Thermal and Bulk Properties of Triblock Terpolymers and Modified Derivatives towards Novel Polymer Brushes

Abstract

:1. Introduction

- (a).

- Due to the complexity of the system, very low domain periodicities for the PB domains can be formed without miscibility constraints.

- (b).

- Poly(butadiene) can be chemically modified leading to the addition of the -OH functional group in each PB monomeric unit, making the modified PB a sacrificial segment during the film formation, a fact that renders the use of homopolymer brushes unnecessary.

2. Materials and Methods

2.1. Materials

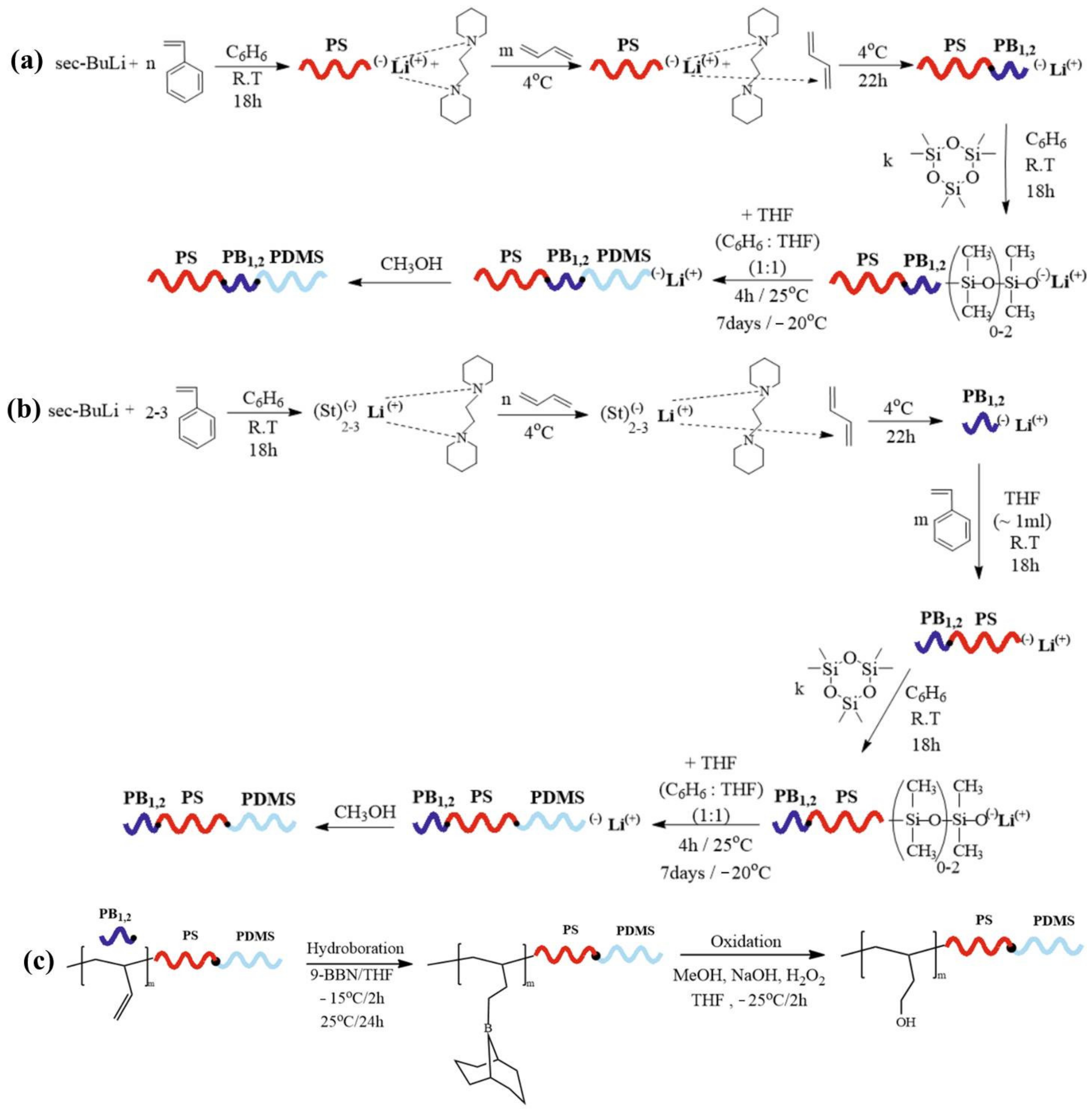

2.1.1. Synthesis of PS-b-PB1,2-b-PDMS

2.1.2. Synthesis of PB1,2-b-PS-b-PDMS

2.1.3. Chemical Modification Reactions of PB1,2

2.2. Methods

3. Results and Discussion

3.1. Structure/Properties Relationship

3.2. Sample 1 (Sample Number as Indicated in Table 1)

