Study on the Influence of Accelerated Aging on the Properties of an RTV Anti-Pollution Flashover Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

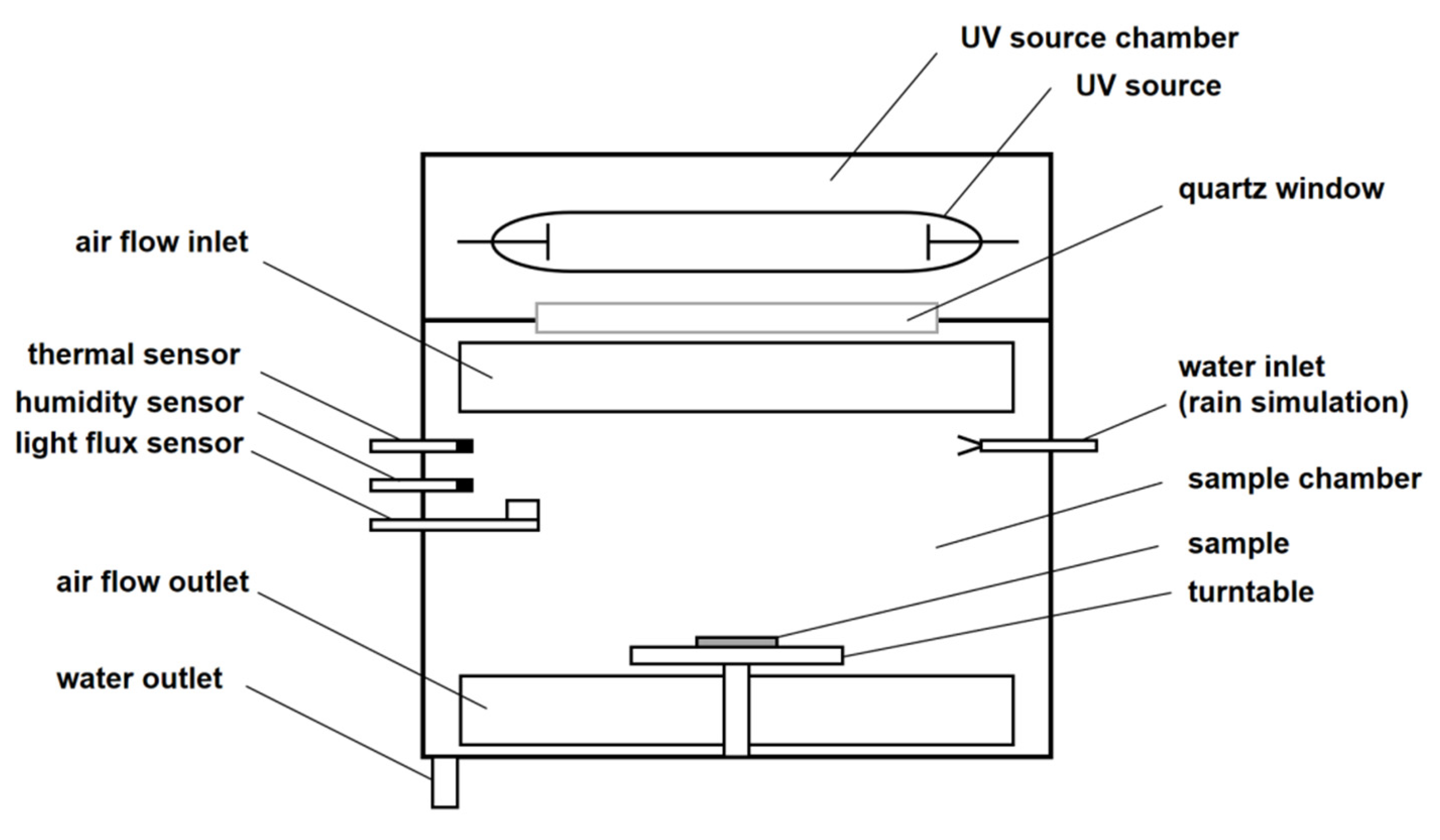

2.2. Accelerated Aging Test

2.3. Experimental Setups

2.3.1. Measurement of Color and Gloss

2.3.2. Observation of Micro Morphology of Coating Surface

2.3.3. Infrared Spectroscopy

2.3.4. Static Contact Angle Test

2.3.5. High Voltage Breakdown Test

3. Experimental Results and Discussion

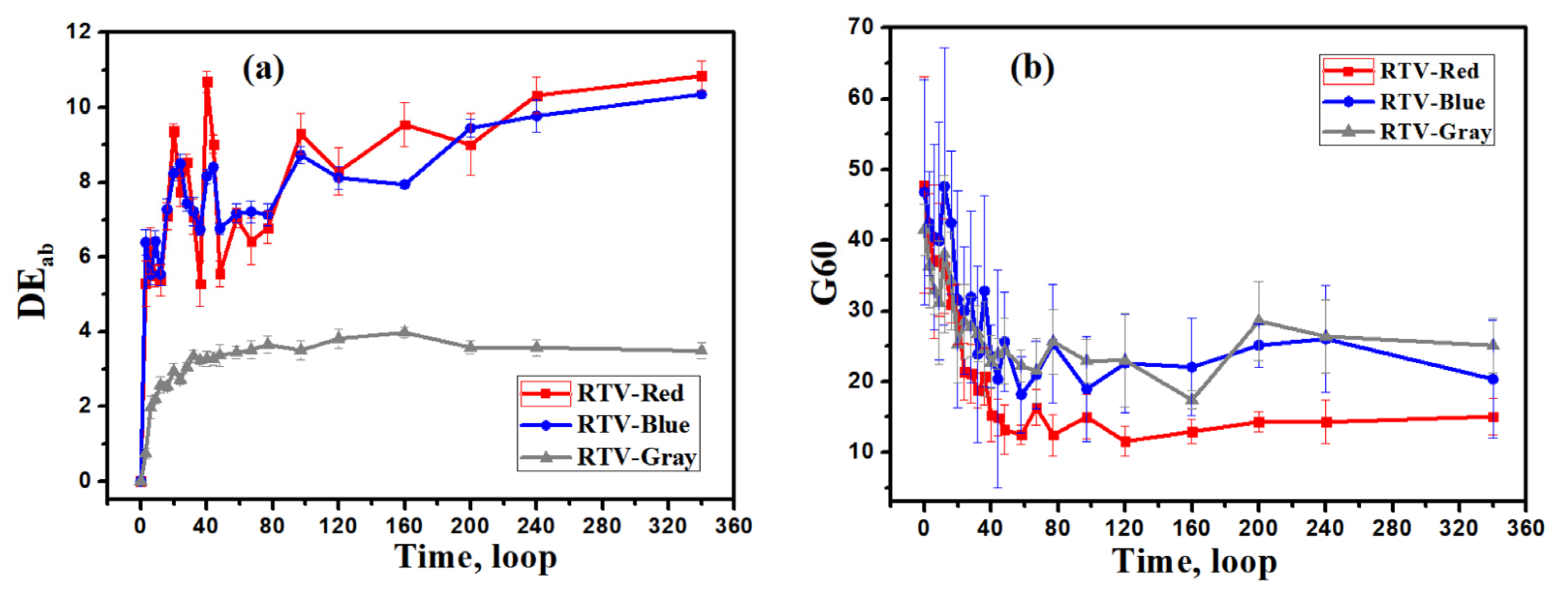

3.1. Color and Gloss Change

3.2. Change in the Micro-Morphology and Element Composition

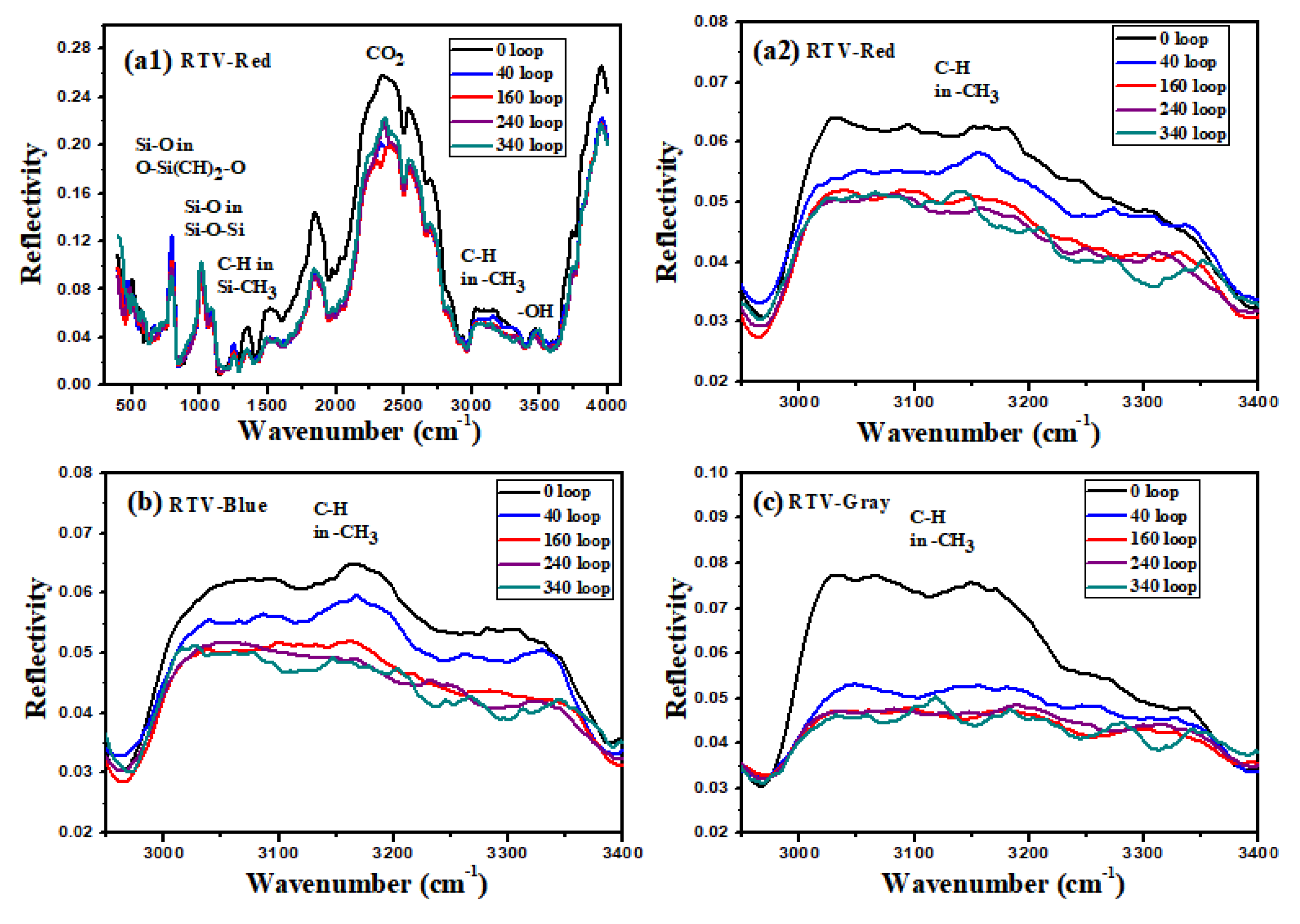

3.3. Changes in IR Reflectance Spectra

