Assessment of Thermochromic Packaging Prints’ Resistance to UV Radiation and Various Chemical Agents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Printing Substrates

2.2. Printing Inks

2.3. Printing Trials

2.4. Assessment of Prints’ Resistance to Specific Chemical Agents

2.5. Assessment of Prints’ Resistance to UV Radiation

2.6. Visual Evaluation

2.7. Spectrophotometric Measurements

3. Results and Discussion

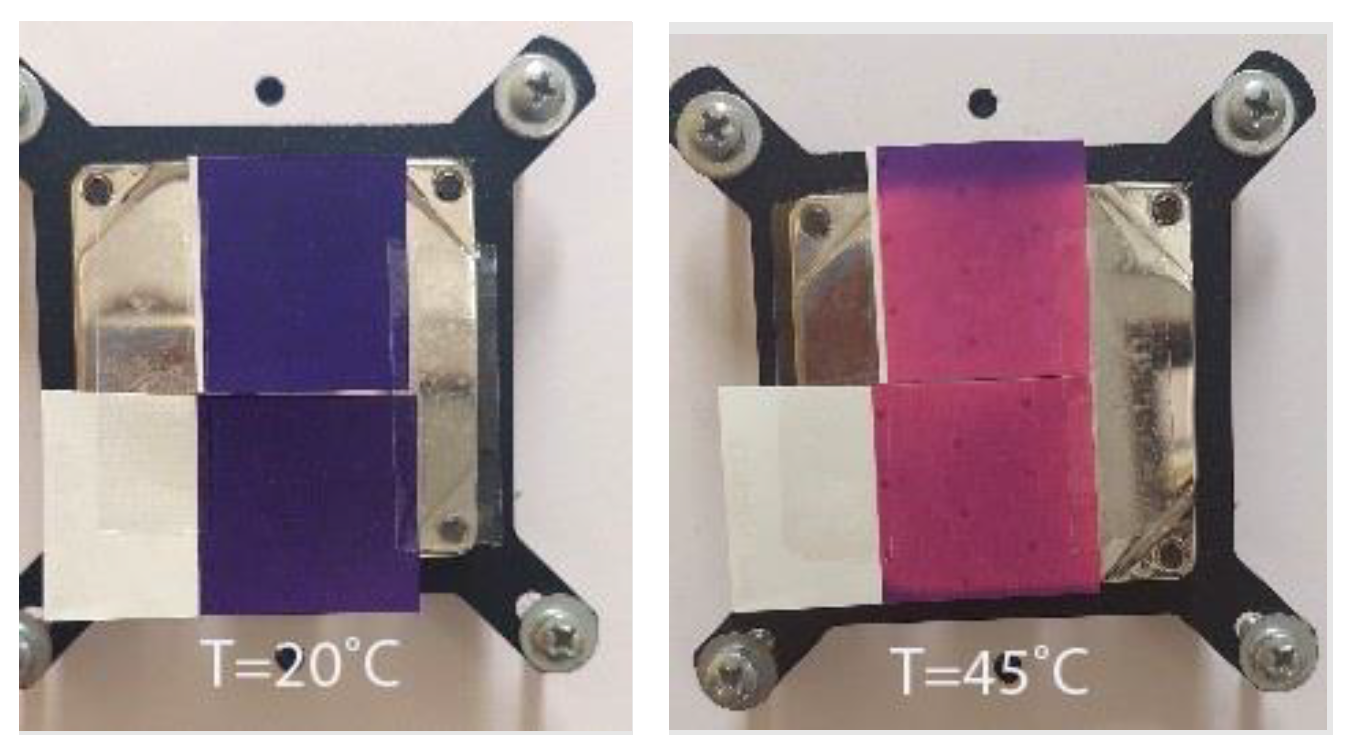

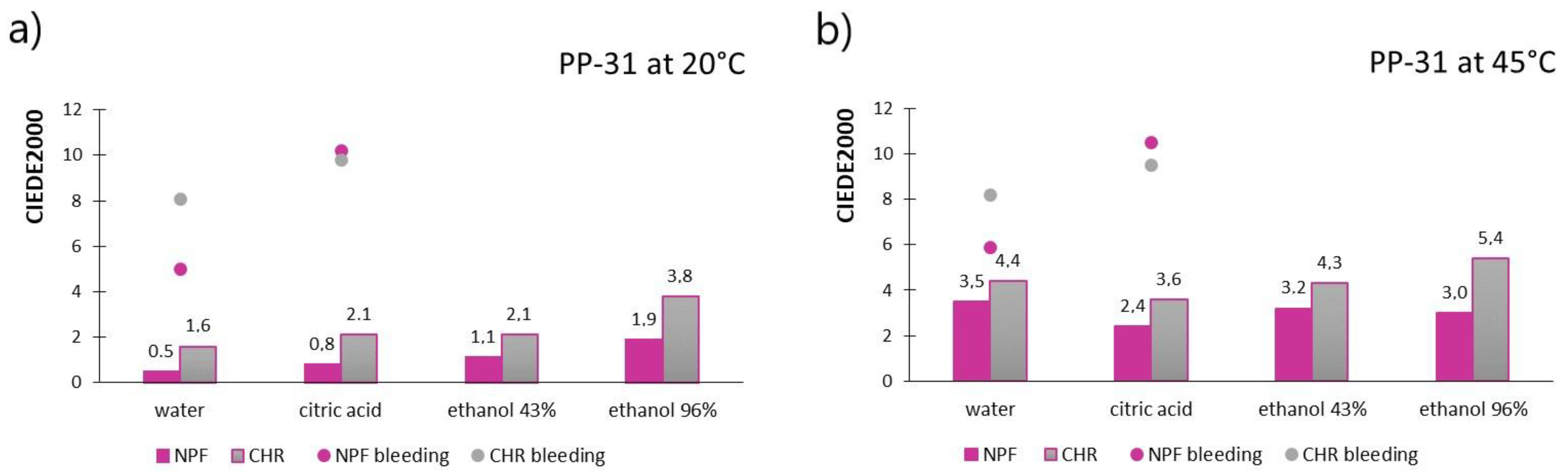

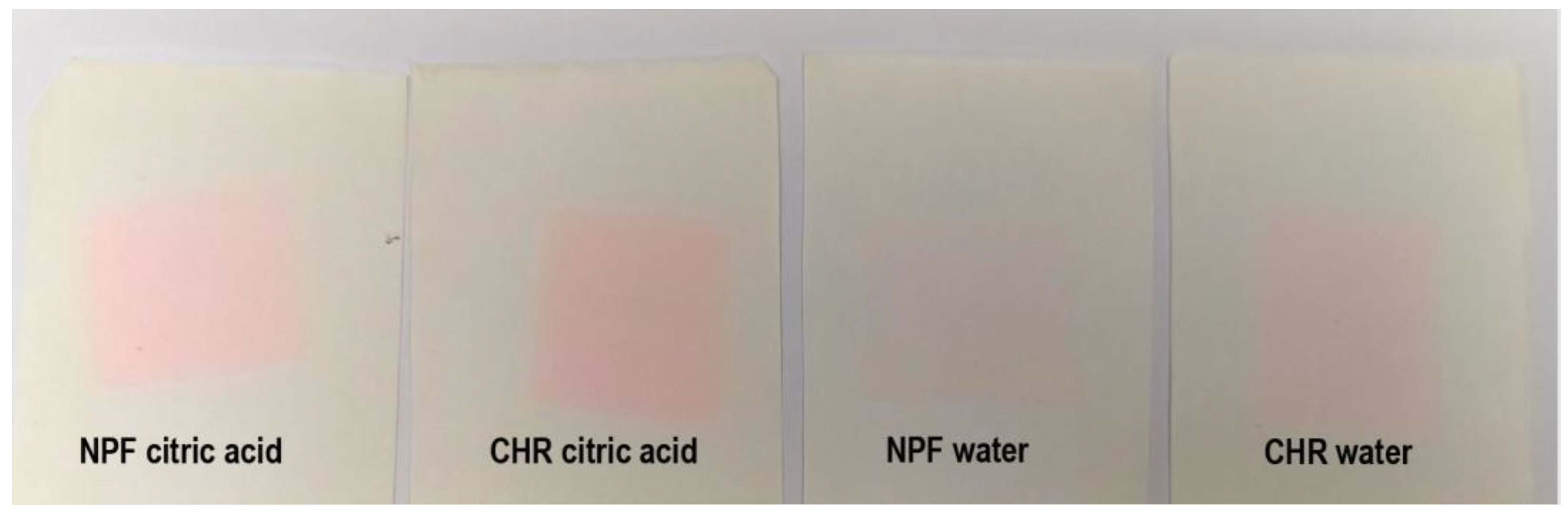

