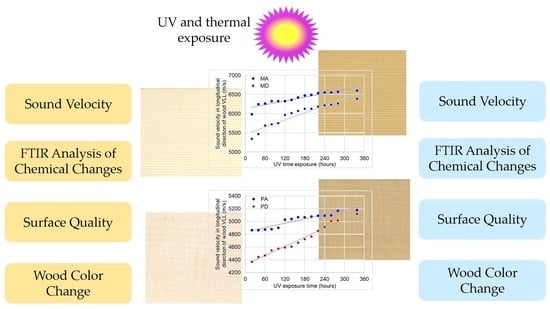

Aging of Wood for Musical Instruments: Analysis of Changes in Color, Surface Morphology, Chemical, and Physical-Acoustical Properties during UV and Thermal Exposure

Abstract

:1. Introduction

2. Materials and Methods

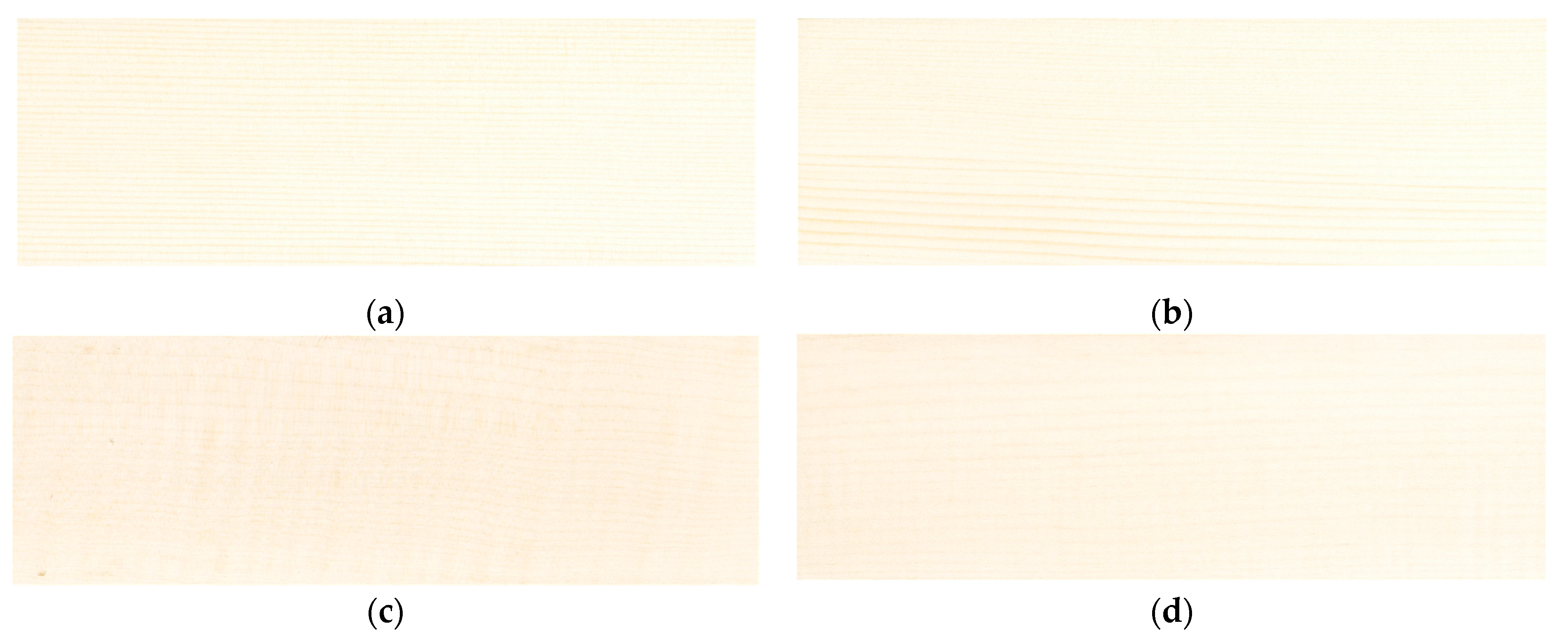

2.1. Materials

2.2. Methods

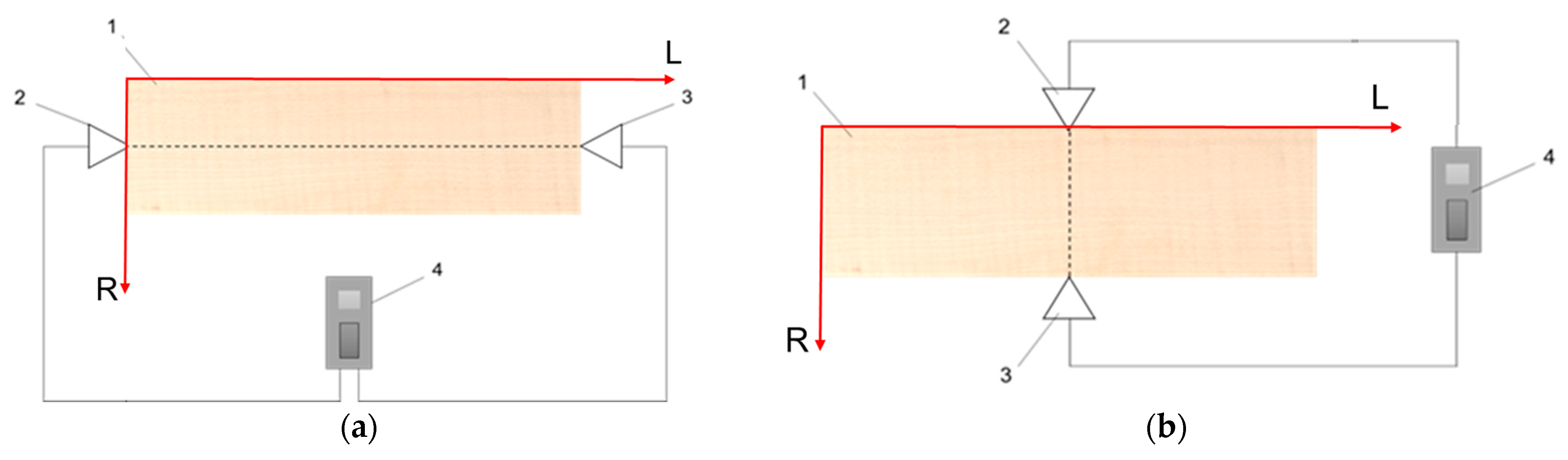

2.2.1. UV and Thermal Exposure

2.2.2. Wood Color Change Measurements

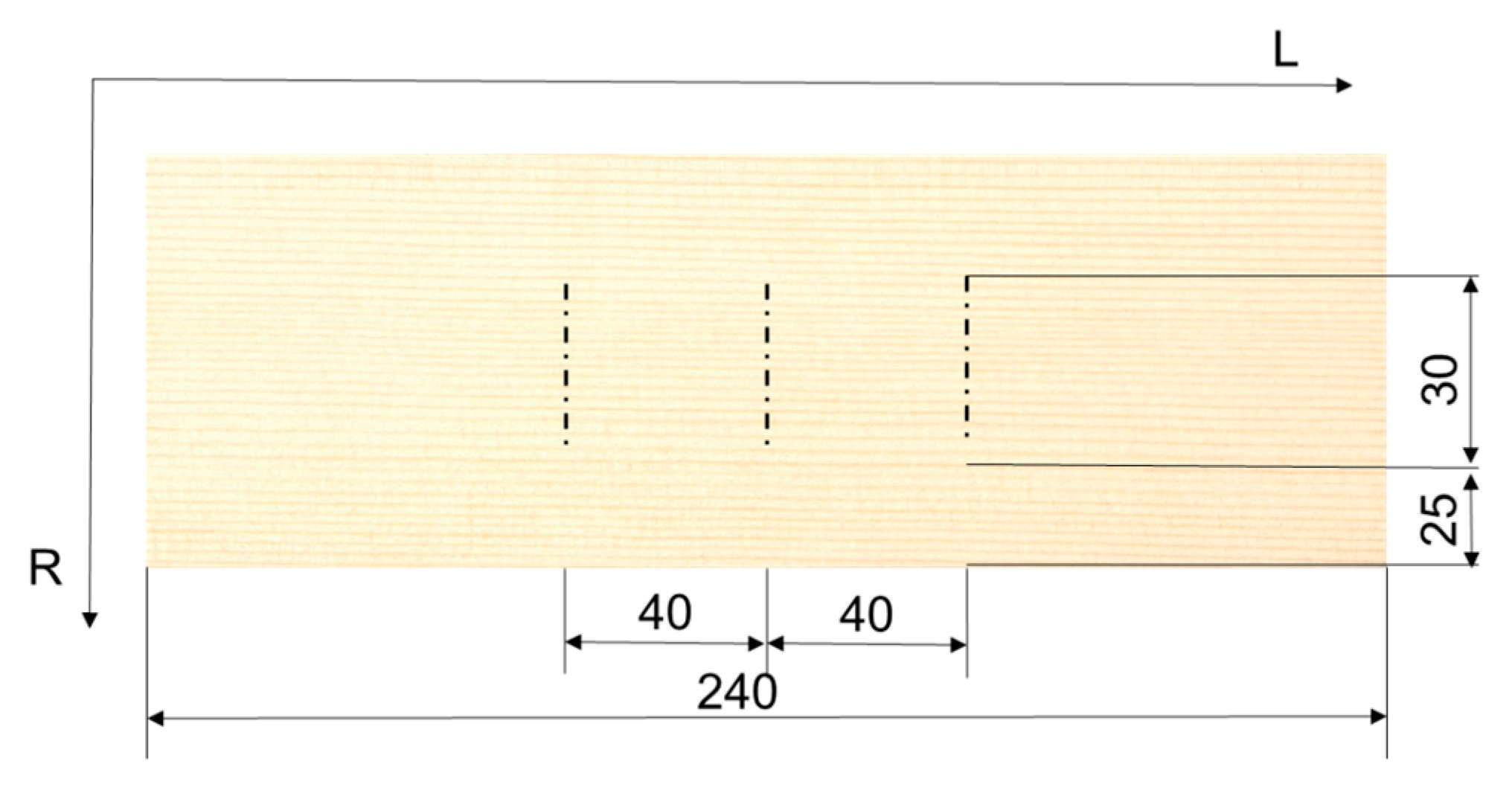

2.2.3. Surface Quality Measurements

2.2.4. FTIR Analysis of Chemical Changes on Wood Surfaces

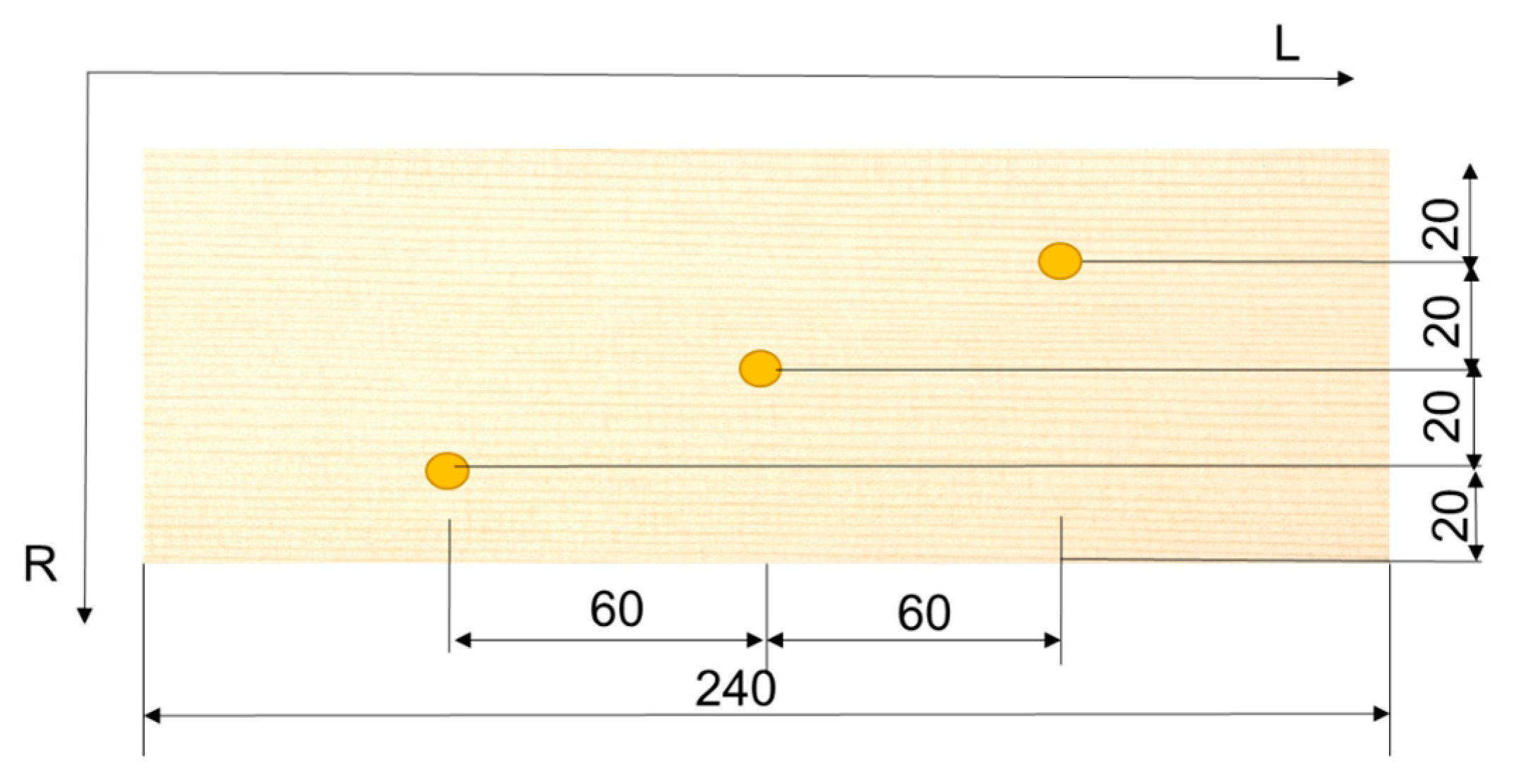

2.2.5. Sound Velocity Measurements

3. Results and Discussions

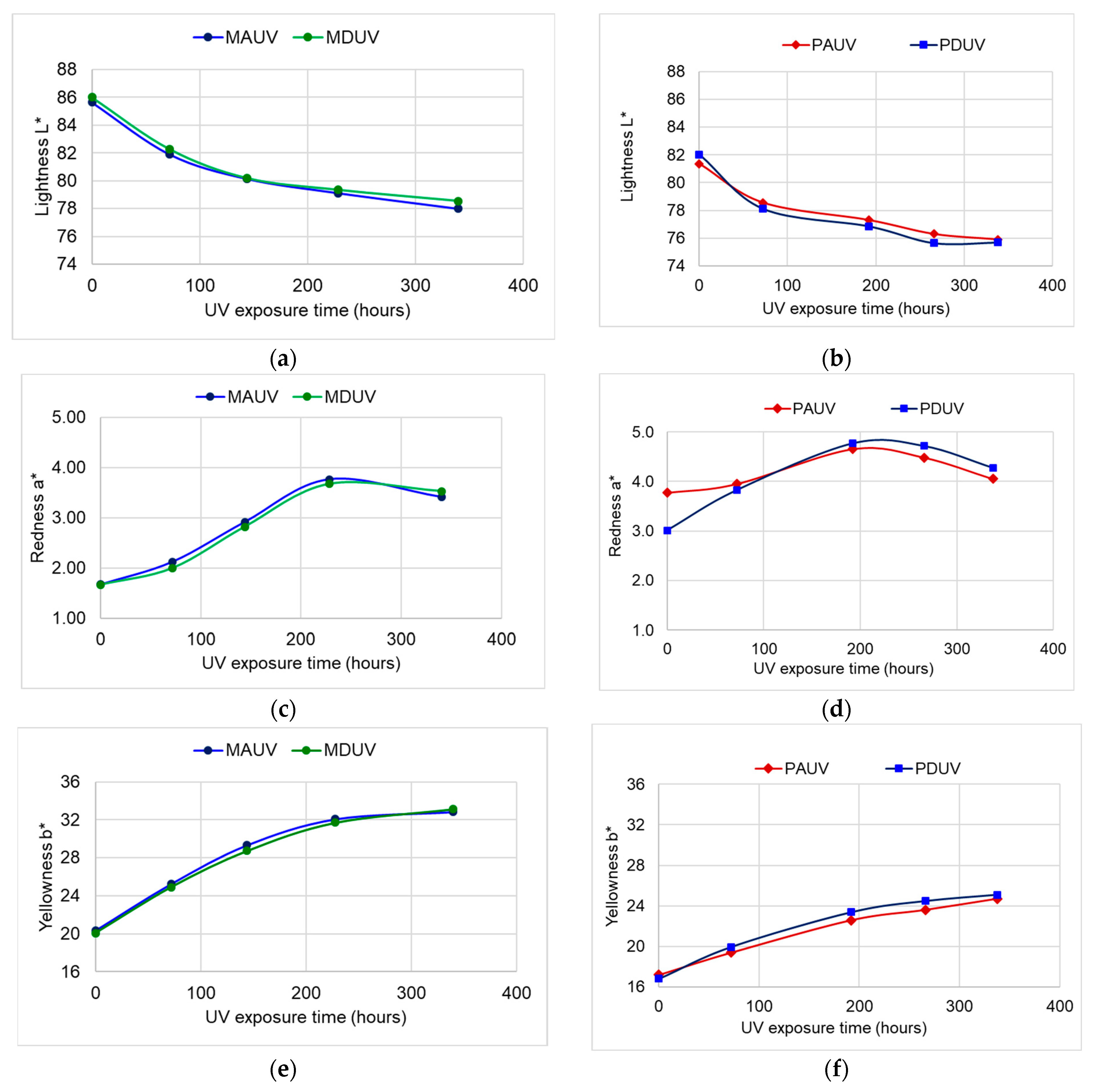

3.1. Changes in Color Parameters

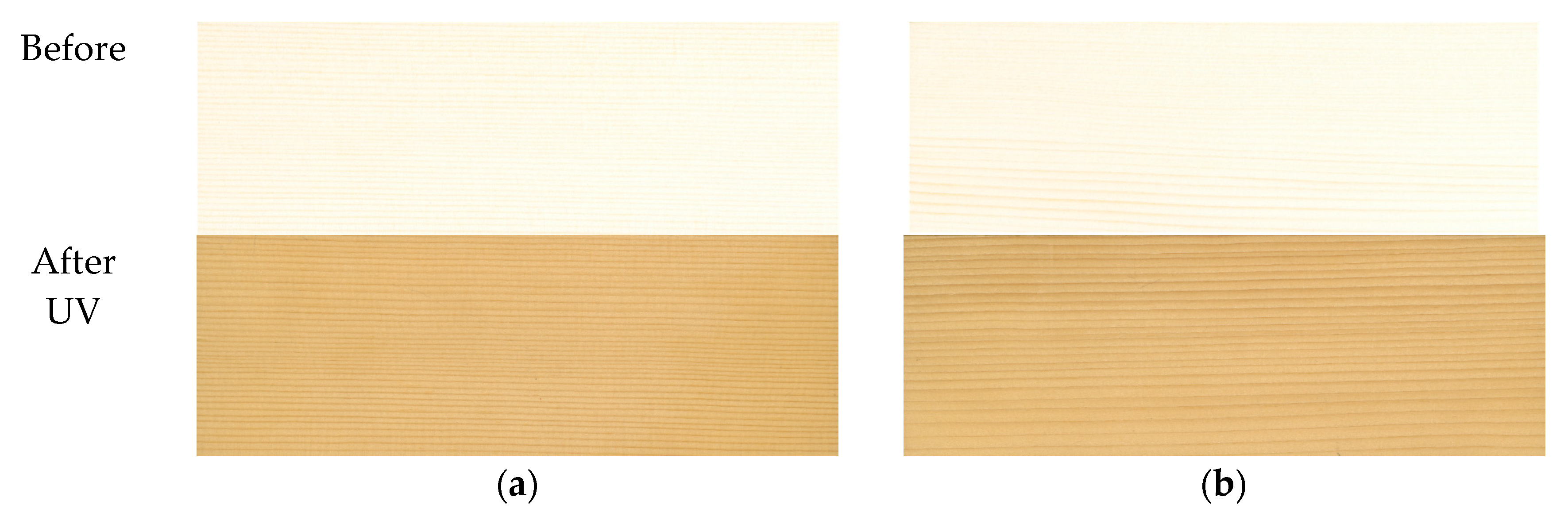

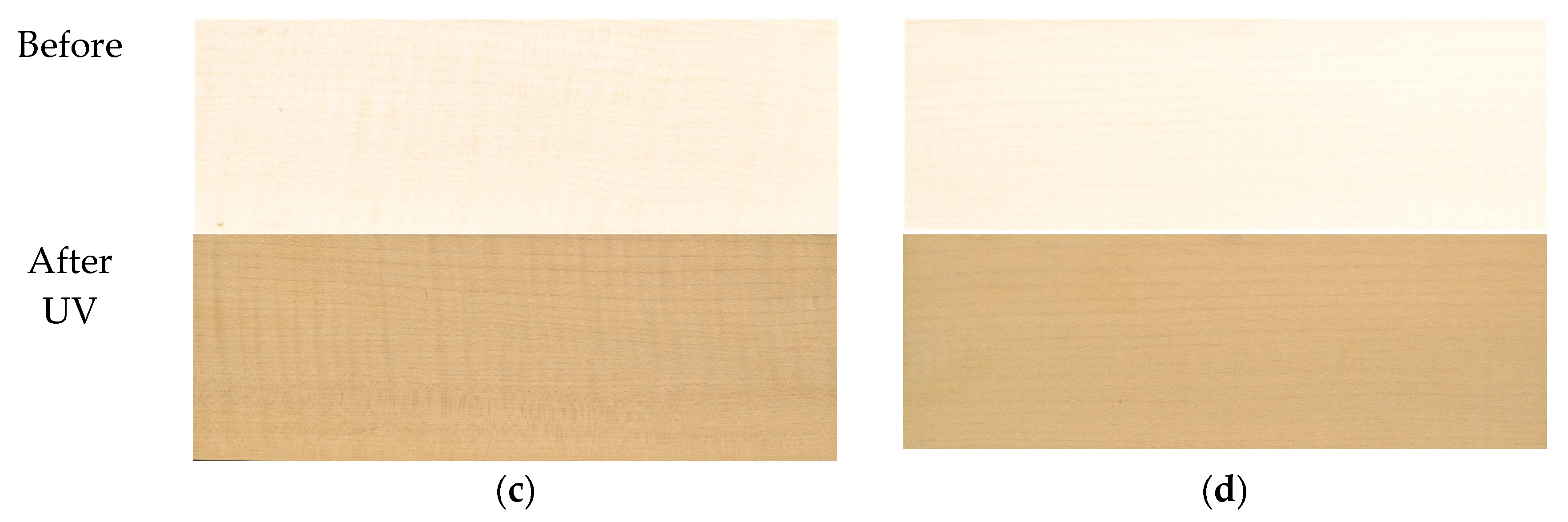

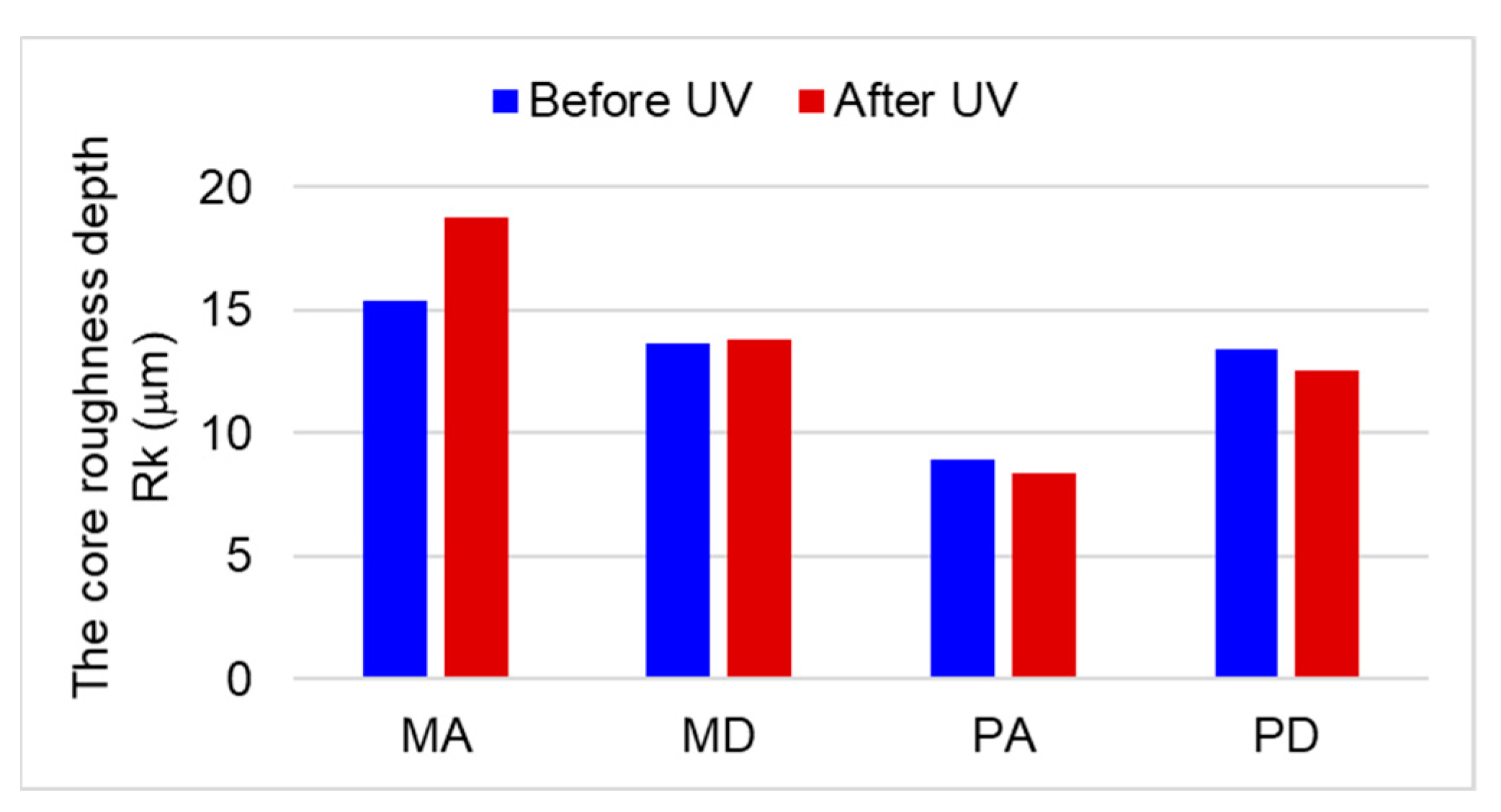

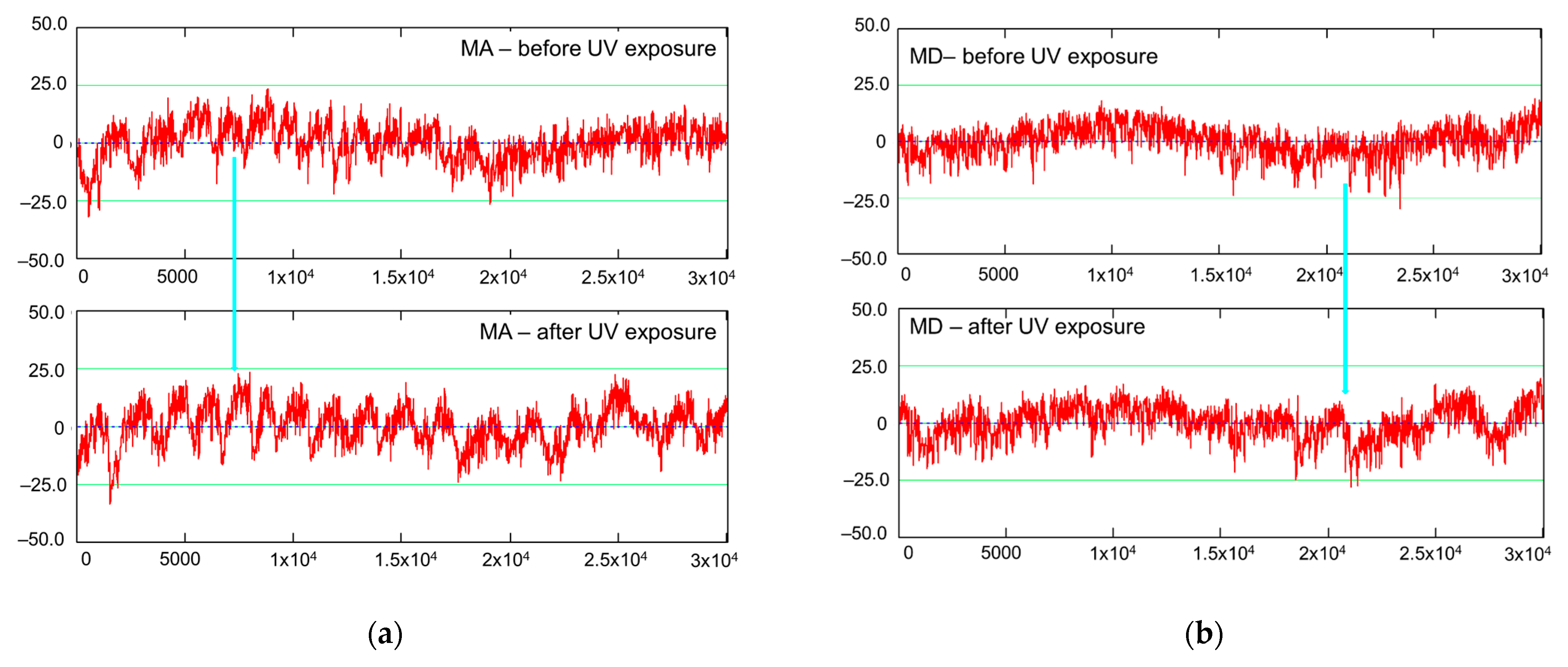

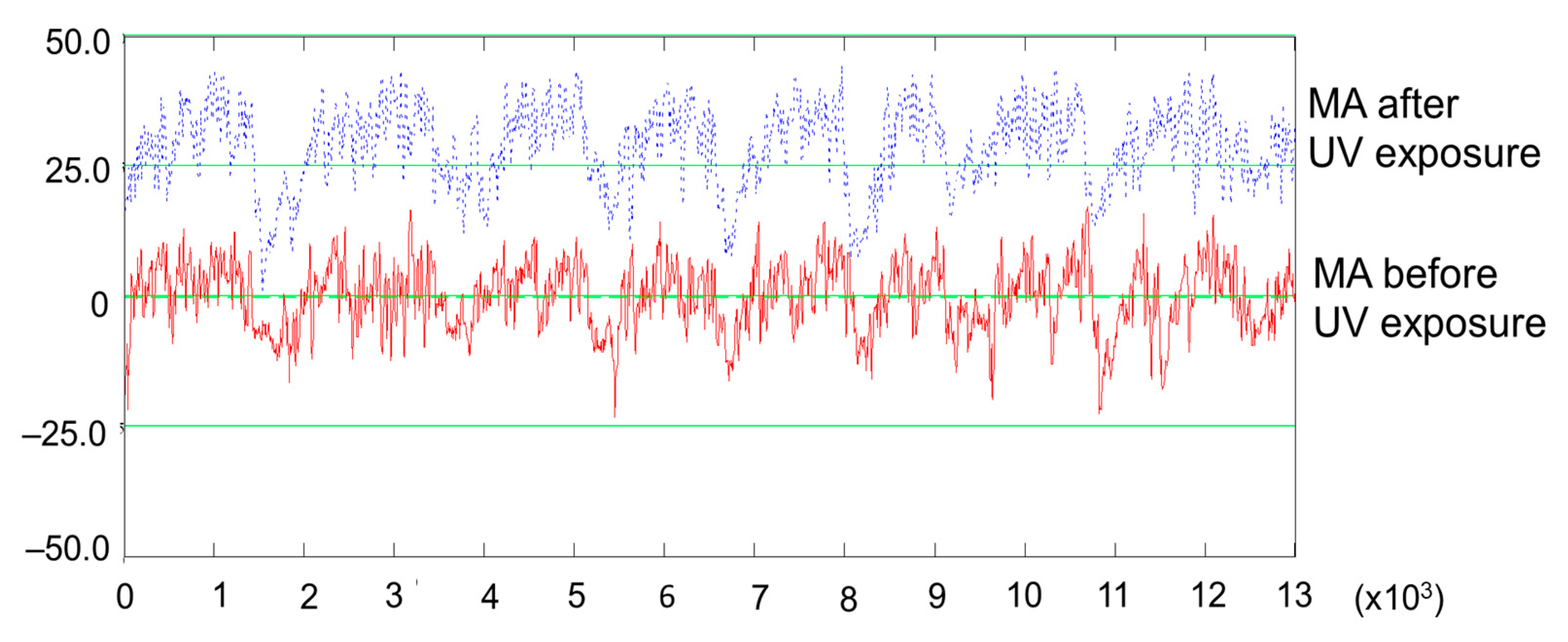

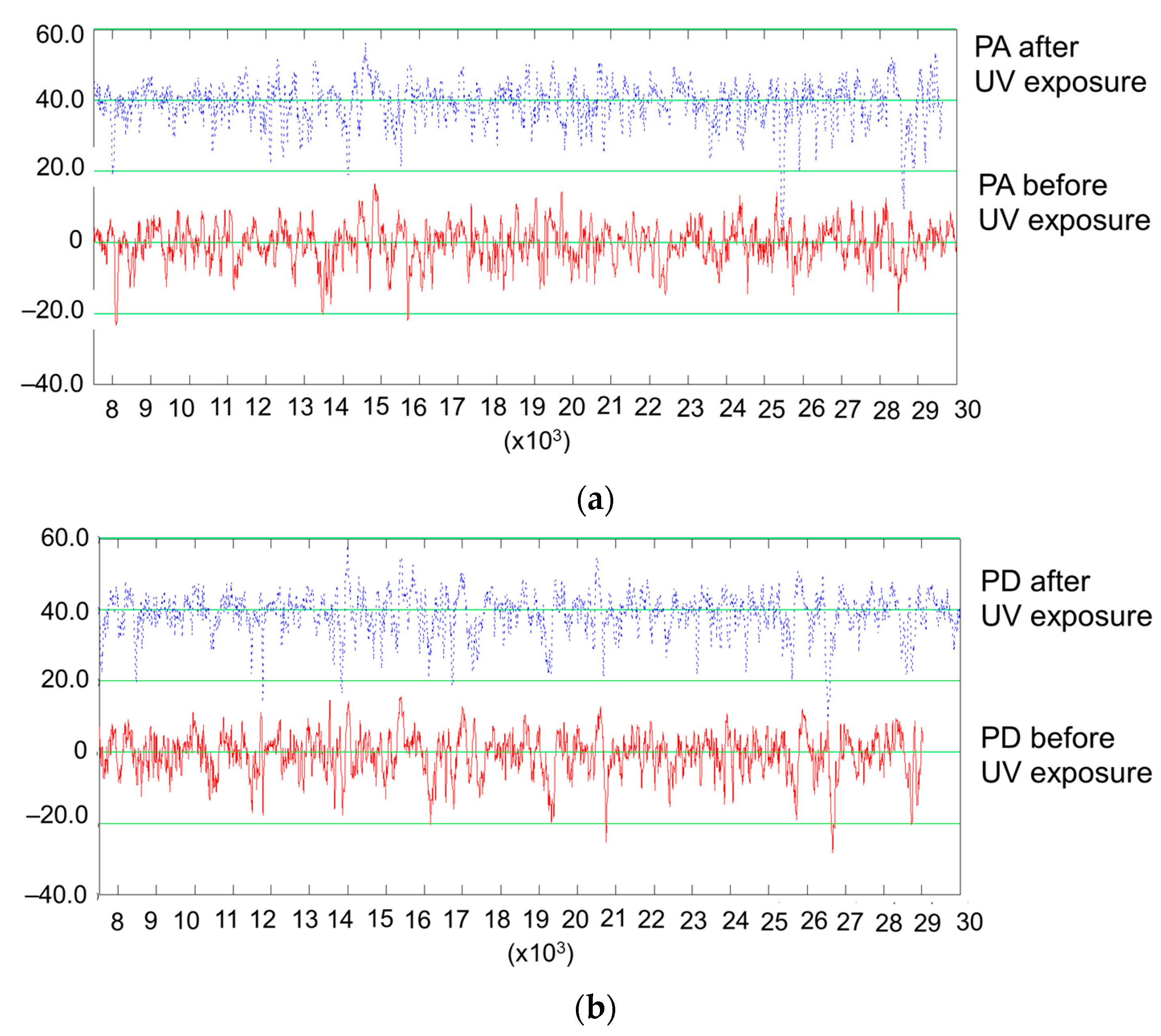

3.2. Study on the Surface Morphology

3.2.1. Surface Morphology Parameters for Spruce and Maple, before and after the UV Treatment

3.2.2. The Effect of UV Treatment on Spruce Wood

