Influence of Biochar and Bio-Oil Loading on the Properties of Epoxy Resin Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Methodology

2.2. Experimental Setup and Procedure

2.2.1. Pyrolysis of Biomass

2.2.2. Preparation of Bio-Based Epoxy Blends

2.3. Analytical Techniques

2.3.1. Thermogravimetric Analysis (TGA)

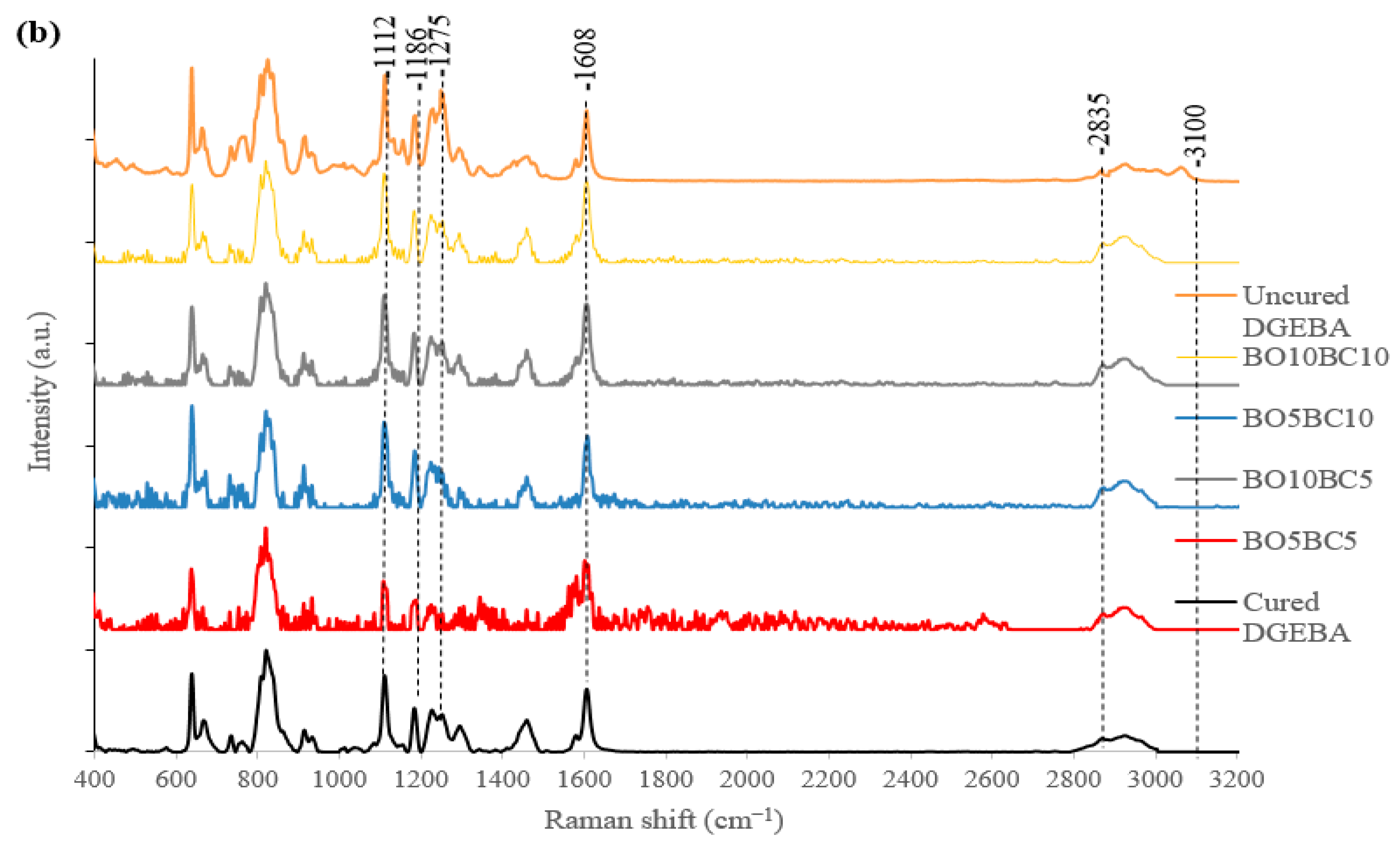

2.3.2. Raman Spectroscopy

2.3.3. Mechanical Analysis

3. Results and Discussion

3.1. Thermal Degradation Properties

3.2. Cross-Linking Analysis

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kobayashi, M.; Tukamoto, K.; Tomita, B. Application of Liquefied Wood to a New Resin System—Synthesis and Properties of Liquefied Wood/Epoxy Resins. Holzforschung 2000, 54, 93–97. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Elliott, D.; Beckman, D.; Bridgwater, A.; Diebold, J.; Gevert, S.; Solantausta, Y. Developments in direct thermochemical liquefaction of biomass: 1983–1990. Energy Fuels 1991, 5, 399–410. [Google Scholar] [CrossRef]

