Static and Dynamic Properties Study on Interface between New Polymer Materials and Silty Clay Based on Ring Shear Tests

Abstract

:1. Introduction

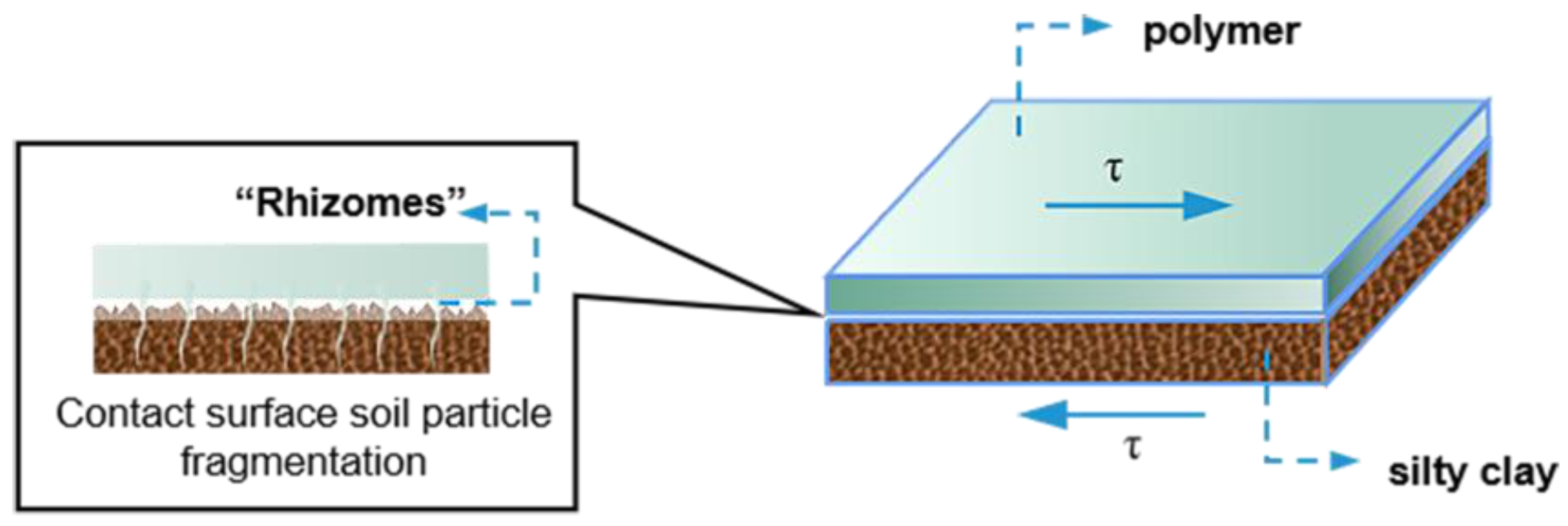

2. Ring Shear Test Research on Polymer–Soil Interface Properties

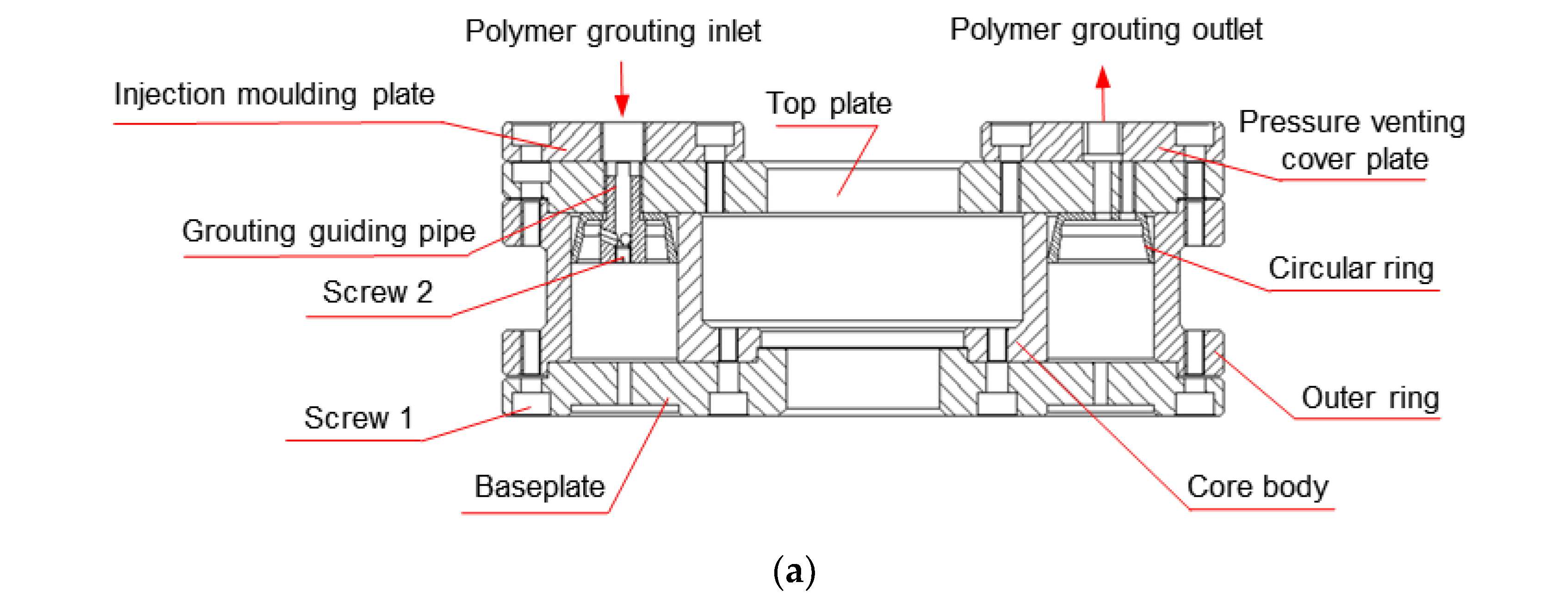

2.1. Test Equipment

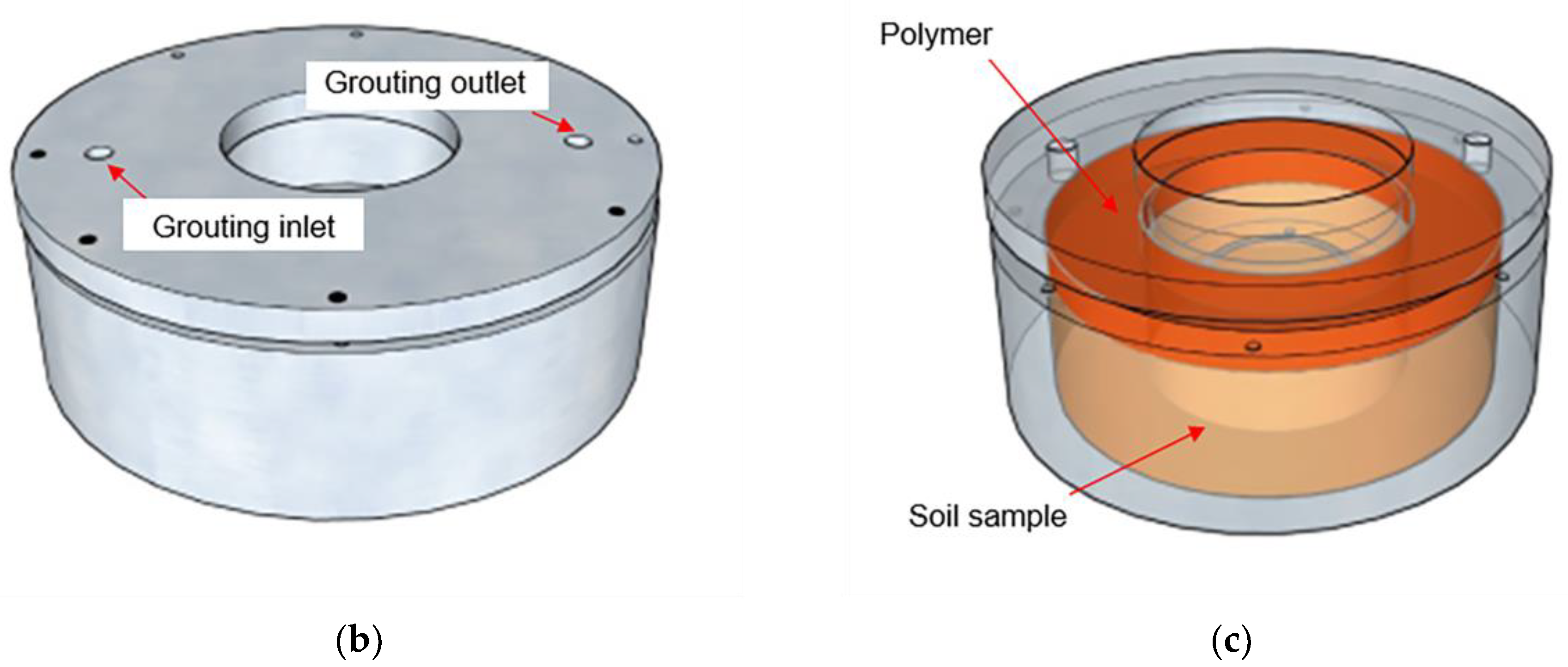

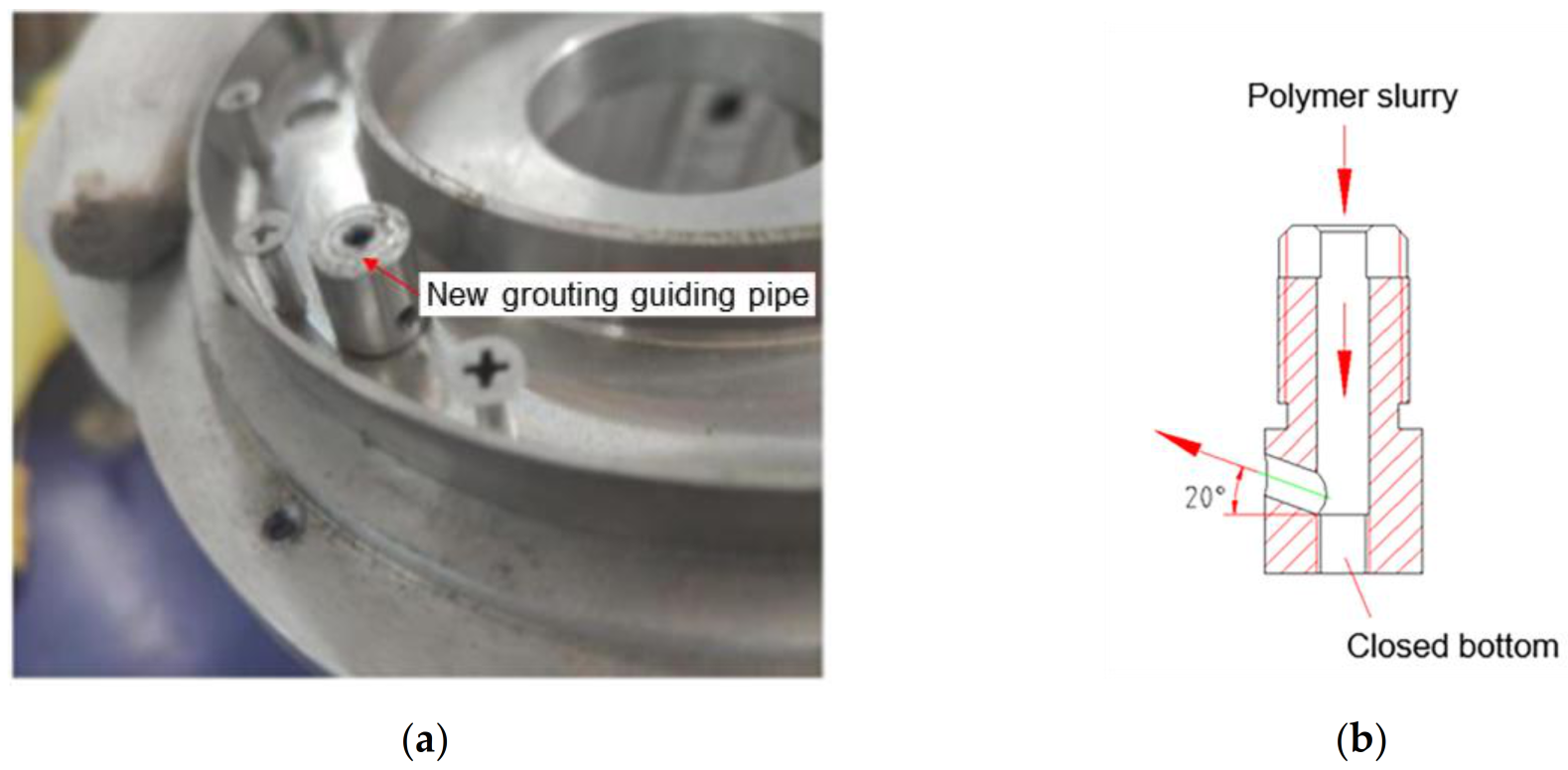

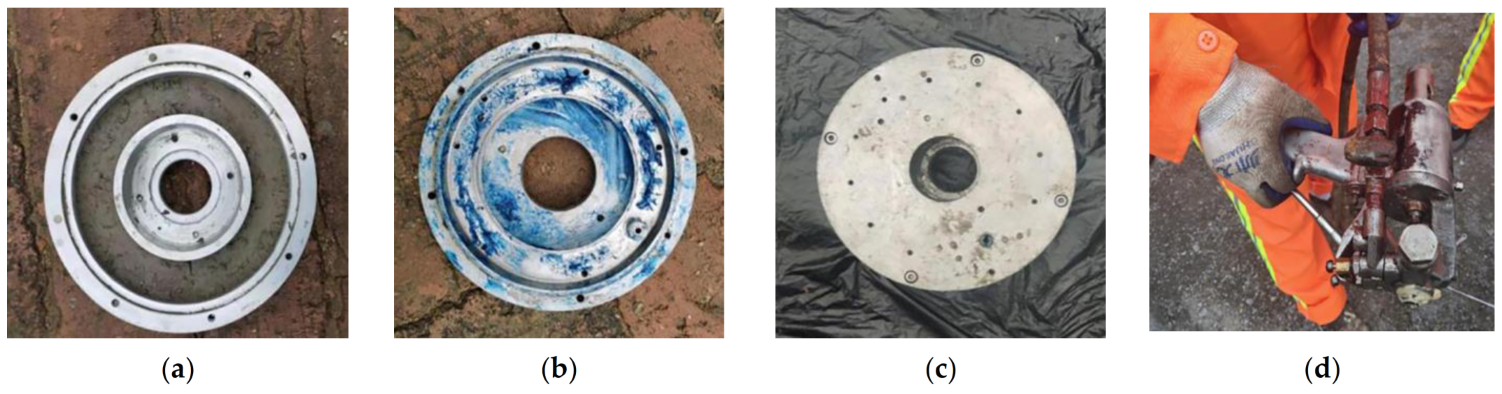

2.2. Mould Design

2.3. Preparation of Samples

2.4. Experimental Methodology

3. Analysis of Static Test Results of Polymer–Soil Interface

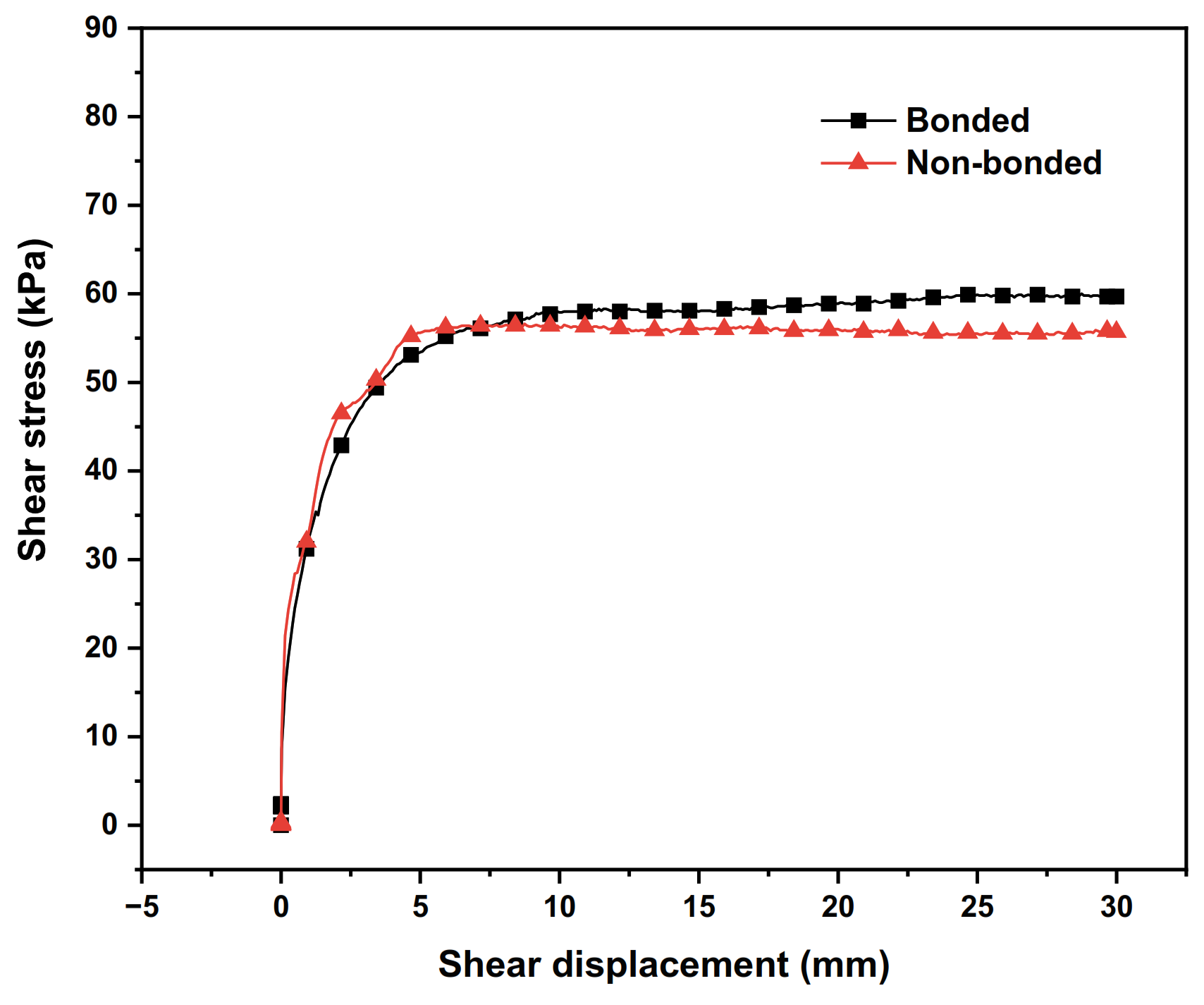

3.1. Influence of Different Bonding States

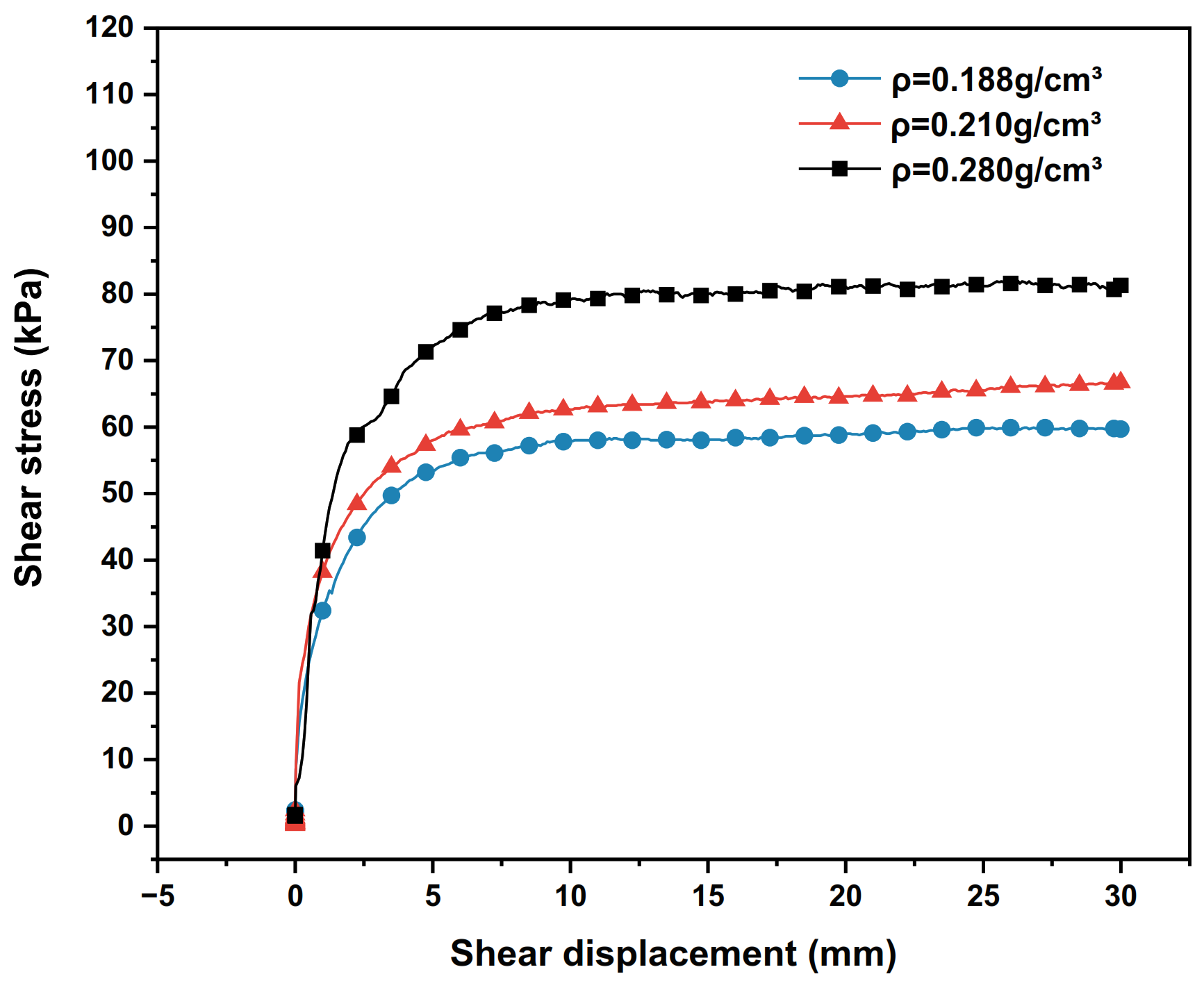

3.2. Influence of Polymer Density

3.3. Influence of Vertical Stress

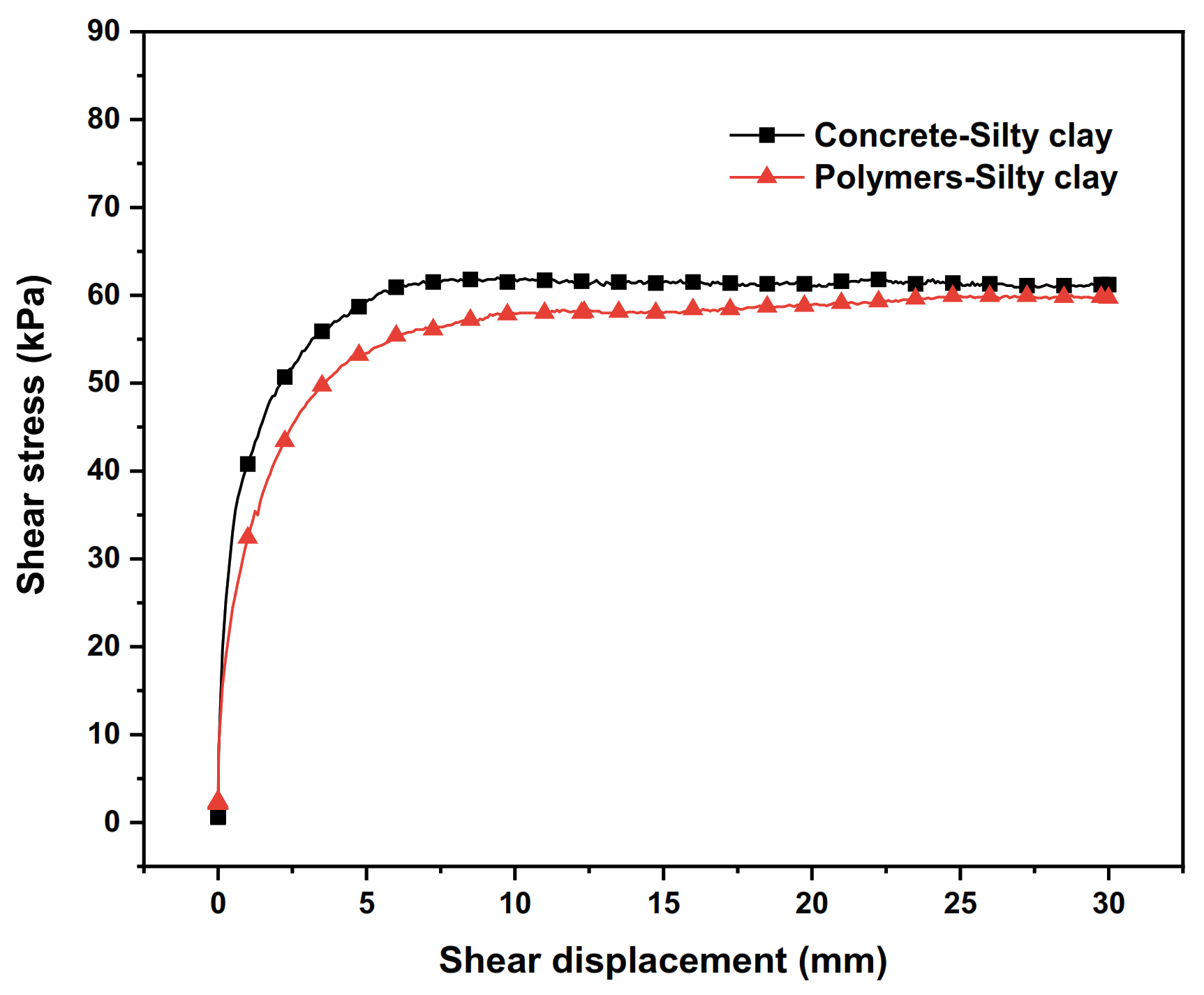

3.4. Influence of Dam Construction Materials

3.5. Influence of Different Anti-Seepage Bodies

3.6. Influence of Additional Polymer Anti-Seepage Wall in the DAM Body

4. Analysis of Dynamic Test Results of Polymer–Soil Interface

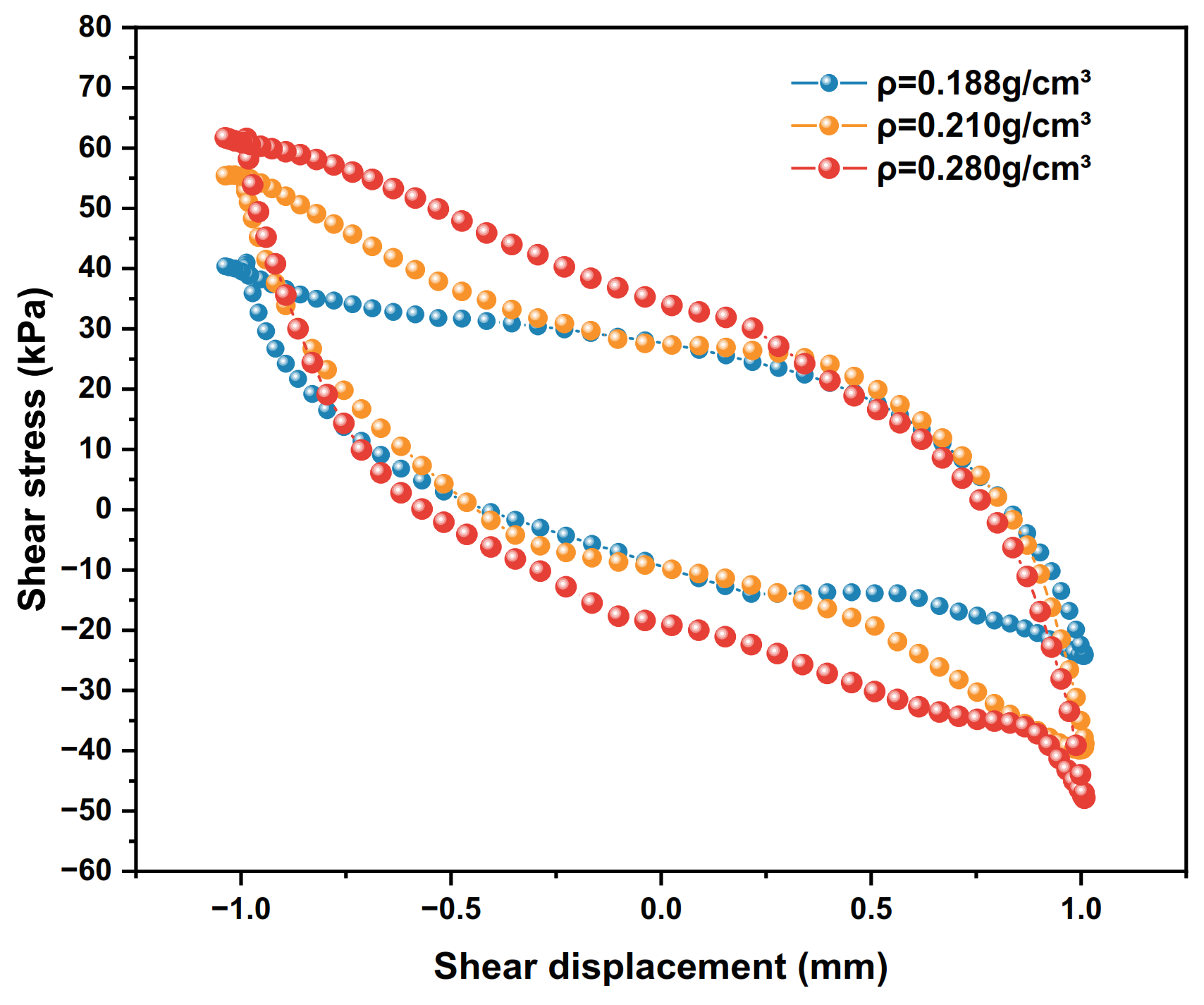

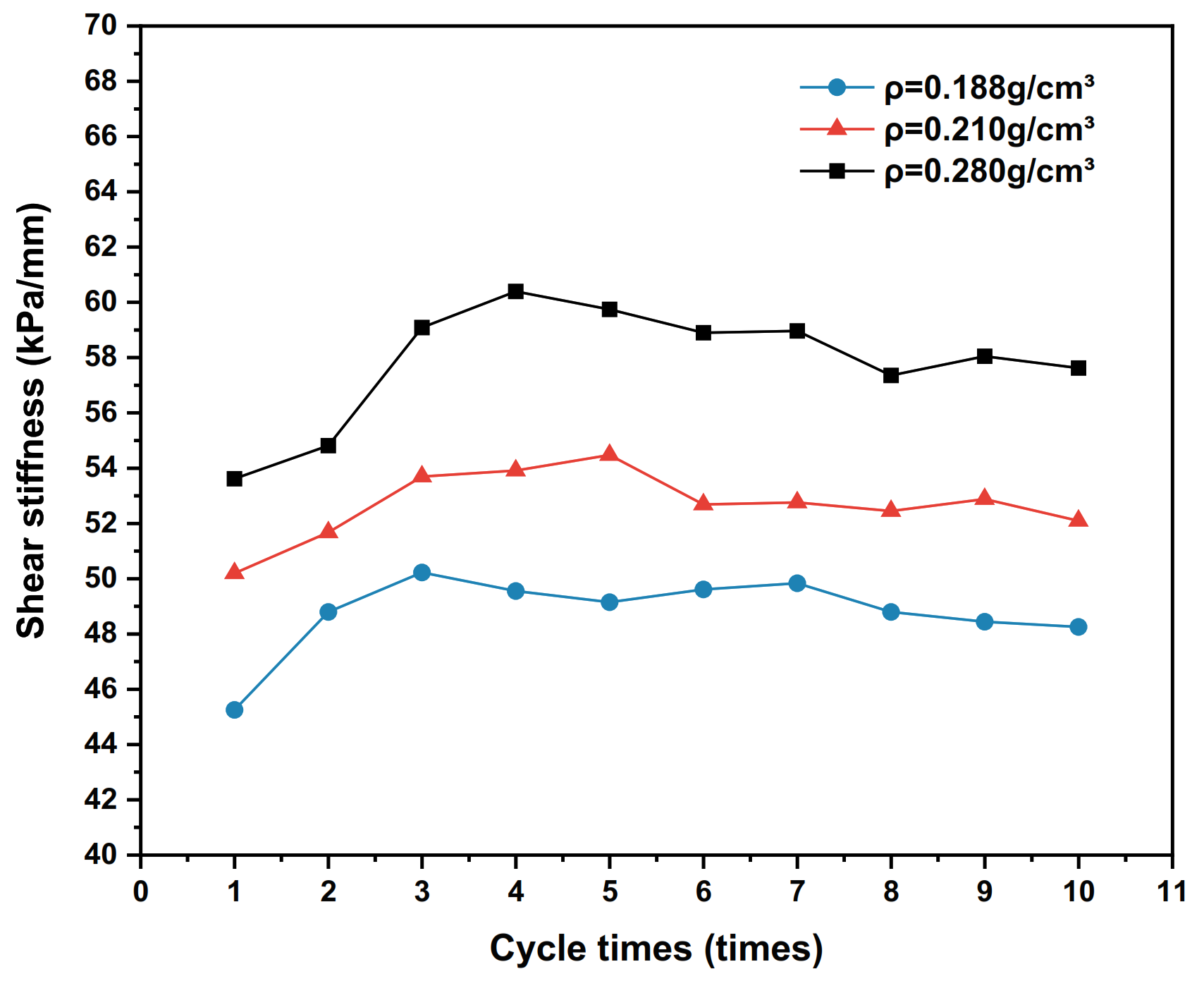

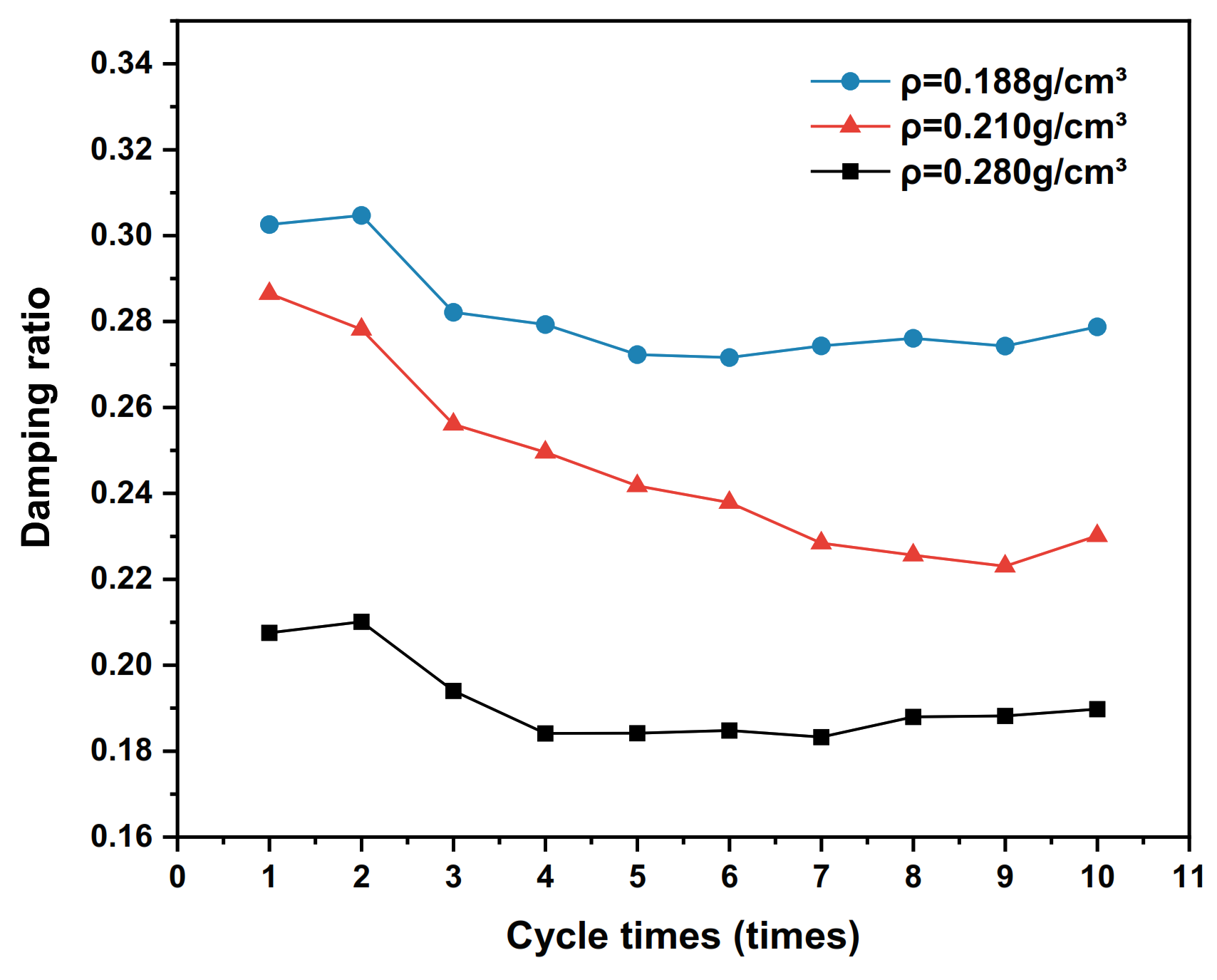

4.1. Influence of Polymer density

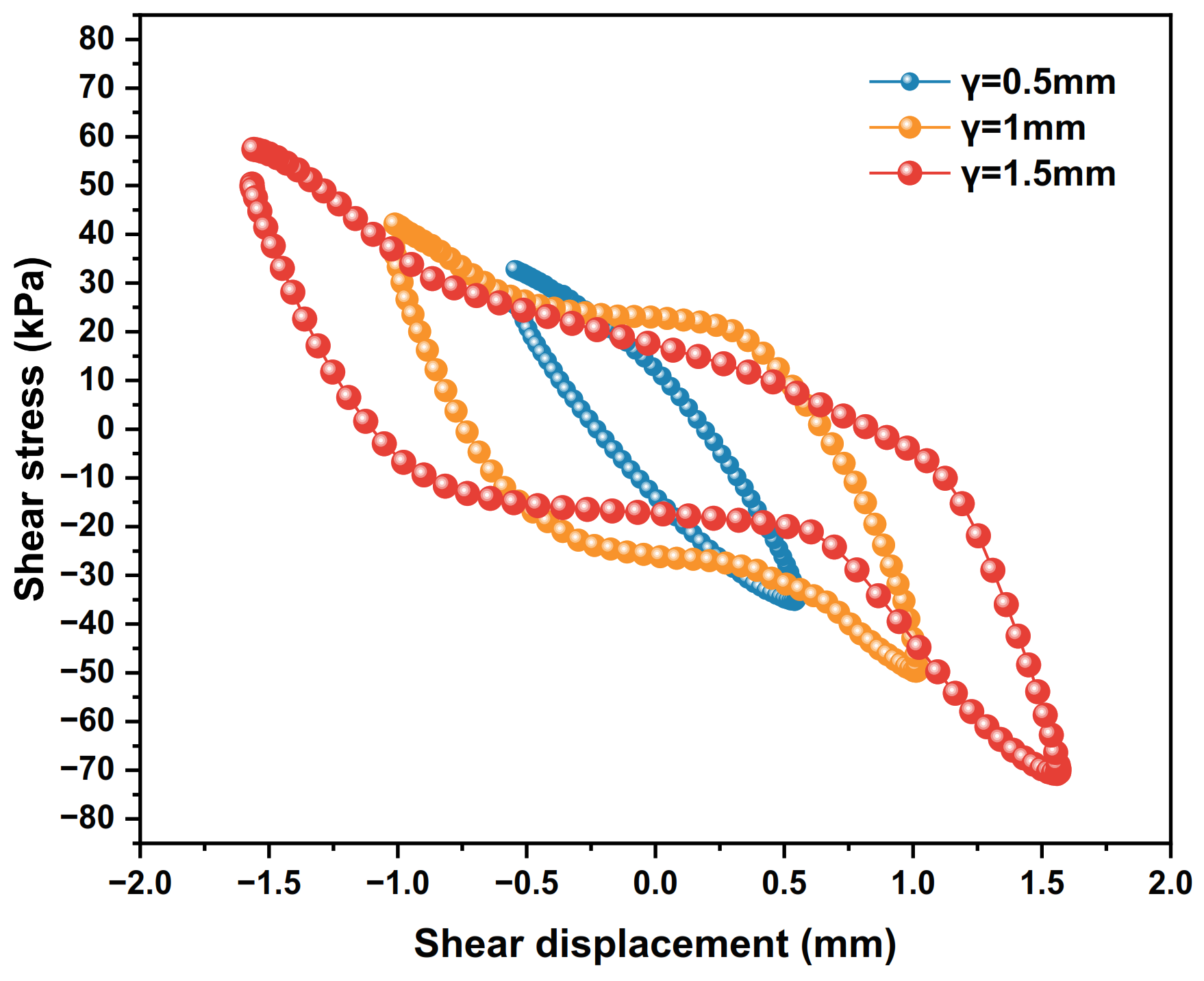

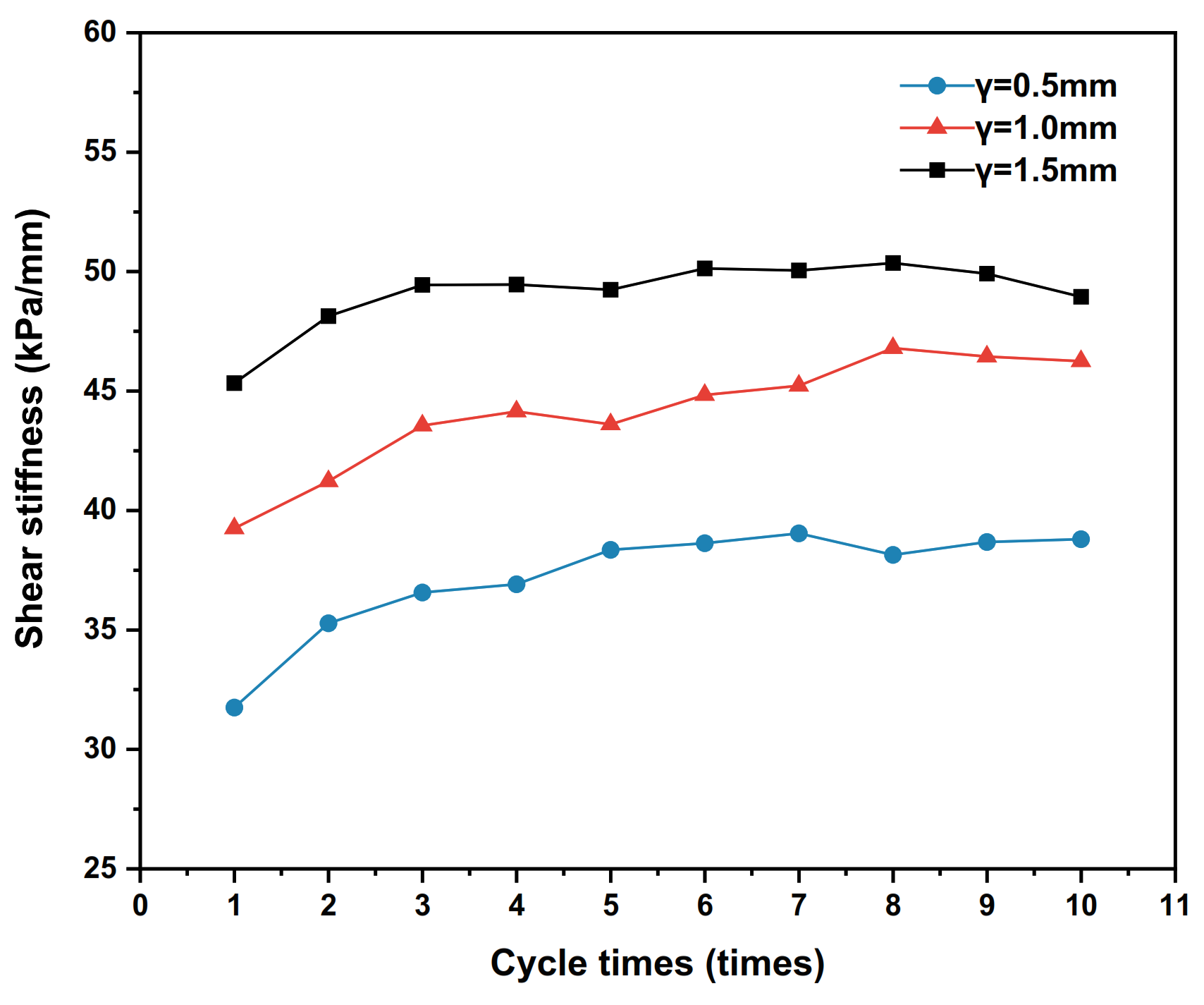

