Three-Dimensionally Printed Expandable Structural Electronics Via Multi-Material Printing Room-Temperature-Vulcanizing (RTV) Silicone/Silver Flake Composite and RTV

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of 3D-Printed RTV-Based Ink

2.2. Characterization of 3D-Printed RTV-Based Inks and Electronic Components

2.3. Multi-material Printing for Electronics and Actuators

3. Results

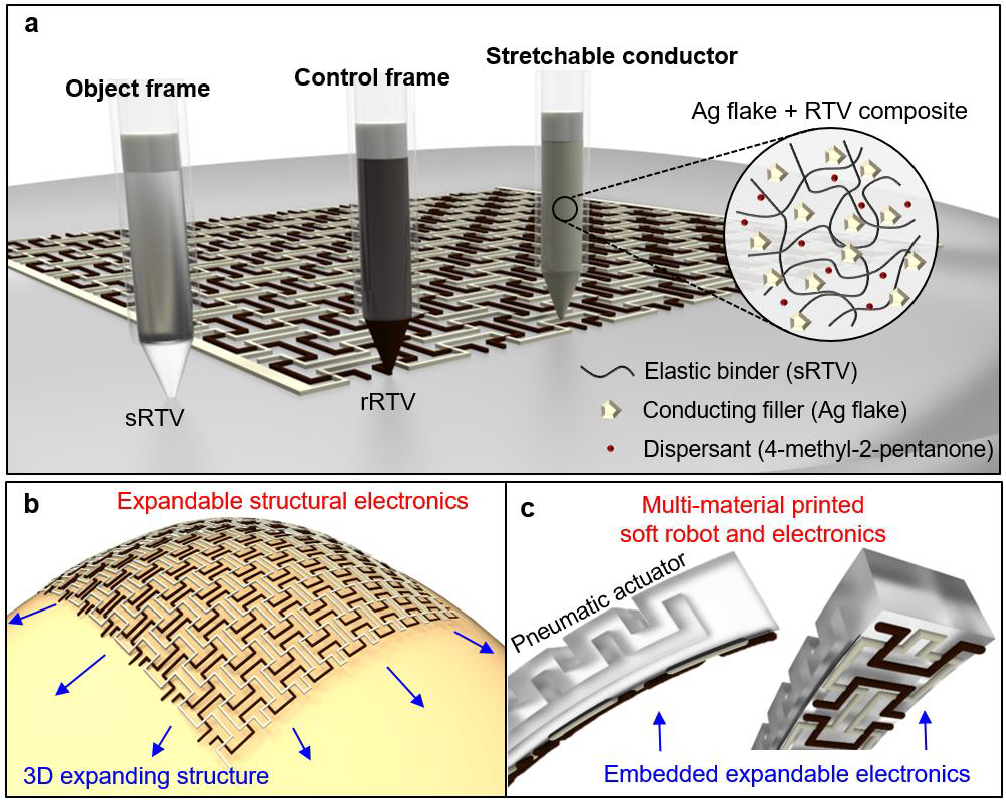

3.1. Overview of 3D-Printed Expandable Structural Electronics

3.2. Characterization of 3D-Printable Soft Electronic Inks

3.3. A 3D-Printed Microstructure with a Negative Poisson’s Ratio for Expandable Soft Electronics

3.4. Three-Dimensionally Printed Control Frames for Expandable Soft Electronics and Their Applications

3.5. Fully 3D-Printed Soft Actuators Embedded in Expandable Soft Electronics

4. Discussion

5. Conclusions

- ▪

- Merits:

- -

- Expandable structural electronics, in the form of metamaterial structures (missing-rib formations) were made possible by configuring voxelated elastic conductors and frame materials via multi-material printing.

- -

- A modified missing-rib-structured conductor with a control frame (Ag-RTV/RTV) showed stable resistance up to a 100% strain change.

- -

- A stereographically designed missing-rib-structured tactile sensor, strain sensor, heater, and monolithically integrated sensors/interconnection embedded pneumatic soft actuator were demonstrated.

