In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Foam Fabrication

2.3. Characterisation

3. Results and Discussion

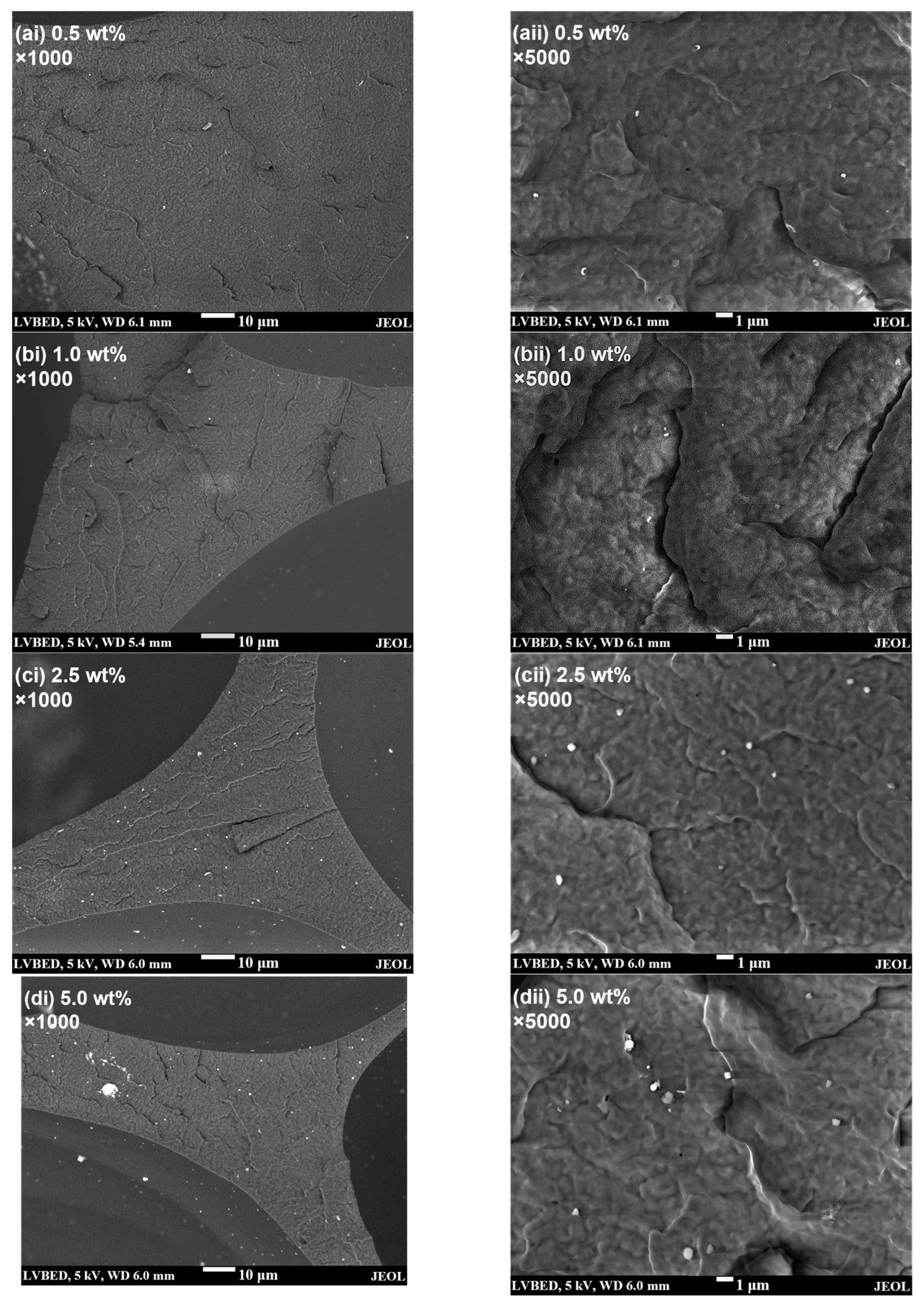

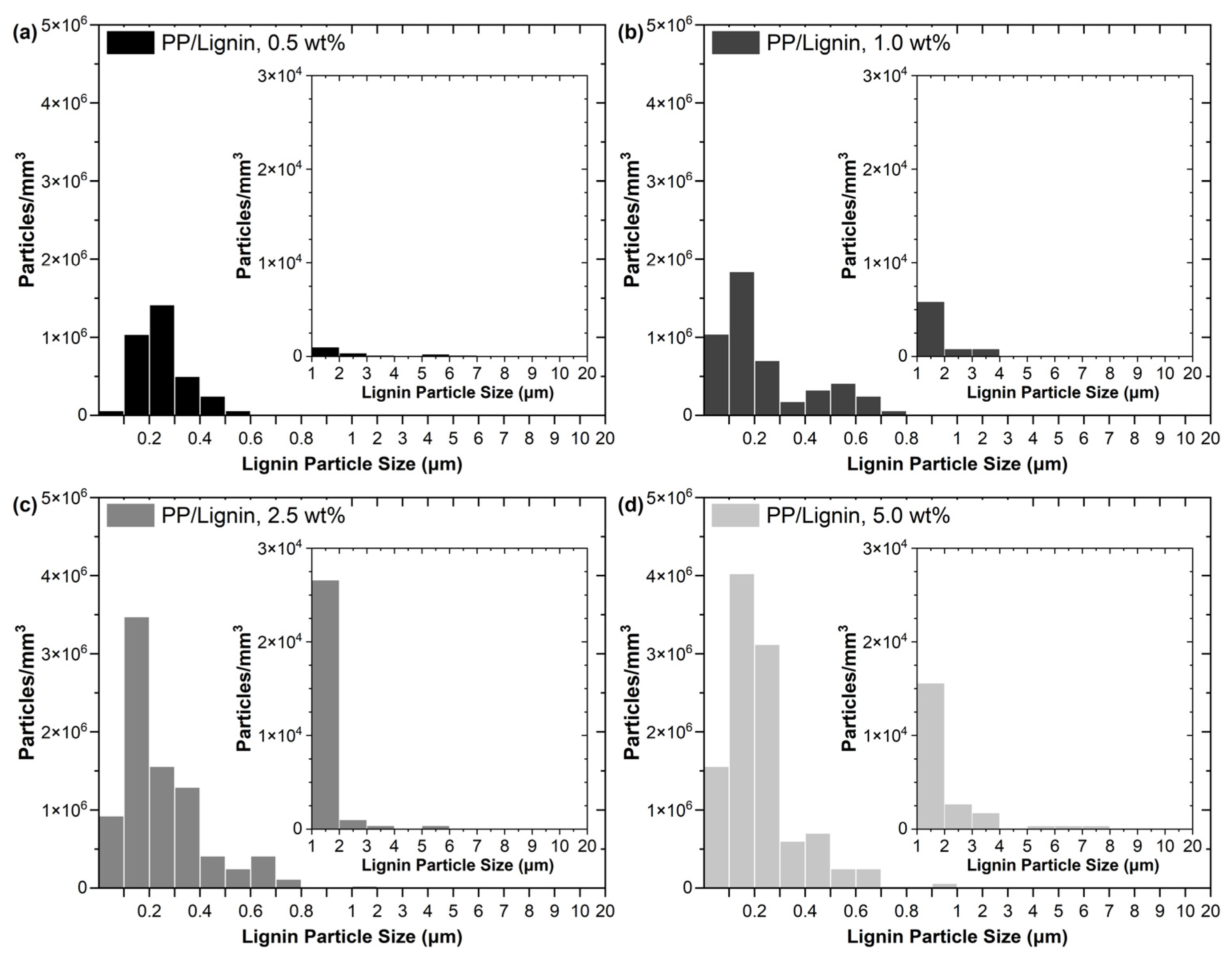

3.1. In Situ Dispersion of Lignin in PP via scCO2 Extrusion Foaming of PP/Lignin

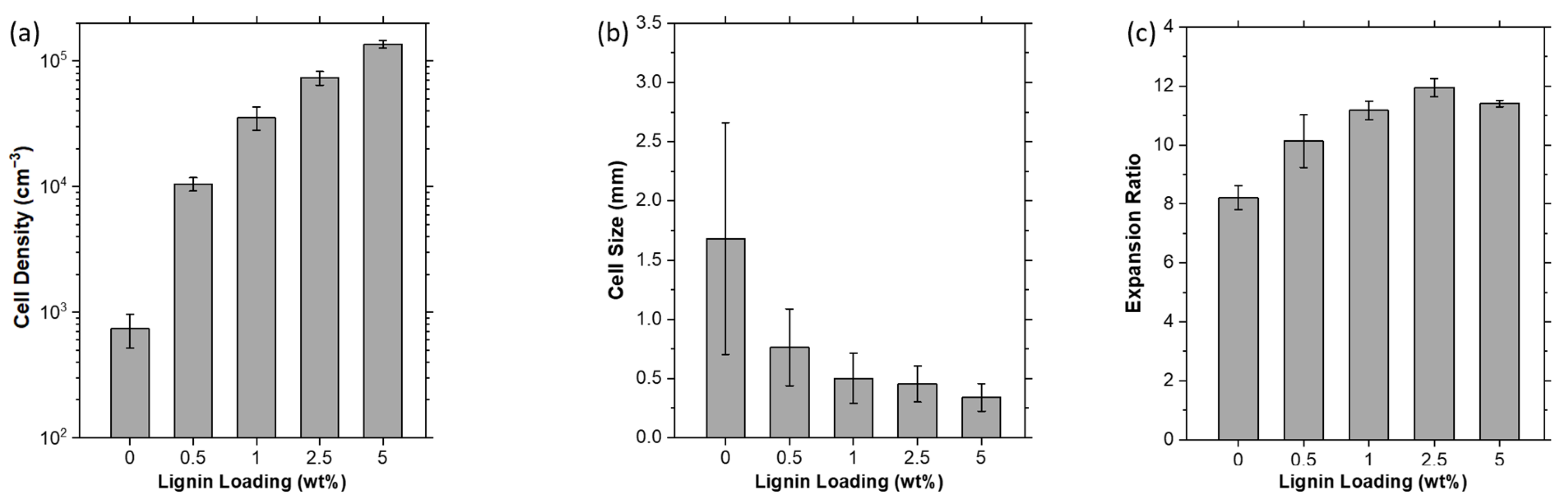

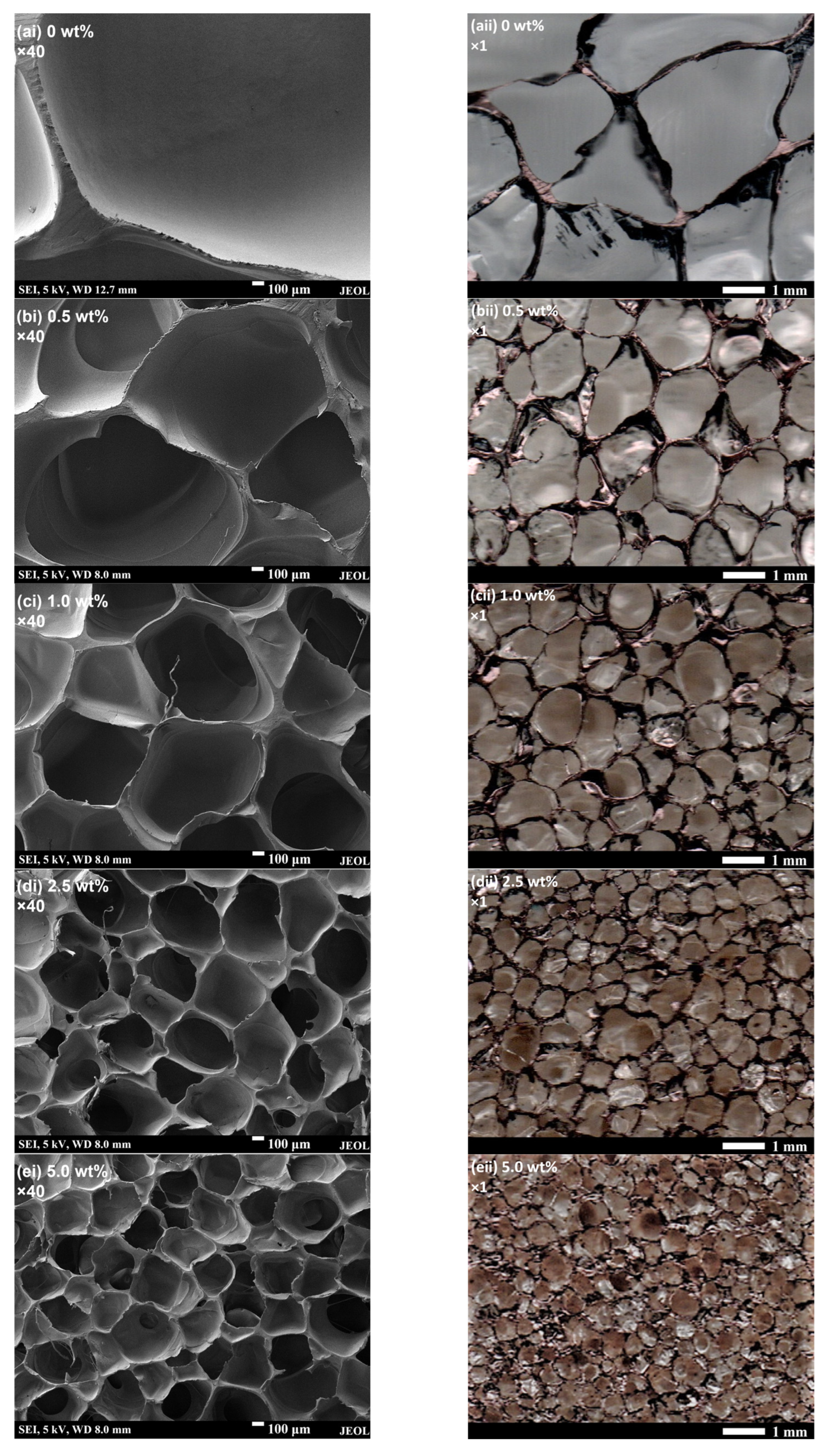

3.2. Nucleating Effect of Lignin in scCO2 Foaming of PP

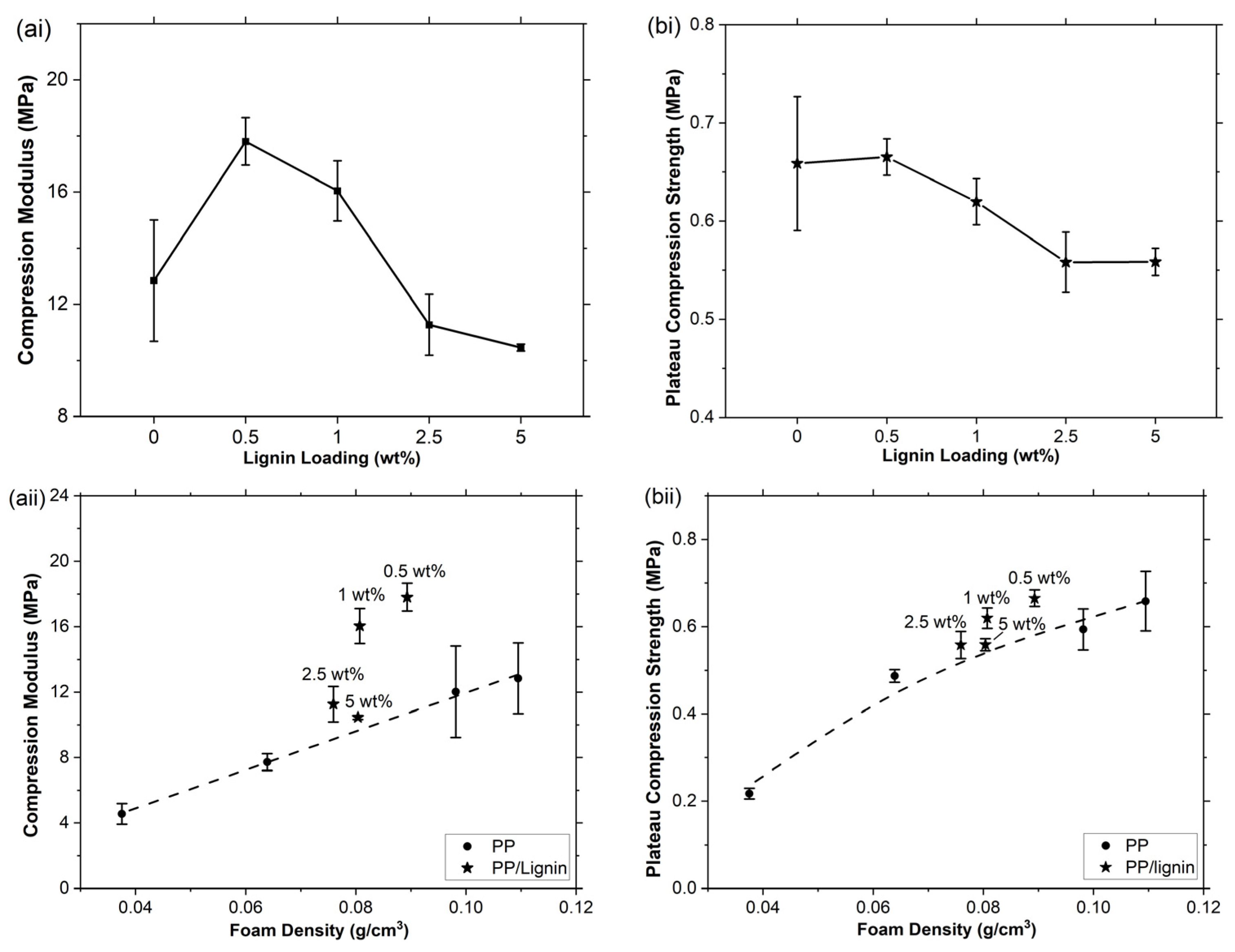

3.3. Compression and Energy Cushioning Properties of the PP/Lignin Foams