3.2.3. The Effect of UV Treatment on the Surface Morphology of Sycamore Maple Wood

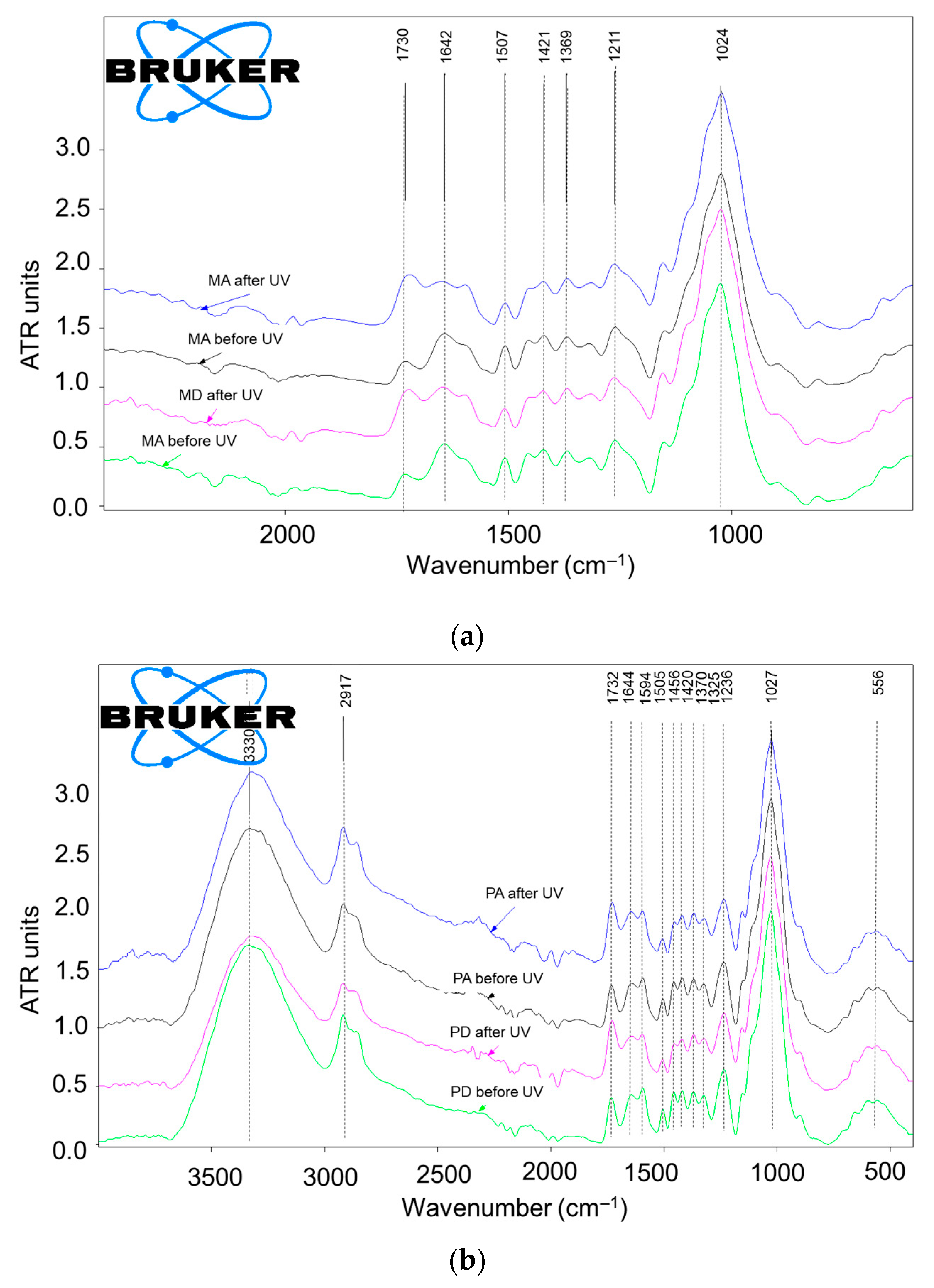

3.3. FTIR Spectroscopy

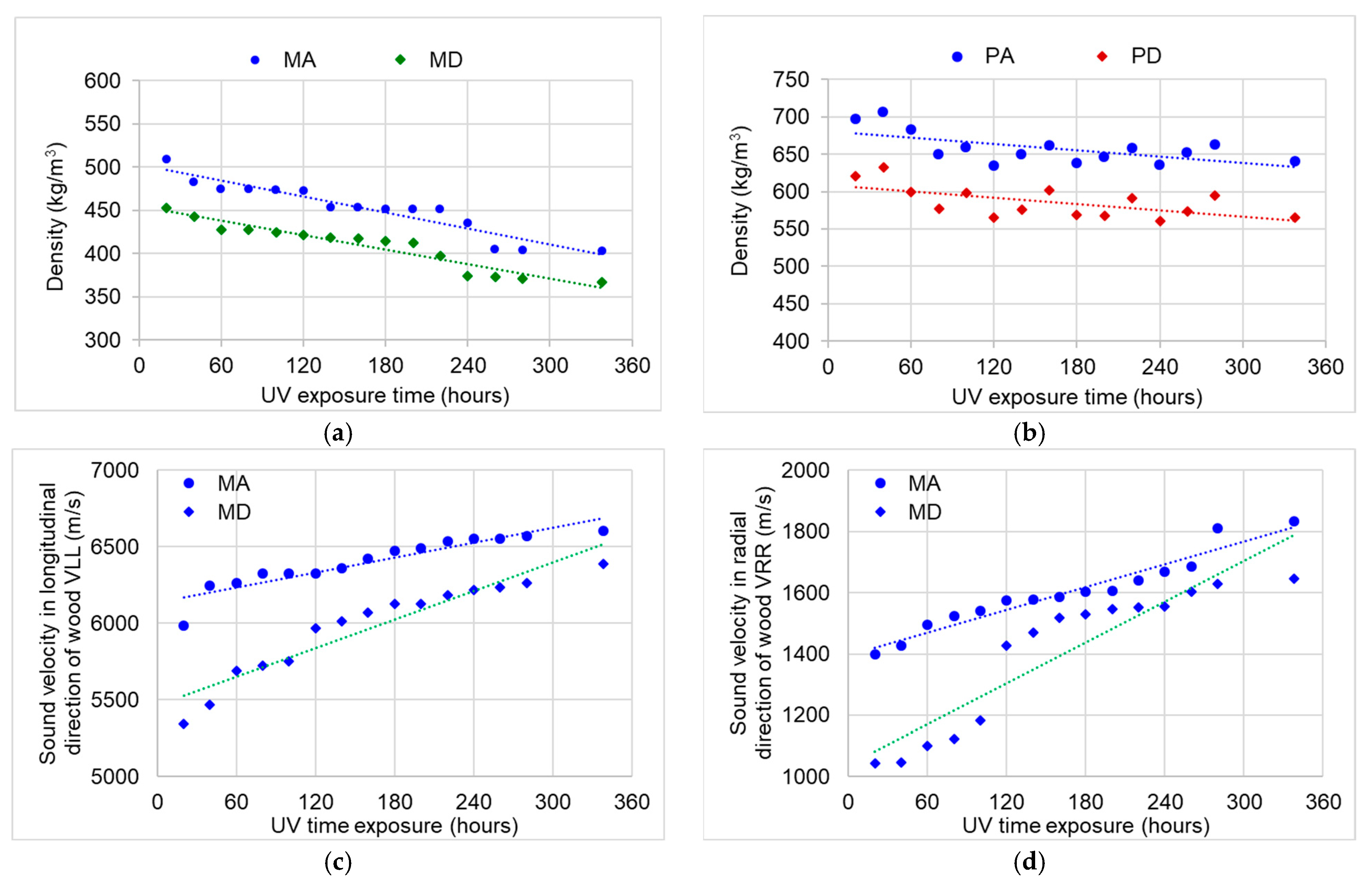

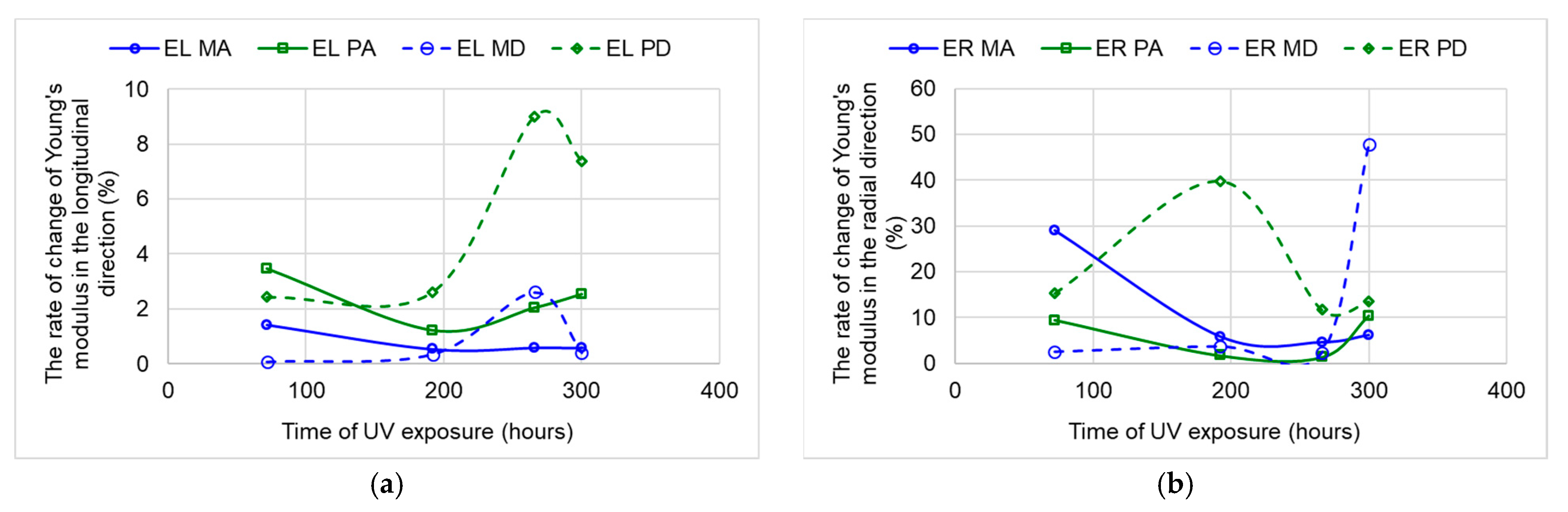

3.4. Changes in Acoustic Properties

4. Conclusions

- The UV treatment induced an increase in the total color change, which was more accentuated in spruce compared to sycamore maple. However, the differences in the color change between the two quality classes (A and D) were insignificant;

- The FTIR results indicated a more advanced aging process for spruce compared to maple under the same experimental conditions. This difference resulted mostly from the formation of more carbonyl-containing chromophores by oxidative processes, which is in good accordance with the greater color changes measured in the spruce samples compared to the sycamore maple samples;

- A wavier surface after the UV treatment increased the area of exposure and degradation, and this was more pronounced for quality class A;

- For both species, the sound speed increased after the UV treatment in thee longitudinal as well as in the radial direction. UV exposure improved the sound speed to the greatest extent for quality