Effect of Hybrid Filler, Carbon Black–Lignocellulose, on Fire Hazard Reduction, including PAHs and PCDDs/Fs of Natural Rubber Composites

Abstract

:1. Introduction

2. Methods

2.1. Materials

2.2. Preparation of Composites

2.3. Determination of Natural Filler Distribution in Polymer Matrix

2.4. Cone Calorimeter

2.5. Optical Smoke Density

3. Determination of PCDDs/Fs and PAHs

3.1. Sampling

3.2. Determination of PCDDs/Fs

3.3. Determination of PAH

3.4. Determination of Toxicometric Indicators

3.5. Mechanical Properties

4. Results

4.1. Morphology of Studied Composites

4.2. Fire Hazard

4.2.1. Flammability

4.2.2. Smoke Emission

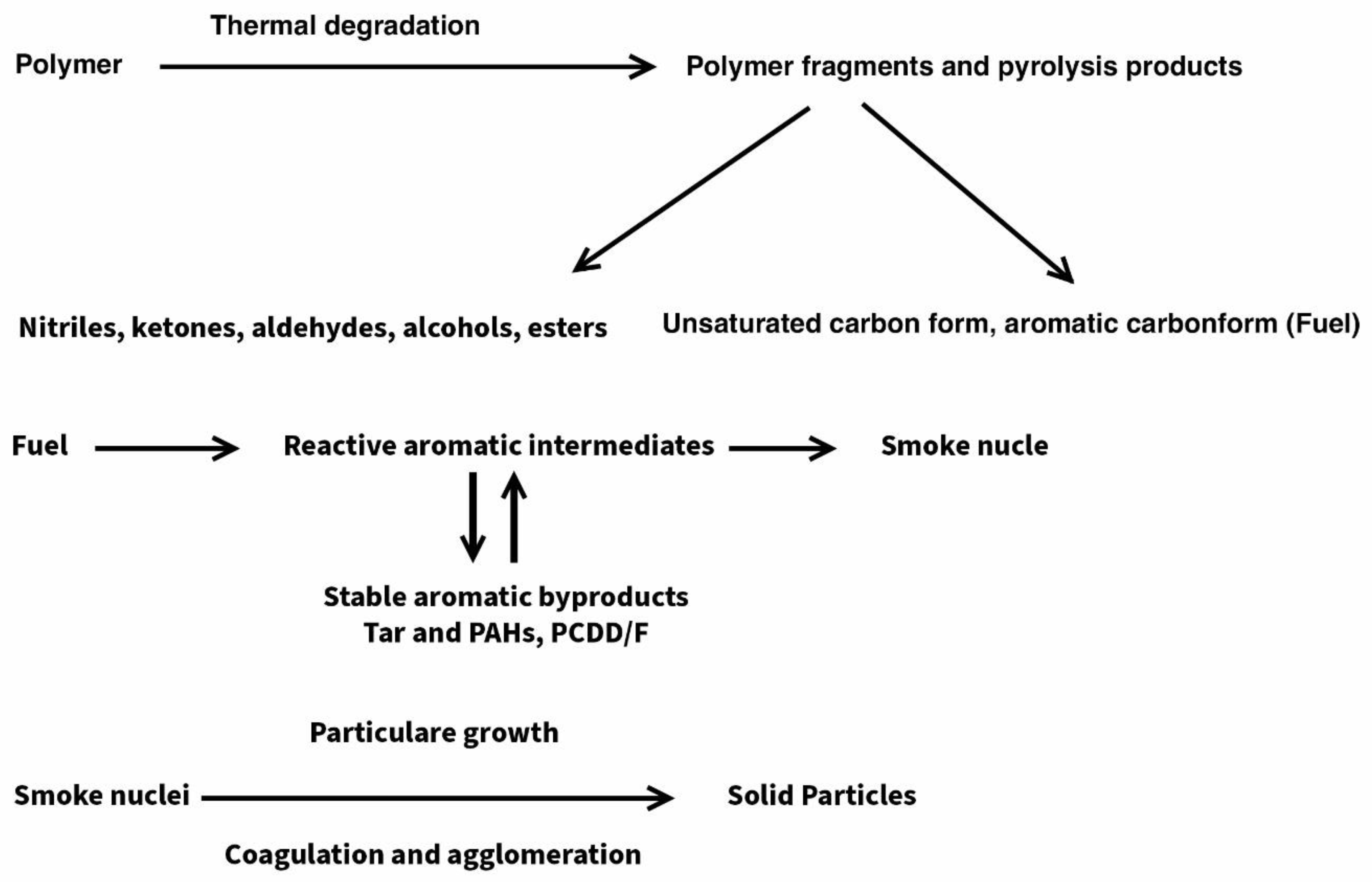

4.2.3. Dioxin/Furan (PCDD/F) and PAH Toxicity

- mi—the mass of a single congener;

- TEFi—the toxicity equivalency factor for the i PCDD/F congener in relation to congener 2, 3, 7, 8-TCDD.

