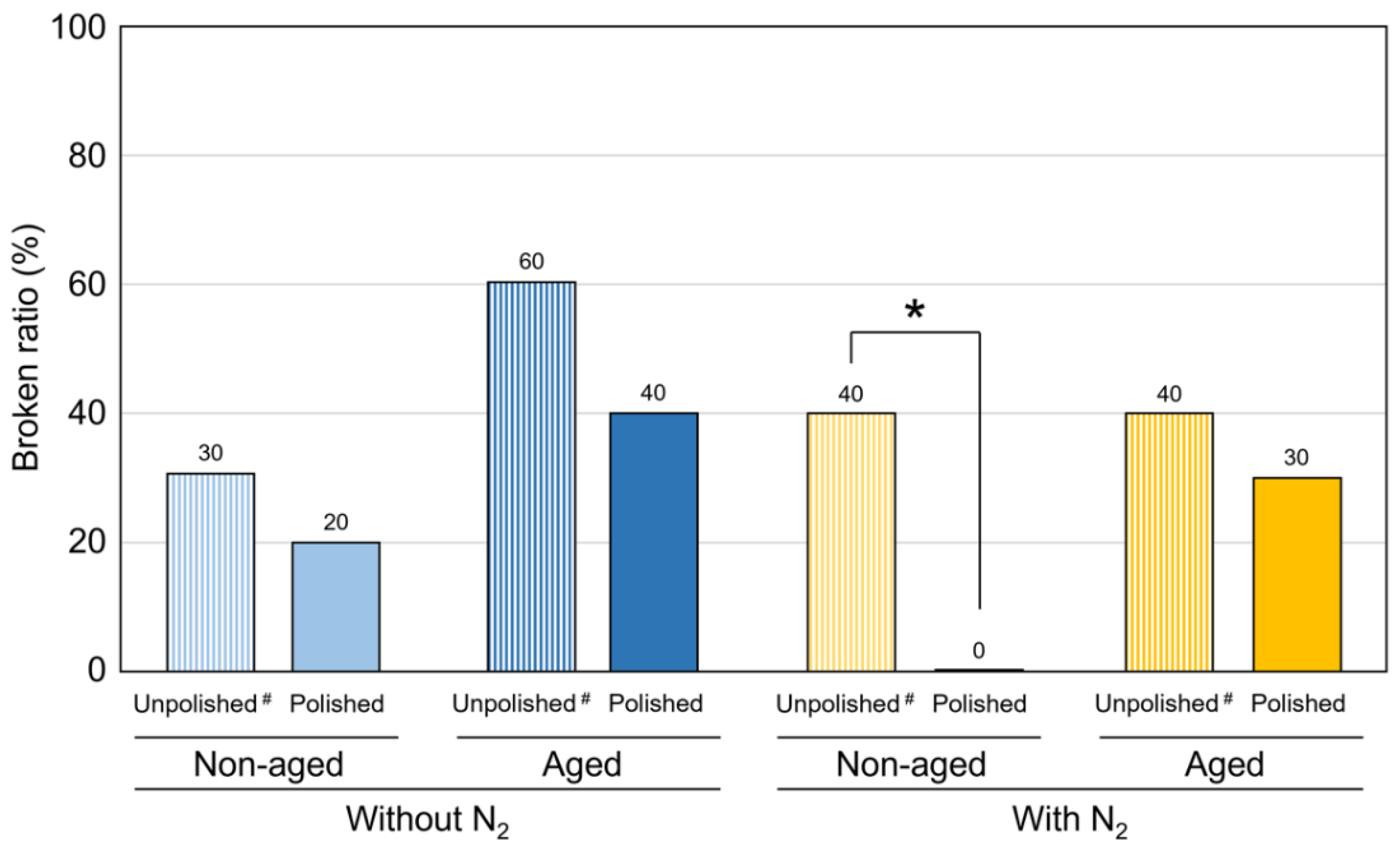

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Watanabe, H.; Fellows, C.; An, H. Digital Technologies for Restorative Dentistry. Dent. Clin. 2022, 66, 567–590. [Google Scholar] [CrossRef] [PubMed]