3.4. Change in the Static Contact Angle

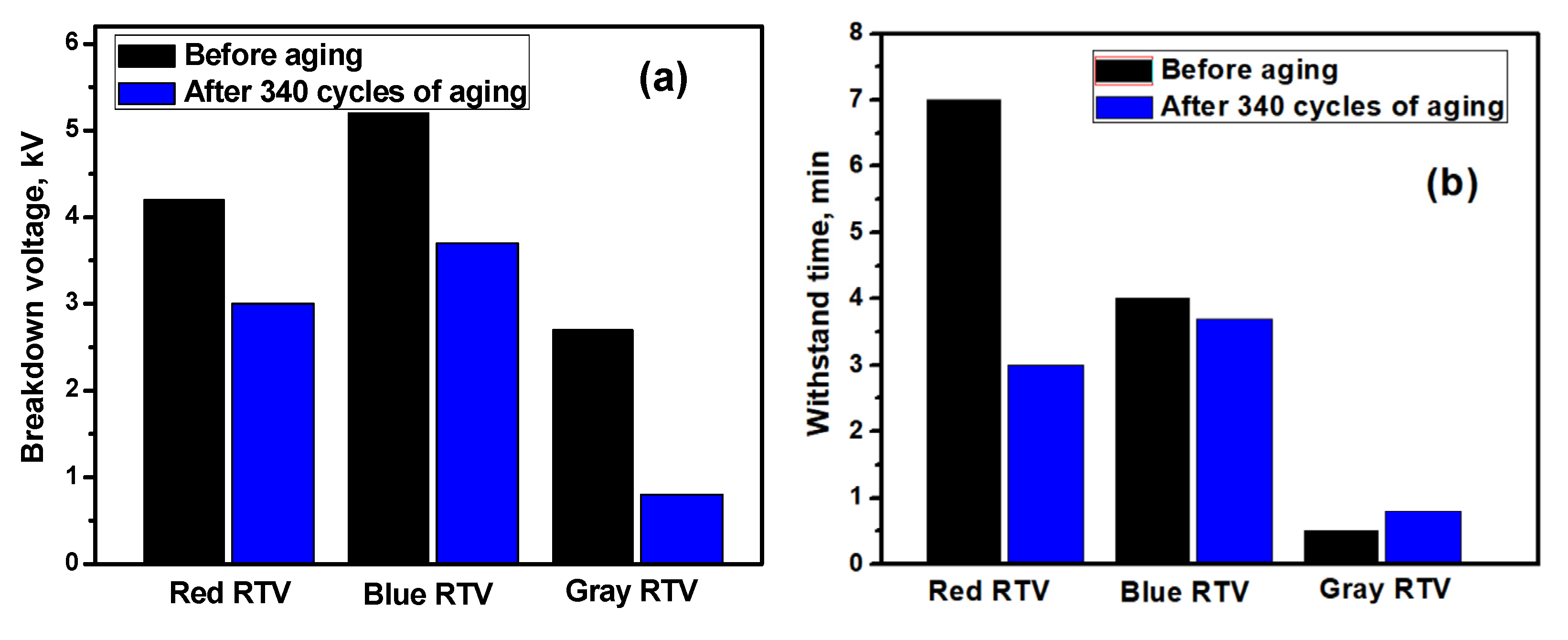

3.5. High Voltage Breakdown Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, R.-Z.; Liu, Z.; Sun, D.; Liu, Y.; Wei, W. Application Progress of Superhydrophobic Compounds in the Field of Metal Corrosion and Protection. Surf. Technol. 2021, 50, 170–177. [Google Scholar]

- Xu, Z. Study of RTV Coating Hydrophobicity and Its Influence on Insulator Electric Field and Pollution Flashover Characteristic; North China Electric Power University: Beijing, China, 2011. [Google Scholar]

- Liang, Y.; Sun, M.; Wang, X.; Gao, T.; Dong, P. Influence of Temperature on Electrical Characteristics of Composite Bushings Repaired by RTV. Insul. Mater. 2020, 53, 83–87. [Google Scholar]