class A (of the two species) and for radial direction sound propagation. The quality class A samples registered a sound speed increase in the radial direction of 14.5% (spruce) and 15.5% (maple) when compared to class D (9.7% spruce; 11.5% sycamore maple). The sound velocity increased by app. 5–6% in the longitudinal direction;

- The most important changes in the stiffness of the class A boards (spruce and sycamore maple) occurred in the first 72 h of exposure to thermal and UV radiation and after 200 h for the class D samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stoel, B.C.; Borman, T.M. A Comparison of Wood Density between Classical Cremonese and Modern Violins. PLoS ONE 2008, 3, e2554. [Google Scholar] [CrossRef]

- Stanciu, M.D.; Mihălcică, M.; Dinulică, F.; Nauncef, A.M.; Purdoiu, R.; Lăcătuș, R.; Gliga, G.V. X-ray Imaging and Computed Tomography for the Identification of Geometry and Construction Elements in the Structure of Old Violins. Materials 2021, 14, 5926. [Google Scholar] [CrossRef]

- Su, C.K.; Chen, S.Y.; Chung, J.H.; Li, G.C.; Brandmair, B.; Huthwelker, T.; Fulton, J.L.; Borca, C.N.; Huang, S.J.; Nagyvary, J.; et al. Materials Engineering of Violin Soundboards by Stradivari and Guarneri. Angew. Chem. Int. Ed. Engl. 2021, 60, 19144–19154. [Google Scholar] [CrossRef] [PubMed]