- Francisco, I.; Ribeiro, M.P.; Marques, F.; Travassos, R.; Nunes, C.; Pereira, F.; Caramelo, F.; Paula, A.B.; Vale, F. Application of Three-Dimensional Digital Technology in Orthodontics: The State of the Art. Biomimetics 2022, 7, 23. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.S.; Jiang, H.B. A Review of 3D Printing in Dentistry: Technologies, Affecting Factors, and Applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef] [PubMed]

- Valenti, C.; Isabella Federici, M.; Masciotti, F.; Marinucci, L.; Xhimitiku, I.; Cianetti, S.; Pagano, S. Mechanical properties of 3D-printed prosthetic materials compared with milled and conventional processing: A systematic review and meta-analysis of in vitro studies. J. Prosthet. Dent. 2022, in press. [Google Scholar] [CrossRef] [PubMed]

- Tigmeanu, C.V.; Ardelean, L.C.; Rusu, L.C.; Negrutiu, M.L. Additive Manufactured Polymers in Dentistry, Current State-of-the-Art and Future Perspectives-A Review. Polymers 2022, 14, 3658. [Google Scholar] [CrossRef] [PubMed]

- Anadioti, E.; Kane, B.; Zhang, Y.; Bergler, M.; Mante, F.; Blatz, M.B. Accuracy of Dental and Industrial 3D Printers. J. Prosthodont. 2022, 31, 30–37. [Google Scholar] [CrossRef] [PubMed]

- Ellakany, P.; Fouda, S.M.; Mahrous, A.A.; AlGhamdi, M.A.; Aly, N.M. Influence of CAD/CAM Milling and 3D-Printing Fabrication Methods on the Mechanical Properties of 3-Unit Interim Fixed Dental Prosthesis after Thermo-Mechanical Aging Process. Polymers 2022, 14, 4103. [Google Scholar] [CrossRef]

- Al Hamad, K.Q.; Al-Rashdan, B.A.; Ayyad, J.Q.; Al Omrani, L.M.; Sharoh, A.M.; Al Nimri, A.M.; Al-Kaff, F.T. Additive Manufacturing of Dental Ceramics: A Systematic Review and Meta-Analysis. J. Prosthodont. 2022, 31, e67–e86. [Google Scholar] [CrossRef]

- Goodacre, B.J.; Goodacre, C.J. Additive Manufacturing for Complete Denture Fabrication: A Narrative Review. J. Prosthodont. 2022, 31, 47–51. [Google Scholar] [CrossRef]

- Chou, W.T.; Chuang, C.C.; Wang, Y.B.; Chiu, H.C. Comparison of the internal fit of metal crowns fabricated by traditional casting, computer numerical control milling, and three-dimensional printing. PLoS ONE 2021, 16, e0257158. [Google Scholar] [CrossRef]

- Schutz, B.M.; Sudbury, D.; Scott, N.; Mayoh, B.; Chan, B. Customized Three-Dimensional Printed Splints for Neonates in the Neonatal Intensive Care Unit: Three Case Reports. Am. J. Occup. Ther. 2022, 76, 7606205020. [Google Scholar] [CrossRef]

- Wickström, H.; Hilgert, E.; Nyman, J.O.; Desai, D.; Karaman, D.Ş.; de Beer, T.; Sandler, N.; Rosenholm, J.M. Inkjet printing of drug-loaded mesoporous silica nanoparticles-a platform for drug development. Molecules 2017, 22, 2020. [Google Scholar] [CrossRef] [Green Version]

- Panwar, A.; Tan, L.P. Current status of bioinks for micro-extrusion-based 3D bioprinting. Molecules 2016, 21, 685. [Google Scholar] [CrossRef] [PubMed]

- Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. Selective laser sintering (SLS) 3D printing of medicines. Int. J. Pharm. 2017, 529, 285–293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- van Noort, R. The future of dental devices is digital. Dent. Mater. 2012, 28, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Özcan, M. Additive manufacturing technologies used for processing polymers: Current status and potential application in prosthetic dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef] [Green Version]

