Determination of Elastic Modulus, Stress Relaxation Time and Thermal Softening Index in ZWT Constitutive Model for Reinforced Al/PTFE

Abstract

:1. Introduction

2. Experiment

2.1. Preparation of Reinforced Al/PTFE

2.2. Quasi-Static Compression Experiment

2.3. Dynamic Compression Experiment

2.4. Basic Parameters of Dynamic Compression Experiment

3. Experimental Results and Analysis

3.1. Results of Quasi-Static Compression Experiment

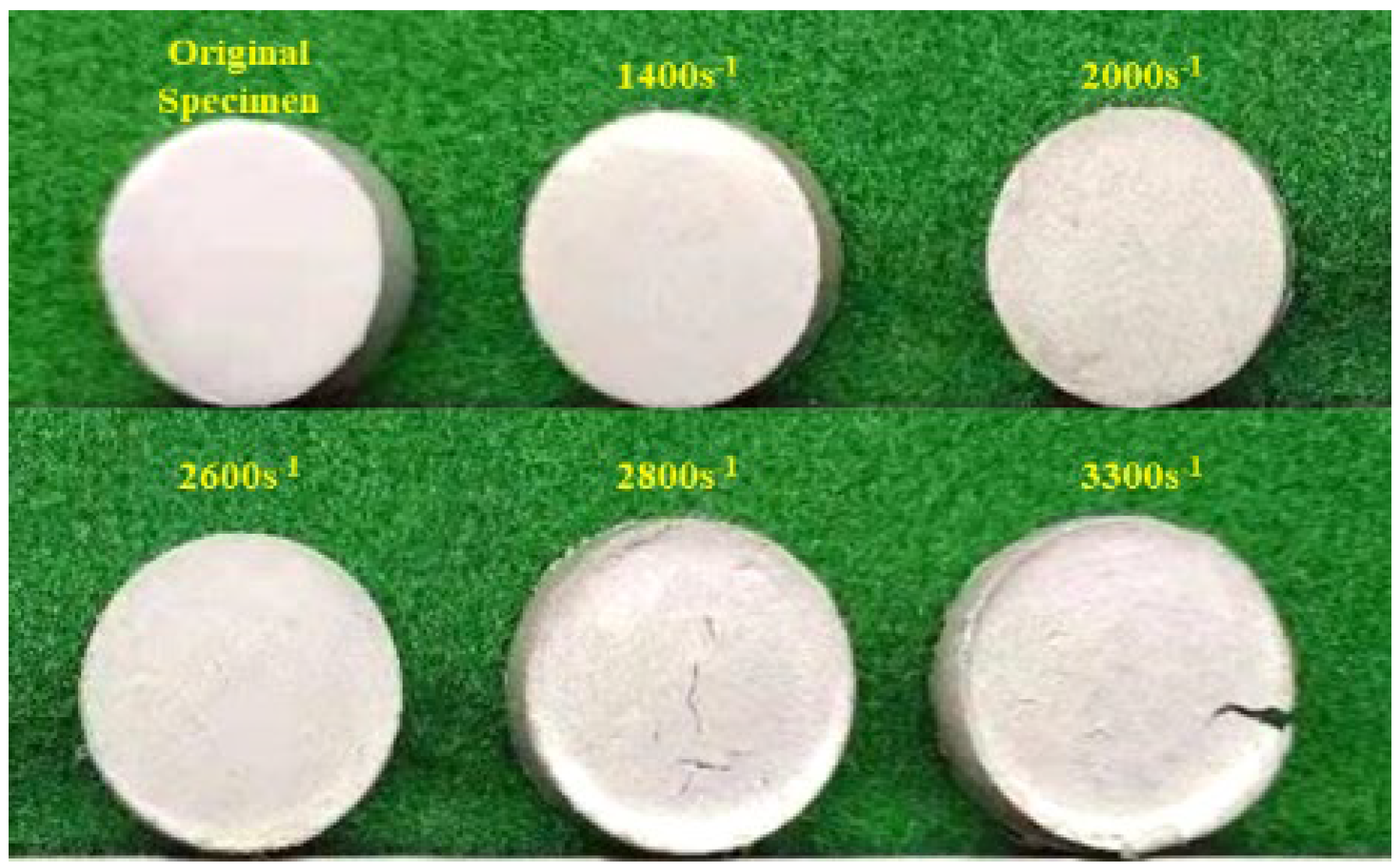

3.2. Results of Dynamic Compression Experiment

3.2.1. Effect of Pressing Pressure on Dynamic Compression Properties of Specimens

3.2.2. Effect of Strain Rate on Dynamic Compression Properties of Specimens

3.2.3. Effect of Temperature on Dynamic Compression Properties of Specimens

3.3. Microstructure Characterization and Dynamic Compression Process of Reinforced Al/PTFE

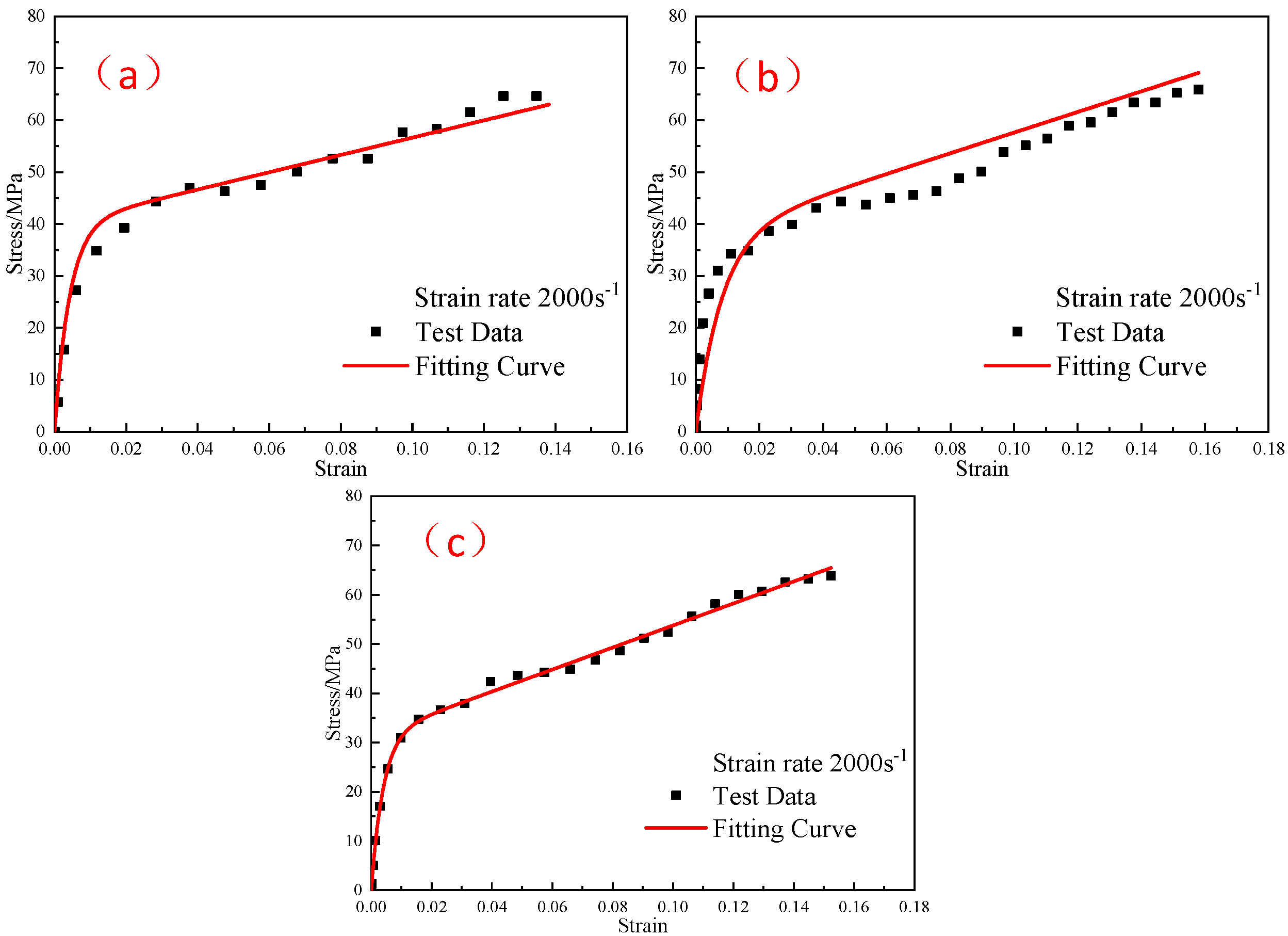

4. Constitutive Equation of Reinforced Al/PTFE Active Materials at Room Temperature

4.1. ZWT Constitutive Model

4.2. ZWT Constitutive Model Considering Pressing Pressure

4.2.1. Determination of Constitutive Model Parameters

4.2.2. Verification of Constitutive Model