- Kishi, H.; Akamatsu, Y.; Noguchi, M.; Fujita, A.; Matsuda, S.; Nishida, H. Synthesis of epoxy resins from alcohol-liquefied wood and the mechanical properties of the cured resins. J. Appl. Polym. Sci. 2011, 120, 745–751. [Google Scholar] [CrossRef]

- Kishi, H.; Fujita, A.; Miyazaki, H.; Matsuda, S.; Murakami, A. Synthesis of wood-based epoxy resins and their mechanical and adhesive properties. J. Appl. Polym. Sci. 2006, 102, 2285–2292. [Google Scholar] [CrossRef]

- Wu, C.-C.; Lee, W.-J. Curing behavior and adhesion properties of epoxy resin blended with polyhydric alcohol-liquefied Cryptomeria japonica wood. Wood Sci. Technol. 2011, 45, 559–571. [Google Scholar] [CrossRef]

- Asafu-Adjaye, O.A.; Street, J.; Bansode, A.; Auad, M.L.; Peresin, M.S.; Adhikari, S.; Liles, T.; Via, B.K. Fast Pyrolysis Bio-Oil-Based Epoxy as an Adhesive in Oriented Strand Board Production. Polymers 2022, 14, 1244. [Google Scholar] [CrossRef]

- Liu, Y.; Via, B.K.; Pan, Y.; Cheng, Q.; Guo, H.; Auad, M.L.; Taylor, S. Preparation and characterization of epoxy resin cross-linked with high wood pyrolysis bio-oil substitution by acetone pretreatment. Polymers 2017, 9, 106. [Google Scholar] [CrossRef]

- Mao, A.; Shi, S.Q.; Steele, P. Flakeboard bonded with polymeric diphenylmethane diisocyanate/bio-oil adhesive systems. For. Prod. J. 2011, 61, 240–245. [Google Scholar] [CrossRef]

- Hilten, R.N.; Das, K. Comparison of three accelerated aging procedures to assess bio-oil stability. Fuel 2010, 89, 2741–2749. [Google Scholar] [CrossRef]

- Pütün, A.E.; Özcan, A.; Pütün, E. Pyrolysis of hazelnut shells in a fixed-bed tubular reactor: Yields and structural analysis of bio-oil. J. Anal. Appl. Pyrolysis 1999, 52, 33–49. [Google Scholar] [CrossRef]

- Paul, A.S.; Panwar, N.L.; Salvi, B.L.; Jain, S.; Sharma, D. Experimental investigation on the production of bio-oil from wheat straw. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–16. [Google Scholar] [CrossRef]

- Wei, N.; Via, B.K.; Wang, Y.; McDonald, T.; Auad, M.L. Liquefaction and substitution of switchgrass (Panicum virgatum) based bio-oil into epoxy resins. Ind. Crops Prod. 2014, 57, 116–123. [Google Scholar] [CrossRef]

- Xu, J.; Brodu, N.; Mignot, M.; Youssef, B.; Taouk, B. Synthesis and characterization of phenolic resins based on pyrolysis bio-oil separated by fractional condensation and water extraction. Biomass Bioenergy 2022, 159, 106393. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, K.; Sahoo, P.; Bhowmik, S. Study of mechanical properties of wood dust reinforced epoxy composite. Procedia Mater. Sci. 2014, 6, 551–556. [Google Scholar] [CrossRef]

- Song, X.; Zheng, S.; Huang, J.; Zhu, P.; Guo, Q. Miscibility, morphology and fracture toughness of tetrafunctional epoxy resin/poly (styrene-co-acrylonitrile) blends. J. Mater. Sci. 2000, 35, 5613–5619. [Google Scholar] [CrossRef]

- Pan, Y.; Pan, Y.; Cheng, Q.; Liu, Y.; Essien, C.; Via, B.; Wang, X.; Sun, R.; Taylor, S. Characterization of epoxy composites reinforced with wax encapsulated microcrystalline cellulose. Polymers 2016, 8, 415. [Google Scholar] [CrossRef]

- Bekeshev, A.; Mostovoy, A.; Kadykova, Y.; Akhmetova, M.; Tastanova, L.; Lopukhova, M. Development and analysis of the physicochemical and mechanical properties of diorite-reinforced epoxy composites. Polymers 2021, 13, 2421. [Google Scholar] [CrossRef]