- Tulcan, A.; Vasilescu, M.D.; Tulcan, L. Study of the influence of technological parameters on generating flat part with cylindrical features in 3D printing with resin cured by optical processing. Polymers 2020, 2, 1941. [Google Scholar] [CrossRef]

- Wada, J.; Wada, K.; Gibreel, M.; Wakabayashi, N.; Iwamoto, T.; Vallittu, P.K.; Lassila, L. Effect of Nitrogen Gas Post-Curing and Printer Type on the Mechanical Properties of 3D-Printed Hard Occlusal Splint Material. Polymers 2022, 14, 3971. [Google Scholar] [CrossRef]

- Wada, J.; Wada, K.; Gibreel, M.; Wakabayashi, N.; Iwamoto, T.; Vallittu, P.K.; Lassila, L. Effect of 3D Printer Type and Use of Protection Gas during Post-Curing on Some Physical Properties of Soft Occlusal Splint Material. Polymers 2022, 14, 4618. [Google Scholar] [CrossRef]

- Reymus, M.; Lümkemann, N.; Stawarczyk, B. 3D-printed material for temporary restorations: Impact of print layer thickness and post-curing method on degree of conversion. Int. J. Comput. Dent. 2019, 22, 231–237. [Google Scholar] [PubMed]

- Li, P.; Lambart, A.L.; Stawarczyk, B.; Reymus, M.; Spintzyk, S. Postpolymerization of a 3D-printed denture base polymer: Impact of post-curing methods on surface characteristics, flexural strength, and cytotoxicity. J. Dent. 2021, 115, 103856. [Google Scholar] [CrossRef] [PubMed]

- Figuerôa, R.M.S.; Conterno, B.; Arrais, C.A.G.; Sugio, C.Y.C.; Urban, V.M.; Neppelenbroek, K.H. Porosity, water sorption and solubility of denture base acrylic resins polymerized conventionally or in microwave. J. Appl. Oral Sci. 2018, 26, e20170383. [Google Scholar] [CrossRef] [PubMed]

- Gibreel, M.; Perea-Lowery, L.; Vallittu, P.K.; Lassila, L. Characterization of occlusal splint materials: CAD-CAM versus conventional resins. J. Mech. Behav. Biomed. Mater. 2021, 124, 104813. [Google Scholar] [CrossRef]

- Vallittu, P.K. Unpolymerized surface layer of autopolymerizing polymethyl methacrylate resin. J. Oral Rehabil. 1999, 26, 208–212. [Google Scholar] [CrossRef]

- Shawkat, E.S.; Shortall, A.C.; Addison, O.; Palin, W.M. Oxygen inhibition and incremental layer bond strengths of resin composites. Dent. Mater. 2009, 25, 1338–1346. [Google Scholar] [CrossRef]

- Franz, A.; König, F.; Lucas, T.; Watts, D.C.; Schedle, A. Cytotoxic effects of dental bonding substances as a function of degree of conversion. Dent. Mater. 2009, 25, 232–239. [Google Scholar] [CrossRef]

- Bural, C.; Aktaş, E.; Deniz, G.; Ünlüçerçi, Y.; Kızılcan, N.; Bayraktar, G. Effect of post-polymerization heat-treatments on degree of conversion, leaching residual MMA and in vitro cytotoxicity of autopolymerizing acrylic repair resin. Dent. Mater. 2011, 27, 1135–1143. [Google Scholar] [CrossRef]

- Berli, C.; Thieringer, F.M.; Sharma, N.; Müller, J.A.; Dedem, P.; Fischer, J.; Rohr, N. Comparing the mechanical properties of pressed, milled, and 3D-printed resins for occlusal devices. J. Prosthet. Dent. 2020, 124, 780–786. [Google Scholar] [CrossRef]

- Perea-Lowery, L.; Gibreel, M.; Vallittu, P.K.; Lassila, L. Evaluation of the mechanical properties and degree of conversion of 3D printed splint material. J. Mech. Behav. Biomed. Mater. 2021, 115, 104254. [Google Scholar] [CrossRef]

