Effects of Cathode GDL Gradient Porosity Distribution along the Flow Channel Direction on Gas–Liquid Transport and Performance of PEMFC

Abstract

:1. Introduction

2. Model Descriptions

2.1. Geometric Model

2.2. Model Assumptions

- (1)

- The system works at a steady state.

- (2)

- The reaction gas is considered an incompressible ideal gas.

- (3)

- The reactant is set to laminar flow, owing to the low gas-flow velocity and Reynolds number (The maximum Re in this study is 47, much less than 2000) [31].

- (4)

- (5)

- The temperatures of the walls and inlet channels are constant.

- (6)

- All the components in the PEMFC are isotropic except for the cathode GDL.

- (7)

- Contact resistance between components is ignored [34].

- (8)

- The effect of gravity is ignored [34].

2.3. Governing Equations

2.3.1. The Conservation of Mass

2.3.2. The Conservation of Momentum

2.3.3. The Conservation of Energy

2.3.4. The Conservation of Species

2.3.5. The Electric and Proton Transport

2.3.6. The Dissolved Water Transports

2.3.7. The Liquid Water Transport

2.4. Numerical Methodology

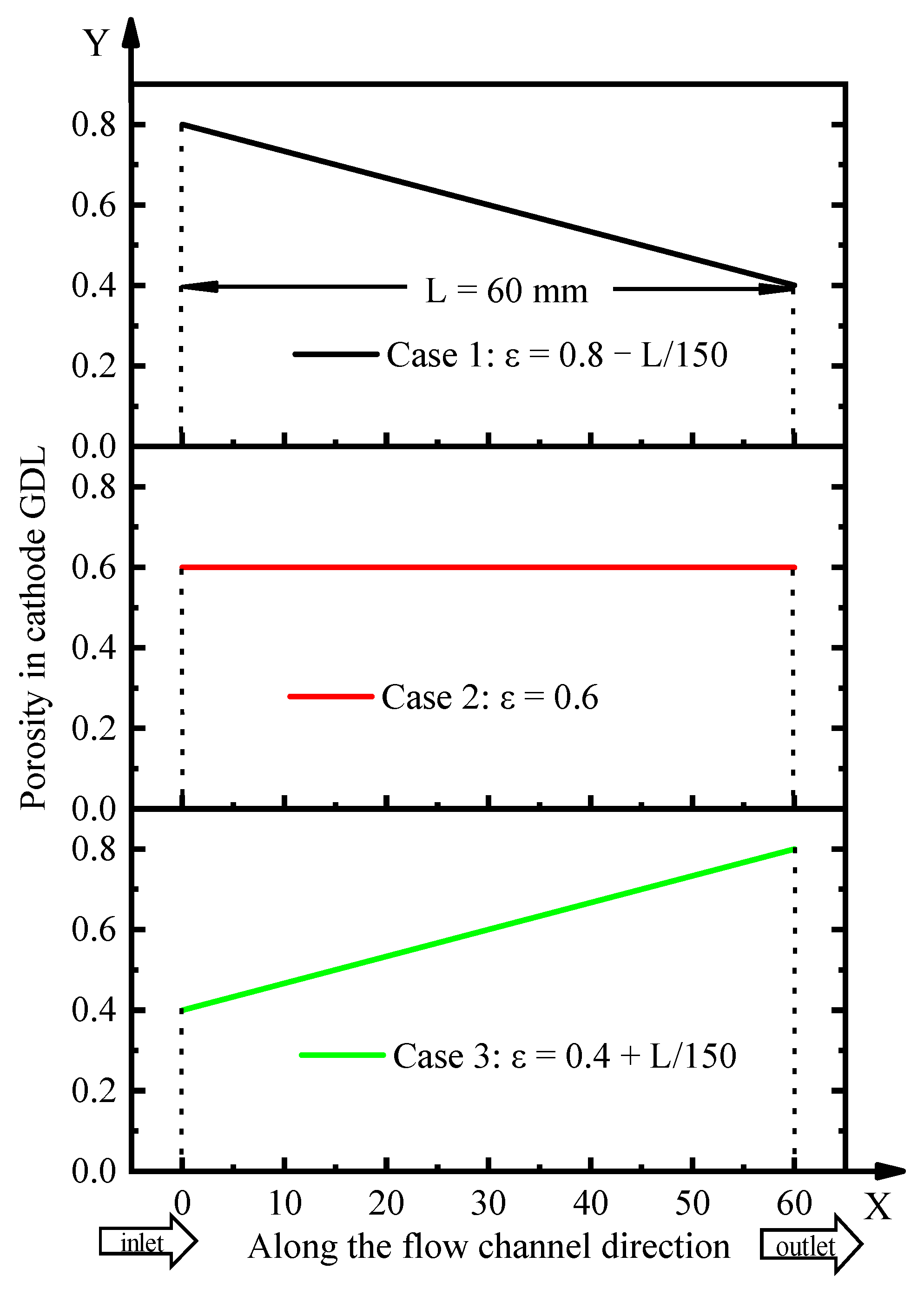

2.5. GDL Gradient Porosity Calculation Case Study

2.6. Boundary Conditions

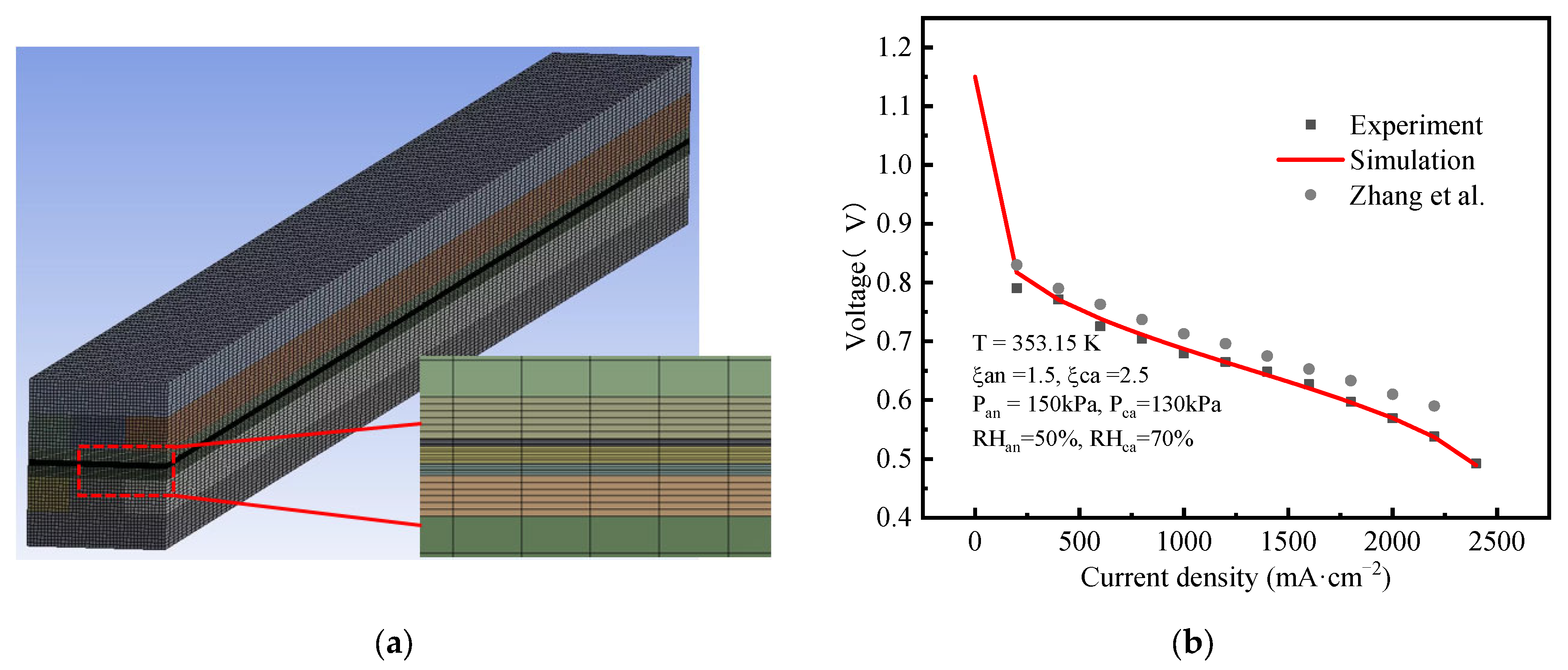

2.7. Mesh Independence Study and Model Validation

3. Results and Discussions

3.1. Effects of Gradient Porosity Distribution on the Cell Performance