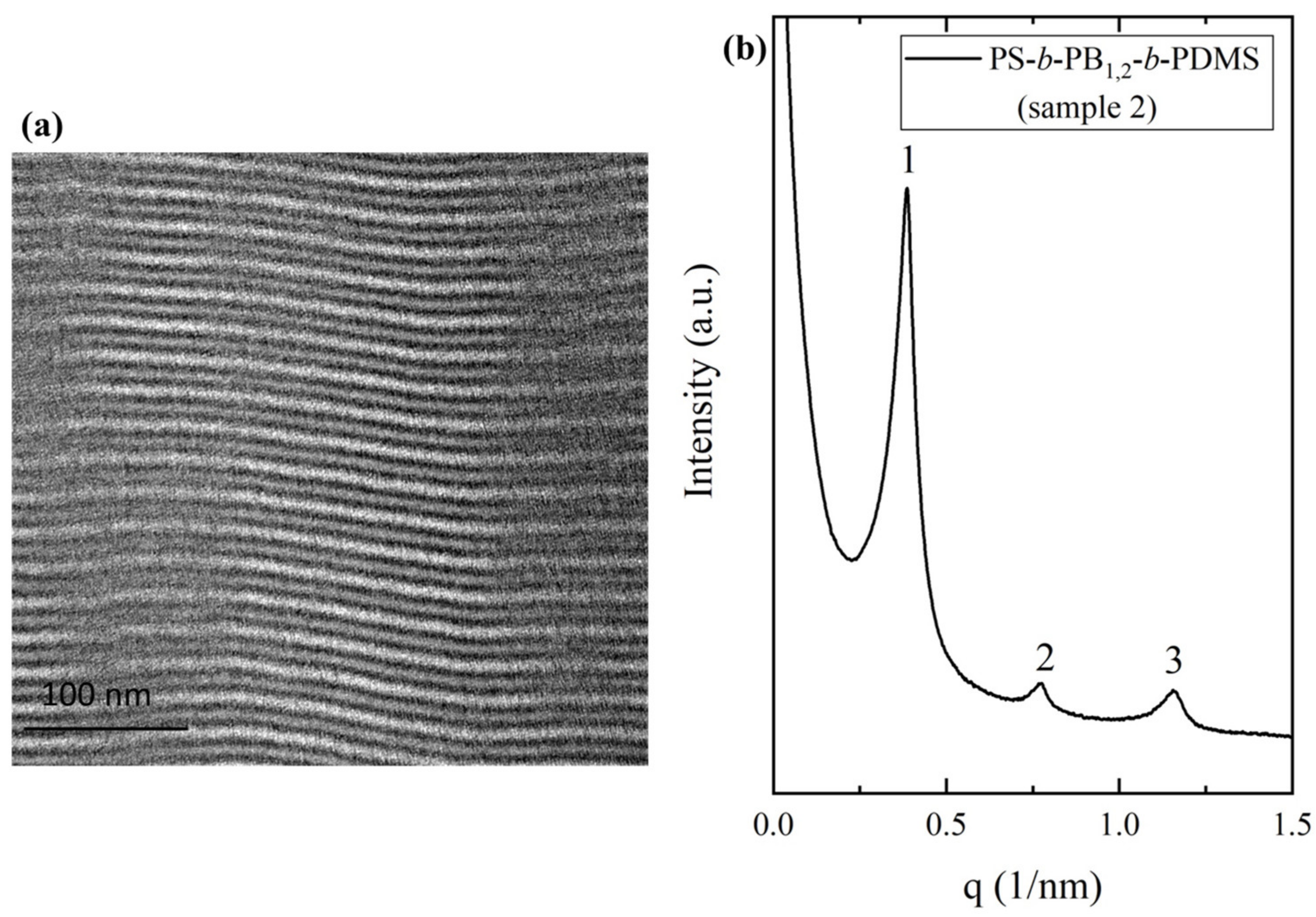

3.3. Sample 2 (Sample Number as Indicated in Table 1)

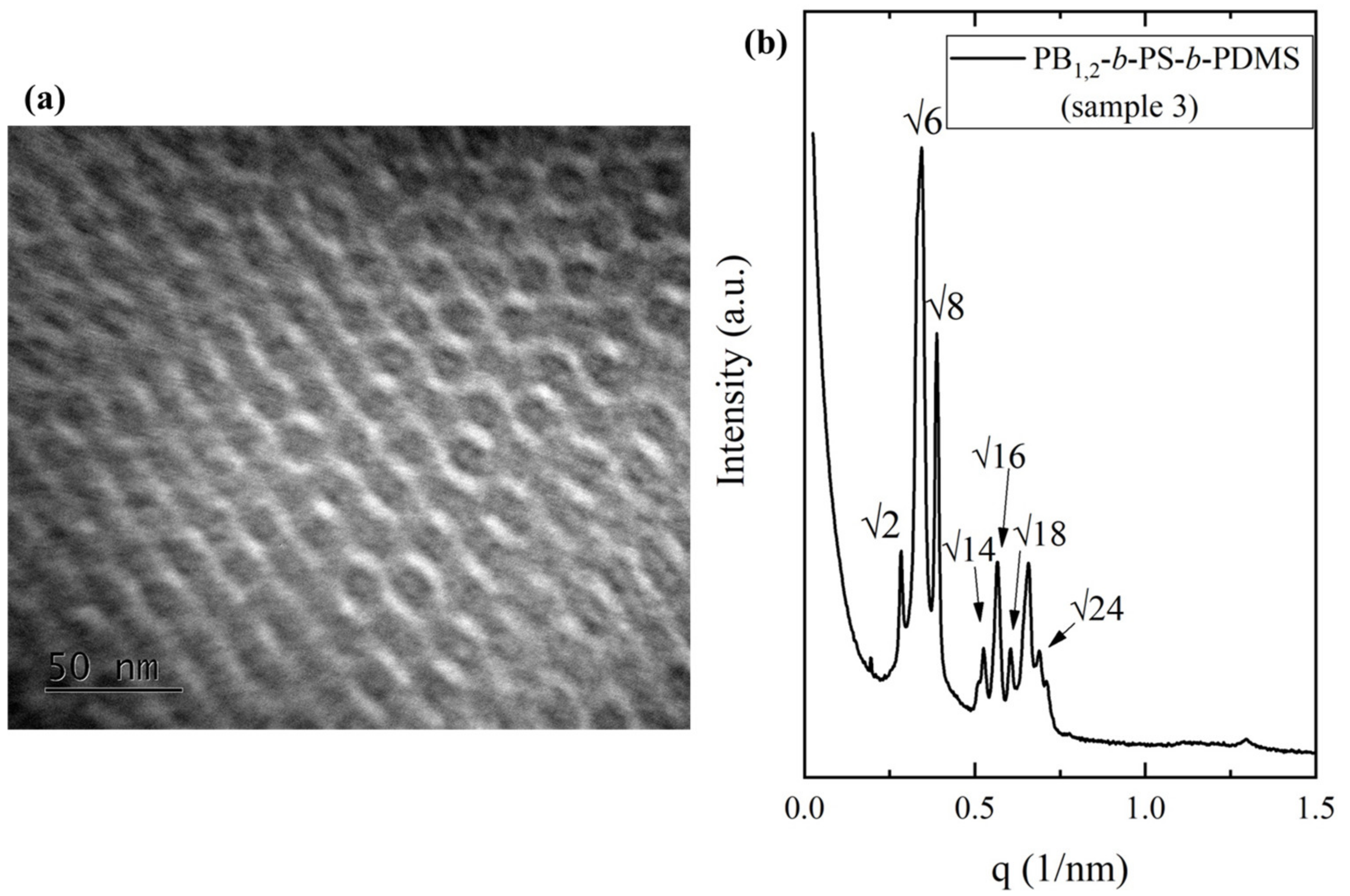

3.4. Sample 3 (Sample Number as Indicated in Table 1)

3.5. Chemical Modification Reactions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Angelopoulou, P.P.; Moutsios, I.; Manesi, G.-M.; Ivanov, D.A.; Sakellariou, G.; Avgeropoulos, A. Designing high χ copolymer materials for nanotechnology applications: A systematic bulk vs. thin films approach. Prog. Polym. Sci. 2022, 135, 101625. [Google Scholar] [CrossRef]

- Park, C.; Yoon, J.; Thomas, E.L. Enabling nanotechnology with self-assembled block copolymer patterns. Polymer 2003, 44, 6725–6760. [Google Scholar] [CrossRef]

- Bates, F.S. Polymer-Polymer Phase Behavior. Science 1991, 251, 898–904. [Google Scholar] [CrossRef]

