Tribological and Mechanical Applications of Liquid-Crystal-Polymer-Modified Carbon-Fiber-Reinforced Polyamide–Polyurethane Composites

Abstract

:1. Introduction

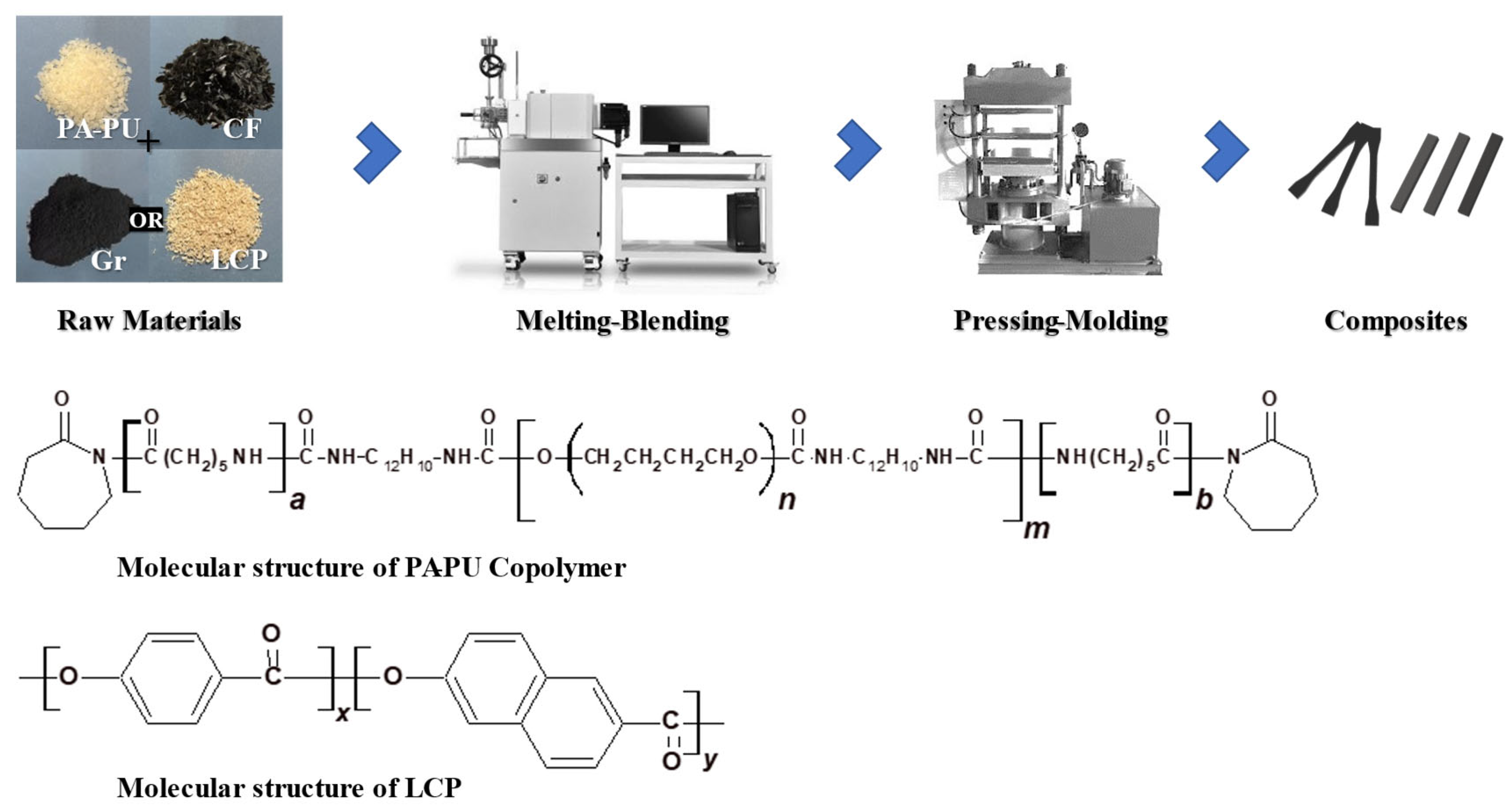

2. Materials and Methods

2.1. Materials

2.2. Preparation of PA-PU Copolymer Composites

2.3. Characterization

3. Results and Discussion

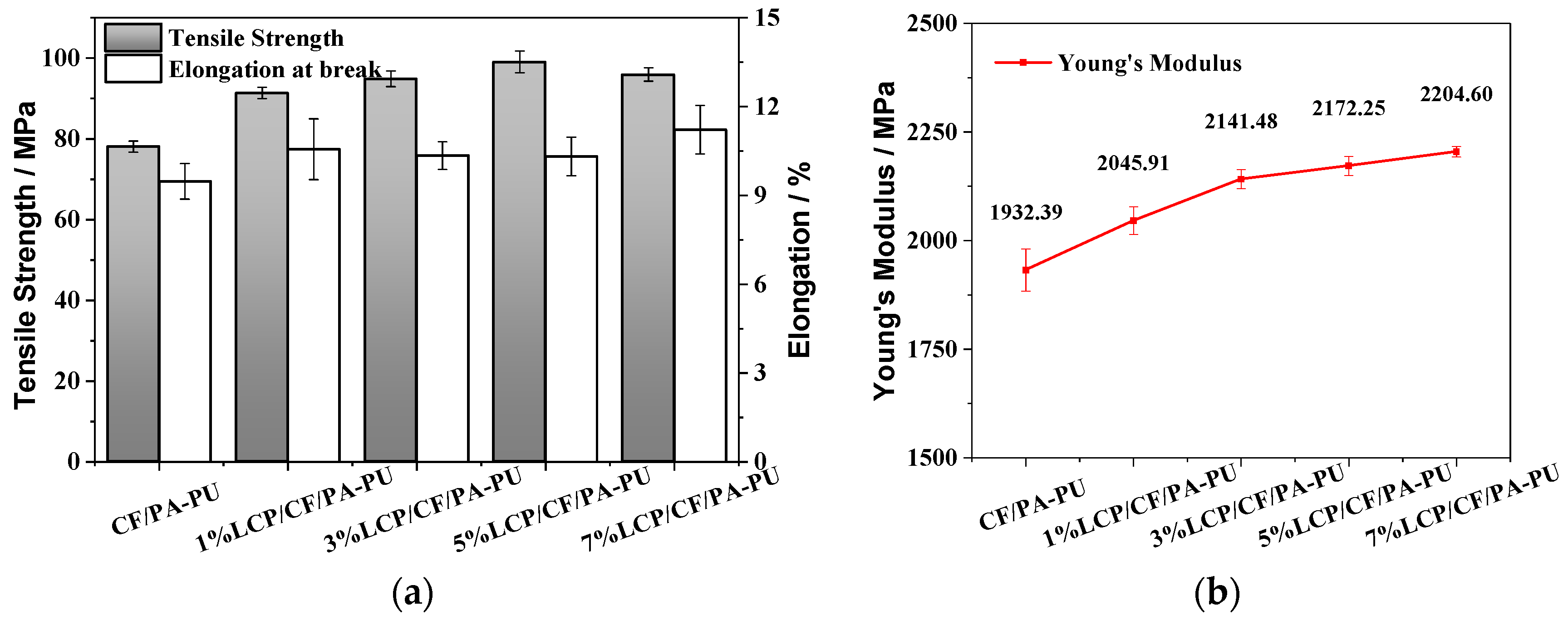

3.1. Tensile Properties

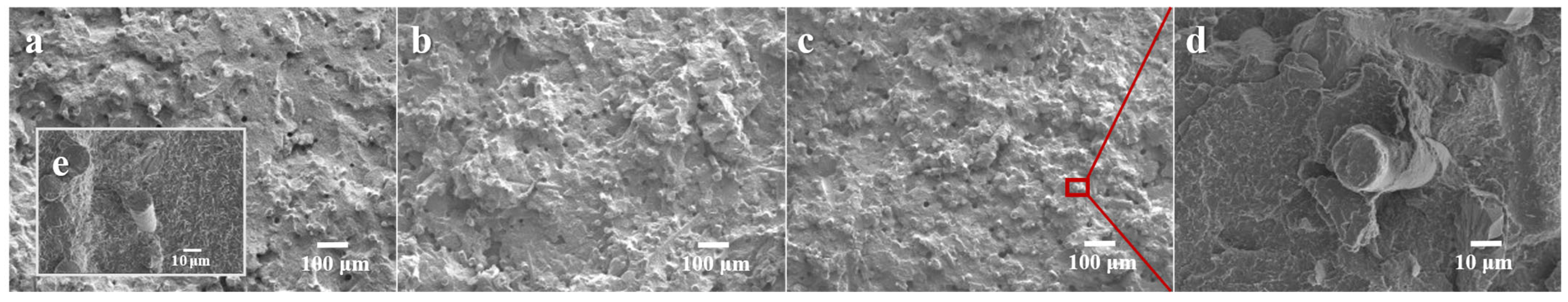

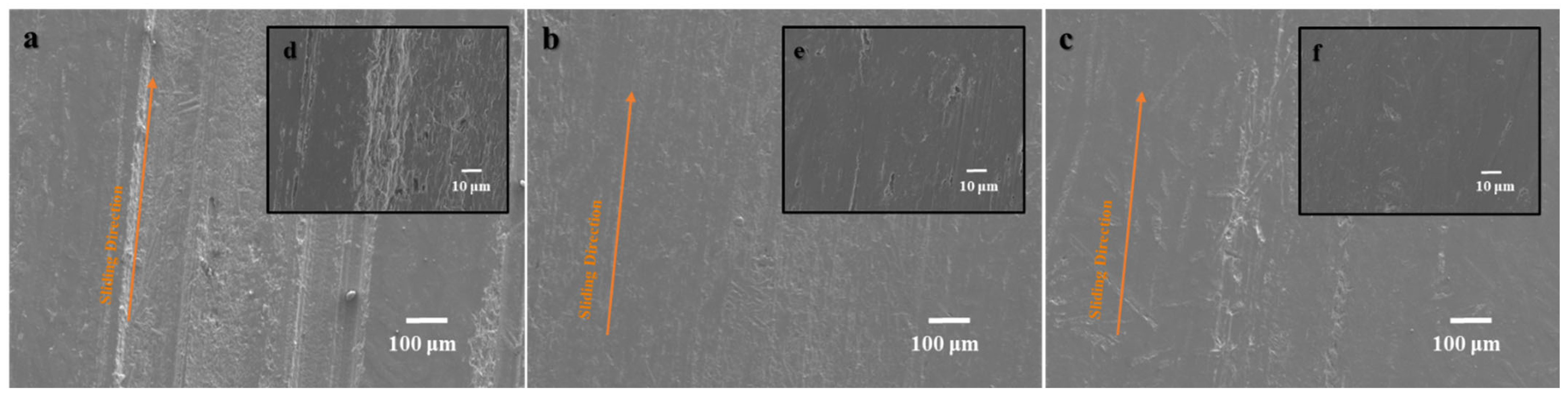

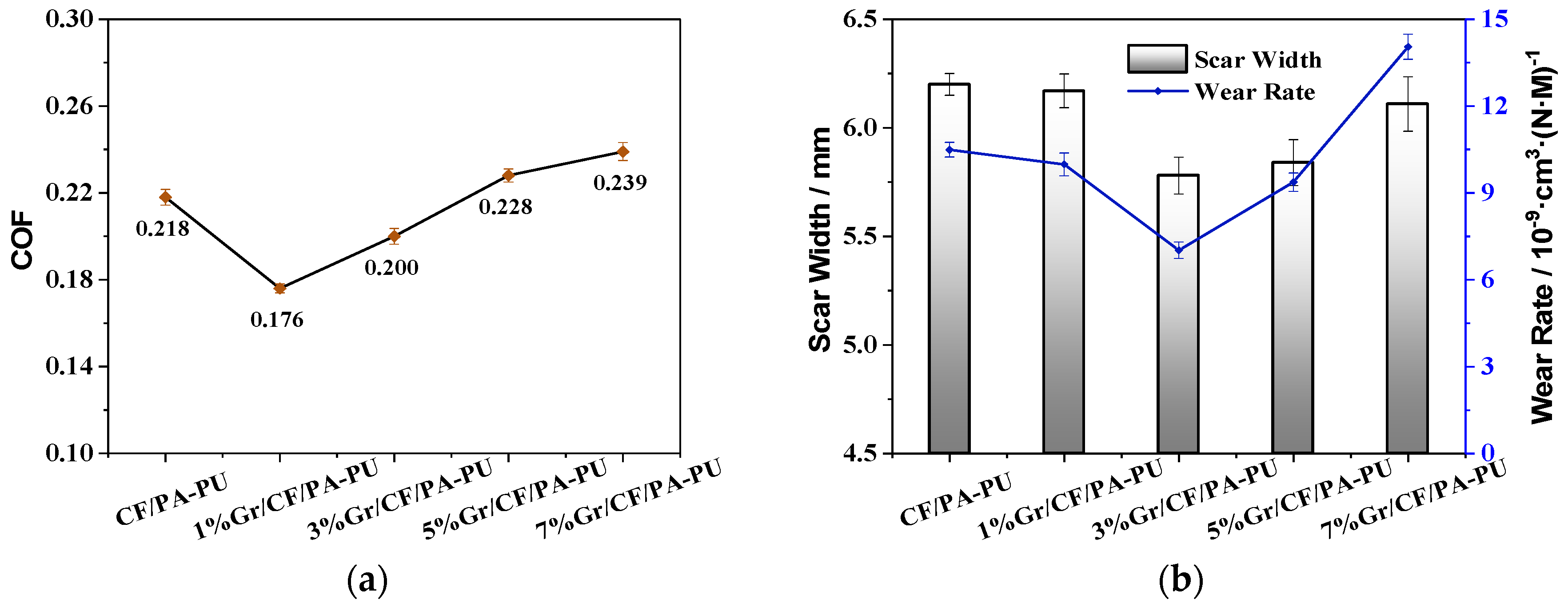

3.2. Tribological Properties

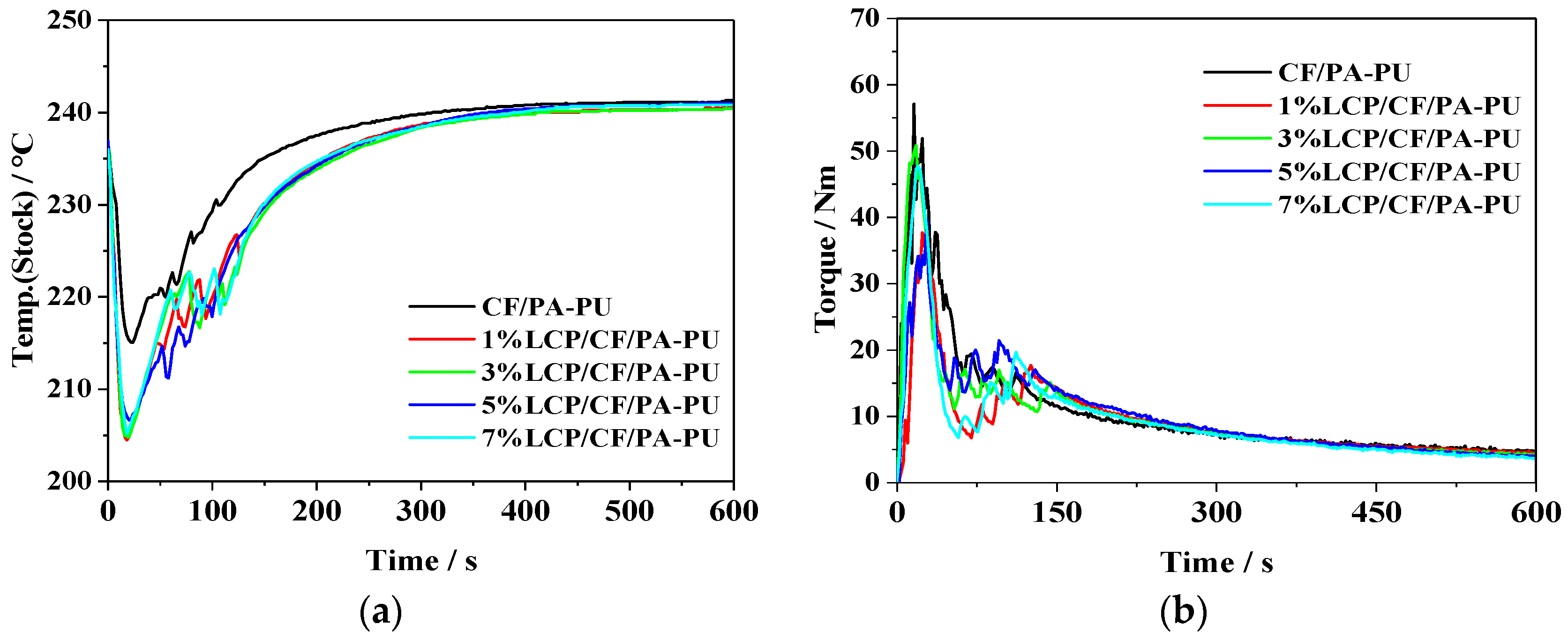