3.2. Physical Field Distribution at High Current Density

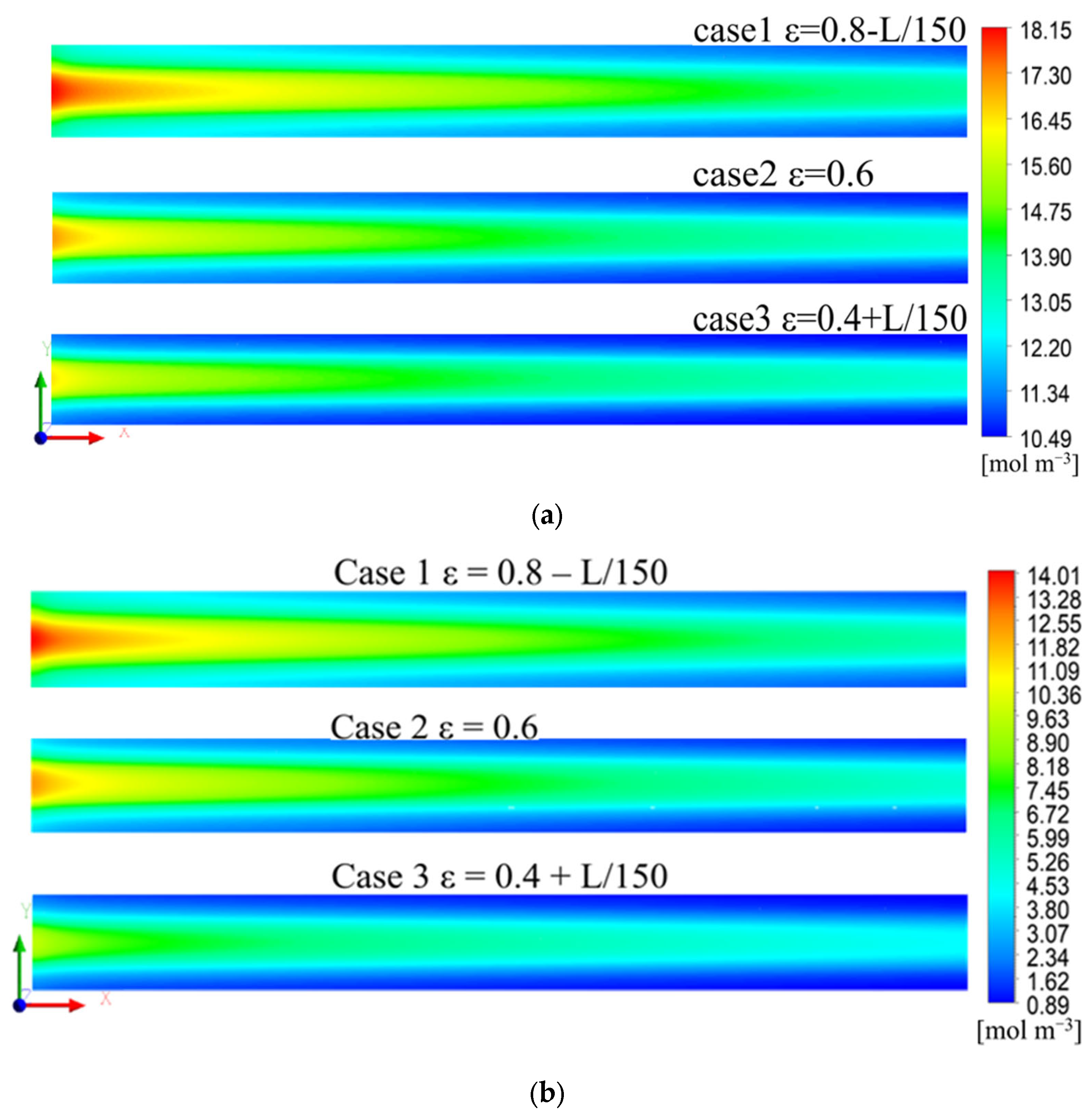

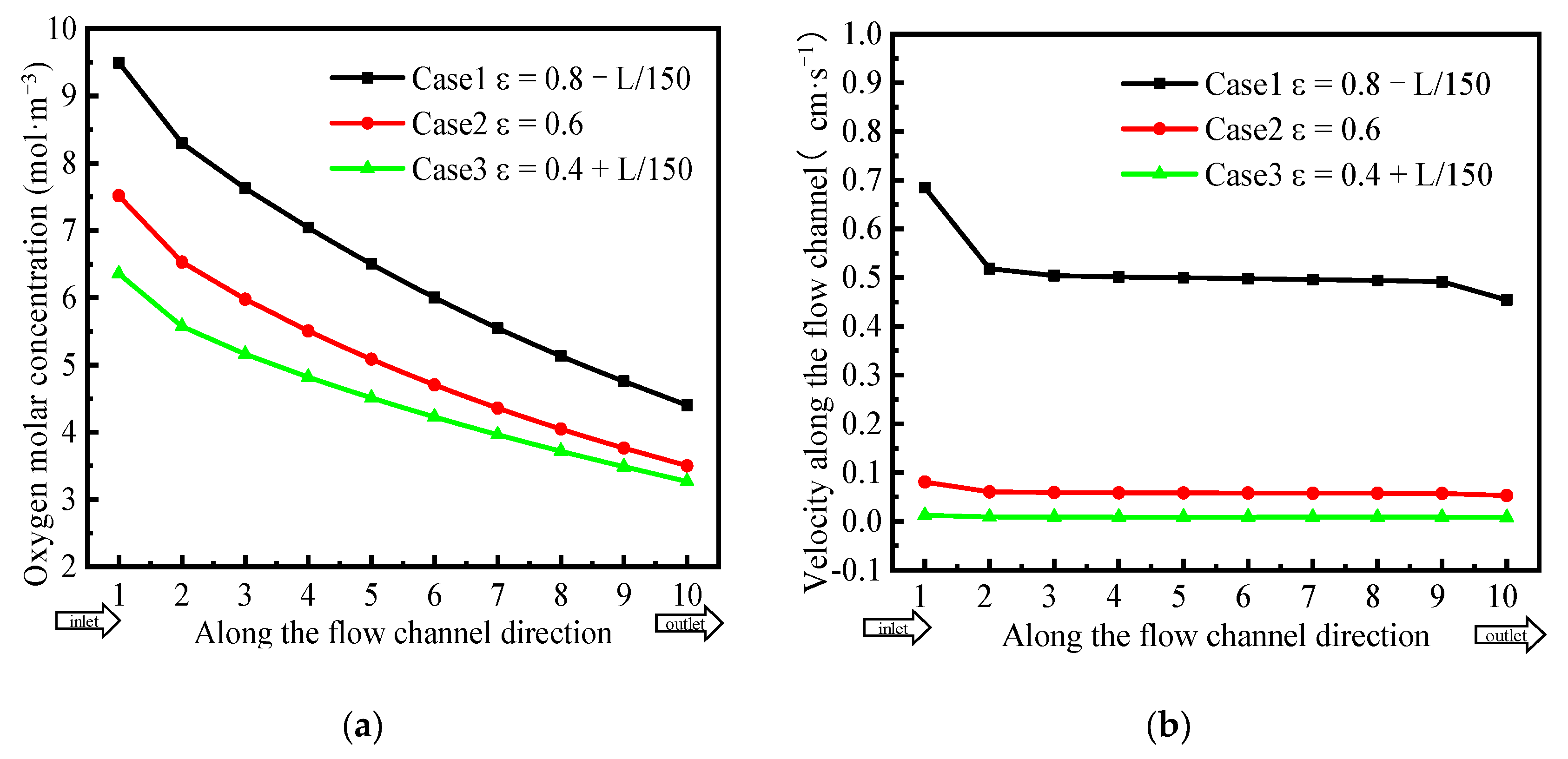

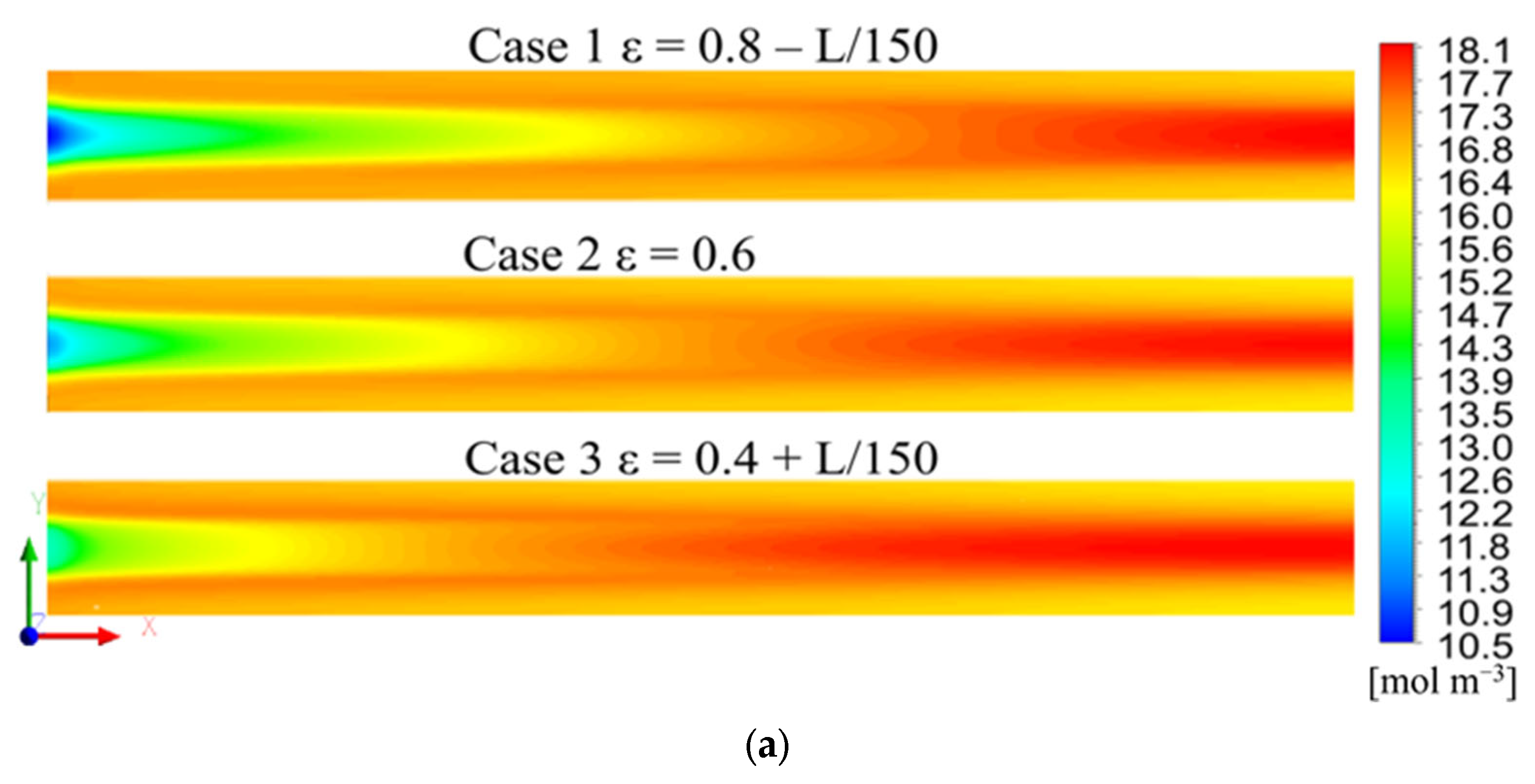

3.2.1. Distribution of Oxygen Molar Concentration

3.2.2. Distribution of the Water Vapor Molar Concentration and Temperature

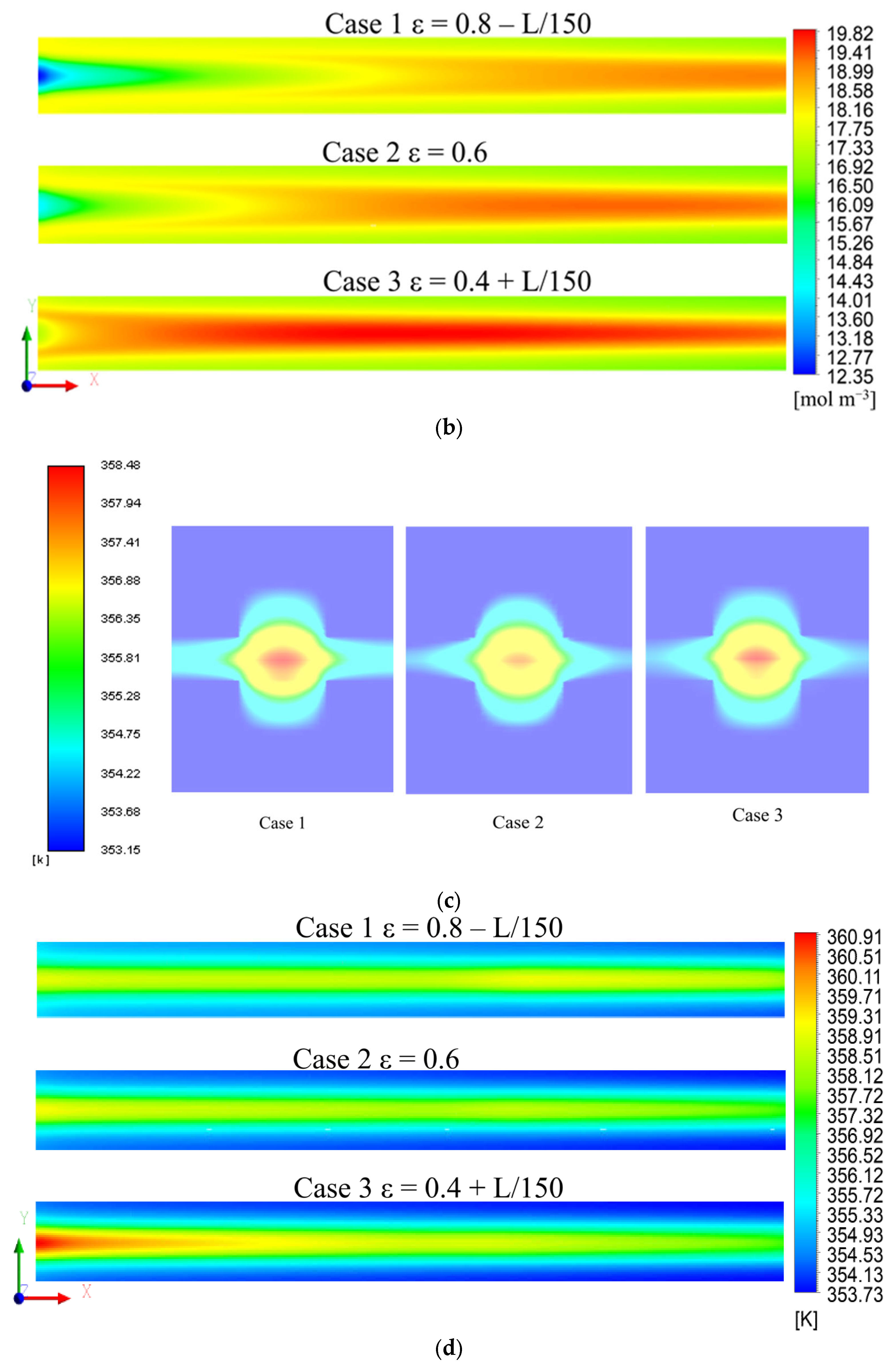

3.2.3. Distribution of Liquid Saturation

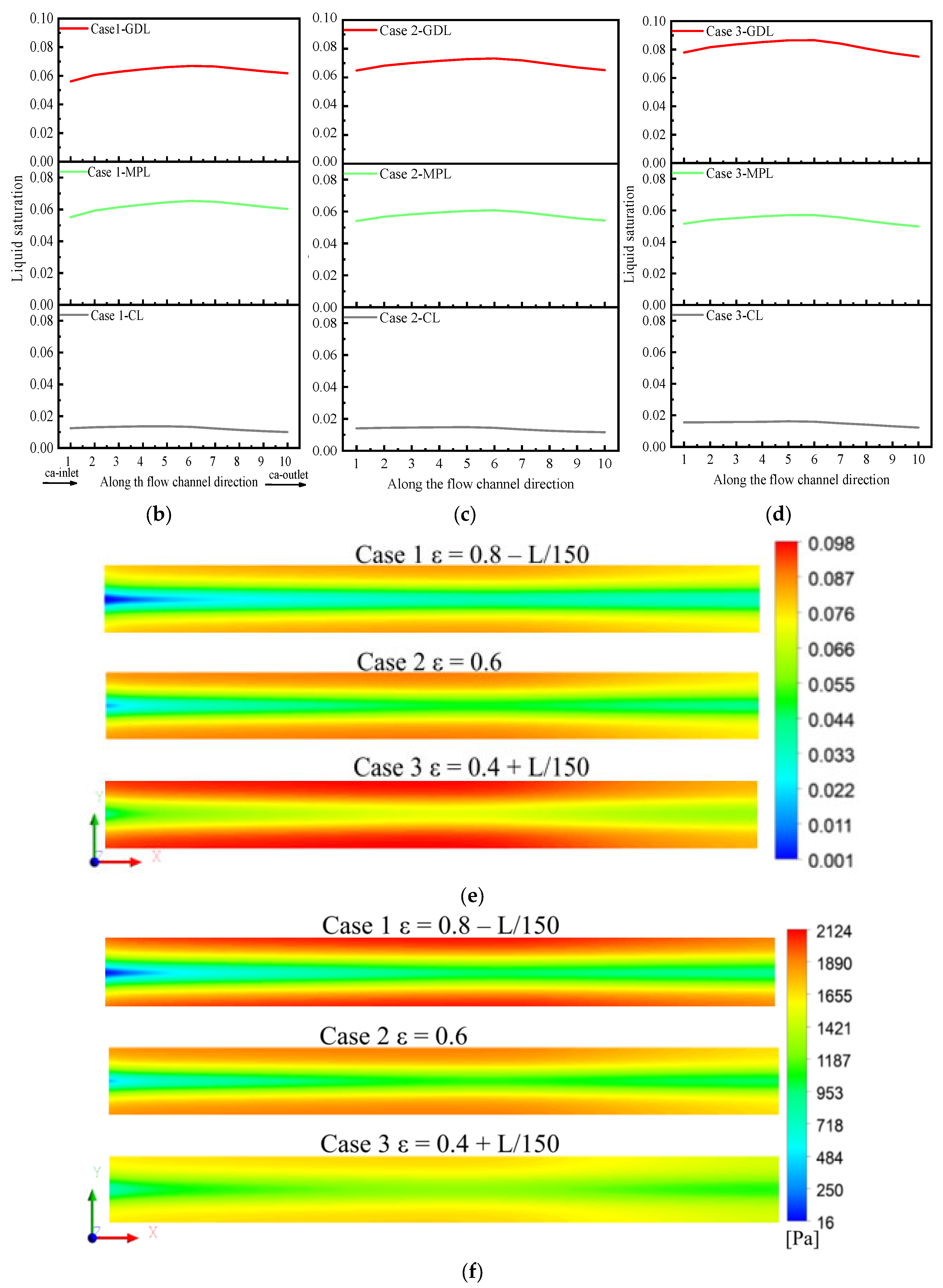

3.2.4. Distribution of Current Density and Membrane Water

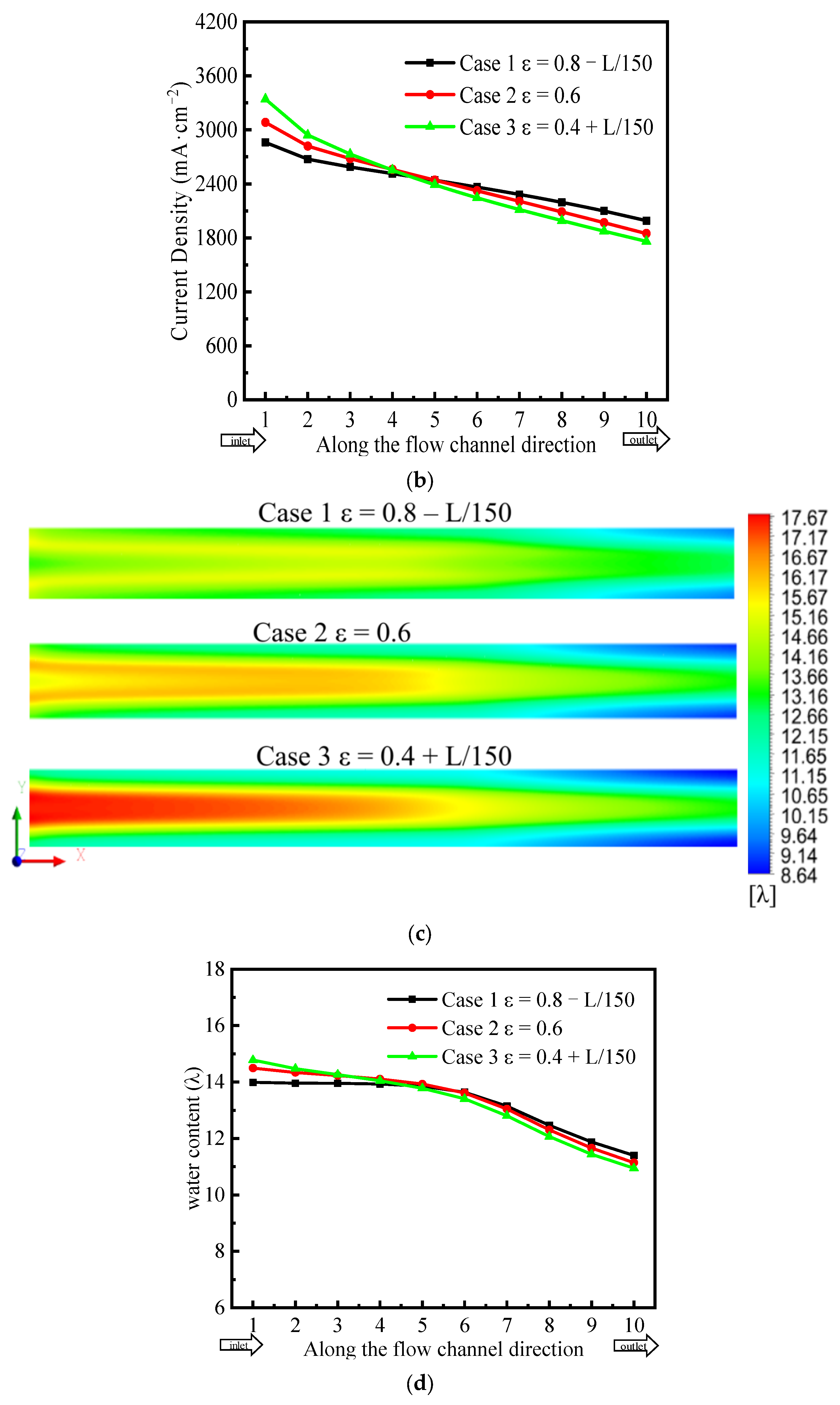

3.3. Physical Field Distribution at Low Current Density

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| a | Water activity |

| A | Specific active surface area (m−1) |

| Concentrations (mol m−3) | |

| Constant-pressure specific heat (J mol−1 K−1) | |

| Effective diffusion coefficient (m2 s−1) | |

| Fiber diameter (mm) | |

| Effective diffusion coefficient (m2 s−1) | |

| Diffusion coefficient of water content (m2 s−1) | |

| EW | Equivalent weight of the proton exchange membrane (g kmol−1) |

| F | Faraday’s constant (96,487 C mol−1) |

| Reference transfer current densities (A m−2) | |

| Permeability (m2) | |

| Effective heat conductivity | |

| Molecular masses (g mol−1) | |

| Osmotic drag coefficient | |

| Pressure (Pa) | |

| Universal gas constant (8.314 J mol−1 K−1) | |

| s | Liquid saturation |