- Bates, F.S.; Fredrickson, G.H. Block Copolymer Thermodynamics: Theory and Experiment. Ann. Rev. Phys. Chem. 1990, 41, 525–557. [Google Scholar] [CrossRef]

- Sinturel, C.; Bates, F.S.; Hillmyer, M.A. High χ-Low N Block Polymers: How Far Can We Go? ACS Macro Lett. 2015, 4, 1044–1050. [Google Scholar] [CrossRef]

- Tureau, M.S.; Epps, T.H., III. Nanoscale Networks in Poly[isoprene-block-styrene-block-(methyl methacrylate)] Triblock Copolymers. Macromol. Rapid Commun. 2009, 30, 1751–1755. [Google Scholar] [CrossRef]

- Lee, J.; Park, J.; Jung, J.J.; Lee, D.; Chang, T. Phase Behavior of Polystyrene-b-polyisoprene-b-poly(methyl methacrylate) Triblock Terpolymer upon Solvent Vapor Annealing. Macromolecules 2019, 52, 5122–5130. [Google Scholar] [CrossRef]

- Lee, S.; Subramanian, A.; Tiwale, N.; Kisslinger, K.; Mumtaz, M.; Shi, L.-Y.; Aissou, K.; Nam, C.-Y.; Ross, C.A. Resolving Triblock Terpolymer Morphologies by Vapor-Phase Infiltration. Chem. Mater. 2021, 32, 5309–5316. [Google Scholar] [CrossRef]

- Zapsas, G.; Patil, Y.; Bilalis, P.; Gnanou, Y.; Hadjichristidis, N. Poly(vinylidene fluoride)/Polymethylene-Based Block Copolymers and Terpolymers. Macromolecules 2019, 52, 1976–1984. [Google Scholar] [CrossRef]

- Hong, S.; Higuchi, T.; Sugimori, H.; Kaneko, T.; Abetz, V.; Takahara, A.; Jinnai, H. Highly oriented and ordered double-helical morphology in ABC triblock terpolymer films up to micrometer thickness by solvent evaporation. Polym. J. 2012, 44, 567–572. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.-F.; Chiu, P.-T.; Yang, C.-Y.; Xie, Y.-C.; Lee, J.-Y.; Tsai, J.C.; Prasad, I.; Jinnai, H.; Thomas, E.L.; Ho, R.-M. Networks with controlled chirality via self-assembly of chiral triblock terpolymers. Sci. Adv. 2020, 6, eabc3644. [Google Scholar] [CrossRef]