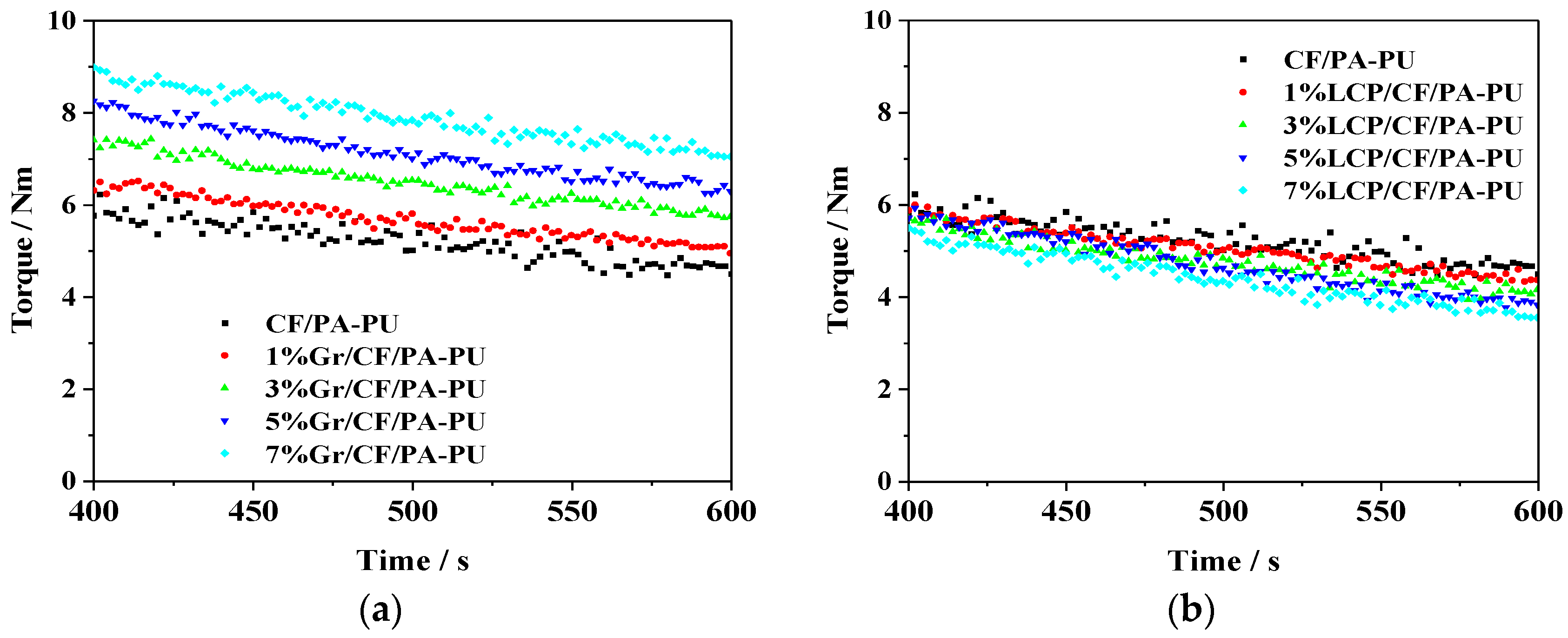

3.3. Processing Properties

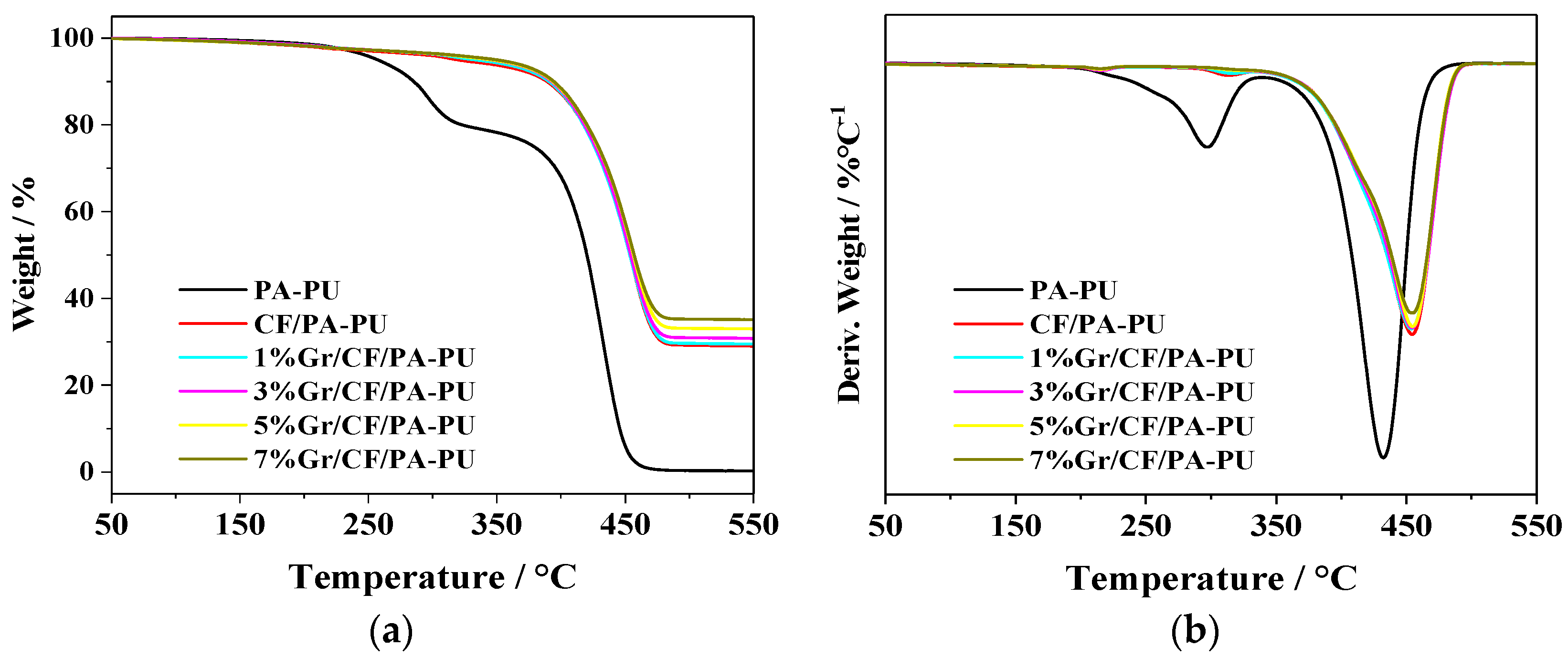

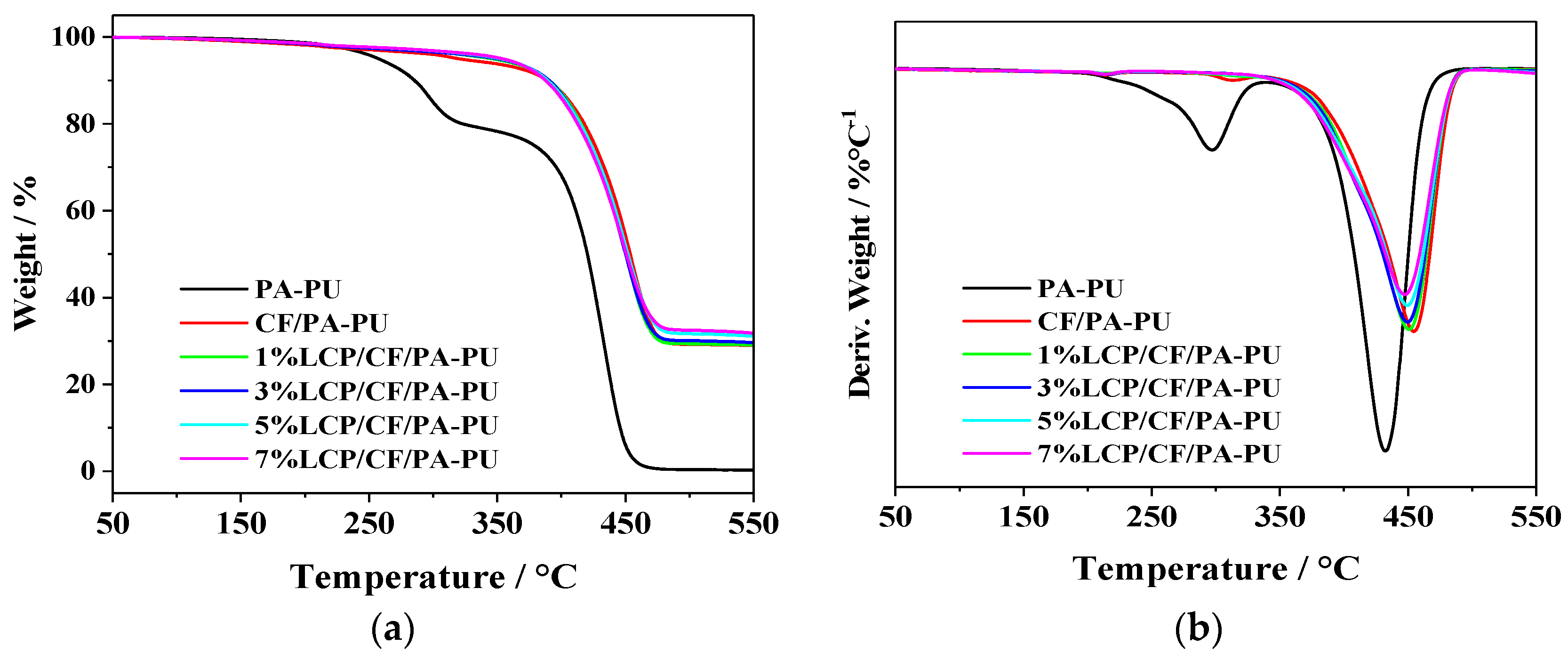

3.4. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, D.-X.; Deng, X.; Wang, J.; Yang, J.; Li, X. Mechanical and tribological properties of polyamide 6–polyurethane block copolymer reinforced with short glass fibers. Wear 2010, 269, 262–268. [Google Scholar] [CrossRef]

- Zou, X.; Liu, B.; Wen, J.; Zeng, W.; Jing, B.; Dai, W. Improvement of polyamide/thermoplastic polyurethane blends with polyamide 6-polyurethane copolymer prepared via suspension polymerization as compatibilizer. J. Appl. Polym. Sci. 2020, 137, 49155. [Google Scholar] [CrossRef]