4.2.4. Toxicometric Indicators

4.3. Mechanical Properties

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| NR | natural rubber |

| S | sulphur |

| MBT | 2-mercaptobenzothiazole |

| SA | stearic acid |

| ZnO | zinc oxide |

| CB | carbon black |

| CS:CB 2:1 | straw as a lignocellulose filler with carbon black at mass ratio of 2:1 |

| CM:CB 2:1 | Miscanthus as a lignocellulose filler with carbon black at mass ratio of 2:1 |

| CW:CB 2:1 | beech wood as a lignocellulose filler with carbon black at mass ratio of 2:1 |

| CS:CB 5:1 | straw as a lignocellulose filler with carbon black at mass ratio of 5:1 |

| CM:CB 5:1 | Miscanthus as a lignocellulose filler with carbon black at mass ratio of 5:1 |

| CW:CB 5:1 | beech wood as a lignocellulose filler with carbon black at mass ratio of 5:1 |

| MPP | melamine polyphosphate |

| ti | time to ignition, s |

| tf-o | time to flameout, s |

| HRR | heat release rate, kW/m2 |

| HRRmax | maximum heat release rate, kW/m2 or W/g |

| tHRRmax | time to maximum heat release rate, s |

| THRR | temperature of the maximum heat release rate, °C |

| HRC | heat release capacity, J/g/K |

| THR | total heat release, MJ/m2 or kJ/g |

| EHC | effective heat of combustion, MJ/kg |

| EHCmax | maximum effective heat of combustion, MJ/kg |

| MLR | mass loss rate, g/s |

| MLRmax | maximum mass loss rate, g/s |

| AMLR | average mass loss rate, g/m2/s |

| FIGRA | HRRmax/tHRRmax, kW/m2/s |

| MARHE | maximum average heat release rate, kW/m2 |

| SDmax | maximum smoke specific optical density |

| VOF4 | integral of specific optical density over the first 4 min |

| WLC50 | toxicometric index for a single component according to the PN-88/B-02855 standard |

| WLC50M | toxicometric index for number of components according to the PN-88/B-02855 standard |

| WLC50SM | mean toxicometric index according to the PN-88/B-02855 standard |

| LC50,i | the limiting concentration of the given i-th thermal degradation product causing the death of 50% of the test animal population after a 30 min exposure, g/m3 |

| Ei | specific emission, gi/g |

| LOQ | limit of quantification |

| PCDD | polychlorinated-p-dioxin |

| PCDF | polychlorinated-p-furan |

| PAH | polycyclic aromatic hydrocarbon |

| TEQ | toxic equivalency |

| TEF | toxicity equivalency factor for i-th congener PCDDs/Fs in reference to congener 2,3,7,8-TCDD |

| TS | tensile strength |

| Eb | elongation at break |

References

- Xu, X.; Liu, F.; Jiang, L.; Zhu, J.Y.; Haagenson, D.; Wiesenborn, D.P. Cellulose Nanocrystals vs. Cellulose Nanofibrils: A Comparative Study on Their Microstructures and Effects as Polymer Reinforcing Agents. ACS Appl. Mater. Interfaces 2013, 5, 2999–3009. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Yang, X.; Wang, W. Reinforcing Linear Low-Density Polyethylene with Surfactant-Treated Microfibrillated Cellulose. Polymers 2019, 11, 441. [Google Scholar] [CrossRef] [PubMed]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulose whiskers versus microfibrils: Influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 2009, 10, 425–432. [Google Scholar] [CrossRef]

- Herrera, N.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: Mechanical, thermal and optical properties. Compos. Sci. Technol. 2015, 106, 149–155. [Google Scholar] [CrossRef]

- Lo Re, G.; Engström, J.; Wu, Q.; Malmström, E.; Gedde, U.W.; Olsson, R.T.; Berglund, L. Improved Cellulose Nanofibril Dispersion in Melt-Processed Polycaprolactone Nanocomposites by a Latex-Mediated Interphase and Wet Feeding as LDPE Alternative. ACS Appl. Nano Mater. 2018, 1, 2669–2677. [Google Scholar] [CrossRef]