| S | Source terms (k mol m−3 s−1, kg m−3 s−1) |

| Water generation rate | |

| Mass change rate between liquid and dissolved phases | |

| Mass change rate between gas and dissolved phases | |

| Mass change Rate between gas and liquid | |

| Temperature (K) | |

| Velocity (m s−1) | |

| Open-circuit voltage (V) | |

| Greek letters | |

| α | Transfer coefficient |

| ε | Bulk porosity |

| η | Overpotential (V) |

| θ | Contact angle (°) |

| μ | Dynamic viscosity (kg m−1 s−1) |

| ω | Volume fraction of ionomer in catalyst layer |

| λ | Water content |

| Mass exchange rate constants | |

| Density (kg m−3) | |

| φ | Electrical potential (V) |

| σ | Surface tension (J cm−2) |

| ξ | Stoichiometry |

| Subscripts and superscripts | |

| an | Anode |

| BP | Bipolar plate |

| ca | Cathode |

| cond | Condensation |

| eff | Effective |

| ele | Electronic |

| eq | Equilibrium |

| evap | Evaporation |

| g | Gas phase |

| gd | Gas to dissolved phase |

| gl | Gas to liquid phase |

| H2 | Hydrogen |

| i | The ith species |

| in | Inlet |

| ion | Ionic |

| lq | Liquid water |

| ld | Liquid phase to dissolved phase |

| mem | Membrane |

| O2 | Oxygen |

| out | Outlet |

| r | Relative |

| sat | Saturation |

| wv | water vapor |

References

- Khosravi, H.S.; Abbas, Q.; Reichmann, K. Electrochemical aspects of interconnect materials in PEMFCs. Int. J. Hydrogen Energy 2021, 46, 35420–35447. [Google Scholar] [CrossRef]