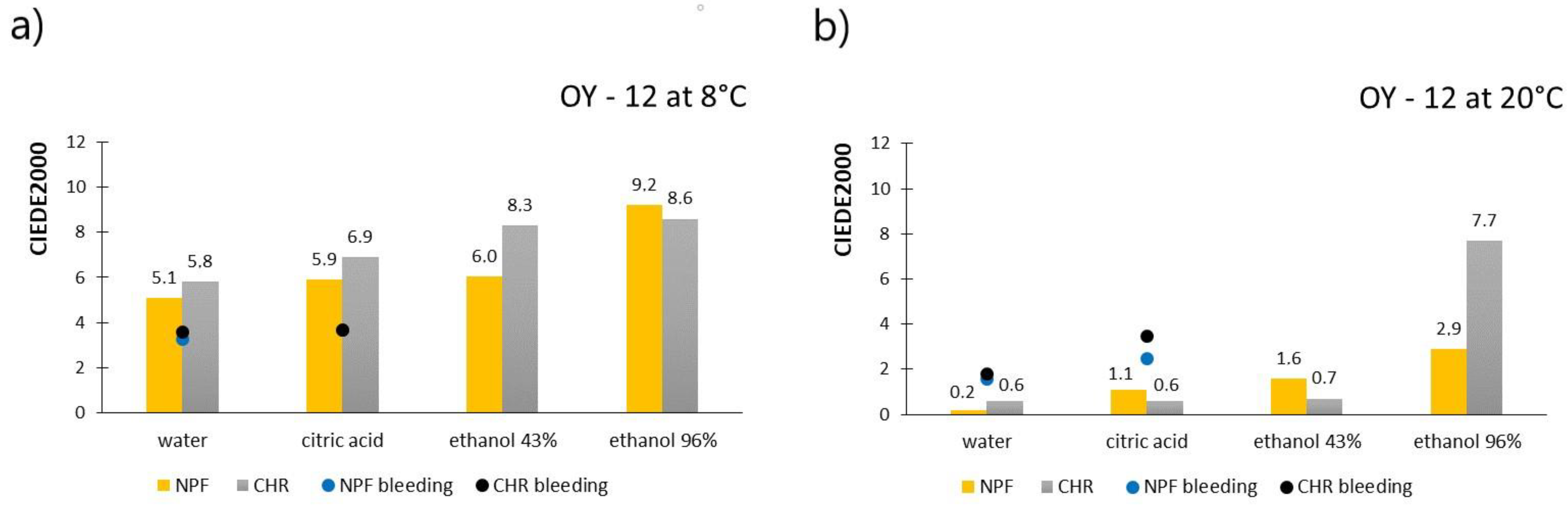

3.1. Results of Prints’ Chemical Resistance

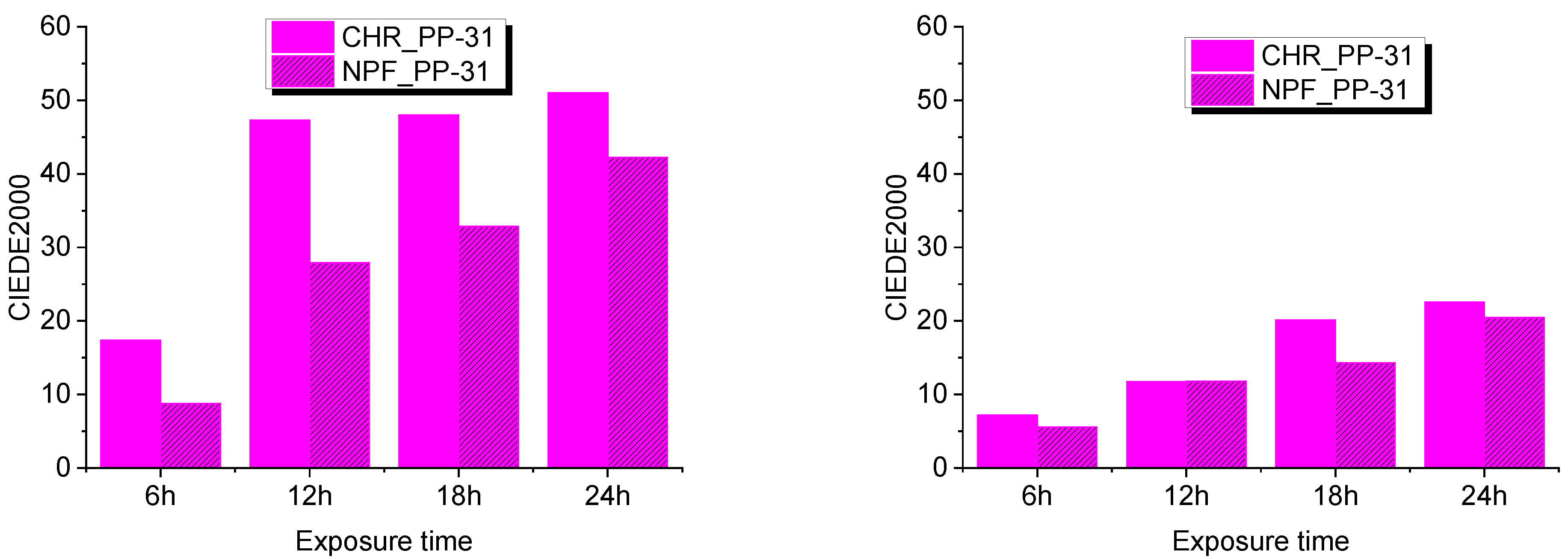

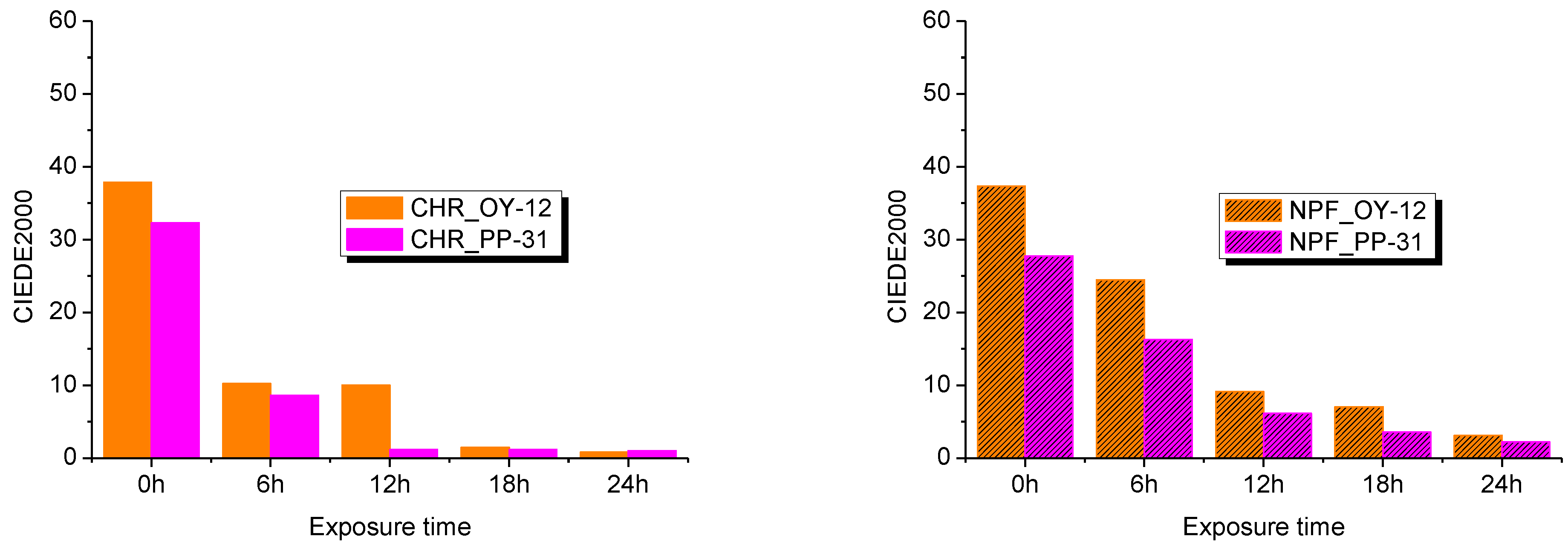

3.2. Results of Prints’ UV Stability

Visual Evaluation of Prints

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Arman Kandirmaz, E.; Ozcan, A.; Er Ulusoy, D. Production of thermochromic microcapsulated inks for smart packaging and examination of printability properties. Pigment Resin Technol. 2020, 49, 273–281. [Google Scholar] [CrossRef]