- Lutz, B.; Cheng, L.; Guan, Z.; Wang, L.; Zhang, F. Analysis of a fractured 500 kV composite insulator-identification of aging mechanisms and their causes. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1723–1731. [Google Scholar] [CrossRef]

- Marzinotto, M.; Mazzanti, G.; Panara, A.; Pirovano, G. Comparison of the Quick Flashover Voltages for RTV Pre-coated Insulators Sampled over the Years from the Italian AC Transmission Grid. IEEE Trans. Power Deliv. 2022, 37, 4603–4611. [Google Scholar] [CrossRef]

- Wu, W.; Zhangm, R.; Yuan, T.; Wang, Y.; Cai, Y.; Zhang, H. Analysis and Suggestions on Resistance to Impulse Punture Test in Air of Disc Suspension Insulators After Coated with RTV. Insul. Mater. 2018, 51, 81–85. [Google Scholar]

- Ahmad, F.; Akbar, M.; Ullah, R. AC Performance of HTV-SR and Its Hybrids Loaded with Nano-/Micro-Silica/ATH Fillers. Arab. J. Sci. Eng. 2020, 46, 1103–1114. [Google Scholar] [CrossRef]

- Geng, R. Analysis of hydrophobic migration characteristics and aging characteristics of RTV coatings. Commun. Insul. Mater. 1999, 3, 16–19. [Google Scholar]

- Homma, H.; Mirley, C.L.; Ronzello, J.A.; Boggs, S.A. Field and laboratory aging of RTV silicone insulator coatings. IEEE Trans. Power Deliv. 2000, 15, 1298–1303. [Google Scholar] [CrossRef]