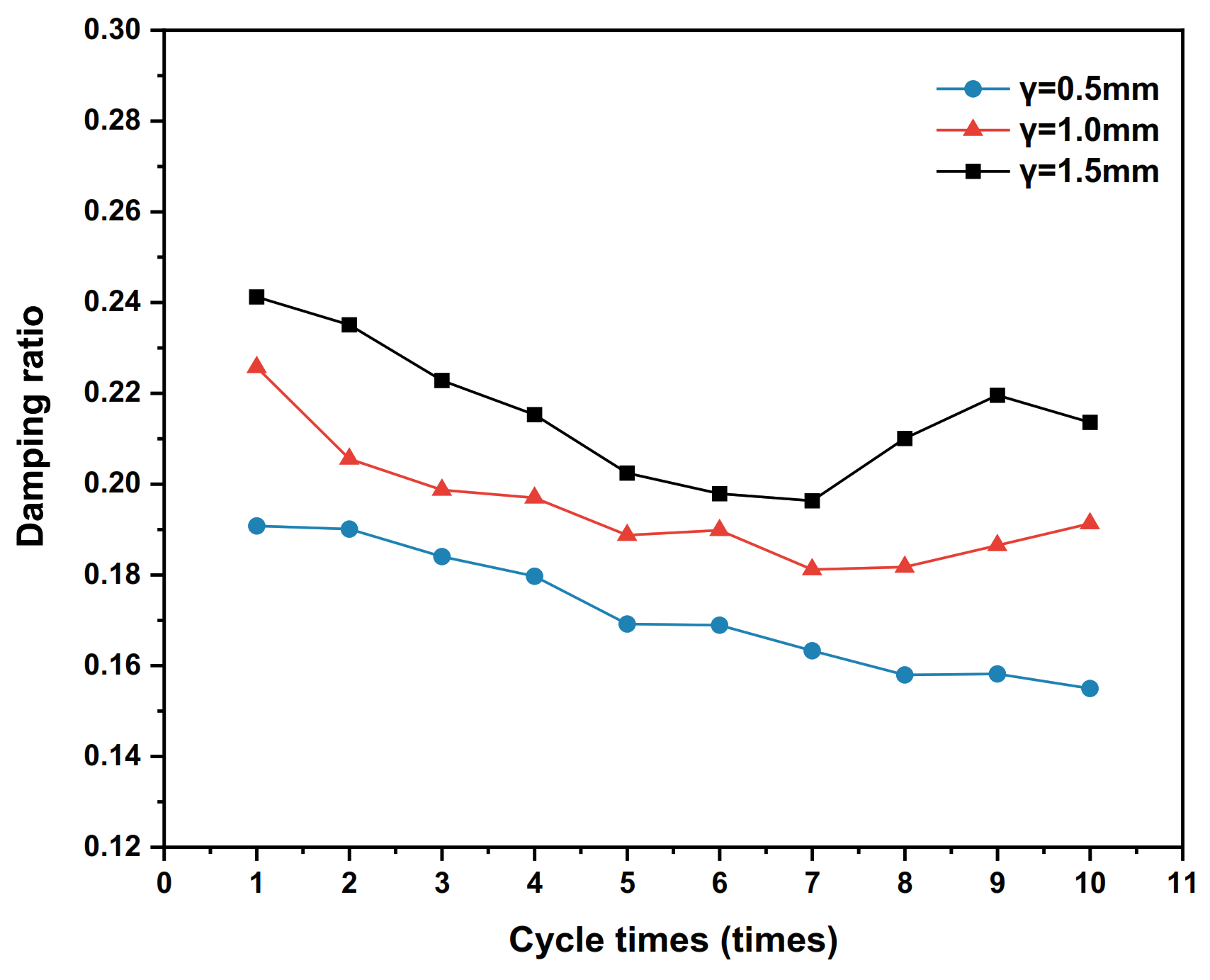

4.2. Influence of Shear Displacement Amplitude

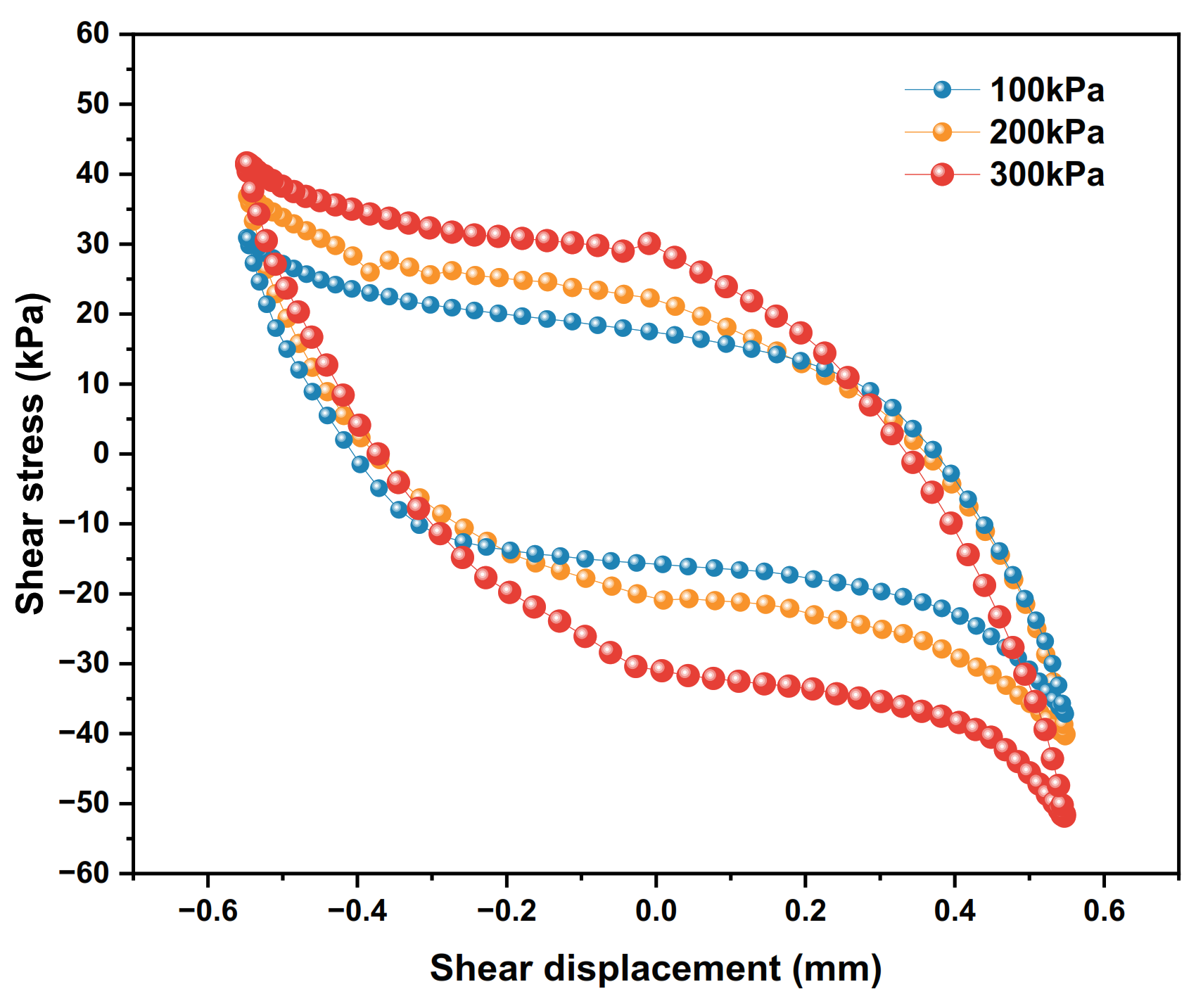

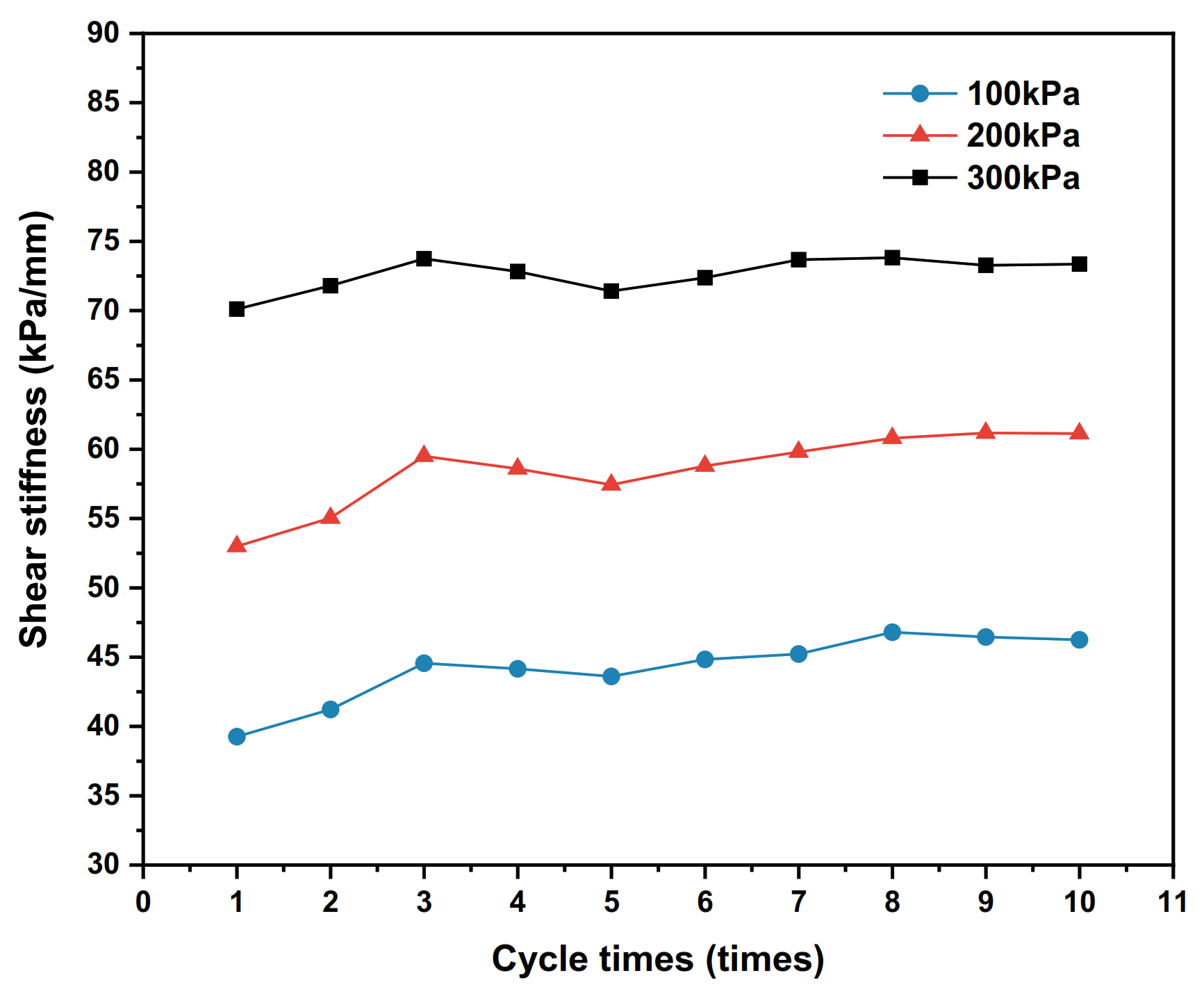

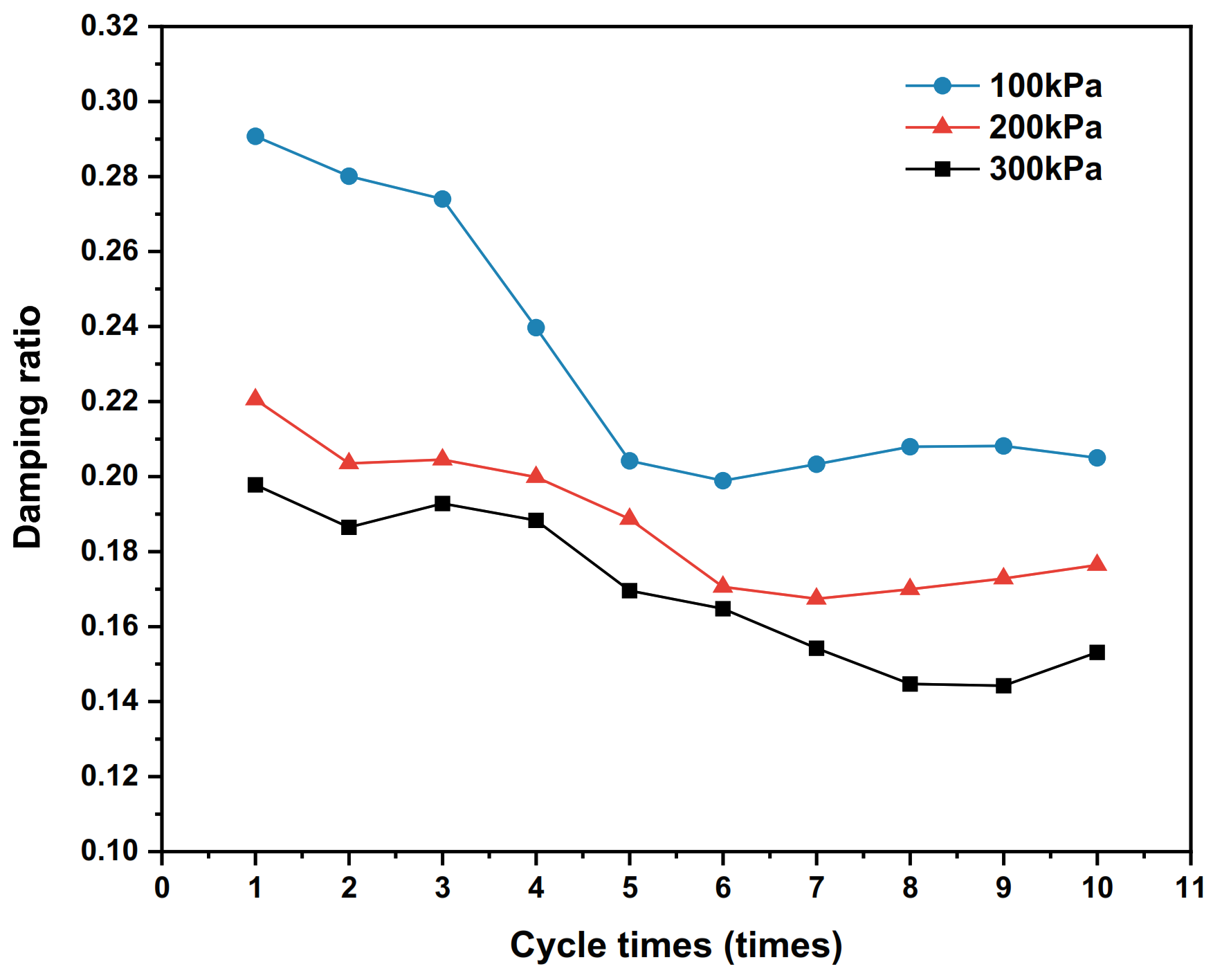

4.3. Influence of Vertical Stress

5. Nonlinear Constitutive Model of Polymer–Soil Interface

5.1. Static Interface Model

5.2. Dynamic Interface Model

5.3. Implementation of Interface Unit

5.4. Interface Model Validation

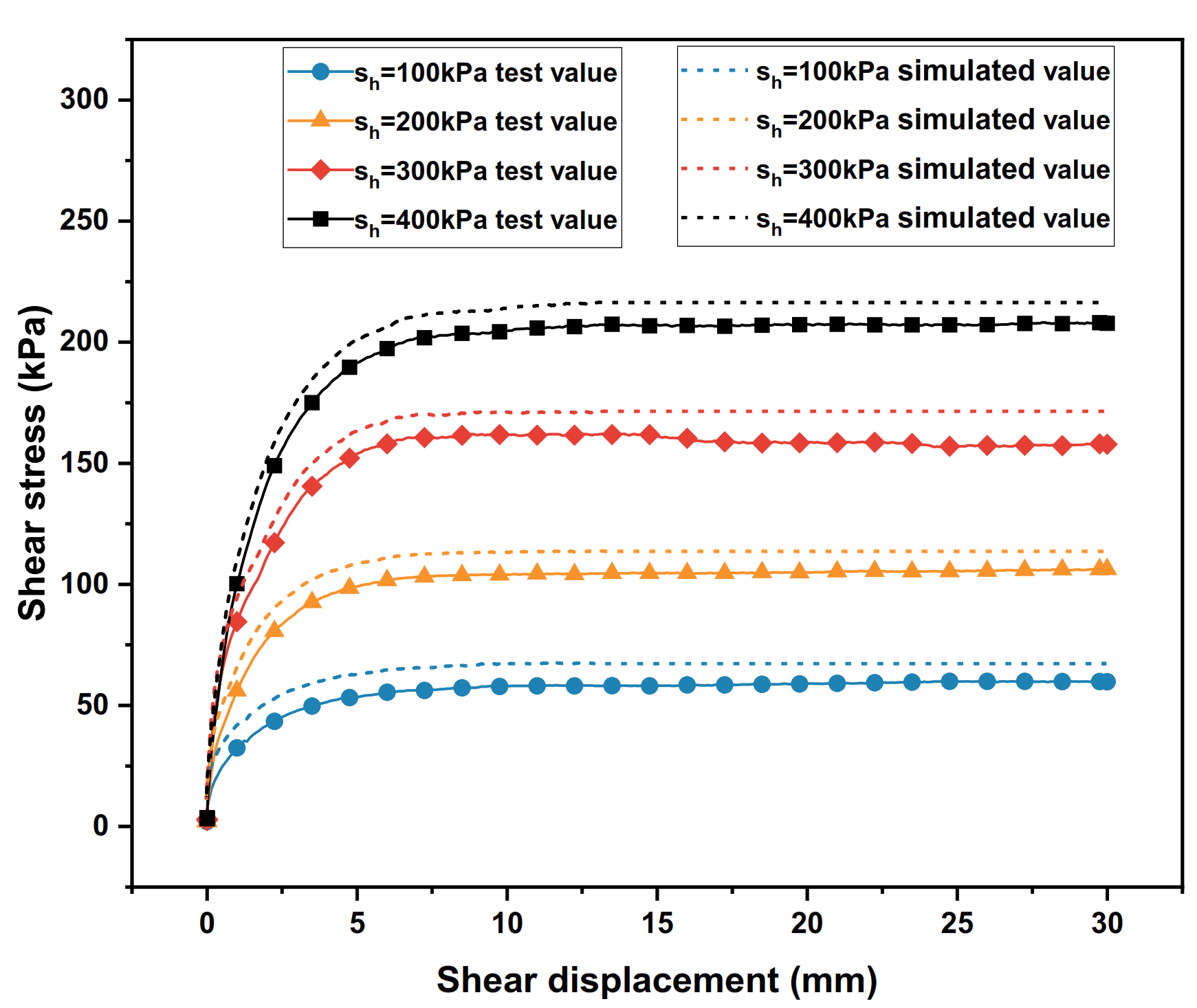

5.4.1. Static Shear Model Verification

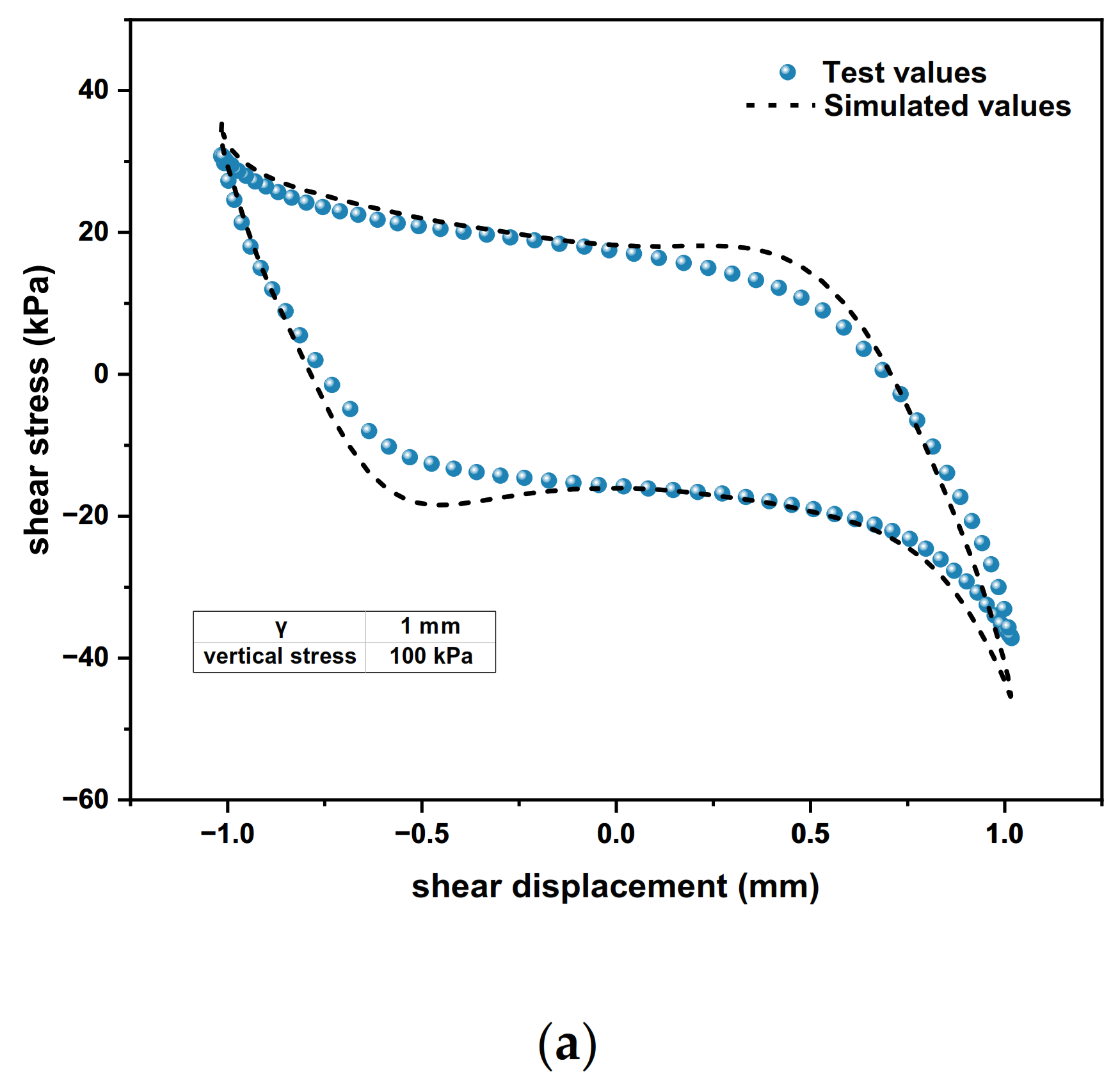

5.4.2. Dynamic Shear Model Validation

6. Conclusions

- (1)

- The interface properties of polymer–silty clay are better than those of the polymer–silty interface, concrete–silty clay interface and plain soil interface, which are reflected in the higher shear strength, greater adhesive force of the polymer–silty clay interface and more obvious improvement in the shear properties of the earth–rock dam. As the viscosity of the soil increases, the adhesive force and internal friction angle of the interface increase as well, and the silty clay contains more clay particles compared to the silty clay, which enhances the adsorption and adhesion of the interface between the polymer and the nearby soil, resulting