- Bao, X.; Wu, F.; Wang, J. Thermal degradation behavior of epoxy resin containing modified carbon nanotubes. Polymers 2021, 13, 3332. [Google Scholar] [CrossRef]

- Hameed, A.; Islam, M.; Ahmad, I.; Mahmood, N.; Saeed, S.; Javed, H. Thermal and mechanical properties of carbon nanotube/epoxy nanocomposites reinforced with pristine and functionalized multiwalled carbon nanotubes. Polym. Compos. 2015, 36, 1891–1898. [Google Scholar] [CrossRef]

- Balat, M.; Balat, M.; Kırtay, E.; Balat, H. Main routes for the thermo-conversion of biomass into fuels and chemicals. Part 1: Pyrolysis systems. Energy Convers. Manag. 2009, 50, 3147–3157. [Google Scholar] [CrossRef]

- Demirbas, M.F.; Balat, M. Biomass pyrolysis for liquid fuels and chemicals: A review. J. Sci. Ind. Res. 2007, 66, 797–804. [Google Scholar]

- Akhtar, J.; Amin, N.S. A review on operating parameters for optimum liquid oil yield in biomass pyrolysis. Renew. Sustain. Energy Rev. 2012, 16, 5101–5109. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, Y.; Li, T.; Ren, Z. Upgrading of liquid fuel from the pyrolysis of biomass. Bioresour. Technol. 2005, 96, 545–550. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.K.; Strezov, V.; Chan, K.Y.; Ziolkowski, A.; Nelson, P.F. Influence of pyrolysis temperature on production and nutrient properties of wastewater sludge biochar. J. Environ. Manag. 2011, 92, 223–228. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Ryu, C.; Gang, K.S.; Yang, W.; Park, Y.-K.; Jung, J.; Hyun, S. Comparison of biochar properties from biomass residues produced by slow pyrolysis at 500 C. Bioresour. Technol. 2013, 148, 196–201. [Google Scholar] [CrossRef] [PubMed]

- Giorcelli, M.; Savi, P.; Khan, A.; Tagliaferro, A. Analysis of biochar with different pyrolysis temperatures used as filler in epoxy resin composites. Biomass Bioenergy 2019, 122, 466–471. [Google Scholar] [CrossRef]

- Matykiewicz, D. Biochar as an effective filler of carbon fiber reinforced bio-epoxy composites. Processes 2020, 8, 724. [Google Scholar] [CrossRef]

- Minugu, O.P.; Gujjala, R.; Shakuntala, O.; Manoj, P.; Chowdary, M.S. Effect of biomass derived biochar materials on mechanical properties of biochar epoxy composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 5626–5638. [Google Scholar] [CrossRef]

- Hidalgo, P.; Navia, R.; Hunter, R.; Coronado, G.; Gonzalez, M. Synthesis of carbon nanotubes using biochar as precursor material under microwave irradiation. J. Environ. Manag. 2019, 244, 83–91. [Google Scholar] [CrossRef]

- Shahabaz, S.; Mehrotra, P.; Kalita, H.; Sharma, S.; Naik, N.; Noronha, D.J.; Shetty, N. Effect of Al2O3 and SiC Nano-Fillers on the Mechanical Properties of Carbon Fiber-Reinforced Epoxy Hybrid Composites. J. Compos. Sci. 2023, 7, 133. [Google Scholar] [CrossRef]

- Merad, L.; Cochez, M.; Margueron, S.; Jauchem, F.; Ferriol, M.; Benyoucef, B.; Bourson, P. In-situ monitoring of the curing of epoxy resins by Raman spectroscopy. In New Achievements in Materials and Environmental Sciences Names; EDP Sciences: Les Ulis, France, 2007; pp. 155–158. [Google Scholar]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Lyon, R.; Chike, K.; Angel, S. In situ cure monitoring of epoxy resins using fiber-optic Raman spectroscopy. J. Appl. Polym. Sci. 1994, 53, 1805–1812. [Google Scholar] [CrossRef]

- Vašková, H.; Křesálek, V. Raman spectroscopy of epoxy resin crosslinking. In Proceedings of the 13th WSEAS International Conference on Automation Control, Modeling & Simulation (ACMOS’11), Lanzarote, Canary Islands, Spain, 27–29 May 2011. [Google Scholar]