- Gao, H.; Jia, Z.; Guan, Z.; Wang, L.; Zhu, K. Investigation on Field-Aged RTV-Coated Insulators Used in Heavily Contaminated Areas. IEEE Trans. Power Deliv. 2007, 22, 1117–1124. [Google Scholar] [CrossRef]

- Cherney, E.A.; Marzinotto, M.; Gorur, R.S.; Ramirez, I.; Li, S.; El-Hag, A.; Tzimas, A. End-of-life and replacement strategies for RTV silicone coatings. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 253–261. [Google Scholar] [CrossRef]

- Chen, C.; Jia, Z.; Lu, H.; Yang, Z.; Li, T. Field Aging Investigation and Filler Precipitation Analysis on RTV Coated Insulators in China. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2458–2465. [Google Scholar] [CrossRef]

- Abdollahian, A.; El-Hag, A.H.; Jahromi, A.N.; Farahani, M.; Ranjbar, G.A. A Study on the Aging Characteristics of RTV Insulator Coatings. In Proceedings of the Canadian Conference on Electrical and Computer Engineering, Niagra Falls, ON, Canada, 4–7 May 2008. [Google Scholar]

- Devendranath, D.; Aravind, K.A.; Ramulu, A.; Tripathy, A.K. Accelerated-ageing Test for RTV-coated Insulators: Analysis of Electrical and Material Properties. IEE Proc. Gener. Transm. Distrib. 2005, 152, 635–644. [Google Scholar] [CrossRef]

- Gorur, R.S.; Karady, G.G.; Jagota, A.; Shah, M.; Yates, A.M. Aging in Silicone Rubber Used for Outdoor Insulation. IEEE Trans. Power Deliv. 1992, 7, 525–538. [Google Scholar] [CrossRef]

- Yang, H.; Wen, R.; Zhao, H.; Guo, M.; Zhang, L.; Chen, Y. Study on ageing characteristics and evaluation methods of RTV silicone rubber in high humidity area. PLoS ONE 2021, 16, 0251092. [Google Scholar] [CrossRef]

- Ma, B.; Stanislaw, M.G.; Henrik, H. AC and DC zone-induced ageing of HTV silicone rubber. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1984–1994. [Google Scholar] [CrossRef]

- Ma, B.; Johan, A.; Stanislaw, M.G. Evaluating resistance of polymeric materials for outdoor applications to corona and ozone. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 555–565. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Q.; Pang, L.; Gou, X.; Yang, X.; Zhao, J.; Zhou, J. Study of the AC Arc Discharge Characteristics over Polluted Insulation Surface Using Optical Emission Spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3226–3233. [Google Scholar] [CrossRef]

- Jia, B.; Liu, J.; Chen, C.; Wang, X.; Xu, C.; Jia, Z. Aging Phenomena and Condition Assessment Method of RTV Anti-pollution Flashover Coating. High Volt. Appar. 2019, 55, 126–133. [Google Scholar]

- Xia, Y.; Jia, B.; Liu, J.; Chen, C.; Wang, X.; Xu, C. Study on Aging Phenomena of HTV Silicone Rubber of Composite Insulator and Its Evaluation Method. High Volt. Appar. 2019, 55, 163–170. [Google Scholar]

- Verma, A.R.; Reddy, B.S. Aging studies on polymeric insulators under DC stress with controlled climatic conditions. Polym. Test. 2018, 68, 185–192. [Google Scholar] [CrossRef]

- Kumagai, S.; Yoshimura, N. Leakage current characterization for estimating the conditions of ceramic and polymeric insulating surfaces. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 681–690. [Google Scholar] [CrossRef]

- Ullah, R.; Akbar, M.; Amin, S. Measuring electrical, thermal and mechanical properties of DC-stressed HTV silicone rubber loaded with nano/micro-fillers exposed to long-term aging. Appl. Nanosci. 2020, 10, 2101–2111. [Google Scholar] [CrossRef]

- Akbar, M.; Ullah, R.; Qazi, I. Multi-stress aging investigations of HTV silicone rubber filled with Silica/ATH composites for HVAC and HVDC transmission. Eng. Fail. Anal. 2020, 110, 104449. [Google Scholar] [CrossRef]

- Ullah, I.; Amin, M.; Tariq Nazir, M.; Hussain, H. Impact of accelerated ultraviolet weathering on polymeric composite insulators under high voltage DC stress. CSEE J. Power Energy Syst. 2019, 99, 118764698. [Google Scholar]

