Interface Characterization of Consolidated PPGF Tapes on PPGF Mat Material

Abstract

:1. Introduction

1.1. Motivation

1.2. State of the Art

2. Materials and Methods

2.1. Materials Used

2.2. Methodology and Setup

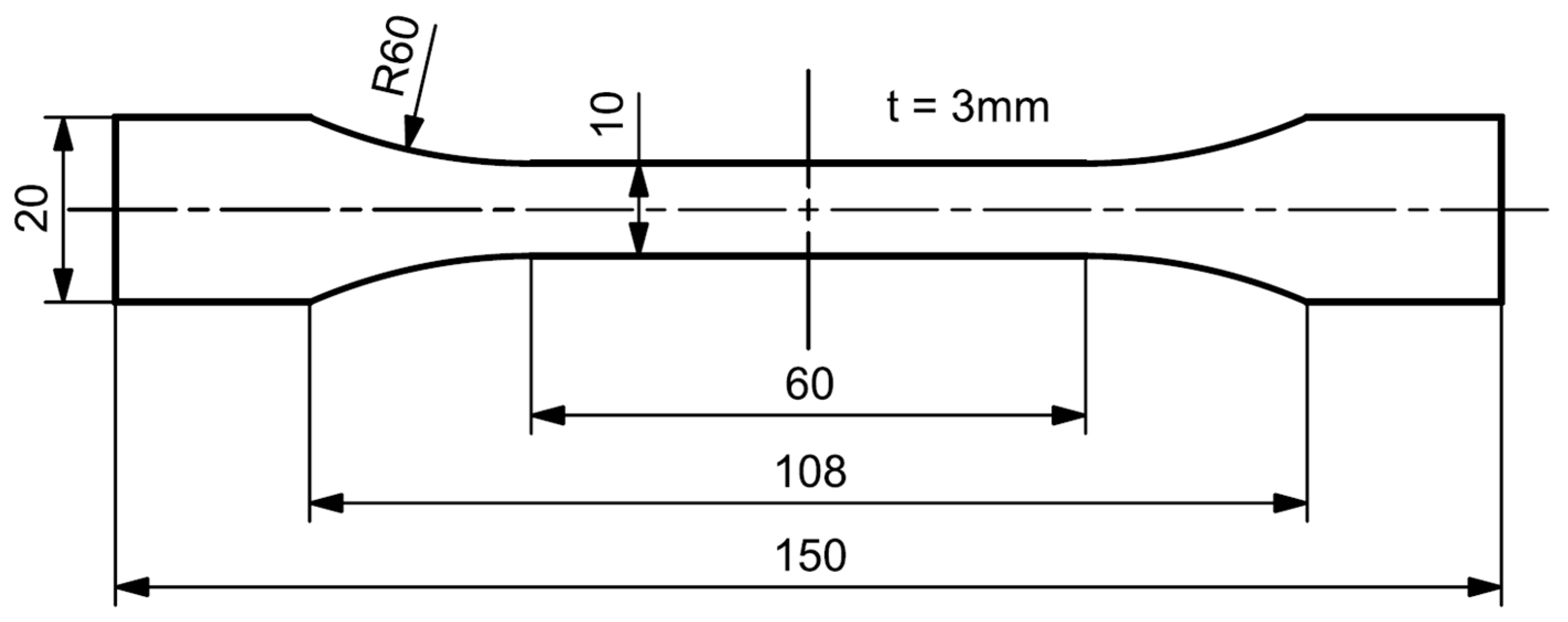