- Zhao, Y.; Mao, Y.; Zhang, W.; Tang, Y.; Wang, P. Reviews on the effects of contaminations and research methodologies for PEMFC. Int. J. Hydrogen Energy 2020, 45, 23174–23200. [Google Scholar] [CrossRef]

- Majlan, E.H.; Rohendi, D.; Daud, W.R.W.; Husaini, T.; Haque, M.A. Electrode for proton exchange membrane fuel cells: A review. Renew. Sustain. Energy Rev. 2018, 89, 117–134. [Google Scholar] [CrossRef]

- Hu, L.; Zhang, M.; Komini Babu, S.; Kongkanand, A.; Litster, S. Ionic Conductivity over Metal/Water Interfaces in Ionomer-Free Fuel Cell Electrodes. ChemElectroChem 2019, 6, 2659–2666. [Google Scholar] [CrossRef]

- Huang, J.; Li, Z.; Zhang, J. Review of characterization and modeling of polymer electrolyte fuel cell catalyst layer: The blessing and curse of ionomer. Front. Energy 2017, 11, 334–364. [Google Scholar] [CrossRef]

- Shi, L.; Xu, S.; Liu, J. Influences of assembly pressure and flow channel size on performances of proton exchange membrane fuel cells based on a multi-model. Int. J. Hydrogen Energy 2022, 47, 7902–7914. [Google Scholar] [CrossRef]

- Mohammedi, A.; Sahli, Y.; Ben Moussa, H. 3D investigation of the channel cross-section configuration effect on the power delivered by PEMFCs with straight channels. Fuel 2020, 263, 116713. [Google Scholar] [CrossRef]

