Multilayered Composites with Carbon Nanotubes for Electromagnetic Shielding Application

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Bulk Materials

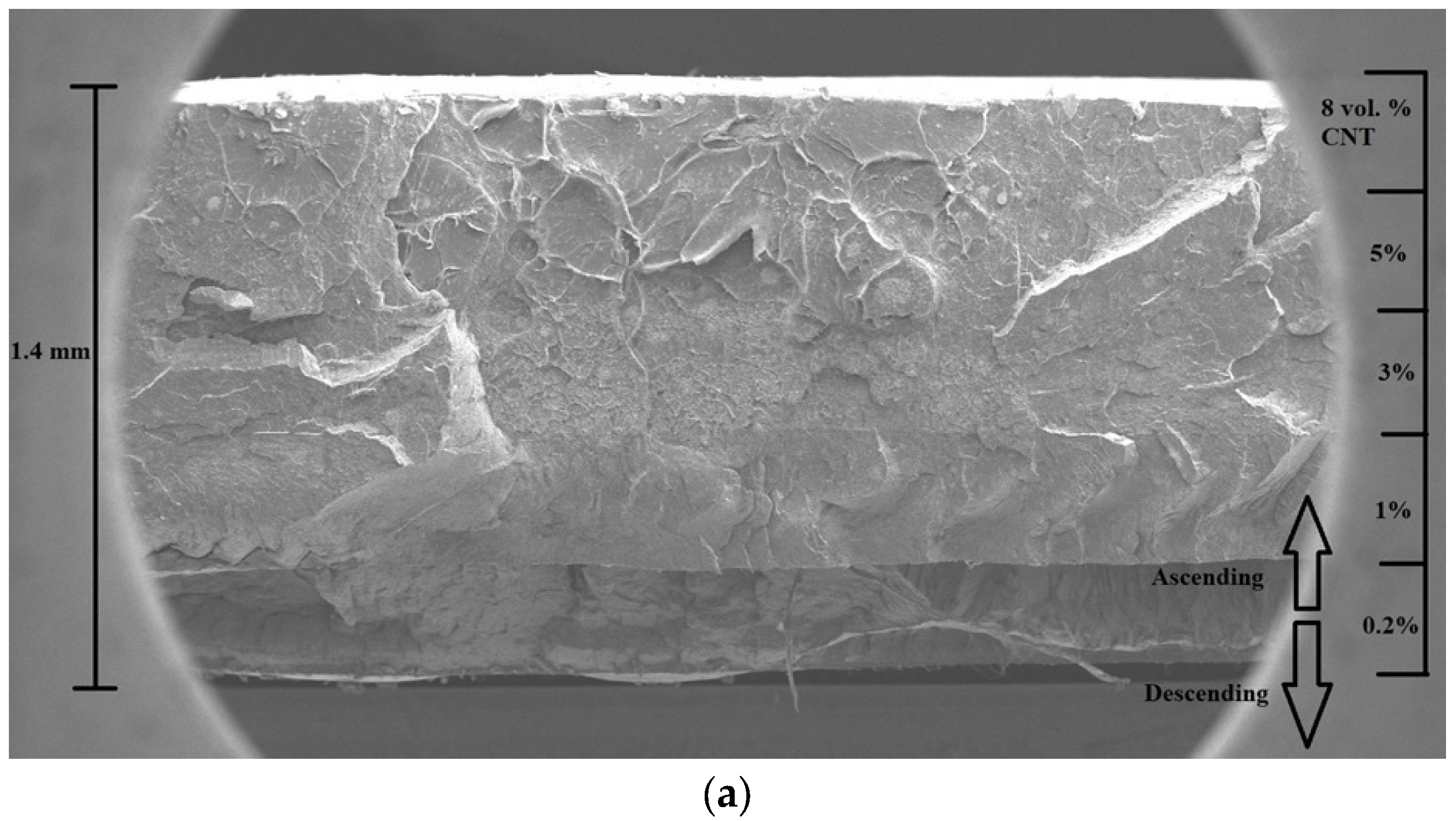

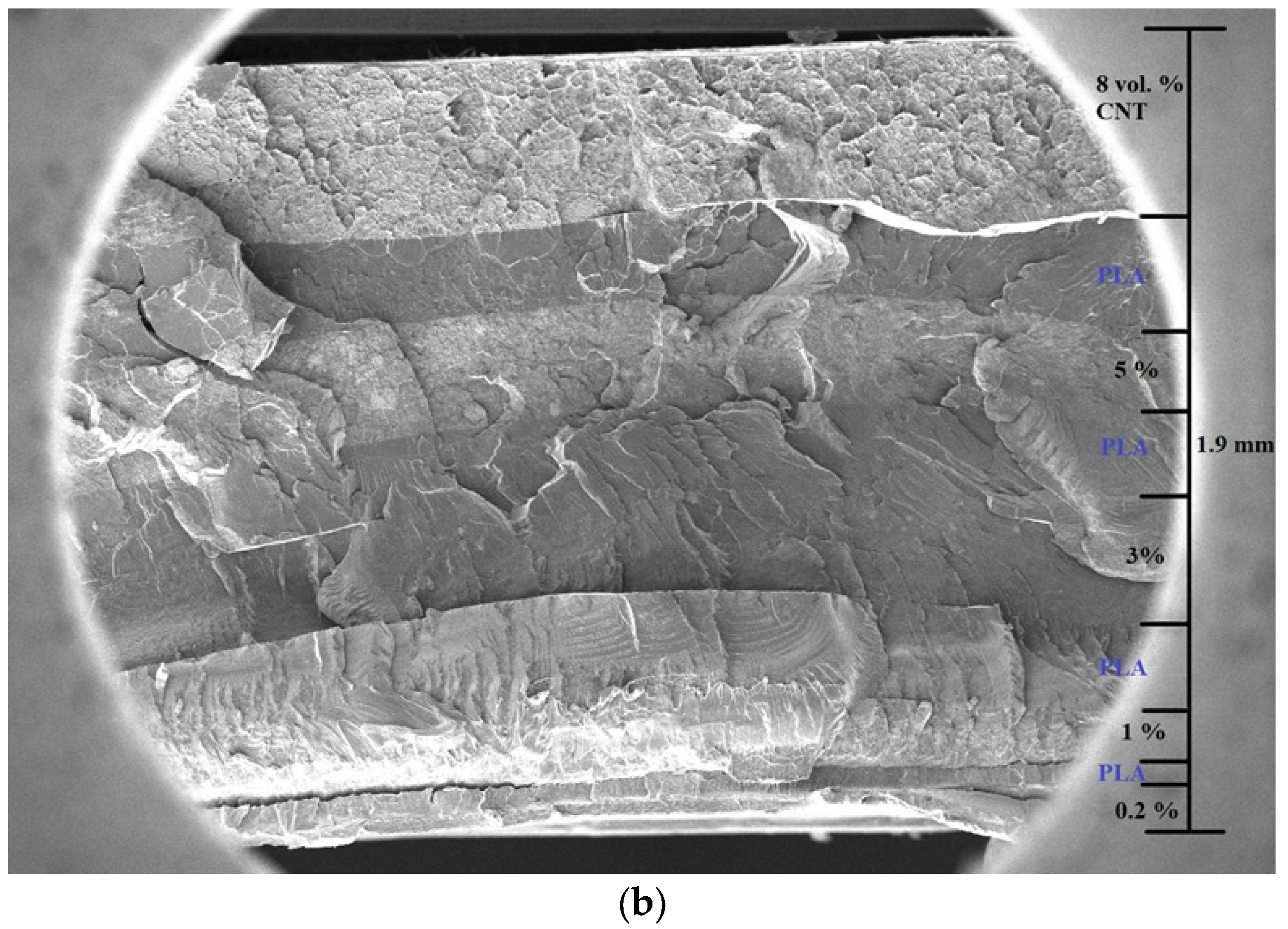

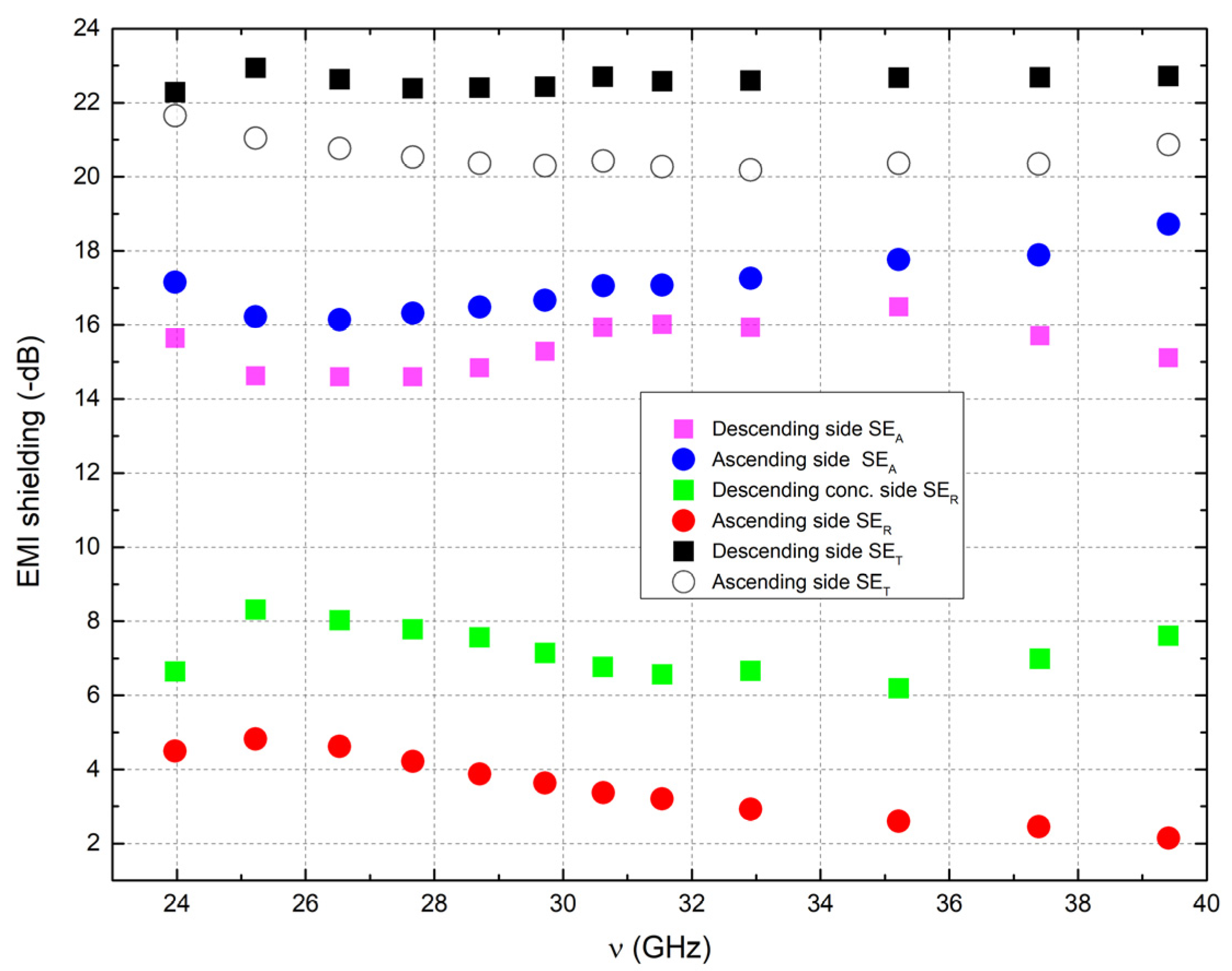

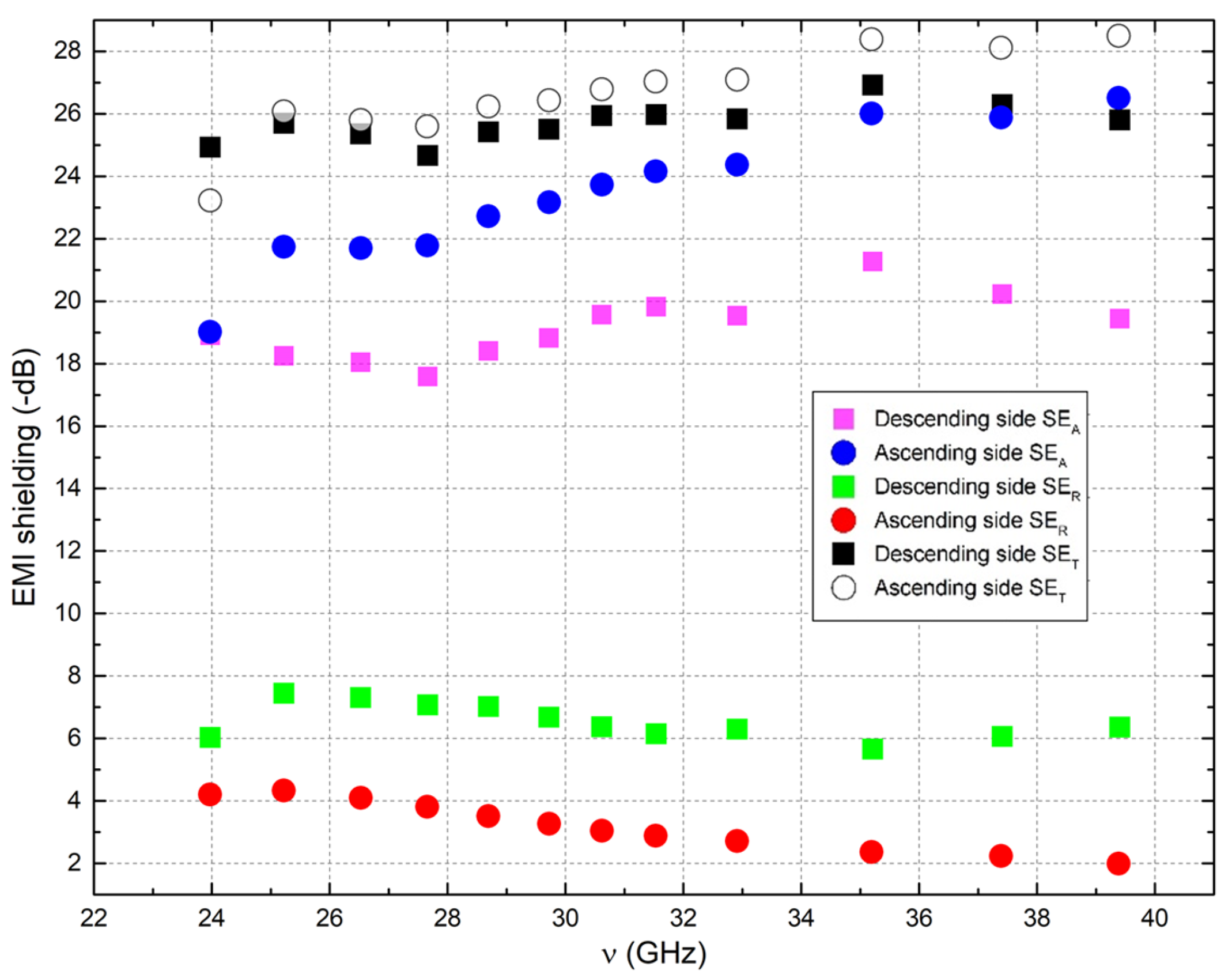

3.2. Layered Structures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Henz, D. Shielding