- Smidt, E.; Schwanninger, M.; Tintner, J.; Böhm, K. Ageing and Deterioration of Materials in the Environment—Application of Multivariate Data Analysis. In Multivariate Analysis in Management, Engineering and Science; IntechOpen: London, UK, 2013. [Google Scholar] [CrossRef]

- Hernandez, V.A.; Romero, R.; Sagredo, N.; Contreras, D.; Evans, P.D. Studies of the Photoprotection of Radiata Pine Wood Using Photocatalytic Nanoparticles. Forests 2022, 13, 1922. [Google Scholar] [CrossRef]

- Tolvaj, L.; Molnár, S. Photodegradation and thermal degradation of outdoor wood. In Proceedings of the Wood Science for Preservation of Cultural Heritage: Mechanical and Biological Factors, Braga, Portugal, 5–7 November 2008; pp. 67–72. [Google Scholar]

- Kojiro, K.; Furuta, Y.; Ohkoshi, M.; Ishimaru, Y.; Yokoyama, M.; Sugiyama, J.; Kawai, S.; Mitsutani, T.; Ozaki, H.; Sakamoto, M.; et al. Changes in micropores in dry wood with elapsed time in the environment. J. Wood Sci. 2008, 54, 515–519. [Google Scholar] [CrossRef]

- Tolvaj, L.; Molnár, Z.; Németh, R. Photodegradation of wood at elevated temperature: Infrared spectroscopic study. J. Photochem. Photobiol. B Biol. 2013, 121, 32–36. [Google Scholar] [CrossRef]