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Franco, P.; De Marco, I. Nanoparticles and Nanocrystals by Supercritical CO2-Assisted Techniques for Pharmaceutical Applications: A Review. Appl. Sci. 2021, 11, 1476. [Google Scholar] [CrossRef]

- Luz, S.M.; Caldeira-Pires, A.; Ferrão, P.M.C. Environmental benefits of substituting talc by sugarcane bagasse fibers as reinforcement in polypropylene composites: Ecodesign and LCA as strategy for automotive components. Resour. Conserv. Recycl. 2010, 54, 1135–1144. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, T.; Li, B.; Li, H.; Cao, Z.; Jin, G.; Zhao, L.; Xin, Z. Anti-Shrinking Foaming of Polyethylene with CO2 as Blowing Agent. J. Supercrit. Fluids 2020, 163, 104883. [Google Scholar] [CrossRef]

- Ramachandran, J.P.; Kottammal, A.P.; Antony, A.; Ramakrishnan, R.M.; Wallen, S.L.; Raveendran, P. Green processing: CO2-induced glassification of sucrose octaacetate and its implications in the spontaneous release of drug from drug-excipient composites. J. CO2 Util. 2021, 47, 101472. [Google Scholar] [CrossRef]

- Weingart, N.; Raps, D.; Lu, M.; Endner, L.; Altstädt, V. Comparison of the Foamability of Linear and Long-Chain Branched Polypropylene—The Legend of Strain-Hardening as a Requirement for Good Foamability. Polymers 2020, 12, 725. [Google Scholar] [CrossRef] [Green Version]

- Sauceau, M.; Fages, J.; Common, A.; Nikitine, C.; Rodier, E. New challenges in polymer foaming: A review of extrusion processes assisted by supercritical carbon dioxide. Prog. Polym. Sci. 2011, 36, 749–766. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Zhao, Q.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. High thermal insulation and compressive strength polypropylene foams fabricated by high-pressure foam injection molding and mold opening of nano-fibrillar composites. Mater. Des. 2017, 131, 1–11. [Google Scholar] [CrossRef]

- Leung, S.; Wong, A.; Wang, L.; Park, C. Mechanism of Extensional Stress-Induced Cell Formation in Polymeric Foaming Processes with the Presence of Nucleating Agents. J. Supercrit. Fluids 2012, 63, 187–198. [Google Scholar] [CrossRef]