- Lee, W.Y.; Chapman, D.V.; Yu, F.; Tait, W.R.T.; Thedford, R.P.; Freychet, G.; Zhernekov, M.; Estroff, L.A.; Wiesner, U.B. Triblock Terpolymer Thin Film Nanocomposites Enabling Two-Color Optical Super-Resolution Microscopy. Macromolecules 2022, 55, 9452–9464. [Google Scholar] [CrossRef]

- Cao, X.; Mao, W.; Mai, Y.; Han, L.; Che, S. Formation of Diverse Ordered Structures in ABC Triblock Terpolymer Templated Macroporous Silicas. Macromolecules 2018, 51, 4381–4396. [Google Scholar] [CrossRef]

- Sun, T.; Tang, P.; Qiu, F.; Yang, Y.; Shi, A.-C. Formation of Single Gyroid Nanostructure by Order-Order Phase Transition Path in ABC Triblock Terpolymers. Macromol. Theory Simul. 2017, 26, 1700023. [Google Scholar] [CrossRef]

- Aissou, K.; Mumtaz, M.; Marcasuzza, P.; Brochon, C.; Cloutet, E.; Fleury, G.; Hadziioannou, G. Highly Ordered Nanoring Arrays Formed by Templated Si-Containing Triblock Terpolymer Thin Films. Small 2017, 13, 1603184. [Google Scholar] [CrossRef]

- Choi, H.K.; Aimon, N.M.; Kim, X.Y.; Gwyther, J.; Manners, I.; Ross, C.A. Hierarchical Templating of a BiFeO3-CoFe2O4 Multiferroic Nanocomposite by a Triblock Terpolymer Film. ACS Nano 2014, 8, 9248–9254. [Google Scholar] [CrossRef]

- Brittain, W.J.; Minko, S. A structural definition of polymer brushes. J. Polym. Sci. Part A Polym. Chem. 2007, 45, 3505–3512. [Google Scholar] [CrossRef]

- Zhao, B.; Brittain, W.J. Polymer brushes: Surface-immobilized macromolecules. Prog. Polym. Sci. 2000, 25, 677–710. [Google Scholar] [CrossRef]

- Feng, C.; Huang, X. Polymer Brushes: Efficient Synthesis and Applications. Acc. Chem. Res. 2018, 51, 2314–2323. [Google Scholar] [CrossRef]

- Edmonson, S.; Osborne, L.V.; Huck, W. Polymer Brushes via surface-initiated polymerizations. Chem. Soc. Rev. 2004, 33, 14–22. [Google Scholar] [CrossRef]

- Chen, W.-L.; Cordero, R.; Tran, H.; Ober, C.K. 50th Anniversary Perspective: Polymer Brushes: Novel Surfaces for Future Materials. Macromolecules 2017, 50, 4089–4113. [Google Scholar] [CrossRef]

- Olivier, A.; Meyer, F.; Raquez, J.-M.; Damman, P.; Dubois, P. Surface-initiated controlled polymerization as a convenient method for designing functional polymer brushes: From self-assembled monolayers to patterned surfaces. Prog. Polym. Sci. 2012, 37, 157–181. [Google Scholar] [CrossRef]

- Zhang, M.; Muller, A.H.E. Cylindrical Polymer Brushes. J. Polym. Sci. Part A Polym. Chem. 2005, 43, 3461–3481. [Google Scholar] [CrossRef]

- Alaboalirat, M.; Qi, L.; Arrington, K.J.; Qian, S.; Keum, J.K.; Mei, H.; Littrell, K.C.; Sumpter, B.G.; Carillo, J.-M.Y.; Verduzco, R. Amphiphilic Bottlebrush Block Copolymers: Analysis of Aqueous Self-Assembly by Small-Angle Neutron Scattering and Surface Tension Measurements. Macromolecules 2018, 52, 465–476. [Google Scholar] [CrossRef]

