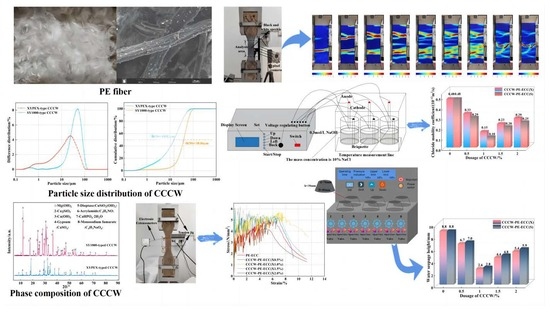

Effect of Cementitious Capillary Crystalline Waterproofing Materials on the Mechanical and Impermeability Properties of Engineered Cementitious Composites with Microscopic Analysis

Abstract

:1. Introduction

2. Experimental Procedure

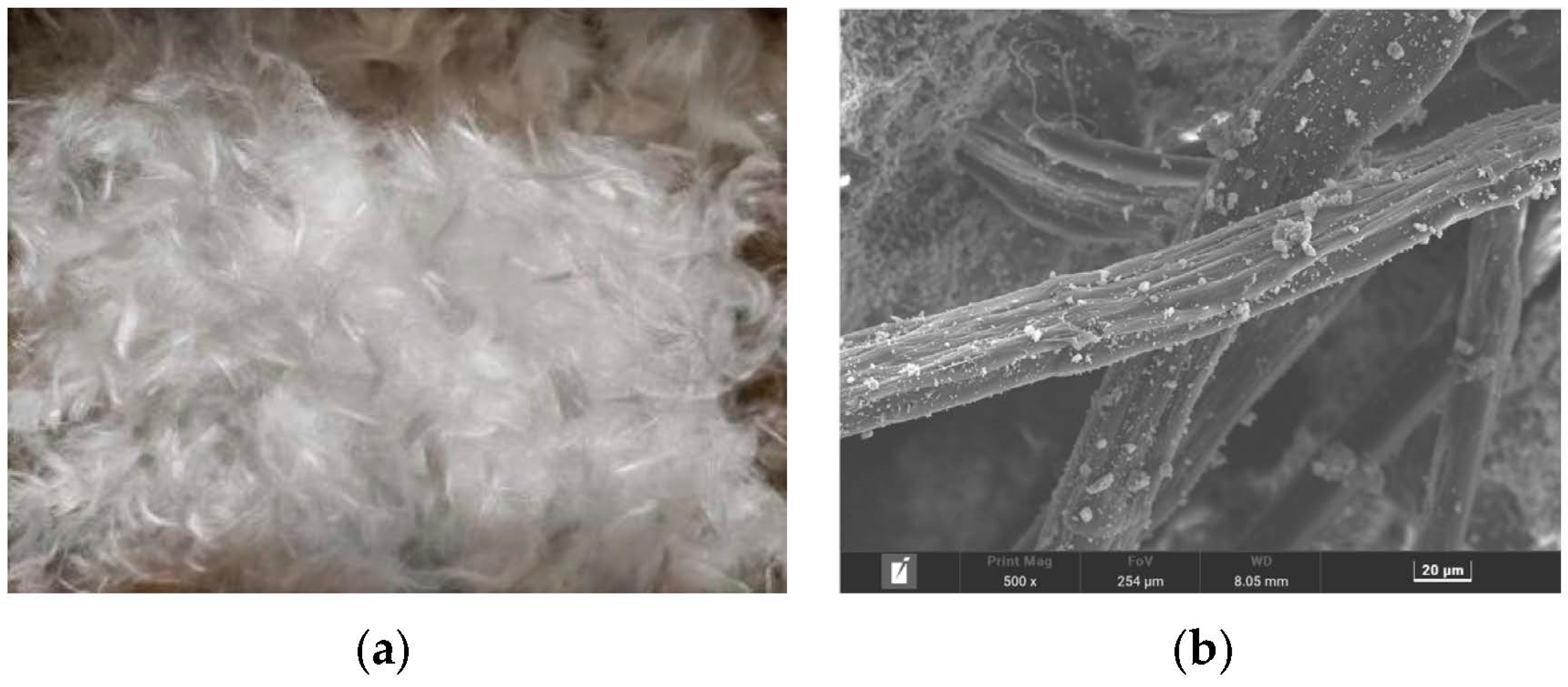

2.1. Materials and Mix Ratio

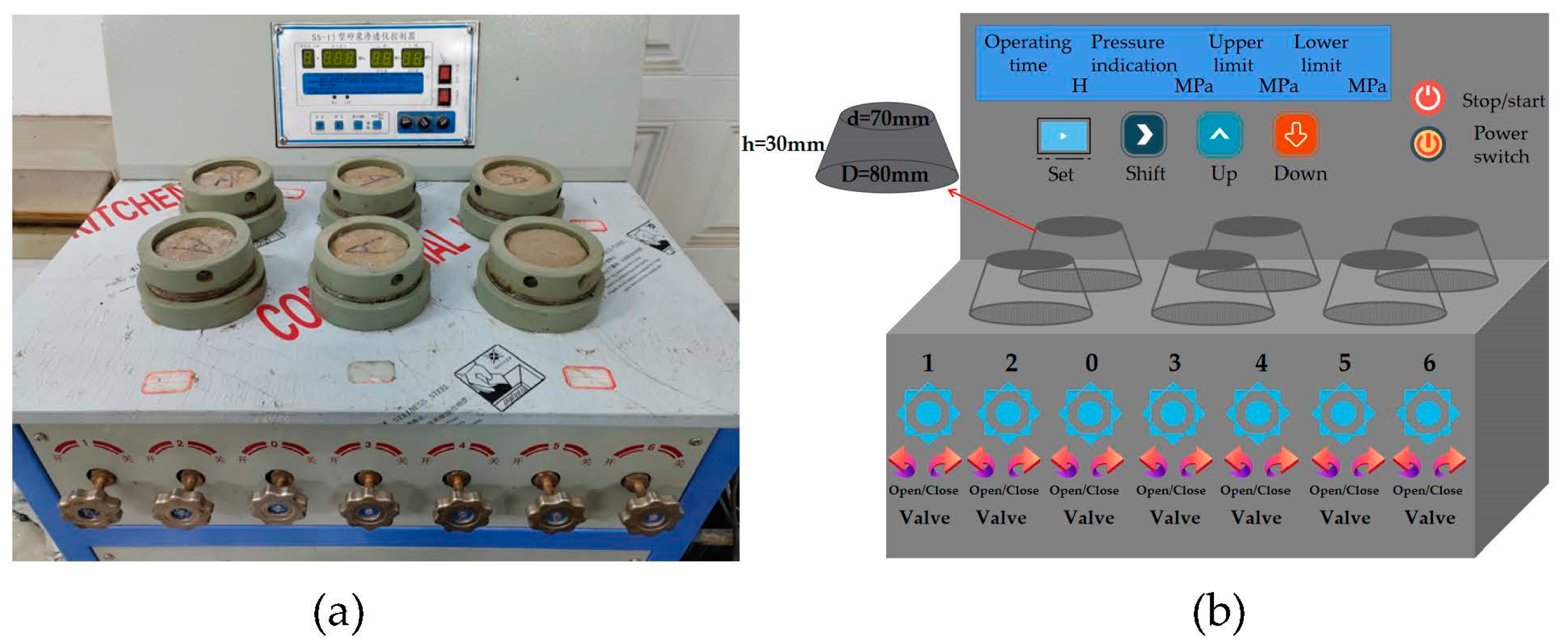

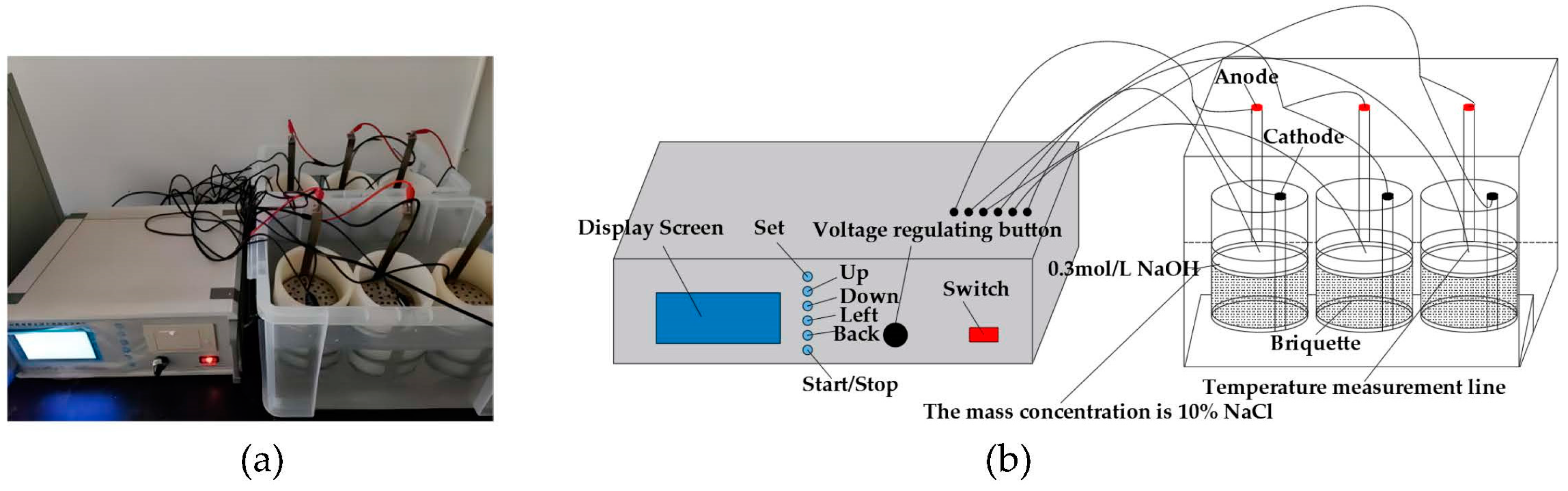

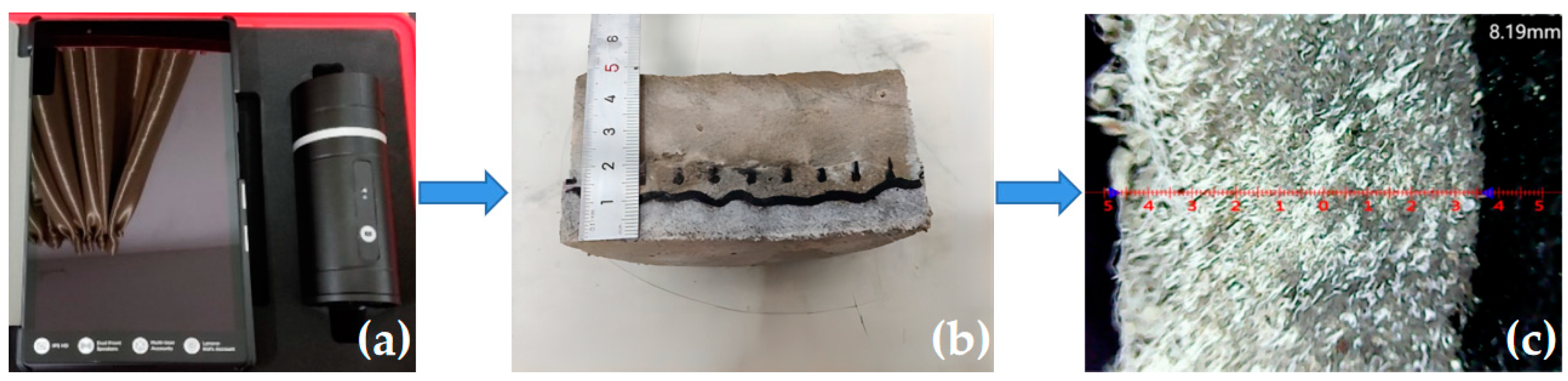

2.2. Experimental Programs

3. Results and Discussion

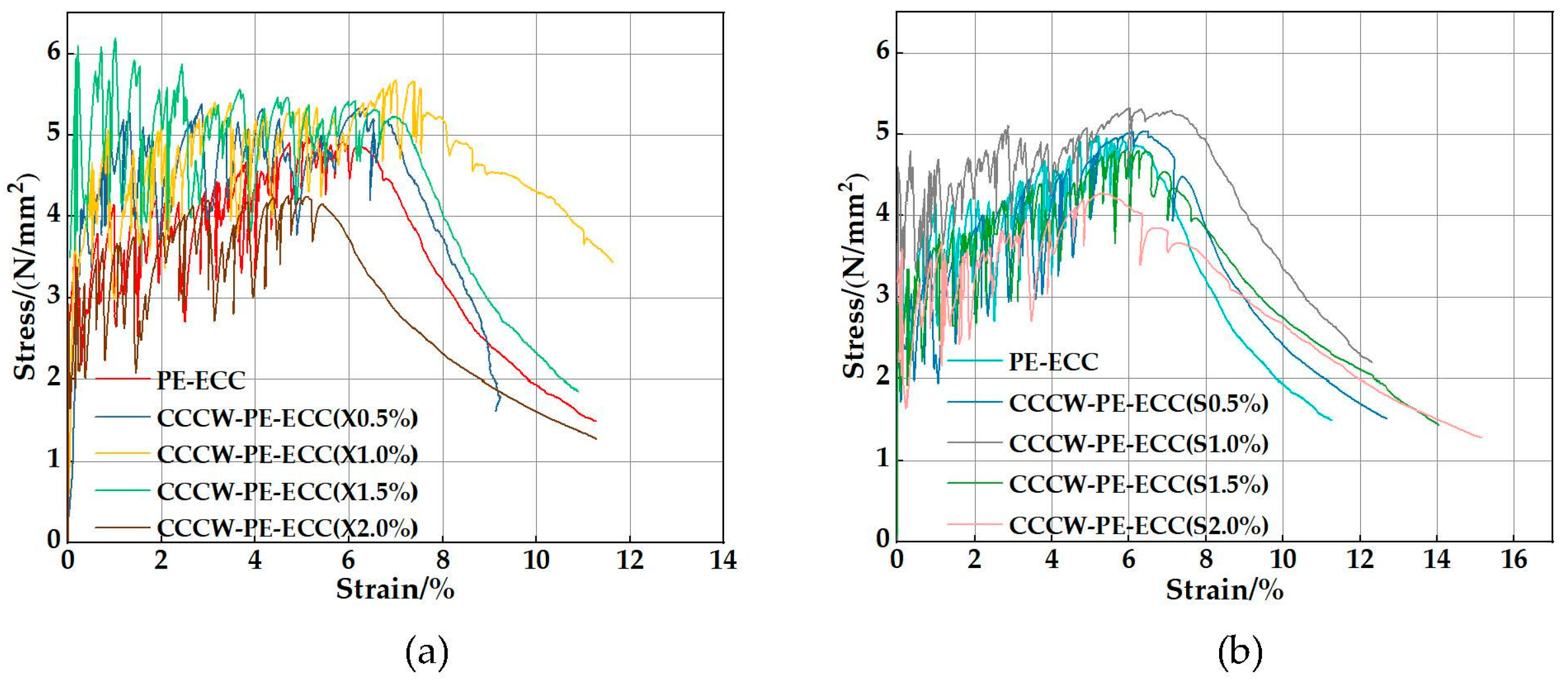