- ▪

- Limitations:

- -

- More investigations are needed to increase the deformation range where the resistance is stable.

- -

- Various cell-opening auxetic structures can be examined for better negative Poisson’s ratios.

- -

- More studies should be conducted into the reliability of Ag-RTV, not only in terms of deformations but also in terms of chemical, humidity, and other real-life factors.

- ▪

- Future scope:

- -

- More complex 3D auxetic structures, consisting of conducting voxels and frame voxels, can be explored for various applications.

- -

- Customized soft electronics with actuators can be demonstrated in cases requiring multi-dimensional deformations, for use in automobiles, aerospace, fashions, etc.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, D.; Nian, Q.; Deng, B.; Jin, S.; Hu, Y.; Wang, W.; Cheng, G.J. Three-dimensional printing of complex structures: Man made or toward nature? ACS Nano 2014, 8, 9710–9715. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Ghabez, P.; Harrison, N.M.; Flanagan, T. Manufacture of Composite Filament for 3D Printing from Short Glass Fibres and Recycled High-Density Polypropylene. In Proceedings of the 8th World Congress on Mechanical, Chemical, and Material Engineering (MCM’22), Prague, Czech Republic, 31 July–2 August 2022. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N.M. Recovery of Particle Reinforced Composite 3D Printing Filament from Recycled Industrial Polypropylene and Glass Fibre Waste. In Proceedings of the 8th World Congress on Mechanical, Chemical, and Material Engineering (MCM’22), Prague, Czech Republic, 31 July–2 August 2022. [Google Scholar] [CrossRef]

- Rezaie, F.; Farshbaf, M.; Dahri, M.; Masjedi, M.; Maleki, R.; Amini, F.; Wirth, J.; Moharamzadeh, K.; Weber, F.E.; Tayebi, L. 3D Printing of Dental Prostheses: Current and Emerging Applications. J. Compos. Sci. 2023, 7, 80. [Google Scholar] [CrossRef]

- Grefen, B.; Becker, J.; Linke, S.; Stoll, E. Design, Production and Evaluation of 3D-Printed Mold Geometries for a Hybrid Rocket Engine. Aerospace 2021, 8, 220. [Google Scholar] [CrossRef]

- Schaffner, M.; Rühs, P.A.; Coulter, F.; Kilcher, S.; Studart, A.R. 3D printing of bacteria into functional complex materials. Sci. Adv. 2017, 3, eaao6804. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Fu, J.; He, Y. A review of 3D printing technologies for soft polymer materials. Adv. Funct. Mater. 2020, 30, 2000187. [Google Scholar] [CrossRef]

- Yan, Q.; Dong, H.; Su, J.; Han, J.; Song, B.; Wei, Q.; Shi, Y. A review of 3D printing technology for medical applications. Engineering 2018, 4, 729–742. [Google Scholar] [CrossRef]

- Chadha, U.; Abrol, A.; Vora, N.P.; Tiwari, A.; Shanker, S.K.; Selvaraj, S.K. Performance evaluation of 3D printing technologies: A review, recent advances, current challenges, and future directions. Prog. Addit. Manuf. 2022, 7, 853–886. [Google Scholar] [CrossRef]

- Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D printing technologies for flexible tactile sensors toward wearable electronics and electronic skin. Polymers 2018, 10, 629. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, S.; Sun, L.; Yang, L.; Zhang, L.; Lou, J.; You, Z. Degradable and Fully Recyclable Dynamic Thermoset Elastomer for 3D-Printed Wearable Electronics. Adv. Funct. Mater. 2020, 31, 2009799. [Google Scholar] [CrossRef]

- Guo, S.Z.; Qiu, K.; Meng, F.; Park, S.H.; McAlpine, M.C. 3D printed stretchable tactile sensors. Adv. Mater. 2017, 29, 1701218. [Google Scholar] [CrossRef]