- White, M.; LeBlanc, M. Thermochromism in commercial products. J. Chem. Educ. 1999, 76, 3–7. [Google Scholar] [CrossRef]

- Johansson, L. Creation of Printed Dynamic Images. Ph.D. Dissertation, Linköping University, Linköping, Sweden, 2006. [Google Scholar]

- Christie, R.; Robertson, S.; Taylor, S. Design Concepts for a Temperature-sensitive Environment Using Thermochromic Colour Change Robert. Colour Des. Creat. 2007, 1, 1–11. [Google Scholar]

- Kerry, J.; Butler, P. Smart Packaging Technologies for Fast Moving Consumer Goods; John Wiley & Sons Ltd.: Chichester, UK, 2008. [Google Scholar]

- Degrees of Perfect Exibition; Behind the Thermochromic Murals That Morph before Your Eyes. Available online: https://mashable.com/ad/feature/thermochromic-murals-exhibit (accessed on 15 December 2022).

- Geng, X.; Li, W.; Wang, Y.; Lu, J.; Wang, J.; Wang, N.; Li, J.; Zhang, X. Reversible thermochromic microencapsulated phase change materials for thermal energy storage application in thermal protective clothing. Appl. Energy 2018, 217, 281–294. [Google Scholar] [CrossRef]

- Štaffová, M.; Kučera, F.; Tocháček, J.; Dzik, P.; Ondreáš, F.; Jančář, J. Insight into color change of reversible thermochromic systems and their incorporation into textile coating. J. Appl. Polym. Sci. 2021, 138, 49724. [Google Scholar] [CrossRef]

- Thamrin, E.S.; Warsiki, E.; Bindar, Y.; Kartika, I.A. Thermochromic ink as a smart indicator on cold product packaging—Review. IOP Conf. Ser. Earth Environ. Sci. 2022, 1063, 012021. [Google Scholar] [CrossRef]

- Leite, L.; Nobre, L.; Boticas, I.; Navarro, M.; Bessa, J.; Cunha, F.; Neves, P.; Alves, N.; Moura, C. Temperature-Sensing Inks for Real-Time Monitoring in Food Packaging. Mater. Proc. 2022, 8, 130. [Google Scholar]

- Kavčič, U.; Mraović, M.; Bračko, S.; Muck, D. Printed thermochromic displays. Color. Technol. 2019, 135, 60–66. [Google Scholar] [CrossRef] [Green Version]

- Galagan, Y.; Su, W. Fadable ink for time—Temperature control of food freshness: Novel new time—Temperature indicator. Food Res. Int. 2008, 41, 653–657. [Google Scholar] [CrossRef]

- Liu, G.; Yu, T.; Yao, Z.; Xu, H.; Zhang, Y.; Xu, X.; Xu, X.; Gao, M.; Sun, Q.; Zhang, T.; et al. ViviPaint: Creating Dynamic Painting with a Thermochromic Toolkit. Multimodal Technol. Interact. 2022, 6, 63. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, Y.; Dong, N.; Li, Z. Fabrication and characterization of reversible thermochromic wood veneers. Sci. Rep. 2017, 7, 16933. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, C.F.; Wu, A.B. Studies on the synthesis and thermochromic properties of crystal violet lactone and its reversible thermochromic complexes. Thermochim. Acta 2005, 425, 7–12. [Google Scholar] [CrossRef]

- MacLaren, D.C.; White, M.A. Design rules for reversible thermochromic mixtures. J. Mater. Sci. 2005, 40, 669–676. [Google Scholar] [CrossRef]

- Seeboth, A.; Lotzsch, D. Thermochromic and Thermotropic Materials; CRC Press by Taylor & Francis Group: Boca Raton, FL, USA, 2013. [Google Scholar]

- Tang, H.; MacLaren, D.C.; White, M.A. New insights concerning the mechanism of reversible thermochromic mixtures. Can. J. Chem. 2010, 88, 1063–1070. [Google Scholar] [CrossRef]

- Phillips, G.K. Combining thermochromics and conventional inks to deter dovument fraud. In Proceedings of the SPIE 3973, Optical Security and Counterfeit Deterrence Techniques III, San Jose, CA, USA, 27–28 January 2000; van Renesse, R.L., Vliegenthart, W.A., Eds.; SPIE: Bellingham, WA, USA, 2000; pp. 99–104. [Google Scholar]