- Glogic, E.; Claverie, M.; Jubayed; Musumeci, V.; Carême, C.; Martin, F.; Sonnemann, G.; Aymonier, C. Greening Pathways for Synthetic Talc Production Based on the Supercritical Hydrothermal Flow Process. ACS Sustain. Chem. Eng. 2021, 9, 16597–16605. [Google Scholar] [CrossRef]

- Tran, T.; Steffen, J.E.; Clancy, K.M.; Bird, T.; Egilman, D.S. Talc, Asbestos, and Epidemiology: Corporate Influence and Scientific Incognizance. Epidemiology 2019, 30, 783–788. [Google Scholar] [CrossRef]

- Tadele, D.; Roy, P.; Defersha, F.; Misra, M.; Mohanty, A.K. A comparative life-cycle assessment of talc- and biochar-reinforced composites for lightweight automotive parts. Clean Technol. Environ. Policy 2020, 22, 639–649. [Google Scholar] [CrossRef]

- Yang, C.; Wang, M.; Xing, Z.; Zhao, Q.; Wang, M.; Wu, G. A new promising nucleating agent for polymer foaming: Effects of hollow molecular-sieve particles on polypropylene supercritical CO2 microcellular foaming. RSC Adv. 2018, 8, 20061–20067. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, G.; Zhao, G.; Dong, G.; Mu, Y.; Park, C.B. Lightweight and strong microcellular injection molded PP/talc nanocomposite. Compos. Sci. Technol. 2018, 168, 38–46. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Zhu, W.; Zhou, H.; Weng, Y.; Zhang, A.; Dong, G.; Zhao, G. Lightweight and strong polypropylene/talc/polytetrafluoroethylene foams with enhanced flame-retardant performance fabricated by microcellular foam injection foaming. Mater. Des. 2022, 215, 110539. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, Q.; Wang, L.; Wang, C.; Guo, B.; Park, C.B.; Wang, G. Development of high thermal insulation and compressive strength BPP foams using mold-opening foam injection molding with in-situ fibrillated PTFE fibers. Eur. Polym. J. 2018, 98, 1–10. [Google Scholar] [CrossRef]

- Qiang, W.; Zhao, L.; Gao, X.; Liu, T.; Liu, Z.; Yuan, W.-K.; Hu, D. Dual role of PDMS on improving supercritical CO2 foaming of polypropylene: CO2-philic additive and crystallization nucleating agent. J. Supercrit. Fluids 2020, 163, 104888. [Google Scholar] [CrossRef]

- Liu, S.; Yin, S.; Duvigneau, J.; Vancso, G.J. Bubble seeding nanocavities: Multiple polymer foam cell nucleation by polydimethylsiloxane-grafted designer silica nanoparticles. ACS Nano. 2020, 14, 1623–1634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dias, O.A.T.; Sain, M.; Cesarino, I.; Leão, A.L. Development of high bio-content polypropylene composites with different industrial lignins. Polym. Adv. Technol. 2018, 30, 70–78. [Google Scholar] [CrossRef] [Green Version]

- Wypych, A. Lignin. In Databook of Adhesion Promoters; ChemTec Publishing: Toronto, ON, Canada, 2018; p. 161. [Google Scholar] [CrossRef]

- Sugiarto, S.; Leow, Y.; Tan, C.L.; Wang, G.; Kai, D. How far is Lignin from being a biomedical material? Bioact. Mater. 2021, 8, 71–94. [Google Scholar] [CrossRef]

- Ibrahim, M.N.M.; Iqbal, A.; Shen, C.C.; Bhawani, S.A.; Adam, F. Synthesis of lignin based composites of TiO2 for potential application as radical scavengers in sunscreen formulation. BMC Chem. 2019, 13, 17. [Google Scholar] [CrossRef] [Green Version]

- Ridho, M.R.; Agustiany, E.A.; Dn, M.R.; Madyaratri, E.W.; Ghozali, M.; Restu, W.K.; Falah, F.; Lubis, M.A.R.; Syamani, F.A.; Nurhamiyah, Y.; et al. Lignin as Green Filler in Polymer Composites: Development Methods, Characteristics, and Potential Applications. Adv. Mater. Sci. Eng. 2022, 2022, 1363481. [Google Scholar] [CrossRef]