- Heiden, A.; Preninger, D.; Lehner, L.; Baumgartner, M.; Drack, M.; Woritzka, E.; Schiller, D.; Gerstmayr, R.; Hartmann, F.; Kaltenbrunner, M. 3D printing of resilient biogels for omnidirectional and exteroceptive soft actuators. Sci. Robot. 2022, 7, eabk2119. [Google Scholar] [CrossRef]

- Zhu, Y.; Joralmon, D.; Shan, W.; Chen, Y.; Rong, J.; Zhao, H.; Xiao, S.; Li, X. 3D printing biomimetic materials and structures for biomedical applications. Bio-Des. Manuf. 2021, 4, 405–428. [Google Scholar] [CrossRef]

- Ali, M.A.; Hu, C.; Yttri, E.A.; Panat, R. Recent advances in 3D printing of biomedical sensing devices. Adv. Funct. Mater. 2022, 32, 2107671. [Google Scholar] [CrossRef]

- Lewis, J.A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 2006, 16, 2193–2204. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-response, stiffness-tunable soft actuator by hybrid multimaterial 3D printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar] [CrossRef]

- Kim, D.H.; Lu, N.; Ma, R.; Kim, Y.S.; Kim, R.H.; Wang, S.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef]

- Jeong, J.W.; Yeo, W.H.; Akhtar, A.; Norton, J.J.; Kwack, Y.J.; Li, S.; Jung, S.Y.; Su, Y.; Lee, W.; Xia, J.; et al. Materials and optimized designs for human-machine interfaces via epidermal electronics. Adv. Mater. 2013, 25, 6839–6846. [Google Scholar] [CrossRef]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef]

- Cianchetti, M.; Laschi, C.; Menciassi, A.; Dario, P. Biomedical applications of soft robotics. Nat. Rev. Mater. 2018, 3, 143–153. [Google Scholar] [CrossRef]

- Gong, M.; Zhang, L.; Wan, P. Polymer nanocomposite meshes for flexible electronic devices. Prog. Polym. Sci. 2020, 107, 101279. [Google Scholar] [CrossRef]

- Gupta, N.; Adepu, V.; Tathacharya, M.; Siraj, S.; Pal, S.; Sahatiya, P.; Kuila, B.K. Piezoresistive pressure sensor based on conjugated polymer framework for pedometer and smart tactile glove applications. Sens. Actuators A Phys. 2023, 350, 114139. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Roshanghias, A.; Oberlercher, H.; Mitterer, T.; Araee, A.; Zangl, H. MWCNT–Epoxy Nanocomposite Sensors for Structural Health Monitoring. Electronics 2018, 7, 143. [Google Scholar] [CrossRef]

- Wang, S.; Xu, J.; Wang, W.; Wang, G.N.; Rastak, R.; Molina-Lopez, F.; Chung, J.W.; Niu, S.; Feig, V.R.; Lopez, J.; et al. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nature 2018, 555, 83–88. [Google Scholar] [CrossRef]

- Keplinger, C.; Sun, J.Y.; Foo, C.C.; Rothemund, P.; Whitesides, G.M.; Suo, Z. Stretchable, transparent, ionic conductors. Science. 2013, 341, 984–987. [Google Scholar] [CrossRef]

- Dickey, M.D. Stretchable and soft electronics using liquid metals. Adv. Mater. 2017, 29, 1606425. [Google Scholar] [CrossRef]

- Gray, D.S.; Tien, J.; Chen, C.S. High-conductivity elastomeric electronics. Adv. Mater. 2004, 16, 393–397. [Google Scholar] [CrossRef]

- Kim, R.H.; Kim, D.H.; Xiao, J.; Kim, B.H.; Park, S.I.; Panilaitis, B.; Ghaffari, R.; Yao, J.; Li, M.; Liu, Z.; et al. Waterproof AlInGaP optoelectronics on stretchable substrates with applications in biomedicine and robotics. Nat. Mater. 2010, 9, 929–937. [Google Scholar] [CrossRef]