- Yu, Y.; Zhan, Z.; He, L.; Yang, X.; Wan, X.; Sui, P.C.; Pan, M. Effects of Distribution Zone Design on Flow Uniformity and Pressure Drop in PEMFC. J. Electrochem. Soc. 2021, 168, 094505. [Google Scholar] [CrossRef]

- Cheng, Z.; Luo, L.; Huang, B.; Jian, Q. Effect of humidification on distribution and uniformity of reactants and water content in PEMFC. Int. J. Hydrogen Energy 2021, 46, 26560–26574. [Google Scholar] [CrossRef]

- Zhang, Q.; Lin, R.; Técher, L.; Cui, X. Experimental study of variable operating parameters effects on overall PEMFC performance and spatial performance distribution. Energy 2016, 115, 550–560. [Google Scholar] [CrossRef]

- Kim, B.; Cha, D.; Kim, Y. The effects of air stoichiometry and air excess ratio on the transient response of a PEMFC under load change conditions. Appl. Energy 2015, 138, 143–149. [Google Scholar] [CrossRef]

- Shi, W.; Kurihara, E.; Oshima, N. Effect of capillary pressure on liquid water removal in the cathode gas diffusion layer of a polymer electrolyte fuel cell. J. Power Source 2008, 182, 112–118. [Google Scholar] [CrossRef]

- Chun, J.H.; Park, K.T.; Jo, D.H.; Kim, S.G.; Kim, S.H. Numerical modeling and experimental study of the influence of GDL properties on performance in a PEMFC. Int. J. Hydrogen Energy 2011, 36, 1837–1845. [Google Scholar] [CrossRef]