5. Constitutive Equation of Reinforced Al/PTFE Active Materials at Low Temperature

5.1. ZWT Constitutive Model Considering Temperature Dependence of Parameters

5.1.1. Establishment of the Constitutive Model

5.1.2. Determination of Constitutive Model Parameters

5.2. Consider the ZWT Constitutive Model with the Addition of Temperature-Dependent Terms

5.2.1. Establishment of the Constitutive Model

5.2.2. Determination of Constitutive Model Parameters

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, F.Y.; Yu, Q.B.; Zheng, Y.F.; Lei, M.A.; Wang, H.F. Damage effects of double-spaced aluminum plates by reactive material projectile impact. Int. J. Impact Eng. 2017, 104, 38–44. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhang, J.; Qiao, L.; Shi, A.S.; Zhang, Y.G.; He, Y.; Guan, Z.W. Experimental study of the compression properties of Al/W/PTFE granular composites under elevated strain rates. Mater. Sci. Eng. A 2013, 581, 48–55. [Google Scholar] [CrossRef]

- Xu, S.L.; Yang, S.Q.; Xu, W.T.; Zhang, W. Research on the mechanical performance of PTFE/Al reactive materials. Chin. J. High Press. Phys. 2009, 23, 384–388. [Google Scholar]

- Xu, S.L.; Yang, S.Q.; Zhao, P.D. The study on the compressive behavior of PTFE/Al energetic composite. Chin. J. Theor. Appl. Mech. 2009, 41, 708–712. [Google Scholar]

- Xu, S.L. Study on the Mechanical Performance of Polytetrafluorethylene/Al Energetic Reactive Materials; National University of Defense Technology: Changsha, China, 2010. [Google Scholar]

- Shen, Y.B. The Chemical and Mechanical Behaviors of Polymer/Reactive Metal Systems under High Strain Rates. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2012. [Google Scholar]

- Liu, T.X. Study on the Mechanical Performance and Application of PTFE/Cu Materials; North University of China: Taiyuan, China, 2015. [Google Scholar]

- Ding, L.L.; Cui, X.X.; Tang, W.H.; Zhong, X.; Zhao, Y.; Huang, Y.; Shi, P.; Xue, X. Research on the constitutive model of PTFE/Al/Si reactive material. Polymers 2022, 14, 1358. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Liu, A.; Ge, C.; Yuan, Y.; Wang, H. Mechanical Properties, Constitutive Behaviors and Failure Criteria of Al-PTFE-W Reactive Materials with Broad Density. Materials 2022, 15, 5167. [Google Scholar] [CrossRef]