chips reduce effects on eeg brain activity induced by electromagnetic radiation in the 5G range. Psychophysiology 2021, 58, s58. [Google Scholar]

- Wan, I.J.; Wang, X.Y.; Li, X.M.; Liao, S.Y.; Lin, Z.Q.; Hu, Y.G.; Zhao, T.; Zeng, X.L.; Li, C.H.; Yu, S.H.; et al. Ultrathin densified carbon nanotube film with “metal like” conductivity, superior mechanical strength, and ultrahigh electromagnetic interference shielding effectiveness. ACS Nano 2020, 14, 14134–14145. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Li, T.W.; Li, E.P.; Zhang, Y.J. A 2.5-D angularly stable frequency selective surface using via-based structure for 5G EMI shielding. IEEE Trans. Electromagn. Compat. 2018, 60, 768–775. [Google Scholar] [CrossRef]

- Wang, L.B.; See, K.Y.; Ling, Y.; Koh, W.J. Study of metal foams for architectural electromagnetic shielding. J. Mater. Civ. Eng. 2012, 24, 488–493. [Google Scholar] [CrossRef]

- Jalali, A.; Zhang, R.Y.; Rahmati, R.; Nofar, M.; Sain, M.; Park, C.B. Recent progress and perspective in additive manufacturing of EMI shielding functional polymer nanocomposites. Nano Res. 2022, 16, 1–17. [Google Scholar] [CrossRef]