- Timar, M.C.; Varodi, A.M.; Gurau, L. Comparative study of photodegradation of six wood species after short-time UV ex-posure. Wood Sci. Technol. 2016, 50, 135–163. [Google Scholar] [CrossRef]

- Liu, X.Y.; Timar, M.C.; Varodi, A.M.; Sawyer, G. An investigation of accelerated temperature-induced ageing of four wood species: Colour and FTIR. Wood Sci. Technol. 2016, 51, 357–378. [Google Scholar] [CrossRef]

- Liu, X.; Timar, M.C.; Varodi, A.M.; Nedelcu, R.; Torcătoru, M.-J. Colour and Surface Chemistry Changes of Wood Surfaces Coated with Two Types of Waxes after Seven Years Exposure to Natural Light in Indoor Conditions. Coatings 2022, 12, 1689. [Google Scholar] [CrossRef]

- Tolvaj, L.; Molnar, Z.; Magoss, E. Measurement of photodegradation-caused roughness of wood using a new optical method. J. Photochem. Photobiol. B Biol. 2014, 134, 23–26. [Google Scholar] [CrossRef] [PubMed]

- Jirouš-Rajković, V.; Miklečić, J. Enhancing Weathering Resistance of Wood—A Review. Polymers 2021, 13, 1980. [Google Scholar] [CrossRef] [PubMed]