- Miyamoto, A.; Lee, S.; Cooray, N.F.; Lee, S.; Mori, M.; Matsuhisa, N.; Jin, H.; Yoda, L.; Yokota, T.; Itoh, A.; et al. Inflammation-free, gas-permeable, lightweight, stretchable on-skin electronics with nanomeshes. Nat. Nanotechnol. 2017, 12, 907–913. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; Sekitani, T.; Reeder, J.; Yokota, T.; Kuribara, K.; Tokuhara, T.; Drack, M.; Schwödiauer, R.; Graz, I.; Bauer-Gogonea, S.; et al. An ultra-lightweight design for imperceptible plastic electronics. Nature 2013, 499, 458–463. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Qi, D.; Xu, C.; Yu, J.; Liu, Y.; Jiang, Y.; Liedberg, B.; Chen, X. High-adhesion stretchable electrodes based on nanopile interlocking. Adv. Mater. 2017, 29, 1603382. [Google Scholar] [CrossRef]

- Yu-Ki, L.; Xi, Z.; Lee, Y.J.; Kim, Y.-H.; Hao, Y.; Choi, H.; Lee, M.-G.; Joo, Y.-C.; Kim, C.; Lien, J.-M.; et al. Computational wrapping: A universal method to wrap 3D-curved surfaces with nonstretchable materials for conformal devices. Sci. Adv. 2020, 6, eaax6212. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, N.; Cao, Y.; Wang, F.; Wang, P.; Ma, Y.; Lu, B.; Hou, G.; Fang, Z.; Liang, Z.; et al. Climbing-inspired twining electrodes using shape memory for peripheral nerve stimulation and recording. Sci. Adv. 2019, 5, eaaw1066. [Google Scholar] [CrossRef]

- Oh, J.Y.; Son, D.; Katsumata, T.; Lee, Y.; Kim, Y.; Lopez, J.; Wu, H.-C.; Kang, J.; Park, J.; Gu, X.; et al. Stretchable self-healable semiconducting polymer film for active-matrix strain-sensing array. Sci. Adv. 2019, 5, eaav3097. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, S.; Xiong, W.; Zhu, C.; Li, K.; Huang, Y. Self-healing kirigami assembly strategy for conformal electronics. Adv. Funct. Mater. 2022, 32, 2109214. [Google Scholar] [CrossRef]

- Jiang, S.; Liu, X.; Liu, J.; Ye, D.; Duan, Y.; Li, K.; Yin, Z.; Huang, Y. Flexible metamaterial electronics. Adv. Mater. 2022, 34, e2200070. [Google Scholar] [CrossRef]

- Junio, R.F.P.; da Silveira, P.H.P.M.; Neuba, L.M.; Monteiro, S.N.; Nascimento, L.F.C. Development and applications of 3D printing-processed auxetic structures for high-velocity impact protection: A review. Eng 2023, 4, 903–940. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, C.; Liao, G.; Liu, J.; Yao, X.; Fu, J. Progress in auxetic mechanical metamaterials: Structures, characteristics, manufacturing methods, and applications. Adv. Eng. Mater. 2020, 22, 2000312. [Google Scholar] [CrossRef]

- Qi, J.; Chen, Z.; Jiang, P.; Hu, W.; Wang, Y.; Zhao, Z.; Cao, X.; Zhang, S.; Tao, R.; Li, Y.; et al. Recent progress in active mechanical metamaterials and construction principles. Adv. Sci. 2022, 9, e2102662. [Google Scholar] [CrossRef]

- Li, F.; Hu, R. Metamaterials-enabled sensing for human-machine interfacing. Sensors 2020, 21, 161. [Google Scholar] [CrossRef]

- Kapnisi, M.; Mansfield, C.; Marijon, C.; Guex, A.G.; Perbellini, F.; Bardi, I.; Humphrey, E.J.; Puetzer, J.L.; Mawad, D.; Koutsogeorgis, D.C.; et al. Auxetic cardiac patches with tunable mechanical and conductive properties toward treating myocardial infarction. Adv. Funct. Mater. 2018, 28, 1800618. [Google Scholar] [CrossRef] [PubMed]