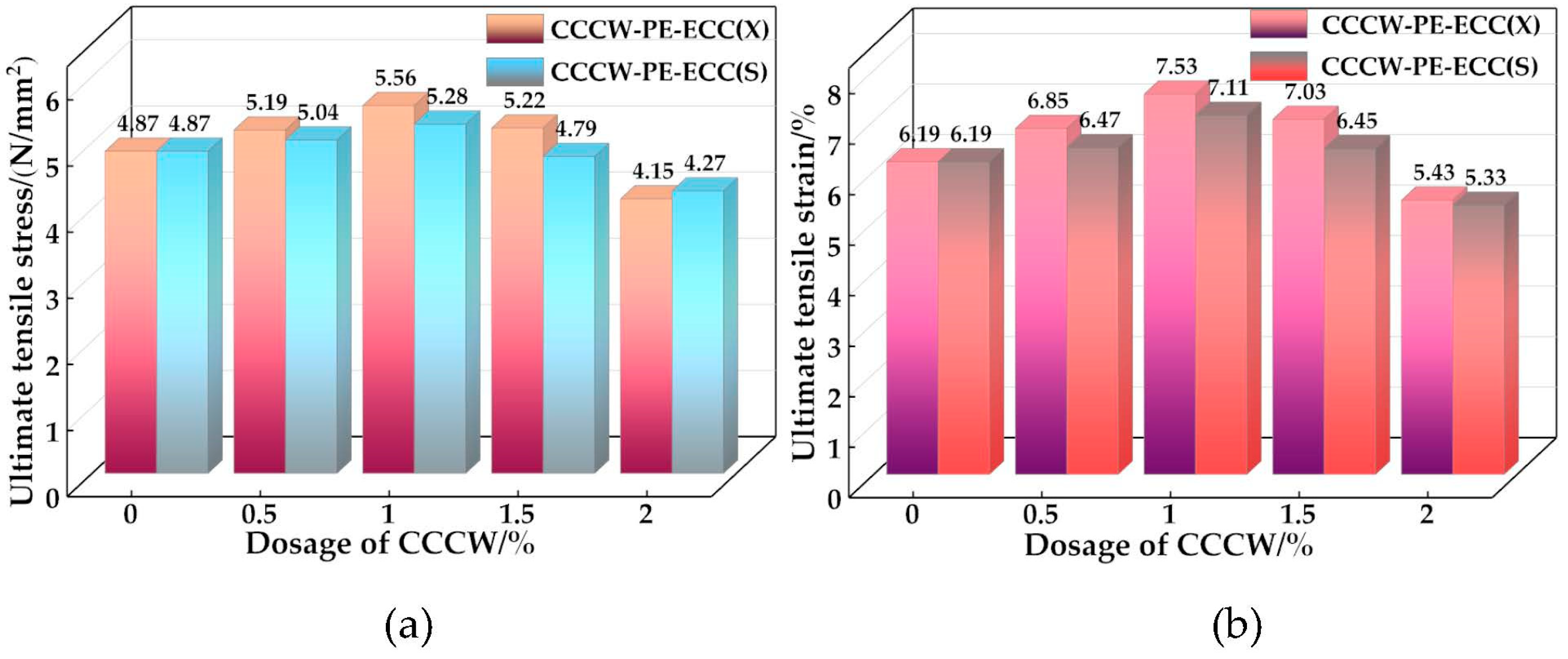

3.1. Mechanical Properties

3.2. Water Seepage Resistance

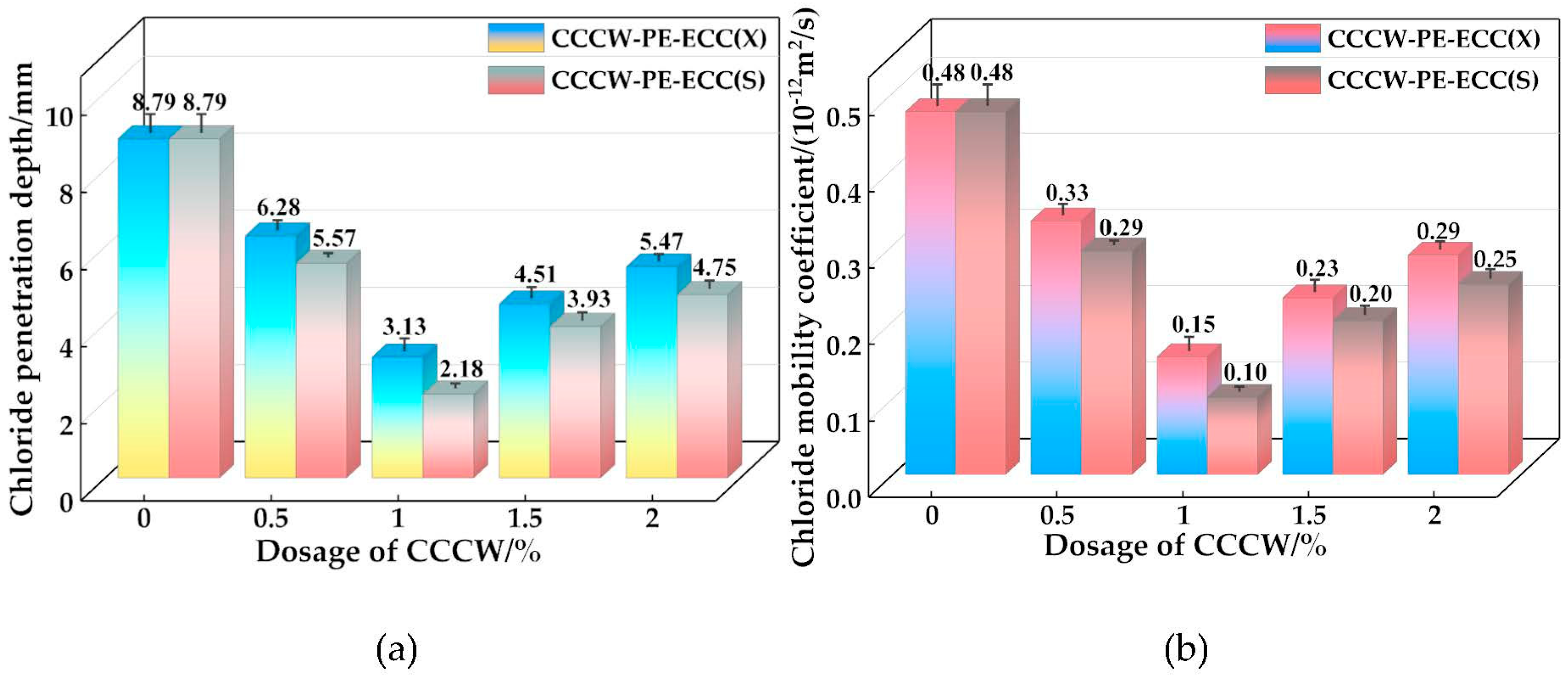

3.3. Anti-Chloride Ion Penetration Performance

4. Microscopic Analysis

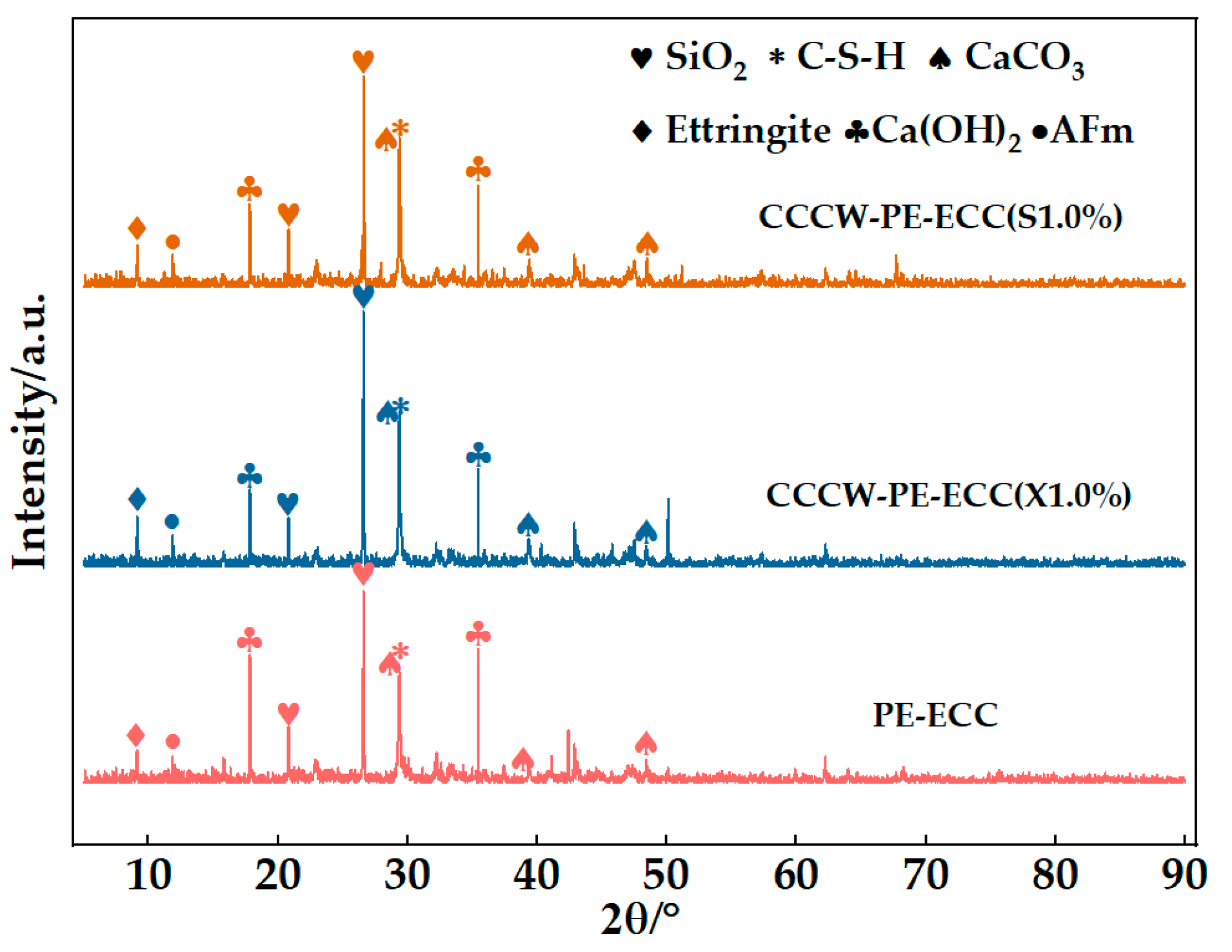

4.1. Phase Composition Testing and Analysis

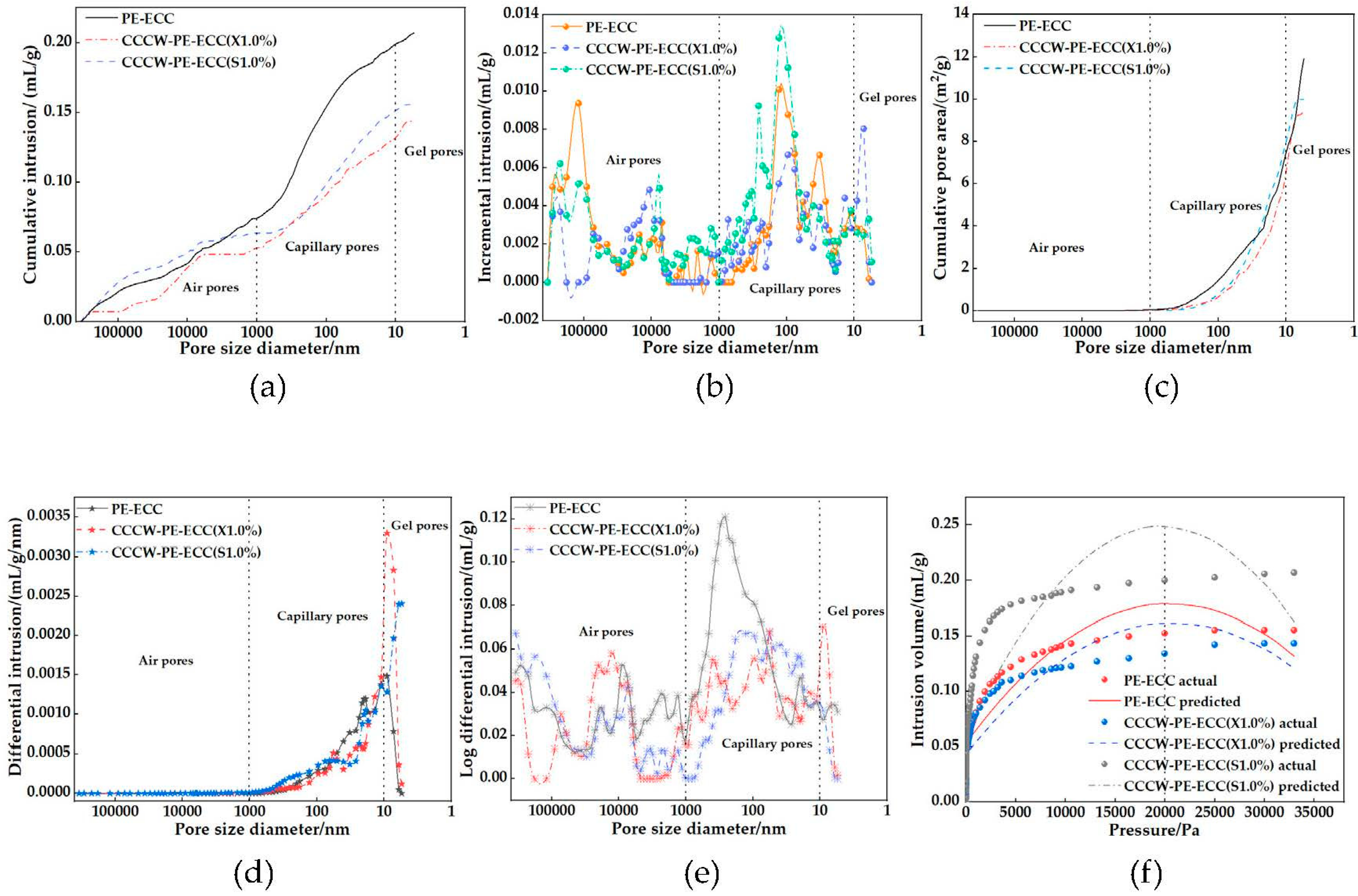

4.2. Pore Structure Testing and Analysis

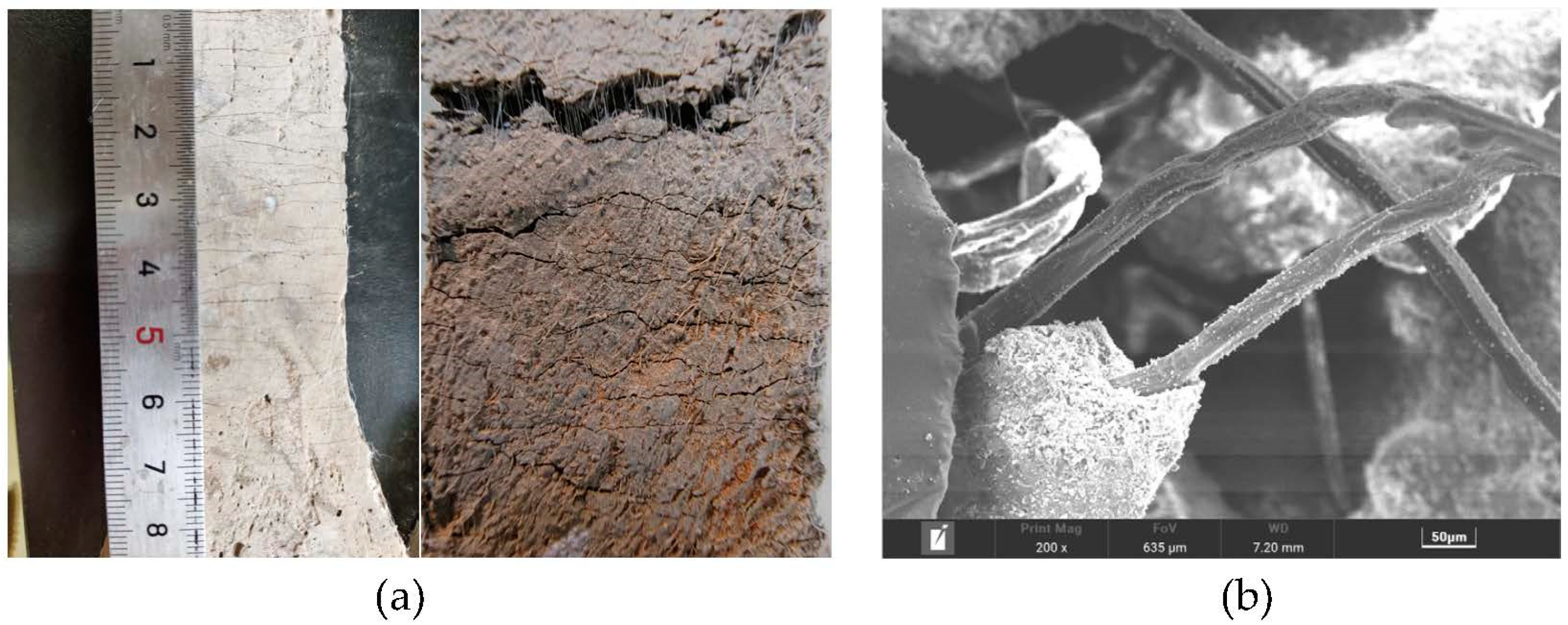

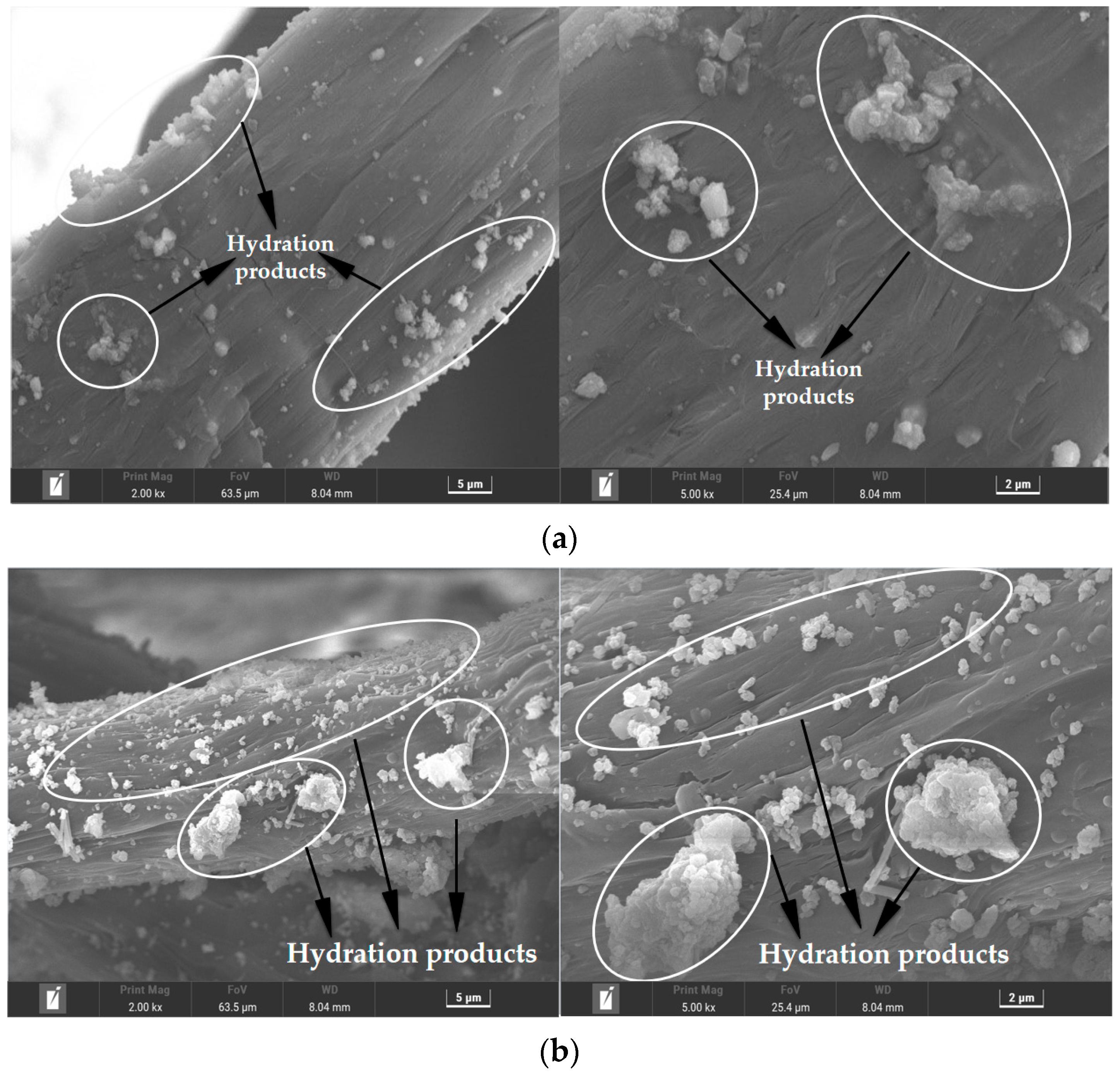

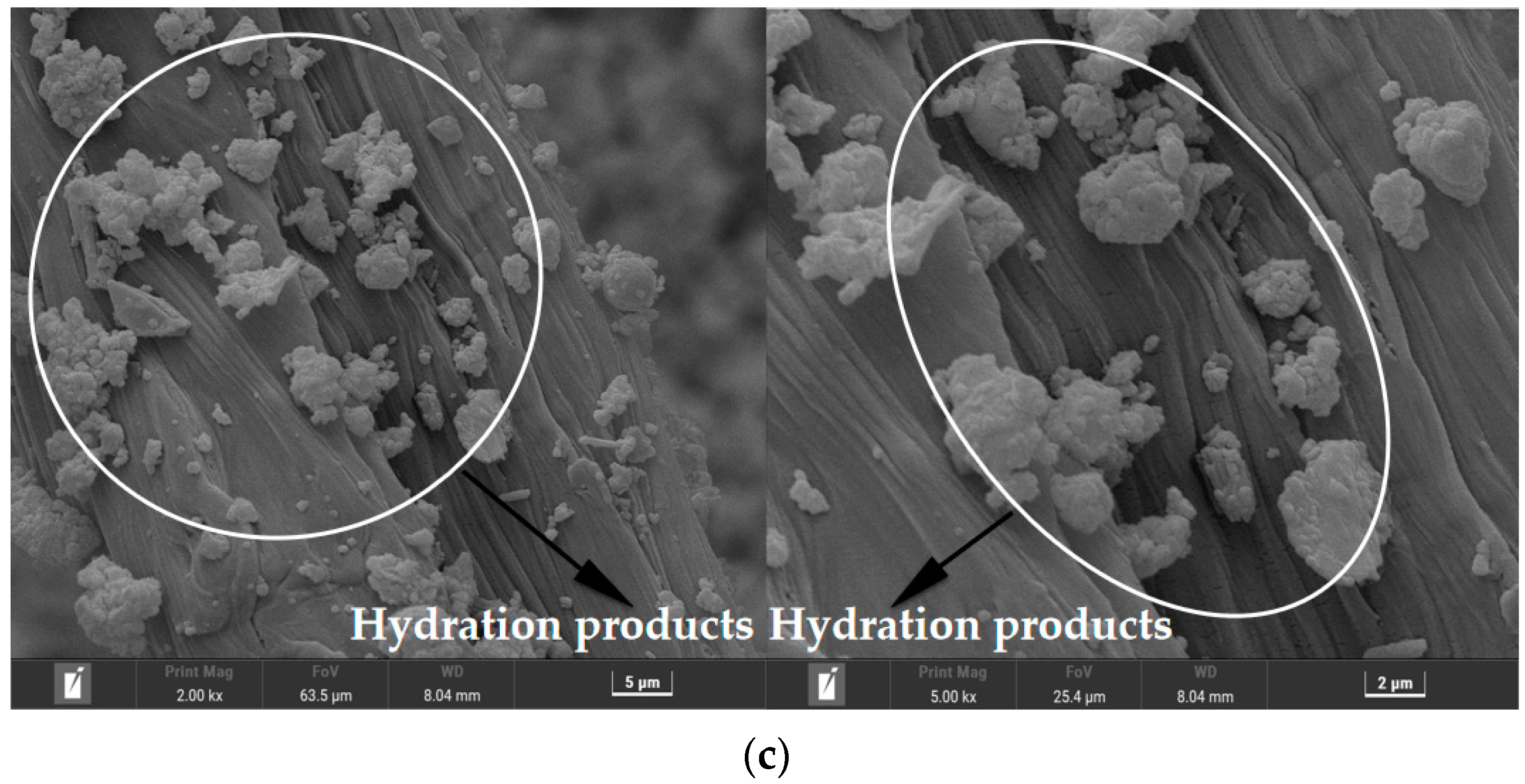

4.3. Micromorphology Test Analysis