- Lee, Y.H.; Wang, L.Y.; Tsai, C.Y.; Lee, C.W. Self-healing nanocomposites with carbon nanotube/graphene/Fe3O4 nanoparticle tricontinuos networks for electromagnetic radiation shielding. ACS Appl. Nanomater. 2022, 5, 16423–16439. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Sandler, J.K.W.; Kirk, J.E.; Kinloch, I.A.; Shaffer, M.S.P.; Windle, A.H. Ulta-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- Bertasius, P.; Meisak, D.; Macutkevic, J.; Kuzhir, P.; Selskis, A.; Volnyanko, E.; Banys, J. Fine tuning of electrical transport and dielectric properties of epoxy/carbon nanotubes composites via magnesium oxide additives. Polymers 2019, 11, 2044. [Google Scholar] [CrossRef] [Green Version]

- Deng, H.; Lin, L.; Ji, M.; Zhang, S.; Yang, M.; Fu, Q. Progress on the morphological control of conductive network in conductive polymer composites and the use as electroactive multifunctional materials. Prog. Polym. Sci. 2014, 39, 627–655. [Google Scholar] [CrossRef]

- Kuzhir, P.; Paddubskaya, A.; Plyushch, A.; Volynets, N.; Maksimenko, S.; Macutkevic, J.; Kranauskaite, I.; Banys, J.; Ivanov, E.; Kotsilkova, R.; et al. Epoxy composites filled with high surface area-carbon fillers: Optimization of electromagnetic shielding, electrical, mechanical, and thermal properties. J. Appl. Phys. 2013, 114, 164304. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H.; Thielemann, P.; Asbeck, P.; Bandaru, P.R. Enhanced dielectric constants and shielding effectiveness of, uniformly dispersed, functionalized carbon nanotubes composites. Appl. Phys. Lett. 2009, 94, 243111. [Google Scholar] [CrossRef] [Green Version]

- Al-Saleh, M.H.; Sundararaj, U. Electromagnetic interference shielding mechanisms of CNT/polymer composites. Carbon 2009, 47, 1738–1746. [Google Scholar] [CrossRef]

- Verma, P.; Saini, P.; Choudhari, V. Designing of carbon nanotube/polymer composites using melt recirculation approach: Effect of aspect ratio on mechanical, electrical and EMI shielding response. Mater. Des. 2015, 88, 269–277. [Google Scholar] [CrossRef]

- Shin, B.; Mondal, S.; Lee, M.; Kim, S.; Huh, Y.; Nah, C.H. Flexible thermoplastic polyurethane-carbon nanotubes composites for electromagnetic interference shielding and thermal management. Chem. Eng. J. 2021, 418, 129282. [Google Scholar] [CrossRef]

- Bleija, M.; Platnieks, O.; Macutkevic, J.; Starkova, O.; Gaidukovs, S. Comparison of carbon-nanoparticle-filled poly (butyle succinate-co-adipate) nanocomposites for electromagnetic applications. Nanomaterials 2022, 12, 3671. [Google Scholar] [CrossRef]

- Adrianse, L.J.; Reedijk, J.A.; Teunissen, P.A.A.; Brom, H.B.; Michels, M.A.J.; Broken-Zijp, J.C.M. High-dilution carbon-black/polymer composites: Hierarchical percolating network derived from HZ to THz ac conductivity. Phys. Rev. Lett. 1997, 78, 1755. [Google Scholar] [CrossRef]

- Palaimiene, E.; Macutkevic, J.; Banys, J.; Selskis, A.; Fierro, V.; Celzard, A.; Schaefer, S.; Shenderova, O. Ultra-low percolation threshold in epoxy resin-onion-like carbon composites. Appl. Phys. Lett. 2018, 113, 033105. [Google Scholar] [CrossRef]

- Wang, C.; Murugadosss, V.; Kong, J.; He, Z.F.; Mai, X.M.; Shao, Q.; Chen, Y.J.; Guo, L.; Liu, C.T.; Angaiah, S.; et al. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon 2018, 140, 696–733. [Google Scholar] [CrossRef]

- Gupta, S.; Tai, N.H. Carbon materials and their composites for electromagnetic interference shielding effectiveness in X-band. Carbon 2019, 152, 159–187. [Google Scholar] [CrossRef]