- Shi, J.; Zhan, Z.; Zhang, D.; Yu, Y.; Yang, X.; He, L.; Pan, M. Effects of Cracks on the Mass Transfer of Polymer Electrolyte Membrane Fuel Cell with High Performance Membrane Electrode Assembly. J. Wuhan Univ. Technol.—Mater Sci Ed. 2021, 36, 318–330. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, L.; Harandi, H.B.; Duan, K.; Zeis, R.; Sui, P.C.; Chuang, P.Y. Microstructure reconstruction of the gas diffusion layer and analyses of the anisotropic transport properties. Energy Convers. Manag. 2021, 241, 114293. [Google Scholar] [CrossRef]

- Jha, V.; Hariharan, R.; Krishnamurthy, B. A 3 dimensional numerical model to study the effect of GDL porosity on high temperature PEM fuel cells. Int. J. Heat Mass Transf. 2020, 161, 120311. [Google Scholar] [CrossRef]

- Xia, L.; Ni, M.; He, Q.; Xu, Q.; Cheng, C. Optimization of gas diffusion layer in high temperature PEMFC with the focuses on thickness and porosity. Appl. Energy 2021, 300, 117357. [Google Scholar] [CrossRef]

- Sim, J.; Kang, M.; Min, K. Effects of basic gas diffusion layer components on PEMFC performance with capillary pressure gradient. Int. J. Hydrogen Energy 2021, 46, 27731–27748. [Google Scholar] [CrossRef]

- Lim, I.S.; Lee, Y.I.; Kang, B.; Park, J.Y.; Kim, M.S. Electrochemical performance and water management investigation of polymer electrolyte membrane fuel cell (PEMFC) using gas diffusion layer with polytetrafluoroethylene (PTFE) content gradients in through-plane direction. Electrochim. Acta 2022, 421, 140509. [Google Scholar] [CrossRef]