5. Conclusions

- (1)

- With increasing CCCW doping, the mechanical properties of the PE-ECC tended to increase first and then decrease, and the mechanical properties were best when the doping amount was 1%. The mechanical properties of the PE-ECC were more obviously improved by the XYPEX-type CCCW, with a compressive strength of 53.8 MPa, flexural strength of 11.8 MPa, an ultimate tensile stress of 5.56 MPa, and an ultimate tensile strain of 7.53 MPa, which were 37.95%, 53.25%, 14.17%, and 21.65% higher than those of the reference, respectively.

- (2)

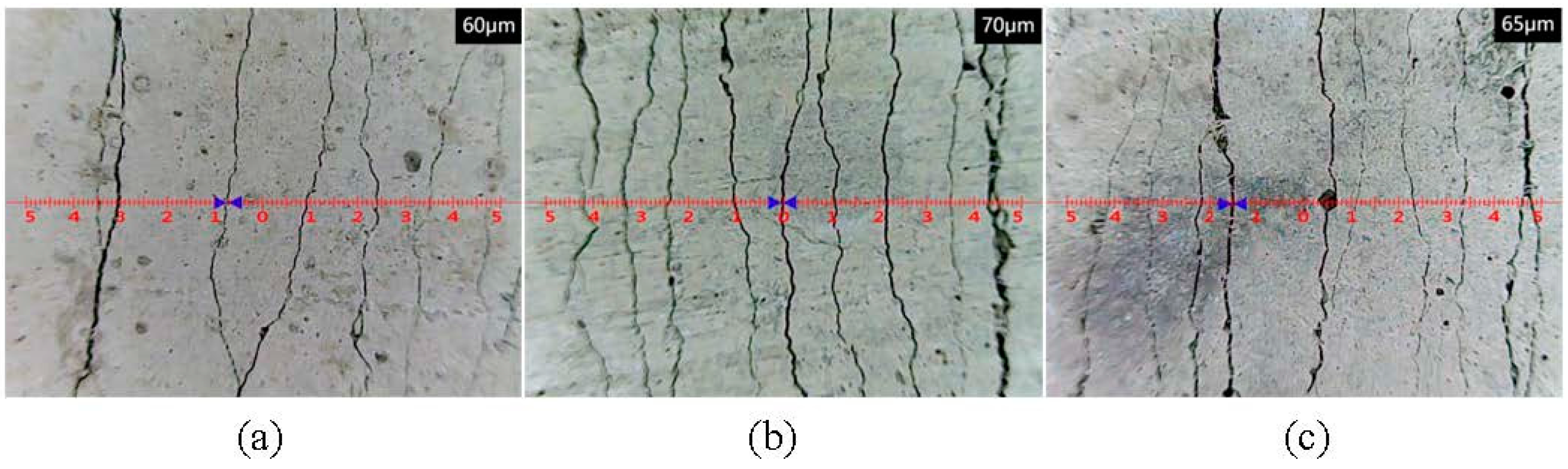

- According to crack width meter and DIC analyses, the number of cracks in the middle region of the dog-bone specimens increased, the crack tolerance increased, the distribution was more uniform, and the crack control ability and tensile ductility were enhanced, after incorporating a suitable amount of the CCCW.

- (3)

- With increased CCCW dosing, the seepage resistance of PE-ECC tended to increase and then decrease, and the best performance of PE-ECC was achieved when the dosing was 1%. CCCW-PE-ECC(X1.0%) and CCCW-PE-ECC(S1.0%) showed the smallest permeation heights, 2.6 mm and 2.8 mm, respectively, which are 69.77% and 68.18% lower than that of the baseline. The chloride ion diffusion coefficients of CCCW-PE-ECC(X1.0%) and CCCW-PE-ECC(S1.0%) exhibit the smallest values, 0.15 × 10−12 m2/s and 0.10 × 10−12 m2/s, respectively, which are 68.75% and 79.17% lower than that of the reference.

- (4)

- Laser particle size distribution meter analysis showed that the XYPEX-type CCCW particle size was finer than that of SY1000. The XRD analysis showed that both CCCWs, with suitable doping, can enhance the C-S-H gel and CaCO3 intensity diffraction peaks of the PE-ECC and that the enhancement of the XYPEX-type CCCW was more obvious. The enhancement of the XYPEX-type CCCW on the PE-ECC against chloride ion permeation is mainly due to the generation of more hydration products to fill the pores and improve the structural compactness, while the SY1000-type CCCW mainly improves the performance against chloride ion permeation because it contains acrylamide and sodium fumarate, which perform an anti-corrosion function.

