Manufacturing Technologies of Polymer Composites—A Review

Abstract

:1. Introduction

2. Manufacturing Technology of Polymer Composites

2.1. Surface Coating Technology

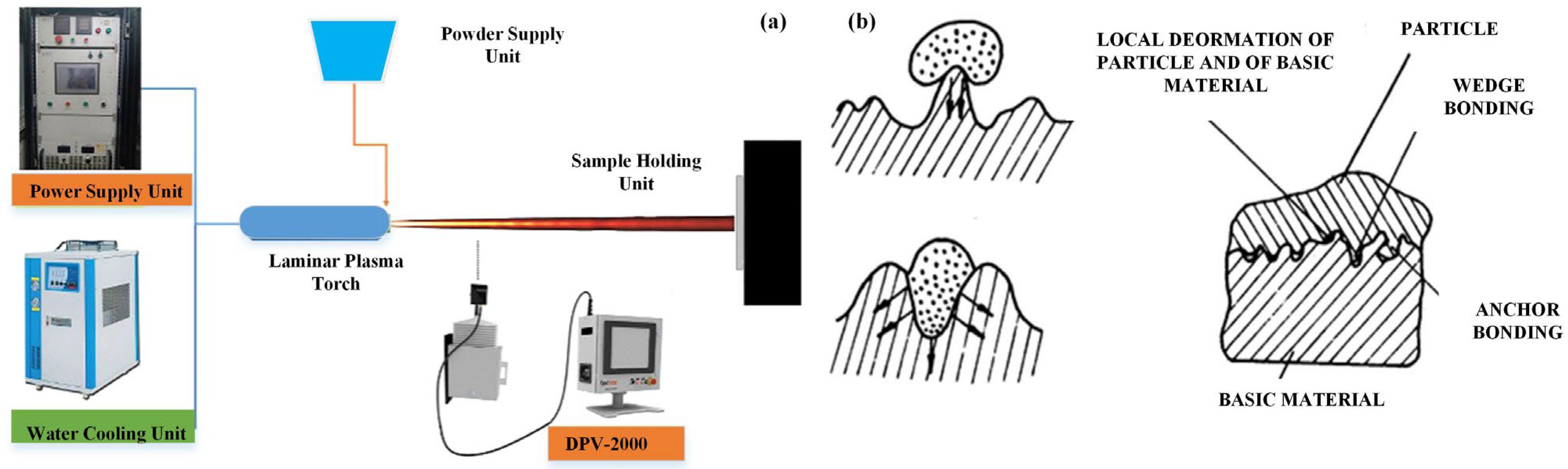

2.1.1. Plasma Spraying

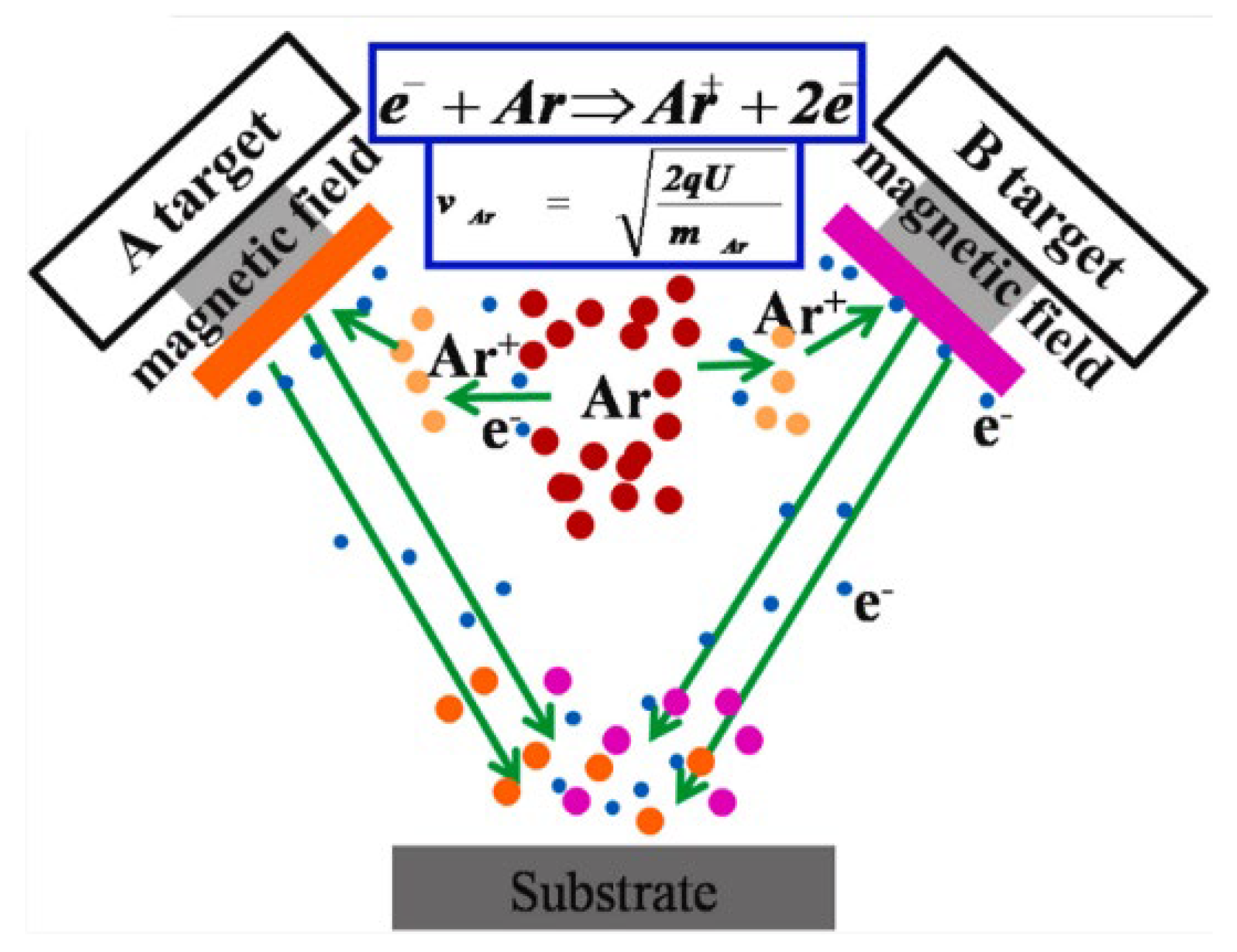

2.1.2. Magnetron Sputtering

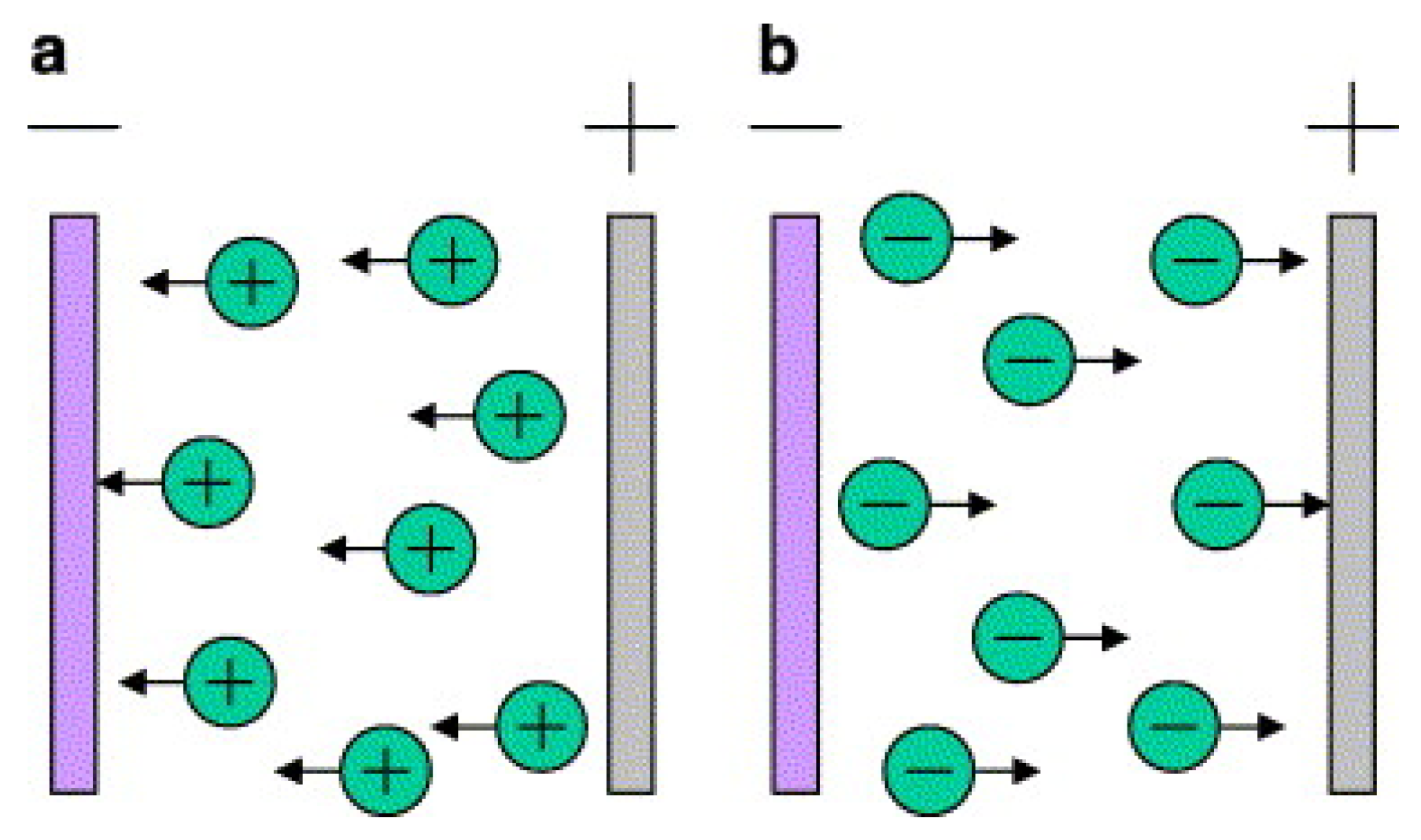

2.1.3. Electrophoretic Deposition or Electrochemical Deposition

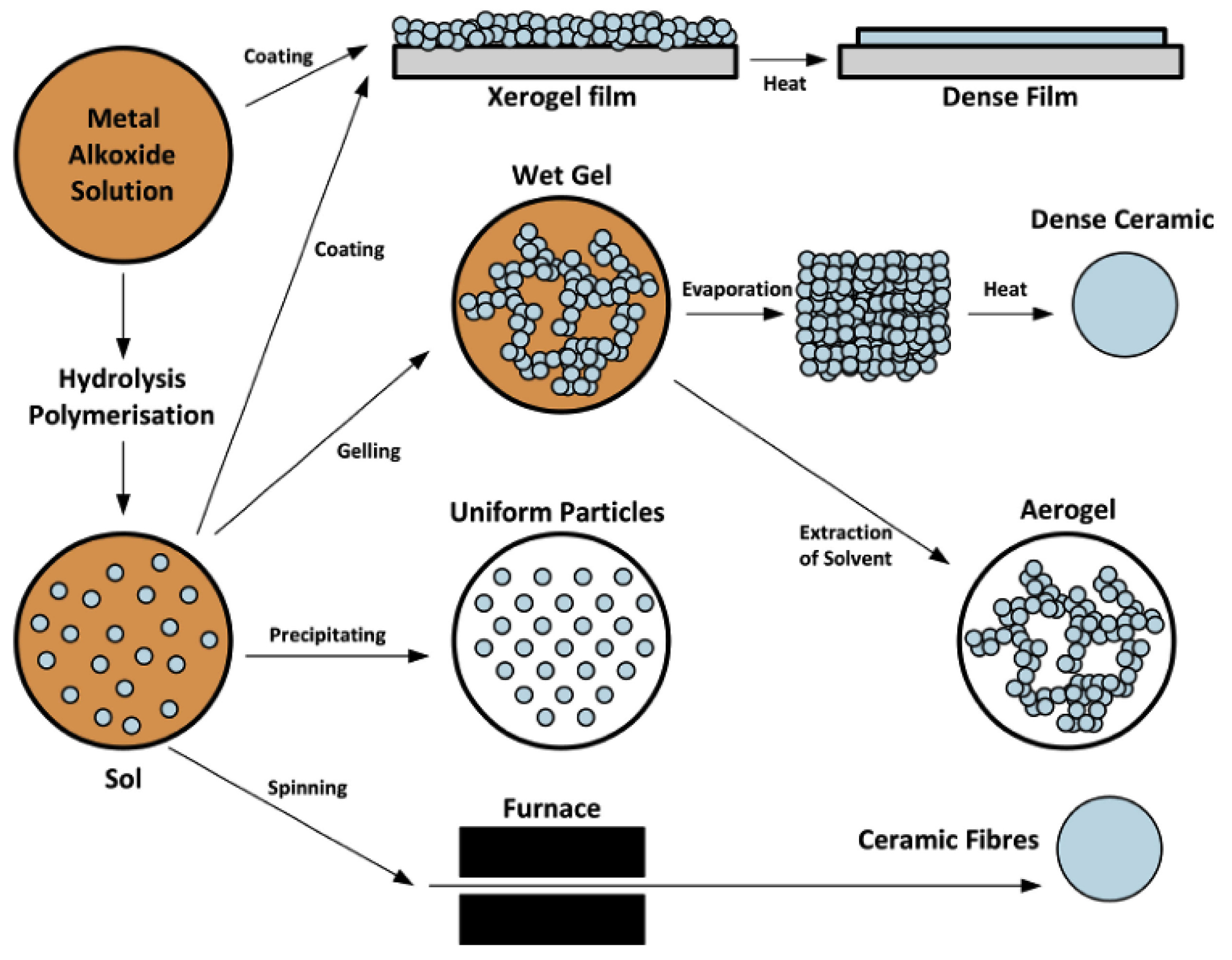

2.1.4. Sol–Gel Technology

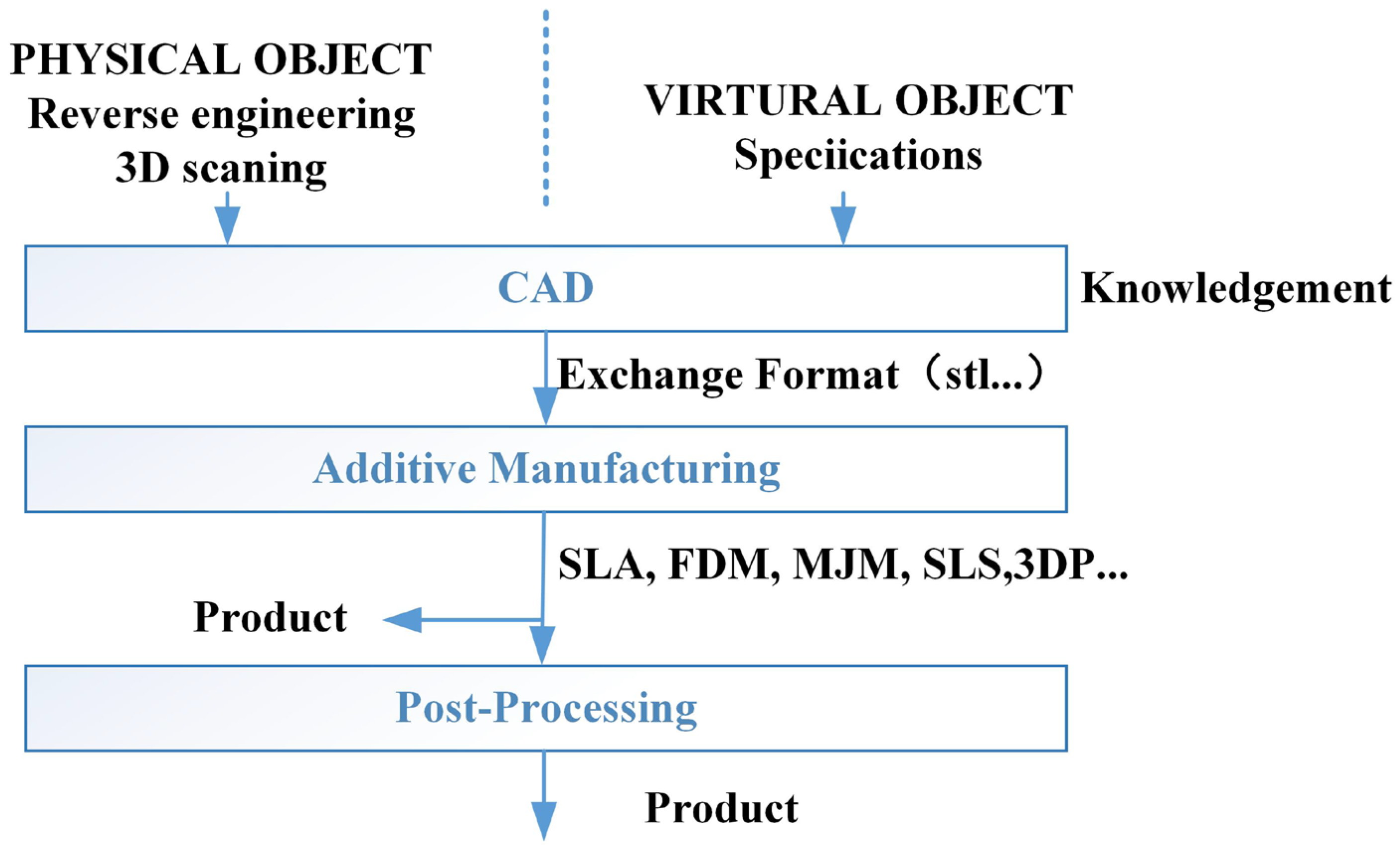

2.2. Additive Manufacturing

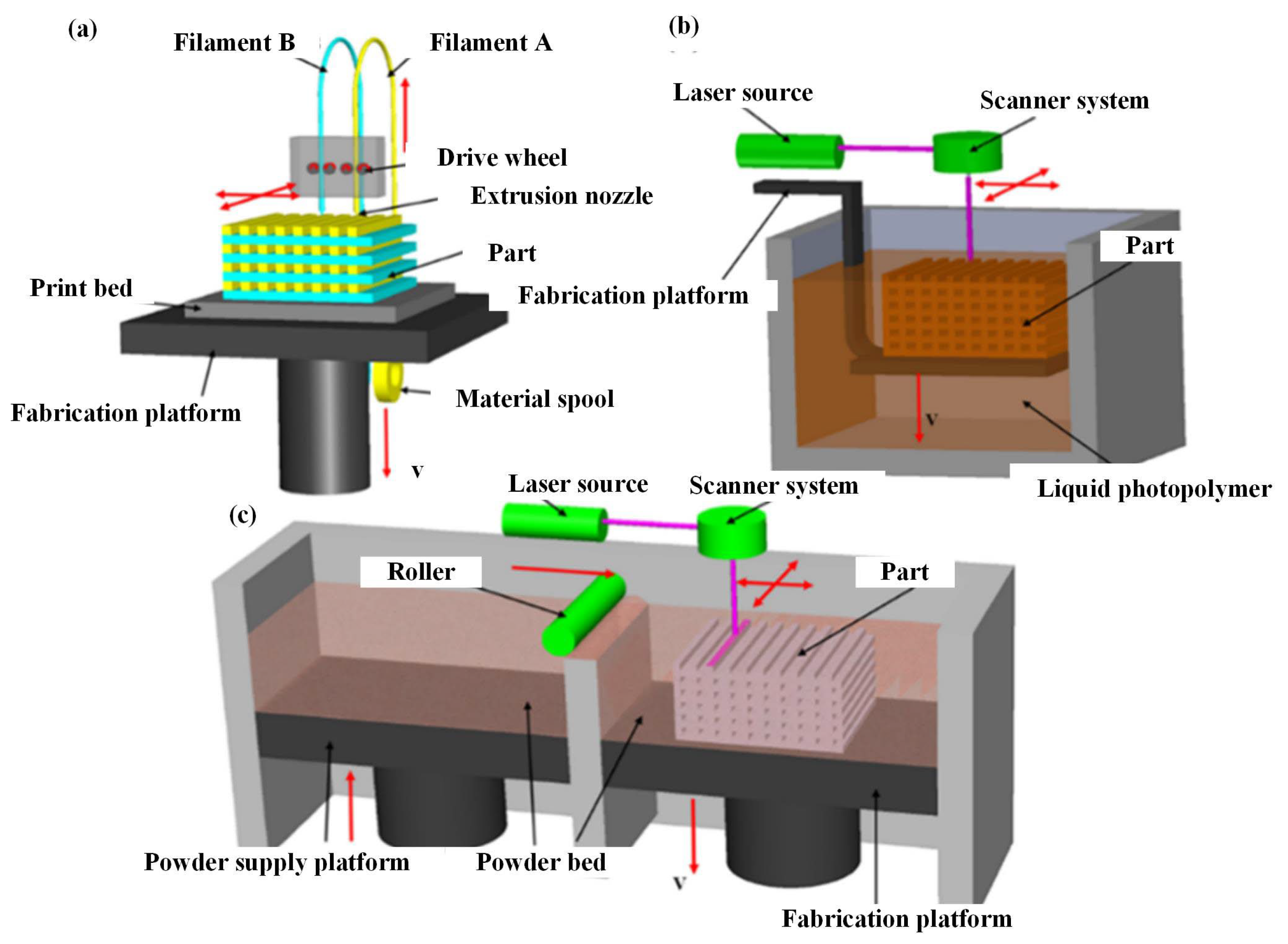

2.2.1. Three-Dimensional Printing

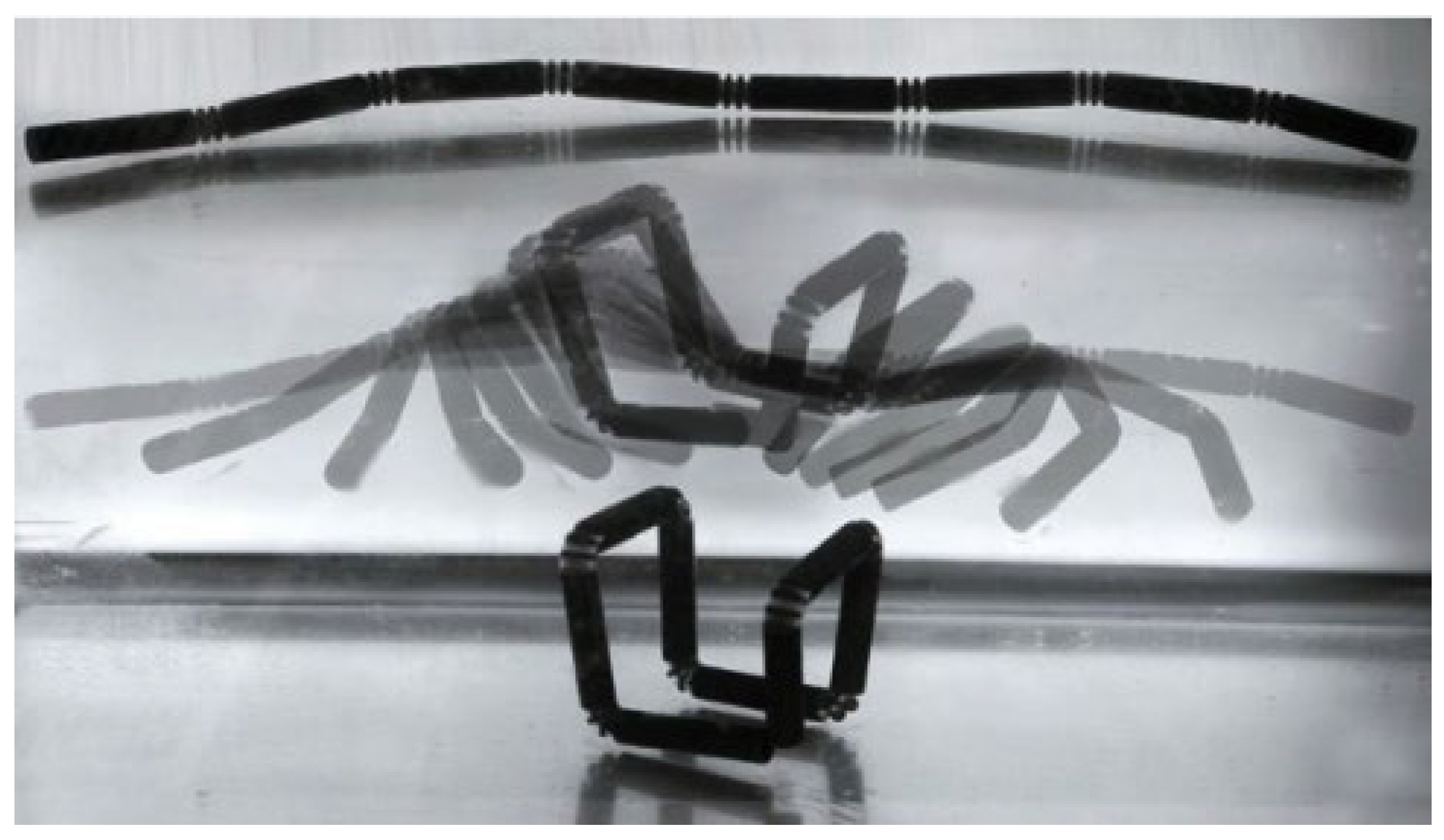

2.2.2. Four-Dimensional Printing

2.2.3. Five-Dimensional Printing

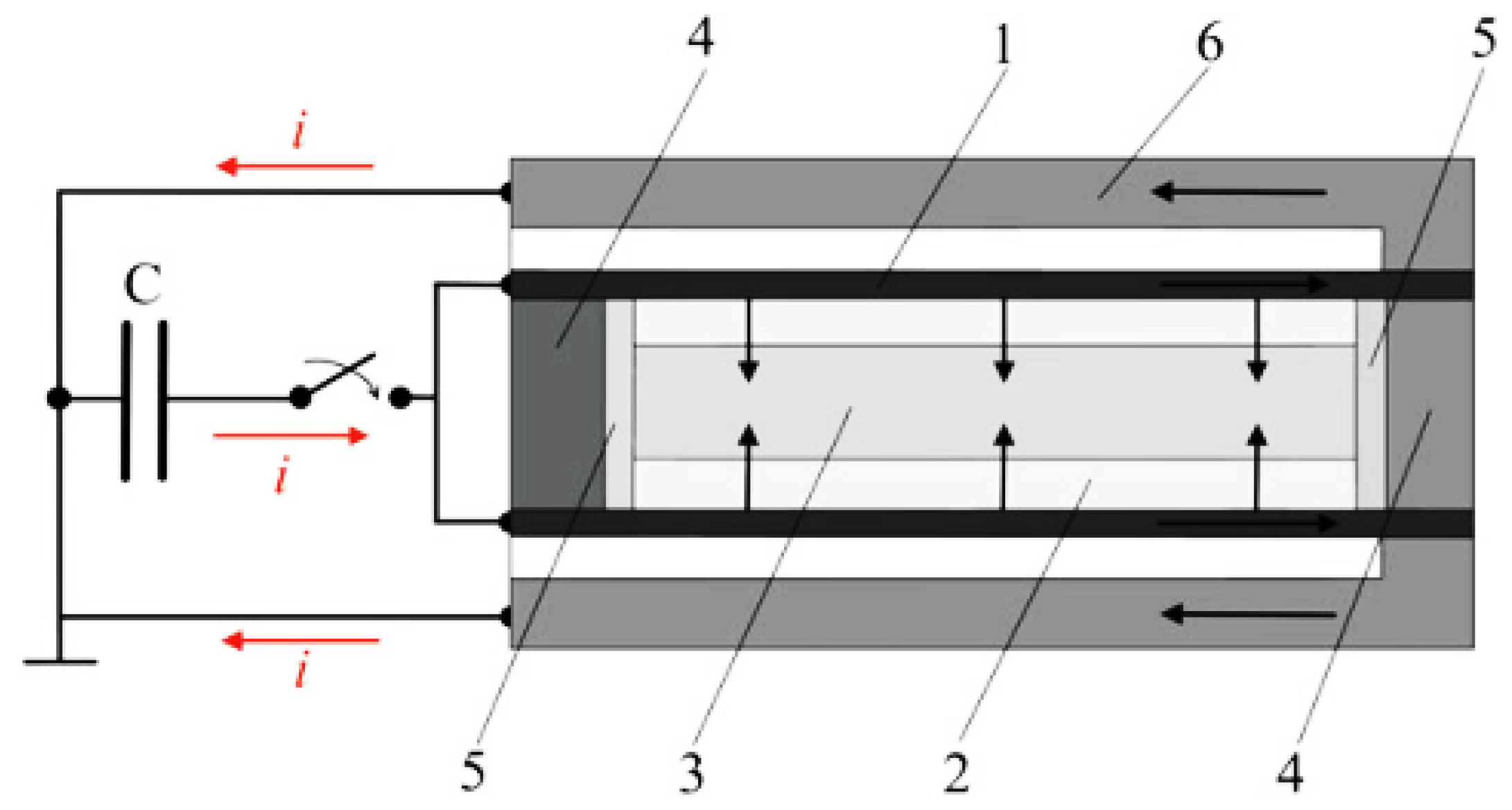

2.3. Magnetic Pulse Powder Compaction Technology