- Kuo, M.-L.; Hu, N. Ultrastructural Changes of Photodegradation of Wood Surfaces Exposed to UV. Holzforschung 1991, 45, 347–353. [Google Scholar] [CrossRef]

- Froidevaux, J.; Volkmer, T.; Ganne-Chédeville, C.; Gril, J.; Navi, P. Viscoelastic behavior of aged and non-aged spruce wood in the radial direction. Wood Mater. Sci. Eng. 2012, 7, 1–12. [Google Scholar] [CrossRef]

- Kránitz, K.; Deublein, M.; Niemz, P. Determination of dynamic elastic moduli and shear moduli of aged wood by means of ultrasonic devices. Mater. Struct. 2013, 47, 925–936. [Google Scholar] [CrossRef]

- Noguchi, T.; Obataya, E.; Ando, K. Effects of aging on the vibrational properties of wood. J. Cult. Heritage 2012, 13, S21–S25. [Google Scholar] [CrossRef]

- Gall, R.; Stanciu, M.D.; Filimon, E.; Cosnita, M.; Gliga, V.G. The influence of artificial aging on resonance wood on its physical characteristics. In Proceedings of the 9th International Conference on Advanced Composite Materials Engineering, Brasov, Romania, 17–18 October 2022; pp. 73–81. [Google Scholar]

- Van Blokland, J.; Adamopoulos, S.; Ahmed, S.A. Performance of Thermally Modified Spruce Timber in Outdoor Above-Ground Conditions: Checking, Dynamic Stiffness and Static Bending Properties. Appl. Sci. 2020, 10, 3975. [Google Scholar] [CrossRef]