in the peak shear stress being further improved. At the same time, compared to conventional concrete-based anti-seepage structures, the polymer bonds with the soil more closely due to adhesive and consolidation effects, which leads to the shear resistance of the polymer–soil being better than the traditional concrete materials.

- (2)

- The bonding state, polymer density and vertical stress affect the static properties of the polymer–silty clay interface, and the specific performances are as follows: the shear resistance of the polymer–silty clay interface in the bonded state is better than that in the non-bonded state; meanwhile, the peak shear stress of the polymer–silty clay interface increases with the increases in polymer density and vertical stress. The influence of the bonding state and polymer density on the static properties of the interface is mainly through changing the adhesion between the soil and the structure to increase the adhesive force and internal friction angle of the interface, and the increase in polymer density enhances the expansion anchorage force of polymer materials and strengthens the shear strength of the interface. When the vertical stress increases, the compactness of the soil near the interface of polymer–silty clay also increases, and the frictional resistance between soil particles increases accordingly as well, which drives more soil particles to flip, roll and rearrange to increase the peak shear stress of the interface.

- (3)

- The polymer density, shear displacement amplitude and vertical stress affect the dynamic properties of the polymer–silty clay interface, and the specific performances are as follows: the hysteresis loop area and dynamic shear stress of the polymer–silty clay interface increase with the increase in polymer density, shear displacement amplitude and vertical stress. The effect of polymer density on the dynamic properties of the interface is mainly through enhancing the shear modulus and shear strength of the polymer materials; the effect of shear displacement amplitude on the dynamic properties of the interface is mainly through acting on the soil near the interface, resulting in a more orderly arrangement of soil particles near the interface of polymer–silty clay, so that the energy absorbed and dissipated increases accordingly, which further improves the shear stress; the influence of vertical stress on the dynamic properties of the interface is mainly through enhancing the frictional restraint between the soil particles near the interface and squeezing the soil near the interface to increase the peak shear stress of the interface hysteresis loop.