- Huang, J.Y.; Fang, X.; Wu, S.Z.; Yang, L.; Yu, Z.; Li, Y. Mechanical response and shear-induced initiation properties of PTFE/Al/MoO3 reactive composites. Materials 2018, 11, 1200. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.W.; He, Y.; He, Y.; Guo, L.; Ge, C.; Wang, H.; Ma, Y.; Gao, H.; Tian, W.; Wang, C. Compressive mechanical properties and shock-induced reaction behavior of Zr/PTFE and Ti/PTFE reactive materials. Materials 2022, 15, 6524. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, H.; Ge, C. Characterization of the Dynamic Response and Constitutive Behavior of PTFE/Al/W Reactive Materials. Propellants Explos. Pyrotech. 2020, 45, 788–797. [Google Scholar] [CrossRef]

- Wu, J.X.; Wang, H.X.; Feng, B.; Li, Y.; Wu, S.; Yin, Q.; Yu, Z.; Huang, J. The effect of temperature-induced phase transition of PTFE on the dynamic mechanical behavior and impact-induced initiation characteristics of Al/PTFE. Polym. Test. 2020, 91, 106835. [Google Scholar] [CrossRef]

- Feng, B.; Fang, X.; Wang, H.-X.; Dong, W.; Li, Y.-C. The Effect of Crystallinity on Compressive Properties of Al-PTFE. Polymers 2016, 8, 356. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, P.H. Dynamic Mechanical Properties of Tungsten Zirconium Active Material; Beijing Institute of Technology: Beijing, China, 2017. [Google Scholar]

- Chen, P.; Lu, F.Y.; Qin, J.G.; Chen, R.; Chen, J.; Li, Z.B.; Jiang, B.H. Dynamic compressive mechanical properties of tungstenic reactive material. Acta Armamentarii 2015, 36, 1861–1866. [Google Scholar]

- Raftenberg, M.N.; Mock, W., Jr.; Kirby, G.C. Modeling the impact deformation of rods of a pressed PTFE/Al composite mixture. Int. J. Impact Eng. 2008, 35, 1735–1744. [Google Scholar] [CrossRef]

- Casem, D.T. Mechanical Response of an Al-PTFE Composite to Uniaxial Compression Over a Range of Strain Rates and Temperatures; ARL-TR-4560; U.S. Army Aberdeen Proving Ground: Aberdeen, MD, USA, 2008. [Google Scholar]

- Zhang, J. Study on the Dynamic Mechanical Properties of Multifunctional Energetic Structural Material; Nanjing University of Science and Technology: Nanjing, China, 2013. [Google Scholar]

- Wang, L.; Labibes, K.; Azari, Z.; Pluvinage, G. Generalization of split Hopkinson bar technique to use viscoelastic bars. Int. J. Impact Eng. 1994, 15, 669–686. [Google Scholar] [CrossRef]

- Yang, L.; Zhu, Z.; Wang, L. Effects of short-glass-fiber reinforcement on nonlinear viscoelastic behavior of polycarbonate. Explos. Shock. Waves 1986, 6, 1–9. [Google Scholar]

- Yang, L.; Wang, L. An investigation on the linear viscoelastic constitutive relation for a composite on the basis of Eshelby’s theory. Explos. Shock. Waves 1991, 11, 244–251. [Google Scholar]

- Yang, L.; Wang, L. A micromechanical study on the nonlinear viscoelastic constitutive relation of high rigidity particulate-filled polymers. Acta Mech. Sin. 1993, 10, 606–614. [Google Scholar]

- Yang, L.; Wang, L.; Zhu, Z. Micromechanical analysis of the nonlinear elastic and viscoelastic constitutive relation of a polymer filled with rigid particles. Acta Mechanica Sinica 1994, 10, 176–185. [Google Scholar]

- Lai, J.; Sun, W. Dynamic behaviour and visco-elastic damage model of ultra-high performance cementitious composite. Cem. Concr. Res. 2009, 39, 1044–1051. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Zhang, W. Finite element simulation of PMMA aircraft windshield against bird strike by using a rate and temperature dependent nonlinear viscoelastic constitutive model. Compos. Struct. 2014, 108, 21–30. [Google Scholar] [CrossRef]