- (5)

- MIP and SEM showed that the total pore volume, total pore area, permeability, and porosity of the PE-ECC decreased, and that the structure was more compact, after doping with two suitable doses of CCCW. The improvement in the pore structure of the PE-ECC was more obvious after doping with XYPEX-type CCCW. After doping with CCCW, the surface of the PE-ECC matrix was flatter, and the degree of erosion of hydration products on the PE fiber surface was reduced after chloride ion penetration.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beauchemin, S.; Fournier, B.; Duchesne, J. Evaluation of the concrete prisms test method for assessing the potential alkali-aggregate reactivity of recycled concrete aggregates. Cem. Concr. Res. 2018, 104, 25–36. [Google Scholar] [CrossRef]

- Weinberg, K.; Khosravani, M.R. On the tensile resistance of UHPC at impact. Eur. Phys. J. Spec. Top. 2018, 227, 167–177. [Google Scholar] [CrossRef]

- Liu, P.; Feng, C.; Wang, F.; Gao, Y.; Yang, J.; Zhang, W.; Yang, L. Hydrophobic and water-resisting behavior of Portland cement incorporated by oleic acid modified fly ash. Mater. Struct. 2018, 51, 38. [Google Scholar] [CrossRef]

- Song, J.; Li, Y.; Xu, W.; Liu, H.; Lu, Y. Inexpensive and non-fluorinated superhydrophobic concrete coating for anti-icing and anti-corrosion. J. Colloid Interface Sci. 2019, 541, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Song, J.; Zhao, D.; Han, Z.; Xu, W.; Lu, Y.; Liu, X.; Liu, B.; Carmalt, C.J.; Deng, X.; Parkin, I.P. Super-robust superhydrophobic concrete. J. Mater. Chem. A 2017, 5, 14542–14550. [Google Scholar] [CrossRef]

- Yin, B.; Xu, T.; Hou, D.; Zhao, E.; Hua, X.; Han, K.; Zhang, Y.; Zhang, J. Superhydrophobic anticorrosive coating for concrete through in-situ bionic induction and gradient mineralization. Constr. Build. Mater. 2020, 257, 119510. [Google Scholar] [CrossRef]

- Yeganeh, M.; Omidi, M.; Mortazavi, H.; Etemad, A.; Rostami, M.R.; Shafiei, M.E. Enhancement routes of corrosion resistance in the steel reinforced concrete by using nanomaterials. In Smart Nanoconcretes and Cement-Based Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 583–599. [Google Scholar]

- Qiao, C.; Suraneni, P.; Weiss, J. Flexural strength reduction of cement pastes exposed to CaCl2 solutions. Cem. Concr. Compos. 2018, 86, 297–305. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; She, W.; Liu, N.; Liu, Z. In situ observing the erosion process of cement pastes exposed to different sulfate solutions with X-ray computed tomography. Construct. Build. Mater. 2018, 176, 556–565. [Google Scholar] [CrossRef]

- Kayondo, M.; Combrinck, R.; Boshoff, W.P. State-of-the-art review on plastic cracking of concrete. Constr. Build. Mater. 2019, 225, 886–899. [Google Scholar] [CrossRef]

- Li, V.C. On engineered cementitious composites (ECC). J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C. Tailoring ECC for special attributes: A review. Int. J. Concr. Struct. Mater. 2012, 6, 135–144. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C.; Wu, H.C. Conditions for pseudo-strain-hardening in fiber reinforced brittle matrix composites. Appl. Mech. Rev. 1992, 45, 390–394. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C. Engineered Cementitious Composites (ECC)—Bendable Concrete for Sustainable and Resilient Infrastructure; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Zhu, H.; Yu, K.Q.; Li, V.C. Sprayable engineered cementitious composites (ECC) using calcined clay-limestone cement (LC3) and PP fiber. Cem. Concr. Compos. 2021, 115, 103868. [Google Scholar] [CrossRef]

- Figueiredo, T.C.S.P.; Curosu, I.; Gonzales, G.L.G.; Hering, M.; Silva, F.D.; Curbach, M.; Mechtcherine, V. Mechanical behavior of strain-hardening cement-based composites (SHCC) subjected to torsional loading and to combined torsional and axial loading. Mater. Des. 2021, 198, 109371. [Google Scholar] [CrossRef]

- Arce, G.A.; Noorvand, H.; Hassan, M.M.; Rupnow, T.; Dhakal, N. Feasibility of low fiber content PVA-ECC for jointless pavement application. Construct. Build. Mater. 2021, 268, 121131. [Google Scholar] [CrossRef]

- Lin, J.X.; Song, Y.; Xie, Z.H.; Guo, Y.C.; Yuan, B.; Zeng, J.J.; Wei, X. Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 2020, 29, 101097. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Sahmaran, M.; Li, M.; Li, V.C. Transport properties of engineered cementitious composites under chloride exposure. ACI Mater. J. 2007, 104, 604–611. [Google Scholar]

- Miyazato, S.; Hiraishi, Y. Transport properties and steel corrosion in ductile fiber reinforced cement composites. In Proceedings of the Eleventh International Conference on Fracture, Turin, Italy, 20–25 March 2005; pp. 20–25. [Google Scholar]

- Zhuang, S.; Wang, Q. Inhibition mechanisms of steel slag on the early-age hydration of cement. Cem. Concr. Res. 2021, 140, 106283. [Google Scholar] [CrossRef]

- Ma, H.; Yi, C.; Wu, C. Review and outlook on durability of engineered cementitious composite (ECC), Review and outlook on durability of engineered cementitious composite (ECC). Constr. Build. Mater. 2021, 287, 122719. [Google Scholar] [CrossRef]

- Kobayashi, K.; Le Ahn, D.; Rokugo, K. Effects of crack properties and water-cement ratio on the chloride proofing performance of cracked SHCC suffering from chloride attack. Cem. Concr. Compos. 2016, 69, 18–27. [Google Scholar] [CrossRef]

- Kobayashi, K.; Kojima, Y. Effect of fine crack width and water cement ratio of SHCC on chloride ingress and rebar corrosion. Cem. Concr. Compos. 2017, 80, 235–244. [Google Scholar] [CrossRef]

- Li, M.; Li, V.C. Cracking and healing of engineered cementitious composites under chloride environment. ACI Mater. J. 2011, 108, 333–340. [Google Scholar]

- Liu, H.; Zhang, Q.; Li, V.; Su, H.; Gu, C. Durability study on engineered cementitious composites (ECC) under sulfate and chloride environment. Constr. Build. Mater. 2017, 133, 171–181. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Gu, C.; Su, H.; Li, V. Self-healing of microcracks in engineered cementitious Composites under sulfate and chloride environment. Constr. Build. Mater. 2017, 153, 948–956. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Ozbakkaloglu, T. Synthetic fibers for cementitious composites: A critical and in-depth review of recent advances. Constr. Build. Mater. 2019, 207, 491–518. [Google Scholar] [CrossRef]

- Arain, M.F.; Wang, M.X.; Chen, J.Y.; Zhang, H.P. Study on PVA fiber surface modification for strain-hardening cementitious composites (PVA-SHCC). Constr. Build. Mater. 2019, 197, 107–116. [Google Scholar] [CrossRef]

- Yun, H.D.; Kim, S.W.; Lee, Y.O.; Rokugo, K. Tensile behavior of synthetic fiber-reinforced strain-hardening cement-based composite (SHCC) after freezing and thawing exposure. Cold Reg. Sci. Technol. 2011, 67, 49–57. [Google Scholar] [CrossRef]

- Wang, Y.C.; Liu, F.C.; Yu, J.T. Effect of polyethylene fiber content on physical and mechanical properties of engineered cementitious composites. Constr. Build. Mater. 2020, 251, 118917. [Google Scholar] [CrossRef]

- Yu, J.T.; Ye, J.H.; Zhao, B.; Xu, S.L.; Wang, B.; Yu, K.Q. Dynamic response of concrete frames including plain ductile cementitious composites. J. Struct. Eng. 2019, 6, 145. [Google Scholar] [CrossRef]