- (4)

- Polymer density, shear displacement amplitude and vertical stress have similar effects on the shear stiffness of the polymer–silty clay interface: the shear stiffness of the interface increases with the increases in polymer density, shear displacement amplitude and vertical stress. In addition, the damping ratio of the polymer–silty clay interface is negatively correlated with polymer density and vertical stress, while the damping ratio of the polymer–silty clay interface is sensitive to the shear displacement amplitude, and the damping ratio corresponding to the same number of cycles is positively correlated with the shear displacement amplitude.

- (5)

- According to the interface properties of polymer–silty clay, the construction process of the hyperbolic constitutive model is systematically expounded by using mathematical formulae. Verified by numerical simulation, the test values of the shear strength and shear displacement curves of the static shear model and cyclic shear model have a good fitting degree with the simulation values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, F.M.; Wang, J.W.; Shi, M.S.; Li, X.L. Development of dam protection polymer grouting technology. In Proceedings of the International Symposium on Dam Technology and Long-Term Performance, Henan, China, 27 September 2011; pp. 397–401. [Google Scholar]

- Guo, C.C.; Wang, C.J.; Cui, C. Application of non-aqueous reactive polymer grouting technology in road maintenance. Traffic Constr. Manag. 2019, 3, 112–114. [Google Scholar]

- Zhang, J.J.; Xiao, Z.S. Economic Benefit Analysis of Polymer Grouting Technology for Expressway Disease Treatment. Highw. Eng. 2013, 38, 12–15. [Google Scholar]

- Zheng, X.G. Swelling characteristics of back-pressed polymer grouting material and mechanical properties of its consolidated body. China Railw. Sci. 2017, 38, 9–15. [Google Scholar]

- Wang, J.; Fang, H.Y.; Yu, Z.S.; Cao, K.; Wang, F.M. Experimental study on uniaxial compression performance of polymer gravel mixture. J. Build. Mater. 2019, 22, 320–326. [Google Scholar]

- Zhang, P.; Kang, L.Y.; Zheng, Y.X.; Zhang, T.H.; Zhang, B. Influence of SiO2/Na2O molar ratio on mechanical properties and durability of metakaolin-fly ash blend alkali-activated sustainable mortar incorporating manufactured sand. J. Mater. Res. Technol. 2022, 18, 3553–3563. [Google Scholar] [CrossRef]