- Singh, K.; Ohlan, A.; Pham, V.H.; Balasubramaniyan, R.; Varshney, S.; Jang, J.; Hur, S.H.; Choi, W.M.; Kumar, M.; Dhawan, S.K.; et al. Nanostructured graphene/Fe3O4 incorporated polyaniline as a high performance shield agains electromagnetic pollution. Nanoscale 2013, 5, 2411–2420. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.X.; Ma, T.; Shu, J.C.; Cao, M.S. Confinedly tailoring Fe3O4 clusters-NG to tune electromagnetic parameters and microwave absorption with broaden bandwith. Chem. Eng. J. 2018, 332, 321–330. [Google Scholar] [CrossRef]

- Castro-Aguire, E.; Iniguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaseem, B.; Hamad, K.; Deri, F.; Ko, G.I. A review on recent researches on polylactic acid/carbon nanotubes composites. Polym. Bull. 2016, 74, 2921–2937. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, P.; Du, Z.; Liu Ch Shen, C.; Wang, Y. Electromagnetic interference shielding enhancement of poly(lactic acid)—Based carbonaceous nanocomposites by poly(ethylene oxide)—Assisted segregated structure: A comparative study of carbon nanotubes and grapheme nanoplatelets. Adv. Compos. Hybrid Mater. 2022, 5, 209–219. [Google Scholar] [CrossRef]

- Shi, S.; Peng, Z.; Jing, J.; Yang, L.; Chen, Y. 3D printing of delicately controllable cellular nanocomposites based on polylactic acid incorporating grapheme/carbon nanotube hybrids for efficient electromagnetic interference shielding. ACS Sustain. Chem. Eng. 2020, 8, 796–7972. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, K.; Zhang, X.; Hou, J.; Chen, J. Lightweight electromagnetic interference shielding poly(L-lactic acid)/poly(D-lactic acid)carbon nanotubes composite foams prepared by supercritical CO2 foaming. Int. J. Biol. Macromol. 2022, 210, 11–20. [Google Scholar] [CrossRef]

- Tao, J.R.; Yang, D.; Yang, Y.; He, Q.M.; Fei, B.; Wang, M. Migration mechanism of carbon nanotubes and matching viscosity-dependen morphology in Co-continuos Poly(lactic acid)/(Polyε-caprolactone) blend: Towards electromagnetic shielding enhancement. Polymer 2022, 252, 124963. [Google Scholar] [CrossRef]

- Song, W.L.; Cao, M.S.; Lu, M.M.; Bi, S.; Wang, C.Y.; Liu, J.; Yuan, J.; Fan, L.Z. Flexible graphene/polymer composite films in sandwich structures for effective electromagnetic interference shielding. Carbon 2014, 66, 67–76. [Google Scholar] [CrossRef]

- Sajid, H.M.; Afzal, H.; Irfan, M.; Saleem, M.; Jan, R.H.; Javed, S.; Akram, M.A. Design of multilayered 2D nanomaterial composite structures for EMI shielding analysis. ACS Omega 2022, 7, 35586–35594. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, H.; Lan, T.; Bai, Z.; Liu, X. Facile preparation of graphene film and sandwiched flexible poly(arylene ether nitrile)/graphene composite films with high EMI shielding efficiency. Compos. Part A 2022, 154, 106777. [Google Scholar] [CrossRef]

- Wang, M.; Tang, X.H.; Cai, J.H.; Wu, H.; Shen, J.B.; Guo, S.Y. Fabrication, mechanisms and perespectives of conductive polymer composites with multiple interfaces for electromagnetic interference shielding: A review. Carbon 2021, 177, 377–402. [Google Scholar] [CrossRef]

- Grigas, J. Microwave dielectric spectroscopy of ferroelectrics. Ferroelectrics 2009, 380, 37–41. [Google Scholar] [CrossRef]

- Gaidukovs, S.; Zukulis, E.; Bochkov, I.; Vaivodiss, R.; Gaidukova, G. Enhanced mechanical, conductivity and dielectric characteristics of ethylene vinyl acetate copolymer composites filled with carbon nanotubes. J. Thermoplast. Compos. Mater. 2018, 31, 1161–1180. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Neibolts, N.; Barkane, A.; Gaidukova, G.; Thakur, V.K. Poly(buthylene succinate) and graphene nanoplatelet-based sustanaible functional nanocomposite materials: Structure properties relationship. Mater. Today Chem. 2020, 18, 100351. [Google Scholar] [CrossRef]