3. Numerical Simulation of the Polymer Composite Manufacturing Process

3.1. Surface Coating Technology

3.2. Additive Manufacturing

3.3. Magnetic Pulse Powder Compaction Technology

4. Summary and Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muhammad, A.; Rahman, M.R.; Baini, R.; Bakri, M.K.B. 8-Applications of sustainable polymer composites in automobile and aerospace industry. Adv. Sustain. Polym. Compos. 2021, 185–207. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M. Polymer composite materials. A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Pulci, G.; Tirillo, J.; Marra, F.; Fossati, F.; Bartuli, C.; Valente, T. Carbon–phenolic ablative materials for re-entry space vehicles: Manufacturing and properties. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1483–1490. [Google Scholar] [CrossRef]

- Riviere, L.; Causse, N.; Lonjon, A.; Dantras, E.; Lacabanne, C. Specific heat capacity and thermal conductivity of PEEK/Ag nanoparticles composites determined by Modulated-Temperature Differential Scanning Calorimetry. Polym. Degrad. Stab. 2016, 127, 98–104. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hiremath, N.; Young, S.; Ghossein, H.; Penumadu, D.; Vaidy, U.; Theodore, M. Low cost textile-grade carbon-fiber epoxy composites for automotive and wind energy applications. Compos. Part B Eng. 2020, 198, 108156. [Google Scholar] [CrossRef]

- Šerifi, V.; Tarić, M.; Jevtić, D.; Ristovski, A.; Isović, M.Š. Historical Development of Composite Materials. The Annals of the University of Oradea. Econ. Sci. 2018, XXVII (XVII), 1–8. [Google Scholar] [CrossRef]

- Available online: http://mp.ofweek.com/xincailiao/a956714987197 (accessed on 13 July 2022).