- Johansson, L.; Kruse, B. The Influence of Paper Properties on Colour Reproduction with Dynamic Inks. In Proceedings of the International Conference on Imaging: Technology and Applications for the 21st Century, Beijing, China, 23–26 May 2005; pp. 214–215. [Google Scholar]

- Pu, Y.; Fang, J. Preparation and thermochromic behavior of low-temperature thermochromic microcapsule temperature indicators. Colloids Surf. A Physicochem. Eng. Asp. 2022, 653, 129889. [Google Scholar] [CrossRef]

- Bašnec, K.; Perše, L.S.; Šumiga, B.; Huskić, M.; Meden, A.; Hladnik, A.; Podgornik, B.B.; Gunde, M.K. Relation between colour- and phase changes of a leuco dye-based thermochromic composite. Sci. Rep. 2018, 8, 5511. [Google Scholar] [CrossRef]

- WRAP. Thermochromic Inks and Reducing Household Food Waste; WRAP: Banbury, UK, 2013. [Google Scholar]

- Panák, O.; Držková, M.; Kaplanová, M. Insight into the evaluation of colour changes of leuco dye based thermochromic systems as a function of temperature. Dye. Pigment. 2015, 120, 279–287. [Google Scholar] [CrossRef]

- Seeboth, A.; Lo, D.; Ruhmann, R.; Muehling, O. Thermochromic Polymers—Function by Design. Chem. Rev. 2013, 114, 3037–3068. [Google Scholar] [CrossRef]

- Maclaren, D.C.; White, M.A. Competition between dye—Developer and solvent—Developer interactions in a reversible thermochromic system. J. Mater. Chem. 2003, 13, 1701–1704. [Google Scholar] [CrossRef]

- MacLaren, D.C.; White, M.A. Dye–developer interactions in the crystal violet lactone–lauryl gallate binary system: Implications for thermochromism. J. Mater. Chem. 2003, 13, 1695–1700. [Google Scholar] [CrossRef]

- Panák, O.; Kashtalyan, K.; Syrový, T. Producing two-component thermochromic pattern by means of offset printing. In Proceedings of the 2015 IEEE Colour and Visual Computing Symposium (CVCS), Gjovik, Norway, 25–26 August 2015; pp. 1–5. [Google Scholar]

- Hajzeri, M.; Vatič, N.; Panák, O. XIth Symposium on Graphic Arts; University of Pardubice: Pardubice, Czechia, 2013; pp. 109–114. [Google Scholar]

- Urbas, R.; Milošević, R.; Kašiković, N.; Pavlović, Ž.; Elesini, U.S. Microcapsules application in graphic arts industry: A review on the state-of-the-art. Iran. Polym. J. (Engl. Ed.) 2017, 26, 541–561. [Google Scholar] [CrossRef]

- Hakami, A.; Srinivasan, S.S.; Biswas, P.K.; Krishnegowda, A.; Wallen, S.L.; Stefanakos, E.K. Review on thermochromic materials: Development, characterization, and applications. J. Coat. Technol. Res. 2022, 19, 377–402. [Google Scholar] [CrossRef]

- Rožić, M.; Vukoje, M.; Kapović, D.; Marošević, L. Solvents interactions with thermochromic print. J. Graph. Eng. Des. 2017, 8, 19–25. [Google Scholar] [CrossRef]

- Friškovec, M.; Kulčar, R.; Klanjšek Gunde, M. Light fastness and high-temperature stability of thermochromic printing inks. Color. Technol. 2013, 129, 214–222. [Google Scholar] [CrossRef]

- Rožić, M.; Kulčar, R.; Jamnicki, S.; Lozo, B.; Gregor-Svetec, D. UV stability of thermochromic ink on paper containing clinoptilolite tuff as a filler. Cellul. Chem. Technol. 2015, 49, 693–699. [Google Scholar]

- Vukoje, M.; Kulčar, R.; Itrić Ivanda, K.; Bota, J.; Cigula, T. Improvement in Thermochromic Offset Print UV Stability by Applying PCL Nanocomposite Coatings. Polymers 2022, 14, 1484. [Google Scholar] [CrossRef] [PubMed]