- Sinclair, A.; Zhou, X.; Tangpong, S.; Bajwa, D.S.; Quadir, M.; Jiang, L. High-Performance Styrene-Butadiene Rubber Nanocomposites Reinforced by Surface-Modified Cellulose Nanofibers. ACS Omega 2019, 4, 13189–13199. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Masłowski, M.; Rybiński, P.; Strzelec, K. Modified nanoclays/straw fillers as functional additives of natural rubber biocomposites. Polymers 2021, 13, 799. [Google Scholar] [CrossRef] [PubMed]

- Nawamawat, K.; Sakdapipanich, J.T.; Ho, C.C.; Ma, Y.; Song, J.; Vancso, J.G. Surface nanostructure of Hevea brasiliensis natural rubber latex particles. Colloids Surf. A Physicochem. Eng. Asp. 2011, 390, 157–166. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Masłowski, M.; Rybiński, P.; Strzelec, K. Properties of chemically modified (selected silanes) lignocellulosic filler and its application in natural rubber biocomposites. Materials 2020, 13, 4163. [Google Scholar] [CrossRef]

- Rybiński, P.; Mirkhodjaev, U.Z.; Żukowski, W.; Bradło, D.; Gawlik, A.; Zamachowski, J.; Marzec, A.; Szadkowski, B. The effect of the lignocellulosic filler on the reduction of fire hazard od styrene-butadiene rubber composites, including the reduction of smoke, PCDD/F, PAH emissions and toxicity during its thermal decomposition. Polym. Test. 2023, 118, 107900. [Google Scholar] [CrossRef]

- Wen, X.; Wang, Y.; Gong, J.; Liu, J.; Tian, N.; Wang, Y.; Jiang, Z.; Qiu, J.; Tang, T. Thermal and flammability properties of polypropylene/carbon black nanocomposites. Polym. Degrad. Stab. 2012, 97, 793–801. [Google Scholar] [CrossRef]

- Szadkowski, B.; Marzec, A.; Zaborski, M. Effect of different carbon fillers on the properties of nitrile rubber composites. Compos. Interfaces 2019, 26, 729–750. [Google Scholar] [CrossRef]

- Rybiński, P.; Syrek, B.; Marzec, A.; Szadkowski, B.; Kuśmierek, M.; Śliwka-Kaszyńska, M.; Mirkhodjaev, U.Z. Effect of basalt and carbon fillers on fire hazard, thermal and mechanical properties of EPDM rubber composites. Materials 2021, 14, 5245. [Google Scholar] [CrossRef] [PubMed]

- Hartzell, G.E. Engineering analysis if hazards to life safety in fires: The fire effluent toxicity component. Safety Science 2001, 38(2), 147–155. [Google Scholar] [CrossRef]

- Valavanidis, A.; Iliopoulos, N.; Gotsis, G.; Fiotakis, K. Persistent free radicals, heavy metals and PAHs generated in particulate soot emissions and residue ash from controlled combustion of common types of plastic. J. Hazard. Mater. 2008, 156, 277–284. [Google Scholar] [CrossRef]

- You, J.H.; Chiang, P.C.; Ten Chang, K.; Chang, S.C. Polycyclic aromatic hydrocarbons (PAHs) and mutagenicity of soot particulates in air emissions from two-stage incineration of polystyrene. J. Hazard. Mater. 1994, 36, 1–17. [Google Scholar] [CrossRef]

- Wei, J.; Li, H.; Liu, J. Curbing dioxin emissions from municipal solid waste incineration: China’s action and global share. J. Hazard. Mater. 2022, 435, 129076. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, Y.; Dong, J.J.; Shi, L.L.; Nakayama, S.F.; Kido, T.; Jung, C.R.; Ma, C.; Feng, H.; Hang, J.G.; et al. Relationship between dioxins and steroid hormone in 6-year-olds: A follow-up study in an e-waste region of China. Chemosphere 2022, 296, 134018. [Google Scholar] [CrossRef]

- Braun, E.; Levin, B.C. Polyesters: A review of the literature on the products of combustion and toxicity. Fire Mater. 1986, 10, 107–123. [Google Scholar] [CrossRef]

- Hirschler, M.M. Fire hazard and toxic potency of the smoke from burning materials. J. Fire Sci. 1987, 5, 289–307. [Google Scholar] [CrossRef]

- Horcas, I.; Fernández, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 7. [Google Scholar] [CrossRef] [PubMed]

- Rybiński, P.; Żukowski, W.; Bradło, D. Effect of cenospheric fillers on the flammability and fire hazard of silicone rubber composites. J. Therm. Anal. Calorim. 2016, 125, 1373–1386. [Google Scholar] [CrossRef]