- Jonsher, A.K. Dielectric relaxation in solids. J. Phys. D Appl. Phys. 1999, 32, R57–R70. [Google Scholar] [CrossRef]

- Lin, B.; Chen, G.D.; He, F.A.; Li, Y.; Yang, Y.; Shi, B.; Feng, F.R.; Chen, S.Y.; Lam, K.H. Preparation of MWCNTs/PVDF composites with high-content β form crystalline of PVDF and enhanced dielectric constant by electrospinning-hot pressing method. Diam. Relat. Mater. 2023, 131, 109556. [Google Scholar] [CrossRef]

- Plyushch, A.; Macutkevic, J.; Svirskas, S.; Banys, J.; Plausinaitiene, V.; Bychanok, D.; Maksimenko, S.A.; Selskis, A.; Sokal, A.; Lapko, K.N.; et al. Silicon carbide/phosphate ceramics composite for electromagnetic shielding applications whiskers vs particles. Appl. Phys. Lett. 2019, 114, 183105. [Google Scholar] [CrossRef]

- Plyushch, A.; Macutkevic, J.; Kuzhir, P.; Sokal, A.; Lapko, K.; Selskis, A.; Banys, J. Synergy effects in electromagnetic properties of phosphate ceramics with silicon carbide whiskers and carbon nanotubes. Appl. Sci. 2019, 9, 4388. [Google Scholar] [CrossRef] [Green Version]

- Root, D.E.; Verspecht, J.; Horn, J.; Marcu, M. X-Parameters; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Wang, T.; Chen, G.; Zhu, J.; Gong, H.; Zhang, L.; Wu, H. Deep understanding of impedance matching and quarter wavelength theory in electromagnetic wave absorption. J. Colloid Interface Sci. 2021, 595, 1–5. [Google Scholar] [CrossRef] [PubMed]

| Sample | (g/cm3) | Tg (℃) | Tm (°C) | Xc (%) | E (MPa) | σ (MPa) | ε (%) |

|---|---|---|---|---|---|---|---|

| 0% | 1.254 | 50 | 165 | 34 | 819.6 ± 32.5 | 44.1 ± 6.9 | 7.6 ± 0.7 |

| 0.2% | 1.261 | 54 | 165 | 42 | 847.4 ± 66.9 | 48.1 ± 4.1 | 6.9 ± 1.6 |

| 1% | 1.266 | 53 | 164 | 38 | 892.0 ± 14.8 | 50.9 ± 0.2 | 6.8 ± 0.1 |

| 3% | 1.282 | 53 | 166 | 42 | 1024.9 ± 41.0 | 52.3 ± 7.3 | 5.9 ± 0.5 |

| 5% | 1.292 | 52 | 164 | 40 | 1182.9 ± 66.2 | 52.7 ± 2.6 | 5.1 ± 0.8 |

| 8% | 1.310 | 54 | 165 | 45 | 879.3 ± 140.4 | 39.9 ± 12.1 | 4.8 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bertašius, P.; Plyushch, A.; Macutkevič, J.; Banys, J.; Selskis, A.; Platnieks, O.; Gaidukovs, S. Multilayered Composites with Carbon Nanotubes for Electromagnetic Shielding Application. Polymers 2023, 15, 1053. https://doi.org/10.3390/polym15041053

Bertašius P, Plyushch A, Macutkevič J, Banys J, Selskis A, Platnieks O, Gaidukovs S. Multilayered Composites with Carbon Nanotubes for Electromagnetic Shielding Application. Polymers. 2023; 15(4):1053. https://doi.org/10.3390/polym15041053

Chicago/Turabian StyleBertašius, Povilas, Artyom Plyushch, Jan Macutkevič, Jūras Banys, Algirdas Selskis, Oskars Platnieks, and Sergejs Gaidukovs. 2023. "Multilayered Composites with Carbon Nanotubes for Electromagnetic Shielding Application" Polymers 15, no. 4: 1053. https://doi.org/10.3390/polym15041053

APA StyleBertašius, P., Plyushch, A., Macutkevič, J., Banys, J., Selskis, A., Platnieks, O., & Gaidukovs, S. (2023). Multilayered Composites with Carbon Nanotubes for Electromagnetic Shielding Application. Polymers, 15(4), 1053. https://doi.org/10.3390/polym15041053