- Chédeville, C.G.; Jääskeläinen, A.S.; Froidevaux, J.; Hughes, M.; Navi, P. Natural and artifcial ageing of spruce wood as observed by FTIR-ATR and UVRR spectroscopy. Holzforschung 2012, 66, 163–170. [Google Scholar] [CrossRef]

- Cirule, D.; Kuka, E.; Andersone, I.; Andersons, B. Wood discoloration patterns depending on the light source. Heritage Sci. 2022, 10, 158. [Google Scholar] [CrossRef]

- Oltean, L.; Teischinger, A.; Hansmann, C. Wood surface discolouration due to simulated indoor sunlight exposure. Holz Als Roh-Und Werkst. 2008, 66, 51–56. [Google Scholar] [CrossRef]

- Zeniya, N.; Obataya, E.; Endo-Ujiie, K.; Matsuo-Ueda, M. Changes in vibrational properties and colour of spruce wood by hygrothermally accelerated ageing at 95–140 °C and different relative humidity levels. SN Appl. Sci. 2018, 1, 7. [Google Scholar] [CrossRef]

- Obataya, E. Effects of natural and artificial ageing on the physical and acoustic properties of wood in musical instruments. J. Cult. Herit. 2017, 27, S63–S69. [Google Scholar] [CrossRef]

- Ono, T. Frequency responses of wood for musical instruments in relation to the vibrational properties. Acoust. Sci. Technol. 1996, 17, 183–193. [Google Scholar] [CrossRef]

- Danihelová, A.; Vidholdová, Z.; Gergeľ, T.; Kružlicová, L.S.; Pástor, M. Thermal Modification of Spruce and Maple Wood for Special Wood Products. Polymers 2022, 14, 2813. [Google Scholar] [CrossRef]

- Mania, P.; Gąsiorek, M. Acoustic Properties of Resonant Spruce Wood Modified Using Oil-Heat Treatment (OHT). Materials 2020, 13, 1962. [Google Scholar] [CrossRef] [PubMed]

- Dinulică, F.; Stanciu, M.D.; Savin, A. Correlation between Anatomical Grading and Acoustic–Elastic Properties of Resonant Spruce Wood Used for Musical Instruments. Forests 2021, 12, 1122. [Google Scholar] [CrossRef]

- Dinulica, F.; Savin, A.; Stanciu, M.D. Physical and Acoustical Properties of Wavy Grain Sycamore Maple (Acer pseudoplatanus L.) Used for Musical Instruments. Forests 2023, 14, 197. [Google Scholar] [CrossRef]

- Tismanar, I.; Obreja, A.C.; Buiu, O.; Duta, A. VIS-active TiO2—graphene oxide composite thin films for photocatalytic applications. Appl. Surf. Sci. 2020, 538, 147833. [Google Scholar] [CrossRef]

- Yin, H.; Moghaddam, M.S.; Tuominen, M.; Dėdinaitė, A.; Wålinder, M.; Swerin, A. Wettability performance and physicochemical properties of UV exposed superhydrophobized birch wood. Appl. Surf. Sci. 2022, 584, 152528. [Google Scholar] [CrossRef]

- Sahin, H.T.; Mantanis, G.I. Colour changes in wood surfaces modified by a nanoparticulate based treatment. Wood Res. 2011, 56, 525–532. [Google Scholar]

- Stanciu, M.D.; Sova, D.; Savin, A.; Ilias, N.; Gorbacheva, G.A. Physical and Mechanical Properties of Ammonia-Treated Black Locust Wood. Polymers 2020, 12, 377. [Google Scholar] [CrossRef]

- Gurau, L.; Irle, M. Surface Roughness Evaluation Methods for Wood Products: A Review. Curr. For. Rep. 2017, 3, 119–131. [Google Scholar] [CrossRef]

- ISO 4287:2009; Geometrical Product Specifications (GPS). Surface Texture: Profile Method. Terms. Definitions and Surface Texture Parameters. International Organization for Standardization: London, UK, 2009.

- ISO 13565-2:1998; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method. Surfaces Having Stratified Functional Properties. Part 2: Height Characterisation Using the Linear Material Ratio Curve. International Organization for Standardization: London, UK, 1998.

- Gurau, L. The Roughness of Sanded Wood Surfaces. Ph.D. Thesis, Brunel University, London, UK, 2004. [Google Scholar]

- Pandey, K.K.; Vuorinen, T. Comparative study of photodegradation of wood by a UV laser and a xenon light source. Polym. Degrad. Stab. 2008, 93, 2138–2146. [Google Scholar] [CrossRef]

- Müller, U.; Rätzsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-changes of spruce wood as result of UV-irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef] [PubMed]

- Kránitz, K.; Sonderegger, W.; Bues, C.-T.; Niemz, P. Effects of aging on wood: A literature review. Wood Sci. Technol. 2015, 50, 7–22. [Google Scholar] [CrossRef]

- Kataoka, Y.; Kiguchi, M.; Williams, R.S.; Evans, P.D. Violet light causes photodegradation of wood beyond the zone affected by ultraviolet radiation. Holzforschung 2007, 61, 23–27. [Google Scholar] [CrossRef]

- Kataoka, Y. Photodegradation of Wood and Depth Profile Analysis. Mokuzai Gakkaishi 2008, 54, 165–173. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood—Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany; New York, NY, USA, 1984. [Google Scholar]

- Wagenführ, R. Holzatlas (Wood Atlas); Hanser Fachbuchverlag: Leipzig, Germany, 2000. (In German) [Google Scholar]

- Chang, H.-T.; Yeh, T.-F.; Chang, S.-T. Comparisons of chemical characteristic variations for photodegraded softwood and hardwood with/without polyurethane clear coatings. Polym. Degrad. Stab. 2002, 77, 129–135. [Google Scholar] [CrossRef]

- Chang, T.-C.; Chang, H.-T.; Wu, C.-L.; Chang, S.-T. Influences of extractives on the photodegradation of wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

- Agresti, G.; Bonifazi, G.; Calienno, L.; Capobianco, G.; Lo Monaco, A.; Pelosi, C.; Picchio, R.; Serranti, S. Surface Investigation of Photo-Degraded Wood by Colour Monitoring, Infrared Spectroscopy, and Hyperspectral Imaging. J. Spectrosc. 2013, 2013, 380536. [Google Scholar] [CrossRef]

- Crețu, N.; Roșca, I.C.; Stanciu, M.D.; Gliga, V.G.; Cerbu, C. Evaluation of Wave Velocity in Orthotropic Media Based on Intrinsic Transfer Matrix. Exp. Mech. 2022, 62, 1595–1602. [Google Scholar] [CrossRef]

- Danihelova, A.; Spisiak, D.; Halachan, P.; Gergel, T.; Kruzlikova, L. Physico-acoustical characteristics of usual and unusual wood species. Akustika 2015, 35, 22–27. [Google Scholar]

- Kúdela, J.; Kunštár, M. Physical-acoustical characteristics of maple wood with wavy structure. Ann. Warsaw Univ. Life Sci.—SGGW For. Wood Technol. 2011, 75, 12–18. [Google Scholar]

- Yoshikawa, S.; Waltham, C. Woods for Wooden Musical Instruments. In Proceedings of the International Symposium on Musical Acoustics (ISMA) 2014, Le Mans, France, 7–12 July 2014. [Google Scholar]

- Brémaud, I. Acoustical properties of wood in string instruments soundboards and tuned idiophones: Biological and cultural diversity. J. Acoust. Soc. Am. 2012, 131, 807–818. [Google Scholar] [CrossRef] [PubMed]

- Straže, A.; Jerman, J.; Brus, R.; Merela, M.; Gorisek, Z.; Krajnic, L. Selected structural, physical and acoustic properties of sycamore maple wood with fiddleback figure. In Proceedings of the 9th Hardwood Conference, An underutilized resource: Hardwood Oriented Research, Sopron, Hungary, 24–25 June 2021; pp. 261–266. [Google Scholar]

| Wood Samples | Before UV | After UV | Total Variation | Moisture Content (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | ΔE* | ΔL* | Before UV | After UV | ||