- Yeo, J.-S.; Seong, D.-W.; Hwang, S.-H. Chemical surface modification of lignin particle and its application as filler in the polypropylene composites. J. Ind. Eng. Chem. 2015, 31, 80–85. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, M. Maleic anhydride-modified polyolefins as compatibilizer for lignin-reinforced polypropylene composites. Polym. Compos. 2018, 40, 2594–2601. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, W.; Xin, Z.; Zhao, S.; Shi, Y. Relationship between molecular structure, crystallization behavior, and mechanical properties of long chain branching polypropylene. J. Mater. Sci. 2016, 51, 5598–5608. [Google Scholar] [CrossRef]

- Azdast, T.; Hasanzadeh, R. Increasing cell density/decreasing cell size to produce microcellular and nanocellular thermoplastic foams: A review. J. Cell. Plast. 2020, 57, 769–797. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Zheng, W.; Park, C.B. A comprehensive review of cell structure variation and general rules for polymer microcellular foams. Chem. Eng. J. 2022, 430, 132662. [Google Scholar] [CrossRef]

- Liu, Q.X.; Zhu, Y.J.; Yang, G.W.; Yang, Q.B. Nucleation Thermodynamics inside Micro/nanocavity. J. Mater. Sci. Technol. 2008, 24, 183–186. [Google Scholar]

- Park, C.B.; Behravesh, A.; Venter, R.D. Low density microcellular foam processing in extrusion using CO2. Polym. Eng. Sci. 1998, 38, 1812–1823. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, W.; Scarpa, F.; Barton, D.; Rankin, K.; Zhu, Y.; Lang, Z.-Q.; Peng, H.-X. Topological characteristics and mechanical properties of uniaxially thermoformed auxetic foam. Mater. Des. 2021, 211, 110139. [Google Scholar] [CrossRef]

- Chen, L.; Rende, D.; Schadler, L.S.; Ozisik, R. Polymer nanocomposite foams. J. Mater. Chem. A 2013, 1, 3837–3850. [Google Scholar] [CrossRef]

- Zhu, Y.; Luo, G.; Zhang, R.; Cao, P.; Liu, Q.; Zhang, J.; Sun, Y.; Li, J.; Shen, Q.; Zhang, L. Numerical simulation of static mechanical properties of PMMA microcellular foams. Compos. Sci. Technol. 2020, 192, 108110. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, J.; Ling, Y.; Yao, S.; Jiang, X.; Hu, D.; Wang, H.; Zhao, L. Comprehensive analysis of mechanical properties of microcellular polypropylene: Experiment and simulation. Polym. Test. 2022, 116, 107812. [Google Scholar] [CrossRef]

- Chen, Y.; Das, R.; Battley, M. Effects of cell size and cell wall thickness variations on the stiffness of closed-cell foams. Int. J. Solids Struct. 2015, 52, 150–164. [Google Scholar] [CrossRef]

- Li, P.; Guo, Y.B.; Zhou, M.W.; Shim, V.P.W. Response of anisotropic polyurethane foam to compression at different loading angles and strain rates. Int. J. Impact Eng. 2019, 127, 154–168. [Google Scholar] [CrossRef]

- Xiao, Y.; Yin, J.; Zhang, X.; An, X.; Xiong, Y.; Sun, Y. Mechanical Performance and Cushioning Energy Absorption Characteristics of Rigid Polyurethane Foam at Low and High Strain Rates. Polym. Test. 2022, 109, 107531. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, K.H.; Lu, X.; Lau, S.K. In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties. Polymers 2023, 15, 1813. https://doi.org/10.3390/polym15081813

Ho KH, Lu X, Lau SK. In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties. Polymers. 2023; 15(8):1813. https://doi.org/10.3390/polym15081813

Chicago/Turabian StyleHo, Keen Hoe, Xuehong Lu, and Soo Khim Lau. 2023. "In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties" Polymers 15, no. 8: 1813. https://doi.org/10.3390/polym15081813

APA StyleHo, K. H., Lu, X., & Lau, S. K. (2023). In Situ Dispersion of Lignin in Polypropylene via Supercritical CO2 Extrusion Foaming: Effects of Lignin on Cell Nucleation and Foam Compression Properties. Polymers, 15(8), 1813. https://doi.org/10.3390/polym15081813