- Reulier, M.; Avérous, L. Elaboration, morphology and properties of renewable thermoplastics blends, based on polyamide and polyurethane synthesized from dimer fatty acids. Eur. Polym. J. 2015, 67, 418–427. [Google Scholar] [CrossRef]

- Yang, C.; Xie, G.; Kang, J.; Zhang, L. Research on polyamide based self-lubricating composites: A review. Polym. Compos. 2022, 43, 5767–5782. [Google Scholar] [CrossRef]

- Vodyakov, V.N.; Radaykina, E.A.; Kotin, A.V.; Kuznetsov, V.V.; Murneva, M.I. New polyamide composites for friction power cylinders of agricultural machinery. In Key Engineering Materials; Trans. Tech. Publications Ltd.: Aedermannsdorf, Switzerland, 2019; pp. 157–161. [Google Scholar]

- Uematsu, H.; Kurita, D.; Nakakubo, S.; Yamaguchi, A.; Yamane, M.; Kawabe, K.; Tanoue, S. Mechanical behavior of unidirectional carbon fiber-reinforced polyamide 6 composites under transverse tension and the structure of polyamide 6 among carbon fibers. Polym. J. 2020, 52, 1195–1201. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, Y.; Wang, K.; Gao, G.; Ahzi, S. Synergistic reinforcement of polyamide-based composites by combination of short and continuous carbon fibers via fused filament fabrication. Compos. Struct. 