- Ludwigs, S.; Böker, A.; Voronov, A.; Rehse, N.; Magerle, R.; Krausch, G. Self-assembly of functional nanostructures from ABC triblock copolymers. Nat. Mater. 2003, 2, 744–747. [Google Scholar] [CrossRef]

- Luzinov, I.; Tsukruk, V.V. Ultrathin Triblock Copolymer Films on Tailored Polymer Brushes. Macromolecules 2002, 35, 5963–5973. [Google Scholar] [CrossRef]

- Huizhen Mah, A.; Mei, H.; Basu, P.; Laws, T.S.; Ruchhoeft, P.; Verduzco, R.; Stein, G.E. Swelling responses of surface-attached bottlebrush polymer networks. Soft Matter. 2018, 14, 6728–6736. [Google Scholar]

- Mao, G.; Wang, J.; Clingman, S.R.; Ober, C.K.; Chen, J.T.; Thomas, E.L. Molecular Design, Synthesis, and Characterization of Liquid Crystal-Coil Diblock Copolymers with Azobenzene Side Groups. Macromolecules 1997, 30, 2556–2567. [Google Scholar] [CrossRef]

- Politakos, N.; Weinman, C.J.; Paik, M.Y.; Sundaram, H.S.; Ober, C.K.; Avgeropoulos, A. Synthesis, molecular, and morphological characterization of initial and modified diblock copolymers with organic acid chloride derivatives. J. Polym. Sci. Part A Polym. Chem. 2011, 49, 4292–4305. [Google Scholar] [CrossRef]

- Politakos, N.; Moutsios, I.; Manesi, G.-M.; Artopoiadis, K.; Tsitoni, K.; Moschovas, D.; Piryazev, A.A.; Kotlyarskiy, D.S.; Kortaberria, G.; Ivanov, D.A.; et al. Molecular and Structure-Properties Comparison of an Anionically Synthesized Diblock Copolymer of the PS-b-PI Sequence and Its Hydrogenated or Sulfonated Derivatives. Polymers 2021, 13, 4167. [Google Scholar] [CrossRef]

- Jung, Y.S.; Ross, C.A. Orientation-Controlled Self-Assembled Nanolithography Using a Polystyrene-Polydimethylsiloxane Block Copolymer. Nano Lett. 2007, 7, 2046–2050. [Google Scholar] [CrossRef]

- O’ Driscoll, B.M.D.; Kelly, R.A.; Shaw, M.; Mokarian-Tabari, P.; Liontos, G.; Ntetsikas, K.; Avgeropoulos, A.; Petkov, N.; Morris, M.A. Achieving structural control with thin polystyrene-b-polydimethylsiloxane block copolymer films: The complex relationship of interface chemistry, annealing methodology and process conditions. Eur. Polym. J. 2013, 49, 3445–3554. [Google Scholar] [CrossRef]

- Lo, T.-Y.; Krishnan, M.R.; Lu, K.-Y.; Ho, R.-M. Silicon-containing block copolymers for lithographic applications. Prog. Polym. Sci. 2018, 77, 19–68. [Google Scholar] [CrossRef]

- Durand, W.J.; Blachut, G.; Maher, M.J.; Sirard, S.; Tein, S.; Carlson, M.C.; Asano, Y.; Zhou, S.X.; Lane, A.P.; Bates, C.M.; et al. Design of High-χ Block Copolymers for Lithography. J. Polym. Sci. Part A Polym. Chem. 2015, 53, 344–352. [Google Scholar] [CrossRef]

- Jung, Y.S.; Chang, J.B.; Verploegen, E.; Berggren, K.K.; Ross, C.A. A path to ultranarrow patterns using self-assembled lithography. Nano Lett. 2010, 10, 1000–1005. [Google Scholar] [CrossRef]