- Rybiński, P.; Syrek, B.; Żukowski, W.; Bradło, D.; Imiela, M.; Anyszka, R.; Blume, A.; Verbouwe, V. Impact of basalt filler on thermal and mechanical properties, as well as fire hazard of silicone rubber composites, including ceramizable composites. Materials 2019, 12, 2432. [Google Scholar] [CrossRef] [PubMed]

- Smejda-Krzewicka, A.; Rybiński, P.; Bradło, D.; Żukowski, W. Morphology, mechanical and dynamic properties, fire hazard and toxicity of chloroprene and butadiene rubber composites cross-linked with zinc. Materials 2023, 16, 1240. [Google Scholar] [CrossRef]

- Rybiński, P.; Bradło, D.; Żukowski, W.; Syrek, B. Determination of toxic products emissions of polymers thermal decomposition using fluidised bed reactor and FTIR analysis. Polym. Test. 2019, 79, 106040. [Google Scholar] [CrossRef]

- Sen, M.; Copuroglu, M. Influence of gamma irradiation on the ageing characteristic of poly(ethylene-co-vinyl acetate) and poly(ethylene-co-vinyl acetate)/carbon black mixture. J. Therm. Anal. Calorim. 2006, 86, 223–227. [Google Scholar] [CrossRef]

- Burlett, D.J. Thermal techniques to study complex elastomer/filler systems. J. Therm. Anal. Calorim. 2004, 75, 531–544. [Google Scholar] [CrossRef]

- Janowska, G.; Rybiński, P. Influence of carbon black on thermal properties and flammability of cross-linked elastomers. J. Therm. Anal. Calorim. 2008, 3, 697–701. [Google Scholar] [CrossRef]

- Kandola, B.K.; Horrocks, A.R. Complex char formation in flame-retarded fibre-intumescent combinations—IV. Mass loss and thermal barrier properties. Fire Mater. 2000, 24, 265–275. [Google Scholar] [CrossRef]

- Kamath, S.S.; Chandrappa, R.K. Additives used in natural fibre reinforced polymer composites—A review. Mater. Today Proc. 2022, 50, 1417–1424. [Google Scholar] [CrossRef]

- Chapple, S.; Anandjiwala, R. Flammability of natural fiber-reinforced composites and strategies for fire retardancy: A review. J. Thermoplast. Compos. Mater. 2010, 23, 871–893. [Google Scholar] [CrossRef]

- De Chirico, A.; Armanini, M.; Chini, P.; Cioccolo, G.; Provasoli, F.; Audisio, G. Flame retardants for polypropylene based on lignin. Polym. Degrad. Stab. 2003, 79, 139–145. [Google Scholar] [CrossRef]

- Kozłowski, R.; Władyka-Przybylak, M. Flammability and fire resistance of composites reinforced by natural fibers. Polym. Adv. Technol. 2008, 19, 446–453. [Google Scholar] [CrossRef]

- Xia, Y.; Jin, F.; Mao, Z.; Guan, Y.; Zheng, A. Effect of ammonium polyphosphate to pentaerythritol ration on composition and properties of carbonaceous foam deriving from intumescent flame-retardant polypropylene. Polym. Degrad. Stab. 2014, 107, 64–73. [Google Scholar] [CrossRef]

- Woolley, W.D. Smoke and toxic gas production from burning polymers. J. Macromol. Sci. Part A Chem. 1982, 1, 1–33. [Google Scholar] [CrossRef]

- Troitzsch, J. (Ed.) International Plastics Flammability Handbook, 3rd ed.; Carl Hanser: Munich, Germany, 2004; pp. 190–203. [Google Scholar]

- Pasternak, M.; Zinn, B.T.; Browner, R.F. Studies of the chemical mechanism of smoke particulates formation during the combustion of chlorinated polymers. Combust. Sci. Technol. 1982, 28, 263–270. [Google Scholar] [CrossRef]

- Price, D.; Milnes, G.J.; Tayler, P.J.; Scrivens, J.H.; Blease, T.G. Degradation of polymers studied by mass spectroscopy. Polym. Degrad. Stab. 1989, 25, 307–323. [Google Scholar] [CrossRef]

- Grochowalski, A.; Konieczyński, J. PCDDs/PCDFs, dl-PCBs and HCB in the flue gas from coal fired CFB boilers. Chemosphere 2008, 73, 97–103. [Google Scholar] [CrossRef]