- Tadini, P.; Grange, N.; Chetehouna, K.; Gascoin, N.; Senave, S.; Reynaud, I. Thermal degradation analysis of innovative PEKK-based carbon composites for high-temperature aeronautical components. Aerosp. Sci. Technol. 2017, 65, 106–116. [Google Scholar] [CrossRef] [Green Version]

- Krishnakumar, S.; Senthilvelan, T. Polymer composites in dentistry and orthopedic applications—A review. Mater. Today Proc. 2021, 46, 9707–9713. [Google Scholar] [CrossRef]

- Safavi, M.S.; Maria, A.; Roman, S.; Surmenev, A.; Khalil-Allafi, J. RF-magnetron sputter deposited hydroxyapatite-based composite & multilayer coatings: A systematic review from mechanical, corrosion, and biological points of view. Ceram. Int. 2021, 47, 031–3053. [Google Scholar]

- Szymczyk-Ziółkowska, P.; Łabowska, M.B.; Detyna, J.; Michalak, I.; Gruber, P. A review of fabrication polymer scaffolds for biomedical applications using additive manufacturing techniques. Biocybern. Biomed. Eng. 2020, 40, 624–638. [Google Scholar] [CrossRef]

- Safavi, M.S.; Walsh, F.C.; Surmeneva, M.A.; Surmenev, R.A.; Khalil-Allafi, J. Electrodeposited Hydroxyapatite-Based Biocoatings:Recent Progress and Future Challenges. Coatings 2021, 11, 110. [Google Scholar] [CrossRef]

- Mahalingam, S.; Matharu, R.; Homer-Vanniasinkam, S. Edirisinghe, Current methodologies and approaches for the formation of core-sheath polymer fibers for biomedical applications. Appl. Phys. Rev. 2020, 7, 041302. [Google Scholar] [CrossRef]

- Safavi, M.S.; Walsh, F.C.; Visai, L.; Khalil-Allafi, J. Progress in Niobium Oxide-Containing Coatings for Biomedical Applications: A Critical Review. ACS Omega 2022, 7, 9088–9107. [Google Scholar] [CrossRef]

- Gong, K.; Zhou, K.; Qian, X.; Shi, C.; Yu, B. MXene as emerging nanofillers for high-performance polymer composites: A review. Compos. Part B Eng. 2021, 217, 108867. [Google Scholar] [CrossRef]

- Maruthi, N.; Faisal, M.; Raghavendra, N. Conducting polymer based composites as efficient EMI shielding materials: A comprehensive review and future prospects. Synth. Met. 2021, 272, 116664. [Google Scholar] [CrossRef]

- Kumar, D.; Moharana, A.; Kumar, A. Current trends in spinel based modified polymer composite materials for electromagnetic shielding. Mater. Today Chem. 2020, 17, 100346. [Google Scholar] [CrossRef]

- Farea, M.A.; Mohammed, H.Y.; Shirsat, S.M.; Sayyad, P.W.; Ingle, N.N.; Gahouari, T.A.; Mahadik, M.M.; Bodkhe, G.A.; Shirsat, M.D. Hazardous gases sensors based on conducting polymer composites. Chem. Phys. Lett. 2021, 776, 138703. [Google Scholar] [CrossRef]

- Han, Q.; Liu, S.; Liu, Y.; Jin, J.; Li, D.; Cheng, S.; Xiong, Y. Flexible counter electrodes with a composite carbon/metal nanowire/polymer structure for use in dye-sensitized solar cells. Sol. Energy 2020, 208, 469–479. [Google Scholar] [CrossRef]

- Yu, X.; Manthiram, A. A review of composite polymer-ceramic electrolytes for lithium batteries. Energy Storage Mater. 2021, 34, 282–300. [Google Scholar] [CrossRef]

- Anderson, L.; Govindaraj, P.; Ang, A.; Mirabedini, A.; Hameed, N. Modelling, fabrication and characterization of graphene/polymer nanocomposites for electromagnetic interference shielding applications. Carbon Trends 2021, 4, 100047. [Google Scholar] [CrossRef]

- Wang, P.; Li, M.; Zhang, J.; Dong, L.; Lu, H. High-yield water-phase exfoliated few-defect graphene for high performance polymer nanocomposites. J. Appl. Polym. Ci. 2020, 137, 49586. [Google Scholar] [CrossRef]

- Deeraj, B.D.S.; George, G.; Dhineshbabu, N.R.; Bose, S.; Joseph, K. Electrospun ZrO2@ carbon nanofiber mats and their epoxy composites as effective EMI shields in Ku band. Mater. Res. Bull. 2021, 144, 111477. [Google Scholar] [CrossRef]

- EI-Morsy, M.A.; EI-Sharnouby, M.; EI Askarry, A.; Awwad, N.S.; Ibrahium, H.A.; Menazea, A.A. Investigation on optical properties and electrical conductivity behavior of Chitosan/PVP/Se NPs NPs composite produced via one-potential laser ablation for optoelectronic applications. Opt. Quant. Electron. 2022, 54, 661. [Google Scholar] [CrossRef]

- Alqarni, S.A.; Hussein, M.A.; Ganash, A.A.; Khan, A. Composite Material-Based Conducting Polymers for Electrochemical Sensor Applications: A Mini Review. BioNanoScience 2020, 10, 351–364. [Google Scholar] [CrossRef]

- Lee, D.W.; Yoo, B.R. Advanced silica/polymer composites: Materials and applications. J. Ind. Eng. Chem. 2016, 38, 1–12. [Google Scholar] [CrossRef]

- Neto, G.R.A.; Beatrice, C.A.G.; Leiva, D.R.; Pessan, L.A. Polyetherimide-LaNi5 composite films for hydrogen storage applications. Int. J. Hydrogen Energy 2021, 46, 23767–23778. [Google Scholar] [CrossRef]

- Mohandesnezhad, S.; Etminanfar, M.; Mahdavi, S.; Safavi, M.S. Enhanced bioactivity of 316L stainless steel with deposition of polypyrrole/hydroxyapatite layered hybrid coating: Orthopedic applications. Surf. Interfaces 2022, 28, 101604. [Google Scholar] [CrossRef]

- Pang, X.; Zhitomirsky, I. Electrodepostion of nanocomposite organic-inorganic coatings for biomedical applications, International. J. Nanosci. 2005, 4, 409–418. [Google Scholar]

- Li, Z.J.; Zhang, Y.S.; Zhou, X.M. Short fiber reinforced geopolymer composites manufactured by extrusion. J. Mater. Civ. Eng. 2005, 17, 624–631. [Google Scholar] [CrossRef]

- Liu, S.J. Injection molding in polymer matrix composites. Manuf. Tech. Polym. Matrix Compos. PMCs 2012, 15–46. [Google Scholar] [CrossRef]

- Bryant, R.G. Polyimides. Encycl. Polym. Sci. Technol. 2002, 529–555. [Google Scholar] [CrossRef]

- Ward, I.M.; Hine, P.J. The science and technology of hot compaction. Polymer 2004, 45, 1413–1427. [Google Scholar] [CrossRef]

- Alizadeh-Osgouei, M.; Li, Y.; Wen, C. A comprehensive review of biodegradable synthetic polymer-ceramic composites and their manufacture for biomedical applications. Bioact. Mater. 2019, 4, 22–36. [Google Scholar] [CrossRef] [PubMed]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T. 3D printing of PEEK and its composite to increase biointerfaces as a biomedical material-A review. Colloids Surf. B Biointerfaces 2021, 203, 111726. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Shen, F.; Chua, C.K.; Zhou, K. Polymeric composites for powder-based additive manufacturing: Materials and applications. Prog. Polym. Sci. 2019, 91, 141–168. [Google Scholar] [CrossRef]

- Thiruchitrambalam, M.; Kumar, D.B.; Shanmugam, D.; Jawaid, M. A review on PEEK composites–Manufacturing methods, properties and applications. Mater. Today Proc. 2020, 33, 1085–1092. [Google Scholar] [CrossRef]

- Alshahrani, H.A. Review of 4D printing materials and reinforced composites: Behaviors, applications and challenges. J. Sci. Adv. Mater. Devices 2021, 6, 167–185. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, D.; Pei, X.; Wu, X.; Xu, F.; Wang, H.; Cao, M.; Chen, H. Investigation of electromagnetic pulse compaction on conducting graphene/PEKK composite powder. Materials 2021, 14, 636. [Google Scholar] [CrossRef]

- Inamuddin Boddula, R.; Ahamed, M.I.; Asiri, A.M. Polymers Coatings: Technology and Applications; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Zhao, L.; Lee, V.K.; Yoo, S.S.; Dai, G.; Intes, X. The integration of 3-D cell printing and mesoscopic fluorescence molecular tomography of vascular constructs within thick hydrogel scaffolds. Biomaterials 2012, 33, 5325–5332. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef] [PubMed]

- Invernizzi, M.; Natale, G.; Levi, M.; Turri, S.; Griffini, G. UV-assisted 3D printing of glass and carbon fiber-reinforced dual-cure polymer composites. Materials 2016, 9, 583. [Google Scholar] [CrossRef] [Green Version]

- Li, M. Microstructure and Properties of TI6AL4V Alloy Prepared by Magnetic Pulse Compaction and Sintering of Hydrogenated Powder. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2011. [Google Scholar]

- Shi, J. Study on Simulation and Research on Forming Mechanism in Low-voltage Electromagnetic Compaction of Function Ceramics. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2006. [Google Scholar]

- Liu, Y.Z. Study on Densifying Behavior of Electromagnetic Compaction of High Indium and Tin Silver Based Brazing Filler Metal. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2018. [Google Scholar]

- Heimann, R.B. Thermal spraying of biomaterials. Surf. Coat. Technol. 2006, 201, 2012–2019. [Google Scholar] [CrossRef]