- Zuo, K.; Shen, W.; Zhang, W.; Li, L.; Guo, J.; Kang, H. Effect of Ultraviolet Radiation on Properties of Room Temperature Vulcanized Silicone Rubber. Insul. Mater. 2020, 53, 36–40. [Google Scholar]

- Xiangyang, P.; Hongsheng, L.; Rui, W.; Huang, Z.; Wang, Z.; Li, Z. Review on Aging Mechanism and Service Life Prediction of Silicone Rubber Composite Insulator. High Volt. Appar. 2018, 54, 1–8. [Google Scholar]

- Jin, H.; Ma, J.; Zeng, Y.; Ding, C.; Zhang, C.; Gao, N.; Zhang, J. Study on Thermal cooling Aging Characteristics of Room Temperature Vulcanized Silicone Rubber Insulation and Protection Materials. High Volt. Appar. 2020, 56, 159–165. [Google Scholar]

- Peng, Q.-Q.; Liu, M.; Huang, Y.-F.; Ma, G.; Guo, W.; Wang, H. Research Status and Prospects of Surface Protective Coatings for Polymer Matrix Composites. Surf. Technol. 2022, 51, 86–107. [Google Scholar]

- Hu, J.; Tan, C.; Zhong, R.; Liu, Z.; Li, Y. Influence of the Thickness of Room Temperature Vulcanized Silicone Rubber Coatings on the Aging Characteristics of Corona. High Volt. Eng. 2020, 46, 1328–1336. [Google Scholar]

| Atomic Percentage, % | |||

|---|---|---|---|

| Element | Blue RTV | Red RTV | Gray RTV |

| C | 30.1 | 31.5 | 36.8 |

| O | 43.4 | 41.3 | 34.8 |

| Al | 11.1 | 9.5 | 6.9 |

| Si | 15.4 | 16.9 | 20 |

| Fe | - | 0.8 | - |

| Ti | - | - | 1.5 |

| 1st Step | 2nd Step | 3rd Step | 4th Step | |

|---|---|---|---|---|

| Test temperature (°C) | 38 | 47 | 47 | 47 |

| Humidity (%) | 95 | 50 | 95 | 50 |

| Blackboard temperature (°C) | 38 | 70 | 70 | 70 |

| Irradiation intensity (W/m2) | 0 | 800 | 800 | 800 |

| Water spray | ON | OFF | ON | OFF |

| Time (min) | 60 | 40 | 20 | 60 |

| Functional Group | Wave Number/cm−1 |

|---|---|

| Si(CH3)3 | 700 |

| Si-O in O-Si(CH3)2-O | 790~840 |

| Si-O in Si-O-Si | 1000~1100 |

| C-H in Si-CH3 | 1255~1270 |

| C-H | 1410~1440 |

| C-H in CH3 | 2960~2962 |

| OH | 3200~3700 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Li, B.; Zeng, X.; Li, Z.; Wen, Y.; Hu, Q.; Yang, Q.; Zhou, M.; Yang, B. Study on the Influence of Accelerated Aging on the Properties of an RTV Anti-Pollution Flashover Coating. Polymers 2023, 15, 751. https://doi.org/10.3390/polym15030751

Chen J, Li B, Zeng X, Li Z, Wen Y, Hu Q, Yang Q, Zhou M, Yang B. Study on the Influence of Accelerated Aging on the Properties of an RTV Anti-Pollution Flashover Coating. Polymers. 2023; 15(3):751. https://doi.org/10.3390/polym15030751

Chicago/Turabian StyleChen, Junwei, Bo Li, Xiaomei Zeng, Zhenggang Li, Yi Wen, Quan Hu, Qiu Yang, Mi Zhou, and Bing Yang. 2023. "Study on the Influence of Accelerated Aging on the Properties of an RTV Anti-Pollution Flashover Coating" Polymers 15, no. 3: 751. https://doi.org/10.3390/polym15030751

APA StyleChen, J., Li, B., Zeng, X., Li, Z., Wen, Y., Hu, Q., Yang, Q., Zhou, M., & Yang, B. (2023). Study on the Influence of Accelerated Aging on the Properties of an RTV Anti-Pollution Flashover Coating. Polymers, 15(3), 751. https://doi.org/10.3390/polym15030751