- Farquharson, S.; Smith, W.; Rose, J.; Shaw, M. Correlations between molecular (Raman) and macroscopic (rheology) data for process monitoring of thermoset composite. J. Process Anal. Chem. 2002, 7, 45–53. [Google Scholar]

- Adar, F. Introduction to interpretation of Raman spectra using database searching and functional group detection and identification. Spectroscopy 2016, 31, 16–23. [Google Scholar]

- Marina, A.; Man, Y.C.; Amin, I. Virgin coconut oil: Emerging functional food oil. Trends Food Sci. Technol. 2009, 20, 481–487. [Google Scholar] [CrossRef]

- Pershin, S. Raman spectroscopy of the OH group vibrations in structural complexes of liquid water. Opt. Spectrosc. 2005, 98, 543–554. [Google Scholar] [CrossRef]

- Bock, P.; Gierlinger, N. Infrared and Raman spectra of lignin substructures: Coniferyl alcohol, abietin, and coniferyl aldehyde. J. Raman Spectrosc. 2019, 50, 778–792. [Google Scholar] [CrossRef]

- Lukić, I.; Kesić, Ž.; Zdujić, M.; Skala, D. Vegetable oil as a feedstock for biodiesel synthesis. In Vegetable Oil; Holt, B., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2016; pp. 83–128. [Google Scholar]

- Hardis, R.; Jessop, J.L.; Peters, F.E.; Kessler, M.R. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos. Part A Appl. Sci. Manuf. 2013, 49, 100–108. [Google Scholar] [CrossRef]

- Okabe, T.; Oya, Y.; Tanabe, K.; Kikugawa, G.; Yoshioka, K. Molecular dynamics simulation of crosslinked epoxy resins: Curing and mechanical properties. Eur. Polym. J. 2016, 80, 78–88. [Google Scholar] [CrossRef]

- Baroncini, E.A.; Kumar Yadav, S.; Palmese, G.R.; Stanzione, J.F., III. Recent advances in bio-based epoxy resins and bio-based epoxy curing agents. J. Appl. Polym. Sci. 2016, 133, 44103. [Google Scholar] [CrossRef]

- Auad, M.L.; Nutt, S.R.; Stefani, P.M.; Aranguren, M.I. Rheological study of the curing kinetics of epoxy–phenol novolac resin. J. Appl. Polym. Sci. 2006, 102, 4430–4439. [Google Scholar] [CrossRef]

- Spanoudakis, J.; Young, R. Crack propagation in a glass particle-filled epoxy resin: Part 1 Effect of particle volume fraction and size. J. Mater. Sci. 1984, 19, 473–486. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Misra, M.; Mohanty, A.K. Sustainable biocomposites from biobased polyamide 6, 10 and biocarbon from pyrolyzed miscanthus fibers. J. Appl. Polym. Sci. 2017, 134, 44221. [Google Scholar] [CrossRef]

- Tandon, G.P.; Weng, G.J. The effect of aspect ratio of inclusions on the elastic properties of unidirectionally aligned composites. Polym. Compos. 1984, 5, 327–333. [Google Scholar] [CrossRef]

- Das, C.; Tamrakar, S.; Kiziltas, A.; Xie, X. Incorporation of biochar to improve mechanical, thermal and electrical properties of polymer composites. Polymers 2021, 13, 2663. [Google Scholar] [CrossRef]

| Fixed Carbon (%) | Volatile Matter (%) | Ash (%) | Moisture (%) | N (%) | C (%) | H (%) | O (%) | H/C Molar Ratio | O/C Molar Ratio | Mean Particle Size (μm) | Surface Area (m2/g) | Pore Volume (cm3/g) | Pore Diameter (Ȧ) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feedstock | ||||||||||||||

| Wheat straw | 16.11 | 70.41 | 4.75 | 8.61 | 0.63 | 43.11 | 5.81 | 50.45 | 1.62 | 0.80 | ||||

| Hazelnut hull | 37.32 | 51.7 | 1.37 | 8.89 | 0.11 | 35.98 | 6.00 | 57.91 | 2.00 | 1.18 | ||||

| Biochar pyrolyzed | ||||||||||||||

| Wheat straw | 61.89 | 17.44 | 15.61 | 4.84 | 0.36 | 66.27 | 2.21 | 31.16 | 0.40 | 0.18 | 11.7 ± 0.7 * | 57.388 | 0.01 | 10.4 |

| Hazelnut hull | 88.27 | 5.86 | 4.65 | 1.21 | 4.36 | 89.82 | 1.70 | 4.12 | 0.23 | 0.002 | 20.9 ± 0.6 ** | 18.033 | 0.005 | 10.5 |