- Xu, X.; Gao, S.; Zhang, D.; Niu, S.; Jin, L.; Ou, Z. Mechanical behavior of liquid nitrile rubber-modified epoxy resin: Experiments, constitutive model and application. Int. J. Mech. Sci. 2019, 151, 46–60. [Google Scholar] [CrossRef]

- Luo, G.; Wu, C.; Xu, K.; Liu, L.; Chen, W. Development of dynamic constitutive model of epoxy resin considering temperature and strain rate effects using experimental methods. Mech. Mater. 2021, 159, 103887. [Google Scholar] [CrossRef]

- Luo, N.; Fan, X.; Cao, X.; Zhai, C.; Han, T. Dynamic mechanical properties and constitutive model of shale with different bedding under triaxial impact test. J. Pet. Sci. Eng. 2022, 216, 110758. [Google Scholar] [CrossRef]

- Dong, C.; Lu, X.; Zhao, G.; Meng, X.; Li, Y.; Cheng, X. Experiment and applications of dynamic constitutive model of tensile and compression damage of sandstones. Adv. Mater. Sci. Eng. 2021, 2021, 2492742. [Google Scholar] [CrossRef]

- Dar, U.A.; Zhang, W.H.; Xu, Y.J. Numerical implementation of strain rate dependent thermos viscoelastic constitutive relation to simulate the mechanical behavior of PMMA. Int. J. Mech. Mater. Des. 2014, 10, 93–107. [Google Scholar] [CrossRef]

- Vasant, S.J.; Waldorf, M.D. Process for making polytetrafluoroethylene-aluminum composite and product made. U.S. Patent US 6547993, 15 April 2003. [Google Scholar]

- Lu, F.Y.; Chen, R.; Lin, Y.L.; Zhao, P.; Zhang, D. Hopkinson Bar Techniques; Science Press: Beijing, China, 2013. [Google Scholar]

- Cai, J.; Walley, S.; Hunt, R.; Proud, W.; Nesterenko, V.; Meyers, M. High-strain, high-strain-rate flow and failure in PTFE/Al/W granular composites. Mater. Sci. Eng. A 2008, 472, 308–315. [Google Scholar] [CrossRef]

- Wu, Q. Dynamic Characteristics of Energetic Materials Shield Induced by Hypervelocity Impact; Beijing Institute of Technology: Beijing, China, 2016. [Google Scholar]

- Ren, H.L.; Li, W.; Ning, J.G. Effect of temperature on the impact ignition behavior of the aluminum/polytetrafluoroethylene reactive material under multiple pulse loading. Mater. Des. 2020, 189, 108522. [Google Scholar] [CrossRef]

- Wang, L.L.; Huang, D.; Gan, S. Nonlinear Viscoelastic Constitutive Relations and Nonlinear Viscoelastic Wave Propagation for Polymers at High Strain Rates; Springer Japan: Tokyo, Japan, 1996. [Google Scholar]

- Chen, C.; Li, Y.; Chang, M.; Guo, K.; Han, Y.F.; He, L.; Xu, M.; Tang, E. Zhu-Wang-Tang constitutive model of reinforced Al/PTFE materials at medium strain rate. Polym. Compos. 2022, 43, 2089–2102. [Google Scholar] [CrossRef]

- Wang, B.; Hu, S.; Zhou, X. Research of dynamic mechanical behavior and constitutive model of rubber under different temperatures. J. Exp. Mech. 2007, 43, 2089. [Google Scholar]