- Ko, D.; Doh, S.; Park, H.S.; Kim, M.H. The effect of through plane pore gradient GDL on the water distribution of PEMFC. Int. J. Hydrogen Energy 2018, 43, 2369–2380. [Google Scholar] [CrossRef]

- Lim, I.S.; Park, J.Y.; Kang, D.G.; Choi, S.H.; Kang, B.; Kim, M.S. Numerical study for in-plane gradient effects of cathode gas diffusion layer on PEMFC under low humidity condition. Int. J. Hydrogen Energy 2020, 45, 19745–19760. [Google Scholar] [CrossRef]

- Zhan, Z.; Xiao, J.; Li, D.; Pan, M.; Yuan, R. Effects of porosity distribution variation on the liquid water flux through gas diffusion layers of PEM fuel cells. J. Power Source 2006, 160, 1041–1048. [Google Scholar] [CrossRef]

- Zhan, Z.; Xiao, J.; Zhang, Y.; Pan, M.; Yuan, R. Gas diffusion through differently structured gas diffusion layers of PEM fuel cells. Int. J. Hydrogen Energy 2007, 32, 4443–4451. [Google Scholar] [CrossRef]

- Shangguan, X.; Li, Y.; Qin, Y.; Cao, S.; Zhang, J.; Yin, Y. Effect of the porosity distribution on the liquid water transport in the gas diffusion layer of PEMFC. Electrochim. Acta 2021, 371, 137814. [Google Scholar] [CrossRef]

- Carcadea, E.; Varlam, M.; Ismail, M.; Ingham, D.B.; Marinoiu, A.; Raceanu, M.; Jianu, C.; Patularu, L.; Ion-Ebrasu, D. PEM fuel cell performance improvement through numerical optimization of the parameters of the porous layers. Int. J. Hydrogen Energy 2020, 45, 7968–7980. [Google Scholar] [CrossRef]

- Habiballahi, M.; Hassanzadeh, H.; Rahnama, M.; Mirbozorgi, S.A.; Jahanshahi Javaran, E. Effect of porosity gradient in cathode gas diffusion layer of polymer electrolyte membrane fuel cells on the liquid water transport using lattice Boltzmann method. Proc. Inst. Mech. Eng. Part A J. Power Energy 2020, 235, 546–562. [Google Scholar] [CrossRef]

- Kanchan, B.K.; Randive, P.; Pati, S. Implications of non-uniform porosity distribution in gas diffusion layer on the performance of a high temperature PEM fuel cell. Int. J. Hydrogen Energy 2021, 46, 18571–18588. [Google Scholar] [CrossRef]

- Kanchan, B.K.; Randive, P.; Pati, S. Numerical investigation of multi-layered porosity in the gas diffusion layer on the performance of a PEM fuel cell. Int. J. Hydrogen Energy 2020, 45, 21836–21847. [Google Scholar] [CrossRef]

- Yang, P.; Wang, Y.; Yang, Y.; Yuan, L.; Jin, Z. Effects of Gas Diffusion Layer Porosity Distribution on Proton Exchange Membrane Fuel Cell. Energy Technol. 2021, 9, 2001012. [Google Scholar] [CrossRef]

- Sim, J.; Kang, M.; Min, K. Effects of porosity gradient and average pore size in the in-plane direction and disposition of perforations in the gas diffusion layer on the performance of proton exchange membrane fuel cells. J. Power Source 2022, 544, 231912. [Google Scholar] [CrossRef]

- Corda, G.; Fontanesi, S.; d’Adamo, A. Methodology for PEMFC CFD Simulation Including the Effect of Porous Parts Compression. Int. J. Hydrogen Energy 2022, 47, 14658–14673. [Google Scholar] [CrossRef]

- Fan, L.; Zhang, G.; Jiao, K. Characteristics of PEMFC operating at high current density with low external humidification. Energy Convers. Manag. 2017, 150, 763–774. [Google Scholar] [CrossRef]

- Huo, S.; Jiao, K.; Park, J.W. On the water transport behavior and phase transition mechanisms in cold start operation of PEM fuel cell. Appl. Energy 2019, 233, 776–788. [Google Scholar] [CrossRef]

- Rostami, L.; Haghshenasfard, M.; Sadeghi, M.; Zhiani, M. A 3D CFD model of novel flow channel designs based on the serpentine and the parallel design for performance enhancement of PEMFC. Energy 2022, 258, 124726. [Google Scholar] [CrossRef]

- Cao, T.-F.; Lin, H.; Chen, L.; He, Y.-L.; Tao, W.-Q. Numerical investigation of the coupled water and thermal management in PEM fuel cell. Appl. Energy 2013, 112, 1115–1125. [Google Scholar] [CrossRef]

- Ramos-Alvarado, B.; Hernandez-Guerrero, A.; Ellis, M.W. Non-equilibrium two-phase model of the air-cathode of a PEM fuel cell based on GDL experimental water transport characteristics. J. Power Source 2013, 232, 376–388. [Google Scholar] [CrossRef]

- Litster, S.; Sinton, D.; Djilali, N. Ex situ visualization of liquid water transport in PEM fuel cell gas diffusion layers. J. Power Source 2006, 154, 95–105. [Google Scholar] [CrossRef]

- Wang, X.-D.; Huang, Y.-X.; Cheng, C.-H.; Jang, J.-Y.; Lee, D.-J.; Yan, W.-M.; Su, A. An inverse geometry design problem for optimization of single serpentine flow field of PEM fuel cell. Int. J. Hydrogen Energy 2010, 35, 4247–4257. [Google Scholar] [CrossRef]

- Rostami, L.; Mohamad Gholy Nejad, P.; Vatani, A. A numerical investigation of serpentine flow channel with different bend sizes in polymer electrolyte membrane fuel cells. Energy 2016, 97, 400–410. [Google Scholar] [CrossRef]

- Hu, M.; Gu, A.; Wang, M.; Zhu, X.; Yu, L. Three dimensional, two phase flow mathematical model for PEM fuel cell: Part, I. Model development. Energy Convers. Manag. 2004, 45, 1861–1882. [Google Scholar] [CrossRef]

- Gostick, J.T.; Fowler, M.W.; Pritzker, M.D.; Ioannidis, M.A.; Behra, L.M. In-plane and through-plane gas permeability of carbon fiber electrode backing layers. J. Power Source 2006, 162, 228–238. [Google Scholar] [CrossRef]

- Nanadegani, F.S.; Lay, E.N.; Sunden, B. Effects of an MPL on water and thermal management in a PEMFC. Int. J. Energy Res. 2019, 43, 274–296. [Google Scholar] [CrossRef] [Green Version]