2.2.1. Tensile Tests of the PPGF Mat Material

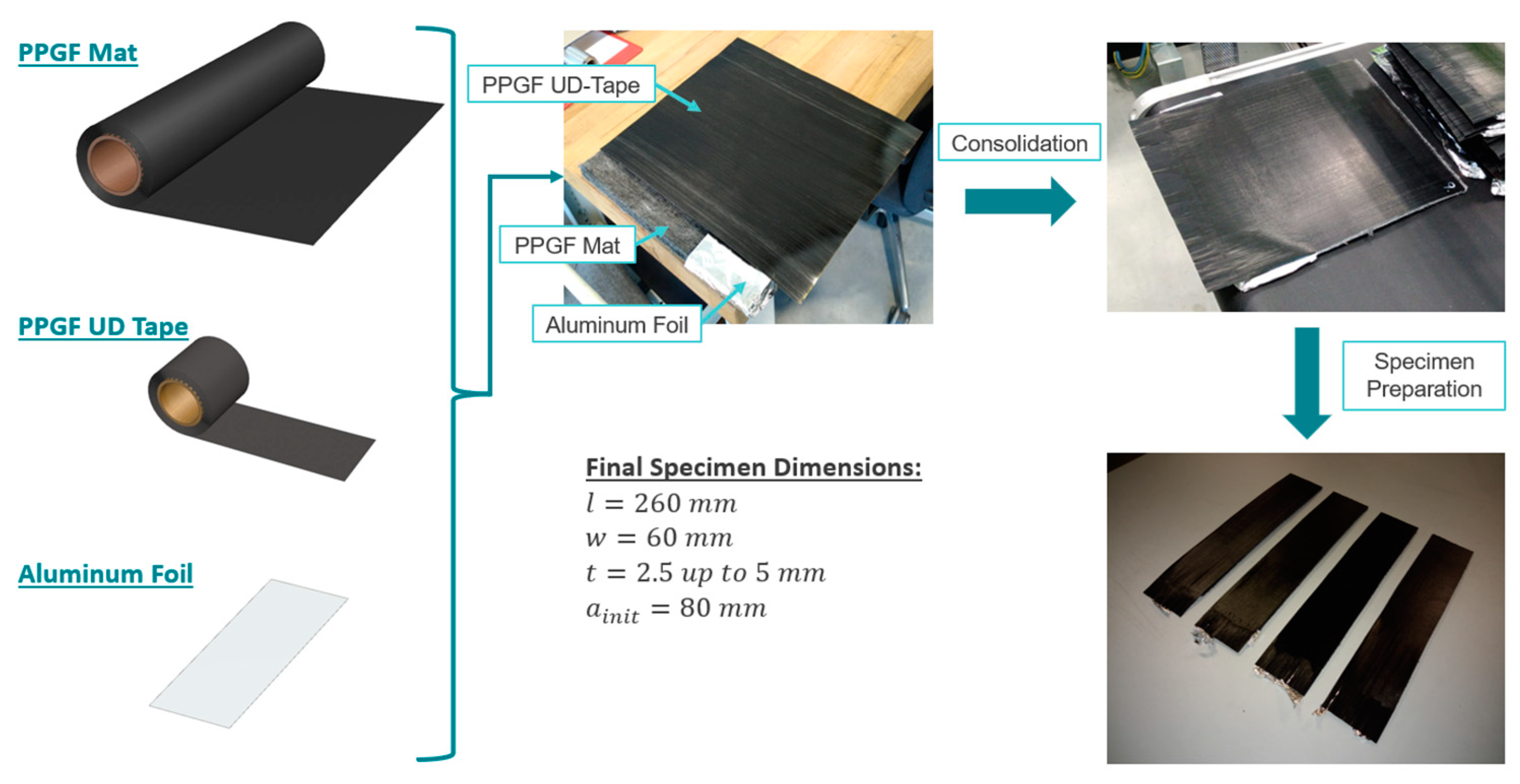

2.2.2. Mandrel Peel Test Specimen

3. Results

3.1. Tensile Tests of the PPGF Mat Material

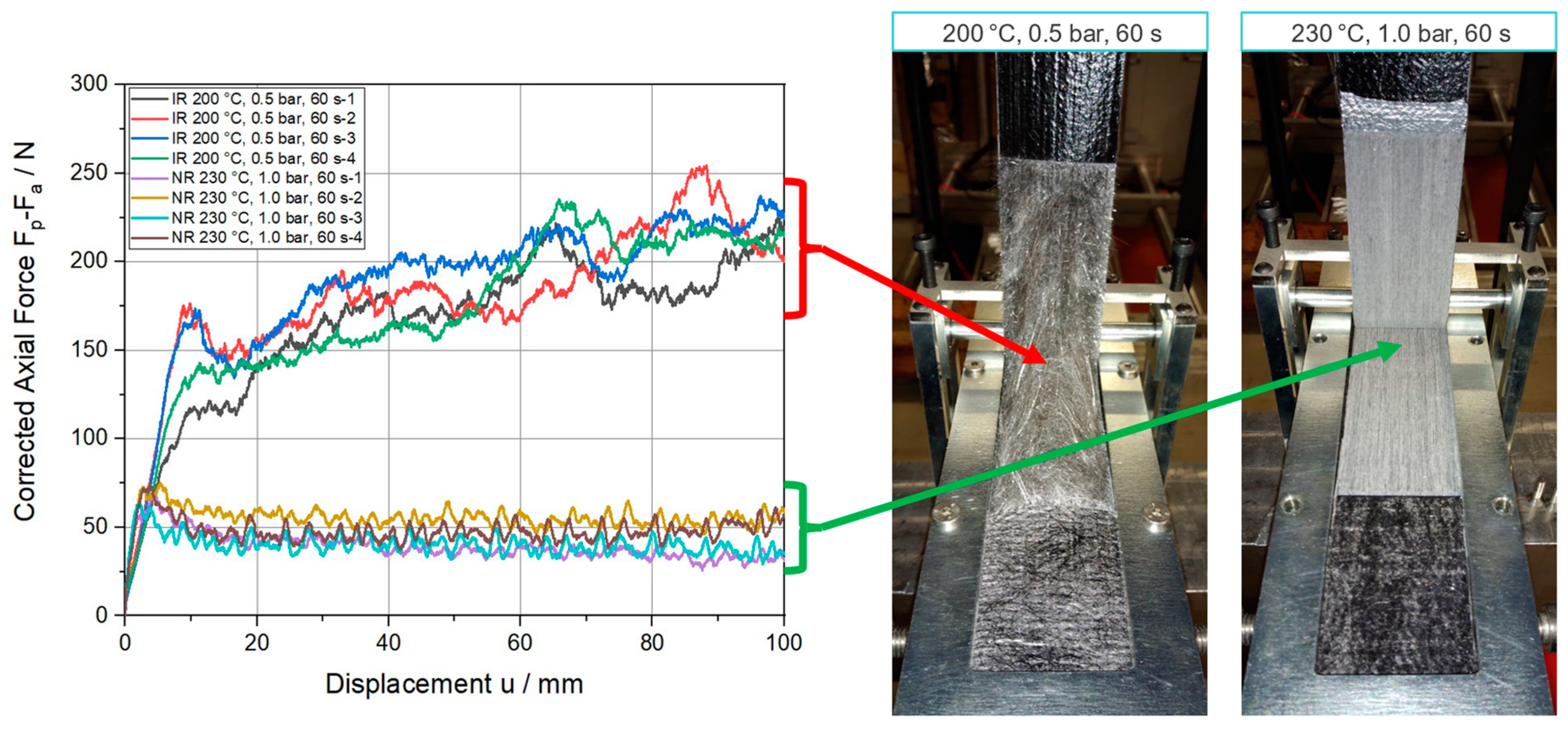

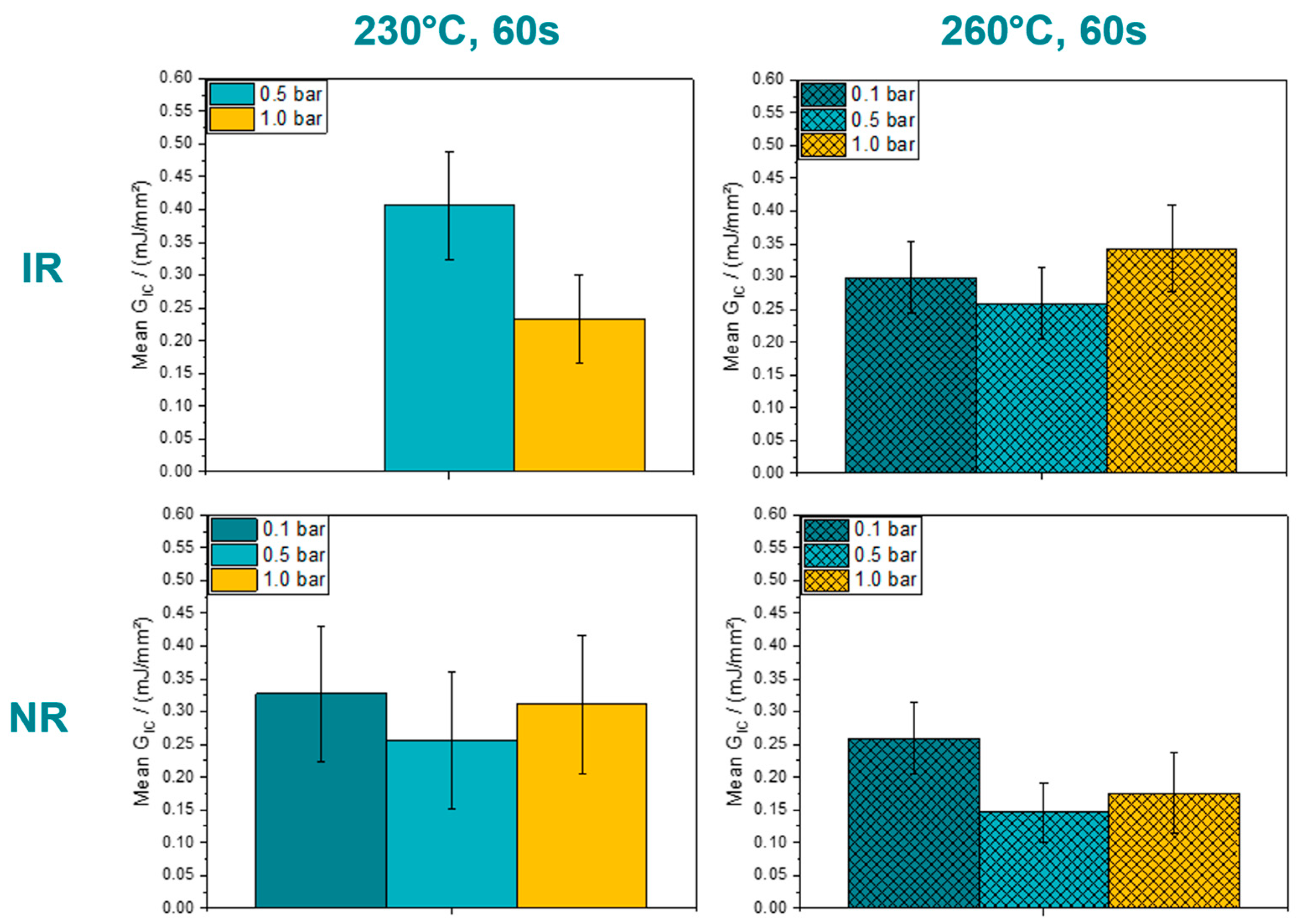

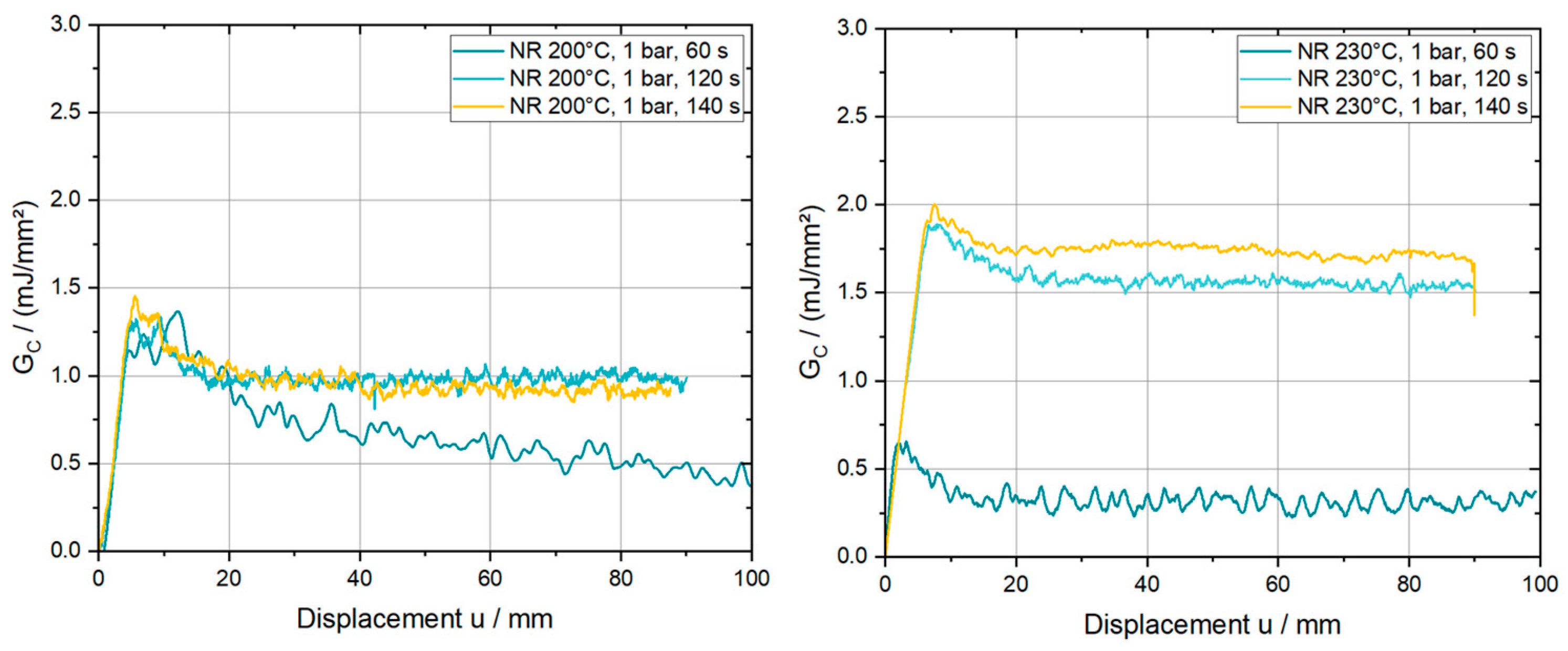

3.2. Mandrel Peel Test

4. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Federation of Reinforced Plastics. Handbook—Reinforced Plastics/Composites, 3rd ed.; Springer Vieweg: Frankfurt am Main, Germany, 2014. [Google Scholar]

- Schürmann, H. Konstruieren Mit Faser-Kunststoff-Verbund, 2nd ed.; Springer Vieweg: Berlin, Germany, 2007. [Google Scholar]

- Kropka, M.; Muehlbacher, M.; Neumeyer, T.; Altstaedt, V. From UD-tape to final part—a comprehensive approach towards thermoplastic composites. Procedia CIRP 2017, 66, 96–100. [Google Scholar] [CrossRef]

- Rettenwander, T.; Fischlschweiger, M.; Machado, M.; Steinbichler, G.; Major, Z. Tailored patch placement on a base load carrying laminate: A computational structural optimisation with experimental validation. Compos. Struct. 2014, 116, 48–54. [Google Scholar] [CrossRef]