| MA | MV | 85.63 | 1.67 | 20.34 | 79.12 | 3.77 | 32.07 | 14.75 | −7.64 | 7.73 | 5.93 |

| SD | 0.21 | 0.14 | 0.88 | 0.13 | 0.06 | 0.77 | 0.25 | 0.12 | |||

| MD | MV | 86.02 | 1.67 | 20.07 | 79.34 | 3.67 | 31.71 | 15.18 | −7.49 | 7.63 | 5.57 |

| SD | 1.02 | 0.47 | 0.31 | 0.64 | 0.22 | 0.62 | 0.12 | 0.4 | |||

| PA | MV | 81.37 | 3.78 | 17.23 | 75.92 | 4.05 | 24.71 | 9.26 | −5.45 | 7.03 | 4.43 |

| SD | 0.14 | 0.10 | 0.30 | 0.34 | 0.17 | 0.48 | 0.35 | 0.32 | |||

| PD | MV | 82.03 | 3.01 | 16.82 | 75.68 | 4.28 | 25.10 | 10.50 | −6.34 | 6.60 | 4.03 |

| SD | 3.35 | 0.26 | 0.66 | 0.98 | 0.87 | 0.47 | 0.85 | 0.25 | |||

| Wood Samples | Ra | Rk | Rpk | Rvk | Rk + Rpk + Rvk | Rt | Wa | |

|---|---|---|---|---|---|---|---|---|

| MA Before UV | MV | 4.61 | 15.37 | 4.37 | 6.02 | 25.75 | 41.23 | 5.61 |

| SD | 0.35 | 1.24 | 0.42 | 1.11 | 2.12 | 4.64 | 1.11 | |

| MA After UV | MV | 5.62 | 18.76 | 4.56 | 7.28 | 30.60 | 48.75 | 18.85 |

| SD | 0.46 | 2.31 | 0.50 | 1.72 | 2.51 | 10.48 | 3.48 | |

| MD Before UV | MV | 4.37 | 13.61 | 3.20 | 7.43 | 24.24 | 39.53 | 3.64 |

| SD | 0.44 | 1.30 | 0.52 | 0.51 | 2.32 | 1.05 | 0.19 | |

| MD After UV | MV | 4.47 | 13.78 | 3.45 | 7.37 | 24.60 | 40.03 | 4.46 |

| SD | 0.43 | 0.93 | 0.03 | 0.94 | 1.89 | 3.13 | 0.12 | |

| PA Before UV | MV | 3.40 | 8.93 | 4.36 | 8.08 | 21.37 | 39.76 | 0.53 |

| SD | 0.60 | 1.27 | 1.58 | 2.16 | 4.42 | 4.57 | 5.42 | |

| PA After UV | MV | 3.34 | 8.40 | 4.80 | 9.03 | 22.23 | 44.53 | 4.44 |

| SD | 0.46 | 1.61 | 1.89 | 0.77 | 3.19 | 5.24 | 15.22 | |

| PD Before UV | MV | 4.69 | 13.44 | 4.52 | 9.71 | 27.66 | 49.49 | 4.72 |

| SD | 0.37 | 1.34 | 0.90 | 0.62 | 1.40 | 5.99 | 6.66 | |

| PD After UV | MV | 4.48 | 12.52 | 4.20 | 10.57 | 27.29 | 45.22 | 3.36 |

| SD | 0.37 | 1.08 | 0.78 | 0.66 | 0.95 | 2.90 | 13.19 |

| The Ratio of the Areas Corresponding to the Wave Number | |||

|---|---|---|---|

| Samples | A1730/A1370 Nonconjugated Carbonyl/(Cel + HCel) | A1504-1507/A1370 Lignin/(Cel + HCel) | A1730/A1504-1507 Nonconjugated Carbonyl/Lignin |

| MA before UV | 1.87 | 1.96 | 0.95 |

| MA after UV | 3.91 | 1.47 | 2.65 |

| MA after UV/MA before | 2.09 | 0.75 | 2.78 |

| MD before | 1.51 | 1.99 | 0.76 |

| MD after UV | 3.56 | 1.38 | 2.58 |

| MD after UV /MD before | 2.36 | 0.69 | 3.41 |

| PA before | 3.91 | 1.11 | 3.52 |

| PA after UV | 5.01 | 0.91 | 5.50 |

| PA after UV /PA before | 1.28 | 0.82 | 1.56 |

| PD before UV | 3.93 | 1.37 | 2.85 |

| PD after UV | 4.67 | 0.84 | 5.54 |

| PD after UV/PD before | 1.19 | 0.61 | 1.94 |

| Spruce MA | Spruce MD | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Initial | 72 h | 192 h | 266 h | 300 h | Initial | 72 h | 192 h | 266 h | 300 h | ||

| ρ (kg*m−3) | MV | 476 | 459 | 444 | 443 | 442 | 431 | 406 | 405 | 404 | 399 |

| SD | 37 | 13 | 35 | 35 | 36 | 30 | 29 | 30 | 28 | 29 | |

| y = −0.1634x + 479.6 | y = −0.0563x + 418.62 | ||||||||||

| VLL (m/s) | MV | 6187 | 6387 | 6458 | 6474 | 6513 | 5776 | 5958 | 5963 | 6075 | 6091 |

| SD | 180 | 108 | 117 | 127 | 134 | 374 | 423 | 238 | 303 | 320 | |

| y = 1.7366x + 6125.9 | y = 3.3054x + 5443.7 | ||||||||||

| VRR (m/s) | MV | 1529 | 1538 | 1602 | 1643 | 1704 | 1329 | 1377 | 1400 | 1426 | 1459 |

| SD | 42 | 113 | 90 | 59 | 113 | 251 | 286 | 263 | 272 | 243 | |

| y = 44.6x + 1452.6 | y = 30.733x + 1306.1 | ||||||||||

| EL (GPa) | MV | 18.27 | 18.53 | 18.63 | 18.74 | 18.85 | 14.50 | 14.51 | 14.56 | 14.94 | 15.00 |

| SD | 2.33 | 0.94 | 2.02 | 2.15 | 2.23 | 2.74 | 2.92 | 2.17 | 2.43 | 2.48 | |

| y = −0.0016x + 18.86 | y = 0.006x + 13.72 | ||||||||||

| ER (GPa) | MV | 0.79 | 1.02 | 1.08 | 1.13 | 1.20 | 0.81 | 0.83 | 0.86 | 0.88 | 1.30 |

| SD | 0.12 | 0.17 | 0.09 | 0.10 | 0.26 | 0.32 | 0.35 | 0.34 | 0.34 | 0.33 | |

| y = 0.0016x + 0.77 | y = 0.0027x + 0.39 | ||||||||||

| Sycamore maple (PA) | Maple PD | ||||||||||

| ρ (kg*m−3) | MV | 695 | 651 | 649 | 648 | 646 | 618 | 582 | 581 | 578 | 573 |

| SD | 12 | 12 | 12 | 11 | 10 | 16 | 17 | 18 | 16 | 15 | |

| y = −0.1428x + 681.13 | y = −0.1408x + 609.17 | ||||||||||

| VLL (m/s) | MV | 4866 | 4937 | 5057 | 5084 | 5149 | 4557 | 4662 | 4755 | 4763 | 4818 |

| SD | 5.20 | 80.30 | 15.59 | 6.35 | 45.31 | 260.29 | 225.16 | 221.52 | 238.53 | 275.65 | |

| y = 0.6465x + 4605.9 | y = 0.6465x + 4605.9 | ||||||||||

| VRR (m/s) | MV | 1947 | 2115 | 2141 | 2130 | 2249 | 1506 | 1641 | 1701 | 1737 | 1831 |

| SD | 70.77 | 70.38 | 55.99 | 65.59 | 43.97 | 237.23 | 249.30 | 226.70 | 252.63 | 283.52 | |

| y = 0.9598x + 1960.4 | y = 0.9191x + 1533.9 | ||||||||||

| EL (GPa) | MV | 15.78 | 16.33 | 16.53 | 16.87 | 17.30 | 11.94 | 12.23 | 12.55 | 13.68 | 14.69 |

| SD | 2.92 | 1.37 | 0.92 | 1.48 | 3.47 | 0.08 | 0.16 | 0.13 | 0.77 | 0.30 | |

| y = 0.004x + 15.92 | y = 0.0005x + 12.94 | ||||||||||

| ER (GPa) | MV | 2.64 | 2.89 | 2.94 | 2.98 | 3.29 | 1.11 | 1.28 | 1.79 | 2.00 | 2.27 |

| SD | 0.136 | 0.052 | 0.108 | 0.103 | 0.17 | 0.14 | 0.05 | 0.11 | 0.10 | 0.17 | |

| y = 0.0026x + 2.5215 | y = 0.0048x + 0.9083 | ||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gurău, L.; Timar, M.C.; Coșereanu, C.; Cosnita, M.; Stanciu, M.D. Aging of Wood for Musical Instruments: Analysis of Changes in Color, Surface Morphology, Chemical, and Physical-Acoustical Properties during UV and Thermal Exposure. Polymers 2023, 15, 1794. https://doi.org/10.3390/polym15071794

Gurău L, Timar MC, Coșereanu C, Cosnita M, Stanciu MD. Aging of Wood for Musical Instruments: Analysis of Changes in Color, Surface Morphology, Chemical, and Physical-Acoustical Properties during UV and Thermal Exposure. Polymers. 2023; 15(7):1794. https://doi.org/10.3390/polym15071794

Chicago/Turabian StyleGurău, Lidia, Maria Cristina Timar, Camelia Coșereanu, Mihaela Cosnita, and Mariana Domnica Stanciu. 2023. "Aging of Wood for Musical Instruments: Analysis of Changes in Color, Surface Morphology, Chemical, and Physical-Acoustical Properties during UV and Thermal Exposure" Polymers 15, no. 7: 1794. https://doi.org/10.3390/polym15071794

APA StyleGurău, L., Timar, M. C., Coșereanu, C., Cosnita, M., & Stanciu, M. D. (2023). Aging of Wood for Musical Instruments: Analysis of Changes in Color, Surface Morphology, Chemical, and Physical-Acoustical Properties during UV and Thermal Exposure. Polymers, 15(7), 1794. https://doi.org/10.3390/polym15071794