2019, 207, 232–239. [Google Scholar] [CrossRef]

- Li, X.; He, J.; Hu, Z.; Ye, X.; Wang, S.; Zhao, Y.; Wang, B.; Ou, Y.; Zhang, J. High strength carbon-fiber reinforced polyamide 6 composites additively manufactured by screw-based extrusion. Compos. Sci. Technol. 2022, 229, 109707. [Google Scholar] [CrossRef]

- Vinayagamoorthy, R. Friction and wear characteristics of fibre-reinforced plastic composites. J. Thermoplast. Compos. Mater. 2020, 33, 828–850. [Google Scholar] [CrossRef]

- Man, Z.; Wang, H.; He, Q.; Kim, D.-E.; Chang, L. Friction and wear behaviour of additively manufactured continuous carbon fibre reinforced PA6 composites. Compos. Part B Eng. 2021, 226, 109332. [Google Scholar] [CrossRef]

- Li, J.; Xia, Y.C. The Friction and Wear Properties of Thermoplastic PA6 Composites Filled with Carbon Fiber. J. Thermoplast. Compos. Mater. 2010, 23, 337–349. [Google Scholar] [CrossRef]

- Jiang, J.; Yao, X.; Xu, C.; Su, Y.; Zhou, L.; Deng, C. Influence of electrochemical oxidation of carbon fiber on the mechanical properties of carbon fiber/graphene oxide/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2017, 95, 248–256. [Google Scholar] [CrossRef]