- Hu, H.; Gopinadhan, M.; Osuji, C.O. Directed self-assembly of block copolymers: A tutorial review of strategies for enabling nanotechnology with soft matter. Soft Matter 2014, 10, 3867–3889. [Google Scholar] [CrossRef]

- Jeong, J.W.; Park, W.I.; Do, L.-M.; Park, J.-H.; Kim, T.-H.; Chae, G.; Jung, Y.S. Nanotransfer Printing with sub-10 nm Resolution Realized using Directed Self-Assembly. Adv. Mater. 2012, 24, 3526–3531. [Google Scholar] [CrossRef]

- Liu, C.-C.; Han, E.; Onses Serdar, M.; Thode, C.J.; Ji, S.; Gopalan, P.; Nealey, P.F. Fabrication of Lithographically Defined Chemically Patterned Polymer Brushes and Mats. Macromolecules 2011, 44, 1876–1885. [Google Scholar] [CrossRef]

- Ipekci, H.H.; Arkaz, H.H.; Serdar Onses, M.; Hancer, M. Superhydrophobic coatings with improved mechanical robustness based on polymer brushes. Surf. Coat. Technol. 2016, 299, 162–168. [Google Scholar] [CrossRef]

- Borah, D.; Rasappa, S.; Senthamaraikannan, R.; Kosmala, B.; Shaw, M.T.; Holmes, J.D.; Morris, M.A. Orientation and Alignment Control of Microphase-Separated PS-b-PDMS Substrate Patterns via Polymer Brush Chemistry. ACS Appl. Mater. Interfaces 2013, 5, 88–97. [Google Scholar] [CrossRef]

- Miskaki, C.; Moutsios, I.; Manesi, G.-M.; Artopoiadis, K.; Chang, C.-Y.; Bersenev, E.A.; Moschovas, D.; Ivanov, D.A.; Ho, R.-M.; Avgeropoulos, A. Self-Assembly of Low-Molecular-Weight Assymetric Linear Triblock Terpolymers: How Low Can We Go? Molecules 2020, 25, 5527. [Google Scholar] [CrossRef] [PubMed]

- Liontos, G.; Manesi, G.-M.; Moutsios, I.; Moschovas, D.; Piryazev, A.A.; Bersenev, E.A.; Ivanov, D.A.; Avgeropoulos, A. Synthesis, Molecular Characterization, and Phase Behavior of Miktoarm Star Copolymers of the ABn and AnB (n = 2 or 3) Sequences, Where A Is Polystyrene and B Is Poly(dimethylsiloxane). Macromolecules 2022, 55, 88–99. [Google Scholar] [CrossRef]

- Fetters, J.L.; Lohse, J.D.; Milner, T.S.; Graessley, W.W. Packing Length Influence in Linear Polymer Melts on the Entanglement, Critical, and Reptation Molecular Weights. Macromolecules 1999, 32, 6847–6851. [Google Scholar] [CrossRef]

- Avgeropoulos, A.; Paraskeva, S.; Hadjichristidis, N.; Thomas, E.L. Synthesis and Microphase Separation of Linear Triblock Terpolymers of Polystyrene, High 1,4-Polybutadiene, and High 3,4-Polyisoprene. Macromolecules 2002, 35, 4030–4035. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, Z.-G. Morphology of ABC triblock copolymers. Macromolecules 1995, 28, 7215–7223. [Google Scholar] [CrossRef]

- Nakazawa, H.; Ohta, T. Microphase separation of ABC-type triblock copolymers. Macromolecules 1993, 26, 5503–5511. [Google Scholar] [CrossRef]