- Kulčar, R.; Vukoje, M.; Krajnović, I.; Rožić, M. Influence of recycled fibres in paper on the UV stability of thermochromic prints. In Proceedings of the 10th International Symposium GRID 2020, Novi Sad, Serbia, 12–14 November 2020; Dedijer, S., Ed.; University of Novi Sad Faculty of Technical Sciences Department of Graphic Engineering and Design: Novi Sad, Serbia, 2020; pp. 161–168. [Google Scholar]

- Jamnicki Hanzer, S.; Kulčar, R.; Vukoje, M.; Širol, P. Mechanical and chemical resistance of thermochromic packaging prints. In Proceedings of the 10th International Symposium GRID, Novi Sad, Serbia, 12–14 November 2020; Dedijer, S., Ed.; University of Novi Sad Faculty of Technical Sciences Department of Graphic Engineering and Design: Novi Sad, Serbia, 2020; pp. 109–118. [Google Scholar]

- Vukoje, M.; Kulčar, R.; Itrić, K.; Rožić, M. Spectroscopic evaluation of thermochromic printed cardboard biodegradation. In Proceedings of the Ninth International Symposium GRID 2018, Novi Sad, Serbia, 8–10 November 2018; Pavlović, Ž., Ed.; Grafički Centar GRID: Šabac, Serbia, 2018; pp. 87–96. [Google Scholar]

- Oda, H. New developments in the stabilization of leuco dyes: Effect of UV absorbers containing an amphoteric counter-ion moiety on the light fastness of color formers. Dye. Pigment. 2005, 66, 103–108. [Google Scholar] [CrossRef]

- Oda, H. Photostabilization of organic thermochromic pigments: Action of benzotriazole type UV absorbers bearing an amphoteric counter-ion moiety on the light fastness of color formers. Dye. Pigment. 2008, 76, 270–276. [Google Scholar] [CrossRef]

- Oda, H. Photostabilization of organic thermochromic pigments. Part 2: Effect of hydroxyarylbenzotriazoles containing an amphoteric counter-ion moiety on the light fastness of color formers. Dye. Pigment. 2008, 76, 400–405. [Google Scholar] [CrossRef]

- Homola, T.J. Color-Changing Inks; AccessScience; McGraw-Hill Education: New York, NY, USA, 2008. [Google Scholar]

- ISO 2836; Graphic Technology—Prints and Printing Inks—Assessment of Resistance of Prints to Various Agents. International Organization for Standardization: Geneva, Switzerland, 2021.

- Astm D3424-09; Standard Test Methods for Evaluating the Relative Lightfastness and Weatherability of Printed Mater. ASTM International: West Conshohocken, PA, USA, 2010; Volume V, pp. 1–5.

- European Organisation for Tehnical Approval (EOTA). Exposure Procedure for Artificial Weathering—TR 010; EOTA: Brussels, Belgium, 2004. [Google Scholar]

- CIE Central Bureau. Colorimetry, 3rd ed.; CIE Central Bureau: Vienna, Austria, 2004. [Google Scholar]

- Yang, Y.; Ming, J.; Yu, N. Color Image Quality Assessment Based on CIEDE2000. Adv. Multimed. 2012, 2012, 273723. [Google Scholar] [CrossRef] [Green Version]

- Schilling, M. Shift Happens… So Measure. Available online: https://inkjetinsight.com/knowledge-base/color-shift-happens-so-measure/ (accessed on 3 February 2023).

- Kumar, M. Interdisciplinarnost Barve 2.Del.; Jeler, S., Kumar, M., Eds.; Društvo koloristov Slovenije: Maribor, Slovenia, 2003; pp. 89–100. [Google Scholar]

- Hansen, C.M. Hansen Solubility Parameters—A User’s Handbook; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2000. [Google Scholar]

- Comyn, J. Adhesion Science; Royal Society of Chemistry: Cambridge, UK, 2021. [Google Scholar]

- Vukoje, M.; Miljanić, S.; Hrenović, J.; Rožić, M. Thermochromic ink–paper interactions and their role in biodegradation of UV curable prints. Cellulose 2018, 25, 6121–6138. [Google Scholar] [CrossRef]

- Nguyen, T.; Gu, X.; Vanlandingham, M.; Byrd, E.; Ryntz, R.; Martin, J.W. Degradation modes of crosslinked coatings exposed to photolytic environment. J. Coat. Technol. Res. 2013, 10, 1–14. [Google Scholar] [CrossRef]