- Bian, X.C.; Cheng, C.; Wang, F.M.; Jiang, J.Q.; Chen, Y.M. Experimental study on dynamic performance and long-term durability of high-speed railway subgrade settlement after polymer grouting repair. J. Geotech. Eng. 2014, 36, 562–568. [Google Scholar]

- Zhang, P.; Wei, S.Y.; Zheng, Y.X.; Wang, F.; Hu, S.W. Effect of single and synergistic reinforcement of PVA fiber and nano-SiO2 on workability and compressive strength of geopolymer composites. Polymers 2022, 14, 3765. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, X.M.; Zhang, Y.M.; Zheng, Y.X.; Wang, T.Y. Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar. Nanotechnol. Rev. 2022, 11, 3195–3206. [Google Scholar] [CrossRef]

- Shi, M.S. Characterization of Polymer Injection Paddle Material and Mechanism of Directional Splitting Paddle Injection for Dykes; Dalian University of Technology: Dalian, China, 2011. [Google Scholar]

- Anti-aging Performance Detection. Technical Information about Uretek Chemieal Resistance to Aging; University of Hanover: Hannover, Germany, 2009. [Google Scholar]

- Wang, F.M.; Li, J.; Shi, M.S. Research and application of new technology for embankment dam impermeability reinforcement. J. Hydropower 2016, 35, 1–11. [Google Scholar] [CrossRef]

- Wang, F.M.; Shi, M.S.; Liu, W.T. Grouting Method for Ultra-Thin Polymeric Impermeable Walls. CN102444128B, 13 November 2013. [Google Scholar]