- Zhang, L.; Yao, X.; Zang, S.; Gu, Y. Temperature- and strain rate-dependent constitutive modeling of the large deformation behavior of a transparent polyurethane interlayer. Polym. Eng. Sci. 2014, 55, 1864–1872. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Eng. Fract. Mech. 1983, 21, 541–548. [Google Scholar]

| Experiment No. | Pressing Pressure (MPa) | Impact Speed (m/s) | Strain Rate (s−1) |

|---|---|---|---|

| No.12 | 200 | 8.2 | 1400 |

| No.13 | 400 | 8.4 | 1400 |

| No.14 | 600 | 9.0 | 1500 |

| No.15 | 800 | 8.9 | 1500 |

| No.16 | 200 | 13.9 | 2000 |

| No.17 | 400 | 12.3 | 2200 |

| No.18 | 600 | 13.8 | 2100 |

| No.19 | 800 | 13.8 | 2200 |

| No.20 | 200 | 18.1 | 2600 |

| No.21 | 400 | 17.3 | 2500 |

| No.22 | 600 | 16.2 | 2500 |

| No.23 | 800 | 16.6 | 2700 |

| No.24 | 200 | 24.3 | 2800 |

| No.25 | 200 | 29.4 | 3300 |

| Experiment No. | Temperature (°C) | Impact Speed (m/s) | Strain Rate (s−1) |

|---|---|---|---|

| No.26 | −20.8 | 8.4 | 1200 |

| No.27 | −28.2 | 8.4 | 1400 |

| No.28 | −40 | 8.1 | 1300 |

| No.29 | −23 | 13.4 | 2000 |

| No.30 | −31 | 15.1 | 2200 |

| No.31 | −40 | 13.3 | 2000 |

| Temperature (°C) | Strain Rate (s−1) | Peak Stress (MPa) | Peak Strain |

|---|---|---|---|

| 23 | 1400 | 54.0 | 0.08 |

| 23 | 2000 | 69.8 | 0.16 |

| −20.8 | 1200 | 70.3 | 0.08 |

| −23 | 2800 | 92.8 | 0.1 |

| −28.2 | 1400 | 79.8 | 0.07 |

| −31 | 2200 | 107.1 | 0.13 |

| −40 | 1300 | 83.5 | 0.086 |

| −40 | 2000 | 117.1 | 0.09 |

| Pressing Pressure (MPa) | |||||

|---|---|---|---|---|---|

| 400 | 123 | 224 | 83.7 | 0.72 | 2.09 |

| 600 | 123 | 224 | 83.7 | 4.9 | 4.06 |

| 800 | 123 | 224 | 83.7 | 6.7 | 2.71 |

| Temperature (°C) | |||||

|---|---|---|---|---|---|

| −40 | 319 | 242 | 0.7 | 5.9 | 12.7 |

| −30 | 105 | 593 | 2.3 | 1.8 | 10.8 |

| −20 | 53 | 631 | 3.4 | 1.6 | 7.61 |

| 23 | 238 | 49 | 1.7 | 4 | 3.68 |

| Parameters | Fitting Equation | Correlation Coefficient |

|---|---|---|

| 0.96 | ||

| 0.91 | ||

| 0.99 | ||

| 0.88 | ||

| 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Guo, Z.; Tang, E. Determination of Elastic Modulus, Stress Relaxation Time and Thermal Softening Index in ZWT Constitutive Model for Reinforced Al/PTFE. Polymers 2023, 15, 702. https://doi.org/10.3390/polym15030702

Chen C, Guo Z, Tang E. Determination of Elastic Modulus, Stress Relaxation Time and Thermal Softening Index in ZWT Constitutive Model for Reinforced Al/PTFE. Polymers. 2023; 15(3):702. https://doi.org/10.3390/polym15030702

Chicago/Turabian StyleChen, Chuang, Zihan Guo, and Enling Tang. 2023. "Determination of Elastic Modulus, Stress Relaxation Time and Thermal Softening Index in ZWT Constitutive Model for Reinforced Al/PTFE" Polymers 15, no. 3: 702. https://doi.org/10.3390/polym15030702

APA StyleChen, C., Guo, Z., & Tang, E. (2023). Determination of Elastic Modulus, Stress Relaxation Time and Thermal Softening Index in ZWT Constitutive Model for Reinforced Al/PTFE. Polymers, 15(3), 702. https://doi.org/10.3390/polym15030702