- Groeneveld, I.; Kanelli, M.; Ariese, F.; van Bommel, M.R. Parameters that affect the photodegradation of dyes and pigments in solution and on substrate—An overview. Dye. Pigment. 2023, 210, 110999. [Google Scholar] [CrossRef]

- Decker, C.; Masson, F.; Schwalm, R. Weathering resistance of waterbased UV-cured polyurethane-acrylate coatings. Polym. Degrad. Stab. 2004, 83, 309–320. [Google Scholar] [CrossRef]

- Decker, C.; Moussa, K.; Bendaikha, T. Photodegradation of UV-cured coatings II. Polyurethane–acrylate networks. J. Polym. Sci. Part A Polym. Chem. 1991, 29, 739–747. [Google Scholar] [CrossRef]

- Bénard, F.; Mailhot, B.; Mallégol, J.; Gardette, J.L. Photoageing of an electron beam cured polyurethane acrylate resin. Polym. Degrad. Stab. 2008, 93, 1122–1130. [Google Scholar] [CrossRef]

- Peinado, C.; Allen, N.S.; Salvador, E.F.; Corrales, T.; Catalina, F. Chemiluminescence and fluorescence for monitoring the photooxidation of an UV-cured aliphatic polyurethane-acrylate based adhesive. Polym. Degrad. Stab. 2002, 77, 523–529. [Google Scholar] [CrossRef]

| Paper Substrate | Abbreviation | Property Unit Method | Basis Weight (g/m2) ISO 536 | Caliper (µm) ISO 534 | ISO Brightness (%) ISO 2470, R457 | Bekk Smoothness (s) ISO 5627 |

|---|---|---|---|---|---|---|

| Niklakett Premium Fashion | NPF | 75 | 74 | 91 | 74 | |

| Chromolux 700 | CHR | 80 | 84 | 89.3 | 300 |

| Property | Value |

|---|---|

| Viscosity at 25 °C | 65–110 poise |

| Density (Approx.) | 8.0 lb./gal |

| Appearance | Viscous Liquid |

| Percent Solids (Approx.) | 99% |

| Percent Volatiles (Approx.) | <1.5% |

| Test Agent | Receptor Surface | Temperature/°C | Test Duration | Contact Condition |

|---|---|---|---|---|

| Water (distilled) | filter paper | 23 ± 2 | 24 h | 1 kg on 54 cm2 |

| Citric acid (w/v = 5%) | filter paper | 23 ± 2 | 1 h | 1 kg on 54 cm2 |

| Ethanol (v/v = 96%) | test tube | 23 ± 2 | 5 min | liquid |

| Ethanol (v/v = 43%) | test tube | 23 ± 2 | 5 min | liquid |

| Color Difference | Perception of Color Difference | Tolerance |

|---|---|---|

| <0.2 | not visible | Acceptable for the printing industry |

| <0.5 | negligible | |

| 0.2–1.0 | noticeable | |

| 1.0–3.0 | visible, but small | |

| 3.0–6.0 | clearly visible, obvious | Unacceptable for the printing industry |

| 6.0–12.0 | extremely large | |

| >12.0 | unacceptable |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamnicki Hanzer, S.; Kulčar, R.; Vukoje, M.; Marošević Dolovski, A. Assessment of Thermochromic Packaging Prints’ Resistance to UV Radiation and Various Chemical Agents. Polymers 2023, 15, 1208. https://doi.org/10.3390/polym15051208

Jamnicki Hanzer S, Kulčar R, Vukoje M, Marošević Dolovski A. Assessment of Thermochromic Packaging Prints’ Resistance to UV Radiation and Various Chemical Agents. Polymers. 2023; 15(5):1208. https://doi.org/10.3390/polym15051208

Chicago/Turabian StyleJamnicki Hanzer, Sonja, Rahela Kulčar, Marina Vukoje, and Ana Marošević Dolovski. 2023. "Assessment of Thermochromic Packaging Prints’ Resistance to UV Radiation and Various Chemical Agents" Polymers 15, no. 5: 1208. https://doi.org/10.3390/polym15051208

APA StyleJamnicki Hanzer, S., Kulčar, R., Vukoje, M., & Marošević Dolovski, A. (2023). Assessment of Thermochromic Packaging Prints’ Resistance to UV Radiation and Various Chemical Agents. Polymers, 15(5), 1208. https://doi.org/10.3390/polym15051208