- Ozcan, M.; Barbosa, S.H.; Melo, R.M.; Galhano, G.A.; Bottino, M.A. Effect of surface conditioning methods on the microtensile bond strength of resin composite to composite after aging conditions. Dent. Mater. 2007, 23, 1276–1282. [Google Scholar] [CrossRef] [PubMed]

- Brendeke, J.; Ozcan, M. Effect of physicochemical aging conditions on the composite-composite repair bond strength. J. Adhes. Dent. 2007, 9, 399–406. [Google Scholar] [PubMed]

| Predictor □ | Flexural Strength # | Flexural Modulus # | VHN # | DC $ | WSP $ | WSL $ |

|---|---|---|---|---|---|---|

| post-curing atmosphere | <0.001 * | <0.001 * | <0.001 * | <0.001 * | 0.038 * | 0.607 |

| polishing | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| aging | <0.001 * | <0.001 * | <0.001 * | – | – | – |

| Post-Curing Atmosphere | Aging | Polishing | Flexural Modulus (GPa) | VHN | ||

|---|---|---|---|---|---|---|

| □ | □ | □ | □ | $ | □ | $ |

| Without N2 | non-aged | Unpolished # | 2.21 (0.11) | a | 12.5 (0.4) | a |

| □ | □ | Polished | 2.60 (0.11) | b | 16.9 (0.2) | b |

| □ | aged | Unpolished # | 1.70 (0.14) | c | 12.1 (0.4) | c |

| □ | □ | Polished | 2.13 (0.11) | a | 12.7 (0.5) | a |

| □ | □ | □ | □ | □ | □ | □ |

| With N2 | non-aged | Unpolished # | 2.13 (0.13) | a | 15.7 (0.5) | d |

| □ | □ | Polished | 2.54 (0.12) | b | 17.0 (0.2) | b |

| □ | aged | Unpolished # | 2.11 (0.07) | a | 15.3 (0.5) | d |

| □ | □ | Polished | 2.12 (0.13) | a | 12.5 (0.4) | a |

| Post-Curing Atmosphere | Polishing | DC (%) | WSP (%) | WSL (%) | |||

|---|---|---|---|---|---|---|---|

| $ | $ | $ | |||||

| Without N2 | Unpolished # | 64.7 (6.4) | a | 1.685 (0.004) | a | 0.495 (0.020) | a |

| – | Polished | 96.0 (3.0) | b | 1.657 (0.006) | b | 0.139 (0.022) | b |

| – | □ | □ | □ | □ | □ | □ | □ |

| With N2 | Unpolished # | 92.3 (4.5) | b | 1.696 (0.006) | a | 0.496 (0.036) | a |

| – | Polished | 97.3 (3.7) | b | 1.664 (0.017) | b | 0.138 (0.022) | b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wada, J.; Wada, K.; Gibreel, M.; Wakabayashi, N.; Iwamoto, T.; Vallittu, P.K.; Lassila, L. Effect of Surface Polishing on Physical Properties of an Occlusal Splint Material for Additive Manufacturing under Protection Gas Post-Curing Condition. Polymers 2023, 15, 625. https://doi.org/10.3390/polym15030625

Wada J, Wada K, Gibreel M, Wakabayashi N, Iwamoto T, Vallittu PK, Lassila L. Effect of Surface Polishing on Physical Properties of an Occlusal Splint Material for Additive Manufacturing under Protection Gas Post-Curing Condition. Polymers. 2023; 15(3):625. https://doi.org/10.3390/polym15030625

Chicago/Turabian StyleWada, Junichiro, Kanae Wada, Mona Gibreel, Noriyuki Wakabayashi, Tsutomu Iwamoto, Pekka K. Vallittu, and Lippo Lassila. 2023. "Effect of Surface Polishing on Physical Properties of an Occlusal Splint Material for Additive Manufacturing under Protection Gas Post-Curing Condition" Polymers 15, no. 3: 625. https://doi.org/10.3390/polym15030625