- Jinho, S.; Kwangmin, L.; Jeongtae, K.; Hyeju, S.; Hyunseung, K.; Hyun-Pil, L.; Kwidug, Y.; Gyejeong, O.; Seokwoo, L.; Heekyun, O.; et al. Hydroxyapatite coatings on nanotubular titanium dioxide thin films prepared by radio frequency magnetron sputtering. J. Nanosci. Nanotechnol. 2013, 13, 5807–5810. [Google Scholar]

- Boccaccini, A.R.; Keim, S.; Ma, R.; Li, Y.; Zhitomirsky, I. Electrophoretic deposition of biomaterials. J. R. Soc. Interface 2010, 7, 581–613. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Layrolle, P.; Ito, A.; Tateishi, T. Sol-gel synthesis of amorphous calcium phosphate and sintering into microporous hydroxyapatite bioceramics. J. Am. Ceram. Soc. 1998, 81, 1421–1428. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Hamzah, E.; Bagheriyan, S.; Daroonparvar, M.; Kasiri-Asgarani, M.; Shah, A.M.; Medraj, M. Preparation and performance of plasma/polymer composite coatings on magnesium alloy. J. Mater. Eng. Perform. 2016, 25, 3948–3959. [Google Scholar] [CrossRef]

- Schürmann, U.; Takele, H.; Zaporojtchenko, V.; Faupel, F. Optical and electrical properties of polymer metal nanocomposites prepared by magnetron co-sputtering. Thin Solid Film. 2006, 515, 801–804. [Google Scholar] [CrossRef]

- Samal, S.; Besra, L.; Singh, B.P.; Bhattacarjee, S. Multi-walled carbon nanotubes polymer composites by electrophoretic deposition. In Proceedings of the 2011 International Conference on Nanoscience, Technology and Societa Implications, Bhubaneswar, India, 8–10 December 2011; pp. 1–6. [Google Scholar]

- Mascia, L.; Lavorgna, M. Nanostructured polymer composites by sol–gel method. Wiley Encycl. Compos. 2011, 1–20. [Google Scholar] [CrossRef]

- Ratha, I.; Datta, P.; Balla, V.K.; Nandi, S.K.; Kundu, B. Effect of doping in hydroxyapatite as coating material on biomedical implants by plasma spraying method: A review. Ceram. Int. 2021, 47, 4426–4445. [Google Scholar] [CrossRef]

- Liu, S.H.; Zhang, H.Y.; Wang, Y.P.; Ji, G.; Li, L.; Xu, P.; Huang, J.H.; Zhang, S.L.; Li, C.X.; Li, C.J. Microstructural evolution of alumina coatings by a novel long laminar plasma spraying method. Surf. Coat. Technol. 2019, 363, 210–220. [Google Scholar] [CrossRef]

- Filiaggi, M.J.; Coombs, N.A.; Pilliar, R.M. Characterization of the interface in the plasma-sprayed HA coating/Ti-6Al-4Vimplant system. J. Biomed. Mater. Res. 1991, 25, 1211–1229. [Google Scholar] [CrossRef] [PubMed]

- Ruzbarsky, J.; Panda, A. Plasma and Thermal Spraying. In SpringerBriefs in Applied Sciences and Technology; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–23. [Google Scholar]

- Yang, Y.; Kim, K.H.; Ong, J.L. A review on calcium phosphate coatings produced using a sputtering process—An alternative to plasma spraying. Biomaterials 2005, 26, 327–337. [Google Scholar] [CrossRef] [PubMed]

- Palka, V.; Postrkova, E.; Koerten, H.K. Some characteristics of hydroxylapatite powder particles after plasma spraying. Biomaterials 1998, 19, 1763–1772. [Google Scholar] [CrossRef] [PubMed]

- Baolong, G.; Deyi, L.; Jiajun, Z.; Wulin, Y.; Licai, F.; Lingping, Z. Construction of magnetron sputtering non-equilibrium Miedema’s model for application in Ag-Mo thin films. Phys. B Condens. Matter 2021, 602, 412541. [Google Scholar] [CrossRef]

- Ramos, M.C.M.; Lluch, M.M.S. High-Flux DC Magnetron Sputtering. In Gas-Phase Synthesis of Nanoparticles; Wiley-VHC: Weinheim, Germany, 2017. [Google Scholar]

- Kang, Y.M.; Kwon, S.H.; Choi, J.H.; Cho, Y.J.; Song, P.K. Properties of Ce-doped ITO films deposited on polymer substrate by DC magnetron sputtering. Thin Solid Film. 2010, 518, 3081–3084. [Google Scholar] [CrossRef]

- Lackner, J.M.; Waldhauser, W.; Ganser, C.; Teichert, C.; Kot, M.; Major, L. Mechanisms of topography formation of magnetron-sputtered chromium-based coatings on epoxy polymer composites. Surf. Coat. Technol. 2014, 241, 80–85. [Google Scholar] [CrossRef]

- Ma, Y.; Li, L.; Qian, J.; Qu, W.; Luo, R.; Wu, F.; Chen, R. Materials and structure engineering by magnetron sputtering for advanced lithium batteries. Energy Storage Mater. 2021, 39, 203–224. [Google Scholar] [CrossRef]

- Rtimi, S.; Konstantinidis, S.; Britun, N.; Bensimon, M.; Khmel, I.; Nadtochenko, V. Extracellular bacterial inactivation proceeding without Cu-ion release: Drastic effects of the applied plasma energy on the performance of the Cu-polyester (PES) samples. Appl. Catal. B Environ. 2018, 239, 245–253. [Google Scholar] [CrossRef]

- Twu, M.J.; Chiou, A.H.; Hu, C.C.; Hsu, C.Y.; Kuo, G.G. Properties of TiO2 films deposited on flexible substrates using direct current magnetron sputtering and using high power impulse magnetron sputtering. Polym. Degrad. Stab. 2015, 117, 1–7. [Google Scholar] [CrossRef]

- Ganesan, R.; Akhavan, B.; Hiob, M.A.; McKenzie, D.R.; Weiss, A.S.; Bilek, M.M.M. HiPIMS carbon coatings show covalent protein binding that imparts enhanced hemocompatibility. Carbon 2018, 139, 118–128. [Google Scholar] [CrossRef]

- Zhitomirsky, I. Electrophoretic deposition of organic–inorganic nanocomposites. J. Mater. Sci. 2006, 41, 8186–8195. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Cho, J.; Subhani, T.; Kaya, C.; Kaya, F. Electrophoretic deposition of carbon nanotube-ceramic nanocomposites. J. Eur. Ceram. Soc. 2010, 30, 1115–1129. [Google Scholar] [CrossRef]

- Pishbin, F.; Cordero-Arias, L.; Cabanas-Polo, S.; Boccaccini, A.R. 12-Bioactive polymer–calcium phosphate composite coatings by electrophoretic deposition. In Surface Coating and Modification of Metallic Biomaterials; Woodhead Publishing: Soston, UK, 2015; pp. 359–377. [Google Scholar]

- Besra, L.; Liu, M. A review on fundamentals and applications of electrophoretic deposition (EPD). Prog. Mater. Sci. 2007, 52, 1–61. [Google Scholar] [CrossRef]

- Sikkema, R.; Baker, K.; Zhitomirsky, I. Electrophoretic deposition of polymers and proteins for biomedical applications. Adv. Colloid Interface Sci. 2020, 284, 102272. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Pang, X.; Zhitomirsky, I. Electrophoretic deposition of chiral polymers and composites. Colloids Surf. B Biointerfaces 2011, 87, 505–509. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Teng, K.; Li, N.; Li, X.; Chen, L.; Niu, J.; Fu, H.; Zhao, L.; Liu, Y. Mechanical, thermal and interfacial performances of carbon fiber reinforced composites flavored by carbon nanotube in matrix/interface. Compos. Struct. 2017, 159, 761–772. [Google Scholar] [CrossRef]

- Kumari, S.; Panigrahi, A.; Singh, S.K.; Pradhan, S.K. Enhanced corrosion resistance and mechanical properties of nanostructured graphene-polymer composite coating on copper by electrophoretic deposition. J. Coat. Technol. Res. 2018, 15, 583–592. [Google Scholar] [CrossRef]

- Tian, Q.; Liu, H. Electrophoretic deposition and characterization of nanocomposites and nanoparticles on magnesium substrates. Nanotechnology 2015, 26, 175102. [Google Scholar] [CrossRef]

- Yamane, M.; Caldwell, J.B.; Moore, D.T. Preparation of gradient-index glass rods by the sol-gel process. MRS Online Proc. Libr. OPL 1986, 73, 765–768. [Google Scholar] [CrossRef]

- Chen, C.Y.; Wang, S.C.; Tien, Y.H.; Tasi, W.T.; Lin, C.K. Hybrid manganese oxide films for supercapacitor application prepared by sol–gel technique. Thin Solid Film. 2009, 518, 1557–1560. [Google Scholar] [CrossRef]

- Jianfeng, H. Principle and Technology of Sol-Gel; Chemical Industry Press: Beijing, China, 2005. [Google Scholar]

- Camara, R.M.; Portela, R.; Gutierrez-Martin, F.; Sanchez, B. Photocatalytic activity of TiO2 films prepared by surfactant-mediated sol–gel methods over commercial polymer substrates. Chem. Eng. J. 2016, 283, 535–543. [Google Scholar] [CrossRef]

- Camara, R.M.; Crespo, E.; Portela, R.; Suarez, S.; Bautista, L.; Gutierrez-Martin, F.; Sanchez, B. Enhanced photocatalytic activity of TiO2 thin films on plasma-pretreated organic polymers. Catal. Today 2014, 230, 145–151. [Google Scholar] [CrossRef]

- Liu, W.; Sun, L.; Luo, Y.; Wu, R.; Jiang, H.; Chen, Y.; Zeng, G.; Liu, Y. Facile transition from hydrophilicity to superhydrophilicity and superhydrophobicity on aluminum alloy surface by simple acid etching and polymer coating. Appl. Surf. Sci. 2013, 280, 193–200. [Google Scholar] [CrossRef]

- Yamaguchi, N.; Tadanaga, K.; Matsuda, A.; Minami, T.; Tatsumisago, M. Formation of anti-reflective alumina films on polymer substrates by the sol–gel process with hot water treatment. Surf. Coat. Technol. 2006, 201, 3653–3657. [Google Scholar] [CrossRef]

- Qiu, M.; Fan, S.; Cai, Y.; Xu, N. Co-sintering synthesis of bi-layer titania ultrafiltration membranes with intermediate layer of sol-coated nanofibers. J. Membr. Sci. 2010, 365, 225–231. [Google Scholar] [CrossRef]

- Addonizio, M.L.; Fusco, L. Adhesion and Barrier Properties Analysis of Silica-Like Thin Layer on Polyethylene Naphthalate Substrates for Thin Film Solar Cells. Adv. Sci. Technol. 2010, 74, 113–118. [Google Scholar]

- ISO/ASTM 52900; Additive Manufacturing-General Principles-Fundamentals and Vocabulary. National Standards Authority of Ireland: Dublin, Ireland, 2021.