| Relative Content (%) | ||

|---|---|---|

| Composition | Wheat Straw | Hazelnut Hull |

| Aromatic compound: | ||

| Aromatic hydrocarbon | 6.67 | 7.1 |

| Phenols | 36.37 | 28.37 |

| Aliphatic hydrocarbons | 26.24 | 18 |

| Ketone | 10.22 | 9.22 |

| Ether | - | 20 |

| Amine | 5 | - |

| Non identified | 10.5 | 17.31 |

| Sample | Tonset (°C) a | Tendset (°C) b | T5% (°C) c | T10% (°C) d | T50% (°C) e | Tmax (°C) f | Rm800 (%) g |

|---|---|---|---|---|---|---|---|

| DGEBA | 320 | 420 | 73.01 | 222.37 | 363.9 | 365.72 | 3.04 |

| Wheat straw | |||||||

| BO5BC5 | 305 | 420 | 278.17 | 307.78 | 401.31 | 338.31 | 12.35 |

| BO5BC10 | 320 | 422 | 280.27 | 317.93 | 386.87 | 365.11 | 15.05 |

| BO10BC5 | 300 | 425 | 269.13 | 295 | 453.46 | 323.33 | 2.76 |

| BO10BC10 | 295 | 420 | 277.59 | 303.22 | 452.53 | 325.99 | 11.06 |

| Hazelnut hull | |||||||

| BO5BC5 | 300 | 400 | 291.44 | 312.52 | 412.83 | 338.19 | 12.83 |

| BO5BC10 | 320 | 425 | 286.93 | 323.04 | 385.50 | 367.85 | 12.05 |

| BO10BC5 | 325 | 420 | 290.55 | 321.94 | 387.33 | 361.36 | 13.54 |

| BO10BC10 | 320 | 420 | 293.30 | 325.29 | 389.71 | 365.08 | 15.50 |

| Sample | Degree of Crosslinking (α) |

|---|---|

| DGEBA | 72.161 |

| Wheat straw | |

| BO5BC5 | 70.014 |

| BO5BC10 | 71.686 |

| BO10BC5 | 70.965 |

| BO10BC10 | 71.832 |

| Hazelnut hull | |

| BO5BC5 | 72.879 |

| BO5BC10 | 69.881 |

| BO10BC5 | 71.739 |

| BO10BC10 | 71.630 |

| Sample | Tensile Strength (MPa) | Max. Deformation (mm/mm) | Young’s Modulus (MPa) |

|---|---|---|---|

| DGEBA | 7.52 ± 1.09 | 0.010 | 1093.69 ± 128.83 |

| Wheat straw | |||

| BO5BC5 | 10.96 ± 1.82 | 0.005 | 2519.38 ± 194.37 |

| BO5BC10 | 13.58 ± 3.97 | 0.010 | 1955.90 ± 83.35 |

| BO10BC5 | 8.73 ± 0.85 | 0.00 | 3091.31 ± 362.84 |

| BO10BC10 | 13.02 ± 9.3 | 0.005 | 3982.05 ± 582.65 |

| Hazelnut hull | |||

| BO5BC5 | 14.04 ± 6.30 | 0.006 | 3060.02 ± 252.49 |

| BO5BC10 | 4.11 ± 1.86 | 0.003 | 3138. ±19.55 |

| BO10BC5 | 10.93 ± 2.49 | 0.005 | 3270.30 ± 1470.47 |

| BO10BC10 | 18.11 ± 3.35 | 0.005 | 3957.84 ± 130.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hidalgo, P.; Salgado, L.; Ibacache, N.; Hunter, R. Influence of Biochar and Bio-Oil Loading on the Properties of Epoxy Resin Composites. Polymers 2023, 15, 1895. https://doi.org/10.3390/polym15081895

Hidalgo P, Salgado L, Ibacache N, Hunter R. Influence of Biochar and Bio-Oil Loading on the Properties of Epoxy Resin Composites. Polymers. 2023; 15(8):1895. https://doi.org/10.3390/polym15081895

Chicago/Turabian StyleHidalgo, Pamela, Luis Salgado, Nayadeth Ibacache, and Renato Hunter. 2023. "Influence of Biochar and Bio-Oil Loading on the Properties of Epoxy Resin Composites" Polymers 15, no. 8: 1895. https://doi.org/10.3390/polym15081895

APA StyleHidalgo, P., Salgado, L., Ibacache, N., & Hunter, R. (2023). Influence of Biochar and Bio-Oil Loading on the Properties of Epoxy Resin Composites. Polymers, 15(8), 1895. https://doi.org/10.3390/polym15081895