- Kim, S.W.; Park, T.; Um, M.K.; Lee, J.; Seong, D.G.; Yi, J.W. Effect of caprolactam modified phenoxy-based sizing material on reactive process of carbon fiber-reinforced thermoplastic polyamide-6. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106104. [Google Scholar] [CrossRef]

- Fei, J.; Liu, T.; Luo, L.; Zhou, M.; Zhao, B.; Huang, J.F. Improvements of mechanical and tribological properties of carbon fiber reinforced composites via chemically grafting MA onto MnO2 nanosheets as interphase. J. Compos. Mater. 2021, 55, 1609–1619. [Google Scholar] [CrossRef]

- Zhu, Z.; Bai, S.; Wu, J.; Xu, L.; Li, T.; Ren, Y.; Liu, C. Friction and wear behavior of resin/graphite composite under dry sliding. J. Mater. Sci. Technol. 2015, 31, 325–330. [Google Scholar] [CrossRef]

- Sarath, P.; Reghunath, R.; Thomas, S.; Haponiuk, J.T.; George, S.C. An investigation on the tribological and mechanical properties of silicone rubber/graphite composites. J. Compos. Mater. 2021, 55, 3827–3838. [Google Scholar] [CrossRef]

- Bai, J.; Song, J.; Wei, J. Tribological and mechanical properties of MoS2 enhanced polyamide 12 for selective laser sintering. J. Mater. Process. Technol. 2019, 264, 382–388. [Google Scholar] [CrossRef]

- Unal, H.; Mimaroglu, A. Friction and wear performance of polyamide 6 and graphite and wax polyamide 6 composites under dry sliding conditions. Wear 2012, 289, 132–137. [Google Scholar] [CrossRef]

- Yi-lan, Y.; Chen-ming, L.; Du-xin, L.; Shi-jun, L.; Guo-wen, H. Tribological and flame retardant modification of polyamide-6 composite. J. Cent. South Univ. 2019, 26, 88–97. [Google Scholar]

- Golaz, B.; Tetouani, S.; Diomidis, N.; Michaud, V.; Mischler, S. Processing and tribology of thermoplastic polyurethane particulate composite materials. J. Appl. Polym. Sci. 2012, 125, 3745–3754. [Google Scholar] [CrossRef]

- Vikram, K.; Bhaumik, S.; Pramanik, S. Effect of graphite on tribological and mechanical properties of PA6/5GF composites. J. Therm. Anal. Calorim. 2023, 1–15. [Google Scholar] [CrossRef]

- Japić, D.; Kulovec, S.; Kalin, M.; Slapnik, J.; Nardin, B.; Huskić, M. Effect of Expanded Graphite on Mechanical and Tribological Properties of Polyamide 6/Glass Fibre Composites. Adv. Polym. Technol. 2022, 2022, 997488. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, X.; Pei, X. Study on the synergistic effect of carbon fiber and graphite and nanoparticle on the friction and wear behavior of polyimide composites. Mater. Des. 2010, 31, 3761–3768. [Google Scholar] [CrossRef]

- Dai, J.-h.; Liang, F.; Zhang, R.; Lu, W.-Z.; Fan, G.-f. Study on modification of ZnNb2O6/PTFE microwave composites with LCP fiber. Ceram. Int. 2022, 48, 2362–2368. [Google Scholar] [CrossRef]

- Xu, F.; Xin, Y.; Li, T. Tribological enhancement effect of main-chain thermotropic liquid crystalline polymer. Compos. Part A Appl. Sci. Manuf. 2018, 108, 69–78. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Gumennyi, I.V. Flow of polymer blends—Developing a deformation-induced morphology followed by analytical scanning electron microscopy. Phys. Fluids 2022, 34, 123105. [Google Scholar] [CrossRef]

- de Kort, G.W.; Bouvrie, L.H.C.; Rastogi, S.; Wilsens, C.H.R.M. Thermoplastic PLA-LCP Composites: A Route toward Sustainable, Reprocessable, and Recyclable Reinforced Materials. ACS Sustain. Chem. Eng. 2020, 8, 624–631. [Google Scholar] [CrossRef]

- de Kort, G.W.; Rastogi, S.; Wilsens, C.H. Controlling processing, morphology, and mechanical performance in blends of polylactide and thermotropic polyesters. Macromolecules 2019, 52, 6005–6017. [Google Scholar] [CrossRef]

- Tjong, S.C.; Li, R.K.Y.; Xie, X. Properties of in situ composites based on semiflexible thermotropic liquid crystalline copolyesteramide and polyamide 66 blends. Polym. J. 2000, 32, 907–914. [Google Scholar] [CrossRef]