- Grochowalski, A. PCDDs and PCDFs concentration in combustion gases and bottom ash from incineration of hospital wastes in Poland. Chemosphere 1998, 37, 2279–2291. [Google Scholar] [CrossRef]

- Moździerz, A.; Juszko-Piekut, M.; Stojko, J. Health effects of polycyclic aromatc hydrocarbons air pollution. Ann. Acad. Med. Silesiensis 2010, 64, 60–65. [Google Scholar]

- Rybiński, P.; Janowska, G.; Dobrzyńska, R.; Kucharska, A. Effect of halogenless flame retardants on the thermal properties, flammability, and fire hazard of cross-linked EVM/NBR rubber blends. J. Therm. Anal. Calorim. 2014, 115, 771–782. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Masłowski, M.; Rybiński, P.; Strzelec, K. Straw/nano-additive hybrids as functional fillers for natural rubber biocomposites. Materials 2021, 14, 321. [Google Scholar] [CrossRef] [PubMed]

| Composite | C-1 | C-2 | C-3 | C-4 | C-5 | C-6 | C-7 |

|---|---|---|---|---|---|---|---|

| NR | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| S | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| MBT | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| SA | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| ZnO | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| CB | 20 | − | − | − | − | − | − |

| MPP | − | 10 | 10 | 10 | 10 | 10 | 10 |

| CS:CB (2:1) | − | 20 | − | − | − | − | − |

| CS:CB (5:1) | − | − | 20 | − | − | − | − |

| CM:CB (2:1) | − | − | − | 20 | − | − | − |

| CM:CB (5:1) | − | − | − | − | 20 | − | − |

| CW:CB (2:1) | − | − | − | − | − | 20 | − |

| CW:CB (5:1) | − | − | − | − | − | − | 20 |

| Sample | C-1 | C-2 | C-3 | C-4 | C-5 | C-6 | C-7 |

|---|---|---|---|---|---|---|---|

| ti (s) | 76 | 53 | 58 | 47 | 66 | 75 | 91 |

| tf-o (s) | 258 | 339 | 321 | 259 | 288 | 271 | 423 |

| HRR (kW/m2) | 229.3 | 146.9 | 170.8 | 197.4 | 183.4 | 187.4 | 111.8 |

| HRRmax (kW/m2) | 402.5 | 344.9 | 389.3 | 359.5 | 342.1 | 333.5 | 250.1 |

| tHRRmax (s) | 155 | 125 | 135 | 125 | 155 | 175 | 210 |

| THR (MJ/m2) | 30.8 | 31.8 | 35.1 | 31.1 | 30.1 | 27.1 | 27.0 |

| EHC (MJ/kg) | 26.7 | 20.3 | 21.3 | 20.6 | 19.1 | 17.8 | 16.2 |

| EHCmax (MJ/kg) | 41.4 | 49.3 | 49.1 | 44.2 | 48.1 | 47.2 | 43.9 |

| MLR (g/s) | 0.076 | 0.064 | 0.07 | 0.084 | 0.085 | 0.093 | 0.061 |

| MLRmax (g/s) | 0.254 | 0.229 | 0.293 | 0.237 | 0.228 | 0.238 | 0.212 |

| AMLR (g/m2×s) | 19.26 | 15.73 | 18.82 | 16.94 | 17.76 | 16.70 | 13.20 |

| FIGRA (kW/m2s) | 2.59 | 2.75 | 2.88 | 2.86 | 2.21 | 1.90 | 1.19 |

| MARHE (kW/m2) | 163.8 | 160.3 | 175.0 | 174.3 | 149.4 | 139.1 | 100.3 |

| Sample | SDMAX | VOF4 |

|---|---|---|

| C-1 | 451.7 | 707.4 |

| C-2 | 471.1 | 667.4 |