- Molinda, G. Reinforcing Coal Mine Roof with Polyurethane Injection: 4 Case Studies. Geotech. Geol. Eng. 2008, 26, 553–566. [Google Scholar] [CrossRef]

- Zelanko, J.C.; Karfakis, M.G. Development of a polyester-based pumpablegrout. Int. J. Rock Mech. Min. Sci. 1997, 34, 357. [Google Scholar] [CrossRef]

- Yang, D.Y. Research on the Application of Polymer Grouting in the Rapid Repair of Asphalt Pavement Internal Damage of Highway. Wuhan Engineering University: Wuhan, China, 2015. [Google Scholar]

- Shi, M.S.; Xia, W.Y.; Wang, F.M.; Liu, H.; Pan, Y.H. Experimental study on bond performance between polymer anchor and silt. J. Geotech. Eng. 2014, 36, 724–730. [Google Scholar]

- Cheng, H.; Zeng, G.D.; Zhou, M.; Wang, X.A.; Zhang, J.S.; Wang, J. Study on peak shear strength model of clay-concrete interface considering roughness effect. Eng. Sci. Technol. 2021, 53, 168–177. [Google Scholar] [CrossRef]

- Wei, W. Experimental Study on Mechanical Properties of Interface between Silty Sand and Concrete Structure; Tarim University: Alar, China, 2021. [Google Scholar] [CrossRef]

- Feng, D.G.; Zhang, J.M. Experimental study of the effect of normal stiffness on the three-dimensional properties of soil-structure interfaces. Geotech. Mech. 2018, 39, 3929–3936. [Google Scholar] [CrossRef]

- Liu, F.C.; Shang, S.P.; Wang, H.D. Single-shear experimental study on the properties of powdered clay-concrete interface. J. Rock Mech. Eng. 2011, 30, 1720–1728. [Google Scholar]

- Liang, H.A.; Chen, H.K.; Chai, X.J. Study on the effect of roughness on the shear properties of powdered clay-structure interface. Highway 2019, 64, 236–242. [Google Scholar]

- Kishida, H.; Uesugi, M. Tests of the interface between sand and steel in the simple shear apparatus. Géotechnique 1987, 37, 45–52. [Google Scholar] [CrossRef]

- Bishop, A.W.; Green, G.E.; Garga, V.K. A new ring shear apparatus and its application to the measurement of residual strength. Geotechnique 1971, 21, 273–328. [Google Scholar] [CrossRef]

- Wu, J.S.; Jiang, P. Dynamic shear properties of soil-concrete interfaces. J. Geotech. Eng. 1992, 2, 61–66. [Google Scholar]

- Yang, Y.L.; Zhu, J.G.; Yu, T. Study on the mechanical properties of soil-structure interface in ring shear test. Geotechnics 2009, 30, 3256–3260. [Google Scholar] [CrossRef]

- Han, P.P. Research on Mechanical Properties of Collapsible Loess-Concrete Structure Contact Surface; Lanzhou Jiaotong University: Gansu, China, 2020. [Google Scholar] [CrossRef]

- Clough, G.W.; Duncan, J.M. Finite element analyses of retaining wall properties. J. Soil Mech. Found. Div. 1971, 97, 1657–1673. [Google Scholar] [CrossRef]

- Fei, K.; Zhang, J.W. Application of ABAQUS in Geotechnical Engineering; China Water Conservancy and Hydropower Press: Beijing, China, 2010. [Google Scholar]

- Boulon, M.; Nova, R. Modelling of soil structure interface properties: A comparison between elastoplastic and rate-type laws. Comput. Geotech. 1990, 9, 21–46. [Google Scholar] [CrossRef]

- Esterhuizen, J.J.B.; Filz, G.M.; Duncan, J.M. Constitutive Behavior of geosynthetic interfaces. J. Geotech. Geoenvironmental Eng. 2001, 127, 834–840. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, C.J.; Zhang, X.J. Experimental study on the shear performance of polymer grouting materials. Peoples Yellow River 2021, 43, 139–143. [Google Scholar] [CrossRef]

- Cen, W.J.; Sheng, X.X.; Wen, L.S. Numerical simulation and application of dynamic shear characteristics of geomembrane interface. J. Hydraul. Water Transp. Eng. 2021, 2, 103–108. [Google Scholar] [CrossRef]

- Hou, J.; Xing, X.; Xu, D.; Lu, Q. Experimental study on dynamic shear characteristics of geomembrane-geotextile interface. Geomechanics 2022, 43, 365–376. [Google Scholar] [CrossRef]

- Xu, J.H. Seismic Characteristics of Permafrost Site and Dynamic Response Analysis of Pile Foundation in Northwest Cold Region; South China University of Technology: Guangzhou, China, 2019. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Zhang, J.W. Dynamic viscoelastic properties of non-water reactive polymer materials based on dynamic thermomechanical analysis. J. Constr. Mater. 2020, 23, 1398–1409. [Google Scholar] [CrossRef]

- He, F. Research on Nonlinear Shear Creep Characteristics of Frozen Silt-Concrete Interface; Lanzhou Jiaotong University: Lanzhou, China, 2019. [Google Scholar] [CrossRef]

- Wu, P.F. Experimental Study on Strength Characteristics of Pile-Soil Interface and Numerical Simulation of Bearing Capacity of Pile Foundation in Permafrost Regions; China University of Mining and Technology: Xuzhou, China, 2021. [Google Scholar] [CrossRef]

| Main Parameters | Value | Unit |

|---|---|---|

| exercise frequency | 0–5 | Hz |

| shear rate | 0.0008–314 | mm/min |

| consolidation stress | 0–1000 | kPa |

| vertical displacement | 0–50 | mm |

| sample inner diameter | 100 | mm |

| sample outer diameter | 150 | mm |

| cross-sectional area | 98.16 | cm2 |

| Item | Technical Indicators |

|---|---|

| Appearance | Light brown transparent liquid |

| Viscosity/(mPa·s) | 60–600 |

| Induced coagulation time/s | 10–13000 |

| Expansion ratio/% | 350–1000 |

| Permeability coefficient k(cm/s) | 1 × 10−9 |

| Elastic modulus E (MPa) | 58.11 |

| Poisson’s ratio μ | 0.26 |

| Specific Gravity Gs | Void Ratio e | Water Content Ω (%) | Permeability Coefficient k (cm/s) | Elastic Modulus E (MPa) | Poisson’s Ratio μ | Cohesion C (kPa) | Internal Friction Angle φ (°) |

|---|---|---|---|---|---|---|---|

| 2.7 | 0.804 | 21 | 2.3 × 10−5 | 37.2 | 0.35 | 22.2 | 11.3 |

| Test Type | Test Number | Type of Interface | Water Content | Shear Rate | Density | Vertical Stress |

|---|---|---|---|---|---|---|

| (%) | (mm/min) | (g/cm3) | (kPa) | |||

| static shear | A-1 | polymer–silty clay (bonding) | 21 | 1 | 0.188 | 100 |

| A-2 | polymer–silty clay (non-bonded) | |||||

| B-1 | polymer–silty clay | 21 | 1 | 0.188 | 100 | |

| B-2 | 0.210 | |||||

| B-3 | 0.280 | |||||

| C-1 | polymer–silty clay | 21 | 1 | 0.188 | 100 | |

| C-2 | 200 | |||||

| C-3 | 300 | |||||

| C-4 | 400 | |||||

| D-1 | polymer–silty clay | 21 | 1 | 0.188 | 100 | |

| D-2 | polymer–silt | |||||

| E-1 | polymer–silty clay | 21 | 1 | 0.188 | 100 | |

| E-2 | concrete–silty clay | —— | ||||

| F-1 | polymer–silty clay | 21 | 1 | 0.188 | 100 | |

| F-2 | plain soil | —— |

| Test Type | Test Number | Type of Interface | Density | Cycle Amplitude | Vertical Stress |

|---|---|---|---|---|---|

| (g/cm3) | (mm) | (kPa) | |||

| cyclic shear | G-1 | polymer–silty clay | 0.188 | 1 | 100 |

| G-2 | 0.210 | ||||

| G-3 | 0.280 | ||||

| H-1 | polymer–silty clay | 0.188 | 0.5 | 100 | |

| H-2 | 1 | ||||

| H-3 | 1.5 | ||||

| I-1 | polymer–silty clay | 0.188 | 1 | 100 | |

| I-2 | 200 | ||||

| I-3 | 300 |

| Type of Interface | c/kPa | φ/° |

|---|---|---|

| polymer–silty clay (bonding) | 9.05 | 25.55 |

| polymer–silty clay (non-bonded) | 4.85 | 25.13 |

| Type of Interface | c/kPa | φ/° |

|---|---|---|

| polymer–silty clay (ρ = 0.188 g/cm3) | 9.05 | 25.55 |

| polymer–silty clay (ρ = 0.210 g/cm3) | 15.20 | 26.61 |

| polymer–silty clay (ρ = 0.280 g/cm3) | 34.90 | 27.11 |

| Type of Interface | c/kPa | φ/° |

|---|---|---|

| polymer–silty clay | 9.05 | 25.55 |

| polymer–silt | 7.75 | 21.45 |

| Type of Interface | c/kPa | φ/° |

|---|---|---|

| polymer–silty clay | 9.05 | 25.55 |

| concrete–silty clay | 5.50 | 28.90 |

| Type of Interface | c/kPa | φ/° |

|---|---|---|

| polymer–silty clay | 9.05 | 25.55 |

| plain soil | 8.63 | 24.84 |

| Interface | n | ||||||

|---|---|---|---|---|---|---|---|

| polymer–soil | 1137 | 1137 | 0.89 | 0.45 | 26.57 | 10 | 100 |

| Interface | n | k | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Polymer–soil | 1137 | 1137 | 0.89 | 0.45 | 26.57 | 10 | 100 | 0.31 | 0.27 | 1.25 | 1.84 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Li, J.; Zhang, J.; Liu, G. Static and Dynamic Properties Study on Interface between New Polymer Materials and Silty Clay Based on Ring Shear Tests. Polymers 2023, 15, 634. https://doi.org/10.3390/polym15030634

Li J, Li J, Zhang J, Liu G. Static and Dynamic Properties Study on Interface between New Polymer Materials and Silty Clay Based on Ring Shear Tests. Polymers. 2023; 15(3):634. https://doi.org/10.3390/polym15030634

Chicago/Turabian StyleLi, Jia, Jie Li, Jingwei Zhang, and Guangzong Liu. 2023. "Static and Dynamic Properties Study on Interface between New Polymer Materials and Silty Clay Based on Ring Shear Tests" Polymers 15, no. 3: 634. https://doi.org/10.3390/polym15030634

APA StyleLi, J., Li, J., Zhang, J., & Liu, G. (2023). Static and Dynamic Properties Study on Interface between New Polymer Materials and Silty Clay Based on Ring Shear Tests. Polymers, 15(3), 634. https://doi.org/10.3390/polym15030634