- Tierney, J.; Gillespie, J.W. Modeling of In Situ Strength Development for the Thermoplastic Composite Tow Placement Process. J. Compos. Mater. 2006, 40, 1413–1506. [Google Scholar] [CrossRef]

- Mantell, S.C.; Springer, G.S. Manufacturing Process Models for Thermoplastic Composites. J. Compos. Mater. 1992, 26, 2348–2377. [Google Scholar] [CrossRef]

- Sonmez, F.O.; Hahn, H.T. Analysis of the On-Line Consolidation Process in Thermoplastic Composite Tape Placement. J. Compos. Mater. 1997, 10, 543–572. [Google Scholar] [CrossRef]

- Kawashita, L.F.; Moore, D.R.; Williams, J.G. Protocols for the Measurement of Adhesive Fracture Toughness by Peel Tests. J. Adhes. 2006, 82, 973–995. [Google Scholar] [CrossRef]

- Grouve, W.J.B.; Warnet, L.L.; Akkterman, R. Critical assessment of the mandrel peel test for fiber reinforced thermoplastic laminates. Eng. Fract. Mech. 2013, 101, 96–108. [Google Scholar] [CrossRef]

- Nettles, A.T.; Gregory, E.D.; Jackson, J.R. Using the Climbing Drum Peel (CDP) Test to Obtain a GIC Value for Core/Face Sheet Bonds. J. Compos. Mater. 2007, 41, 2863–2969. [Google Scholar] [CrossRef]

- Daghia, F.; Cluzel, C. The Climbing Drum Peel Test: An alternative to the Double Cantilever Beam for the determination of fracture toughness of monolithic laminates. Compos. Part A Appl. Sci. Manuf. 2015, 78, 70–83. [Google Scholar] [CrossRef]

- Weidmann, F.; Ziegmann, G.; Wieser, J. A review of mode I dominant interfacial fracture toughness test methods of skin-core bonding for thermoplastic composite sandwich structures. J. Thermoplast. Compos. Mater. 2022, 35, 08927057221083493. [Google Scholar] [CrossRef]

- Kawashita, L.F.; Moore, D.R.; Williams, J.G. The development of a mandrel peel test for the measurement of adhesive fracture toughness of epoxy-metal laminates. J. Adhes. 2004, 80, 147–167. [Google Scholar] [CrossRef]

- Kawashita, L.F.; Moore, D.R.; Williams, J.G. Comparison of Peel Tests for Metal-Polymer Laminates for Aerospace Applications. J. Adhes. 2007, 81, 561–586. [Google Scholar] [CrossRef]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Molinari, M.; Aguie-Beghin, V. Langmuir–Blodgett Procedure to Precisely Control the Coverage of Functionalized AFM Cantilevers for SMFS Measurements: Application with Cellulose Nanocrystals. Langmuir 2018, 34, 9376–9386. [Google Scholar] [CrossRef]

- Berzin, F.; Lemkhanter, L.; Marcuello, C.; Chabbert, B.; Aguie-Beghin, V.; Molinari, M.; Castellani, R.; Vergnes, B. Influence of the polarity of the matrix on the breakage mechanisms of lignocellulosic fibers during twin-screw extrusion. Polym. Compos. 2020, 41, 805–1145. [Google Scholar] [CrossRef]

- Jung, G.; Mitschang, P.; Park, C. New GMT material suitable for various polymers and high glass fibre content. Plast. Rubber Compos. 2015, 44, 117–122. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Xiong, H.; Hamila, N.; Boisse, P. Consolidation Modeling during Thermoforming of Thermoplastic Composite Prepregs. Materials 2019, 12, 2853. [Google Scholar] [CrossRef] [PubMed]