- Kumar, P.; Roy, S.; Hegde, H.; Bharti, S.; Kumar, M. Chapter 8–4D and 5D printing: Healthcare’s new edge. In 3D Printing Technology in Nanomedicine; Elsevier: Amsterdam, The Netherlands, 2019; pp. 143–163. [Google Scholar]

- Gardan, J. Additive manufacturing technologies for polymer composites: State-of-the-art and future trends. In Structure and Properties of Additive Manufactured Polymer Components; Woodhead Publishing: Soston, UK, 2020; pp. 3–15. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: Berlin, Germany, 2015. [Google Scholar]

- Mustapha, K.B.; Metwalli, K.M. A review of fused deposition modelling for 3D printing of smart polymeric materials and composites. Eur. Polym. J. 2021, 156, 110591. [Google Scholar] [CrossRef]

- Kenzari, S.; Bonina, D.; Dubois, J.M.; Fournee, V. Quasicrystal–polymer composites for selective laser sintering technology. Mater. Des. 2012, 35, 691–695. [Google Scholar] [CrossRef]

- Graf, D.; Bermejo, A.; Martinez, L.; Gleissner, U.; Megnin, C.; Eiselt, T.; Mauck, M.; Hanemann, T. Polymer-ceramic-composites for 3D inkjet printing. In Proceedings of the Mikro System Technik 2017 Congress, München, Germany, 23–25 October 2017; pp. 1–4. [Google Scholar]

- Nagarajan, B.; Mertiny, P.; Qureshi, A.J. Magnetically loaded polymer composites using stereolithography—Material processing and characterization. Mater. Today Commun. 2020, 25, 101520. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Ushakov, N.M.U.; Kosobudskii, I.D. Impact of UV Pulsed Laser Radiation and of the Electron Flow on Dielectric States of Polymer Composite Nanomaterial Based on LDPE Matrix. Semiconductor 2018, 52, 543–547. [Google Scholar] [CrossRef]

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Majid, F.; Zekeriti, N.; Lahlou, M.; Rhanim, R.; Lahlou, M.; Rhanim, H.; Mrani, B. Mechanical behavior and crack propagation of ABS 3D printed specimens. Procedia Struct. Integr. 2020, 28, 1719–1726. [Google Scholar] [CrossRef]

- Roy, R.; Mukhopadhyay, A. Tribological studies of 3D printed ABS and PLA plastic parts. Mater. Today Proc. 2021, 41, 856–862. [Google Scholar] [CrossRef]

- Caulfield, B.; McHugh, P.E.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Dermanaki Farahani, R.; Dubé, M. Printing polymer nanocomposites and composites in three dimensions. Adv. Eng. Mater. 2018, 20, 1700539. [Google Scholar] [CrossRef]

- Joyee, E.B.; Lu, L.; Pan, Y. Analysis of mechanical behavior of 3D printed heterogeneous particle-polymer composites. Compos. Part B Eng. 2019, 173, 106840. [Google Scholar] [CrossRef]

- Boparai, K.; Singh, R.; Singh, H. Comparison of tribological behaviour for Nylon6-Al-Al2O3 and ABS parts fabricated by fused deposition modelling: This paper reports a low cost composite material that is more wear-resistant than conventional ABS. Virtual Phys. Prototyp. 2015, 10, 59–66. [Google Scholar] [CrossRef]

- Isakov, D.V.; Lei, Q.; Castles, F.; Stevens, C.J.; Grovenor, C.R.M.; Grant, P.S. 3D printed anisotropic dielectric composite with meta-material features. Mater. Des. 2016, 93, 423–430. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Imeri, A.; Fidan, I.; Elkelany, M. 3D printed fiber reinforced polymer composites-Structural analysis. Compos. Part B Eng. 2019, 175, 107112. [Google Scholar] [CrossRef]

- Perez, A.R.T.; Roberson, D.A.; Wicker, R.B. Fracture surface analysis of 3D-printed tensile specimens of novel ABS-based materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef] [Green Version]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Hmeidat, N.S.; Pack, R.C.; Talley, S.J.; Moore, R.B.; Compton, B.G. Mechanical anisotropy in polymer composites produced by material extrusion additive manufacturing. Addit. Manuf. 2020, 34, 101385. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fibre–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Moumen, A.E.; Tarfaoui, M.; Lafdi, K. Additive manufacturing of polymer composites: Processing and modelling approaches. Compos. Part B Eng. 2019, 171, 166–182. [Google Scholar] [CrossRef]

- Klift, F.V.D.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D printing of continuous carbon fibre reinforced thermoplastic (CFRTP) tensile test specimens. Open J. Compos. Mater. 2016, 6, 18. [Google Scholar] [CrossRef] [Green Version]

- Yang, D.; Zhang, H.; Wu, J.; McCarthy, E.D. Fibre flow and void formation in 3D printing of short-fibre reinforced thermoplastic composites: An experimental benchmark exercise. Addit. Manuf. 2021, 37, 101686. [Google Scholar] [CrossRef]

- Kokkinis, D.; Schaffner, M.; Studart, A.R. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 2015, 6, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Llewellyn-Jones, T.M.; Drinkwater, B.W.; Trask, R.S. 3D printed components with ultrasonically arranged microscale structure. Smart Mater. Struct. 2016, 25, 02T01. [Google Scholar] [CrossRef] [Green Version]

- Duigou, A.L.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D printing: Fundamentals, materials, applications and challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Zheng, Z.; Liu, Y.; Jinsong, L. Magnetic programming of 4D printed shape memory composite structures. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105571. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, L.; Bian, W.; Liu, Y.; Leng, J. 4D printed electroinduced continuous carbon fibre reinforced shape memory polymer composites with excellent bending resistance. Compos. Part B Eng. 2020, 194, 108034. [Google Scholar] [CrossRef]

- dos Santos, D.M.; Correa, D.S.; Medeiros, E.S.; Oliveira, J.E.; Mattoso, L.H.C. Advances in Functional Polymer Nanofibers: From Spinning Fabrication Techniques to Recent Biomedical Applications. ACS Appl. Mater. Interfaces 2020, 12, 45673–45701. [Google Scholar] [CrossRef]

- Park, Y.; Jung, J.; Chang, M. Research Progress on Conducting Polymer-Based Biomedical Applications. Appl. Sci. 2019, 9, 1070. [Google Scholar] [CrossRef] [Green Version]

- Sadiq, S.H.A.J.; Patil, P.P. Review on 4D and 5D printing technology. Int. Res. J. Eng. Technol. 2020, 7, 744–751. [Google Scholar]

- Reddy, P.R.; Devi, P.A. Review on the advancements of additive manufacturing-4D and 5D printing. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 397–402. [Google Scholar]

- Georgantzinos, S.K.; Giannopoulos, G.I.; Bakalis, P.A. Additive manufacturing for effective smart structures: The idea of 6D printing. J. Compos. Sci. 2021, 5, 119. [Google Scholar] [CrossRef]

- Azhdar, B.; Stenberg, B.; Kari, L. Development of a high-velocity compaction process for polymer powders. Polym. Test. 2005, 24, 909–919. [Google Scholar] [CrossRef]

- Azhdar, B.; Stenberg, B.; Kari, L. Determination of dynamic and sliding friction, and observation of stick-slip phenomenon on compacted polymer powders during high-velocity compaction. Polym. Test. 2006, 25, 1069–1080. [Google Scholar] [CrossRef]

- Azhdar, B.; Stenberg, B.; Kari, L. Polymer–nanofiller prepared by high-energy ball milling and high velocity cold compaction. Polym. Compos. 2008, 29, 252–261. [Google Scholar] [CrossRef]

- Souriou, D.; Goeuriot, P.; Bonnefoy, O.; Thnmas, G.; Dore, F. Influence of the formulation of an alumina powder on compaction. Powder Technol. 2009, 190, 152–159. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, V.V.; Ivin, S.Y.; Khrustov, V.R.; Kotov, Y.A.; Murzakaev, A.M.; Nikonov, A.V.; Paranin, S.N.; Spirin, A.V. Fabrication of nanoceramic hin-wall tubes by magnetic pulsed compaction and thermal sintering. Sci. Sinter. 2005, 37, 55–60. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Dudina, D.V. Sintering in the Constant Electric Field in the Noncontact Mode and in Magnetic Field. In Field-Assisted Sintering; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Qu, X. Principle and Technology of Powder Metallurgy; Metallurgical Industry Press: Beijing, China, 2013. [Google Scholar]

- Lee, J.G.; Lim, C.H.; Kim, H.S.; Hong, S.J.; Kim, M.T.; Kang, B.C.; Park, D.K.; Lee, M.K.; Rhee, C.K. Highly dense steel components prepared by magnetic pulsed compaction of iron-based powders. Powder Technol. 2012, 228, 254–257. [Google Scholar] [CrossRef]

- Cui, J.; Huang, X.; Dong, D.; Li, G. Effect of discharge energy of magnetic pulse compaction on the powder compaction characteristics and spring back behavior of copper compacts. Met. Mater. Int. 2021, 27, 3385–3397. [Google Scholar] [CrossRef]

- Dong, D.; Fu, S.; Jiang, H.; Li, G.; Cui, J. Study on the compaction characteristics of CNTs/TC4 composites based on electromagnetic warm compaction. J. Alloys Compd. 2021, 857, 158046. [Google Scholar] [CrossRef]

- Dong, D.; Huang, X.; Cui, J.; Li, G.; Jiang, H. Effect of aspect ratio on the compaction characteristics and micromorphology of copper powders by magnetic pulse compaction. Adv. Powder Technol. 2020, 31, 4354–4364. [Google Scholar] [CrossRef]