- Feng, X.; Burke, C.J.; Zhuo, M.; Guo, H.; Yang, K.; Reddy, A.; Prasad, I.; Ho, R.M.; Avgeropoulos, A.; Grason, G.M.; et al. Seeing mesoatomic distortions in soft-matter crystals of a double-gyroid block copolymer. Nature 2019, 575, 175–179. [Google Scholar] [CrossRef]

| Sample | A-b-B-b-C | (a) (g/mol) | (a) (g/mol) | (a) (g/mol) | (a) (g/mol) | ĐSEC (b) | fA (c) | fB (c) | fC (c) | 1,2-Microstructure (c) (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | PS-b-PB1,2-b-PDMS | 4.000 | 4.000 | 10.000 | 18.000 | 1.06 | 0.22 | 0.22 | 0.56 | 100 |

| 2 | PS-b-PB1,2-b-PDMS | 4.000 | 1.500 | 4.700 | 10.200 | 1.04 | 0.39 | 0.15 | 0.46 | 100 |

| 3 | PB1,2-b-PS-b-PDMS | 1.400 | 4.100 | 3.400 | 8.900 | 1.07 | 0.16 | 0.46 | 0.38 | 100 |

| χ | PS | PB1,2 | PDMS |

|---|---|---|---|

| PS | - | 0.130 | 0.479 |

| PB1,2 | 0.130 | - | 0.074 |

| Modified Sample | A-b-B-b-C | (g/mol) | (g/mol) | (g/mol) | (g/mol) | fA | fB | fC |

|---|---|---|---|---|---|---|---|---|

| 1 | PS-b-PB1,2-b-PDMS (modified) | 4.000 | 5.300 | 10.000 | 19.300 | 0.21 | 0.27 | 0.52 |

| 2 | PS-b-PB1,2-b-PDMS (modified) | 4.000 | 1.900 | 4.700 | 10.600 | 0.38 | 0.18 | 0.44 |

| 3 | PB1,2-b-PS-b-PDMS (modified) | 1.900 | 4.100 | 3.400 | 9.400 | 0.20 | 0.44 | 0.36 |

| Sample | A-b-B-b-C | Contact Angle (Degree) Unmodified (±2°) | Contact Angle (Degree) Modified (±2°) |

|---|---|---|---|

| 1 | PS-b-PB1,2-b-PDMS | 102.7 | 85.0 |

| 2 | PS-b-PB1,2-b-PDMS | 103.2 | 83.1 |

| 3 | PB1,2-b-PS-b-PDMS | 101.3 | 88.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Artopoiadis, K.; Miskaki, C.; Manesi, G.-M.; Moutsios, I.; Moschovas, D.; Piryazev, A.A.; Karabela, M.; Zafeiropoulos, N.E.; Ivanov, D.A.; Avgeropoulos, A. Thermal and Bulk Properties of Triblock Terpolymers and Modified Derivatives towards Novel Polymer Brushes. Polymers 2023, 15, 848. https://doi.org/10.3390/polym15040848

Artopoiadis K, Miskaki C, Manesi G-M, Moutsios I, Moschovas D, Piryazev AA, Karabela M, Zafeiropoulos NE, Ivanov DA, Avgeropoulos A. Thermal and Bulk Properties of Triblock Terpolymers and Modified Derivatives towards Novel Polymer Brushes. Polymers. 2023; 15(4):848. https://doi.org/10.3390/polym15040848

Chicago/Turabian StyleArtopoiadis, Konstantinos, Christina Miskaki, Gkreti-Maria Manesi, Ioannis Moutsios, Dimitrios Moschovas, Alexey A. Piryazev, Maria Karabela, Nikolaos E. Zafeiropoulos, Dimitri A. Ivanov, and Apostolos Avgeropoulos. 2023. "Thermal and Bulk Properties of Triblock Terpolymers and Modified Derivatives towards Novel Polymer Brushes" Polymers 15, no. 4: 848. https://doi.org/10.3390/polym15040848

APA StyleArtopoiadis, K., Miskaki, C., Manesi, G.-M., Moutsios, I., Moschovas, D., Piryazev, A. A., Karabela, M., Zafeiropoulos, N. E., Ivanov, D. A., & Avgeropoulos, A. (2023). Thermal and Bulk Properties of Triblock Terpolymers and Modified Derivatives towards Novel Polymer Brushes. Polymers, 15(4), 848. https://doi.org/10.3390/polym15040848