- Komatsu, S.; Wetzel, B.; Friedrich, K. Novel liquid crystal polymers with tailored chemical structure for high barrier, mechanical and tribological performance. In Liquid Crystalline Polymers: Volume 2—Processing and Applications; Springer: Berlin/Heidelberg, Germany, 2015; pp. 15–39. [Google Scholar]

| Samples | PA-PU (wt.%) | CF (wt.%) | Gr (wt.%) | LCP (wt.%) |

|---|---|---|---|---|

| CF/PA-PU | 70.0 | 30.0 | 0 | 0 |

| 1%Gr/CF/PA-PU | 69.0 | 30.0 | 1.0 | 0 |

| 3%Gr/CF/PA-PU | 67.0 | 30.0 | 3.0 | 0 |

| 5%Gr/CF/PA-PU | 65.0 | 30.0 | 5.0 | 0 |

| 7%Gr/CF/PA-PU | 63.0 | 30.0 | 7.0 | 0 |

| 1%LCP/CF/PA-PU | 69.0 | 30.0 | 0 | 1.0 |

| 3%LCP/CF/PA-PU | 67.0 | 30.0 | 0 | 3.0 |

| 5%LCP/CF/PA-PU | 65.0 | 30.0 | 0 | 5.0 |

| 7%LCP/CF/PA-PU | 63.0 | 30.0 | 0 | 7.0 |

| Samples | Equilibrium Torque /Nm | Equilibrium Temperature /°C | Energy Consumption /KNm·g−1 |

|---|---|---|---|

| CF/PA-PU | 4.79 ± 0.10 | 241.39 ± 0.25 | 0.472 ± 0.004 |

| 1%Gr/CF/PA-PU | 5.10 ± 0.03 | 243.46 ± 0.32 | 0.505 ± 0.007 |

| 3%Gr/CF/PA-PU | 5.83 ± 0.09 | 244.20 ± 0.43 | 0.524 ± 0.004 |

| 5%Gr/CF/PA-PU | 6.41 ± 0.10 | 245.41 ± 0.24 | 0.564 ± 0.008 |

| 7%Gr/CF/PA-PU | 7.22 ± 0.09 | 246.30 ± 0.33 | 0.570 ± 0.012 |

| 1%LCP/CF/PA-PU | 4.43 ± 0.11 | 240.43 ± 0.15 | 0.469 ± 0.004 |

| 3%LCP/CF/PA-PU | 4.16 ± 0.04 | 240.27 ± 0.52 | 0.452 ± 0.002 |

| 5%LCP/CF/PA-PU | 3.91 ± 0.05 | 240.95 ± 0.24 | 0.436 ± 0.003 |

| 7%LCP/CF/PA-PU | 3.64 ± 0.11 | 240.82 ± 0.33 | 0.401 ± 0.009 |

| Samples | Initial Decomposition Temperature T5%/°C | Temperature of the Maximum Decomposition Rate/°C | Mass Loss/% | Residual Mass/% | ||

|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 1 | Stage 2 | |||

| PA-PU | 257.29 | 296.33 | 433.89 | 21.10 | 78.72 | 0.18 |

| CF/PA-PU | 308.96 | 296.48 | 454.54 | 5.62 | 65.30 | 29.08 |

| 1%Gr/CF/PA-PU | 333.54 | 316.84 | 454.52 | 5.05 | 65.45 | 29.50 |

| 3%Gr/CF/PA-PU | 345.04 | - | 455.12 | - | 69.20 | 30.80 |

| 5%Gr/CF/PA-PU | 345.84 | - | 455.52 | - | 67.03 | 32.97 |

| 7%Gr/CF/PA-PU | 349.84 | - | 455.63 | - | 64.90 | 35.10 |

| 1%LCP/CF/PA-PU | 346.05 | - | 451.39 | - | 70.78 | 29.22 |

| 3%LCP/CF/PA-PU | 349.77 | - | 450.15 | - | 70.08 | 29.92 |

| 5%LCP/CF/PA-PU | 352.79 | - | 449.93 | - | 68.46 | 31.54 |

| 7%LCP/CF/PA-PU | 354.30 | - | 448.03 | - | 67.65 | 32.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Wang, X.; Li, X.; Liu, C.; Li, G.; Luo, Y. Tribological and Mechanical Applications of Liquid-Crystal-Polymer-Modified Carbon-Fiber-Reinforced Polyamide–Polyurethane Composites. Polymers 2023, 15, 2033. https://doi.org/10.3390/polym15092033

Zhou Z, Wang X, Li X, Liu C, Li G, Luo Y. Tribological and Mechanical Applications of Liquid-Crystal-Polymer-Modified Carbon-Fiber-Reinforced Polyamide–Polyurethane Composites. Polymers. 2023; 15(9):2033. https://doi.org/10.3390/polym15092033

Chicago/Turabian StyleZhou, Zhen, Xiaoqing Wang, Xiaomeng Li, Chang Liu, Guoping Li, and Yunjun Luo. 2023. "Tribological and Mechanical Applications of Liquid-Crystal-Polymer-Modified Carbon-Fiber-Reinforced Polyamide–Polyurethane Composites" Polymers 15, no. 9: 2033. https://doi.org/10.3390/polym15092033

APA StyleZhou, Z., Wang, X., Li, X., Liu, C., Li, G., & Luo, Y. (2023). Tribological and Mechanical Applications of Liquid-Crystal-Polymer-Modified Carbon-Fiber-Reinforced Polyamide–Polyurethane Composites. Polymers, 15(9), 2033. https://doi.org/10.3390/polym15092033