- Roland, W.; Hammer, A.; Leimhofer, C.; Kapshammer, A.; Hild, S. Application of a novel testing device to characterize the layer adhesion of co-extruded polymer sheets. Mat. Today 2022, 62, 2652–2657. [Google Scholar] [CrossRef]

- Barocio, E.; Brenken, B.; Favaloro, A.; Ramirez, M.; Ramirez, J.; Pipes, R.B. Prediction of the Degree of Bonding in the Extrusion Deposition Additive Manufacturing Process of Semi Crystalline Polymer Composites; Purdue University: West Lafayette, IN, USA, 2018. [Google Scholar]

- Machado, M.; Cakmak, U.D.; Kallai, I.; Major, Z. Thermomechanical viscoelastic analysis of woven-reinforced thermoplastic-matrix composites. Compos. Struct. 2016, 157, 256–264. [Google Scholar] [CrossRef]

- Grouve, W.J.B.; Warnet, L.L.; Rietman, B.; Vissner, H.A.; Akkerman, R. Optimization of the tape placement process for carbon-PPS composites. Compos. Part A Appl. Sci. Manuf. 2013, 50, 44–53. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M. Scientific Advancements in Composite Materials for Aircraft: A review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef]

- Stelzer, P.S.; Cakmak, U.D.; Eisner, L.; Doppelbauer, L.K.; Kallai, I.; Schweizer, G.; Prammer, H.R.; Major, Z. Experimental feasibility and enviromental impacts of compression molded discontinuous carbon fiber composites with opportunities for circular economy. Compos. B. Eng. 2022, 234, 109638. [Google Scholar] [CrossRef]

- Alwekar, S.; Ogle, R.; Kim, S.; Vaidya, U. Manufacturing and characterization of continuous fiber-reinforced thermoplastic tape overmolded long fiber thermoplastic. Compos. B. Eng. 2021, 207, 108597. [Google Scholar] [CrossRef]

| Property | Value | Unit |

|---|---|---|

| Density ρ | 1.5 | g/cm3 |

| Tensile Modulus E11 | 28,000 | MPa |

| Tensile Modulus E22 | 3720 | MPa |

| Tensile Strength X11 | 720 | MPa |

| Strain at Break ϵmax | 1.9 | % |

| Process Parameters—Heating Press | |

| Temperature/°C | 200, 230, 260 |

| Closing Pressure/bar | 0.2, 0.5, 1.0 |

| Consolidation Time/s | 60, 120 *, 140 * |

| Process Parameters—Cooling Press | |

| Temperature/°C | 40 |

| Closing Pressure/bar | 5.0 |

| Consolidation Time/s | 60.0 |

| Property | IR | 45° | NR | Unit |

|---|---|---|---|---|

| Young’s Modulus E | 1900 | 2100 | 3100 | MPa |

| (Standard Deviation) | (110) | (210) | (220) | (MPa) |

| Poisson Ratio ν | 0.36 | 0.33 | 0.31 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapshammer, A.; Miron, M.C.; Dangl, L.; Major, Z. Interface Characterization of Consolidated PPGF Tapes on PPGF Mat Material. Polymers 2023, 15, 935. https://doi.org/10.3390/polym15040935

Kapshammer A, Miron MC, Dangl L, Major Z. Interface Characterization of Consolidated PPGF Tapes on PPGF Mat Material. Polymers. 2023; 15(4):935. https://doi.org/10.3390/polym15040935

Chicago/Turabian StyleKapshammer, Andreas, Matei Constantin Miron, Lukas Dangl, and Zoltan Major. 2023. "Interface Characterization of Consolidated PPGF Tapes on PPGF Mat Material" Polymers 15, no. 4: 935. https://doi.org/10.3390/polym15040935

APA StyleKapshammer, A., Miron, M. C., Dangl, L., & Major, Z. (2023). Interface Characterization of Consolidated PPGF Tapes on PPGF Mat Material. Polymers, 15(4), 935. https://doi.org/10.3390/polym15040935