- Olvera, D.; Sohrabi Molina, M.; Hendy, G.; Monaghan, M.G. Electroconductive melt electrowritten patches matching the mechanical anisotropy of human myocardium. Adv. Funct. Mater. 2020, 30, 1909880. [Google Scholar] [CrossRef]

- Kim, B.S.; Lee, K.; Kang, S.; Lee, S.; Pyo, J.B.; Choi, I.S.; Char, K.; Park, J.H.; Lee, S.S.; Lee, J.; et al. 2D reentrant auxetic structures of graphene/CNT networks for omnidirectionally stretchable supercapacitors. Nanoscale 2017, 9, 13272–13280. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.W.; Kim, T.Y.; Park, H.K.; You, I.; Kwak, J.; Kim, J.C.; Hwang, H.; Kim, H.S.; Jeong, U. Hygroscopic auxetic on-skin sensors for easy-to-handle repeated daily use. ACS Appl. Mater. Interfaces 2018, 10, 40141–40148. [Google Scholar] [CrossRef]

- Han, S.; Jung, S.; Jeong, S.; Choi, J.; Choi, Y.; Lee, S.Y. High-performance, biaxially stretchable conductor based on Ag composites and hierarchical auxetic structure. J. Mater. Chem. C 2020, 8, 1556–1561. [Google Scholar] [CrossRef]

- Jang, B.; Won, S.; Kim, J.; Kim, J.; Oh, M.; Lee, H.; Kim, J. Auxetic meta-display: Stretchable display without image distortion. Adv. Funct. Mater. 2022, 32, 2113299. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, C.; Liao, G.; Liu, J.; Yao, X.; Fu, J. High-performance auxetic bilayer conductive mesh-based multi-material integrated stretchable strain sensors. ACS Appl. Mater. Interfaces 2021, 13, 23038–23048. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Z.; Matsuhisa, N.; Qi, D.; Leow, W.R.; Yang, H.; Yu, J.; Chen, G.; Liu, Y.; Wan, C.; et al. Auxetic mechanical metamaterials to enhance sensitivity of stretchable strain sensors. Adv. Mater. 2018, 30, e1706589. [Google Scholar] [CrossRef]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D printing of soft electronics. Adv. Mater. 2017, 29, 1703817. [Google Scholar] [CrossRef]

- Su, R.; Wen, J.; Su, Q.; Wiederoder, M.S.; Koester, S.J.; Uzarski, J.R.; McAlpine, M.C. 3D printed self-supporting elastomeric structures for multifunctional microfluidics. Sci. Adv. 2020, 6, eabc9846. [Google Scholar] [CrossRef]

- Ge, G.; Wang, Q.; Zhang, Y.-Z.; Alshareef, H.N.; Dong, X. 3D Printing of Hydrogels for Stretchable Ionotronic Devices. Adv. Funct. Mater. 2021, 31, 2107437. [Google Scholar] [CrossRef]

- Ji, J.; Ge, X.; Pang, X.; Liu, R.; Wen, S.; Sun, J.; Liang, W.; Ge, J.; Chen, X. Synthesis and Characterization of Room Temperature Vulcanized Silicone Rubber Using Methoxyl-Capped MQ Silicone Resin as Self-Reinforced Cross-Linker. Polymers 2019, 11, 1142. [Google Scholar] [CrossRef]

- Liao, K.; Zhu, J. A Facile and Cost-Effective Method to Prepare a Robust Superhydrophobic RTV Silicone Coating. Coatings 2021, 11, 312. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Meng, R.; Zhao, Y.; Guo, W. Preparation and properties of room-temperature-vulcanized silicone rubber using modified dopamine as a crosslinking agent. Mater. Res. Express 2022, 9, 045304. [Google Scholar] [CrossRef]