| C-3 | 436.6 | 551.7 |

| C-4 | 434.4 | 592.0 |

| C-5 | 402.0 | 536.8 |

| C-6 | 398.5 | 609.4 |

| C-7 | 399.2 | 505.0 |

| Dioxin pg/g | C-1 | C-3 | C-5 | C-7 |

|---|---|---|---|---|

| 2,3,7,8-Tetrachlorodibenzo-p-dioxin | 0.5656 | 0.1016 | 0.1907 | 0.2491 |

| 1,2,3,7,8-Pentachlorodibenzo-p-dioxin | 1.8094 | <LOQ | <LOQ | 1.5466 |

| 1,2,3,4,7,8-Hexachlorodibenzo-p-dioxin | 0.2107 | 0.1092 | 0.0652 | 0.0205 |

| 1,2,3,6,7,8-Hexachlorodibenzo-p-dioxin | 0.3737 | 0.1926 | 0.1150 | 0.0362 |

| 1,2,3,7,8,9-Hexachlorodibenzo-p-dioxin | 0.1567 | 0.1291 | 0.0499 | 0.0448 |

| 1,2,3,4,6,7,8-Heptachlorodibenzo-p-dioxin | 0.0231 | <LOQ | <LOQ | <LOQ |

| Octachlorodibenzo-p-dioxin | 0.001 | 0.0019 | <LOQ | 0.0013 |

| 2,3,7,8-Tetrachlorodibenzofuran | 0.1786 | 0.0515 | 0.0923 | 0.1196 |

| 1,2,3,7,8-Pentachlorodibenzofuran | 0.0185 | <LOQ | <LOQ | 0.0141 |

| 2,3,4,7,8-Pentachlorodibenzofuran | <LOQ | 0.1076 | 0.0898 | 0.4281 |

| 1,2,3,4,7,8-Hexachlorodibenzofuran | 0.0871 | 0.1450 | 0.0514 | 0.2387 |

| 1,2,3,6,7,8-Hexachlorodibenzofuran | 0.0412 | 0.0686 | 0.0243 | 0.0767 |

| 2,3,4,6,7,8-Hexachlorodibenzofuran | <LOQ | 0.0214 | 0.0247 | <LOQ |

| 1,2,3,7,8,9-Hexachlorodibenzofuran | 0.1643 | 0.0891 | <LOQ | 0.1338 |

| 1,2,3,4,6,7,8-Heptachlorodibenzofuran | 0.1898 | 0.0597 | <LOQ | 0.0806 |

| 1,2,3,4,7,8,9-Heptachlorodibenzofuran | 0.1679 | <LOQ | 0.0838 | 0.1067 |

| Octachlorodibenzofuran | 0.0046 | 0.0033 | <LOQ | <LOQ |

| Sum | 3.9921 | 1.0806 | 0.7870 | 3.0969 |

| Congener PCDDs | TEF | Congener PCDFs | TEF |

|---|---|---|---|

| 2,3,7,8-TCDD | 1 | 2,3,7,8-TCDF | 0.1 |

| 1,2,3,7,8-P5CDD | 1 | 1,2,3,7,8-P5CDF | 0.05 |

| 1,2,3,4,7,8-H6CDD | 0.1 | 2,3,4,7,8-P5CDF | 0.5 |

| 1,2,3,6,7,8-H6CDD | 0.1 | 1,2,3,4,7,8-H6CDF | 0.1 |

| 1,2,3,7,8,9-H6CDD | 0.1 | 1,2,3,6,7,8-H6CDF | 0.1 |

| 1,2,3,4,6,7,8-H7CDD | 0.01 | 2,3,4,6,7,8-H6CDF | 0.1 |

| OCDD | 0.0001 | 1,2,3,7,8,9-H6CDF | 0.1 |

| − | − | 1,2,3,4,6,7,8-H7CDF | 0.01 |

| − | − | 1,2,3,4,7,8,9-H7CDF | 0.01 |

| − | − | OCDF | 0.0001 |

| Dioxin pg/g | C-1 | C-3 | C-5 | C-7 |

|---|---|---|---|---|

| 2,3,7,8-Tetrachlorodibenzo-p-dioxin | 0.5656 | 0.1016 | 0.1907 | 0.2491 |

| 1,2,3,7,8-Pentachlorodibenzo-p-dioxin | 1.8094 | <LOQ | <LOQ | 1.5466 |

| 1,2,3,4,7,8-Hexachlorodibenzo-p-dioxin | 0.0211 | 0.0109 | 0.0065 | 0.0021 |

| 1,2,3,6,7,8-Hexachlorodibenzo-p-dioxin | 0.0374 | 0.0193 | 0.0115 | 0.0036 |

| 1,2,3,7,8,9-Hexachlorodibenzo-p-dioxin | 0.0157 | 0.0129 | 0.0050 | 0.0045 |

| 1,2,3,4,6,7,8-Heptachlorodibenzo-p-dioxin | 0.0002 | <LOQ | <LOQ | <LOQ |

| Octachlorodibenzo-p-dioxin | 0.0000 | 0.0000 | <LOQ | 0.0000 |