- Yu, K.Q.; Wang, Y.C.; Yu, J.T.; Xu, S.L. A strain-hardening cementitious composites with the tensile capacity up to 8%. Construct. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- Ye, J.H.; Yu, J.T.; Cui, C.; Wang, Y.C. Flexural size effect of ultra-high ductile concrete under different damage and ductility levels. Cem. Concr. Compos. 2021, 115, 103852. [Google Scholar] [CrossRef]

- Yu, J.T.; Dong, F.Y.; Ye, J.H. Experimental study on the size effect of ultra-high ductile cementitious composites. Construct. Build. Mater. 2020, 240, 117963. [Google Scholar] [CrossRef]

- Hu, X.Y.; Xiao, J.; Zhang, Z.D.; Wang, C.H.; Long, C.Y.; Dai, L. Effects of CCCW on properties of cement-based materials: A review. J. Build. Eng. 2022, 50, 104184. [Google Scholar] [CrossRef]

- Zha, Y.; Yu, J.; Wang, R.; He, P.; Cao, Z. Effect of ion chelating agent on self-healing performance of Cement-based materials. Construct. Build. Mater. 2018, 190, 308–316. [Google Scholar] [CrossRef]

- Zheng, K.; Yang, X.; Chen, R.; Xu, L. Application of a capillary crystalline material to enhance cement grout for sealing tunnel leakage. Construct. Build. Mater. 2019, 214, 497–505. [Google Scholar] [CrossRef]

- Cappellesso, V.G.; Dos Santos Petry, N.; Dal Molin, D.C.C.; Masuero, A.B. Use of crystalline waterproofing to reduce capillary porosity in concrete. J. Build. Pathol. Rehabil. 2016, 1, 9. [Google Scholar] [CrossRef] [Green Version]

- Azarsa, P.; Gupta, R.; Biparva, A. Assessment of self-healing and durability parameters of concretes incorporating crystalline admixtures and Portland Limestone Cement. Cem. Concr. Compos. 2019, 99, 17–31. [Google Scholar] [CrossRef]

- Escoffres, P.; Desmettre, C.; Charron, J.P. Effect of a crystalline admixture on the self-healing capability of high-performance fiber reinforced concrete in service conditions. Constr. Build. Mater. 2018, 173, 763–774. [Google Scholar] [CrossRef]

- Huang, W.; Wang, P.; Yin, W.; Zhang, L.; Shu, W. The crack resistance and impermeability properties of mortar with PP fiber and capillary crystalline material and their mechanism. Adv. Mater. Res. 2010, 168–170, 1381–1387. [Google Scholar] [CrossRef]

- Yu, Y.; Sun, T. Polymer-modified cement waterproofing coating and cementitious capillary crystalline waterproofing materials: Mechanism and applications. Key Eng. Mater. 2017, 726, 527–531. [Google Scholar] [CrossRef]

- Li, G.Y.; Huang, X.F.; Lin, J.S.; Jiang, X.; Zhang, X.Y. Activated chemicals of cementitious capillary crystalline waterproofing materials and their self-healing behavior. Construct. Build. Mater. 2019, 200, 36–45. [Google Scholar] [CrossRef]

- Jo, B.W.; Sikandar, M.A.; Baloch, Z.; Khan, R.M.A. Effect of incorporation of self healing admixture (SHA) on physical and mechanical properties of mortars. J. Ceram. Process. Res. 2015, 16, s138–s143. [Google Scholar]

- Zhang, Y.; Yang, J.; Zhang, W.; Shen, C.; Cai, X.; Zuo, L. Microstructure and mechanism analysis of cement-based capillary crystalline waterproofing material. New Build. Mater. 2017, 44, 68–70. [Google Scholar] [CrossRef]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 4, 566–574. [Google Scholar] [CrossRef]

- GB/T50082-2009; Standard for Long-Term Performance and Durability of Ordinary Concrete. China Building Industry Press: Beijing, China, 2009. (In Chinese)

- GB/T 50476-2008; Design Specification for Durability of Concrete Structures. China Construction Industry Press: Beijing, China, 2008; p. 162. (In Chinese)

- Chousidis, N.; Ioannou, I.; Rakanta, E. Effect of fly ash chemical composition on the reinforcement corrosion, thermal diffusion and strength of blended cement concretes. Construct. Build. Mater. 2016, 126, 86–97. [Google Scholar] [CrossRef]

- Liu, J.; Ou, G.F.; Qiu, Q.W. Chloride transport and microstructure of concrete with/without fly ash under atmospheric chloride condition. Construct. Build. Mater. 2017, 146, 493–501. [Google Scholar] [CrossRef]

| Ingredients (%) | SiO2 | K2O | TiO2 | Fe2O3 | CaO | Al2O3 | SO3 |

|---|---|---|---|---|---|---|---|

| Cement | 19.90 | 0.79 | 0.21 | 3.00 | 64.90 | 4.42 | 2.67 |

| Fly ash | 51.70 | 1.40 | 1.19 | 5.22 | 7.65 | 23.90 | 0.91 |

| Sand | Cement | Fly Ash | Water | HRWR | Fiber | CCCW | |

|---|---|---|---|---|---|---|---|

| PE-ECC | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 0 |

| CCCW-PE-ECC(X0.5%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 6.52 |

| CCCW-PE-ECC(X1.0%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 13.05 |

| CCCW-PE-ECC(X1.5%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 19.57 |

| CCCW-PE-ECC(X2.0%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 26.09 |

| CCCW-PE-ECC(S0.5%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 6.52 |

| CCCW-PE-ECC(S1.0%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 13.05 |

| CCCW-PE-ECC(S1.5%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 19.57 |

| CCCW-PE-ECC(S2.0%) | 474.4 | 593.0 | 711.6 | 387.1 | 4.0 | 14.7 | 26.09 |

| Total Intrusion Volume (mL/g) | Total Pore Area (m2/g) | Average Pore Diameter (nm) | Bulk Density (g/mL) | Apparent Density (g/mL) | Porosity (%) | Permeability (md) | |

|---|---|---|---|---|---|---|---|

| PE-ECC | 0.21 | 11.90 | 62.32 | 1.24 | 1.54 | 24.74 | 476.58 |

| CCCW-PE-ECC(X1.0%) | 0.14 | 9.43 | 47.54 | 1.49 | 2.16 | 19.32 | 122.34 |

| CCCW-PE-ECC(S1.0%) | 0.16 | 9.98 | 53.21 | 1.40 | 1.75 | 20.09 | 197.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Zhao, B.; Yu, J.; Xiao, H.; Long, X.; Meng, J. Effect of Cementitious Capillary Crystalline Waterproofing Materials on the Mechanical and Impermeability Properties of Engineered Cementitious Composites with Microscopic Analysis. Polymers 2023, 15, 1013. https://doi.org/10.3390/polym15041013

Tan Y, Zhao B, Yu J, Xiao H, Long X, Meng J. Effect of Cementitious Capillary Crystalline Waterproofing Materials on the Mechanical and Impermeability Properties of Engineered Cementitious Composites with Microscopic Analysis. Polymers. 2023; 15(4):1013. https://doi.org/10.3390/polym15041013

Chicago/Turabian StyleTan, Yan, Ben Zhao, Jiangtao Yu, Henglin Xiao, Xiong Long, and Jian Meng. 2023. "Effect of Cementitious Capillary Crystalline Waterproofing Materials on the Mechanical and Impermeability Properties of Engineered Cementitious Composites with Microscopic Analysis" Polymers 15, no. 4: 1013. https://doi.org/10.3390/polym15041013

APA StyleTan, Y., Zhao, B., Yu, J., Xiao, H., Long, X., & Meng, J. (2023). Effect of Cementitious Capillary Crystalline Waterproofing Materials on the Mechanical and Impermeability Properties of Engineered Cementitious Composites with Microscopic Analysis. Polymers, 15(4), 1013. https://doi.org/10.3390/polym15041013