- Li, M.; Yu, H.P.; Li, C.F. Microstructure and mechanical properties of Ti6Al4 V powder compacts prepared by magnetic pulse compaction. Trans. Nonferrous Met. Soc. China 2010, 20, 553–558. [Google Scholar] [CrossRef]

- Eremina, M.A.; Lomaeva, S.F.; Paranin, S.N.; Demakov, S.L.; Elsukov, E.P. Effect of compaction method on the structure and properties of bulk Cu+ Cr3C2 composites. Phys. Met. Metallogr. 2016, 117, 510–517. [Google Scholar]

- Choi, S.H.; Ali, B.; Kim, S.Y.; Hyun, S.K.; Park, K.T.; Kim, B.S.; Kim, T.S.; Park, J.S. Fabrication of Ag–SnO2 Contact Materials from Gas-Atomized Ag–Sn Powder Using Combined Oxidation and Ball-Milling Process. Int. J. Appl. Ceram. Technol. 2016, 13, 258–264. [Google Scholar]

- Lee, J.G.; Hong, S.J.; Park, J.J.; Lee, M.K.; Ivanov, V.V.; Rhee, C.K. Fabrication of a yttria thin-wall tube by radial magnetic pulsed compaction of powder-based tapes. Mater. Trans. 2010, 51, 1689–1693. [Google Scholar]

- Ivanov, V.V.; Ivanov, S.N.; Kaigorodov, A.S.; Taranov, A.V.; Khazanov, E.N.; Khrustov, V.R. Transparent Y2O3: Nd3+ ceramics produced from nanopowders by magnetic pulse compaction and sintering. Inorg. Mater. 2007, 43, 1365–1370. [Google Scholar]

- Kim, J.H.; Raihanuzzaman, R.M.; Rhee, C.K.; Lee, J.G.; Lee, M.K.; Hong, S.J. Fabrication and Densification Behavior Analysis of Metalizing Targets Using ZrO2 Nanopowders by Magnetic Pulsed Compaction. Mater. Trans. 2011, 52, 1156–1162. [Google Scholar] [CrossRef] [Green Version]

- Park, H.Y.; Kilicaslan, M.F.; Hong, S.J. Effect of multiple pressures by magnetic pulsed compaction (MPC) on the density of gas-atomized Al–20Si powder. Powder Technol. 2012, 224, 360–364. [Google Scholar] [CrossRef]

- Mironovs, V.; Korjakins, A.; Tatarinov, A.; Barone, E.; Glushchenkov, V. Combined static–dynamic compaction of metal powder and ceramic materials. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012020. [Google Scholar]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar]

- Safavi, M.S.; Bordbar-Khiabani, A.; Khalil-Allafi, J.; Mozafari, M.; Visai, L. Additive Manufacturing: An opportunity for the Fabrication of Near-Net-Shape NiTi Implants. J. Manuf. Mater. Process. 2022, 6, 65. [Google Scholar]

- Ferguen, N.; Mebdoua-Lahmar, Y.; Lahmar, H.; Leclerc, W.; Guessasma, M. DEM model for simulation of crack propagation in plasma-sprayed alumina coatings. Surf. Coat. Technol. 2019, 371, 287–297. [Google Scholar]

- Lin, E.; Chen, Q.; Ozdemir, O.C.; Champagne, V.K.; Muftu, S. Effects of interface bonding on the residual stresses in cold-sprayed Al-6061: A numerical investigation. J. Therm. Spray Technol. 2019, 28, 472–483. [Google Scholar]

- Shayegan, G.; Mahmoudi, H.; Ghelichi, R.; Villafuerte, J.; Wang, J.; Guagliano, M.; Jahed, H. Residual stress induced by cold spray coating of magnesium AZ31B extrusion. Mater. Des. 2014, 60, 72–84. [Google Scholar]

- Yusof, S.N.A.; Manap, A.; Afandi, N.F. Numerical analysis of Al coating using different particle shape in LPCS. IOP Conf. Ser. Earth Environ. Sci. 2016, 32, 012038. [Google Scholar]

- Zhuang, M.; Yuan, J.; Hu, Z.; Li, G.; Zhang, H.Y.; Zhang, J.; Huang, B.; Wang, L. Design and optimization of coating structure for plasma sprayed self-healing MgO coating via finite element method. Ceram. Int. 2021, 47, 2414–2429. [Google Scholar]

- Meng, D.; Li, Y.G.; Jiang, Z.T.; Lei, M.K. Scratch behavior and FEM modelling of Cu/Si (100) thin films deposited by modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2019, 363, 25–33. [Google Scholar]

- Nemeth, S. Modelling of the scratch resistance of particle filled sol–gel coatings on aluminium. Thin Solid Film. 2008, 516, 5355–5359. [Google Scholar]

- Xie, L.; Wang, L.; Niu, Y.; Liu, T.; Chen, W.; Zheng, X.; Huang, Z. Influence of interface morphology of transition layer on the residual stresses of plasma sprayed ZrC-based coatings examined by finite element simulations. Ceram. Int. 2019, 45, 13037–13045. [Google Scholar] [CrossRef]

- Song, X.; Jin, X.Z.; Zhai, W.; Tan, A.W.Y.; Sun, W.; Li, F.; Marinescu, I.; Liu, E. Correlation between the macroscopic adhesion strength of cold spray coating and the microscopic single-particle bonding behaviour: Simulation, experiment and prediction. Appl. Surf. Sci. 2021, 547, 149165. [Google Scholar]

- Compton, B.G.; Post, B.K.; Duty, C.E.; Love, L.; Kunc, V. Thermal analysis of additive manufacturing of large-scale thermoplastic polymer composites. Addit. Manuf. 2017, 17, 77–86. [Google Scholar]

- Kousiatza, C.; Chatzidai, N.; Karalekas, D. Temperature mapping of 3D printed polymer plates: Experimental and numerical study. Sensors 2017, 17, 456. [Google Scholar] [CrossRef] [Green Version]

- Ghorbani, F.; Li, D.; Ni, S.; Zhou, Y.; Yu, B. 3D printing of acellular scaffolds for bone defect regeneration: A review. Mater. Today Commun. 2020, 22, 100979. [Google Scholar]

- Ji, L.B.; Zhou, T.R. Finite element simulation of temperature field in fused deposition modelling. Adv. Mater. Res. 2010, 97–101, 2585–2588. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, H.; Qian, K.; Yang, H.; McGehee, M.; Gu, J.; Luo, D.; Yao, L.; Zhang, Y.J. Material characterization and precise finite element analysis of fibre reinforced thermoplastic composites for 4D printing. Comput. Aided Des. 2020, 122, 102817. [Google Scholar]

- Zhou, X.; Hsieh, S.J.; Sun, Y. Experimental and numerical investigation of the thermal behaviour of polylactic acid during the fused deposition process. Virtual Phys. Prototyp. 2017, 12, 221–233. [Google Scholar]

- Available online: https://www.compositesworld.com/products/siemens-announces-additive-manufacturing-software-tool-to-improve-3d-printing-accuracy (accessed on 29 July 2022).

- Li, F.; Li, H.; Ge, X.; Zhao, J.; Wu, H.; Lin, J.; Huang, G. Numerical simulation of magnetic pulse radial compaction of W-Cu20 powder with a field shaper. Int. J. Adv. Manuf. Technol. 2021, 114, 219–230. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Bokov, A.A.; Boltachev, G.S.; Volkov, N.B.; Zayats, S.V.; Ilyina, A.M.; Nozdrin, A.A.; Paranin, S.N. Modelling and optimization of uniaxial magnetic pulse compaction of nanopowders. Acta Mech. 2013, 224, 3177–3195. [Google Scholar]

- Suhonen, T.; Varis, T.; Dosta, S.; Torrell, M.; Guilemany, J.M. Residual stress development in cold sprayed Al, Cu and Ti coatings. Acta Mater. 2013, 61, 6329–6337. [Google Scholar]

- Qiu, X.; Tariq, N.U.H.; Qi, L.; Tang, J.R.; Cui, X.Y.; Du, H.; Wang, J.Q.; Xiong, T.Y. Effects of dissimilar alumina particulates on microstructure and properties of cold-sprayed alumina/A380 composite coatings. Acta Metall. Sin. Engl. Lett. 2019, 32, 1449–1458. [Google Scholar]

- Luzin, V.; Kirstein, O.; Zahiri, S.H.; Fraser, D. Residual stress buildup in Ti components produced by cold spray additive manufacturing (CSAM). J. Therm. Spray Technol. 2020, 29, 1498–1507. [Google Scholar] [CrossRef]

- Singh, R.; Schruefer, S.; Wilson, S.; Gibmeier, J.; Vassen, R. Influence of coating thickness on residual stress and adhesion-strength of cold-sprayed Inconel 718 coatings. Surf. Coat. Technol. 2018, 350, 64–73. [Google Scholar]

- Coddet, P.; Verdy, C.; Coddet, C.; Debray, F. Mechanical properties of Cu-0.1Ag alloys deposited by cold spray with various powder feed rate and heat treatment. J. Therm. Spray Technol. 2015, 24, 119–125. [Google Scholar]

- Zhu, L.N.; Xu, B.S.; Wang, H.D.; Wang, C.B. Measurement of residual stresses using nanoindentation method. Crit. Rev. Solid State Mater. Sci. 2015, 40, 77–89. [Google Scholar] [CrossRef]

- Islam, M.; Tudryn, G.J.; Picu, C.R. Microstructure modelling of random composites with cylindrical inclusions having high volume fraction and broad aspect ratio distribution. Comput. Mater. Sci. 2016, 125, 309–318. [Google Scholar]

- Jean, A.; Jeulin, D.; Forest, S.; Cantournet, S.; Guyen, F.N. A multiscale microstructure model of carbon black distribution in rubber. J. Microsc. 2011, 241, 243–260. [Google Scholar]

- Sacco, C.; Radwan, A.B.; Anderson, A.; Harik, R.; Gregory, E. Machine learning in composites manufacturing: A case study of automated fibre placement inspection. Compos. Struct. 2020, 250, 112514. [Google Scholar]

- Bocchetta, P.; Frattini, D.; Tagliente, M.; Selleri, F. Electrochemical Deposition of Polypyrrole Nanostructures for Energy Applications: A Review Bentham Science. Curr. Nanosci. 2020, 16, 462–477. [Google Scholar]