| 2,3,7,8-Tetrachlorodibenzofuran | 0.0179 | 0.0052 | 0.0092 | 0.0120 |

| 1,2,3,7,8-Pentachlorodibenzofuran | 0.0009 | <LOQ | <LOQ | 0.0007 |

| 2,3,4,7,8-Pentachlorodibenzofuran | <LOQ | 0.0538 | 0.0449 | 0.2141 |

| 1,2,3,4,7,8-Hexachlorodibenzofuran | 0.0087 | 0.0145 | 0.0051 | 0.0239 |

| 1,2,3,6,7,8-Hexachlorodibenzofuran | 0.0041 | 0.0069 | 0.0024 | 0.0077 |

| 2,3,4,6,7,8-Hexachlorodibenzofuran | <LOQ | 0.0021 | 0.0025 | <LOQ |

| 1,2,3,7,8,9-Hexachlorodibenzofuran | 0.0164 | 0.0089 | <LOQ | 0.0134 |

| 1,2,3,4,6,7,8-Heptachlorodibenzofuran | 0.0019 | 0.0006 | <LOQ | 0.0008 |

| 1,2,3,4,7,8,9-Heptachlorodibenzofuran | 0.0017 | <LOQ | 0.0008 | 0.0011 |

| Octachlorodibenzofuran | 0.0000 | 0.0000 | <LOQ | <LOQ |

| TEQ | 2.5010 | 0.2366 | 0.2787 | 2.0794 |

| PAH µg/g | C-1 | C-3 | C-5 | C-7 |

|---|---|---|---|---|

| Naphthalene | 18.35 | 5.47 | 0.63 | 0.68 |

| 2-Methylnaphthalene | 61.45 | 14.21 | 4.11 | 7.48 |

| 1-Methylnaphthalene | 48.95 | 15.03 | 4.27 | 7.21 |

| Acenaphthylene | <LOQ | 3.98 | 2.93 | 3.90 |

| Acenaphthene | 25.27 | 6.66 | 9.62 | 6.10 |

| Fluorene | 113.84 | 28.47 | 22.06 | 24.20 |

| Phenanthrene | 55.88 | 10.90 | 12.96 | 11.25 |

| Anthracene | 61.33 | 0.60 | 1.82 | 1.36 |

| Fluoranthene | 33.90 | 3.32 | 3.71 | 3.77 |

| Pyrene | 125.30 | 7.34 | 10.23 | 8.82 |

| Benz(a)anthracene | 14.60 | 1.06 | 0.80 | 1.15 |

| Chrysene | 8.97 | 1.74 | 1.13 | 1.93 |

| Benzo(b)fluoranthene | 5.61 | 1.07 | 0.61 | 0.71 |

| Benzo(k)fluoranthene | 4.71 | 0.81 | 0.50 | 0.63 |

| Benzo(a)pyrene | 6.63 | 1.08 | 0.69 | 0.83 |

| Indeno(1,2,3-cd)pyrene | 11.07 | 1.17 | 0.89 | 0.75 |

| Dibenz(a,h)anthracene | 9.08 | 1.00 | 0.92 | 0.57 |

| Benzo(g,h,i)perylene | 38.52 | 2.92 | 3.33 | 2.16 |

| Sum | 643.56 | 106.93 | 81.28 | 83.58 |

| Gas | CO2 | CO | NO2 | SO2 | HCl | HCN |

|---|---|---|---|---|---|---|

| LC | 194.4 | 3.75 | 0.205 | 0.7 | 1 | 0.16 |

| Sample | T, °C | WLC50, g/m3 | WLC50M, g/m3 | WLC50SM, g/m3 | |||||

|---|---|---|---|---|---|---|---|---|---|

| CO2 | CO | NO2 | SO2 | HCl | HCN | ||||

| C-1 | 450 | 162 ± 14 | 27 ± 2 | <LOQ | 483 ± 66 | <LOQ | <LOQ | 22.2 ± 0.9 | 32.77 |

| 550 | 200 ± 19 | 13 ± 1 | <LOQ | 315 ± 7 | <LOQ | 305 ± 27 | 11.7 ± 1.4 | ||

| 750 | 70 ± 1 | 3288 ± 514 | <LOQ | 1323 ± 315 | <LOQ | 2165 ± 477 | 64.4 ± 2.8 | ||

| C-3 | 450 | 125 ± 8 | 44 ± 1 | <LOQ | 407 ± 59 | <LOQ | 300 ± 21 | 28.1 ± 0.8 | 38.60 |

| 550 | 110 ± 8 | 12 ± 1 | <LOQ | 253 ± 34 | <LOQ | 62 ± 3 | 8.6 ± 0.6 | ||

| 750 | 86 ± 3 | 4936 ± 1138 | <LOQ | 4021 ± 20 | <LOQ | 1663 ± 310 | 79.0 ± 2.1 | ||

| C-5 | 450 | 105 ± 5 | 43 ± 2 | <LOQ | 981 ± 187 | <LOQ | 184 ± 15 | 25.6 ± 0.9 | 39.60 |