- Wen, X.; Yuan, X.; Lan, L.; Hao, L.; Wang, Y.; Li, S.; Lu, H.; Bao, Z. RTV Silicone Rubber Degradation Induced by Temperature Cycling. Energies 2017, 10, 1054. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, W.; Zhou, Q.; Meng, Y.; Zhong, Y.; Xu, J.; Xiao, C.; Zhang, G.; Zhang, Y. Effects of Vinyl Functionalized Silica Particles on Thermal and Mechanical Properties of Liquid Silicone Rubber Nanocomposites. Polymers 2023, 15, 1224. [Google Scholar] [CrossRef]

- Yoon, I.S.; Kim, S.H.; Oh, Y.; Ju, B.K.; Hong, J.M. Ag flake/silicone rubber composite with high stability and stretching speed insensitive resistance via conductive bridge formation. Sci. Rep. 2020, 10, 5036. [Google Scholar] [CrossRef]

- Oh, M.-H.; Kim, Y.-H.; Lee, S.-M.; Hwang, G.-S.; Kim, K.-S.; Bae, J.-Y.; Kim, J.-Y.; Lee, J.-Y.; Kim, Y.-C.; Kim, S.Y.; et al. Lifetime-configurable soft robots via photodegradable silicone elastomer composites. arXiv 2023, arXiv:2302.14331. [Google Scholar] [CrossRef]

- Smith, C.W.; Grima, J.N.; Evans, K.E. A novel mechanism for generating auxetic behaviour in reticulated foams: Missing rib foam model. Acta Mater. 2000, 48, 4349–4356. [Google Scholar] [CrossRef]

- Gaspar, N.; Ren, X.; Smith, C.; Grima, J.; Evans, K. Novel honeycombs with auxetic behaviour. Acta Mater. 2005, 53, 2439–2445. [Google Scholar] [CrossRef]

- Tang, C.; Li, L.; Wang, L.; Herencia, V.Z.; Ren, J. Numerical and experimental studies on the deformation of missing-rib and mixed structures under compression. Phys. Status Solidi B 2020, 257, 2000150. [Google Scholar] [CrossRef]

- Clausen, A.; Wang, F.; Jensen, J.S.; Sigmund, O.; Lewis, J.A. Topology optimized architectures with programmable Poisson’s ratio over large deformations. Adv. Mater. 2015, 27, 5523–5527. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-Y.; Oh, M.-H.; Park, J.-H.; Kang, S.-H.; Kang, S.-K. Three-Dimensionally Printed Expandable Structural Electronics Via Multi-Material Printing Room-Temperature-Vulcanizing (RTV) Silicone/Silver Flake Composite and RTV. Polymers 2023, 15, 2003. https://doi.org/10.3390/polym15092003

Lee J-Y, Oh M-H, Park J-H, Kang S-H, Kang S-K. Three-Dimensionally Printed Expandable Structural Electronics Via Multi-Material Printing Room-Temperature-Vulcanizing (RTV) Silicone/Silver Flake Composite and RTV. Polymers. 2023; 15(9):2003. https://doi.org/10.3390/polym15092003

Chicago/Turabian StyleLee, Ju-Yong, Min-Ha Oh, Joo-Hyeon Park, Se-Hun Kang, and Seung-Kyun Kang. 2023. "Three-Dimensionally Printed Expandable Structural Electronics Via Multi-Material Printing Room-Temperature-Vulcanizing (RTV) Silicone/Silver Flake Composite and RTV" Polymers 15, no. 9: 2003. https://doi.org/10.3390/polym15092003

APA StyleLee, J.-Y., Oh, M.-H., Park, J.-H., Kang, S.-H., & Kang, S.-K. (2023). Three-Dimensionally Printed Expandable Structural Electronics Via Multi-Material Printing Room-Temperature-Vulcanizing (RTV) Silicone/Silver Flake Composite and RTV. Polymers, 15(9), 2003. https://doi.org/10.3390/polym15092003