- Pungaiya, S.; Kailasanatthan, C. A Reveiw of Surface Coating Technology to Increase the Heat Transfer. Int. J. Mech. Eng. Robot. Res. 2018, 7, 458–465. [Google Scholar] [CrossRef]

- Sushma, S.; Chandrashekar, T.K. A review on heat transfer with nanomaterial Coating. Int. J. Mech. Prod. Eng. 2021, 9, 11–14. [Google Scholar]

- Yade, T.E.; Abdoulaye, D.; Aboubacary, S.; Yande, D.S.; Frederic, G.; Thierry, D. Designing bioinspired parahydrophobic surfaces by electrodeposition of poly(3,4-ethylenedioxypyrrole) and poly (3,4-propylenedioxypyrrole) with mixed hydrocarbon and fluorocarbon chains. Eur. Polym. J. 2019, 110, 76–84. [Google Scholar]

- Jiaying, T.L.; Wei, Z.; Kun, Z. Recent Progress on polymer Materials for Additive Manufacturing. Adv. Funct. Mater. 2020, 30, 1–54. [Google Scholar]

- Beka, D.G.; Hou, Y.; Liu, Y.; Panesar, A. 3D printing to enable multifuncionality in polymer-based composite: A Review. Compos. Part B Eng. 2019, 179, 1–13. [Google Scholar]

| Polymers | Types | Properties | Applications |

|---|---|---|---|

| Epoxy [3] | Thermosetting matrix | Excellent physical, mechanical and electrical insulation properties, bonding properties, processing flexibility, brittle | Coatings, composite materials, casting materials, adhesives, moulding materials and injection moulding materials, electronics, civil engineering, aviation, automotive |

| Polyester resin [1] | Thermosetting matrix | Good manufacturability, curing at room temperature, moulding at normal pressure | General civil industry, automotive, ship, chemicals, electronics |

| Phenolic resin [3] | Thermosetting matrix | Cheaper than epoxy, good resistance to high temperature, water and acid, high shrinkage rate | Powder pressing plastics, glass fibre reinforced plastics, ablative materials, interior decoration, electrical engineering materials |

| PAEK [4] | Thermoplastic matrix | Excellent properties in mechanics, high-temperature, corrosion and UV resistance. | Aviation, automotive, electronic and mechanical components subjected to a harsh environment |

| PEI [5] | Thermoplastic matrix | Heat resistance, inherent flame retardancy, extremely high strength and stiffness, corrosion resistance, excellent performance in moulding processing | Tableware, medical apparatus and equipment, aviation, automotive |

| Country | Time Period/Year | Schemes | Critical Focus |

|---|---|---|---|

| US | 1990–1999 | The Advanced Technology Program | Composite materials; material processing technology in heavy manufacturing industry |

| EU | 2007–2013 | Seventh Framework Programme | Cutting-edge technologies of advanced materials; nanotechnologies, materials and production |

| Japan | 2010 | Japan’s Industrial Structure Outlook 2010 | Nanomaterial; carbon fibres; functional chemicals |

| US | 2013 | The National Network for Manufacturing Innovation | Carbon fibre composites; lightweight materials; 3D printing technology |

| US | 2019 | Nanotechnology Research Plan for 2018–2025 | Nanomaterials |

| Japan | 2020 | Japan’s Industrial Development Report 2020 | Material technology |

| UK | 2020 | Sustainable Composites | Full life cycles of composite materials |

| Technology | Working Principle | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| Surface coating | A film layer is formed on the surface of the substrate | Wide range of optional materials, adaptability to working conditions and good economy | It is difficult to accurately control the film thickness, and subsequent processing is often required | Drug Delivery, corrosion protection, antibacterial activity, pipeline, micro batteries [42] |

| Additive manufacturing | A “bottom-up” manufacturing method by accumulating materials layer by layer | near net forming, Simple operation | Limited materials, slow manufacturing speed | Biomedical application [43], electronics [44], aerospace applications [45] |

| High velocity moulding | A technology for consolidating powder by applying pressure of pulse modulated electromagnetic field | Good economy, fast manufacturing and simple operation | Simple structure of parts and low energy utilisation rate | Medical field [46], ceramic [47], packaging material [48] |

| Surface Coating Technology | Materials | Advantages | Disadvantages | Applications |

|---|---|---|---|---|

| Plasma spraying [53] | Polymer composite coatings | High bonding strength, simple operation, good adjustment performance | Many interaction parameters, difficult to paint inside holes | Preparation of polymer coatings to improve the corrosion resistance of the substrate |

| Magnetron sputtering [54] | Polymer metal nanocomposites | Simple equipment, easy to control, strong adhesion, small damage to the substrate, wide range of applicable materials | Difficult and costly preparation of insulator films | Preparation of metal nanofilms on insulating polymer substrates for applications in sensors, reflectors |

| Electrochemical deposition [55] | Multiwalled carbon nanotubes polymer composites | Simple operation, high flexibility and reliability | Sensitive to the influence of changes in process parameters | Preparation of carbon nanotube-polymer composite films on metal substrates for the protection of metallic materials in ship hulls |

| Sol–gel technology [56] | Nanostructured polymer composites | Good composition control and film homogenisation ability, low temperature | The drying process is prone to cracking, long moulding cycle and high raw material costs | Preparation of polyimide–silicon dioxide composite coating on epoxy resin substrate to improve corrosion resistance |

| Technique | State of Starting Materials | Working Principle |

|---|---|---|

| FDM [93] | Filament | Extrusion and deposition |

| SLS [94] | Powder | Laser scanning and heat induced sintering |

| SLA [95] | Liquid photopolymer | Laser scanning and UV induced curing |

| 3DP [96] | Powder | Drop on demand binder printing |

| Technology | Problem | FE Analysis | Author/Year |

|---|---|---|---|

| Plasma spraying | Simulated crack growth | Discrete element (DEM) model established by C++ program. | Ferguen et al. (2019) [147] |

| Cold spray | Effect of interfacial bonding on residual stress | Single-particle and multiparticle collision models | Lin et al. (2019) [148] |

| Cold spray | Effect of process parameters on residual stress | LS-DYNA | Shayegan et al. (2014) [149] |

| Cold spray | Influence of particle shape on substrate | Smooth Particle Hydrodynamics (SPH) | Yusof et al. (2016) [150] |

| Plasma spraying | Effect of coating thickness and convective heat transfer coefficient on residual stress of coating | ANSYS | Zhuang et al. (2021) [151] |

| Modulated pulsed power magnetron sputtering | Effect of sputtering pressure on scratch behaviour | ABAQUS/Explicit | Meng et al. (2019) [152] |

| Sol–gel | Effect of filler particle size on coating properties | Elastica | Nemeth et al. (2008) [153] |

| Plasma spraying | Effect of interface morphology on residual stress of coating | ANSYS APDL | Xie et al. (2019) [154] |

| Cold spray | Effect of particle temperature on bond strength of coating | ABAQUS/Explicit | Song et al. (2021) [155] |

| Big Area Additive Manufacturing (BAAM) | Thermal evolution | One-dimensional thermal finite difference model | Compton et al. (2017) [156] |

| FDM (3D) | Thermal gradient and residual stress | ABAQUS | Charoula et al. (2017) [157] |

| FDM (3D) | Deformations and residual stress distributions of parts during deposition | ANSYS | Ghorbani et al. (2020) [158] |

| FDM (3D) | Temperature distribution | ANSYS APDL | Ji et al. (2010) [159] |

| 4D printing | Deformation of the designed product | ABAQUS | Yu et al. (2020) [160] |

| FDM (3D) | Distribution of thermal stress and temperature | ANSYS | Zhou et al. (2017) [161] |

| 3D printing | Predict and compensate deformation | PLM/ABAQUS | Siemens (2019) [162] |

| 5D printing | Conceptual model | -- | Reddy PR et al. [123] |

| Magnetic pulse radial compaction | Influence of process parameters on compactness of compacted parts | ANSYS/Multiphysical and ABAQUS/Explicit | Li et al. (2021) [163] |

| Magnetic pulse axial compaction | Influence of process parameters on compactness of compacted parts | Theoretical models of pulsed magnetic fields and dynamics of mechanical systems | Olevsky et al. (2013) [164] |

| Novel Manufacturing | Technical Difficulties | Advantage | Disadvantage | Application |

|---|---|---|---|---|

| Surface coating manufacturing [174,175,176,177] | The connection quality of the interface between the spraying material and the base material, and the uniformity, density and mechanical properties of the layer. | High efficiency, simple equipment, easy to achieve batch production. | There are many factors that affect the quality, which are harmful to the environment and operators. | Realise the modification of surface enhancement and modification |

| Addictive manufacturing [178,179] | Interface bonding strength between layers; Dependence on material size and properties. | No mould is needed to realise moulding of different shapes; low cost and short processing cycle; forming and sintering are completed at the same time. | Low efficiency, low density, low technology maturity, small batch production. | Aerospace parts and human organs with complex structure |

| Magnetic pulse manufacturing [41,131,132] | Control the discharge energy to reduce the impact on the mould and frame. | High efficiency, cold forming, not easy to carbonise, high density, mass production, products with high mechanical properties and electrical conductivity. | Low energy utilisation rate of equipment; post curing treatment is needed; high requirements for mould quality. | Parts with high density requirements |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Xu, F.; Wang, H.; Liu, H.; Yan, F.; Ma, C. Manufacturing Technologies of Polymer Composites—A Review. Polymers 2023, 15, 712. https://doi.org/10.3390/polym15030712

Wu C, Xu F, Wang H, Liu H, Yan F, Ma C. Manufacturing Technologies of Polymer Composites—A Review. Polymers. 2023; 15(3):712. https://doi.org/10.3390/polym15030712

Chicago/Turabian StyleWu, Chenchen, Fan Xu, Huixiong Wang, Hong Liu, Feng Yan, and Chao Ma. 2023. "Manufacturing Technologies of Polymer Composites—A Review" Polymers 15, no. 3: 712. https://doi.org/10.3390/polym15030712

APA StyleWu, C., Xu, F., Wang, H., Liu, H., Yan, F., & Ma, C. (2023). Manufacturing Technologies of Polymer Composites—A Review. Polymers, 15(3), 712. https://doi.org/10.3390/polym15030712