- Jiao, K.; Li, X. Cold start analysis of polymer electrolyte membrane fuel cells. Int. J. Hydrogen Energy 2010, 35, 5077–5094. [Google Scholar] [CrossRef]

- Wu, H.; Li, X.; Berg, P. On the modeling of water transport in polymer electrolyte membrane fuel cells. Electrochim. Acta 2009, 54, 6913–6927. [Google Scholar] [CrossRef]

- Scholz, H. Modellierung und Untersuchung des Wärme—Und Stofftransports und von Flutungsphäno-menen in Niedertemperatur-PEM-Brennstoffzellen. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2015. [Google Scholar]

- Springer, T.E.; Zawodzinski, T.A.; Gottesfeld, S. Polymer electrolyte fuel cell model. J. Electrochem. Soc. India 1991, 138, 2334–2342. [Google Scholar] [CrossRef]

- Bernardi, D.M.; Verbrugge, M.W. A Mathematical Model of the Solid-Polymer-Electrolyte Fuel Cell. J. Electrochem. Soc. 2019, 139, 2477–2491. [Google Scholar] [CrossRef]

- Tao, W.Q.; Min, C.H.; Liu, X.L.; He, Y.L.; Yin, B.H.; Jiang, W. Parameter sensitivity examination and discussion of PEM fuel cell simulation model validation. J. Power Source 2006, 160, 359–373. [Google Scholar] [CrossRef]

- Kanani, H.; Shams, M.; Hasheminasab, M.; Bozorgnezhad, A. Model development and optimization of operating conditions to maximize PEMFC performance by response surface methodology. Energy Convers. Manag. 2015, 93, 9–22. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, L.; Chuang, P.-Y.A.; Djilali, N.; Sui, P.-C. Coupled stress–strain and transport in proton exchange membrane fuel cell with metallic bipolar plates. Appl. Energy 2019, 251, 113316. [Google Scholar] [CrossRef]

- Miao, T.; Tongsh, C.; Wang, J.; Cheng, P.; Liang, J.; Wang, Z.; Chen, W.; Zhang, C.; Xi, F.; Du, Q.; et al. Current density and temperature distribution measurement and homogeneity analysis for a large-area proton exchange membrane fuel cell. Energy 2022, 239, 121922. [Google Scholar] [CrossRef]

| Structure Parameters | Values |

|---|---|

| Length/Width/Height (mm) | 60/2/2.407 |

| Channel depth (mm) | 0.5 |

| Channel width (mm) | 0.8 |

| Rib width (mm) | 0.6 |

| GDL/MPL/CL thickness (mm) | 0.16/0.03/0.009 |

| PEM thickness (mm) | 0.012 |

| Porosity of anode GDL/MPL/CL | 0.7/0.6/0.5 |

| Porosity of cathode GDL | 0.8–0.4/0.6/0.4–0.8 |

| Porosity of cathode MPL/CL | 0.6/0.5 |

| Parameters | Value |

|---|---|

| GDL/MPL/CL Permeability (m2) | 9.1 × 10−12/3.4 × 10−12/3 × 10−14 |

| GDL/MPL/CL electrical conductivity (s·m−1) | 1826.7/3779.2/1162.5 |

| GDL/MPL/CL thermal conductivity (W·m−1·K) | 2.6/5.4/9.3 |

| GDL/MPL/CL specific heat capacity (J·kg−1·K) | 710/710/3300 |

| GDL/MPL/CL contact angle (deg) | 130/140/120 |

| GDL/MPL/CL density (kg·m−3) | 440/1880/1000 |

| Active area (mm2) | 120 |

| Reference anode exchange current density (mA·cm−2) | 1 × 105 |

| Reference cathode exchange current density (mA·cm−2) | 100 |

| Surface/Volume ratio in CL (m−1) | 2 × 10−5 |

| Volume fraction of the ionomer in the CL | ω = 0.25 |

| Anode transfer coefficient | 0.7 |

| Cathode transfer coefficient | 0.3 |

| Effective electron conductivity and ion conductivity | |

| Electro-osmotic drag (EOD) drag coefficient | |

| Reference hydrogen and oxygen concentrations | |

| Gas dynamic viscosity () | |

| Liquid water dynamic viscosity (mPa·s) (at 353.15 K) | = 0.356 |

| Parameters | Value |

|---|---|

| H2 mass fraction in the anode inlet | |

| O2 mass fraction in the cathode inlet | |

| Mass flow in the anode inlet (kg·s−1) | |

| Mass flow in the cathode inlet (kg·s−1) | |

| Relative humidity in anode/cathode | 50%/50% |

| Outlet pressure in anode/cathode (kPa) | 150/150 |

| Stoichiometry in anode/cathode | 1.5/2.0 |

| Temperature (K) | 353.15 |

| Number of Mesh | Voltage (V) | Calculation Time (h) | |

|---|---|---|---|

| Mesh 1 | 132,000 | 0.517574 | 2.7 |

| Mesh 2 | 264,000 | 0.520874 | 5.2 |

| Mesh 3 | 393,600 | 0.523761 | 6.1 |

| Mesh 4 | 787,200 | 0.524113 | 9.2 |

| Mesh 5 | 924,000 | 0.524419 | 13.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, R.; Zhan, Z.; Zhang, H.; Du, Q.; Chen, X.; Xiang, X.; Wen, X.; Pan, M. Effects of Cathode GDL Gradient Porosity Distribution along the Flow Channel Direction on Gas–Liquid Transport and Performance of PEMFC. Polymers 2023, 15, 1629. https://doi.org/10.3390/polym15071629

Zhu R, Zhan Z, Zhang H, Du Q, Chen X, Xiang X, Wen X, Pan M. Effects of Cathode GDL Gradient Porosity Distribution along the Flow Channel Direction on Gas–Liquid Transport and Performance of PEMFC. Polymers. 2023; 15(7):1629. https://doi.org/10.3390/polym15071629

Chicago/Turabian StyleZhu, Ruijie, Zhigang Zhan, Heng Zhang, Qing Du, Xiaosong Chen, Xin Xiang, Xiaofei Wen, and Mu Pan. 2023. "Effects of Cathode GDL Gradient Porosity Distribution along the Flow Channel Direction on Gas–Liquid Transport and Performance of PEMFC" Polymers 15, no. 7: 1629. https://doi.org/10.3390/polym15071629

APA StyleZhu, R., Zhan, Z., Zhang, H., Du, Q., Chen, X., Xiang, X., Wen, X., & Pan, M. (2023). Effects of Cathode GDL Gradient Porosity Distribution along the Flow Channel Direction on Gas–Liquid Transport and Performance of PEMFC. Polymers, 15(7), 1629. https://doi.org/10.3390/polym15071629