| 550 | 99 ± 7 | 12 ± 1 | <LOQ | 223 ± 31 | <LOQ | 53 ± 1 | 8.6 ± 0.3 | ||

| 750 | 93 ± 5 | 4596 ± 1108 | <LOQ | 1560 ± 608 | <LOQ | 2098 ± 571 | 84.6 ± 6.9 | ||

| C-7 | 450 | 91 ± 10 | 39 ± 8 | <LOQ | 584 ± 105 | <LOQ | 122 ± 10 | 21.7 ± 2.7 | 31.75 |

| 550 | 93 ± 7 | 13 ± 1 | <LOQ | 125 ± 17 | <LOQ | 50 ± 3 | 8.6 ± 0.7 | ||

| 750 | 95 ± 1 | 3134 ± 758 | <LOQ | 284 ± 47 | <LOQ | 1117 ± 123 | 65.0 ± 2.0 | ||

| Composite | SE100 MPa | σSE100 MPa | SE200 MPa | σSE200 MPa | SE300 MPa | σSE300 MPa | TS MPa | σTS MPa | Eb % | σEb % |

|---|---|---|---|---|---|---|---|---|---|---|

| C-1 | 0.89 | 0.06 | 1.62 | 0.09 | 2.94 | 0.17 | 15.00 | 0.47 | 603.2 | 16.1 |

| C-2 | 1.08 | 0.02 | 1.88 | 0.05 | 2.78 | 0.07 | 13.85 | 0.03 | 607.5 | 27.8 |

| C-3 | 1.26 | 0.05 | 2.23 | 0.08 | 3.27 | 0.16 | 15.20 | 0.98 | 527.9 | 98.6 |

| C-4 | 0.78 | 0.03 | 1.19 | 0.04 | 1.90 | 0.13 | 16.90 | 0.40 | 640.3 | 5.7 |

| C-5 | 1.22 | 0.08 | 2.10 | 0.22 | 2.97 | 0.33 | 15.40 | 0.87 | 682.4 | 57.2 |

| C-6 | 0.96 | 0.17 | 1.75 | 0.45 | 2.66 | 0.74 | 15.84 | 0.76 | 477.0 | 55.0 |

| C-7 | 1.01 | 0.05 | 1.88 | 0.10 | 2.82 | 5.44 | 13.20 | 1.10 | 652.0 | 13.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rybiński, P.; Mirkhodjaev, U.Z.; Żukowski, W.; Bradło, D.; Gawlik, A.; Zamachowski, J.; Żelezik, M.; Masłowski, M.; Miedzianowska, J. Effect of Hybrid Filler, Carbon Black–Lignocellulose, on Fire Hazard Reduction, including PAHs and PCDDs/Fs of Natural Rubber Composites. Polymers 2023, 15, 1975. https://doi.org/10.3390/polym15081975

Rybiński P, Mirkhodjaev UZ, Żukowski W, Bradło D, Gawlik A, Zamachowski J, Żelezik M, Masłowski M, Miedzianowska J. Effect of Hybrid Filler, Carbon Black–Lignocellulose, on Fire Hazard Reduction, including PAHs and PCDDs/Fs of Natural Rubber Composites. Polymers. 2023; 15(8):1975. https://doi.org/10.3390/polym15081975

Chicago/Turabian StyleRybiński, Przemysław, Ulugbek Zakirovich Mirkhodjaev, Witold Żukowski, Dariusz Bradło, Adam Gawlik, Jakub Zamachowski, Monika Żelezik, Marcin Masłowski, and Justyna Miedzianowska. 2023. "Effect of Hybrid Filler, Carbon Black–Lignocellulose, on Fire Hazard Reduction, including PAHs and PCDDs/Fs of Natural Rubber Composites" Polymers 15, no. 8: 1975. https://doi.org/10.3390/polym15081975

APA StyleRybiński, P., Mirkhodjaev, U. Z., Żukowski, W., Bradło, D., Gawlik, A., Zamachowski, J., Żelezik, M., Masłowski, M., & Miedzianowska, J. (2023). Effect of Hybrid Filler, Carbon Black–Lignocellulose, on Fire Hazard Reduction, including PAHs and PCDDs/Fs of Natural Rubber Composites. Polymers, 15(8), 1975. https://doi.org/10.3390/polym15081975